Correction method for large barrel type part heat treatment elliptical deformation in cold state

A large-scale cylinder and calibration method technology, applied in the field of calibration, can solve problems such as elliptical deformation of large-scale cylinder-type parts, and achieve the effects of saving manpower and material resources, preventing springback and saving energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

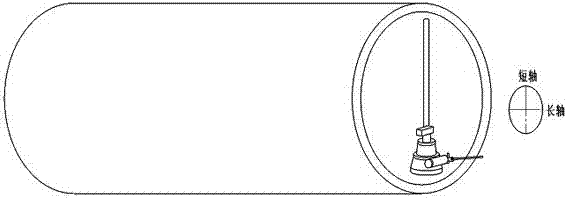

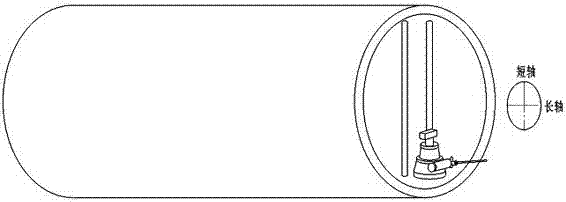

[0021] As shown in the figure, the specific implementation method is as follows:

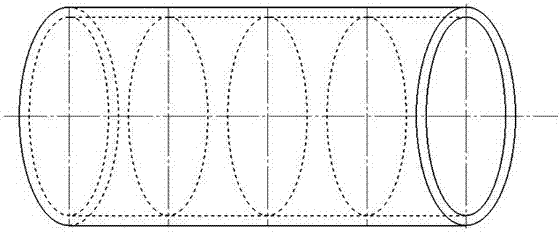

[0022] The material of the cylinder is 18MnD5, the designed outer diameter is 2320mm, the inner diameter is 2204mm, and the height is 3810mm. After quenching and tempering process heat treatment, elliptical deformation occurs in all areas of the height of the cylinder after quenching (water cooling). The most serious part is the short axis of the inner circle is 2155mm, the long axis is 2206mm, and the difference between the long axis and the short axis is more than 50mm, resulting in semi-finishing. There is no processing volume, in order to avoid job scrapping, it is necessary to perform ellipse correction.

[0023] First, lay the cylinder horizontally on the open space, make a support pad below, measure the inner circle with a tape measure and divide it into several areas equally according to the height, each area is about 900mm long, and measure the elliptical deformation of each area of t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com