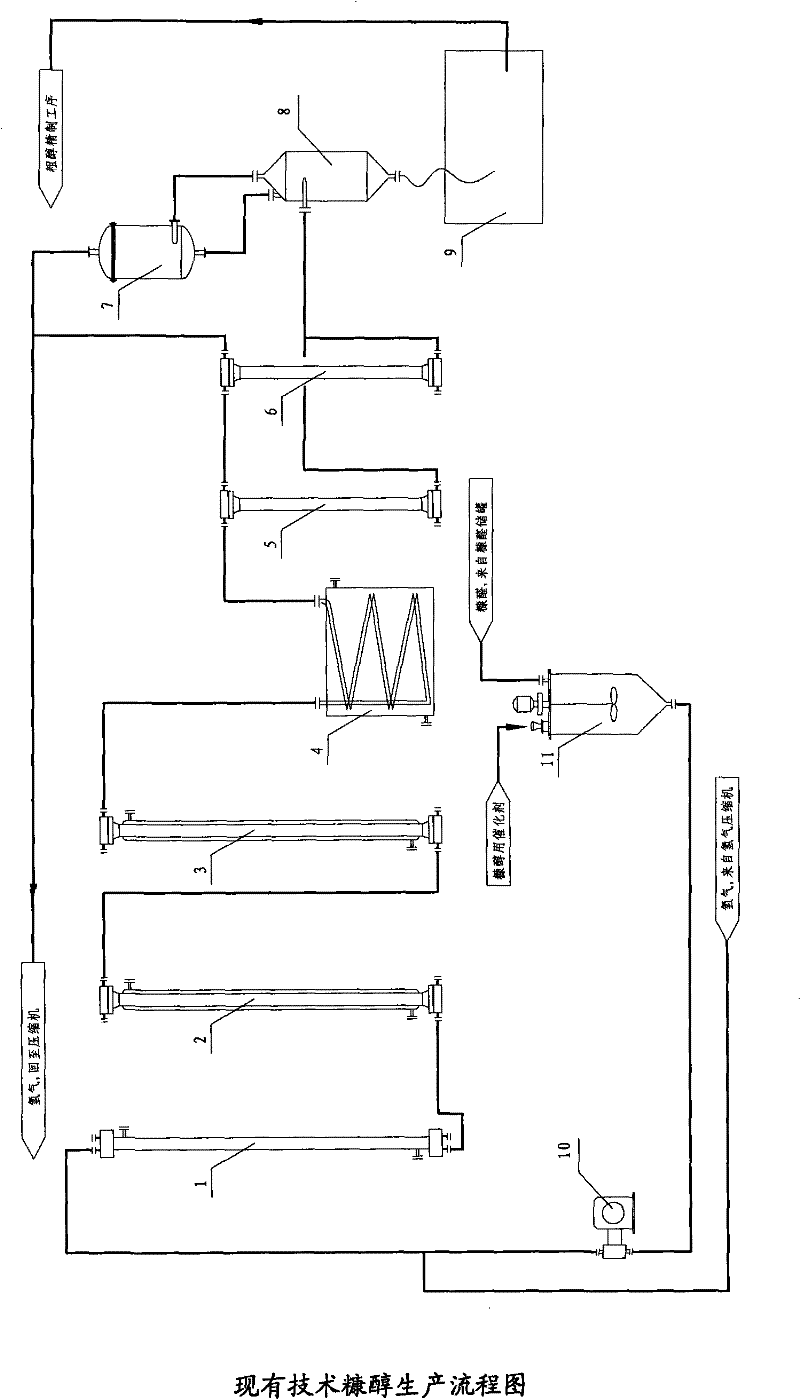

Method for preparing furfuryl alcohol by furfural medium-pressure continuous liquid phase hydrogenation and hydrogenation reactor thereof

A hydrogenation reactor and hydrogen preparation technology, applied in the direction of organic chemistry, etc., can solve the problems of difficult removal of reaction heat and easy occurrence of danger, and achieve the effects of easy control of reaction temperature, saving steam, and increased reaction capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

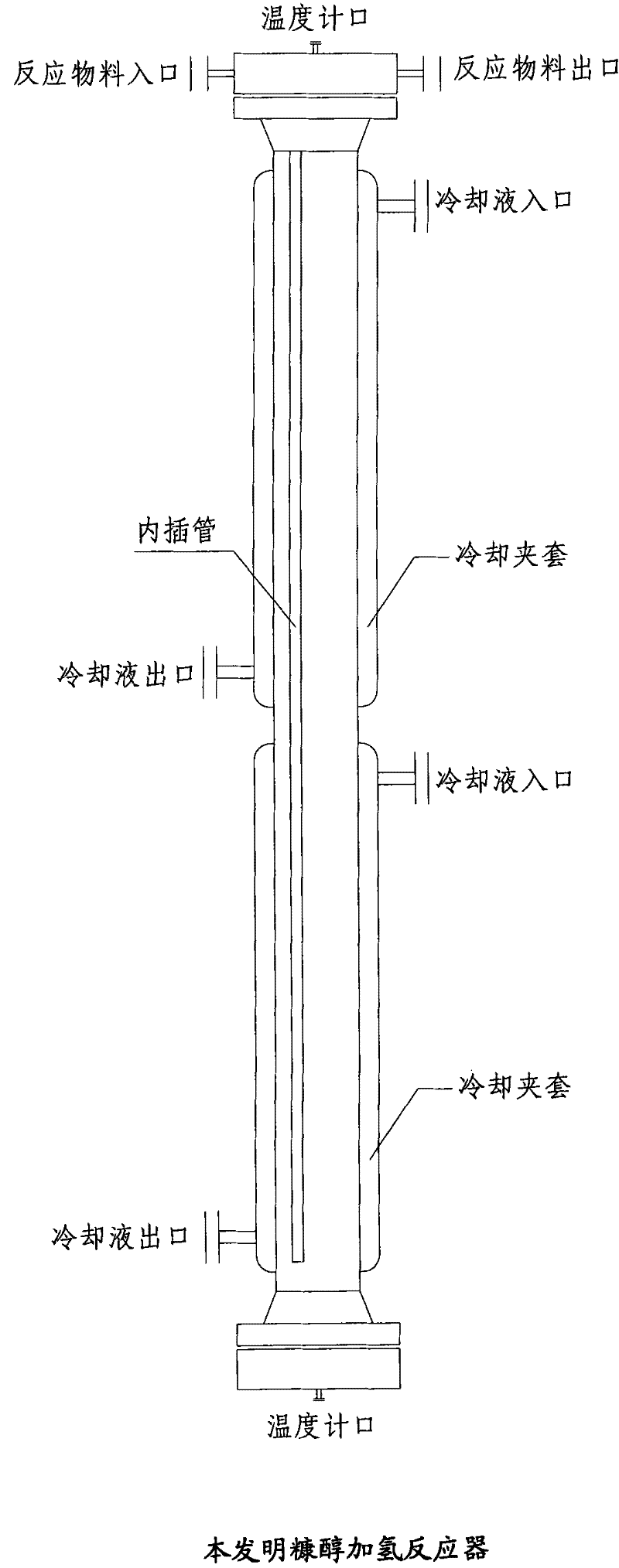

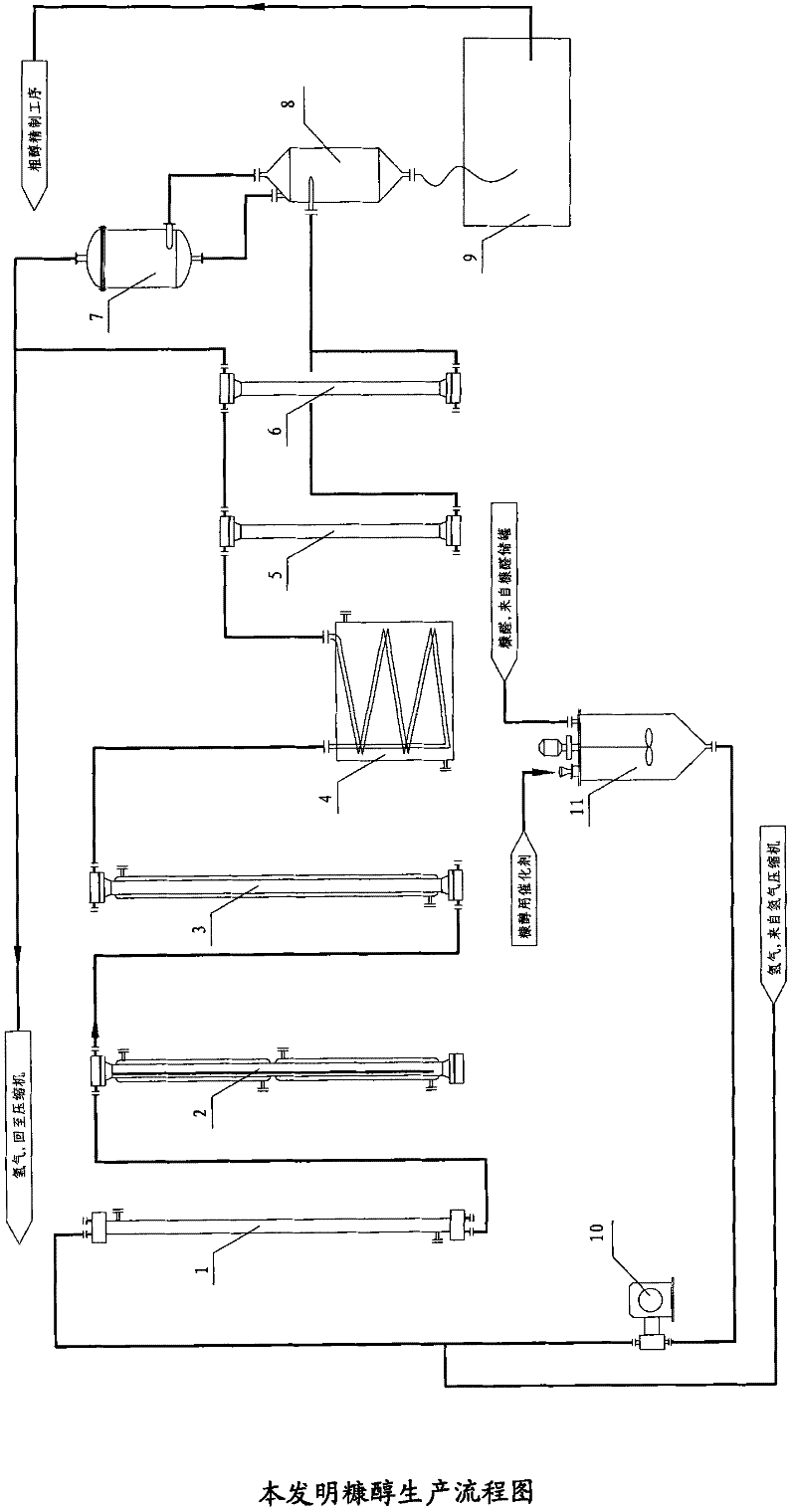

[0037] use image 3 In the process and equipment shown, after furfural and catalyst are mixed evenly, the metering pump enters the preheater together with the hydrogen compressed by the compressor for preheating, and then enters 1# and 2# reactors for hydrogenation reaction, and the reacted materials After cooling in the cooler, it enters the separator for separation. The semi-finished furfuryl alcohol is separated from most of the catalyst in the crude alcohol precipitation tank, and then sent to the refining tower for distillation and refining to obtain the finished furfuryl alcohol.

[0038] Raw furfural purity: content ≥ 98.5% by mass, moisture ≤ 0.1% by mass, acidity ≤ 0.01mol / l; hydrogen purity: content ≥ 99% by volume, oxygen content < 0.1% by volume.

[0039] The specification of 1#, 2# reactor is: internal diameter 132mm, effective length 4.5m; 1# reactor is the present invention (as figure 2 ) of the reactor.

[0040] The inner tube is a seam welded tube with a di...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com