Cam driven exhaust valve actuating system for large two-stroke diesel engine

A diesel engine and exhaust valve technology, applied in engine components, engine control, machine/engine, etc., can solve the problems of no recycling, expensive, energy consumption, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

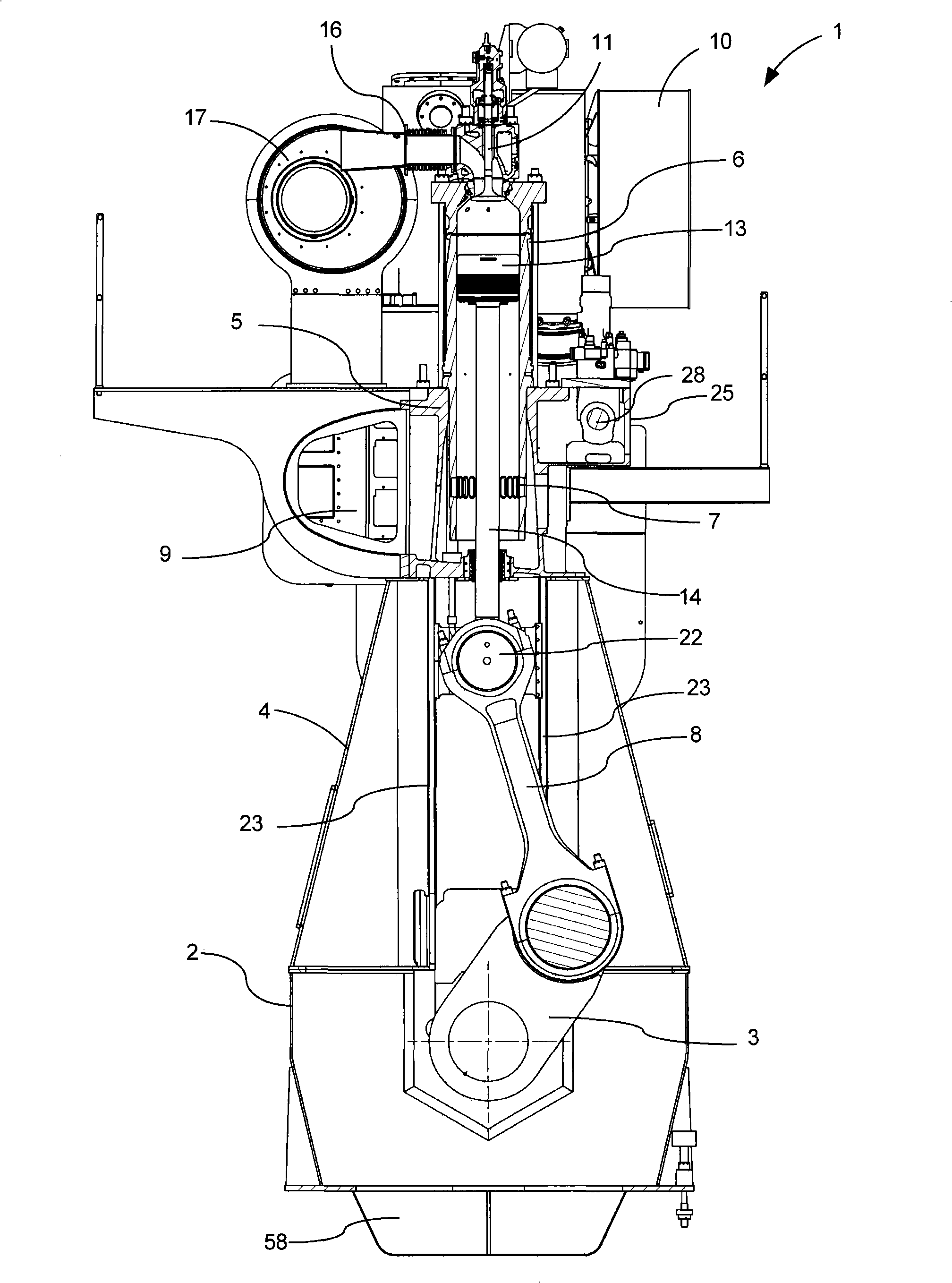

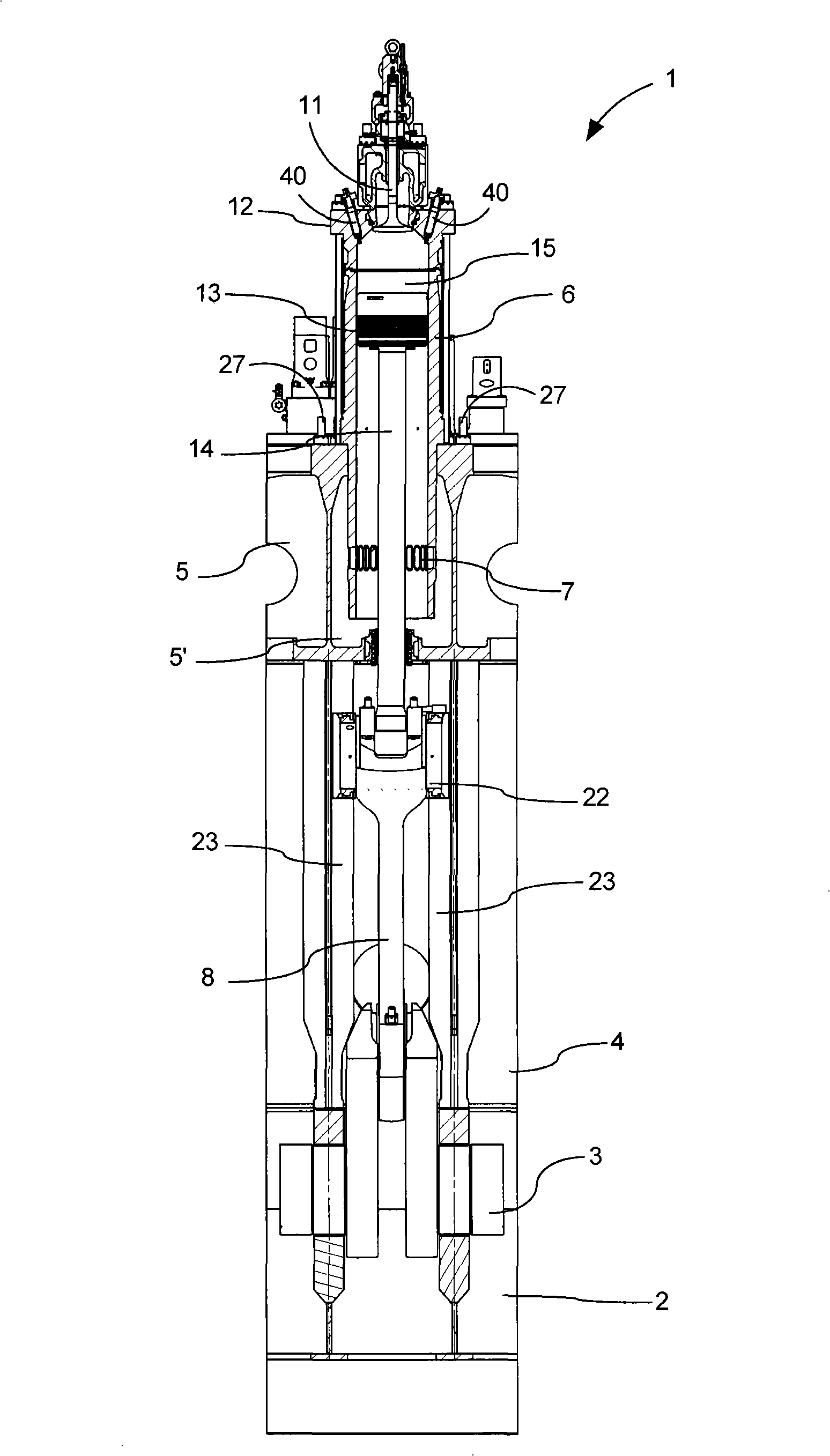

[0033] figure 1 and 2 A cross-sectional view and a longitudinal sectional view (of one cylinder) of an engine 1 according to a preferred embodiment of the invention are shown respectively. The engine 1 is a crosshead single-flow low-speed two-stroke crosshead diesel engine, which can be a propulsion system in a ship or a prime mover of a power plant. These engines typically have 4 to 14 in-line cylinders. The engine 1 is built on a foundation 2 with main bearings for a crankshaft 3 .

[0034] The crankshaft 3 is of the semi-combined type. The crankshaft of the semi-compound type is made of a forged or cast steel crank, which is connected to the main journal by a shrink fit connection.

[0035] The base 2 can be made in one piece or divided into appropriately sized parts according to the production equipment. The base includes side walls and welded beams with bearing supports. This beam is also known in the art as a "transverse truss". An oil pan 58 is welded to the bott...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com