Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

391results about How to "Prevent backfire" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

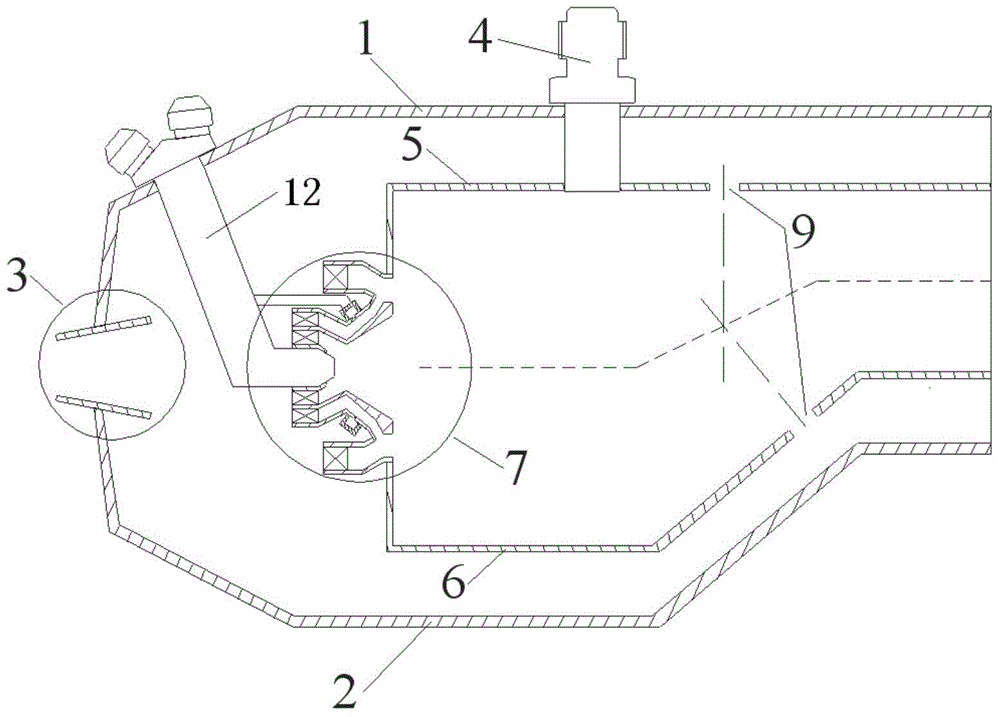

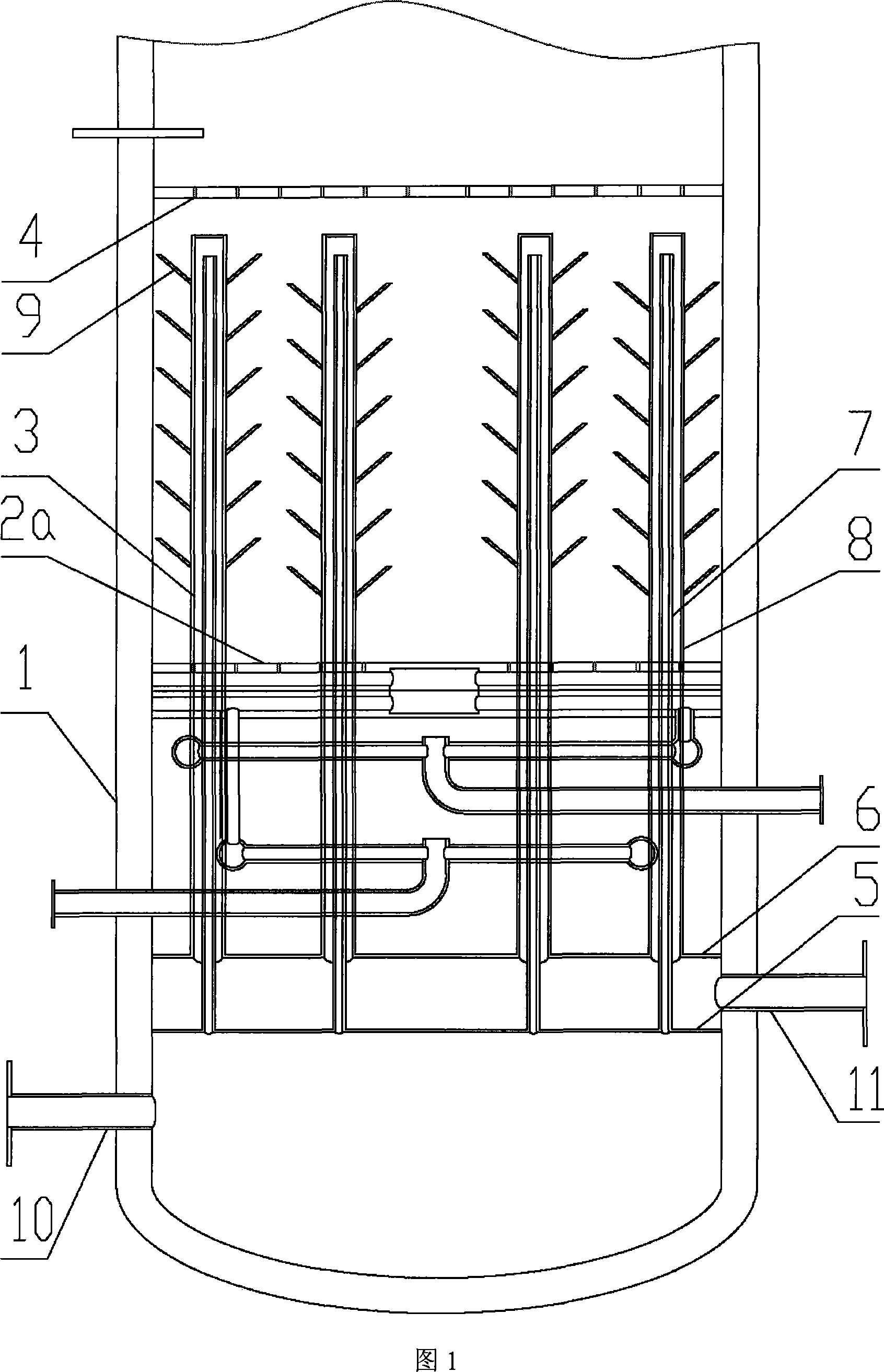

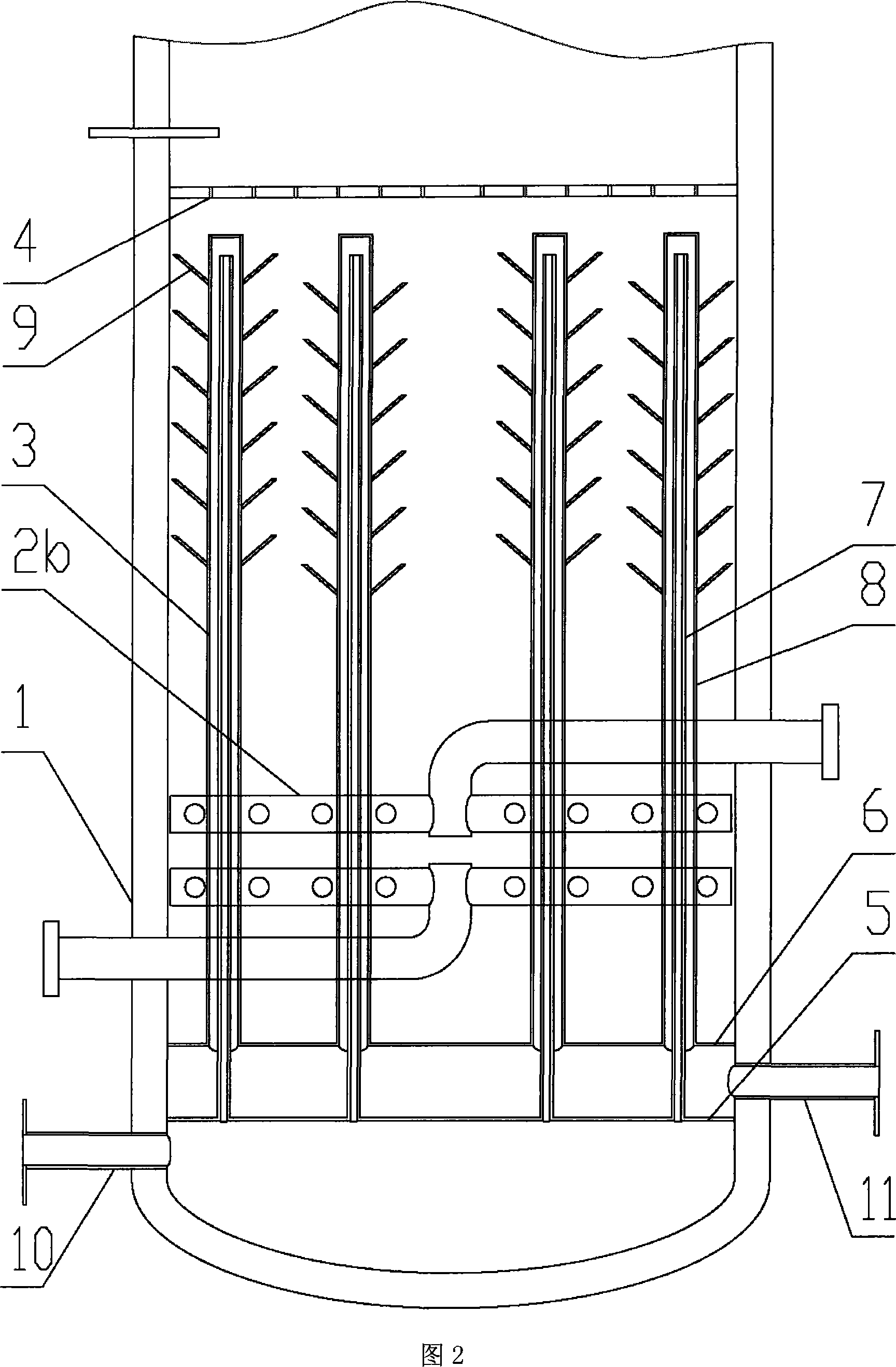

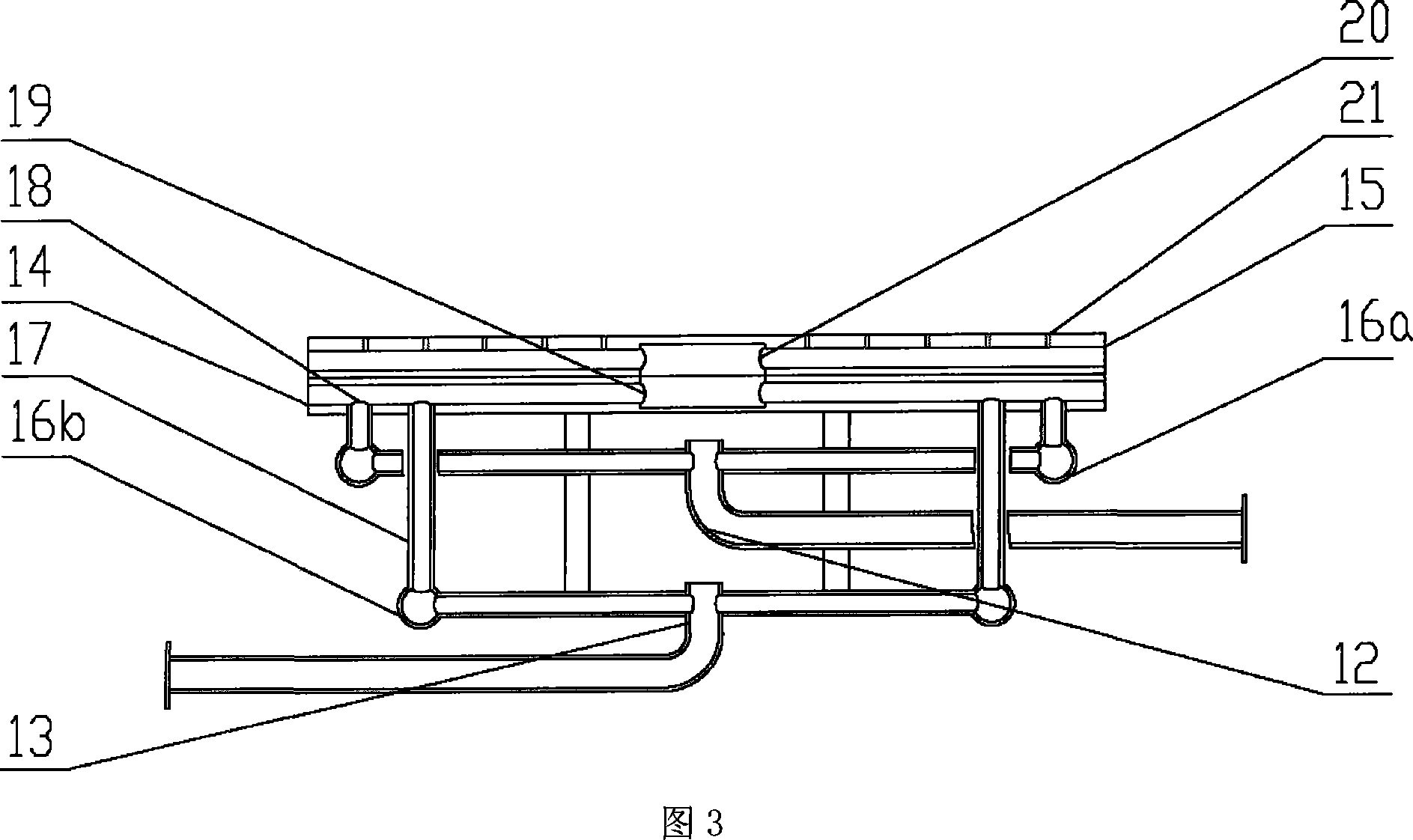

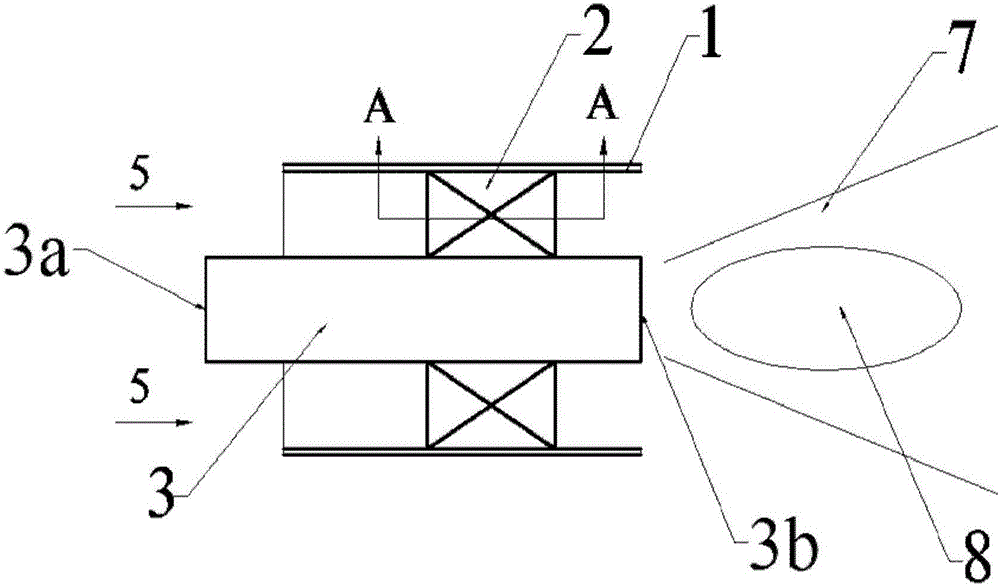

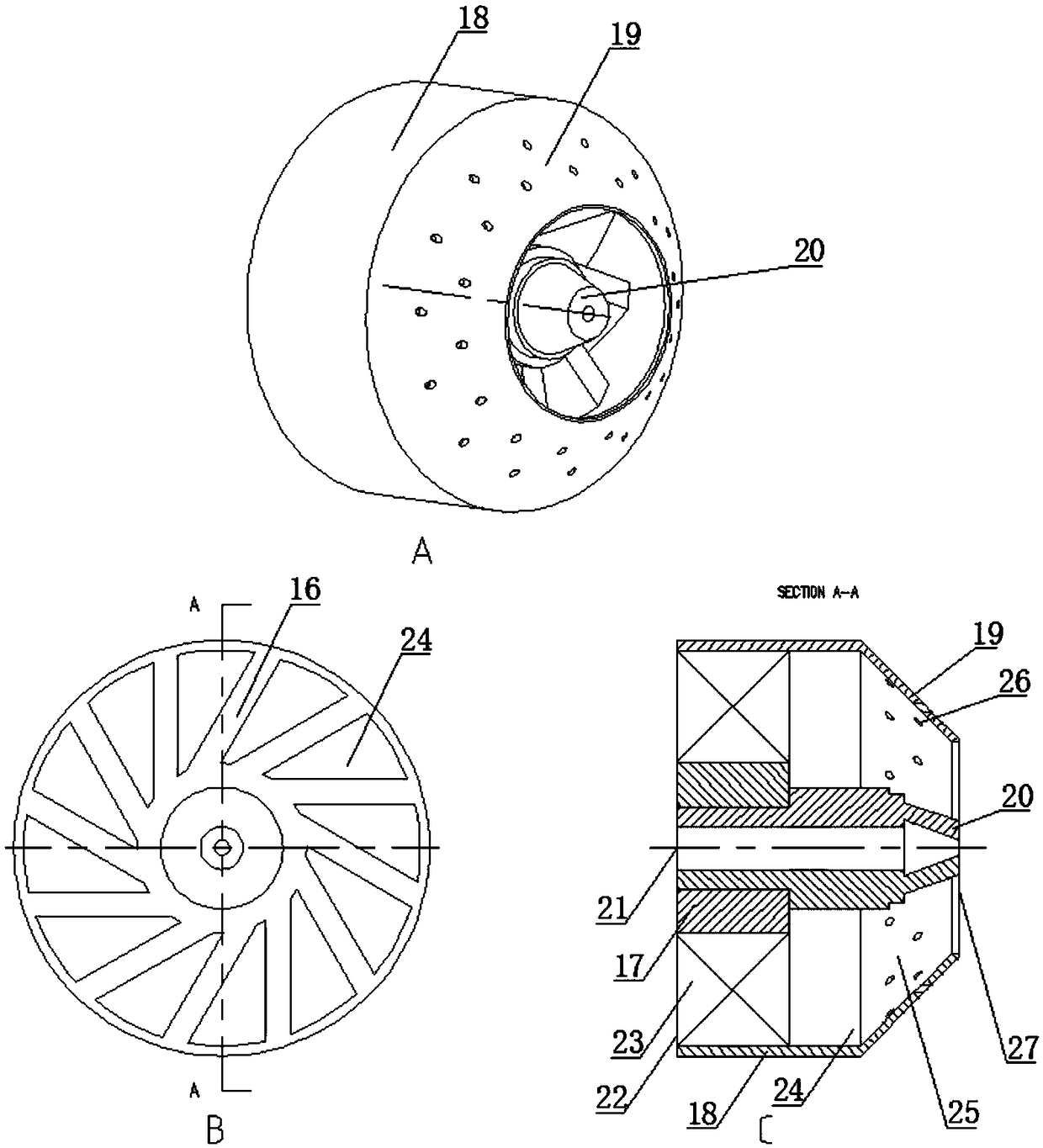

Layered part premixing low-pollution combustor of main combustion level lean oil premixing

ActiveCN104456628AImprove uniformityExtended service lifeContinuous combustion chamberCombustion chamberCoupling

The invention discloses a layered part premixing low-pollution combustor of main combustion level premixing and pre-evaporation. The layered part premixing low-pollution combustor has a pre-heating function. Fuel oil is divided into a main combustion level and an on-duty level. Diffusive combustion is adopted by the on-duty level, lean oil premixed combustion is adopted by the main combustion level, and the premixed combustion of a layered part is achieved through coupling of the diffusive combustion and the lean oil premixed combustion. The on-duty level is composed of a centrifugal atomizing nozzle and first level rotational flow air. The fuel oil of the main combustion level is supplied through multi-point direct-injection type nozzles, and oil and air mixing is enhanced through preheating of second level rotational flow air by combination of transverse jet air and on-duty level flame. The on-duty level is used in part-load conditions such as starting and slow operation, a stable combustion range can be broadened, combustion efficiency can be improved, and emission of CO and UHC is lowered; the on-duty level and the main combustion level work at the same time in the heavy load working condition, the on-duty level provides stable ignition sources for the main combustion level, a main combustion area is in a lean oil state, the temperature is far lower than the adiabatic flame temperature, and emission of NOx of high-load conditions can be reduced remarkably.

Owner:INST OF ENGINEERING THERMOPHYSICS - CHINESE ACAD OF SCI

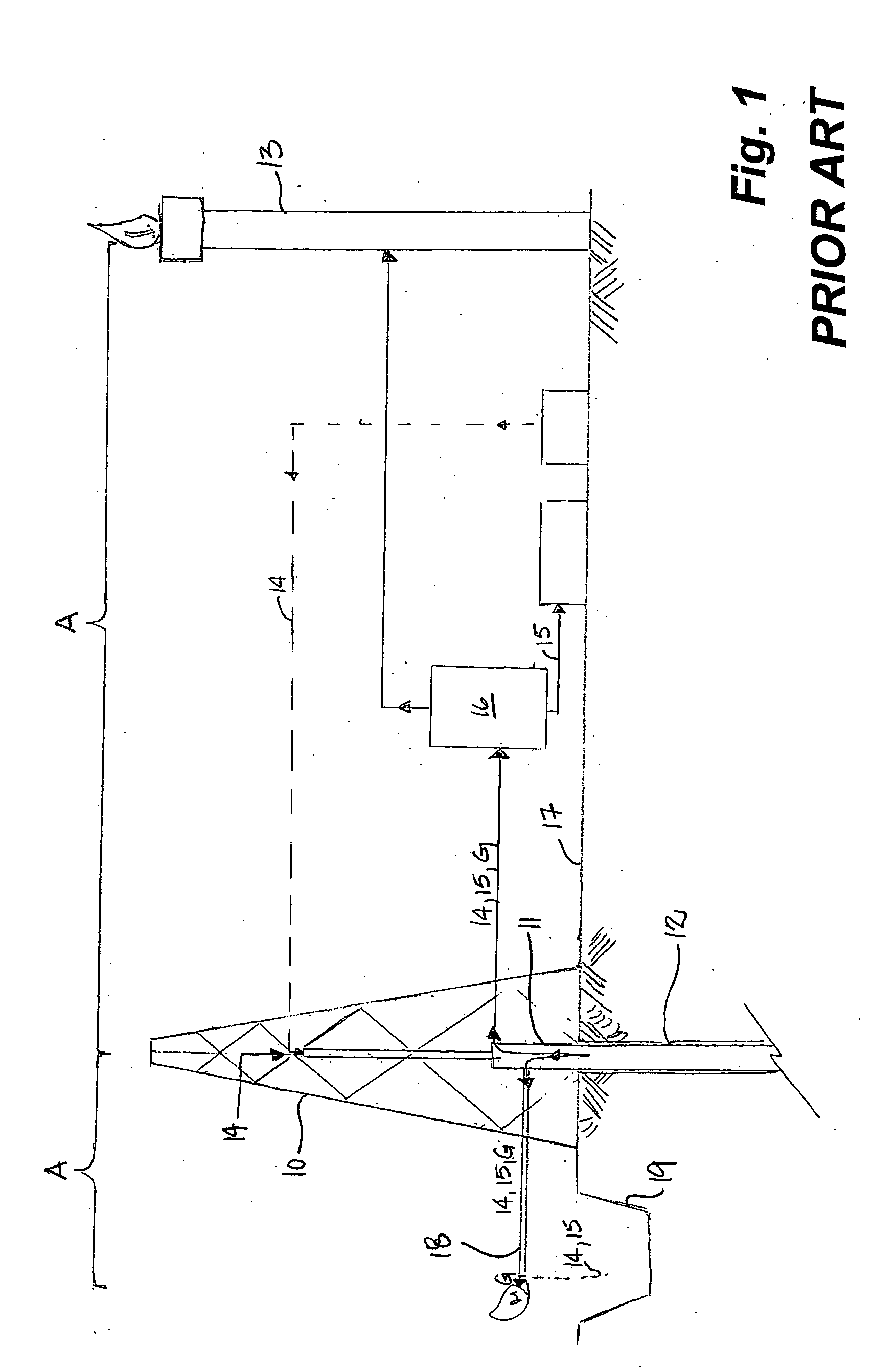

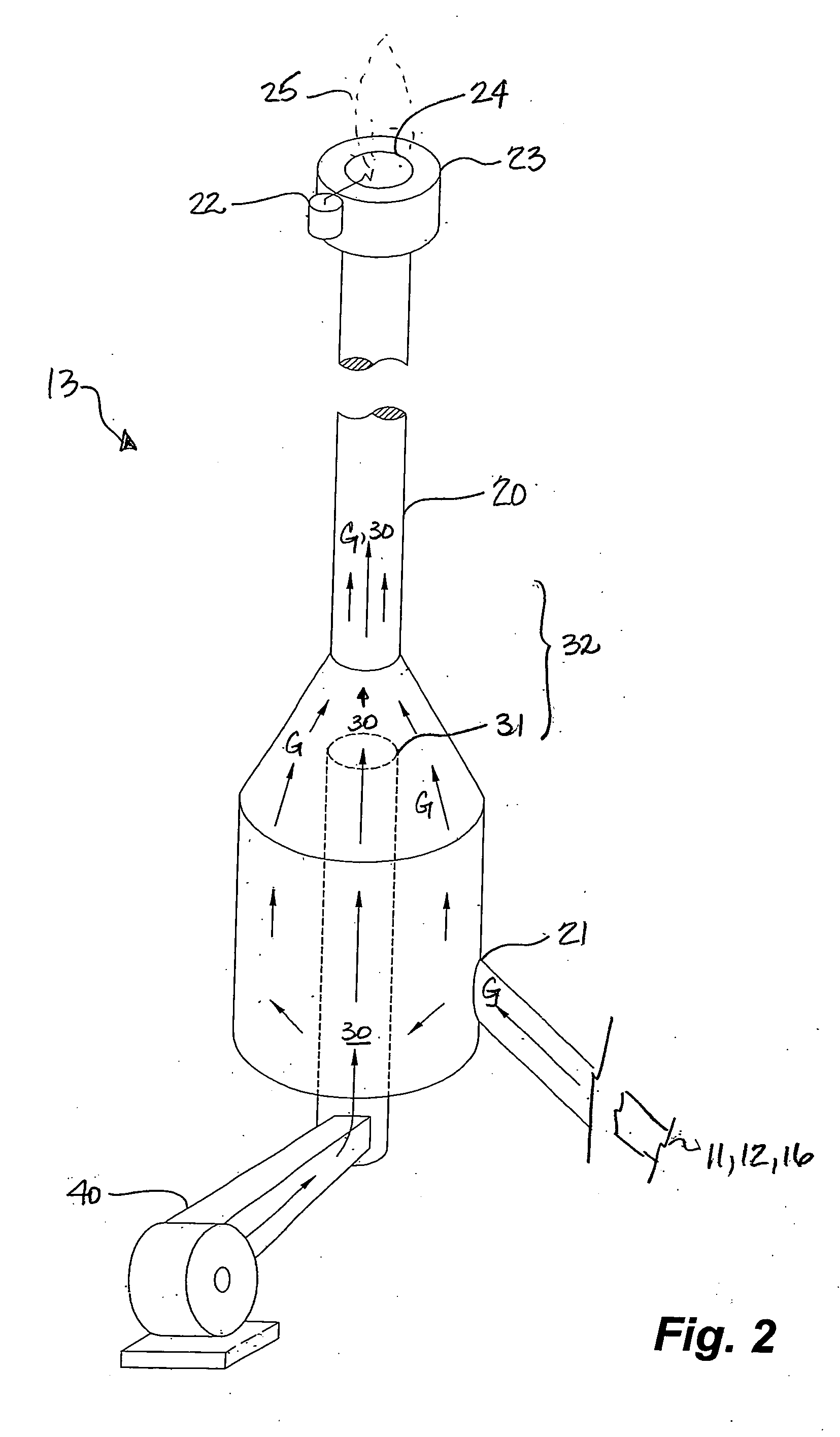

Continuous positive flow backflash prevention system

A method and system for the prevention of backflash from an ignition source in a flare stack to a separator or wellbore particularly during drilling and production. A continuous positive flow of air or exhaust gas is provided into the flow of gases from the wellbore or the separator to ensure that the velocity of the flow is always higher than the velocity at which the flame can propagate backwards into either the separator or the wellbore. This method and system is particularly applicable to balanced, underbalanced and air drilling operations where the flow of gas from the wellbore is intermittent and unpredictable and can stop and start during connection and disconnection of the air used as the drilling fluid.

Owner:SWARTOUT MATT

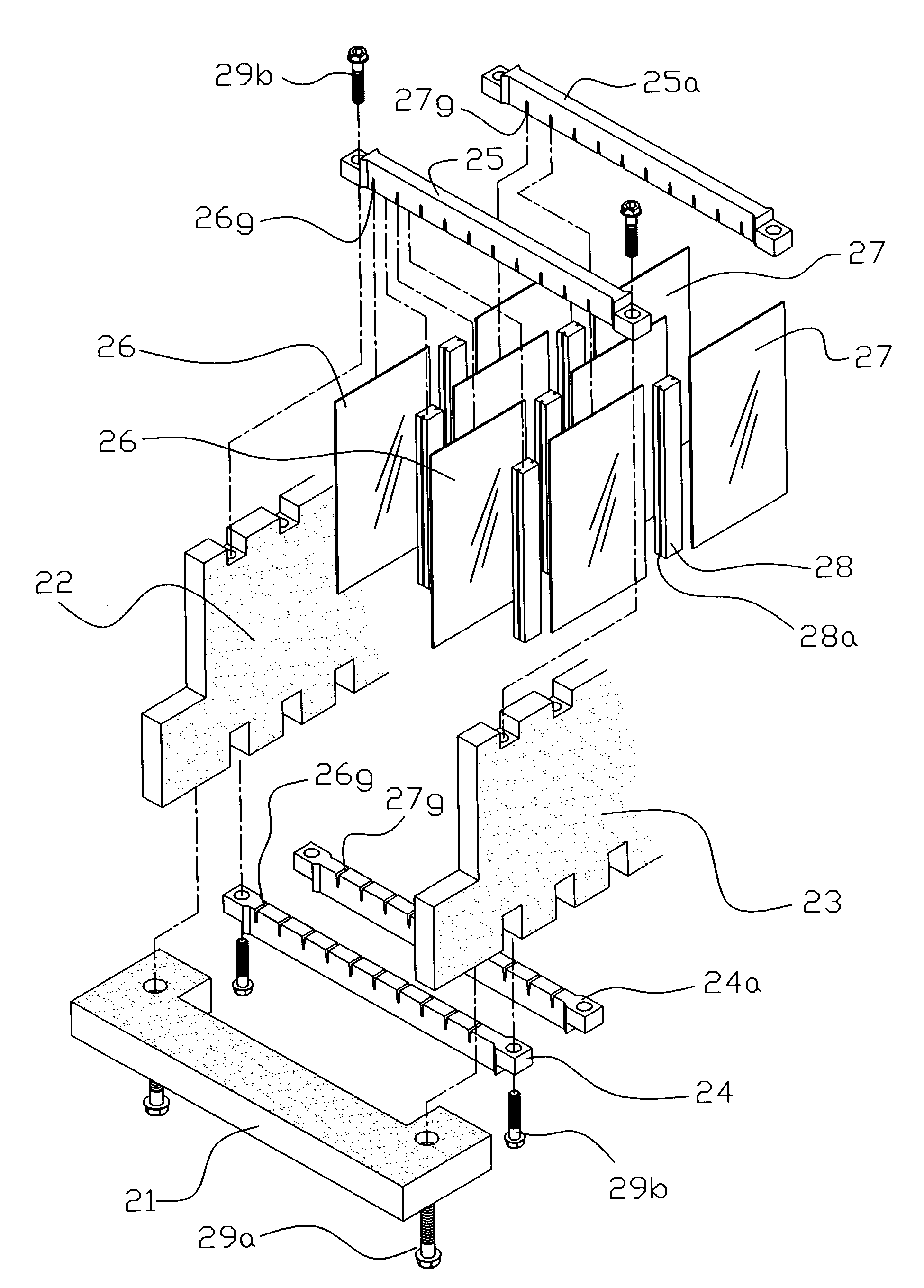

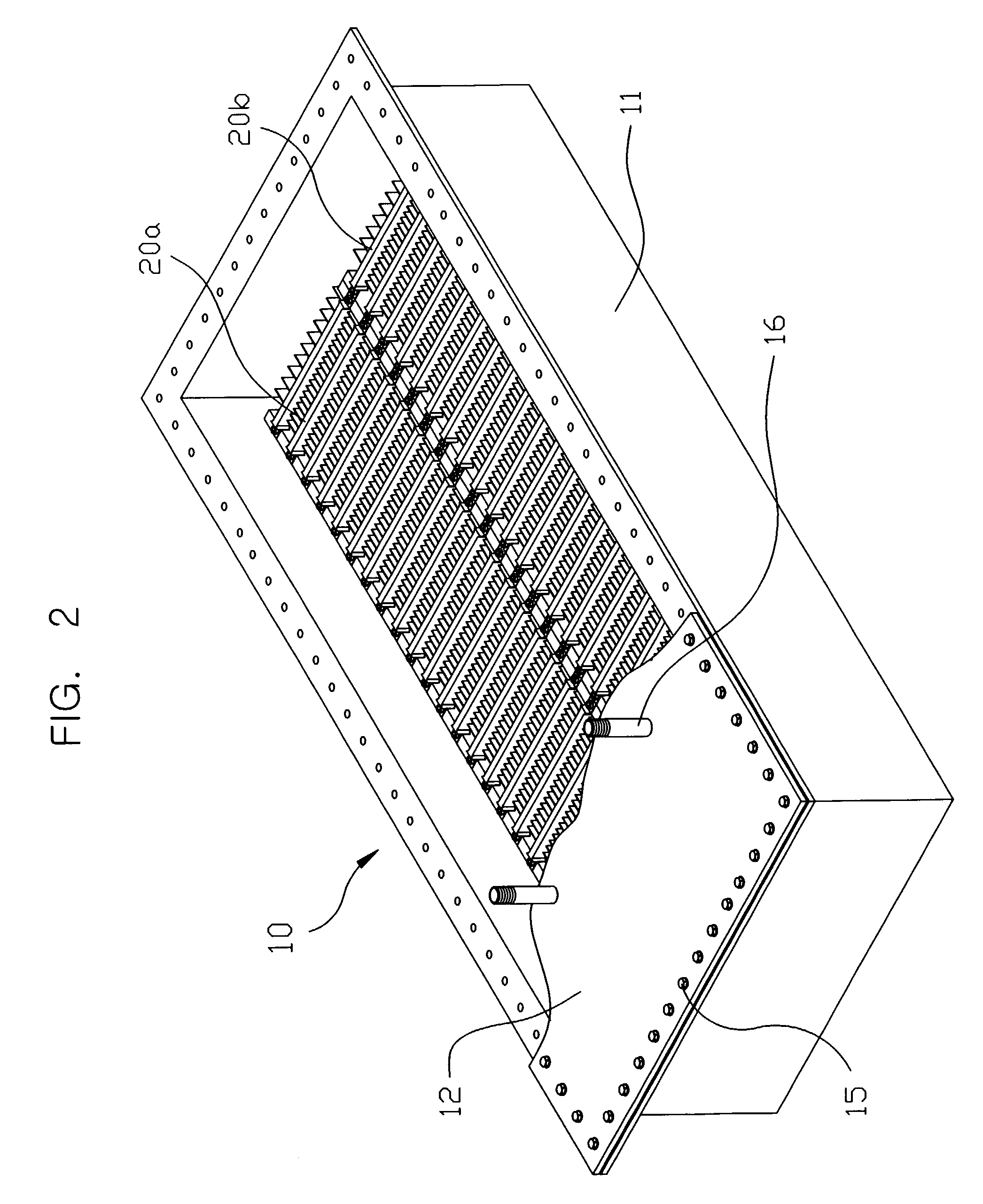

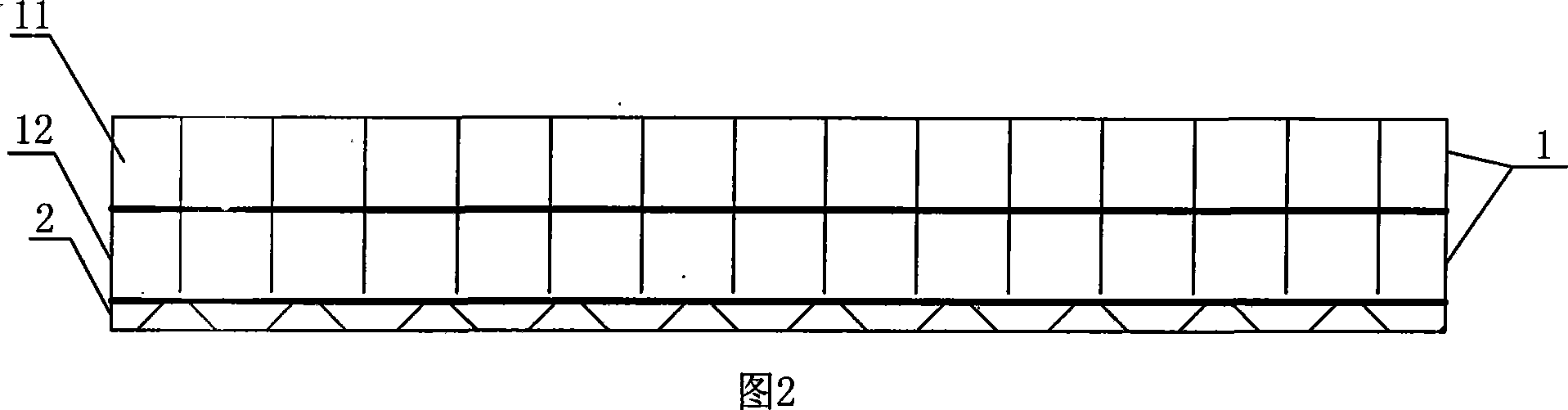

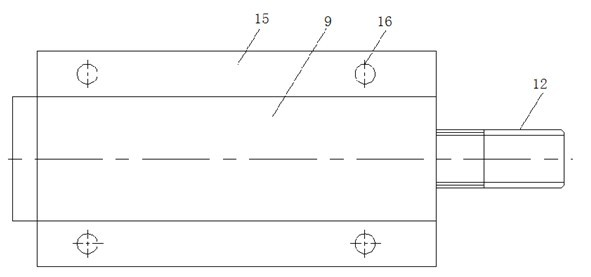

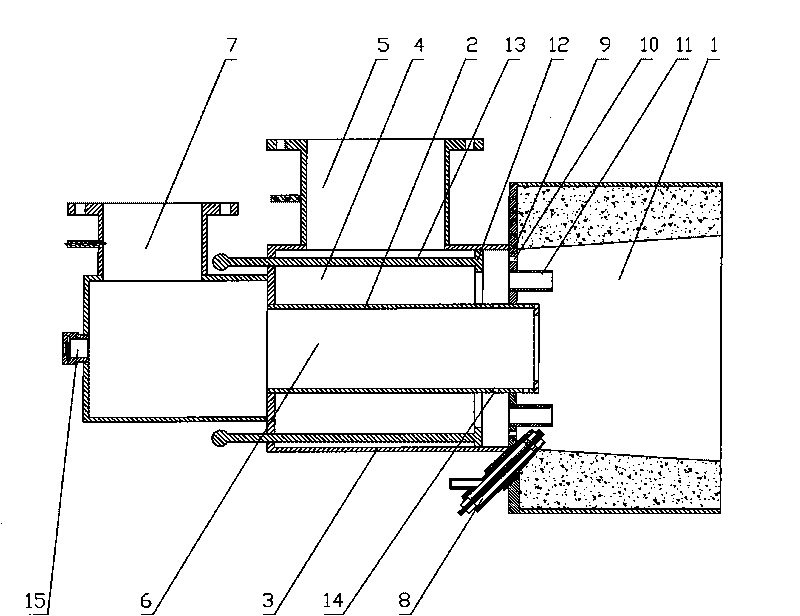

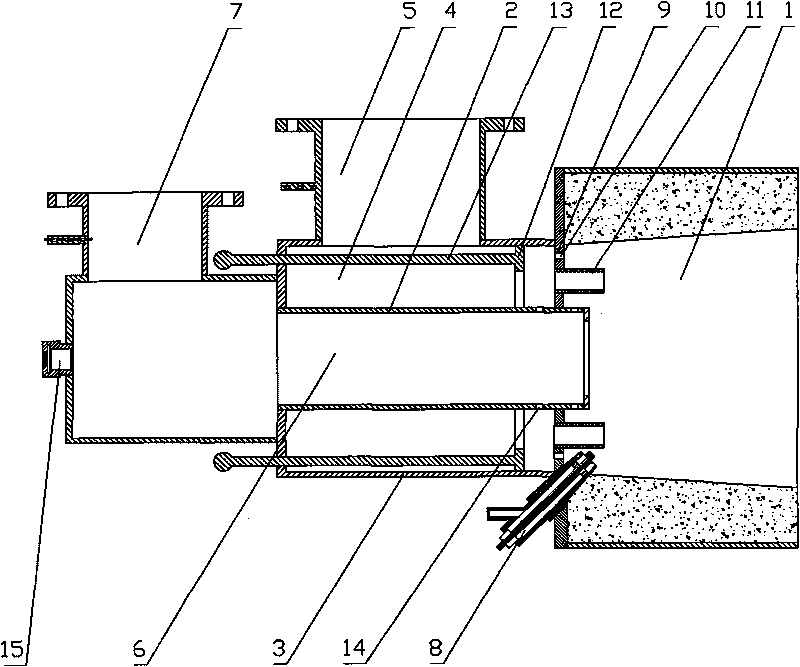

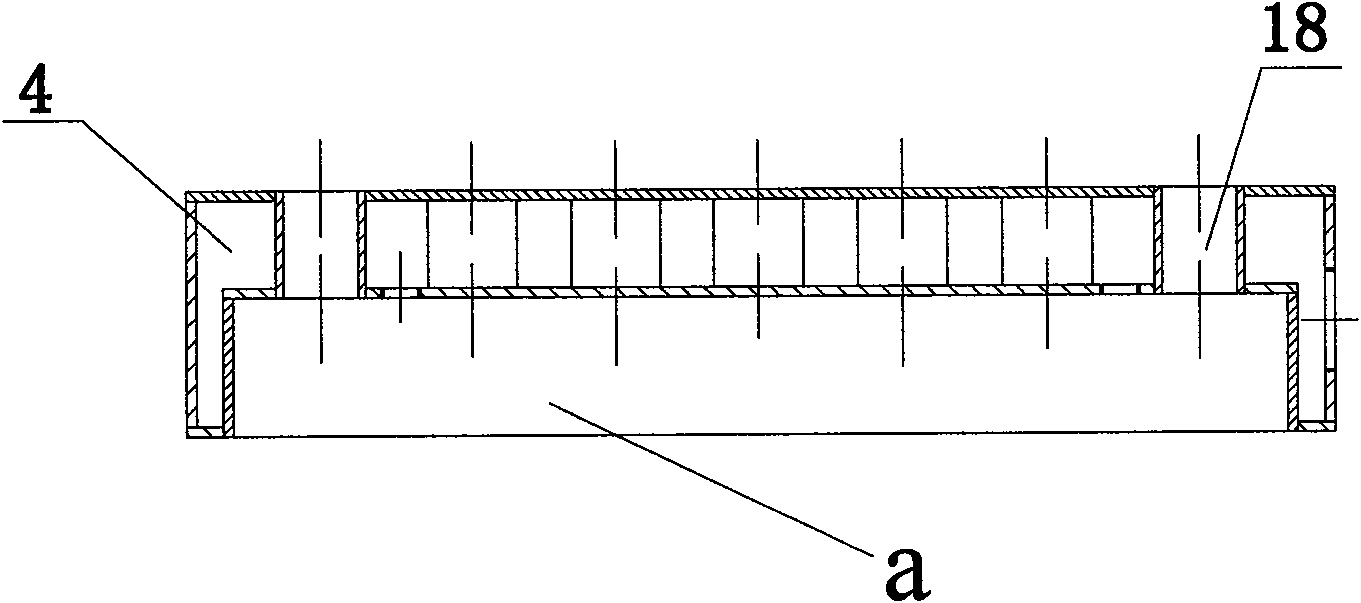

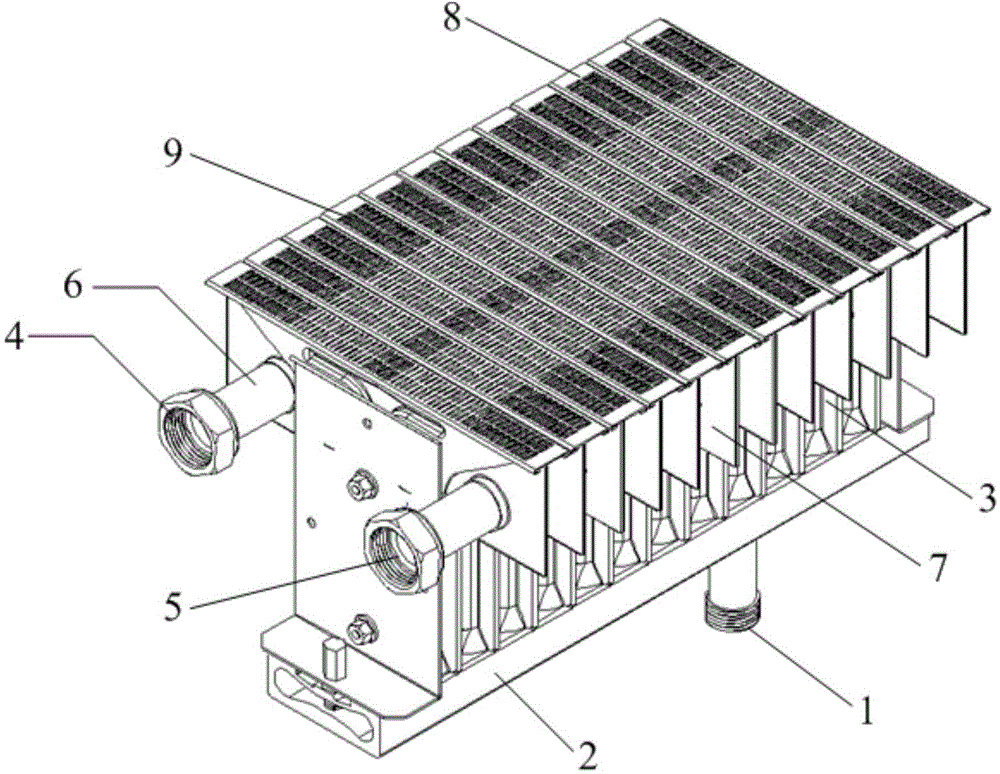

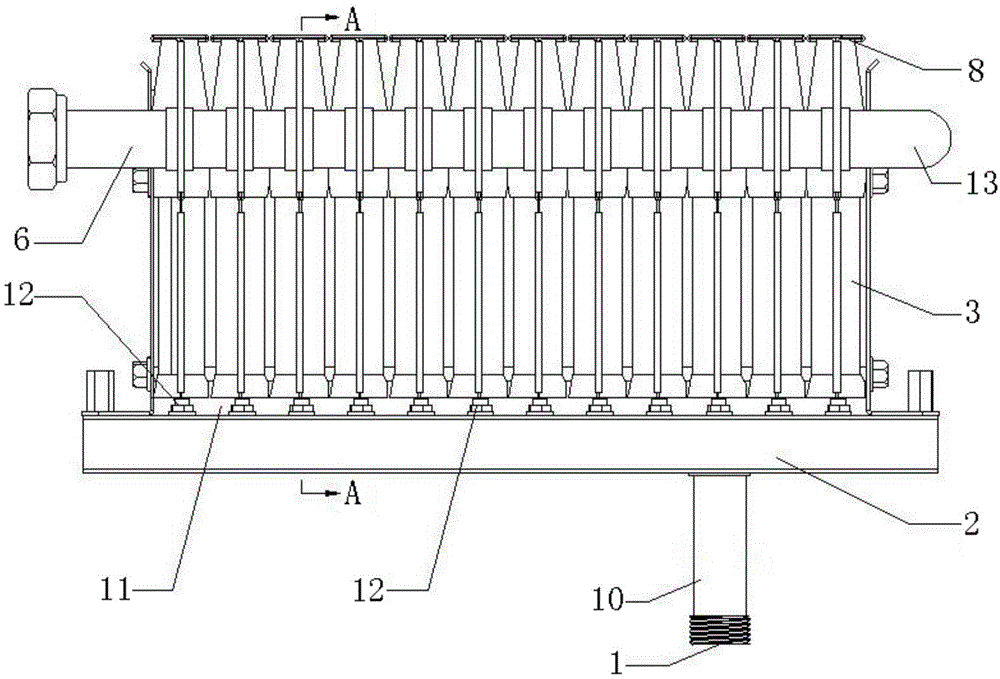

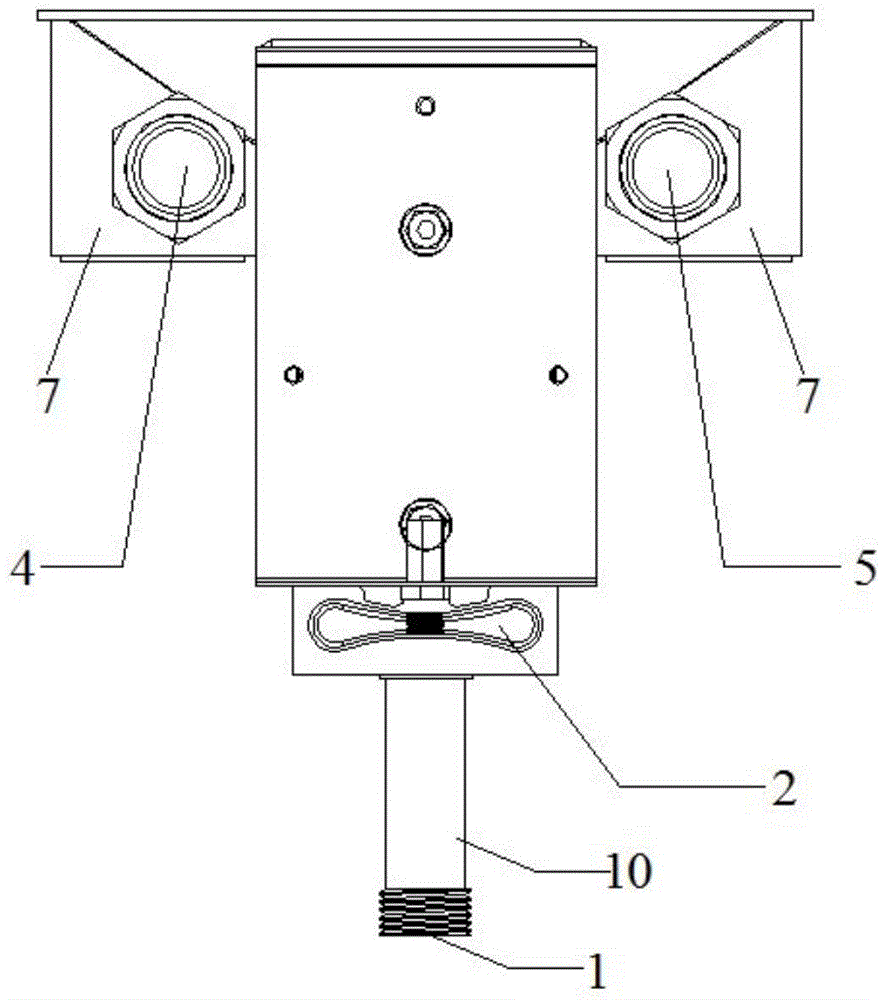

Brown gas mass production apparatus including a line style electrolytic cell

InactiveUS7014740B2Improve electrolysis efficiencyHigh speedCellsPhotography auxillary processesSolenoid valveElectrical battery

Disclosed is a Brown gas mass production apparatus having a line style electrolytic cell in which an electrolytic cell case having an electrolyte distribution and discharging pipe mounted on the inside bottom surface thereof is coated with insulation material on the inner surface thereof, electrode units are disposed by two or three groups in a side-by-side arrangement in the electrolytic cell case, an electrolytic cell upper plate having gas outlet nipples mounted thereon is sealingly coupled to the top surface of the cell case to form a secured sealing between edges of the upper plate and the cell case. The line style electrolytic cell further includes an auxiliary electrolyte tank connected to the electrolytic cell case for maintaining the surface of the electrolyte at a predetermined level just above the top surface of the electrode units in the electrolytic cell according to the operation of a solenoid valve, so that water is automatically fed into the electrolytic cell according to the opening and closing operation of a solenoid valve operated by a level sensor installed in the auxiliary electrolyte tank, and a relatively large horizontal space is formed just above the top surface of the electrode units, so that gas and water are separated directly at the horizontal space.

Owner:KIM SANG NAM

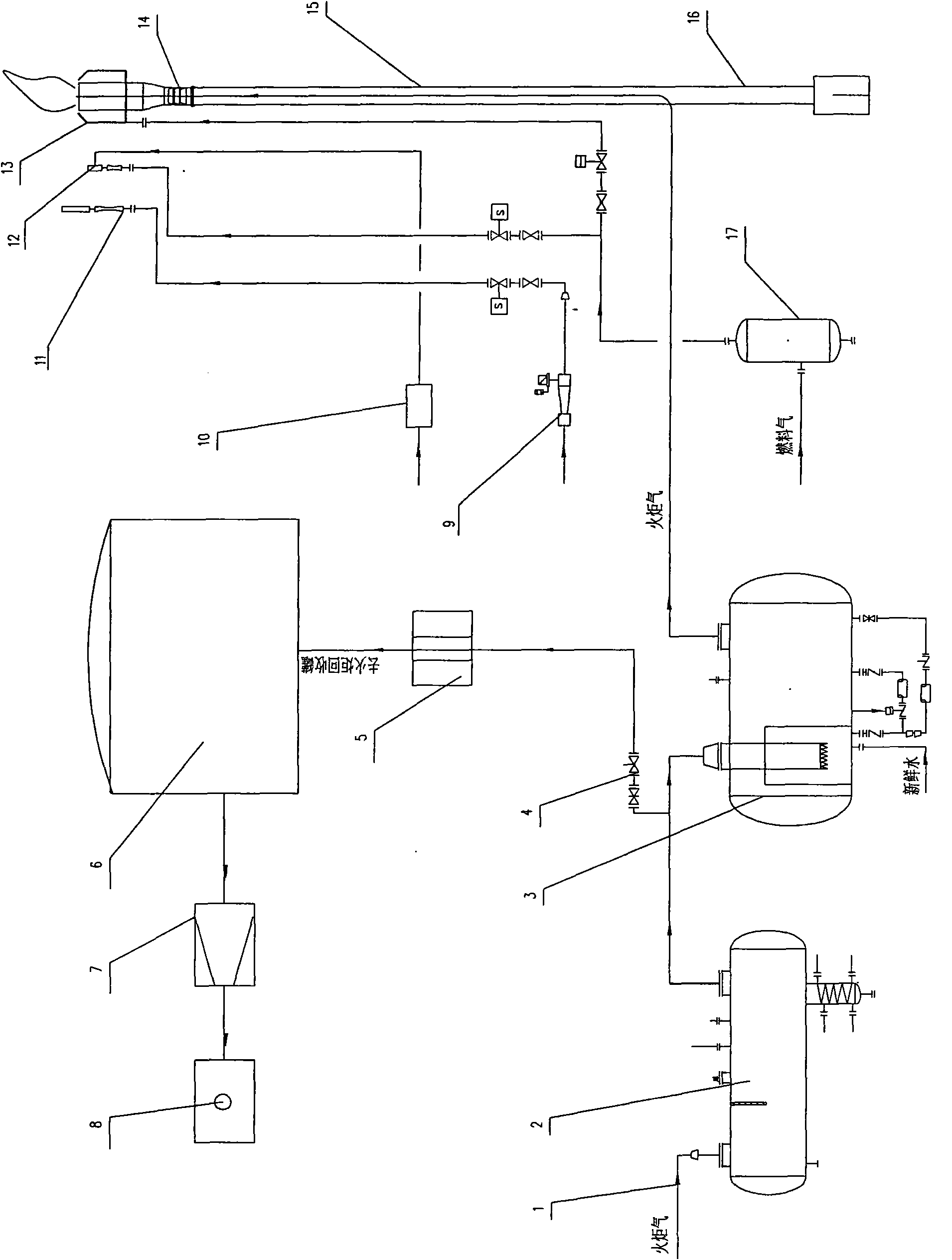

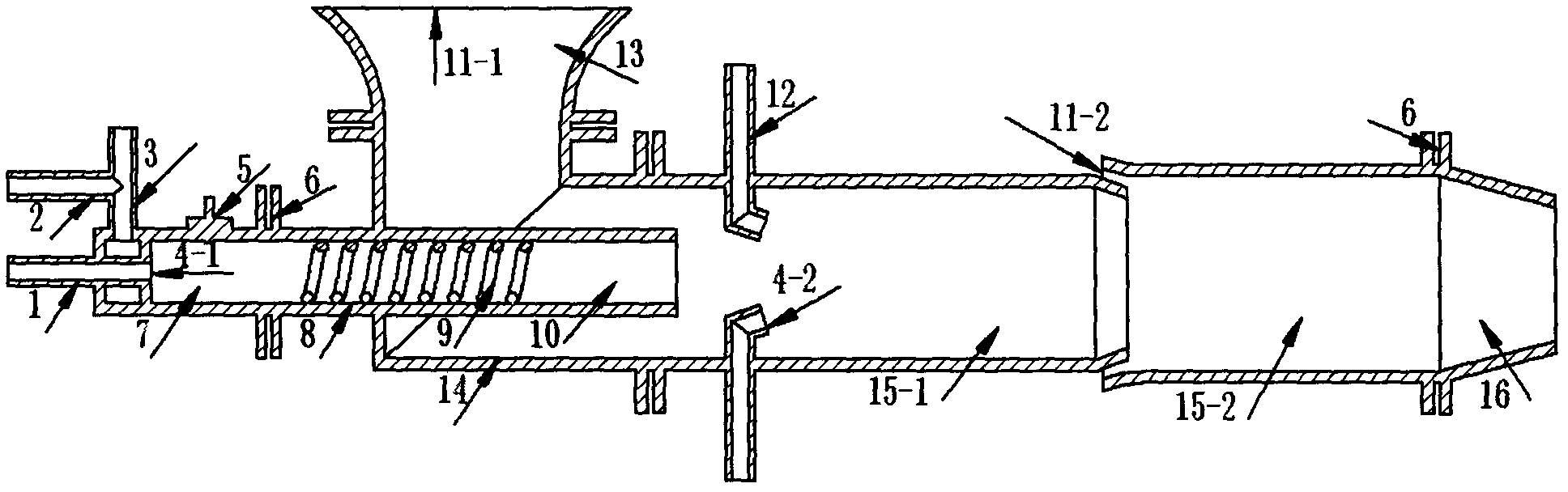

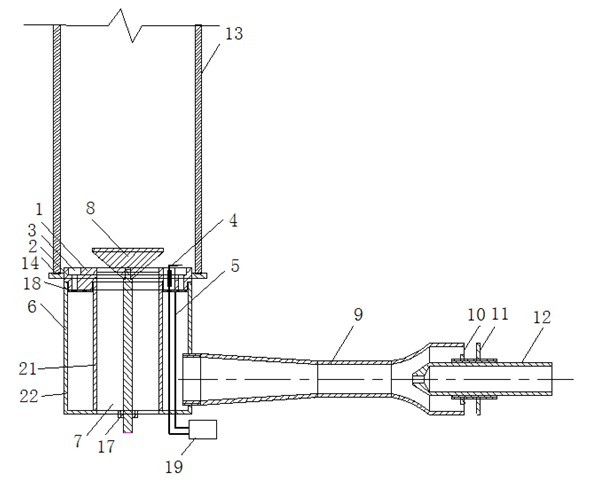

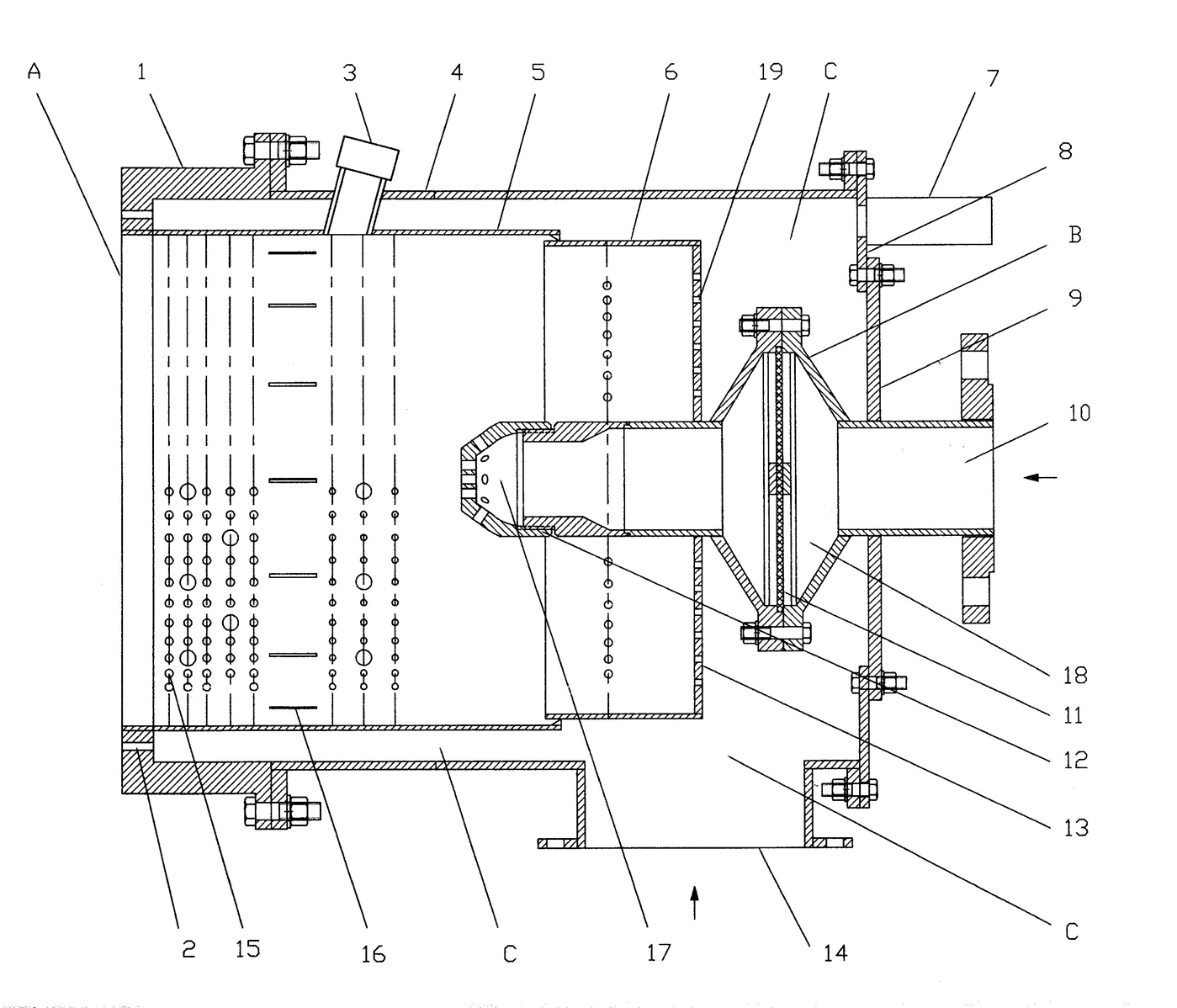

Flare gas safe recovery and discharge system

ActiveCN101672478ARealize automatic controlSafe recyclingIncinerator apparatusAutomatic controlProcess engineering

The invention provides a flare gas safe recovery and discharge system, which comprises a flare gas delivery flask (2), an automatic control water-sealed valve (3), a gas holder (6) and a flare tip (13) and is characterized in that the gas inlet end of the flare gas delivery flask (2) is connected with a flare gas source by a flare gas main pipe (1); one path of the output end of the flare gas delivery flask (2) is connected with a gas torch (6), and the other path thereof is connected with the flare tip (13) via the automatic control water-sealed valve (3); an automatic control valve (4) and aflare gas filtering tank (5) are mounted on the pipeline connecting the flare gas delivery flask (2) with the gas torch (6); the output end of the gas torch (6) is connected with a compressor (7); and the output end of the compressor (7) is connected with a gas appliance (8). The invention has the advantages of simple system structure, convenient manufacturing and installation and safe usage; andthe invention also has the characteristics of being favor of preventing environment, saving energy and the like.

Owner:JIANGSU SUNPOWER TECH

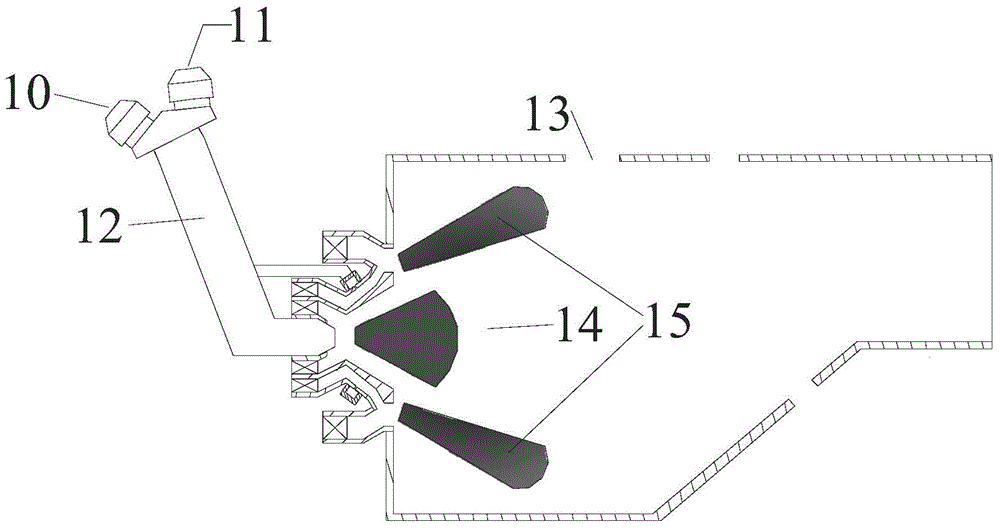

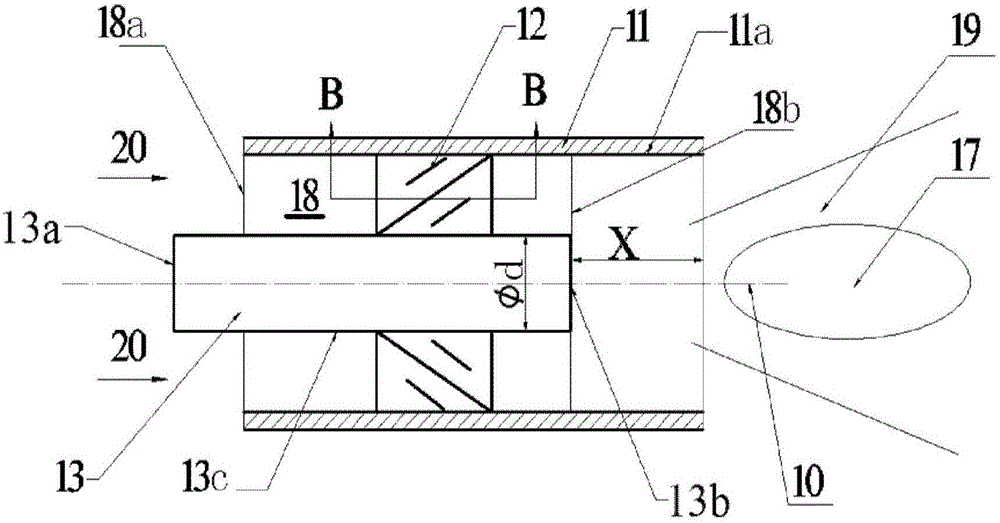

Lean oil direct injection and mixing low-pollution combustion chamber

ActiveCN107543201AGuarantee job stabilityReduce the temperatureContinuous combustion chamberSpontaneous combustionGasoline direct injection

The invention relates to a lean oil direct injection and mixing low-pollution combustion chamber. The lean oil direct injection and mixing low-pollution combustion chamber is composed of a diffuser, acombustion chamber outer case, a combustion chamber inner case, a combustion chamber head, a flame tube outer wall and a flame tube inner wall, wherein combustion air all enters a flame tube from thecombustion chamber head; the combustion chamber head is divided into an on-duty grade and a main combustion grade through a grading and partitioning combustion strategy; the on-duty grade and the main combustion grade both adopt a direct injection and mixing combustion method, the phenomena of spontaneous combustion and tempering are effectively avoided, and the risk of occurrence of oscillationcombustion is lowered; the lean oil direct injection and mixing low-pollution combustion chamber only works in an on-duty grade mode under an idling rating state, the designed partial equivalence ratio is higher, and the work stability of the combustion chamber is guaranteed; and with the increase of the work state of the combustion chamber, the main combustion grade is opened gradually, the maincombustion grade and the on-duty grade work simultaneously under a large state, the designed combustion area average equivalence ratio is lower, the average temperature of the combustion area is effectively lowered, and therefore the generation quantity of pollutants is lowered.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

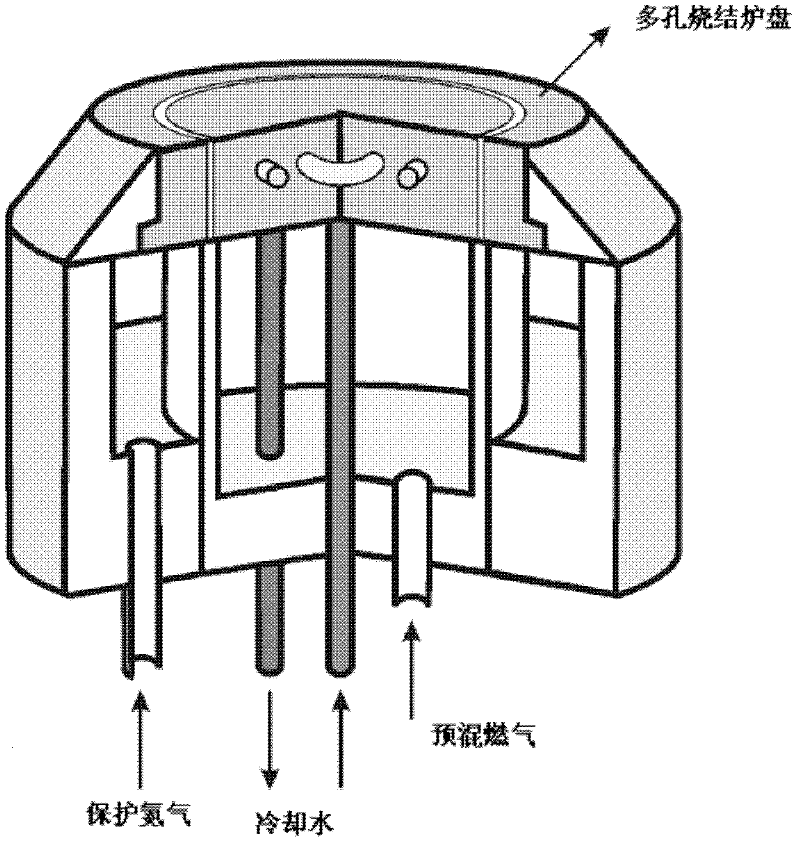

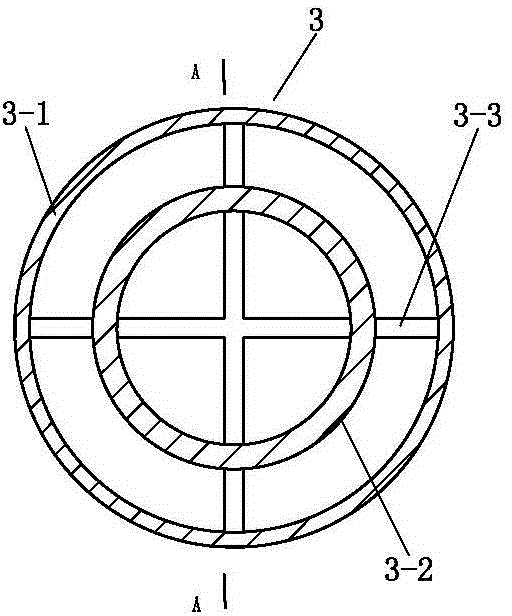

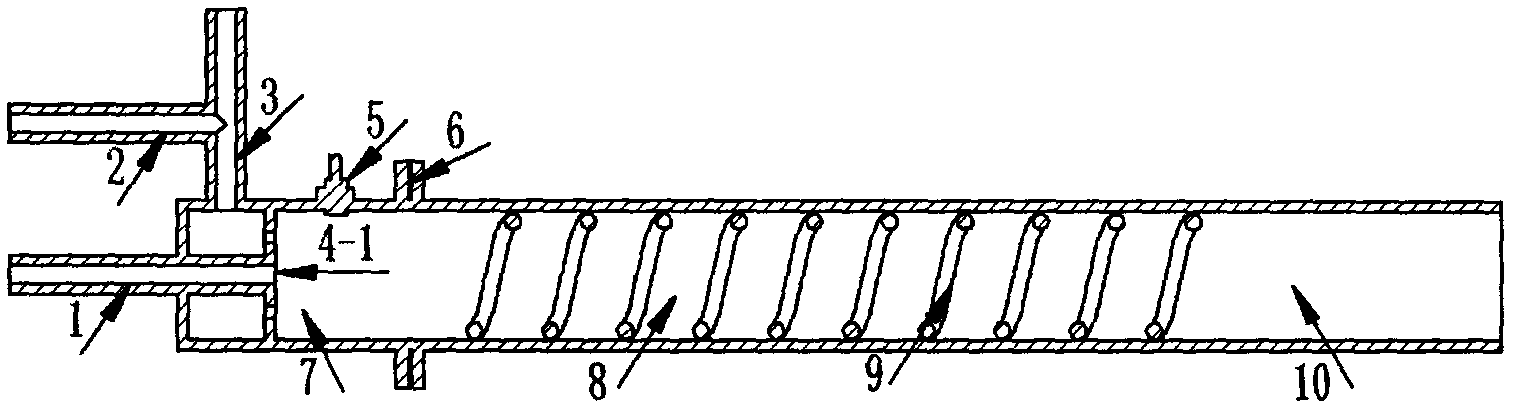

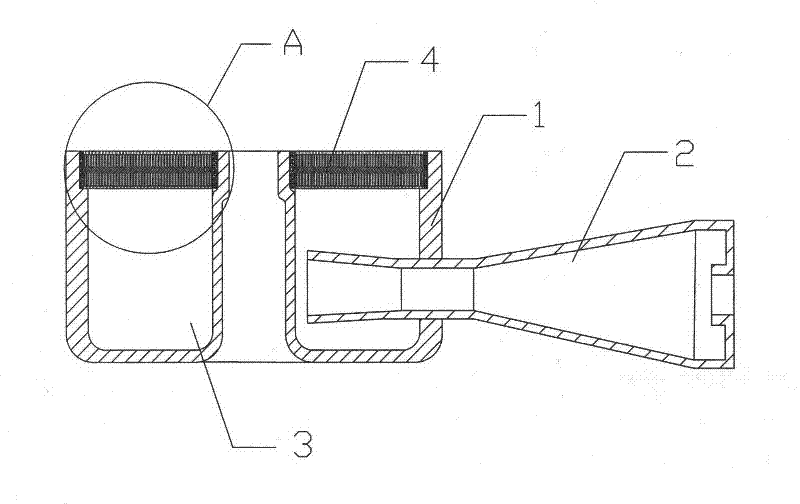

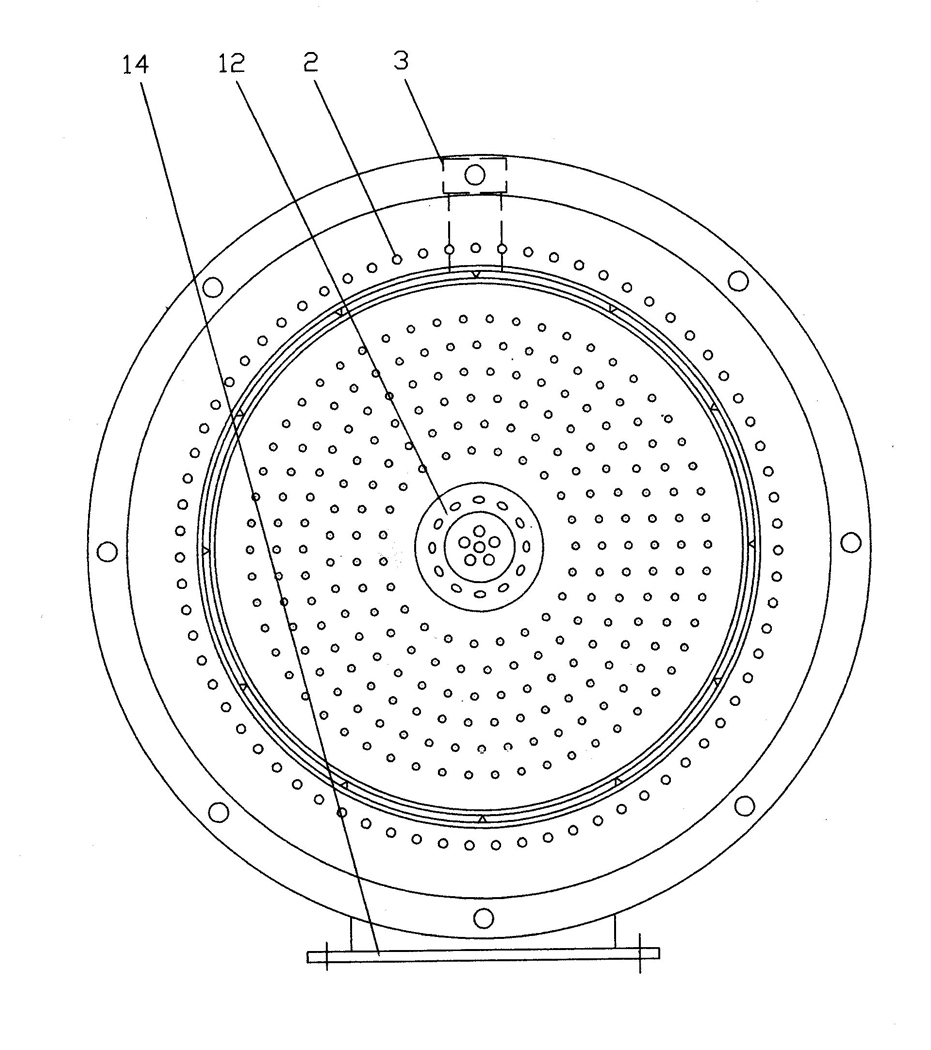

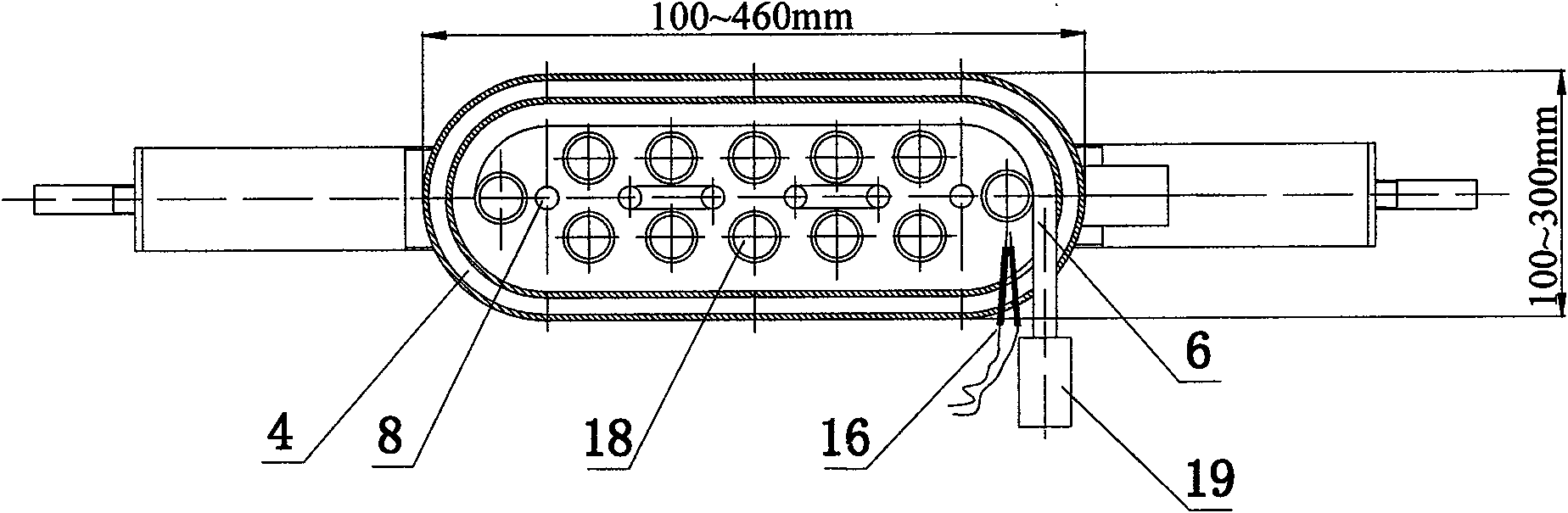

Methane and oxygen pre-mixer

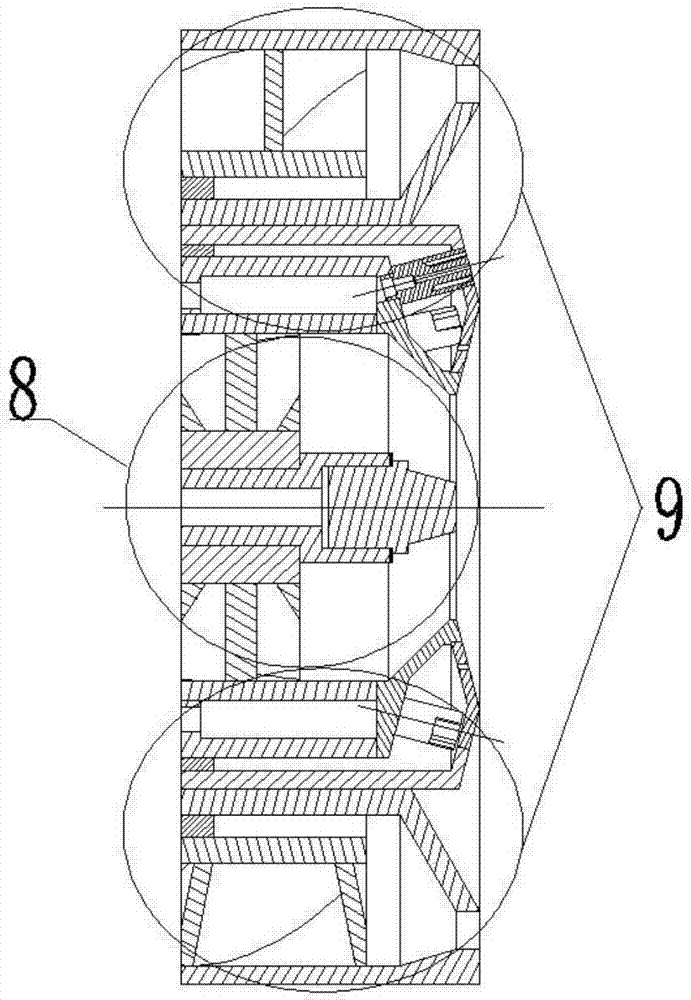

InactiveCN101125282AEvenly distributedRemove in timeHydrogenFlow mixersNuclear engineeringPartial oxidation

The present invention relates to a methane and oxygen pre-mix device, mainly consists of a casing, a gas distributed system, a heat exchange system and a multiorifice gas distribution plate; the gas distributed system adopts the rotational flow or the circular flow gas distributed system; the rotational flow gas distributed system consists of a methane air intake system, an oxygen air intake system, an upper distributor and a lower distributor; the circular flow gas distributed system consists of center feed pipes, cross feed pipes and ring gas distributor of the methane and the oxygen; the heat exchange system consists of an upper separator, a lower separator, a centre internal pipe, an external pipe, a metal fin, a heat exchange medium inlet pipe and a heat exchange medium outlet pipe; via the gas distributed system, the methane and the oxygen have a preliminary mixture in a smaller space, then by the stimulant fluidized bed consisting of the centre internal pipe, the external pipe and the metal fin, circuitously flowing upwards, achieving a molecular level mixture at the exit. The present invention effectively increases the pre-mix effect and guarantees the inflaming retarding and explosion prevention of the pre-mix chamber, having a good function in the industry of methane partial oxidation to syngas.

Owner:TSINGHUA UNIV

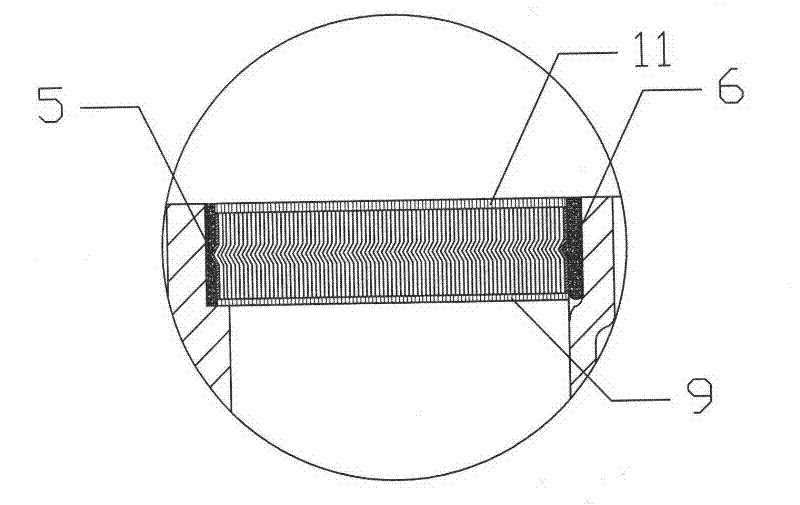

Metal fiber and porous ceramic media surface burner

InactiveCN1995814AExpand the adjustment rangeReduce sulfide contentGaseous fuel burnerMetal fiberAlloy

The invention relates to a metallic fiber and multi-hole ceramic dielectricsurface burner, belonging to heat energy engineering technology area. The burner comprises burner shell, gas pipeline and air pipeline. In the empty cavity constituted by the burner shell, metallic fiber medium in combustion zone and ceramic medium in preheat zone are set from upper to lower in turn and two medium are tightened together. The material of metallic fiber medium in combustion zone is made of Fe-Cr-Al alloy and the material of ceramic medium in preheat zone is made of zirconia or silicon carbide. Compared with ordinary surface burner, the invention can prevent tempering effectively, improve the adjustable range of fuel and air and improve burning temperature in certain range so as to improve thermal efficiency. The burner in invention can burn natural gas, liquefied petroleum gas and mixed gas so on, also burn air fuel with low thermal value which is approached to 1000kcal / m3.

Owner:NORTHEASTERN UNIV

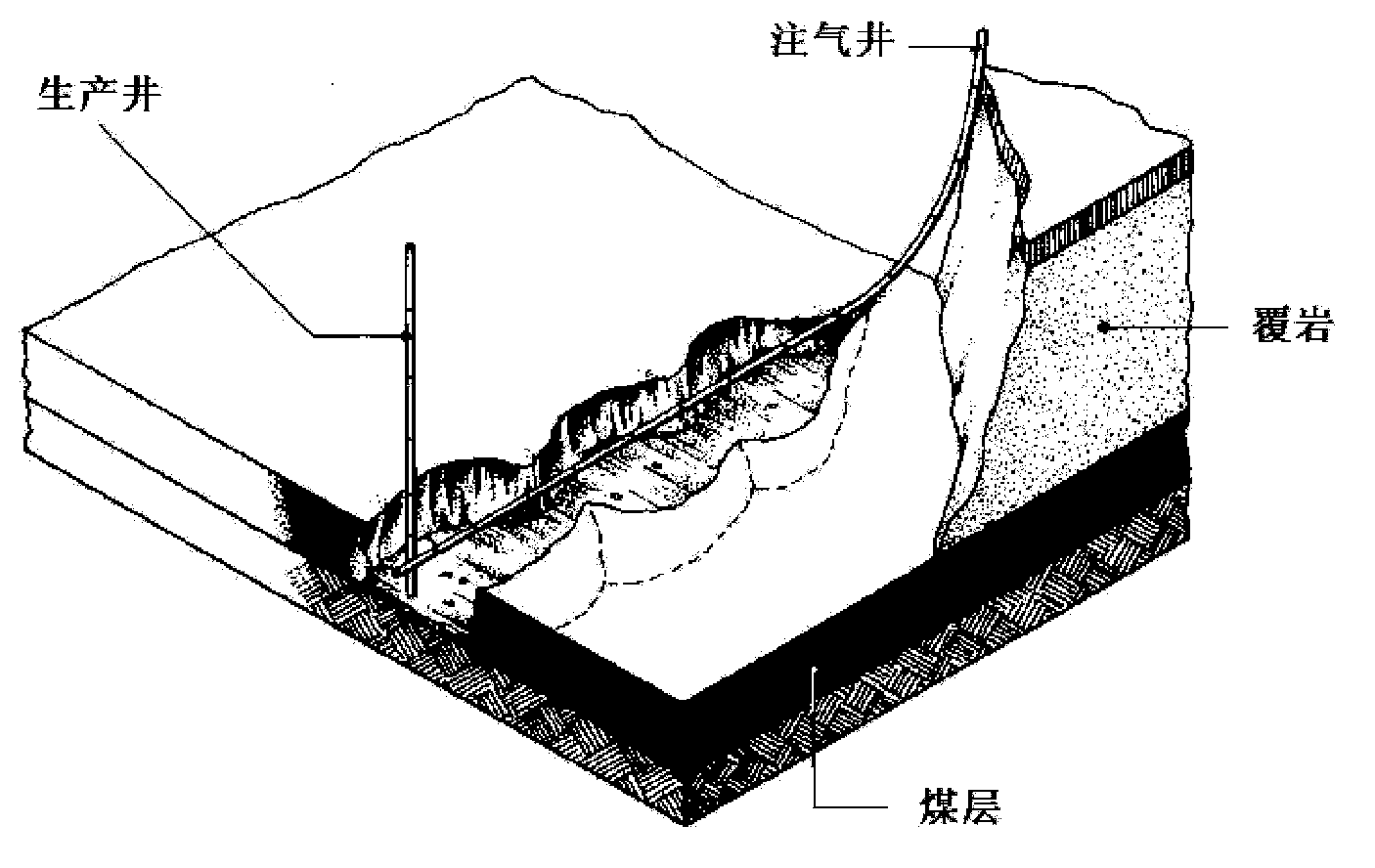

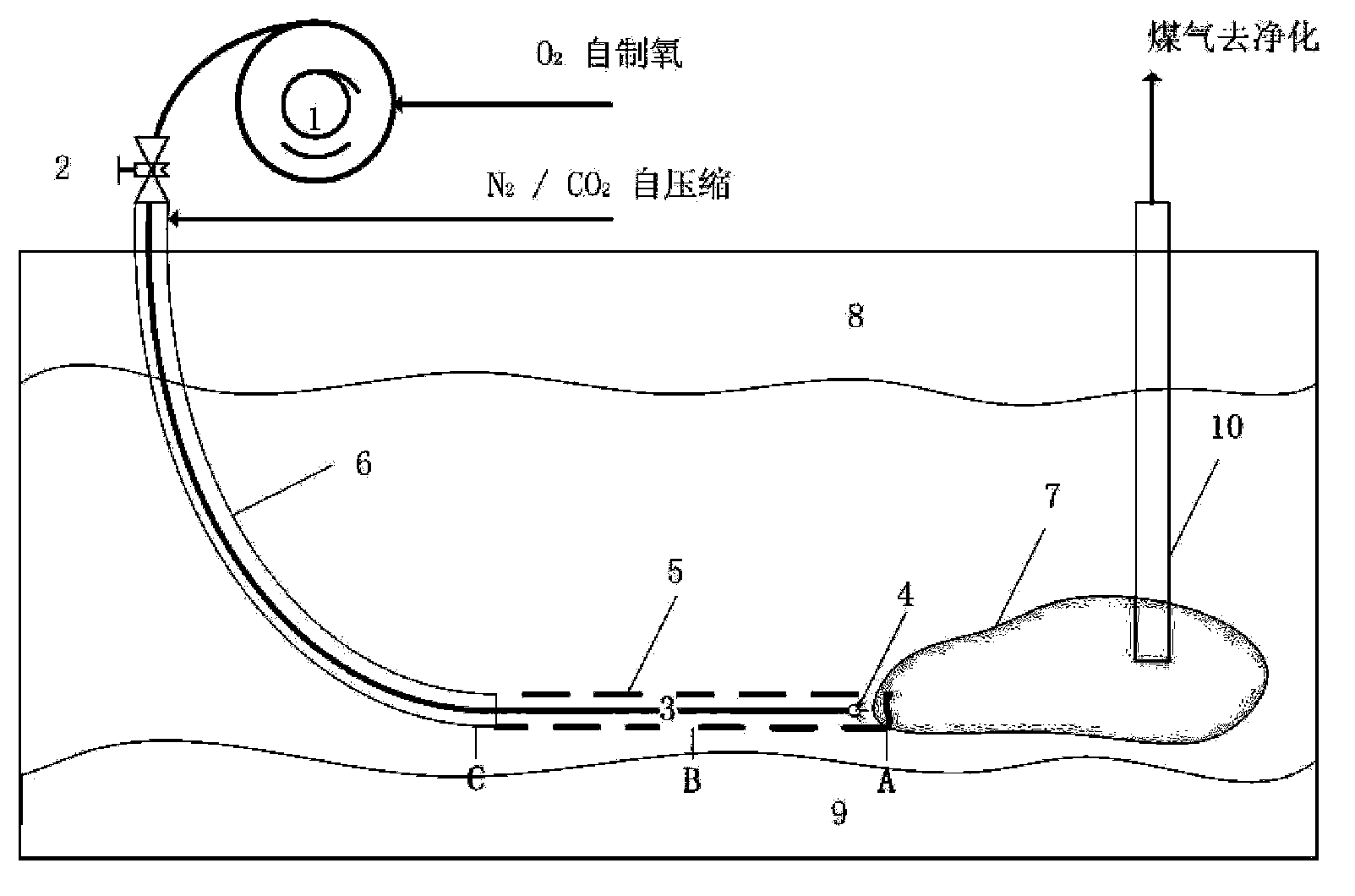

Controllable gas injection point gas injection device, gas injection technology and gasification method

ActiveCN104251133AReduce gasification combustion dead zoneImprove gasification recovery rateConstructionsFluid removalCombustionDirectional well

The invention relates to a controllable gas injection point gas injection device, a gas injection technology and a gasification method. The gas injection device comprises a directional well channel. A continuous oil pipe is arranged in the directional well channel and is communicated with an oxygen / oxygen-enriched gas pipeline; an annular space between the continuous oil pipe and the directional well channel is communicated with an auxiliary gasification agent pipeline and a steam pipeline; and a gas injection well head is arranged at the starting end of the continuous oil pipe, and a nozzle is arranged at the tail end of the continuous oil pipe. On the basis of the directional drilling and continuous oil pipe technology, the directional drilling and continuous oil pipe matched mode is utilized for achieving moving of a gas injection point, and on the principle of adjusting gasification agent injection parameters and controlling reverse combustion at the same time, the aims of adjusting and controlling the position movement and combustion speed of a flame working face and carrying out reverse combustion ignition and gasification of an underground coal seam can be achieved.

Owner:ENN SCI & TECH DEV

Thruster of hydrogen-oxygen catalytic ignition mini rocket

The invention provides a thruster of a hydrogen-oxygen catalytic ignition mini rocket, comprising a catalytic ignition device and a combustor device, wherein the catalytic ignition device comprises an end socket, a catalytic cylinder and a catalytic cylinder baseplate; and the combustor device comprises a graphite lining, a graphite precombustion chamber, a precombustion chamber sleeve, a nozzle steel jacket and a tungsten-doped copper nozzle. The thruster is used for realizing hydrogen-oxygen catalytic ignition which can be used for realizing the purpose of repeated ignition. Hydrogen inletsare uniformly distributed at the back semi-section of the combustor in the thruster in the circumferential direction, thus adjusting the hydrogen-oxygen mixing ratio and achieving an afterburning effect. The thruster is simple in structure and ensures that parts can be disassembled and replaced easily.

Owner:BEIHANG UNIV

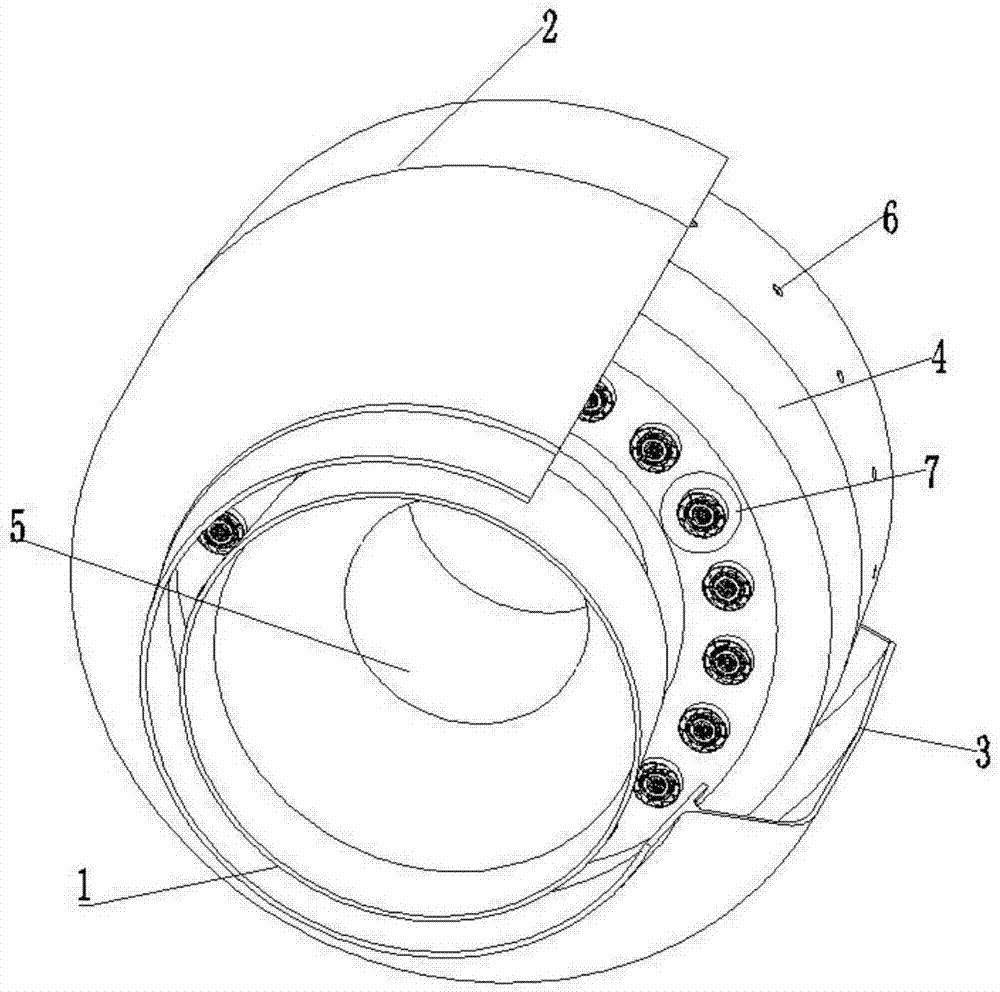

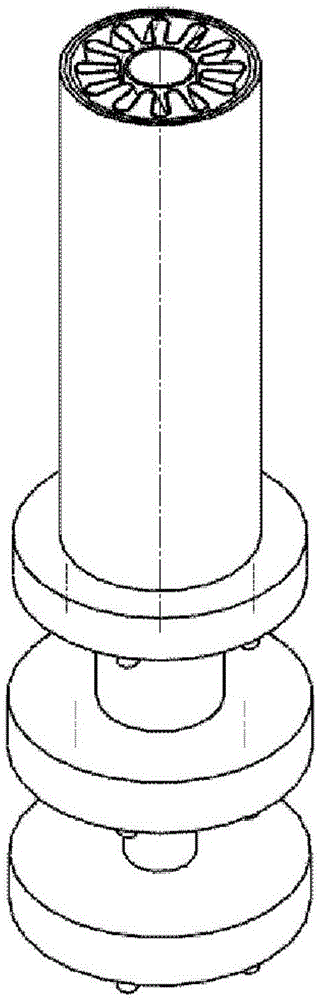

Swirler and pre-mixing combustor adopting same

ActiveCN105737203AReduce or eliminate low speed areasEasy power adjustmentContinuous combustion chamberLow speedCombustor

The invention discloses a swirler. The swirler comprises an outer wall, an inner wall and swirl vanes arranged between the outer wall and the inner wall, wherein the swirl vanes comprise big and small vanes which are arranged in a peripheral direction; both the big vanes and the small vanes comprise straight vane sections parallel to the central line of the swirler and bent vane sections having included angles with the central line of the swirler. A pre-mixing combustor comprising the swirler comprises a combustion gas turbine of the pre-mixing combustor, a boiler, an internal combustion engine or an aero-engine. According to the swirler and the pre-mixing combustor adopting same, the straight vane sections of the big vanes mainly achieve rectifying action, and the bent vane sections of the large vanes are used for regulating an airflow direction; and small vanes are used for regulating airflow speed distribution among large vanes to eliminate a low-speed airflow area, so that a tempering phenomenon is eliminated in a facilitated manner.

Owner:INNER MONGOLIA ZHONGKE PUSHI GAS TURBINE CO LTD

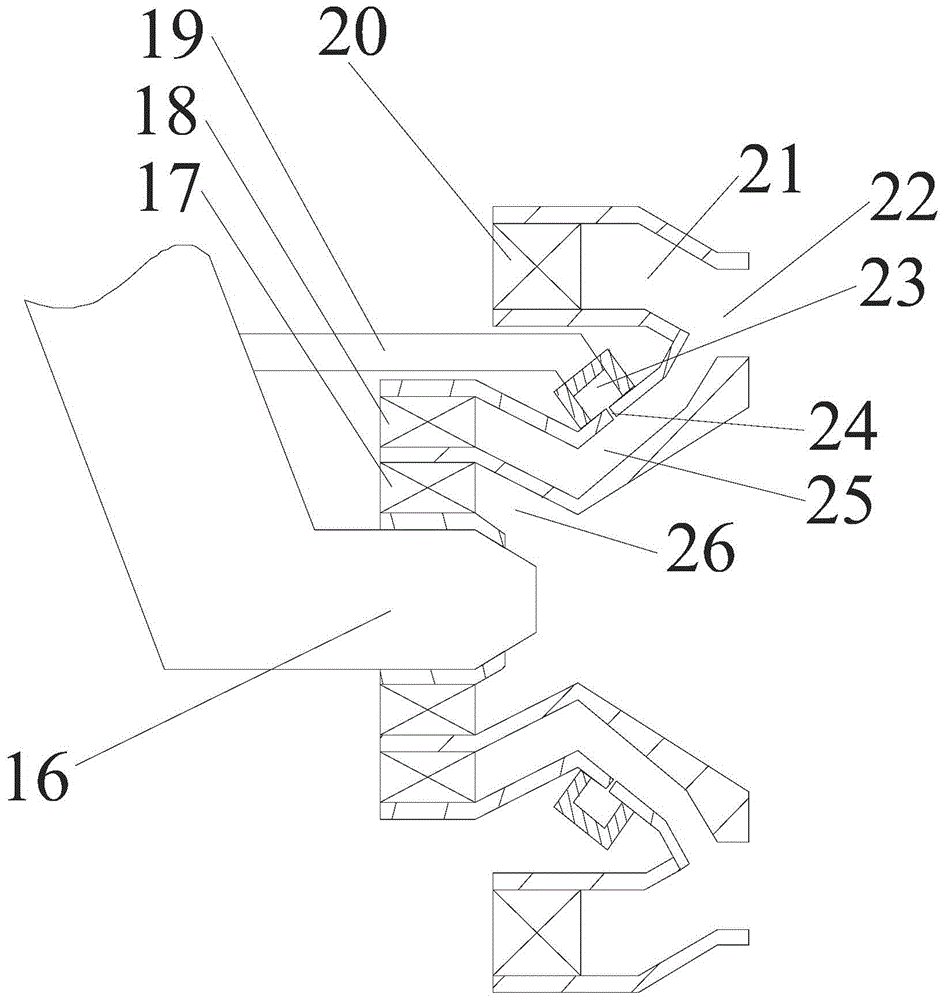

Adjustable nozzle, nozzle array and combustor

ActiveCN105910136ATake advantage ofImprove combustion effectContinuous combustion chamberWave structureCombustor

The invention provides an adjustable nozzle comprising an inner cylinder, an outer cylinder, an outer cylinder sleeve and N layers of outer wave structures clamped between the inner cylinder and the outer cylinder; the outer wave structures are radially arranged in sequence along the periphery; gas channels are formed between adjacent outer wave structures, and between the outer wave structures and the inner and outer cylinders; the outer cylinder sleeve is sleeved outside the outer cylinder, and can axially move along the cylinder shaft, thus switching work modes and adjusting flame positions.

Owner:INST OF ENGINEERING THERMOPHYSICS - CHINESE ACAD OF SCI

Honeycomb heater with infrared radiation function used on gas burner

ActiveCN101050875AUniform and stable flowFast decayDomestic stoves or rangesLighting and heating apparatusFiberCombustor

A cellular heating body being set with infrared radiation function and being used on fuel gas burner is prepared for forming surface cellular heating layer by high-temperature resisting and anticorrosion metal material and utilizing formed surface cellular heating layer as top layer of said cellular heating body, forming mesh body by high-temperature resisting and anticorrosion flexible metal material and utilizing formed mesh body as bottom layer of said cellular heating body.

Owner:罗添翼

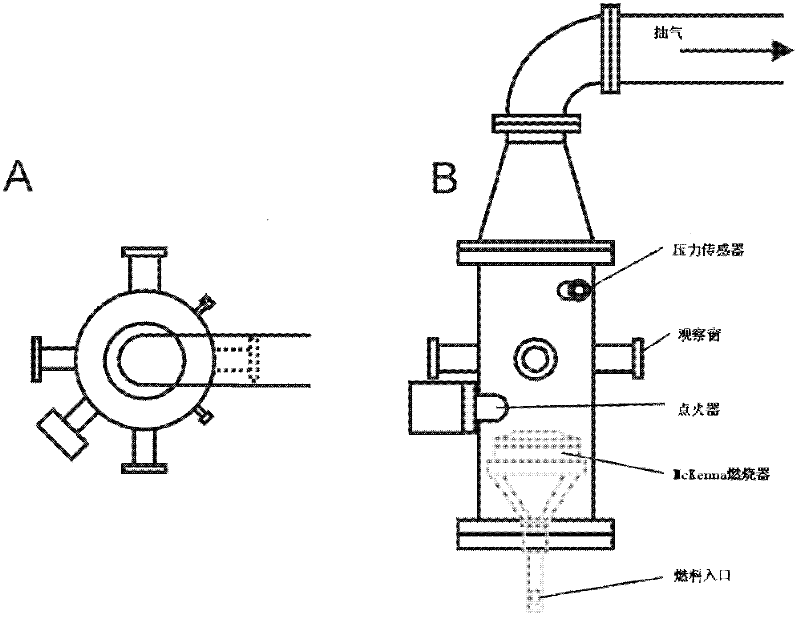

Flat-flamed burner

The invention discloses a flat-flamed burner. The flat-flamed burner comprises such modules as a stove plate (1), a pre-mixing air chamber (2), a protective air chamber (3), an experimental chamber (4), an air exhaust cap (5), a pressure regulator (6), observation window glass (9), a glass sealing cover (10), and the like. The flat-flamed burner is a modularization flat-flamed burner which is compact in structure, convenient in operation, high in safety and reliability, convenient to maintain after the improvement, capable of reducing photometric errors, self-adjustable in pressure and more stable in the generated flat flame. Different modules are designed, and then assembled to a burner of different functions, so that the modularization design method can constantly expand the application range of the flat-flamed burner.

Owner:NAT UNIV OF DEFENSE TECH

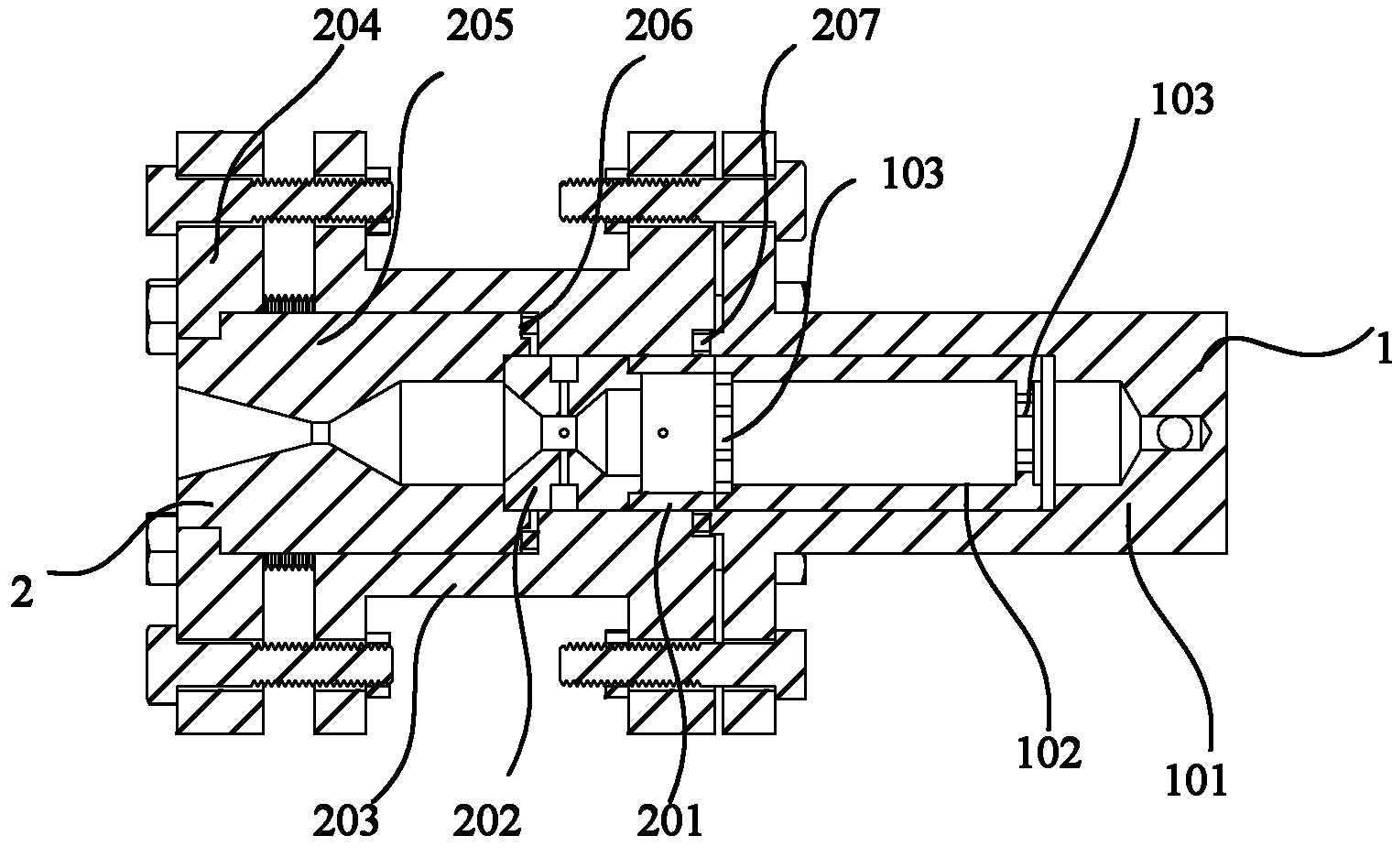

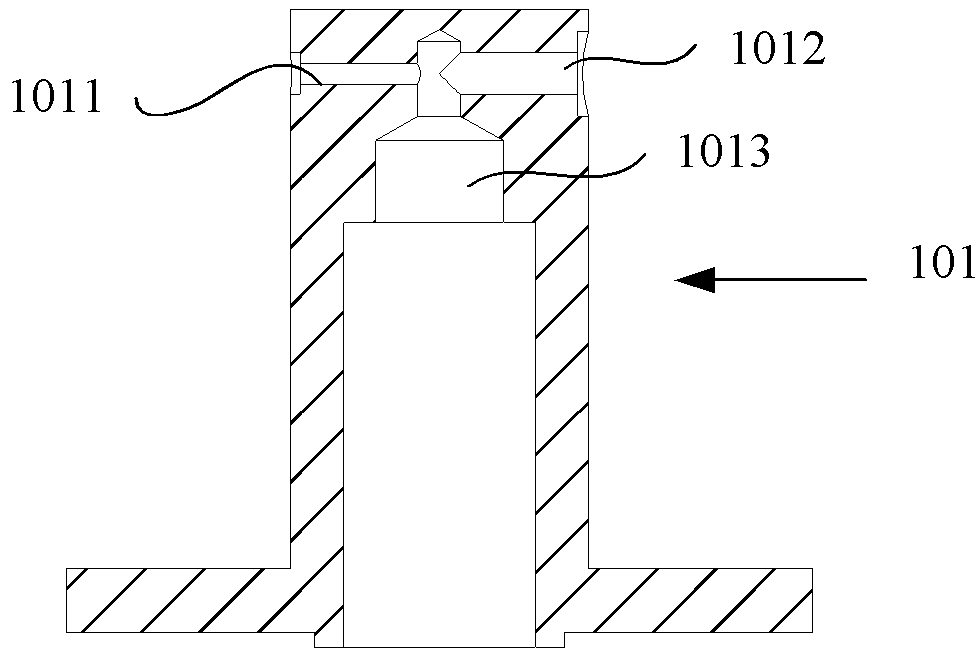

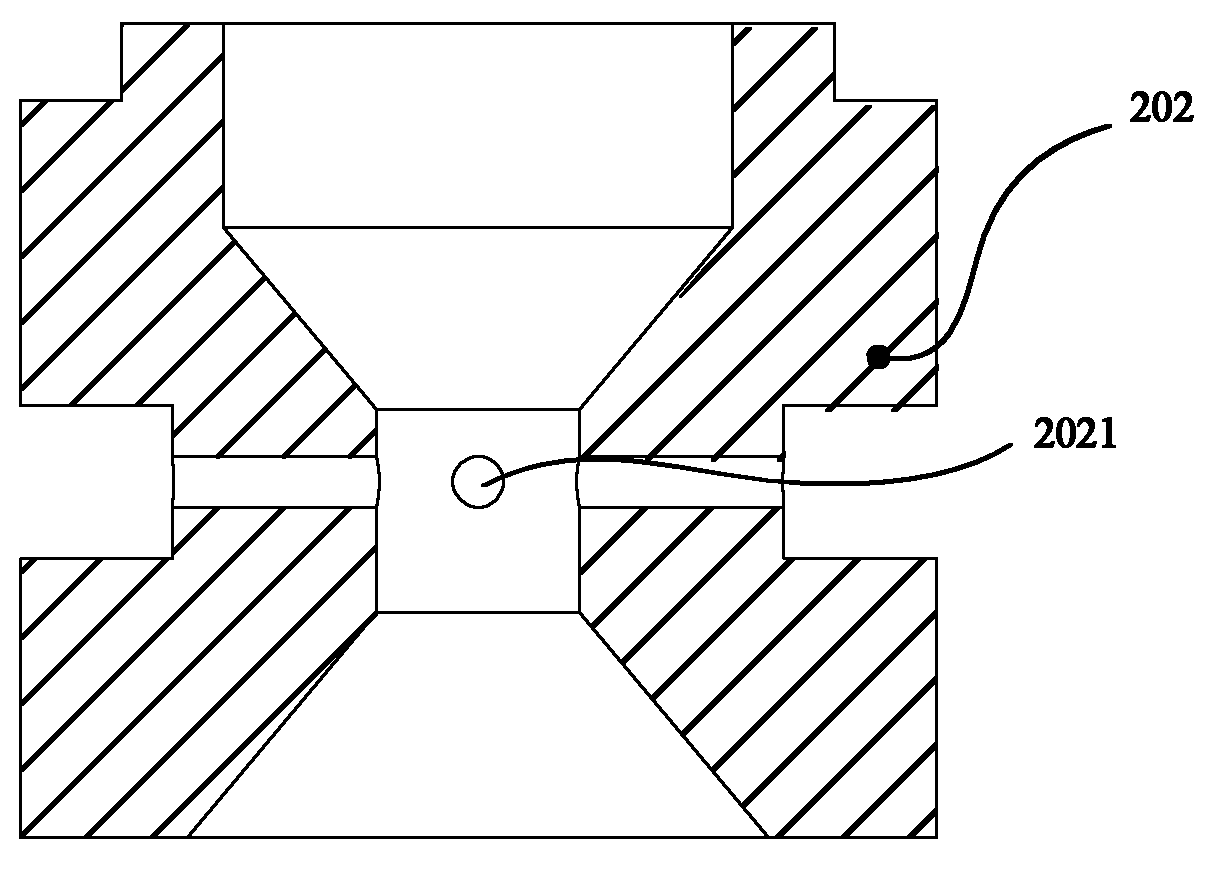

Anti-flashback nozzle and combustion device with the same

ActiveCN101315187AIncrease the turndown ratioPrevent backfireCombustion using gaseous and pulverulent fuelCombustion using liquid and pulverulent fuelCombustionBack-fire

The invention relates to an anti-backfire nozzle for a gas burner and a burning device by adopting the nozzle. The nozzle particularly comprises a shell. A fuel passage, a combustion supporting gas passage, a mixing chamber positioned at the downstream of the fuel passage and the combustion supporting gas passage and a spout are arranged in the shell; the mixing chamber has N-stage mutually-communicating cavities. On the radial section of the nozzle, the cross-sectional area of the cavity positioned at the upstream is smaller than that of the adjacent cavity at the downstream. When little circulating gas enters the cavity at the downstream, the mixed gas is burned in the cavity at the downstream and the adjacent cavity at the upstream. With the sharp increase of pressure of combustion products, the combustion products are instantly jet out of the nozzle, thereby preventing the flame from being blown off by the circulating gas flow. Since the nozzle is specially provided with the anti-backfire structure, the burning device with the nozzle is adaptable to reversal convection blowing, provides good working hot gas flow and ensures good stability and high regulation rate of the nozzle flame.

Owner:ECLIPSE COMBUSTION EQUIP SUZHOU CO LTD

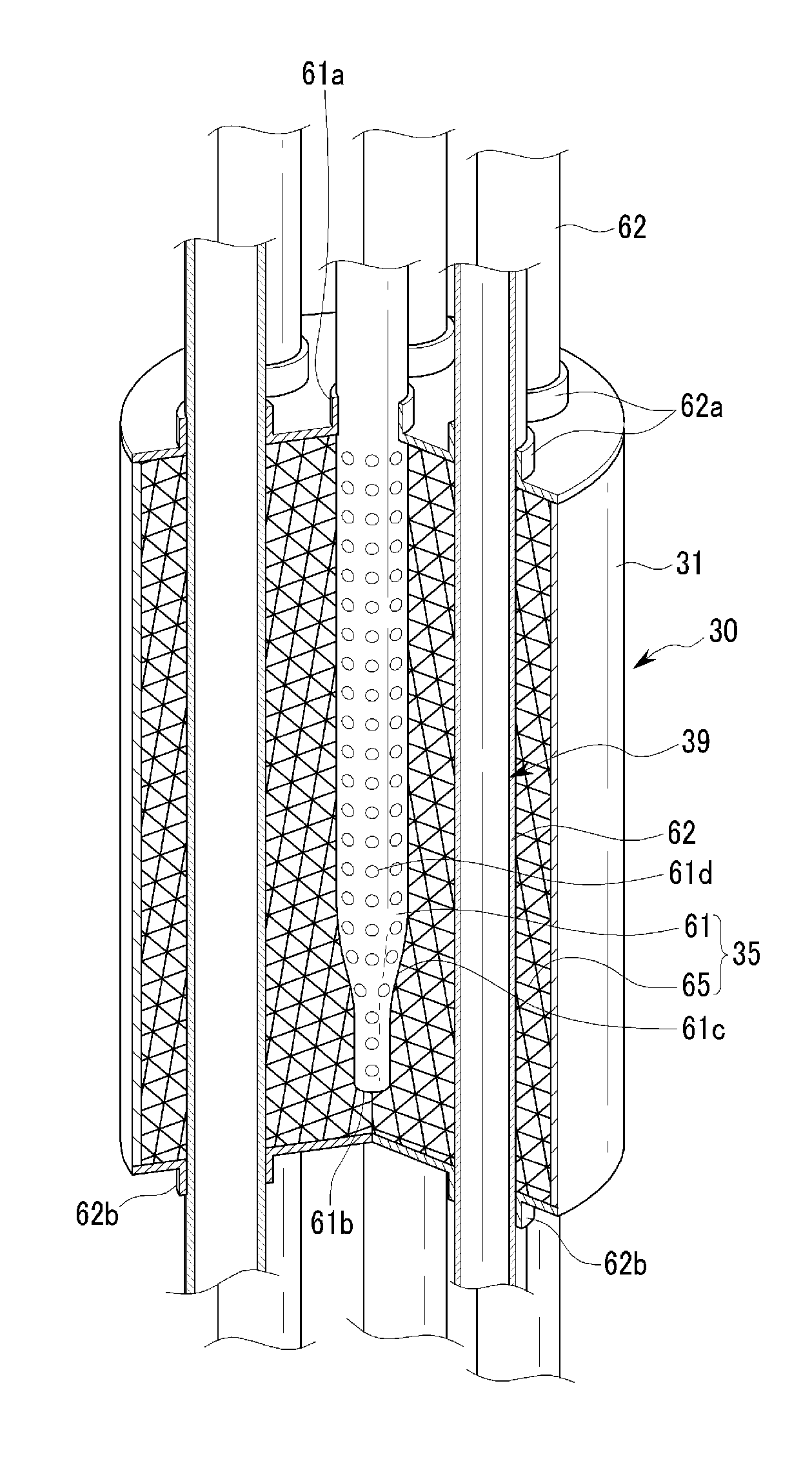

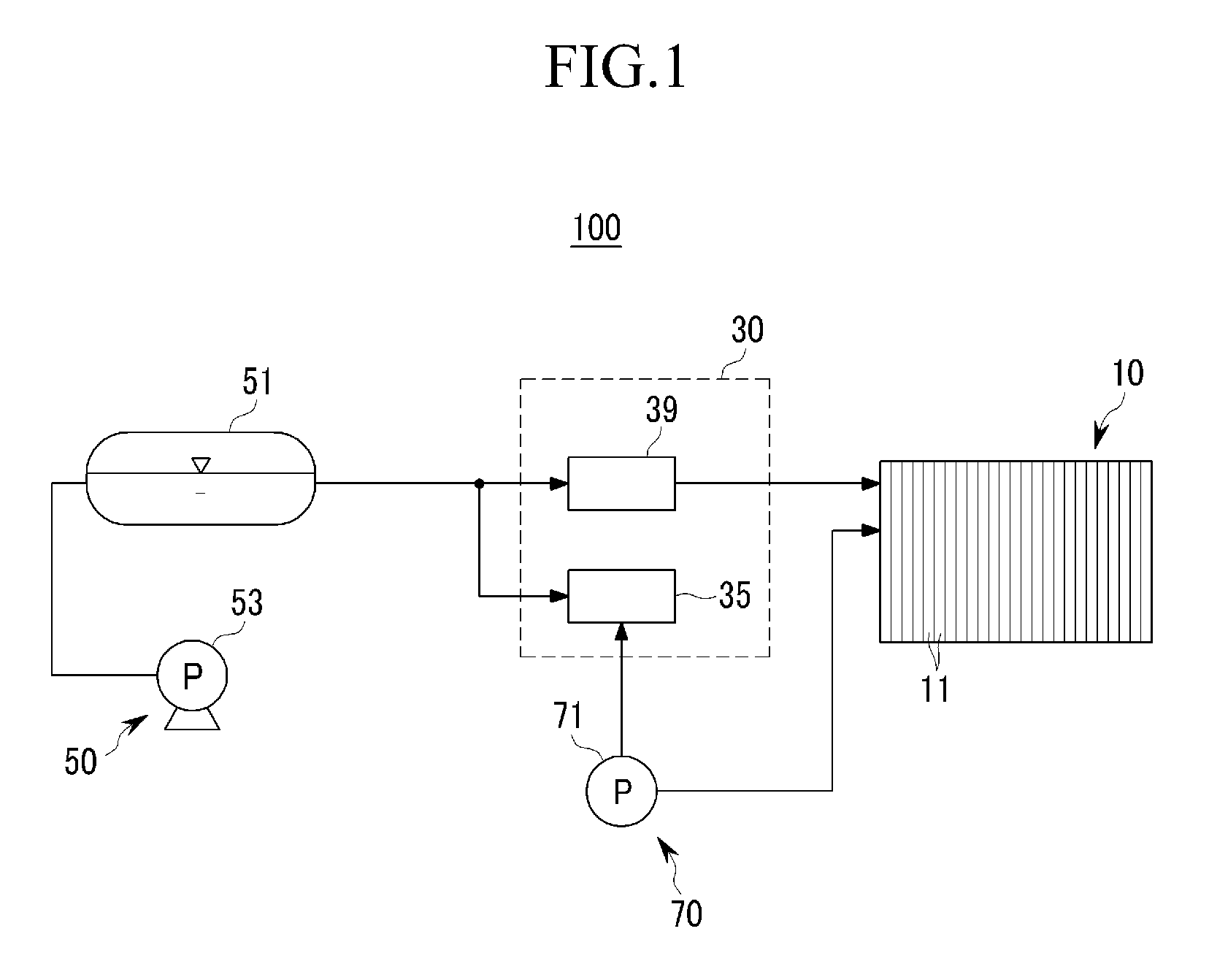

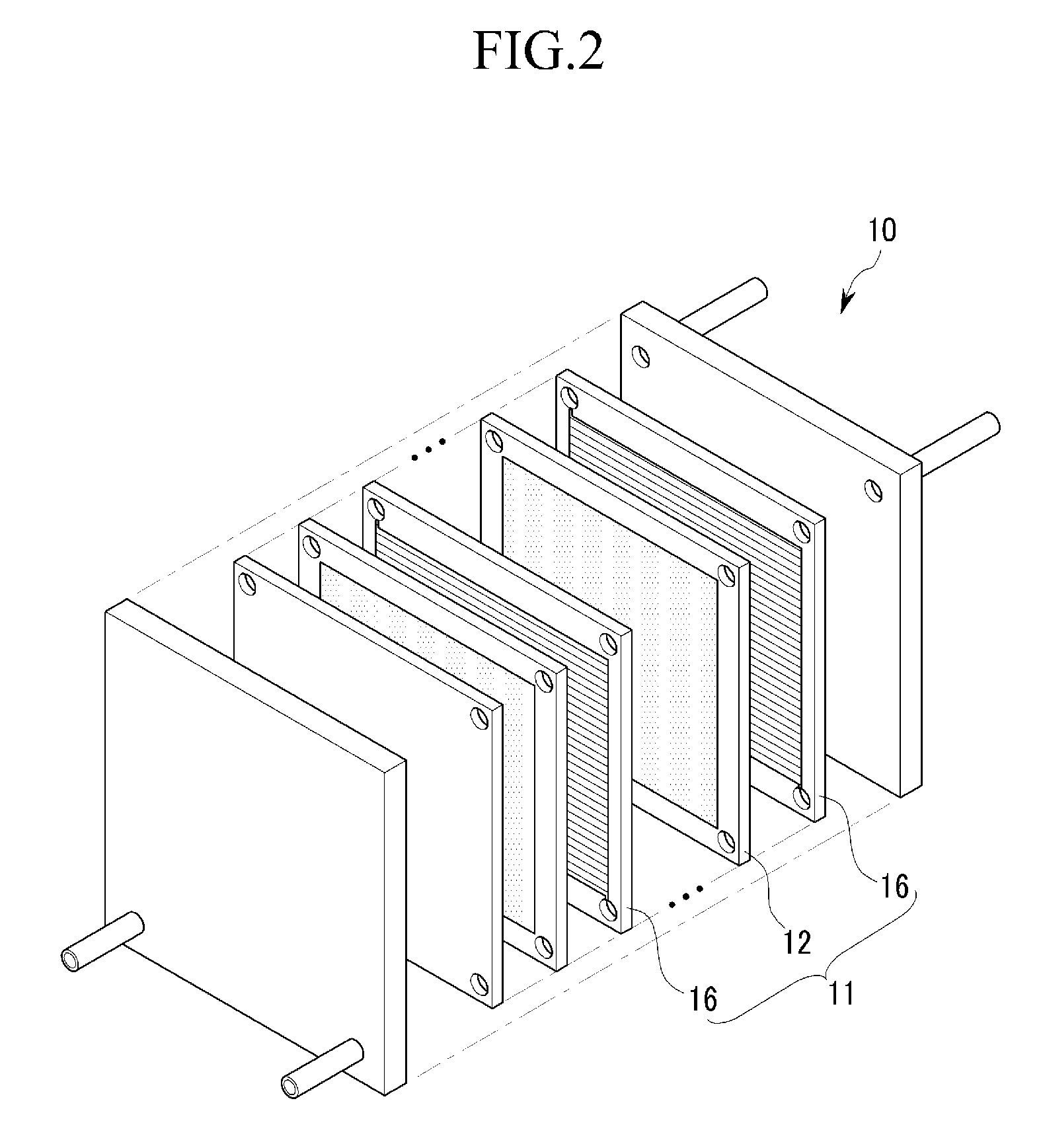

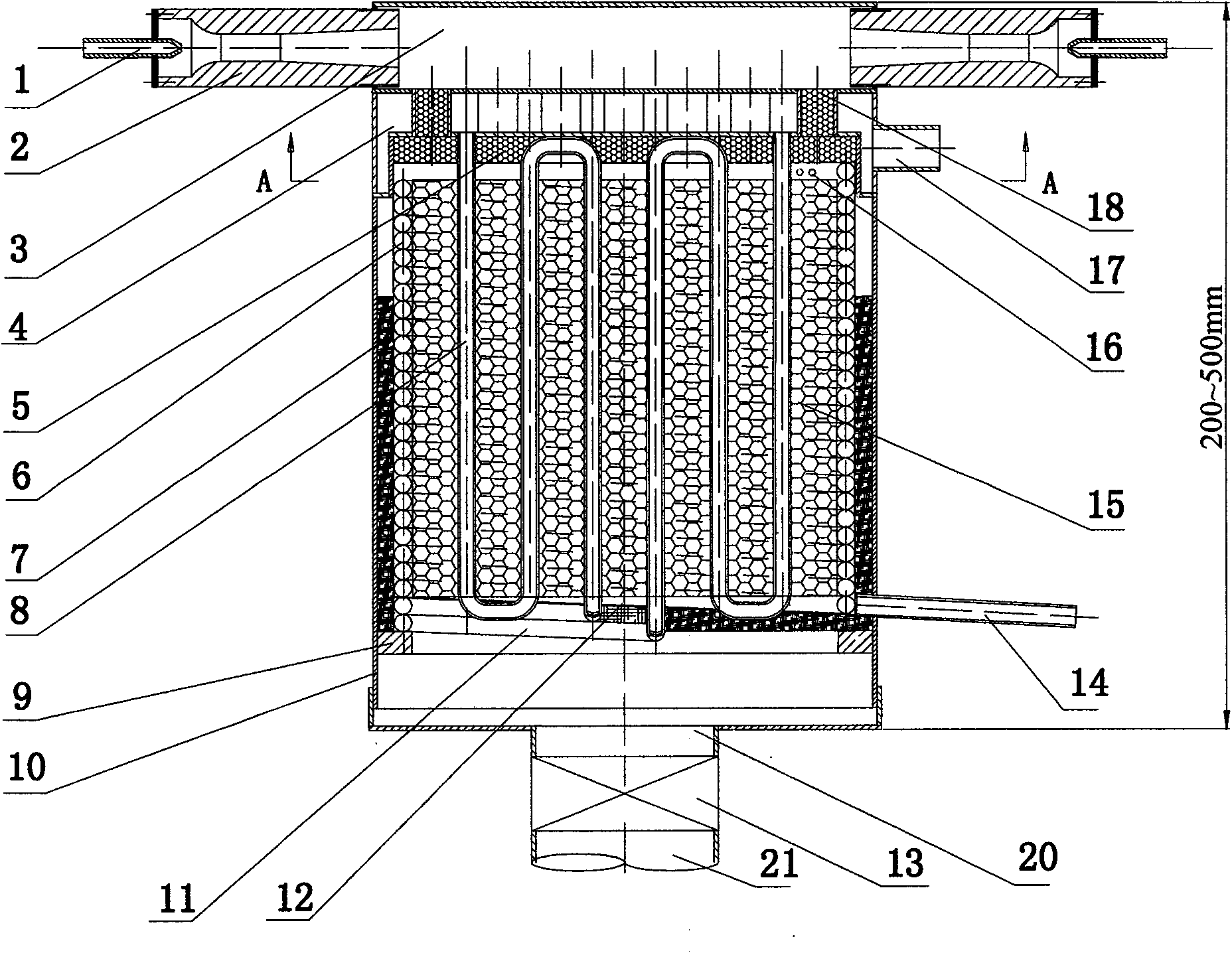

Fuel cell system and reformer

InactiveUS7985506B2Prevent backfireUniform supplyHydrogenFuel cell auxillariesElectrochemical responseChemical reaction

A fuel cell system and a reformer for a fuel cell system prevents backfire and improves efficiency of heat transfer. The fuel cell system includes a reformer generating hydrogen gas from fuel including hydrogen by a catalytic chemical reaction using heat energy, and at least one electricity generating unit generating electrical energy by an electrochemical reaction between the hydrogen gas and oxygen. The reformer includes a case, a heat source, and a reforming reaction part. The case forms an external shape. The heat source is disposed in the case to generate heat energy by an oxidation reaction between fuel and a catalyst, and includes a mesh, an oxidation catalyst layer formed on a surface of the mesh, and at least one fuel injection nozzle supplying the fuel to the oxidation catalyst layer. The reforming reaction part is disposed in the case to generate hydrogen gas from fuel using the heat energy generated from the heat source.

Owner:SAMSUNG SDI CO LTD

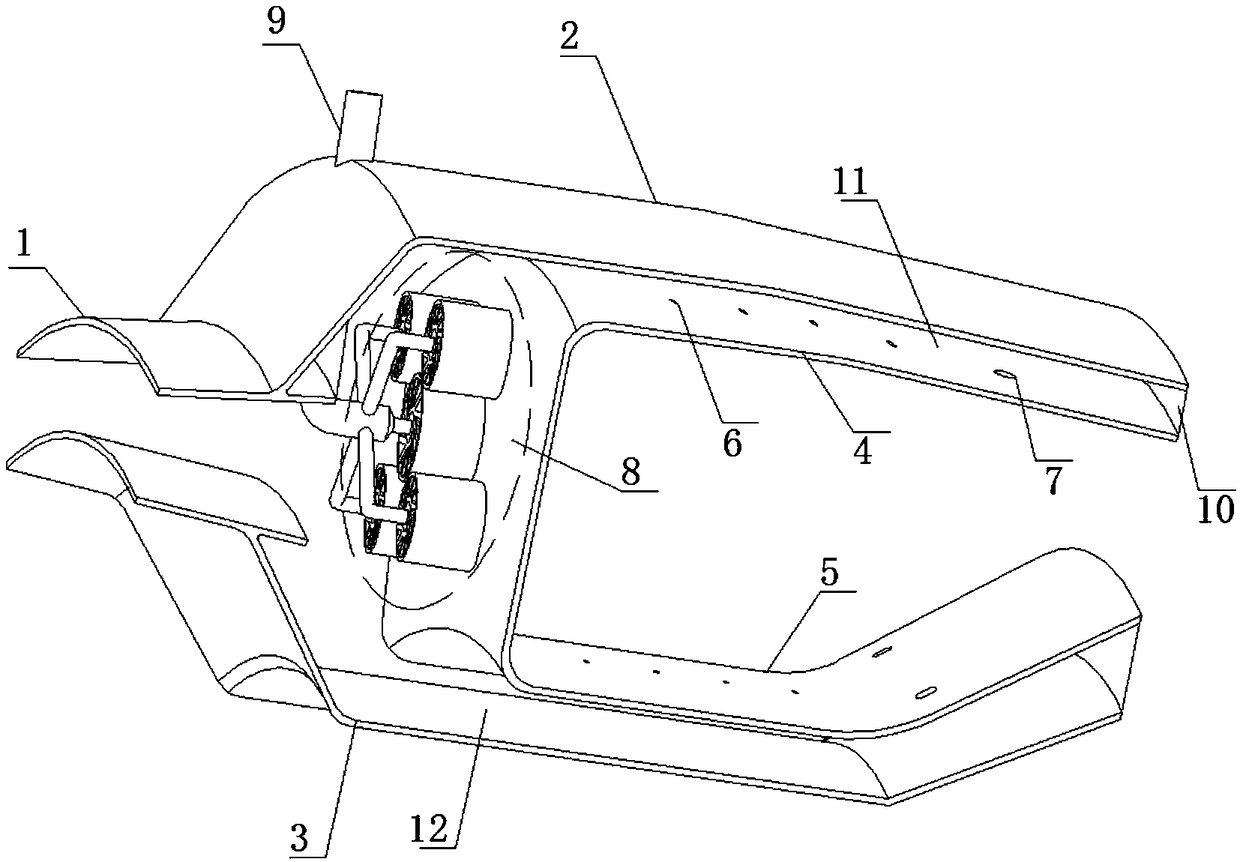

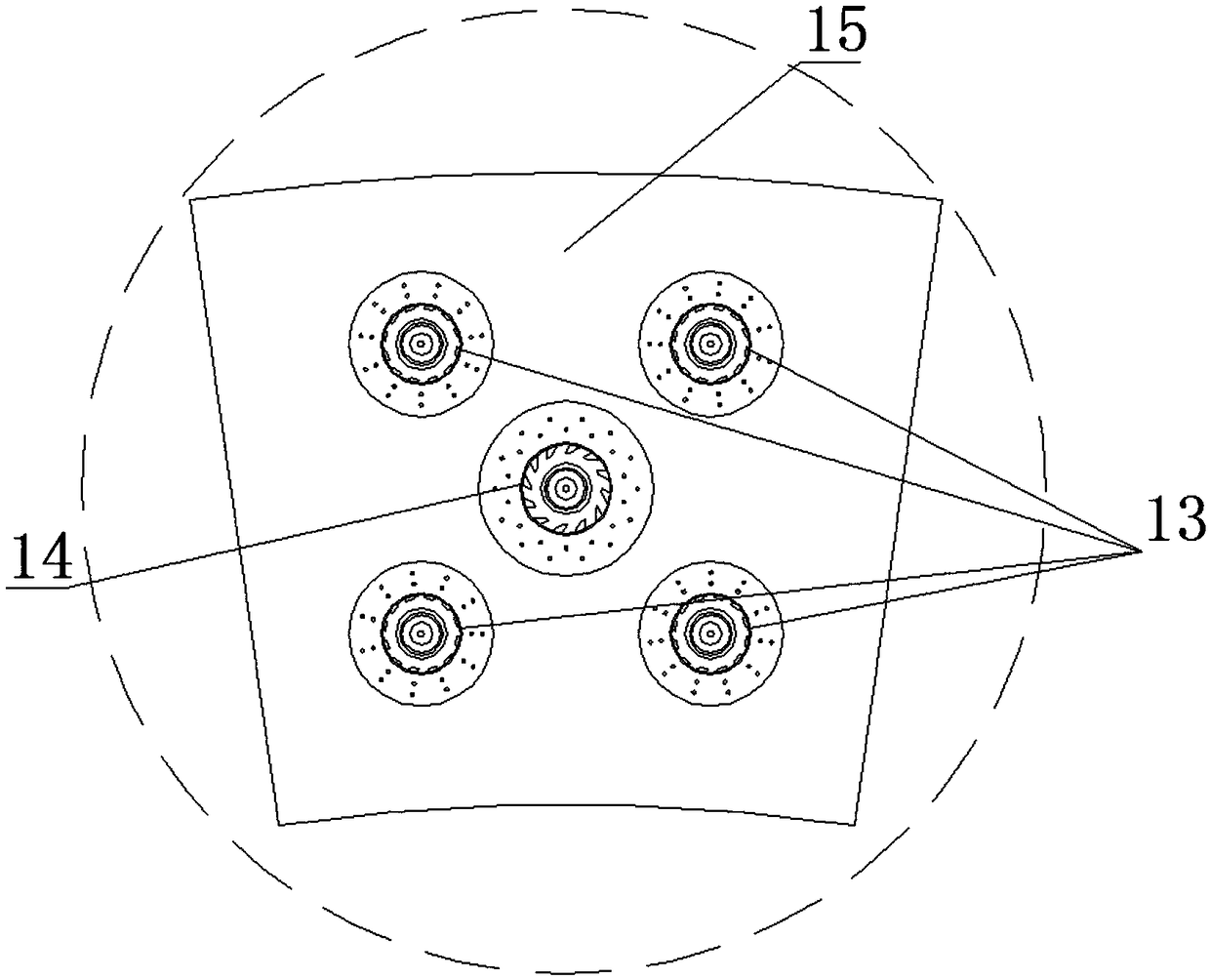

Correction method for large barrel type part heat treatment elliptical deformation in cold state

InactiveCN107186007ASave the preheating processSave manpower and material resourcesFurnace typesHeat treatment furnacesRoom temperatureEngineering

Disclosed is a correction method for large barrel type part heat treatment elliptical deformation in a cold state. Correction is conducted in the cold state of a part, the preheating procedure before correction is omitted, a jack and other existing tools are fully used, and manpower and material resources are saved. The part and a support rod are put into a furnace together, high-temperature tempering is conducted, thus elastic deformation of the part under the room temperature is converted into plastic deformation, and resilience is prevented. The correction method is simple to operate, energy is saved, and practicable and effective effects are achieved.

Owner:CITIC HEAVY INDUSTRIES CO LTD

Multipoint unit direct jetting staged combustion chamber

InactiveCN108954388AGuarantee job stabilityReduce the temperatureContinuous combustion chamberSpontaneous combustionCyclone

The invention relates to a multipoint unit direct jetting staged combustion chamber. A head part of the combustion chamber is provided with an on-duty stage and a main combustion stage; the on-duty stage and the main combustion stage both adopt a direct mixed combustion manner, spontaneous combustion and fire return phenomena are effectively avoided, and the risk of vibration combustion is reduced; in the low-speed running state, only the on-duty stage works, the on-duty stage adopts strong cyclone design, the local equivalence ratio is relatively rich, the stable work of the combustion chamber is guaranteed, along with increase of the working state of the combustion chamber, the main combustion stage is gradually opened, the main combustion stage adopts weak cyclone design, and the fuel gas staying time is effectively shortened; and in the high state, the main combustion stage and the on-duty stage work at the same time, the designed combustion area average equivalence ratio is 0.4-1.2, the combustion area average temperature is effectively reduced, and the contaminant generating quantity is reduced.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

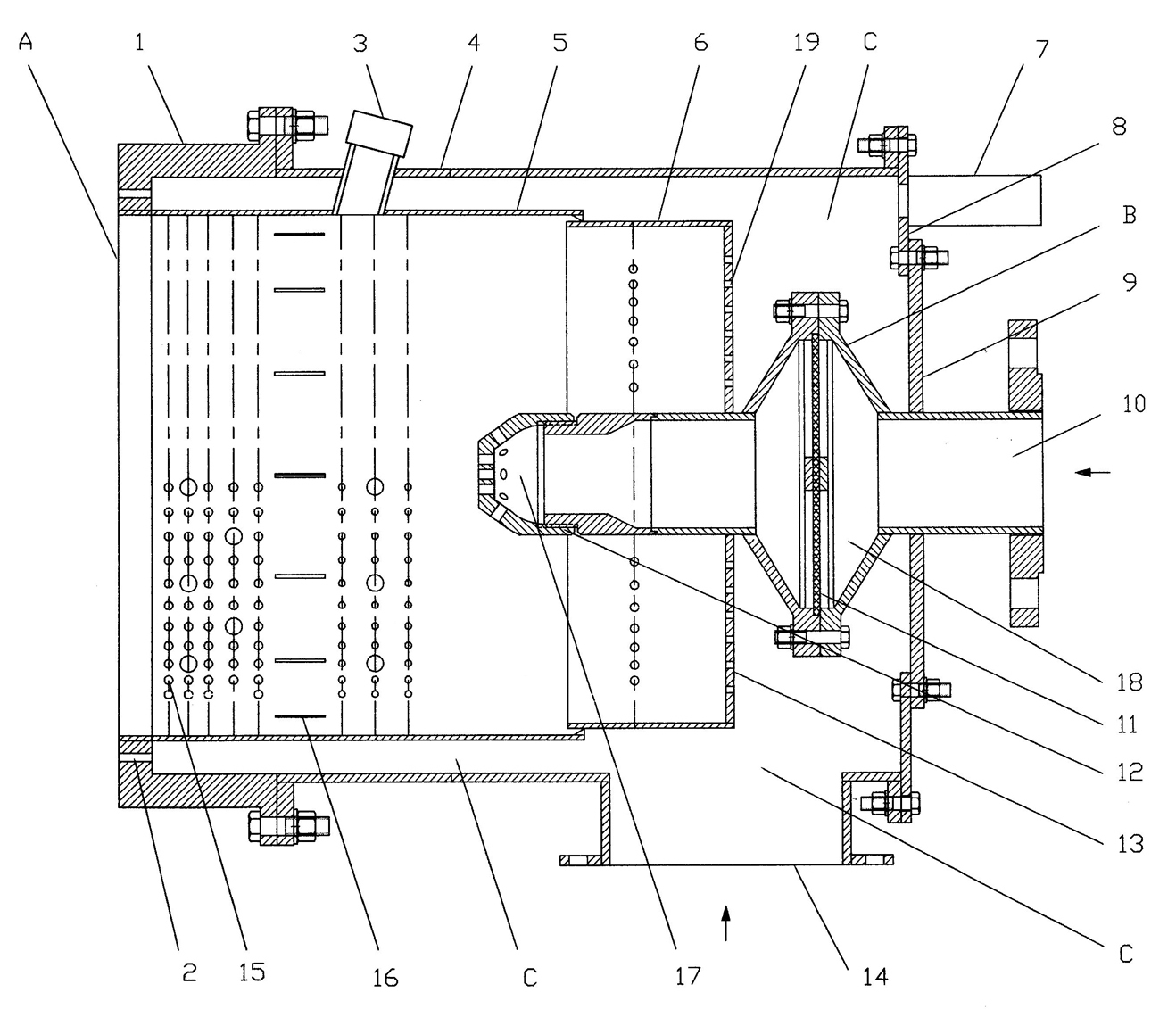

Fluidized bed catalytic deoxidation method and equipment for oxygen-containing coal bed gas

The invention relates to a fluidized bed catalytic deoxidation method for oxygen-containing coal bed gas. The fluidized bed catalytic deoxidation method comprises the following steps that: a fluidized bed deoxidation reactor is preheated to the temperature of 300-400 DEG C; the oxygen-containing coal bed gas is fed into the fluidized bed deoxidation reactor; deoxidation catalyst granules are loaded into a feed hopper and are added into the fluidized bed deoxidation reactor under the action of air blowing and supplying; methane and oxygen in the coal bed gas are subjected to low-temperature catalytic combustion reaction in the fluidized bed deoxidation reactor; the gas moves upwards with the carrying of part of solid catalyst granules and enters a one-stage cyclone separator and a two-stage cyclone separator from the top outlet of the fluidized bed deoxidation reactor, and the collected solid catalyst granules circularly enter the fluidized bed deoxidation reactor under the control of a feed back control valve and air blowing and supplying; and the deoxidated coal bed gas which is subjected to coarse dust removal by the cyclone separators is subjected to fine catalyst dust removal by a high-temperature filter, and then, is transferred to a follow-up system for use. The fluidized bed catalytic deoxidation method for the oxygen-containing coal bed gas has the advantages of good safety, low energy consumption, high deoxidation efficiency, long service life of catalyst and large processing capacity.

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI

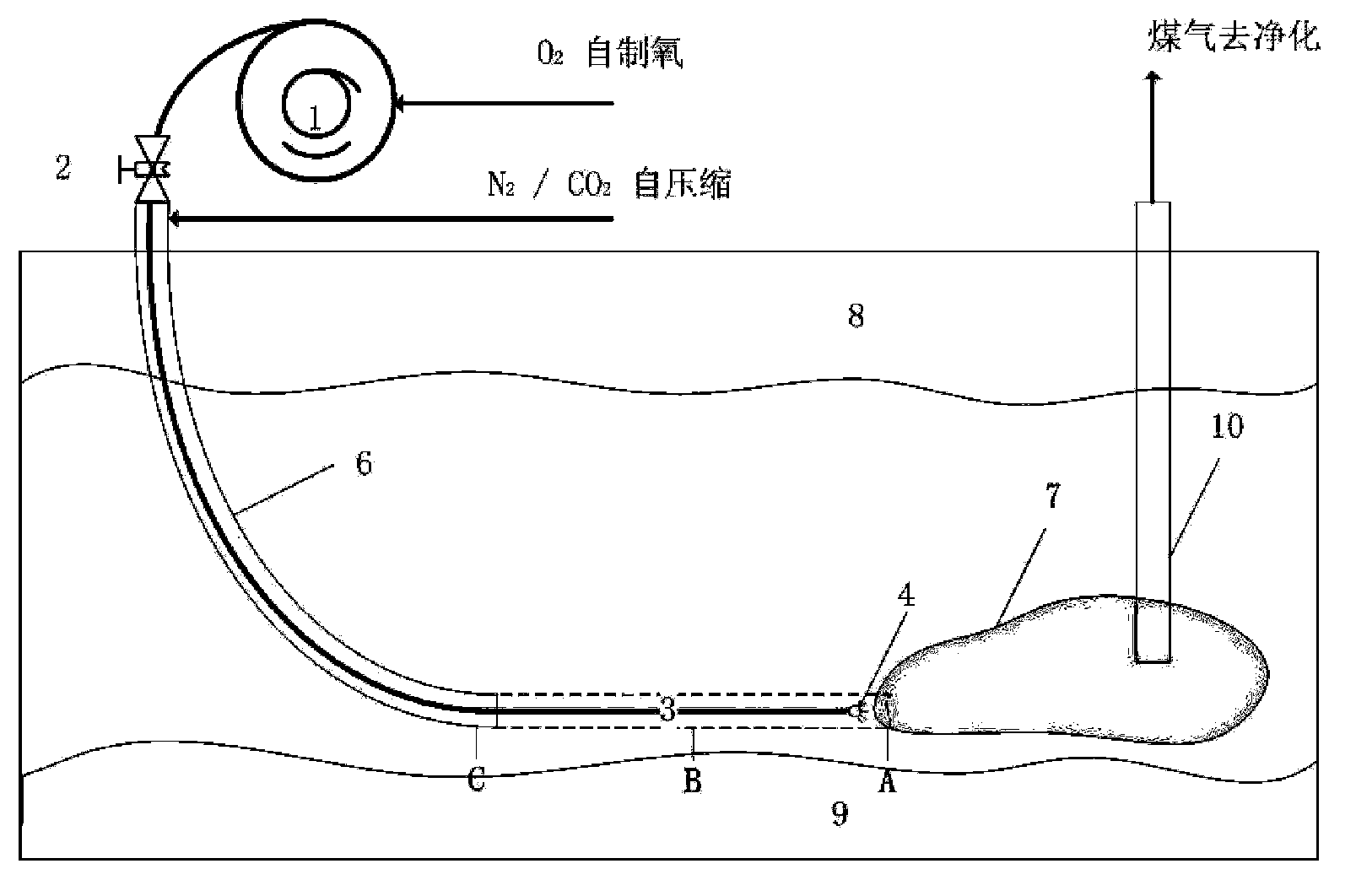

Underground fuel gasification method, gasifying agent delivery pipe and underground fuel gasification system

ActiveCN104895545AAchieve normalAchieve stabilizationConstructionsCoal gasificationWater vaporFuel gasification

The invention discloses an underground fuel gasification method, a gasifying agent delivery pipe and an underground fuel gasification system. The underground fuel gasification method comprises the steps of respectively and continuously delivering water and combustion-supporting gas to an underground fuel gasification reaction zone, atomizing the water delivered to the underground fuel gasification reaction zone by using pressure potential energy of water from the ground to the underground, mixing water vapor produced after atomization with the combustion-supporting gas delivered to the underground fuel gasification reaction zone to form mist gasifying agent, and producing fuel gas through gasification reaction between the mist gasifying agent and the underground fuel in the underground fuel gasification reaction zone by combustion and heating. The gasifying agent delivery pipe comprises a water delivery pipe and a gas delivery pipe. The underground fuel gasification system comprises an underground gasification furnace, the gasifying agent delivery pipe and an atomizing and mixing nozzle. The water and combustion-supporting gas can be mixed in the underground fuel gasification reaction zone to form the mist gasifying agent without using heat, the normalization and stabilization of the underground gasification process are realized, and the production cost is greatly reduced.

Owner:CHINA UNIV OF MINING & TECH (BEIJING)

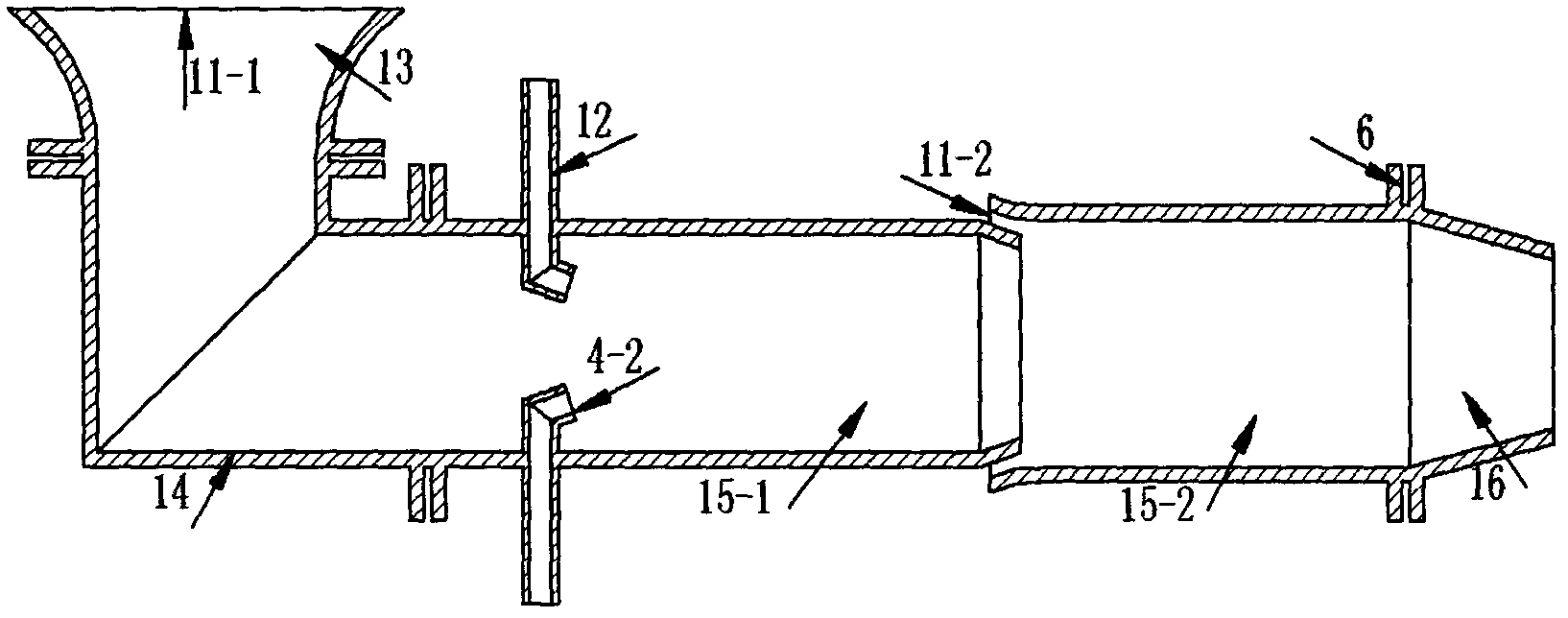

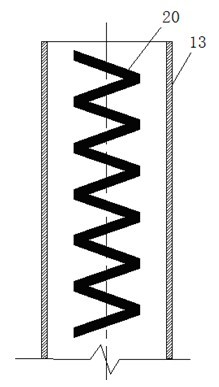

Aspirating type combined pulse detonation engine with secondary detonation

InactiveCN102434317AImprove performanceLong Knock Working TimeRocket engine plantsHigh pressurePulse detonation engine

The invention provides an aspirating type combined pulse detonation engine with a secondary detonation, comprising a predetonation pipe and a main detonation chamber, wherein the main detonation chamber comprises an inspiratory horn nozzle, a rotary joint, a main detonation forming chamber and a contracting nozzle; the rotary joint is a 90 degrees turned circular tube structure; the main detonation forming chamber is composed of two stages circular tubes coaxially connected; the two ends of the rotary joint are fixedly connected with the inspiratory horn nozzle and the first stage circular tube of the main detonation forming chamber; the predetonation pipe is inserted through the pipe wall on one side of the inspiratory horn nozzle, wherein the side is connected with the rotary joint. The aspirating type combined pulse detonation engine makes use of high temperature and high pressure products discharged from the predetonation pipe and can effectively inject outside fresh air into the main detonation forming chamber. The inspiratory horn nozzle is connected with the main detonation forming chamber through the rotary joint to effectively prevent tempering and reversed transmission, and increase the injected air amount. A gap is arranged between the first stage circular tube and the second stage circular tube of the main detonation forming chamber, wherein the outside air enters the main detonation forming chamber through the gap to increase the filling amount of oxidants in back end of the main detonation chamber.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

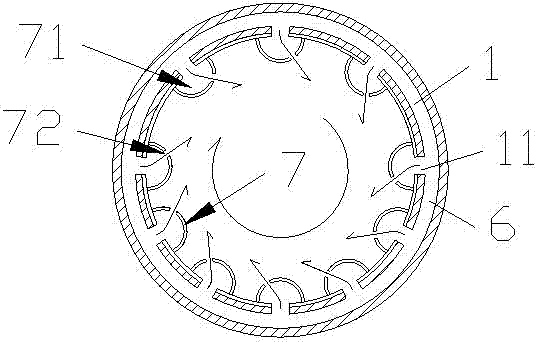

Horizontal type cyclone combustion biomass burning machine

ActiveCN103090364AGuaranteed combustion effectPrevent backfireSolid fuel combustionBlast-producing apparatusAutomotive engineeringAcute angle

The invention provides a horizontal type cyclone combustion biomass burning machine, wherein the horizontal type cyclone combustion biomass burning machine enables fuel to burn sufficiently, prevents the fuel from coking and accumulating and has a long service life. The horizontal type cyclone combustion biomass burning machine comprises a horizontal type cylindrical combustion chamber, wherein one end of the combustion chamber is closed, and the closed end is provided with an outlet of a fuel feeding passageway. A feeding auger is arranged inside the fuel feeding passageway, and a blower nozzle which is used for blowing air to the outlet of the fuel feeding passageway is arranged on the fuel feeding passageway. A wind inlet passageway is formed in the wall of the combustion chamber, a cyclone pipe is arranged on the inner wall of the combustion chamber, and an inner cavity of the cyclone pipe is communicated with the wind inlet passageway. Wind outlets are formed in the cyclone pipe, an acute angle is formed between the axial direction of each wind outlet and the radial direction of the cylindrical combustion chamber, and therefore gas which enters the inner cavity of the cyclone pipe from the wind inlet passageway and comes out from the wind outlets is enabled to form vortexes rotating in the same direction in the cylindrical combustion chamber.

Owner:胡光

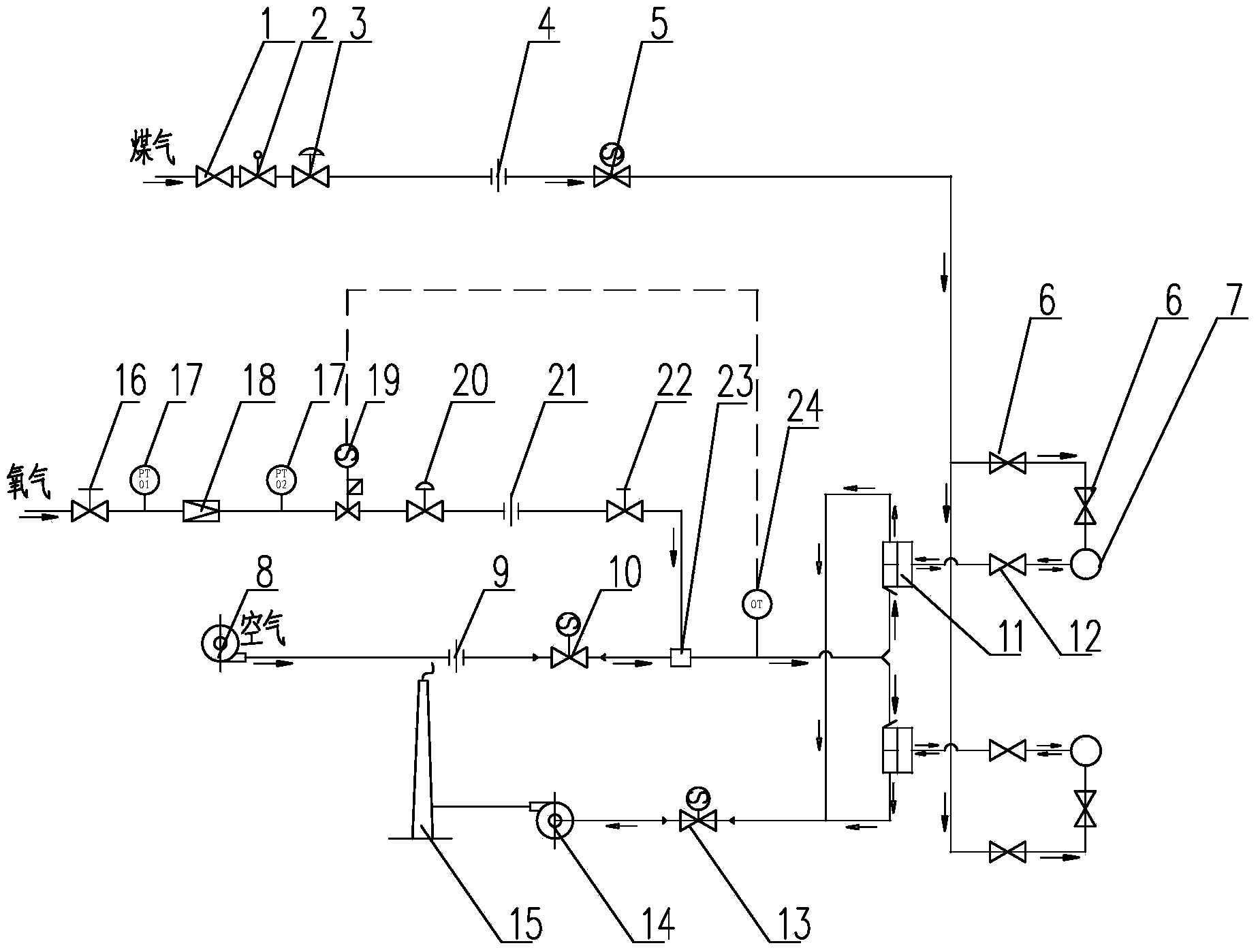

Cold crude gas heat accumulating type oxygen-enriched combustion method and cold crude gas heat accumulating type oxygen-enriched combustion system

InactiveCN103953920AReduce generationPromote environmental protectionDirect carbon-dioxide mitigationIndirect carbon-dioxide mitigationCombustion systemOxygen system

The invention relates to a cold crude gas heat accumulating type oxygen-enriched combustion method and a cold crude gas heat accumulating type oxygen-enriched combustion system. The combustion method comprises the steps of transmitting cold crude gas, generating and transmitting mixed oxygen-enriched air, reversing the oxygen-enriched air by an air-smoke reversing valve, heating the reversed oxygen-enriched air in a heat accumulating type burner, mixing the oxygen-enriched air with gas for burning, discharging smoke, and the like; the combustion system comprises a gas system, an air-smoke system and an oxygen system, wherein the tail end of a pipeline of the oxygen system is connected with a dynamic mixer of the air-smoke system; the tail end of a branch behind the air-smoke reversing valve in the air-smoke system is connected with the heat accumulating type burner of the gas system. Compared with the prior art, the method and the system have the beneficial effects that (1) the burning velocity is increased, the tempering is avoided, and the combustion safety is improved; (2) the ignition temperature of fuel and the burn out time are reduced; (3) the excess air coefficient is reduced, and the amount of the smoke after combustion can be reduced; (4) the production of CO2 and NOX can be effectively reduced, so that the environmental protection can be better realized; (5) the system is simple in structure, convenient to operate and high in degree of automation.

Owner:辽宁向导科技发展有限公司

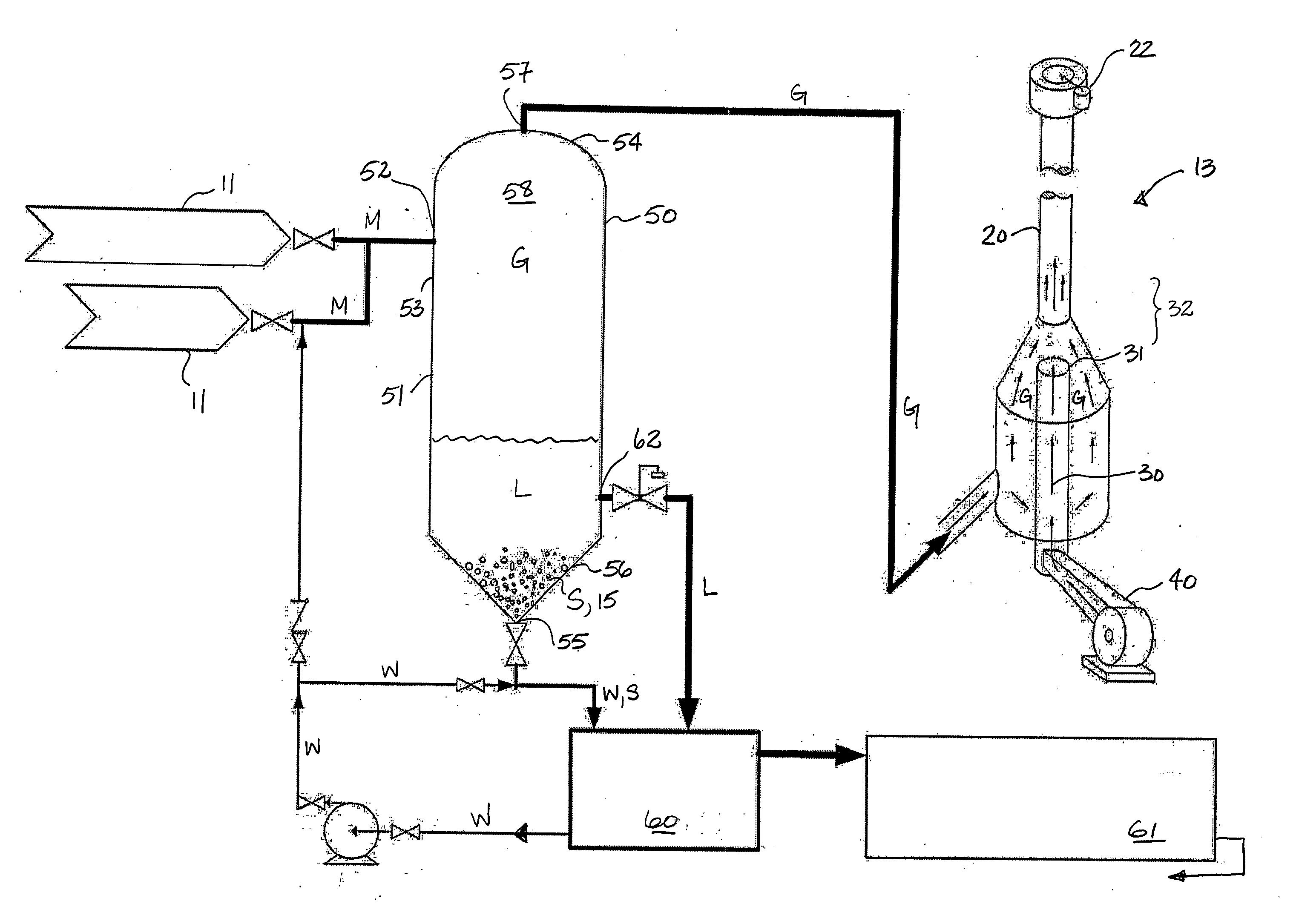

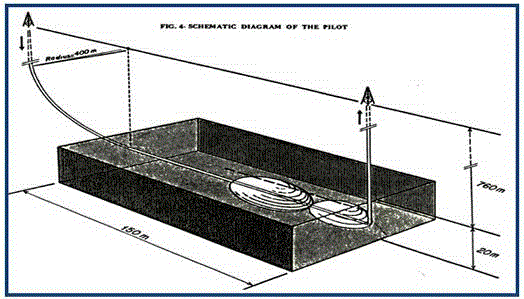

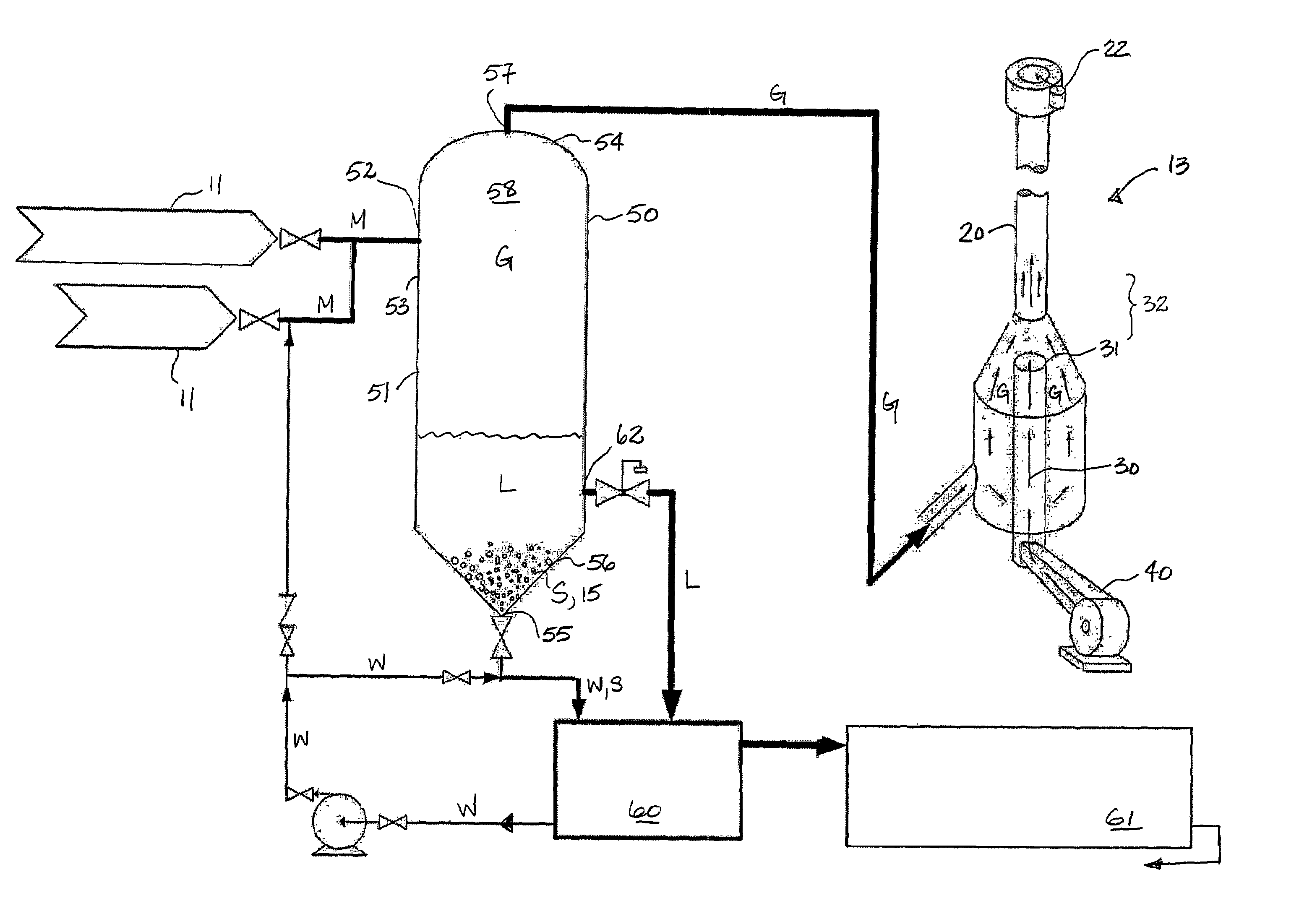

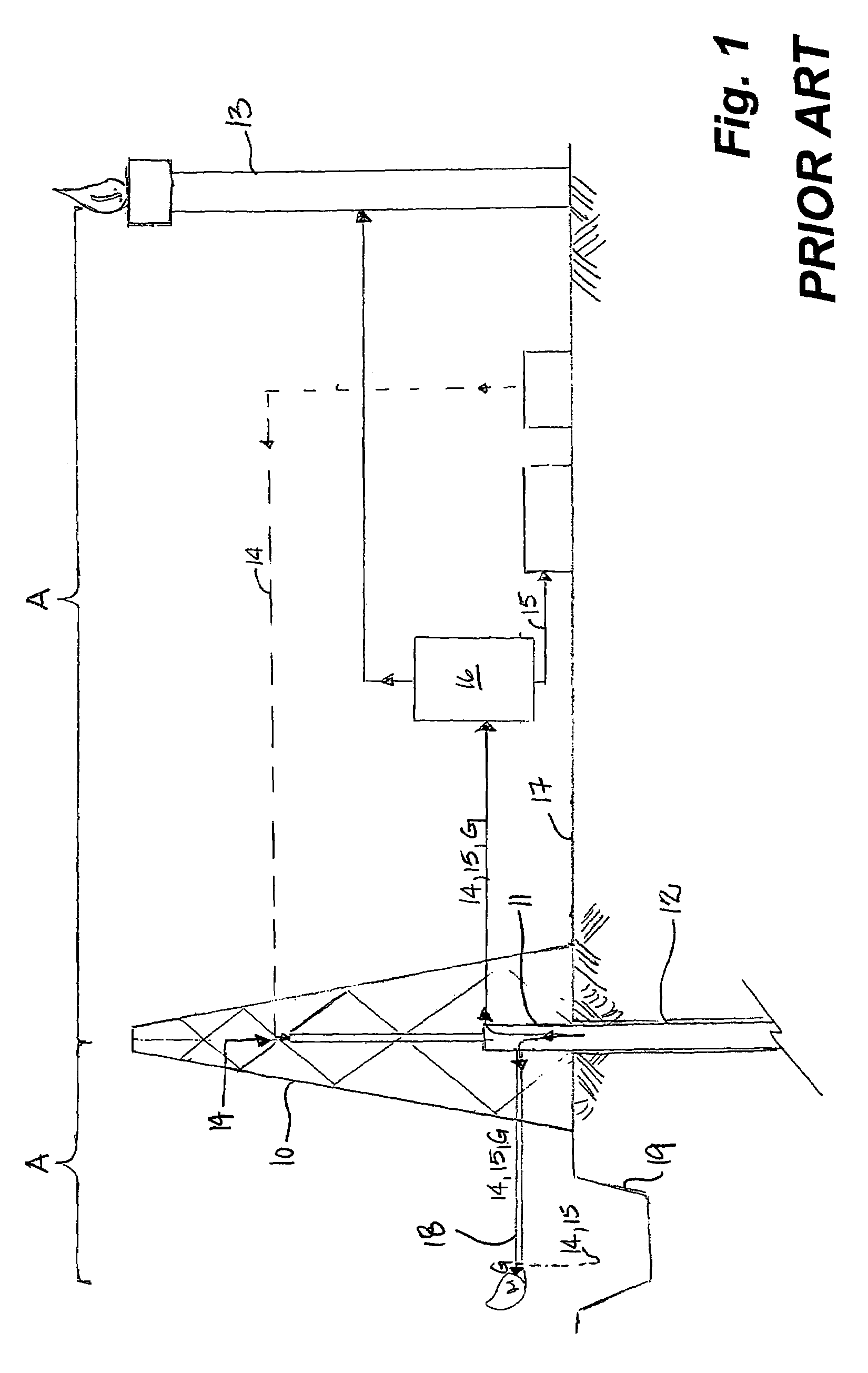

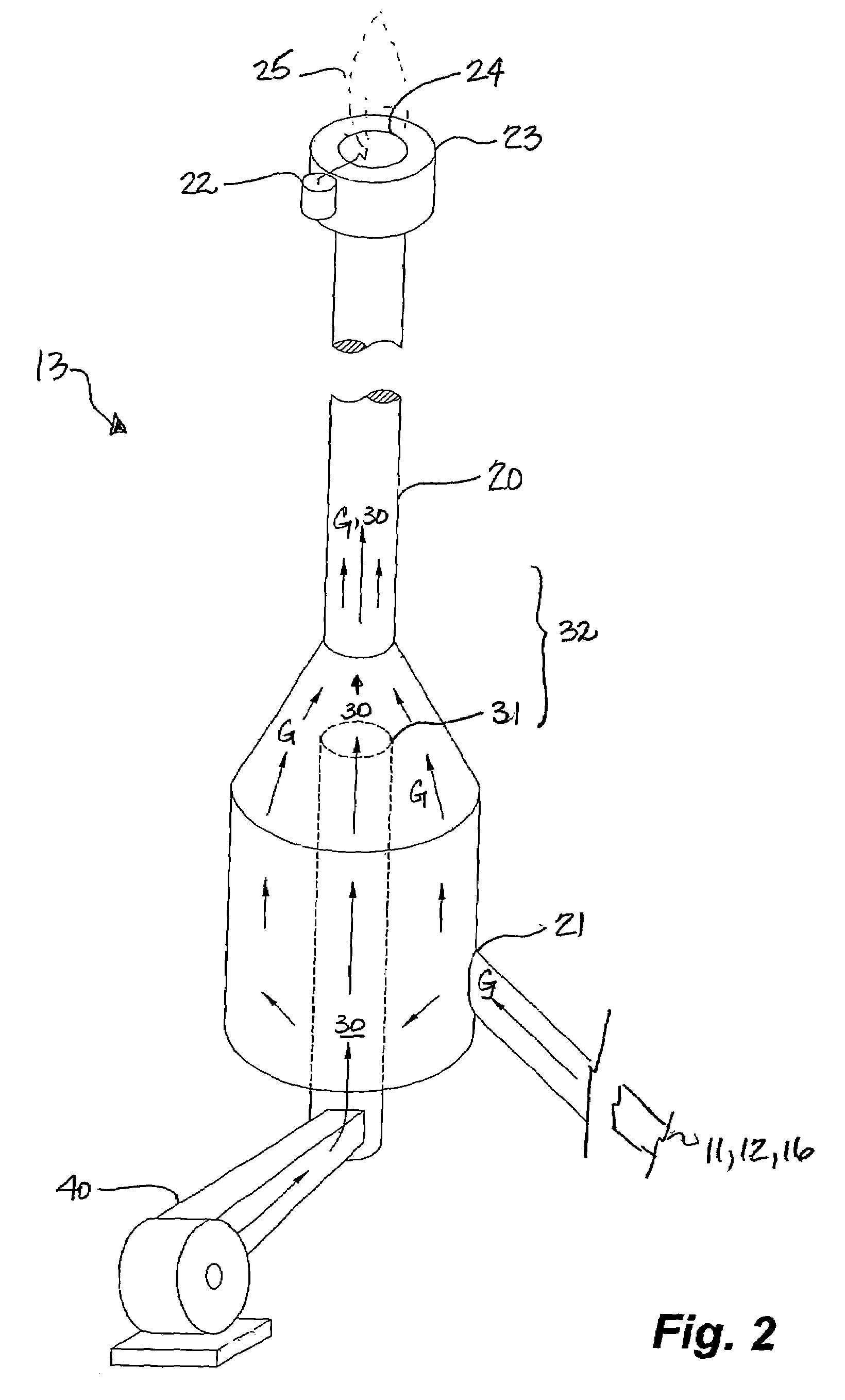

Continuous positive flow backflash prevention system

InactiveUS7156193B2Avoid problemsPrevent flashbackDrilling rodsConstructionsWell drillingEngineering

A method and system for the prevention of backflash from an ignition source in a flare stack to a separator or wellbore particularly during drilling and production. A continuous positive flow of air or exhaust gas is provided into the flow of gases from the wellbore or the separator to ensure that the velocity of the flow is always higher than the velocity at which the flame can propagate backwards into either the separator or the wellbore. This method and system is particularly applicable to balanced, underbalanced and air drilling operations where the flow of gas from the wellbore is intermittent and unpredictable and can stop and start during connection and disconnection of the air used as the drilling fluid.

Owner:SWARTOUT MATT

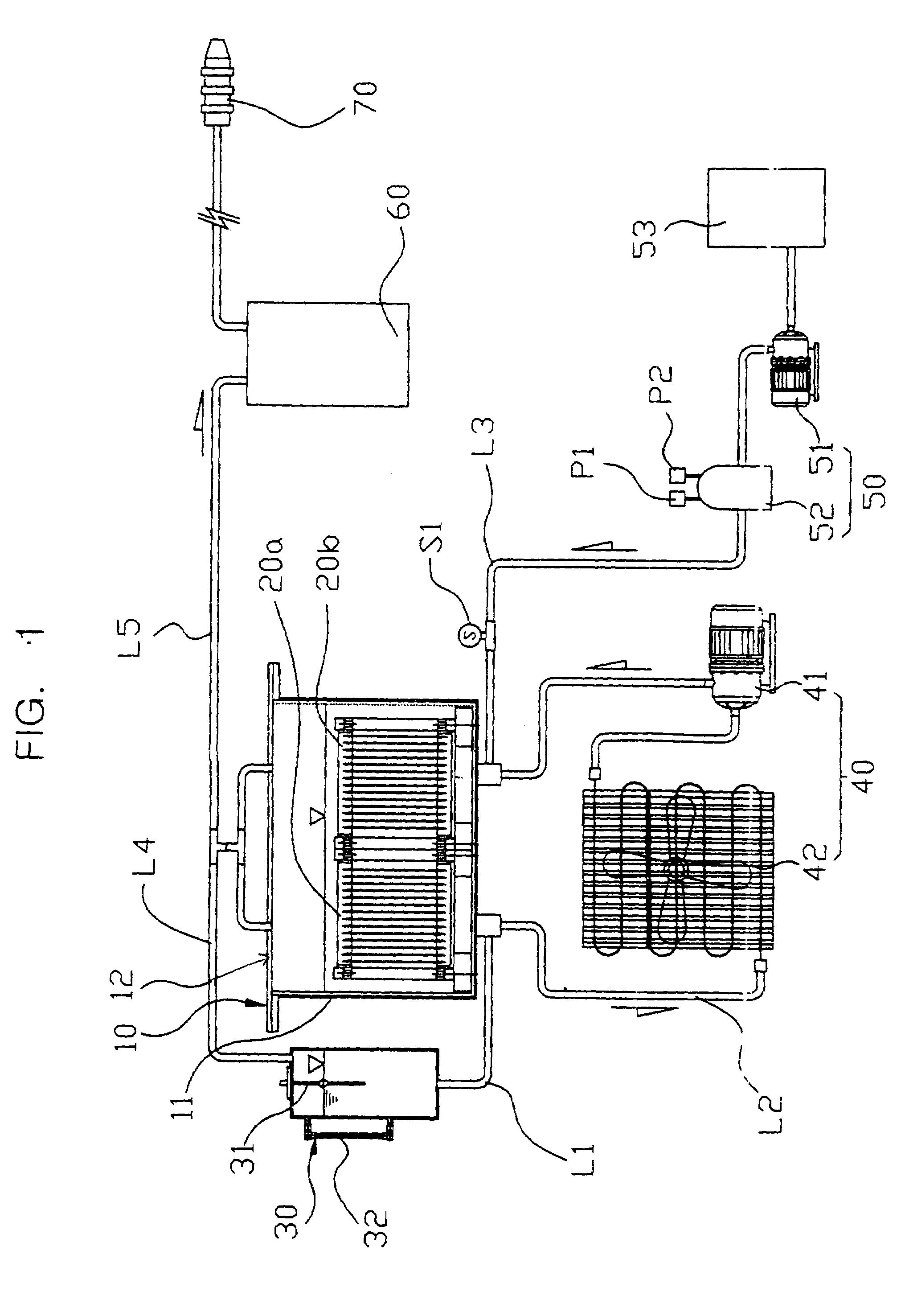

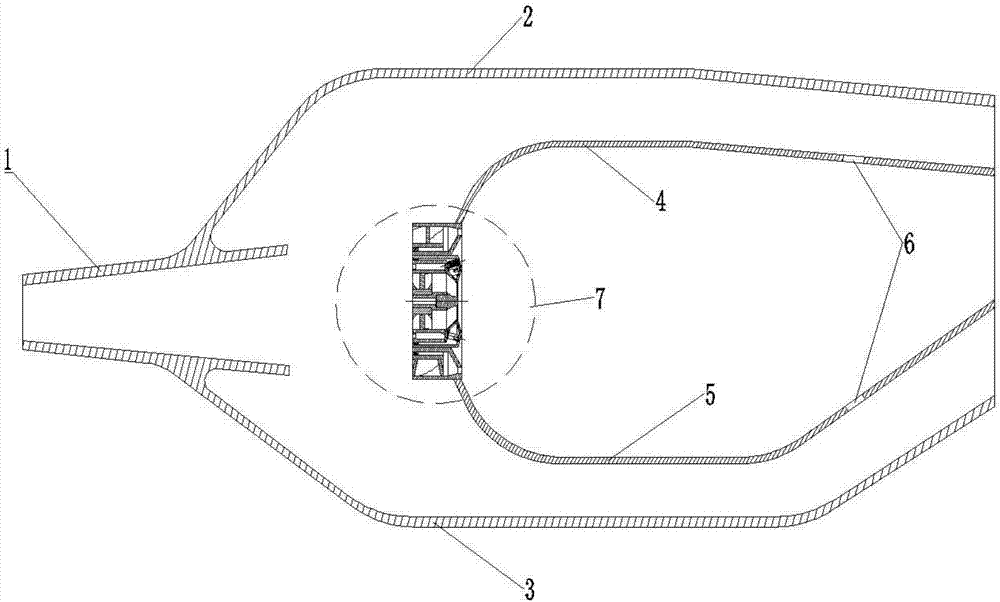

Combustion type waste gas treatment system

InactiveUS6948929B2Improve the heating effectAvoid breakingCombination devicesExhaust apparatusCombustorCombustion chamber

A combustion type waste gas treatment system is capable of oxidatively decomposing a hazardous combustible waste gas while heating efficiently with a structure which allows the waste gas to mix with an auxiliary burning gas efficiently without the occurrence of backfire in a waste gas inlet pipe. The combustion type waste gas treatment system has a burner part and a combustion chamber. Combustion flames are formed to extend from the burner part toward the combustion chamber, and a combustible waste gas is introduced into the combustion flames from waste gas inlet pipes thereby oxidatively decomposing the waste gas. A flow velocity accelerating device makes the flow velocity of the combustible waste gas flowing through the waste gas inlet pipe higher than the burning velocity of the combustible waste gas.

Owner:EBARA CORP

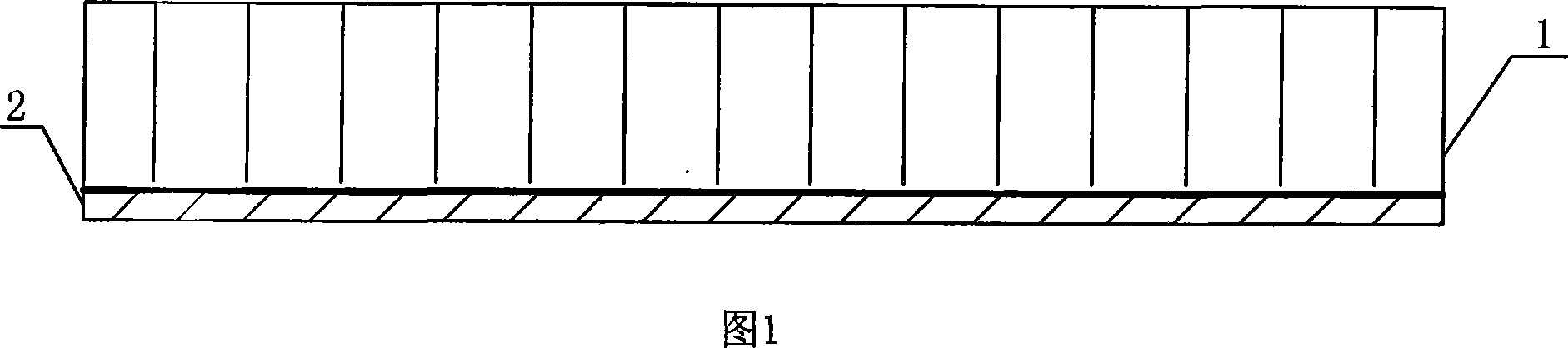

Metal honeycomb energy-gathering air-saving burner for gas stove

InactiveCN102226523APlay the role of voltage stabilization and uniform distributionImprove securityGaseous fuel burnerHoneycombEngineering

The invention relates to a metal honeycomb energy-gathering air-saving burner for a gas stove. The burner provided by the invention comprises a burner body, an injection tube, and a gas mixing chamber, wherein the inner cavity of the upper part of the gas mixing chamber is provided with a metal honeycomb infrared burning plate which is formed by a strip-shaped plain film and a strip-shaped ripple film through staggered stacking or winding or twining, the inner ring and outer ring of the metal honeycomb infrared burning plate are provided with fixed rings. The burner provided by the invention is characterized in that the strip-shaped plain film and the strip-shaped ripple film have molded bent structure in the height direction, the shape of the fixed ring is matched with that of a surface contacted with the metal honeycomb infrared burning plate; the middles of the bent structures, in the height direction, of the strip-shaped plain film and the strip-shaped ripple film are provided with at least more than 1 local bent part, and the bent structures are integrally bent from top to bottom. Based on the structure, the burner provided by the invention has the advantages that the safety performance is better, and the service life is long.

Owner:李长江

Atmospheric gas radiation heating device

ActiveCN101900324AHigh blacknessImprove Radiation AbilityCombustion using gaseous and pulverulent fuelCombustion using liquid and pulverulent fuelEngineeringPetrochemical

The invention discloses an atmospheric gas radiation heating device which comprises a burner, a quartz glass radiant tube and an igniter, wherein the burner comprises a nozzle, an injection tube and a burner head part; the burner head part consists of an inner tube and an outer tube which are concentric, and one end of an annular belt between the inner tube and the outer tube is sealed; the injection tube is communicated with the annular belt; the end of the sealed annular belt of the inner tube is a secondary air inlet, while the other end of the inner tube is provided with an inner flame cover; a corresponding end of the outer tube is provided with an outer flame cover, and a flame hole is formed between the inner flame cover and the outer flame cover; and the inner tube is internally provided with a secondary air conditioning device. The invention has simple structure, convenient mounting, low manufacture and maintenance cost, high burning strength, long service life and large burner load regulation ratio, can meet the requirement of different heating powers to a larger extent and can be widely applied to industrial kilns of the industries of steel, petrochemical industry, machinery, building materials, boilers, waste incineration, and the like.

Owner:ENN CHINA GAS ENVESTMENT

Combustion method of low-pressure and low-concentration methane gas and device

InactiveCN101713538AEfficient combustionImprove ejection abilityIndirect carbon-dioxide mitigationGaseous fuel burnerCombustion chamberProduct gas

The invention discloses a combustion method of low-pressure and low-concentration methane gas. In the combustion method, an inner pipe and an outer pipe which are communicated with a combustion chamber are adopted as an air inlet pipe, wherein the inner pipe is a fuel gas channel, and a channel between the inner pipe and the outer pipe is an air channel; air inside the air channel enters the combustion chamber at high speed and forms negative pressure at the outlet of the fuel gas channel; and the low-pressure and low-concentration methane gas inside the fuel gas channel is absorbed into the combustion chamber and combusts in the combustion chamber in a mixing mode. The invention also provides a combustion device for realizing the combustion method. By utilizing the negative pressure formed at the outlet of the inner pipe when the air enters into the combustion chamber through the air channel and a great injection action generated by the negative pressure on the low-pressure low-concentration methane gas inside the inner pipe, the invention promotes the low-pressure and low-concentration methane gas to enter into the combustion chamber to mix with the air for combustion, and has the advantages of low combustion cost and less discharged pollution of the combustion.

Owner:CHONGQING UNIV

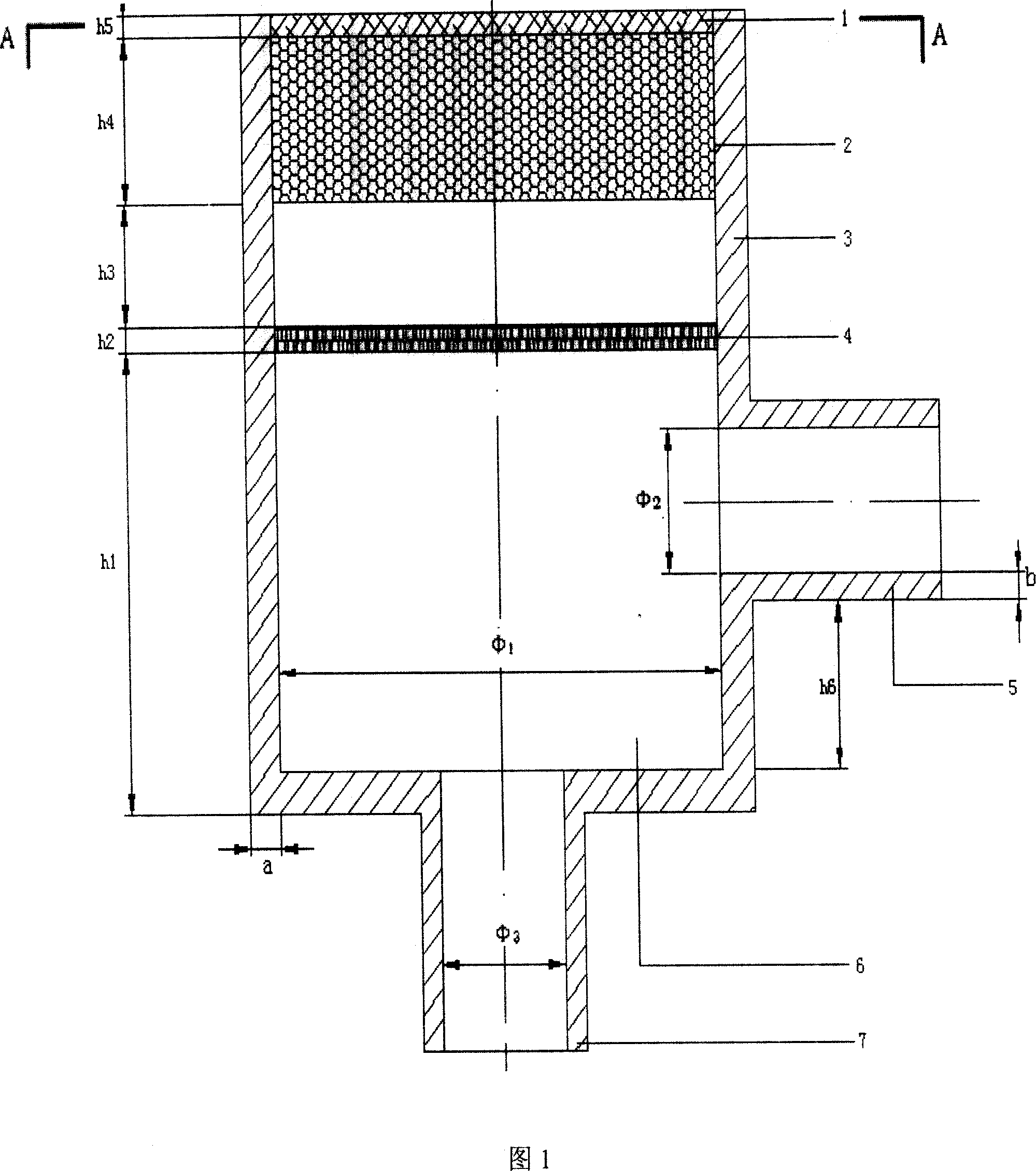

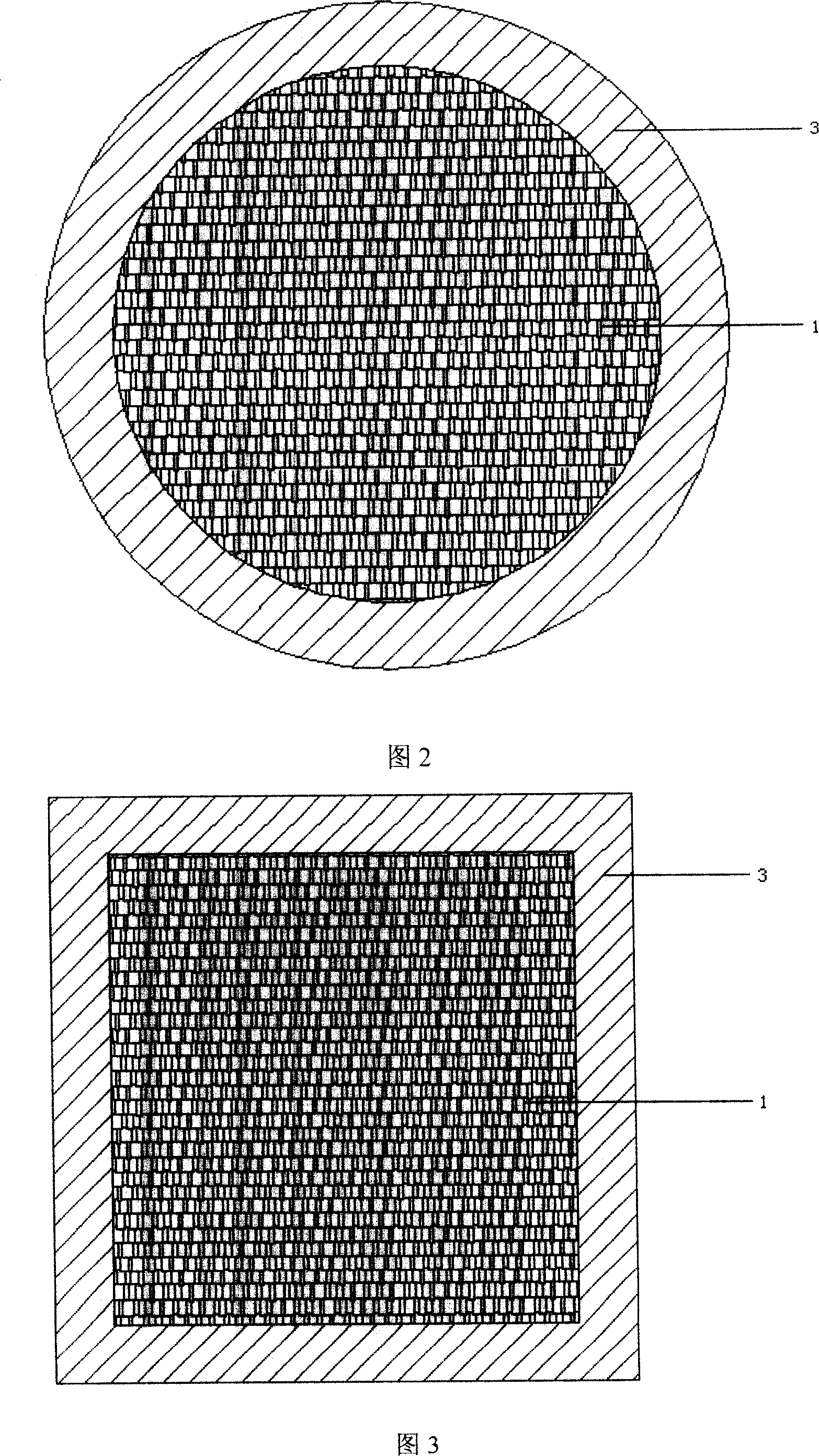

Anti-backfire gas combustor

ActiveCN101975398AImprove securityExtended service lifeGaseous fuel burnerCombustorCombustion chamber

The invention relates to an anti-backfire gas combustor, in particular to a combustor comprising a combustion chamber and an adjustable nozzle assembly. The combustion chamber comprises a high-temperature combustion head, an outer shell, an outer shell end plate, a flame tube and a flame tube end plate, wherein the high-temperature combustion head, the outer shell and the outer shell end plate are arranged outsides, the flame tube and the flame tube end plate are arranged insides, the adjustable nozzle assembly comprises a nozzle, a fire-retardant mesh, a gas inlet and a rear end cover and is arranged in the middle of the flame tube end plate, the nozzle of the adjustable nozzle assembly penetrates into the flame tube, the rear end cover of the adjustable nozzle assembly is fastened with the outer shell end plate through bolts, the high-temperature combustion head, the outer shell and the outer shell end plate are connected into a whole through bolts to form an interlayer hollow cavity together with the flame tube in the combustion chamber and the adjustable nozzle assembly, the flame tube is uniformly provided with radial hybrid air distribution holes and tangential air inlet grooves, the flame tube end plate is uniformly provided with axial air inlets, and combustion air inlets arranged on the outer shell are communicated with the interlayer hollow cavity and the air distribution holes or the air inlet grooves. The invention has high safety performance and long service life and is more energy-saving and environment-friendly.

Owner:游述怀

Porous-medium gas hot water heater

ActiveCN101566386AFast and efficient deliveryLower exhaust gas temperatureWater heatersCombustion chamberPorous medium

The invention discloses a porous-medium gas hot water heater, relating to a heater in which a pipe is wound into a spiral form to separate the continuous flows of water and a heating medium; the heater is structurally characterized in that: fine-pore porous medium materials are filled in an anti-backfire channel and a groove of a water cooling sleeve; macropore porous medium materials, which are metal fibers or foamed ceramics, are filled in a combustion chamber; heat exchanging tubes exchange heat directly with the macropore porous medium materials in the combustion chamber to conduct radiation or or heat exchange with the form of heat conduction, and high temperature fume realizes strong heat exchange between the peripheral dense heat exchanging tubes and the macropore porous-medium materials and leads the fume to be cooled rapidly and steam to condense directly on the tube walls; therefore, the heat conduction of the combustion chamber is strengthened and the heat released by the combustion can be rapidly and effectively transferred to water so that the steam in the fume condenses to recycle the condensation heat of water, thus realizing the goal of ultimately absorbing the heat released by the combustion. The hot water heater has simple structure and heat efficiency of over 96 percent, meeting the Grade-I energy efficiency standard for household rapid water heaters.

Owner:河北泓碳能源技术有限公司

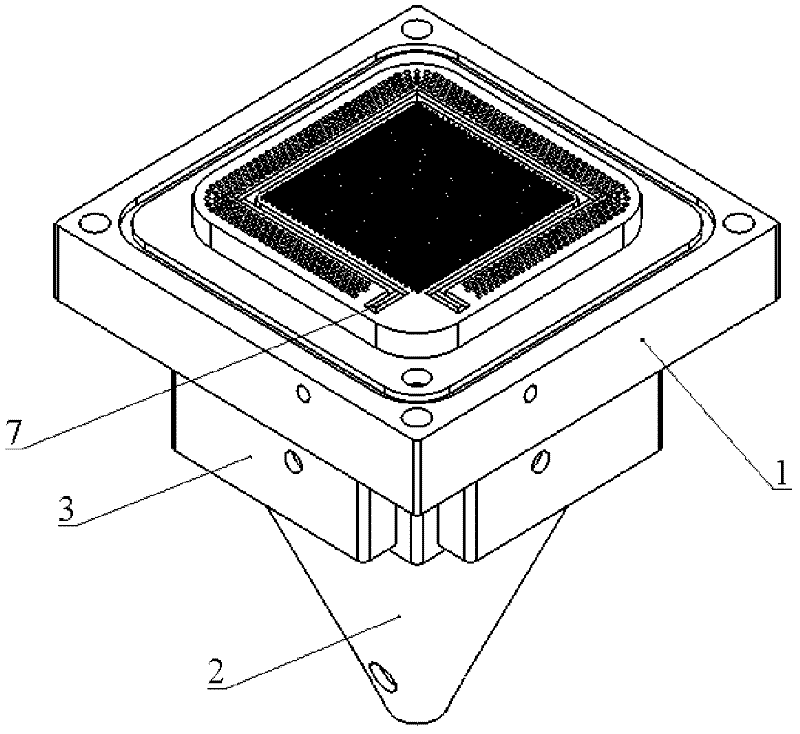

Water cooled fully-areated burner

InactiveCN104566372ACompact structureImprove combustion efficiencyBurner coolingGaseous fuel burnerNuclear engineeringMixed gas

The invention discloses a water cooled fully-areated burner. The water cooled fully-areated burner comprises a gas fuel distributing system, a gas fuel-air mixing structure, a burning system and a cooling system. The gas fuel distributing system comprises a fuel gas inlet, a fuel gas inlet pipe, a fuel gas distributing chamber and a spray nozzle; the gas fuel-air mixing system comprises an air inlet, a gas mixing cavity and a mixed gas distributing cavity; the burning system comprises a burning flame hole plate and flame holes; the cooling system comprises a cooling water inlet, a cooling water outlet, a cooling water pipeline, fins and a U-type connecting pipe. The water cooled fully-areated burner is compact in structure, high in burning efficiency and low in emission of carbon monoxide and nitric oxide; the cooling system can take away heat of the flame hole plate through flowing of cooling water, thereby reducing the temperature of the flame hole plate, further avoiding backfire and also effectively reducing the deformation damage of thermal stress to the flame hole plate. The water cooled fully-areated burner can be applied to commercial and civil heat and domestic hot water supply systems or devices as well as to small and medium size industrial gas heating devices.

Owner:TIANJIN CHENGJIAN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com