Crosshead bearing for large two-stroke diesel engine

A cross-head, two-stroke technology, used in engine lubrication, rotating bearings, cross-heads, etc., can solve problems such as high peak pressure, steep pressure gradient, etc., and achieve the effect of low dynamic load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

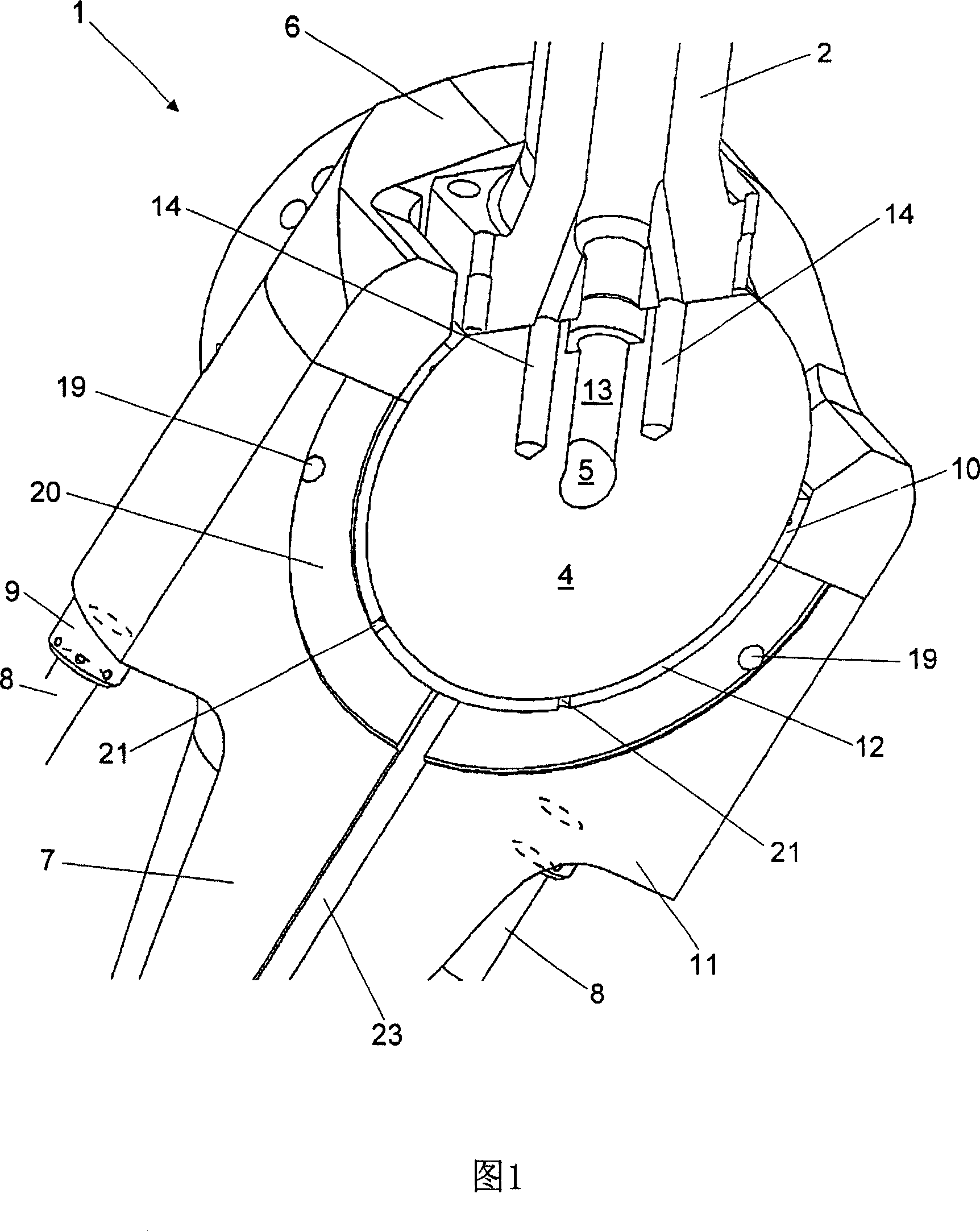

[0032] A crosshead bearing 1 for a large two-stroke diesel engine according to a first embodiment is shown in FIG. 1 . The piston rod 2 is connected with a hydraulic fastening bolt to a crosshead bearing 4 provided with an axial bore 5 closed at its axial end. A one piece crosshead bearing cap 6 with an angular cutout for the piston rod 2 is fixed to the connecting rod 7 by bolts 8 and nuts 9 tightened by hydraulic jacks. The bearing cap 6 is provided with a thin walled upper steel casing 10 adjoining the inner bearing surface with white metal. The connecting rod 7 is provided with an integral seat 11 holding a thin-walled lower steel shell 12 adjoining the inner bearing surface, for example with white metal. The lower shell 12 within the seat 11 effectively functions as a unitary member, but may also be formed from two or more sections that are stacked closely together to form a continuous bearing surface, i.e. between the parts forming the shell. The transitions are tight ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com