Exhaust valve actuator for large-scale two-stroke diesel engine

An actuator and exhaust valve technology, applied in the direction of engine components, machines/engines, non-mechanically actuated valves, etc., can solve problems such as large hydraulic energy of exhaust valves, fuel saving losses, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

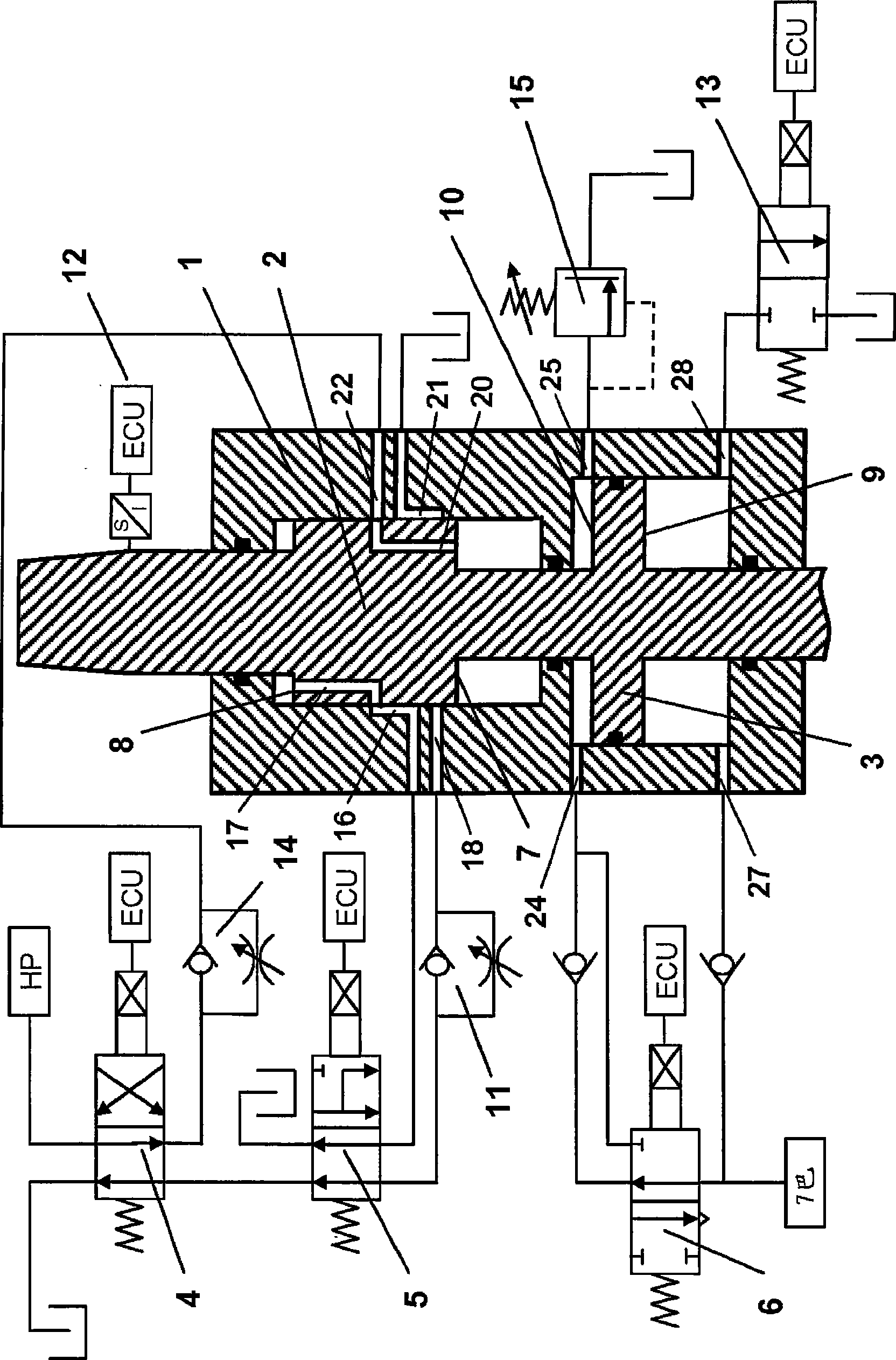

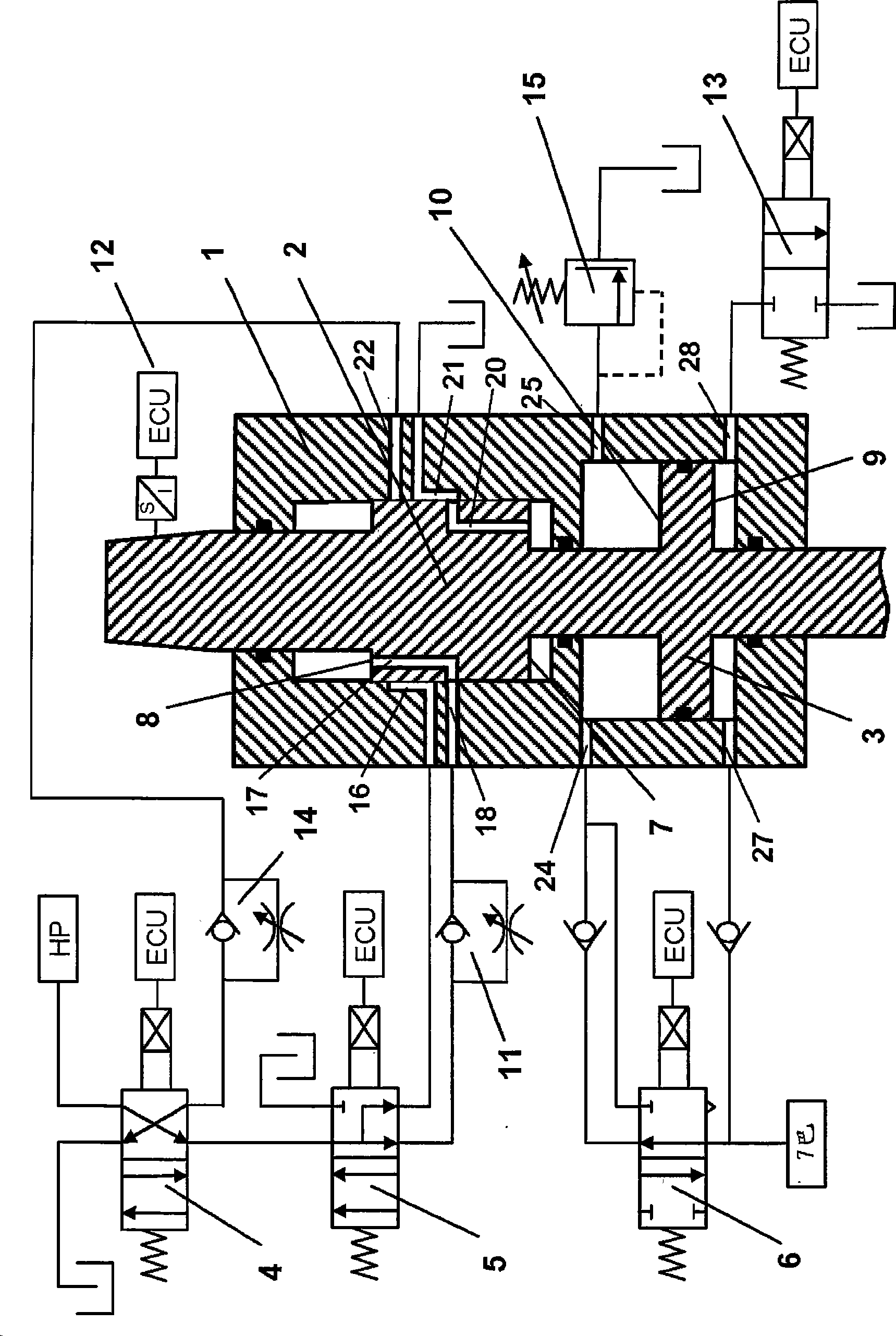

[0033] The exhaust valve actuator according to the invention is used to actuate the exhaust valves of a low speed two-stroke diesel engine (not shown), which may be a propulsion engine in a ship or a prime mover in a power plant. These engines typically have 6-16 cylinders and the bore can exceed 1m. The exhaust valves are correspondingly large and can weigh up to 400kg or more. These turbocharged engines range in engine power from 100,000kW (for the largest models) to 1600kW (for the smaller models).

[0034] The operation of the exhaust valve according to the invention is electronically controlled, ie an electronic signal from an electronic control unit determines when the exhaust valve opens and when it closes. The electronic control unit receives signals from sensors that determine the angular position of the crankshaft. The engine thus does not require a camshaft to operate the exhaust valves.

[0035]The exhaust valves are opened and closed by means of exhaust valve a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com