Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

200results about How to "Save steam" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Preparation method of reinforced polypropylene foamed beads

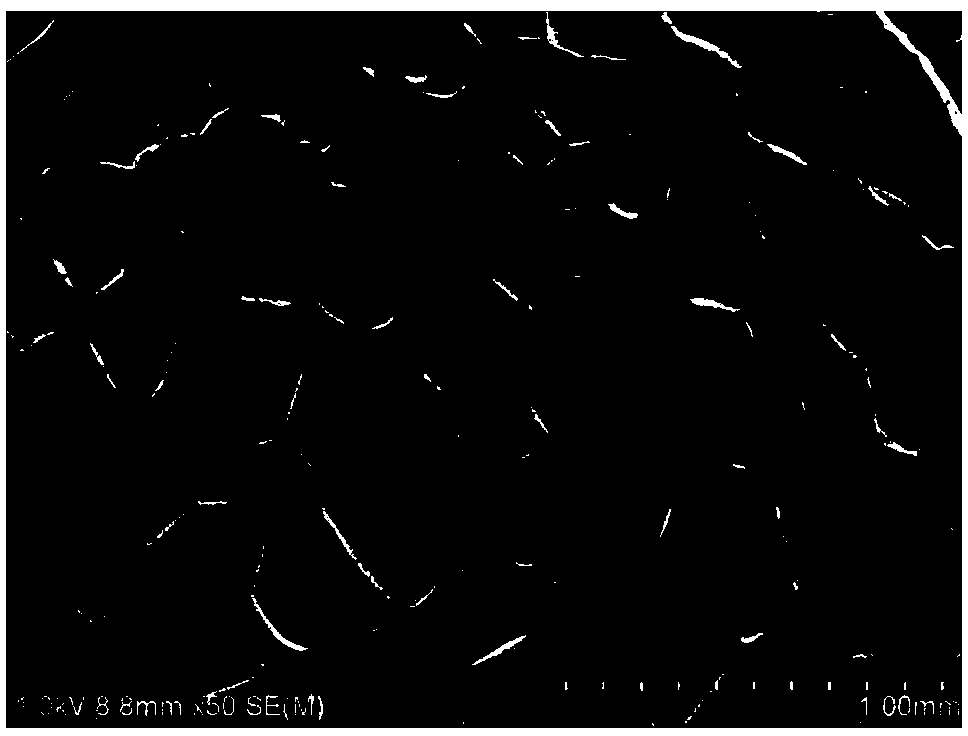

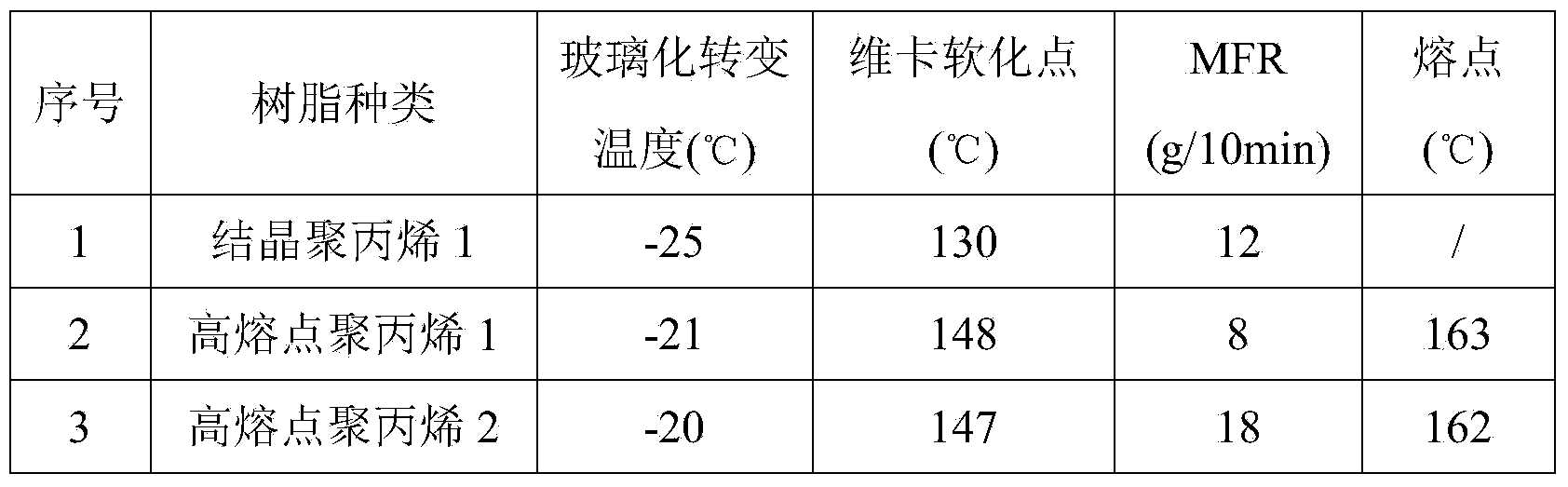

The invention relates to a preparation method of reinforced polypropylene foamed beads. The method comprises the following steps of: (a), mixing, extruding, drawing and pelletizing two polypropylene resins and nucleation auxiliary agent through an extruder to prepare polypropylene particles; and (b), putting the reinforced polypropylene particles in a reaction kettle for heating and pressing to generate outward expanding internal pressure under high temperature and high pressure, and temporarily releasing the internal pressure to atmosphere to obtain the reinforced polypropylene foamed beads with certain multiplying power. In the step (a), two polypropylene resins comprise one easily-crystallized polypropylene raw material and one high-melting-point polypropylene raw material; the melting point of the high-melting-point polypropylene is 150-170 DEG C; nucleation agent is added in the step (a) and accounts for 0.01-2% of the adding amount of the two polypropylene resins by weight percentage; and the particle size of the nucleation agent is 0.5-2 microns.

Owner:WUXI HI TEC ENVIRONMENTAL MATERIAL CO LTD

Method for producing compound fertilizer by high tower granulating

ActiveCN1935748ALower melting temperatureAchieve low temperature meltingFertiliser formsUrea compound fertilisersMelting tankPhosphate

The invention discloses a method for producing urea-base grain compound fertilizer by high-tower prilling, comprising pulping and prilling, where the pulping adopts three-step series continuous gradual cooling pulping method, comprising the steps of: adding fluxing agent and urea in a melting tank, melting the urea at low temperature and making the urea melt flow into the first stage mixing tank; in the first stage mixing tank, adding unreactable raw materials into the urea melt, and making the mixed melt flow into the second stage mixing tank; in the second stage mixing tank, adding in ammium phosphate and mixing for less than 4 min, and obtaining mixed melted pulp; spraying the mixed melted pulp through the double-speed rotating prilling nozzle of the high tower into a prilling tower to complete prilling. And it has advantages of low temperature operation, low energy consumption, low loss, good pulp fluidity, good operating environment. And the produced compound fertilizer grains are round, less broken and uniform.

Owner:拉多美科技集团股份有限公司

Production method of instant burdock flavor powder

The invention discloses a production method of instant burdock flavor powder, belonging to the filed of food. The invention uses fresh burdock as a main raw material and maltodextrin, sucrose, milk, cocoa powder, fruit and vegetable and the like as accessories; the raw materials are selected, washed, peeled off, washed, dipped for color conserve, sliced, preliminary cooked for sterilization, smashed, coarsely grinded, homogenized by high-shearing, decomposed by enzyme and the like, and then the obtained product is blended, homogenized by high-shearing, dried by spraying, cooled, packed and the like to obtain the instant burdock flavor powder. The invention is characterized by combining the methods of enzymic reaction and high-shearing homogenizer wet superfine grinding for processing burdock, thus enhancing the fineness of burdock fiber, increasing the instant ability of the product. The invention adopts spray drying for evaporation of water at low drying temperature, therefore, the burdock flavor powder of the invention enjoys good instant ability and color and low waste of nutrient components. Compared with the existing dry ground which is used in the production of instant burdock flavor powder, wet grinding can save electricity by over 10% and steam by over 30% in producing a ton of the product.

Owner:XUZHOU UNIV OF TECH

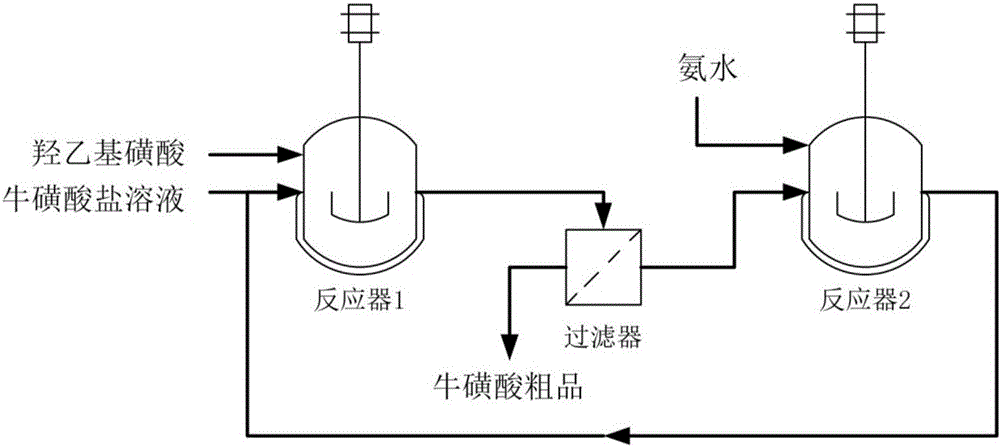

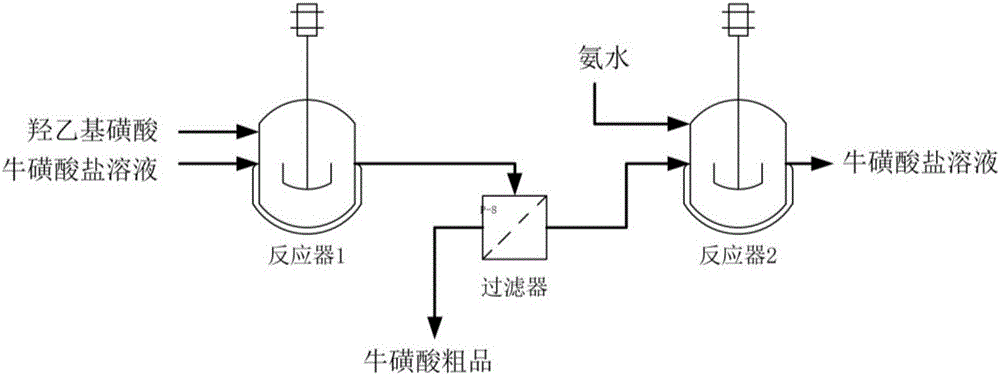

Taurine preparation method

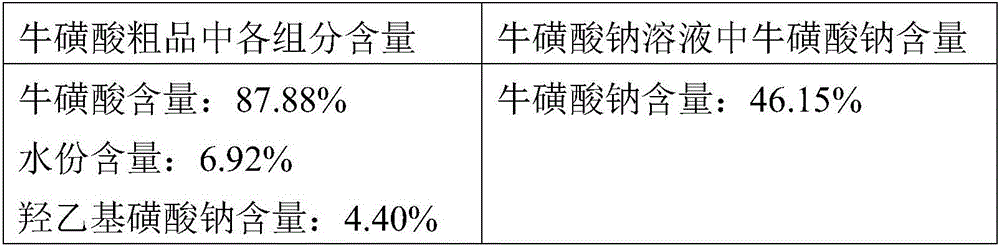

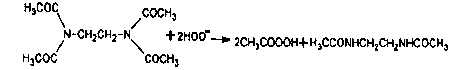

ActiveCN106008280ASolve the problem of excessive sulfateAvoid it happening againOrganic compound preparationSulfonic acids salts preparationAmmoniaSalt solution

The invention provides a taurine preparation method which is characterized by comprising the following steps: (a) mixing isethionic acid with a taurine salt solution until the pH value of the system reaches 5.0-9.5; (b) separating the liquid phase and solid phase in the system, wherein the obtained solid phase is a crude product of taurine, and the obtained liquid phase is an isethionate solution; and (c) adding ammonia water into the obtained liquid phase for reacting to obtain an isethionate-containing solution. In the taurine preparation method, the problem caused by adjusting pH with sulfuric acid in traditional technology is avoided; by circularly utilizing the cation radical in isethionate and without introducing new raw material or reagent, the use of dangerous chemical raw materials is reduced, the production technology is greatly simplified, the utilization rate of raw materials and the product yield are increased, and the production cost is remarkably reduced.

Owner:QIANGJIANG YONGAN PHARMA

Energy-saving high-efficiency foaming molding mold

InactiveCN101474843ASmall heat capacitySuppression of cooling temperature dropInsulation layerHeat energy

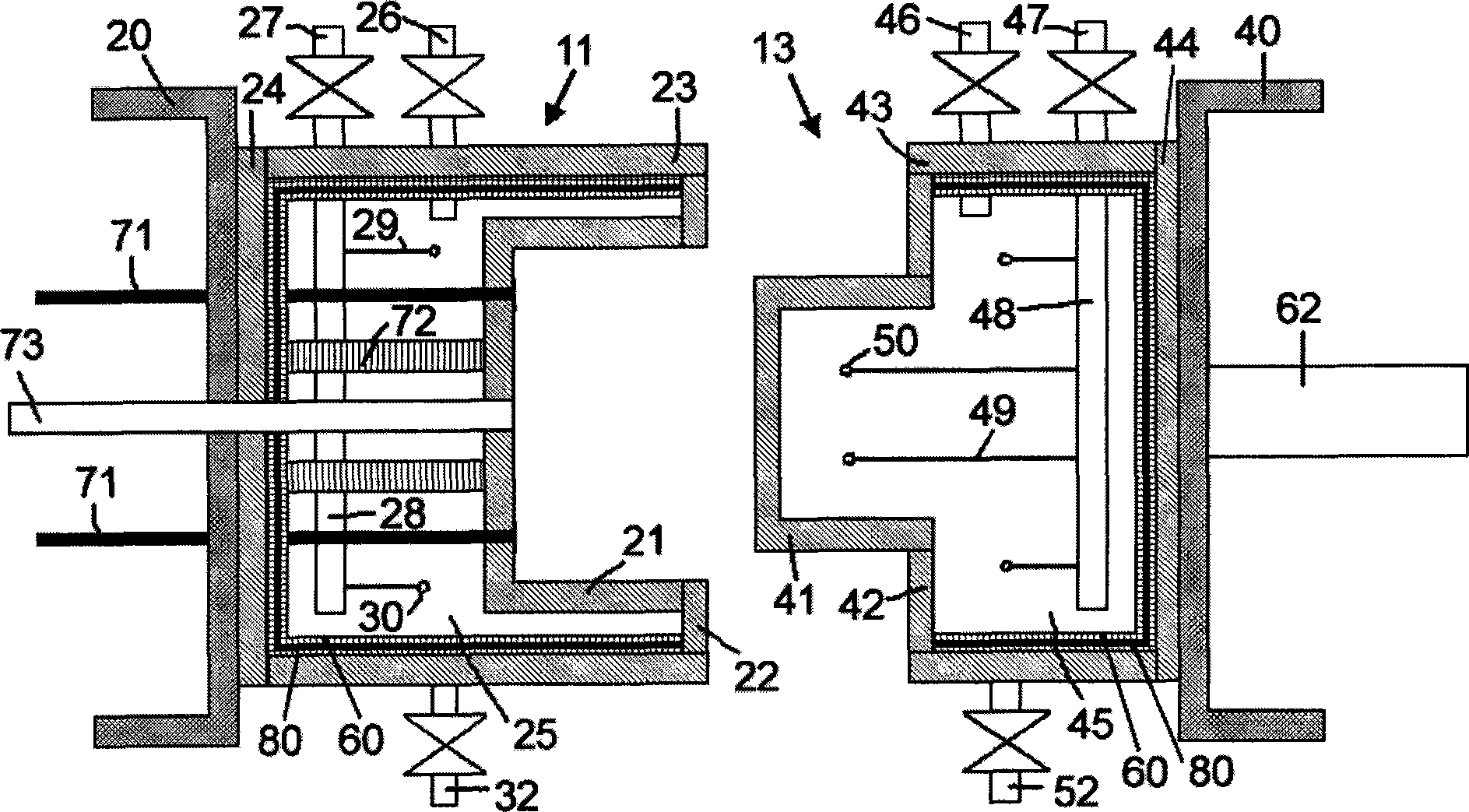

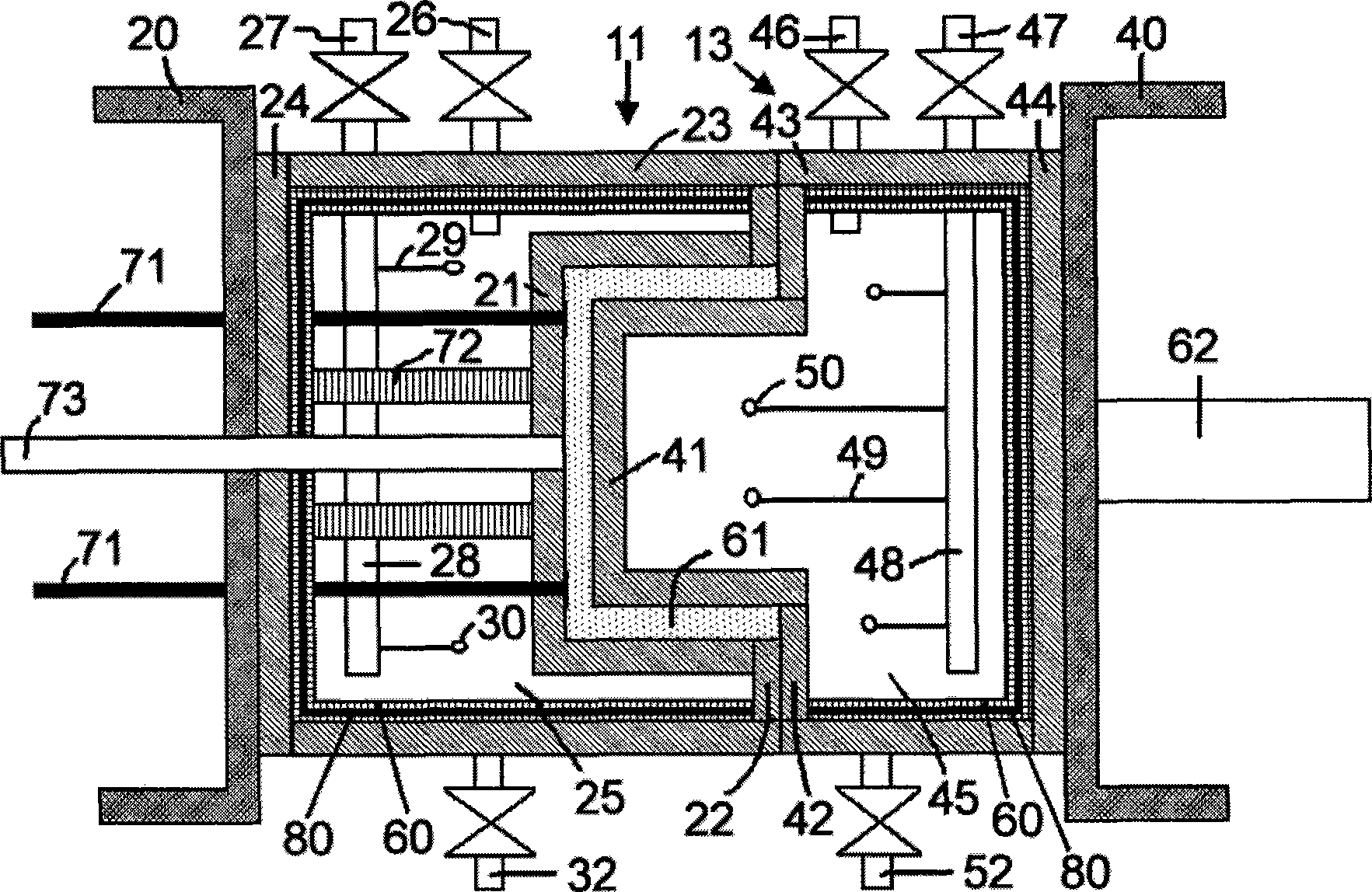

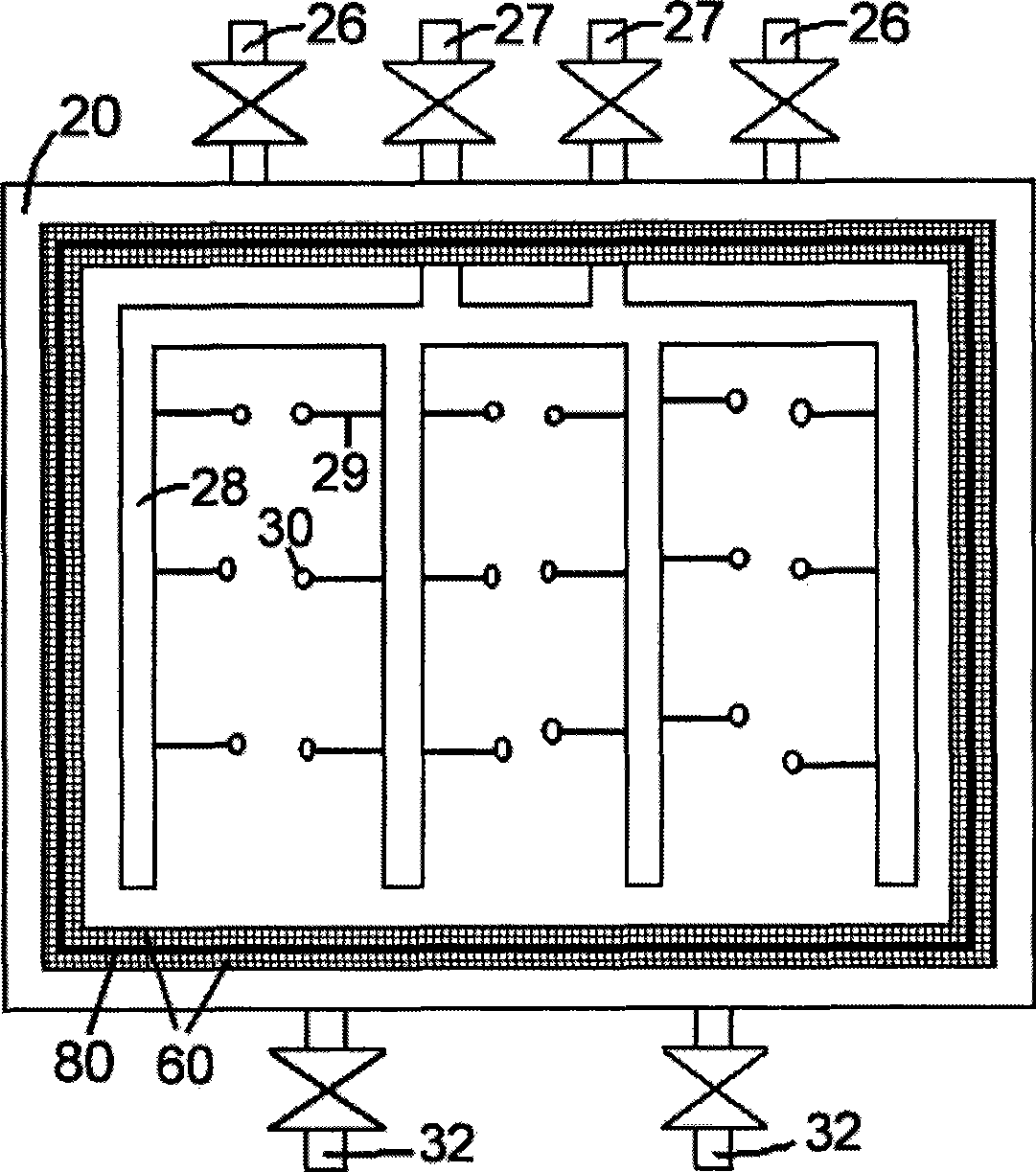

The present invention discloses a foaming shaping mold which has the advantages of energy saving and high efficiency. The foaming shaping mold comprises a cavity die (11) and a terrace die (13). The inner part of the cavity die (11) and terrace die (13) are respectively installed with steam chambers (25, 45) which are respectively composed by the enclosing of cores (21, 41), mold frames (23, 43), installation plates (22, 42) and backboards (24, 44). At least one part or total part of mold frames (23, 43) of cavity die (11) and terrace die (13), the installation plates (22, 42) and the backboards (24, 44) at the surface facing the steam chambers (25, 45) are installed with tortoise shell net (80). A heat insulation layer (60) is coated outside the tortoise shell net (80). The foaming shaping mold of the invention has the advantages of simple structure, convenient construction and low cost. The accessory heat insulation layer has the advantages of no easy break-off, long service lifetime, and stable and reliable capability. The foaming shaping mold of the invention also has the advantages of effectively reduced steam consumption rate, saved heat energy of steam, increased production efficiency of product, and suitability for generalization.

Owner:苏州雅安节能科技有限公司

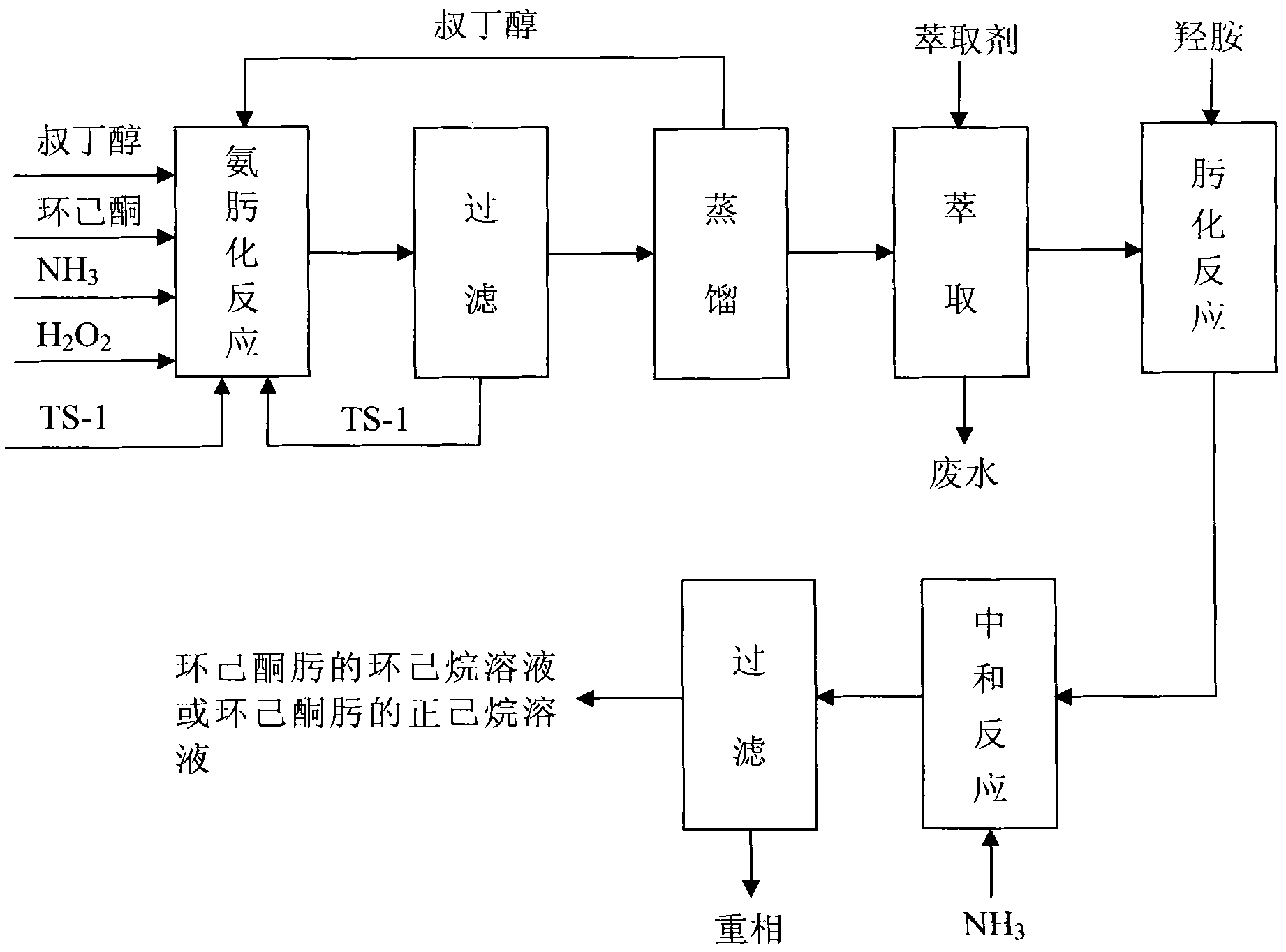

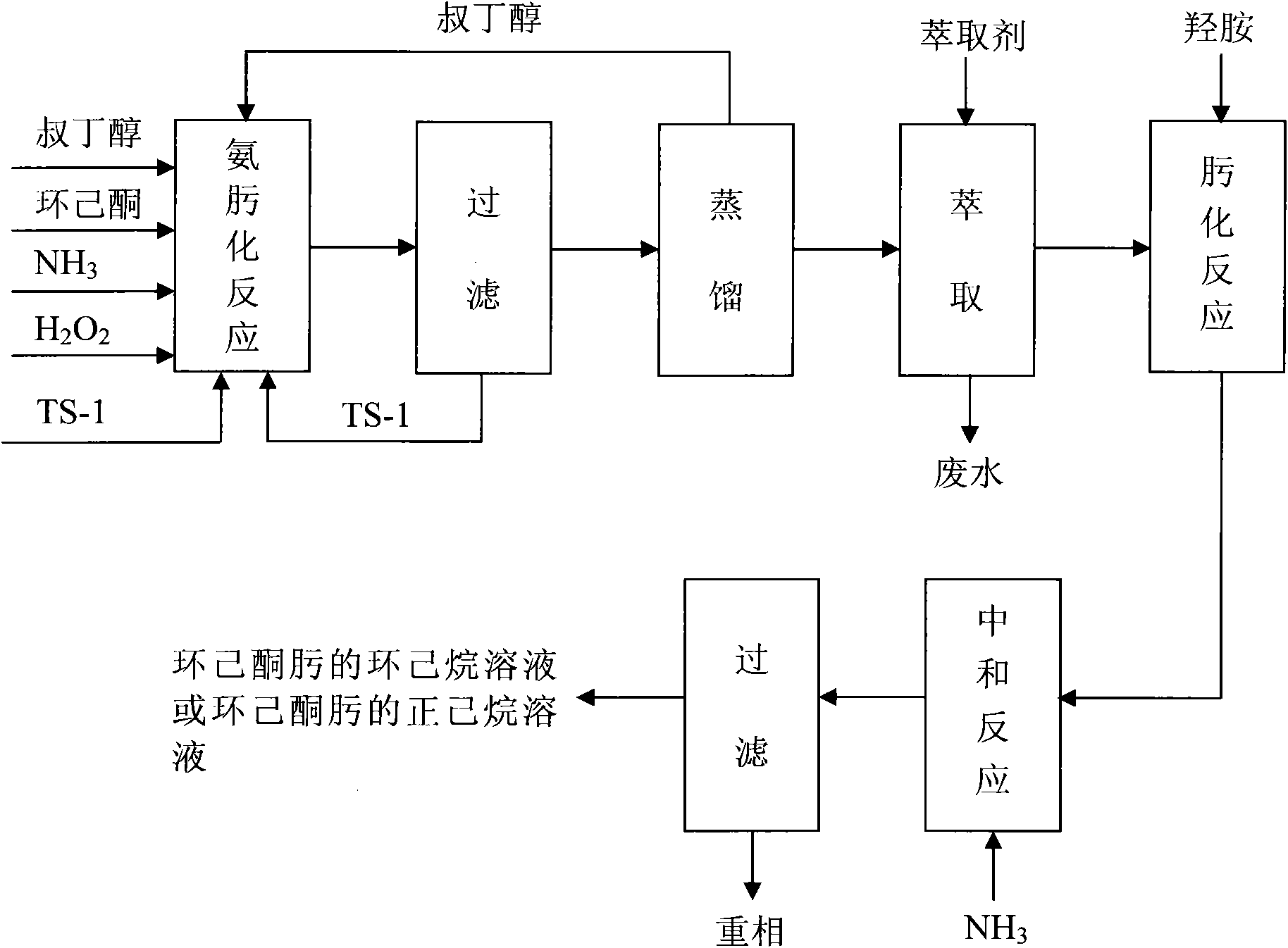

Preparation process of cyclohexanone-oxime

InactiveCN101781232AReduce consumptionEliminate safety and environmental hazardsOximes preparationChemical recyclingSolventHydroxylamine Hydrochloride

The invention discloses a preparation process of cyclohexanone-oxime. The process comprises the following steps: carrying out ammoximation under the condition of the existence of catalyst and tertiary butanol solvent, and filtering, distilling and leaching when the conversion ratio of cyclohexanone is 99.5% in the ammoximation; then adding hydroxylamine for performing oximation reaction; and finally neutralizing and filtering to obtain the cyclohexanone-oxime solution when the conversion ratio of the cyclohexanone is 100%. The process combines two different kinds of the oximation reactions to ensure that the conversion ratio of the cyclohexanone reaches to 100%, solves the defect that the cyclohexanone can not be fully converted in the existing ammoximation process, reduces the consumption of hydrogen peroxide and eliminates safety hidden troubles brought by excessive hydrogen peroxide. Compared with the traditional process, the process of the invention abrogates working procedures such as regenerating extractant by rectification, removing ketone, dealcoholization tower, regenerating cyclohexanone-oxime by rectification and the like, saves equipment investment and reduces energy consumption; and as for a device by which the annual cyclohexanone-oxime yield is 100,000 tons, the saved equipment investment is close to ** million yuan, and the saved energy sources such as water, electricity, steam and the like are close to ** yuan.

Owner:河北美邦工程科技股份有限公司

Preparation process of urea-formaldehyde resin adhesive

InactiveCN100999652AReduce manufacturing costReduce packageAldehyde/ketone condensation polymer adhesivesReaction temperatureResin adhesive

The present invention is process of preparing urea-formaldehyde resin adhesive. The preparation process includes the following steps: 1. adding formaldehyde in 420-600 weight portions into a reaction kettle and regulating pH value to 7.0-9.0 with alkali; 2. adding liquid urea from a urea synthesizing apparatus in 185-395 weight portions into the reaction kettle, reaction at 90-95 deg.c for 0.5-1.5 hr, regulating pH value to 4.0-5.5 with acid and further reaction until the solution becomes turbid and has viscosity of 15-20 CP; 3. regulating pH value to 7.0-7.6 with alkali and adding liquid urea of other 10-15 weight portions; 4. decompression dewatering, adding liquid urea of other 5-10 weight portions and modifier of 3-30 weight portions at temperature not higher than 70 deg.c and absolute pressure of 0.08-0.19 atm; and 5. regulating pH value to 7.5-8.5 with alkali, cooling to below 50 deg.c, discharging and packing.

Owner:水煤浆气化及煤化工国家工程研究中心

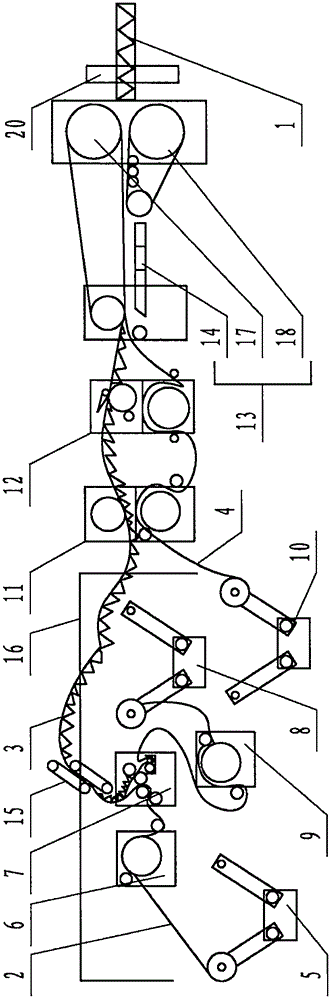

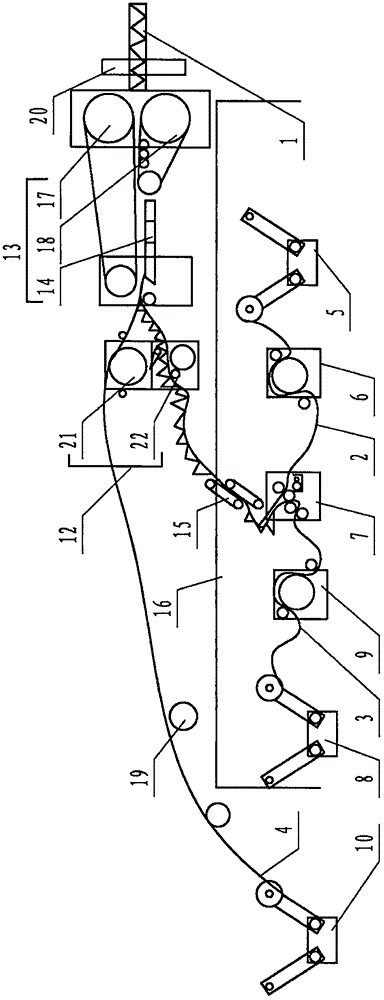

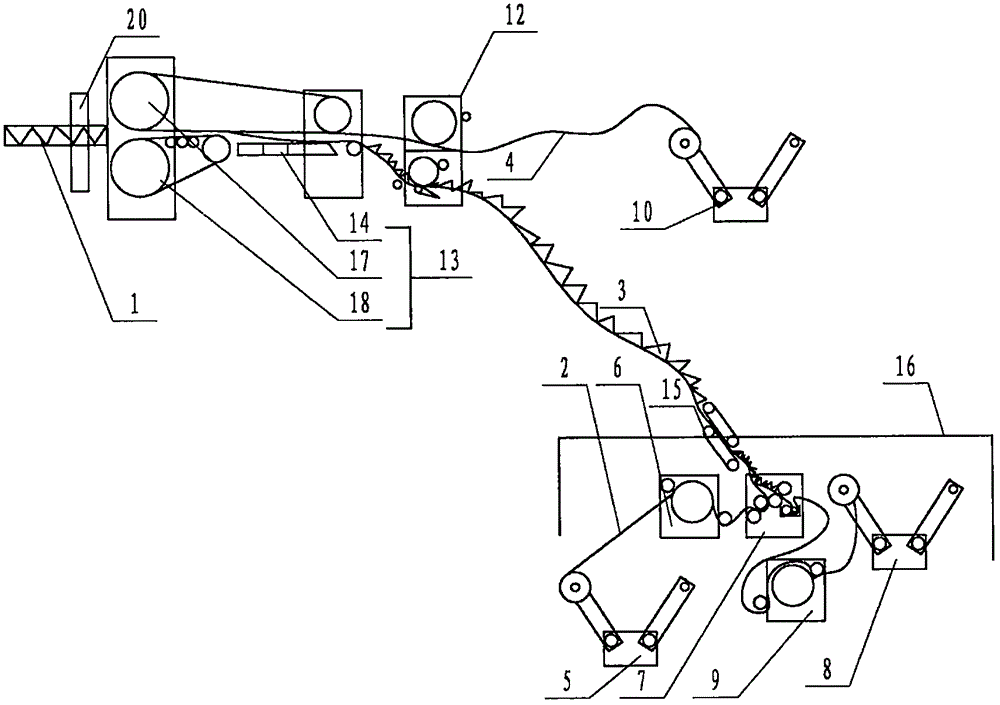

Improved corrugated board production line and production process thereof

InactiveCN105881982ASave secondary warm-upLow costMechanical working/deformationPaper/cardboard layered productsProduction linePulp and paper industry

The invention relates to an improved corrugated board production line which comprises an inner body paper rack used for placing corrugated inner paper of the corrugated board, an inner paper preheating cylinder used for heating the corrugated inner paper, a corrugated body paper rack used for placing the corrugated paper, a corrugated paper preheating cylinder used for heating the corrugated paper, a corrugating machine used for corrugating the corrugated paper and adhering the corrugated inner paper and the corrugated paper, a surface body paper rack used for placing corrugated surface paper, a pasting machine used for gluing the to-be-adhered upper surface of the corrugated paper, and a double-faced machine used for adhering the to-be-adhered upper surface of the corrugated paper and the lower surface of the corrugated surface paper. The improved corrugated board production line disclosed by the invention is compact in structure, reasonable in design and convenient to use, has the capacities of saving energy, reducing consumption, optimizing the process and lowering the cost, and is suitable for large-scale popularization.

Owner:周景勇

Efficient, energy-saving and low-emission fur dyeing machine and fur dyeing method

InactiveCN103924400AIncrease contact timeImprove uniformityTextile treatment machine arrangementsLiquid/gas/vapor textile treatmentContact timeDyeing

The invention relates to the field of fur dyeing equipment, in particular to an efficient, energy-saving and low-emission fur dyeing machine. By the aid of the efficient, energy-saving and low-emission fur dyeing machine, a uniform and good dyeing effect can be realized. The efficient, energy-saving and low-emission fur dyeing machine comprises a framework, a dyeing drum, a motor and a gearbox. A plurality of partition plates are arranged on the inner annular wall of the dyeing drum, and a temperature detector is arranged in the dyeing drum. A bath ratio adopted in a fur dyeing method implemented by the aid of the efficient, energy-saving and low-emission fur dyeing machine is 1:2-5. The efficient, energy-saving and low-emission fur dyeing machine and the fur dyeing method have the advantages that the turning time of fur in the dyeing drum and the fur and dye contact time can be prolonged owing to the partition plates and structural arrangement of the partition plates, so that the dyeing uniformity can be effectively improved, wastage of dye can be reduced, the dye can be controlled precisely, the dyeing effect can be improved, and the dyeing cost can be greatly lowered.

Owner:TONGXIANG NEW ERA FUR

Pretreatment method for preparation of biomass fuels by comprehensive utilization of all components of plant straw

InactiveCN106701836APromote degradationLarge specific surface areaBiofuelsSolid fuelsPretreatment methodBiofuel

The invention discloses a pretreatment method for preparation of biomass fuels by comprehensive utilization of all components of plant straw, and relates to the field of comprehensive utilization of all components of plant straw, wherein the pretreatment method comprises the steps: plant straw after being cut into sections is successively subjected to washing treatment for two times before and after steam explosion, steam explosion treatment, extrusion treatment, crushing treatment, pre-enzymolysis treatment, cracking treatment, and enzymolysis treatment, and finally a pre-product for preparing the biomass fuels is obtained; a straw washing liquid obtained after washing treatment and an extrusion liquid obtained after extrusion treatment are used for producing marsh gas, and a liquid, gas and solid biomass fuels can be obtained after the pre-product is treated. The method realizes separation and high-valued complete utilization of the all components of the plant straw, namely hemicellulose, cellulose, lignin and a small amount of components, can achieve no pollutant emission, and has the advantages of easy industrialization operation, good economic benefits, and remarkable comprehensive social benefits.

Owner:北京利晟新能生物科技中心(有限合伙)

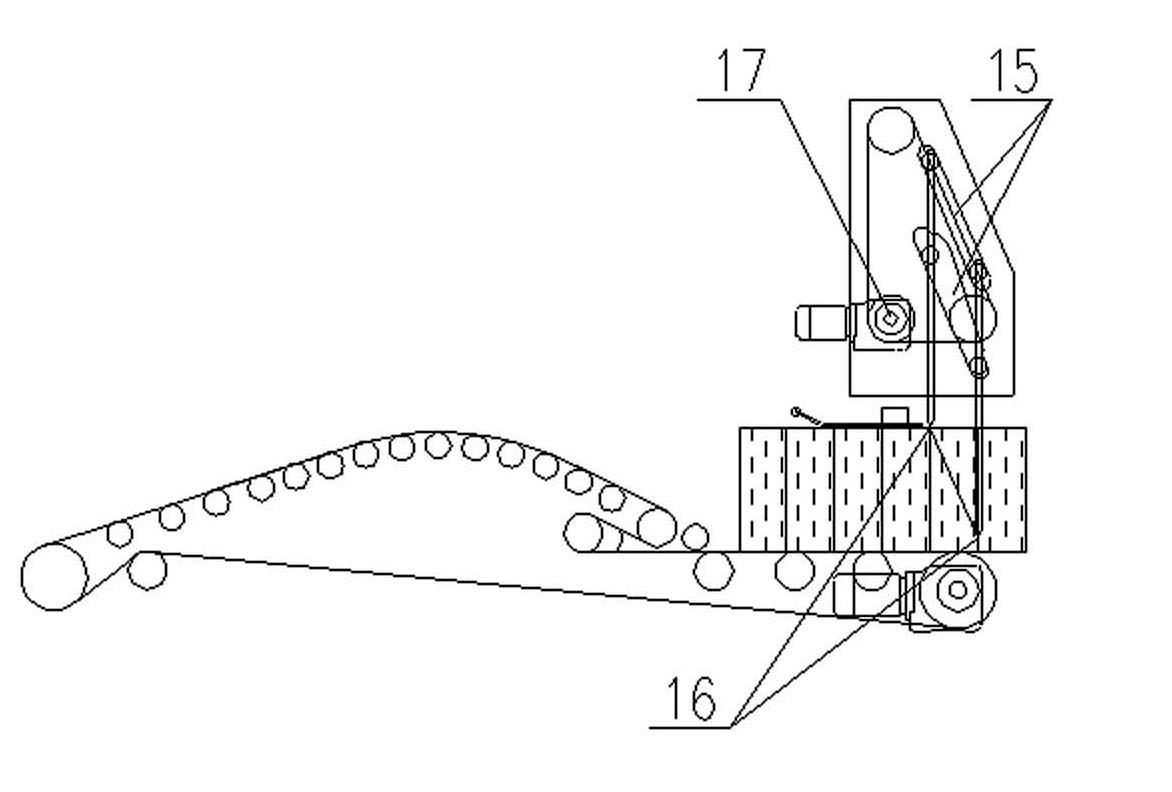

Novel low-density tobacco packet remoistening device

The invention discloses a low-density tobacco packet remoistening device, which comprises a vertical cutting machine, wherein the output end of the vertical cutting machine is connected with a leather belt conveyor capable of weighing and a loosening and remoistening machine in turn; and a pre-loosening device is connected and arranged between the leather belt conveyor and the loosening and remoistening machine. By taking the advantage of the natural lamination characteristics of tobacco blocks, the cut tobacco blocks are made to undergo flexible deformation in geometric form and heating and wetting treatment by the pre-loosening device so as to be softened and remoistened initially. Thus, broken tobacco in subsequent processing in a cylinder of the loosening and remoistening machine is reduced, processing temperature is lowered, the consumption of vapor is reduced, the heating and wetting uniformity is improved, and low-strength loosening and remoistening are realized.

Owner:QINHUANGDAO TOBACCO MACHINERY

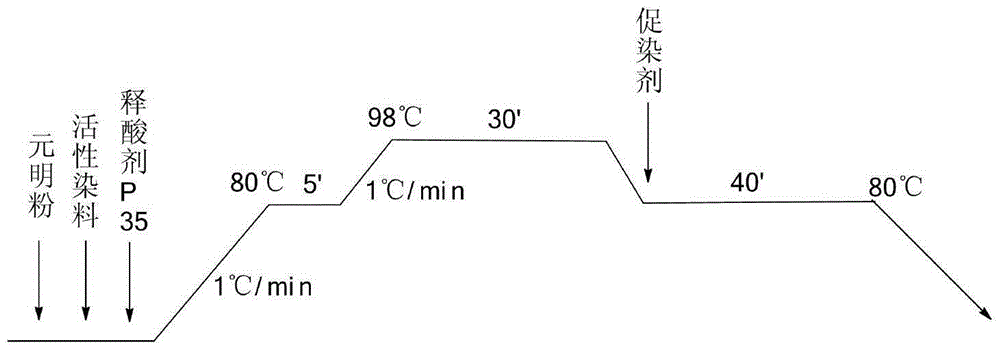

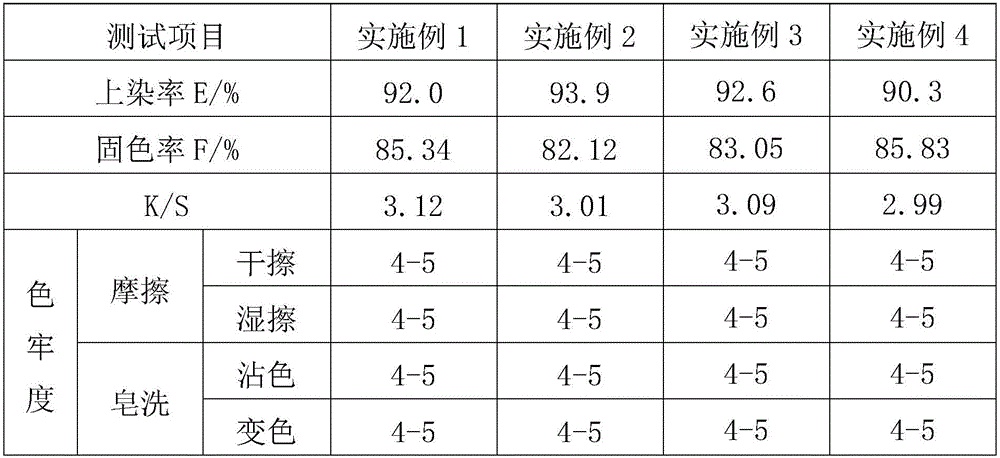

One-bath dyeing method for brocade cotton through reactive dyes

The invention discloses a one-bath dyeing method for brocade cotton through reactive dyes. The method comprises steps as follows: step (1), brocade cotton cloth is pretreated, dye liquor is added, and the bath ratio of the brocade cotton cloth to the dye liquor is 1: (4-6); step (2), the dye liquor is gradiently heated to 95-100 DEG C, the cloth is kept at the temperature to be dyed for 30-40 min, the dye liquor is cooled to 80-85 DEG C, a dyeing accelerant solution is added, and color fixation is performed for 40-50 min; step (3), the dyed brocade cotton is obtained through aftertreatment after dyeing in the step (2) is completed. One-bath dyeing of the brocade cotton is realized through coordination of the temperature, an acid-releasing agent, anhydrous sodium sulphate and the reactive dyes, a process is simple, energy is saved, and the prepared dyed brocade cotton has high washing fastness and small chromatic aberration.

Owner:浙江劲光纺织科技有限公司

Volatile aluminum fin punching oil and preparation method thereof

The invention discloses volatile aluminum fin punching oil and a preparation method thereof. The volatile aluminum fin punching oil consists of 80-99.9 percent of carbon-hydrogen solvent basic oil and 0.1-20 percent of volatile lubricating additive, and is prepared with a simple stepwise mixing method. The volatile aluminum fin punching oil has the major advantages that the solvent and the additive are volatilized easily, so that a certain flash point is realized while excellent processing lubricating property is ensured in fin processing when the volatile aluminum fin punching oil is applied to fin punching, the safety is ensured, a processed part can be volatilized completely within short time at the room temperature without heating or baking, residues do not exist, the production process of a customer is simplified while the processing requirements of the customer can be completely met, energy, steam or liquefied gas and the like for drying and degreasing are saved, and objective cost reduction is realized.

Owner:苏州铱诺化学材料有限公司

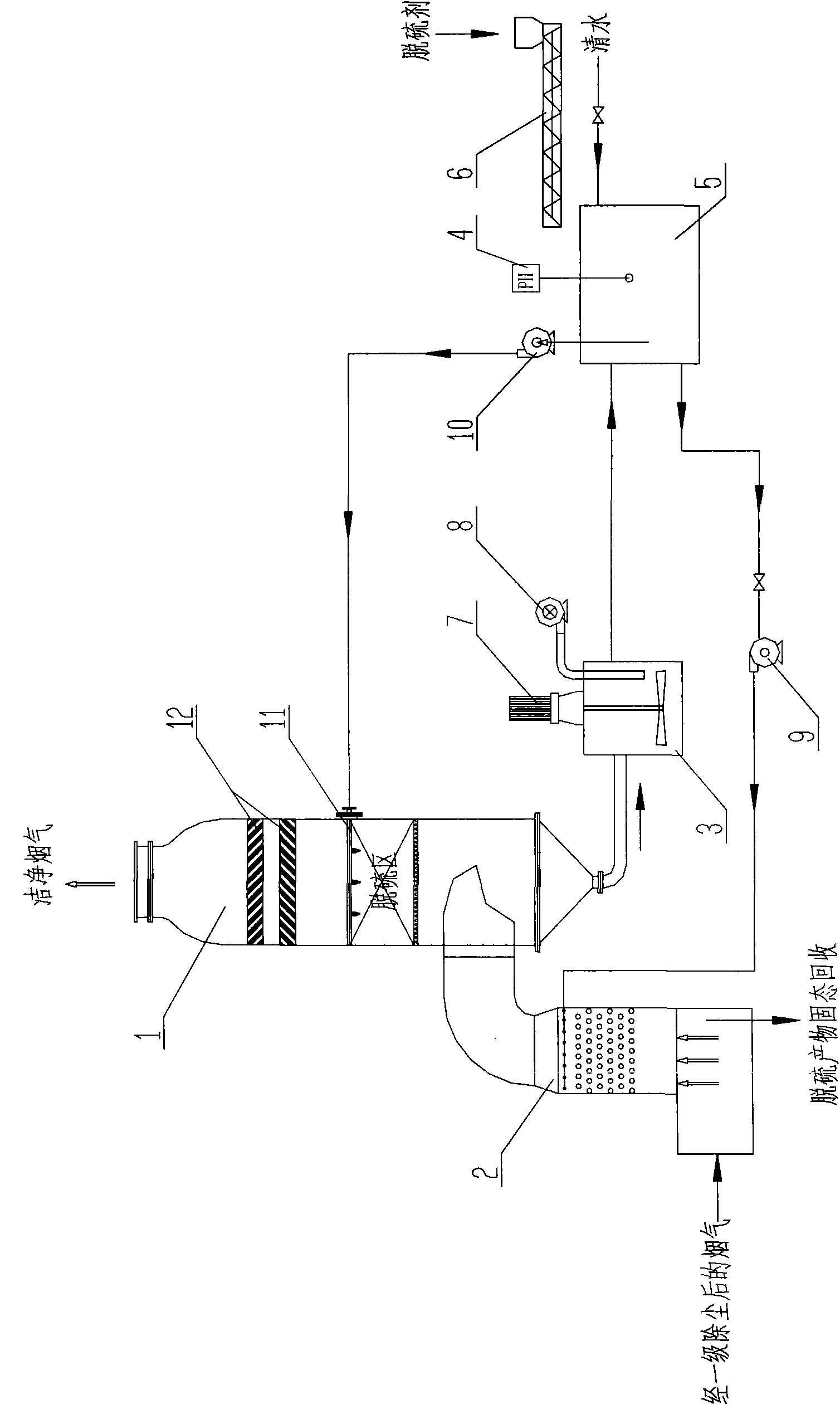

Low energy consumption flue gas wet desulphurization process

InactiveCN101780368ALow purityPurity does not affectDispersed particle separationIncreasing energy efficiencyEnergy expenditureCarbonate

The invention provides a low energy consumption flue gas wet desulphurization process. A desulphurizing tower is adopted as a sulphur dioxide absorber, flue gas after primary dust removal reacted with cleaning solution containing alkaline absorbing agent in reverse washing cycle to remove sulphur dioxide in the flue gas, meanwhile part of circulating water (determined according to desulphurization product amount) is extracted and enters into a flue gas crystallizing evaporator to be evaporated before the desulphurization tower, and temperature of the flue gas is reduced while desulphurization product is separated out by crystallization. The process of the invention utilizes flue gas crystallizing evaporator to evaporate desulphurization product, thus substituting desulphurization product dehydration equipment; flue gas waste heat is effective utilized and substitutes energy consumption in dehydration of desulphurization product, water consumption in dehydration process is reduced, thus being applicable to flue gas sulphur dioxide removal by adopting calcium series or ammonia series (liquid ammonia, ammonia water, ammonium acid carbonate) desulphurizing agent; and operation energy consumption is low, thus having good economic benefit and social benefit.

Owner:张蕊

Production technique of EPS (expandable polystyrene) foam articles

The invention discloses a production technique of EPS (expandable polystyrene) foam articles. The production technique is characterized by comprising the following steps: pre-foaming, curing, feeding, preparing mould, heating and forming, water cooling, vacuum cooling, demoulding, trimming, drying, trimming, packaging and storing in warehouse, and the production technique improves the compressed air, water circular cooling and drying process. The technique disclosed by the invention has simple and reasonable technique procedures and utilizes two paths of compressed air supply systems, so that the pipeline pressure is very stable, an electromagnetic valve acts flexibly, a cylinder switching valve quickly and reliably acts, and a cooling water circulating system can quickly cool to improve the cooling efficiency, save the electric energy and vapor and reasonably utilize the energy sources; besides, a mixed mode of high and low temperature air is used, so that the articles are not deformed or expanded irrespective to the foaming density, the drying time is shortened and the resources are reasonably utilized.

Owner:安徽艾柯泡塑股份有限公司

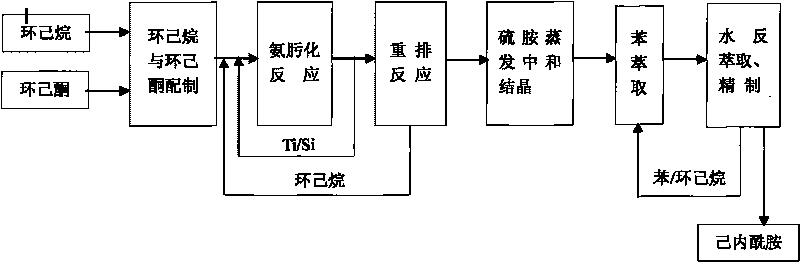

Process for preparing caprolactam

The invention discloses a process for preparing caprolactam, which comprises the following steps: after mixing cyclohexanone and cyclohexane evenly, carrying out an oxamidine reaction to obtain a cyclohexane solution of cyclohexanone oxime; enabling the cyclohexane solution of the cyclohexanone oxime and oleum to react to generate a caprolactam sulfate solution, curing the caprolactam sulfate solution, then carrying out a neutralization reaction on the cured caprolactam sulfate solution and ammonia, afterwards separating the two materials to obtain a crude product of caprolactam and then carrying out extraction and water back extraction respectively to prepare a finished product. Because of the existence of a cyclohexane inert solvent, rectification and separation do not need to be carried out after the oxamidine reaction, and only a rearrangement reaction needs to be carried out after the water phase of a catalyst is separated, thereby saving a rectification device and the steam consumption; as a result, a caprolactam enterprise with an annual yield of a hundred thousand tons can save energy worth approximately 60000000 yuan every year and can also save the one-off equipment investment totaling 60000000 yuan, the technological process of caprolactam is simplified, the procedures of water washing, extraction, distillation and the like are reduced, the production period is shortened, and the annual yield is enhanced.

Owner:河北美邦工程科技股份有限公司

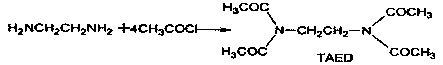

Scouring enzyme, and preparation method, application and application method thereof

InactiveCN102797146ALess fiber damageEasy to cleanBiochemical fibre treatmentBleaching apparatusSodium silicateChemistry

The invention relates to a scouring enzyme which is characterized by comprising the following raw materials in percentage by weight: 30-50% of sodium metasilicate, 3-10% of alkaline pectin compound enzyme, 20-50% of sodium carbonate, 5-10% of non-ionic surface active agent, 3-8% of peroxide oxydol activating agent, and 2-5% of sodium nitrilo triacetate; and the peroxide oxydol activating agent is prepared by compounding tetraacetylethylenediamine (TAED) and sodium percarbonate at a mass ratio of 1:2. The preparation method of the scouring enzyme comprises the following steps: non-ionic surface active agent and sodium carbonate are mixed uniformly and then are added with alkaline pectin compound enzyme to be mixed uniformly; peroxide oxydol activating agent and sodium nitrilo triacetate are added in the mixture in sequence; and sodium metasilicate is added finally, and the mixture is uniformly mixed and stirred for about one hour. The scouring enzyme can be used for boiling and bleaching of cotton yarn, cotton cloth, flax and ordinary cotton fabric or other mixed fabric before dyeing and has the advantages of simple process, low energy consumption, short time and low damage to fiber.

Owner:JIANGSU NIMATE SCI & TECH CO LTD

Wet-type ammonia process three-circulation desulphurization technique suitable for sintered flue gas

ActiveCN101474530AGuaranteed concentrationIncrease concentrationDispersed particle separationMaterials scienceAmmonium sulfate

The invention provides a wet ammonia process ternary cycle desulfurization process applicable to sintering flue gas. In the process, the desulphurization of the sintering flue gas in the steel industry is realized by the methods of three-stage circulation absorption, outside tower oxidation, saturation and crystallization. The invention provides the desulfurization process for the sintering desulfurization reserved currently in the nation; the desulfurization process has low investment, low running cost and can realize resource recovery. Home grown coking waste ammonia or other ammonia of the steel industry are used for treating SO2 in the waste gas in a sintering machine so as to treat wastes with processes of wastes against one another; the absorptivity of the SO2 is high; the loss of the outlet ammonia of the system is low; in the running process, a great amount of steam is not needed and solid ammonium sulphate with fine quality is generated and sold as fertilizer. The invention belongs to the desulfurization process which changes waste into valuable, not only reduces the emission of sulfur dioxide, but also brings tremendous environmental benefits and definite economic benefit.

Owner:无锡高达环境科技有限公司 +1

Method for preparing bamboo pulp with full liquid phase pre-hydrolytic sulfate rapid displacement cooking

InactiveCN102321990ASuitable viscosityHigh degree of polymerizationPulp bleachingPulping with inorganic basesTriple effectAlpha-Cellulose

The invention discloses a method for preparing bamboo pulp with full liquid phase pre-hydrolytic sulfate rapid displacement cooking. The method comprises the following steps of preparing for materials, washing the materials, pre-hydrolyzing, cooking, washing, selecting, bleaching, regulating the polymerization degree, dechlorinating and acid-treating. According to the method, after the cooking stage is finished, the obtained pulp has alpha cellulose content of not less than 95%, pentosan of not more than 4% and average polymerization degree of 550-700; and after the acid treating is finished, the obtained pulp has alpha cellulose content of not less than 93%, pentosan content of not more than 4.0%, average polymerization degree of 500-650 and whiteness of 82-86%. The processes of full liquid phase hydrolysis, full liquid phase cooking, hydrolysate recycling, recycled black liquor displacement cooking and chlorine dioxide clean bleaching are adopted in the method disclosed by the invention. The method has the characteristics of high whiteness, low viscosity and high polymerization degree of products, thus wastewater pollution is greatly reduced, the temperature rise time and steam are saved, the triple effects of energy saving, emission reduction and production increasing are achieved, and the problems of large wastewater pollution, high energy consumption and low capacity existing in the traditional pre-hydrolytic sulfate method for preparing pulp.

Owner:SICHUAN YONGFENG PAPER MAKING JOINT STOCK

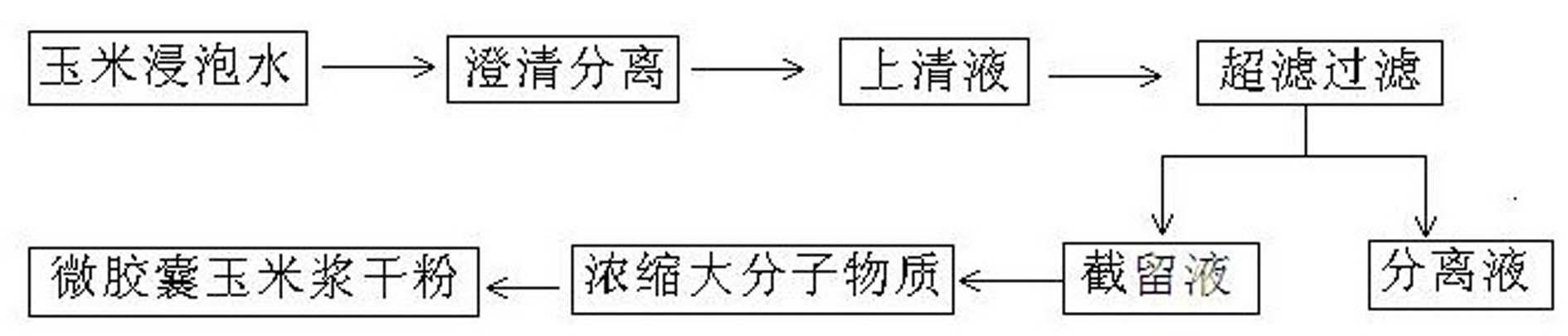

Method for preparing instant dried corn steep liquor powder by using corn steep liquor

InactiveCN102550937AHigh retention rateImprove concentrationMicroorganismsFood preparationUltrafiltrationSeparation technology

The invention discloses a method for preparing instant dried corn steep liquor powder by using corn steep liquor. The method comprises the following steps of: separating the corn steep liquor into a permeate and a trapped fluid by an ultrafiltration membrane separation technology, treating a separation liquid with lower molecular weight by a lime milk neutralization method to prepare inositol and produce a supernatant, mixing the supernatant and a separation liquid with high molecular weight, concentrating the mixed liquor by using a 'four-effect evaporation' system, adding a certain amount of maltodextrin into the concentrated mixed liquor, and preparing microencapsulated instant dried corn steep liquor powder through spray drying. By the method, the retention rate of protein is high in the ultrafiltration membrane separation process; during concentration by using the 'four-effect evaporation' system, steam is saved, and energy consumption is reduced; and the corn steep liquor is wrapped by a microcapsulation technology, so that the corn steep liquor is easy to dry, preserve and transport.

Owner:HENAN XINYUAN BIOTECH CO LTD

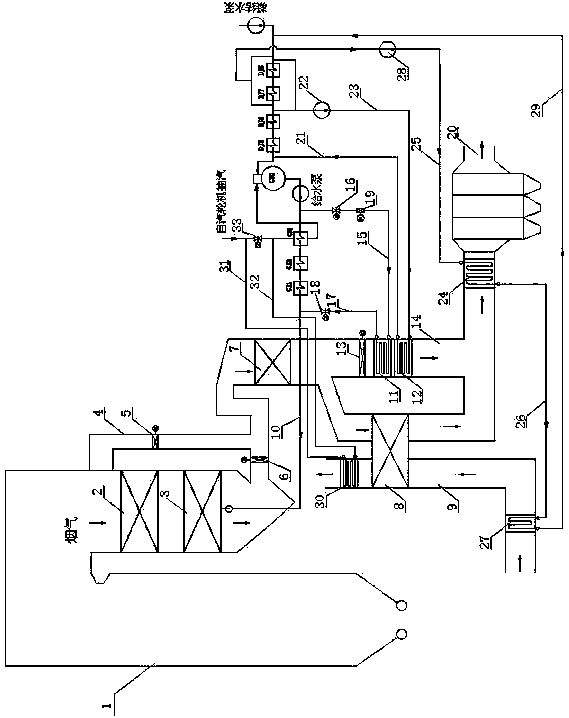

Boiler full-load denitration coupling flue gas waste heat gradient utilization system

PendingCN107687634AEasy to useSolve the problem of decouplingFeed water supplyCombustion processAir preheaterLow load

The invention relates to the field of boiler full-load denitration putting-into-operation and exhausted smoke waste heat utilization and particularly discloses a boiler full-load denitration couplingflue gas waste heat gradient utilization system. The boiler full-load denitration coupling flue gas waste heat gradient utilization system comprises a boiler; a low-temperature heater, a coal economizer, a denitration device, an air preheater and an electric dust remover are sequentially mounted in a flue gas channel of the boiler in the advancing direction of flue gas. The boiler full-load denitration coupling flue gas waste heat gradient utilization system is characterized in that a high-temperature denitration bypass flue is arranged in the position, between an inlet of the low-temperatureheater and an inlet of the denitration device, of the flue gas channel; an air preheater bypass flue is arranged in the position, between an outlet of the denitration device and an inlet of the electric dust remover, of the flue gas channel; and a high-temperature coal economizer and a medium-temperature coal economizer are sequentially arranged in the air preheater bypass flue in the advancing direction of the flue gas. According to the boiler full-load denitration coupling flue gas waste heat gradient utilization system, the denitration device can be effectively put into use under the low load condition of the boiler, and the splitting problem of the denitration device due to decreasing of the load of the boiler is solved; and gradient utilization of waste heat of the flue gas is achieved, high energy level extracted steam is effectively squeezed out, the power generation load is increased, and the overall benefits of a power plant are promoted.

Owner:SHANDONG HONGAO POWER TECHNOLOGY CO LTD

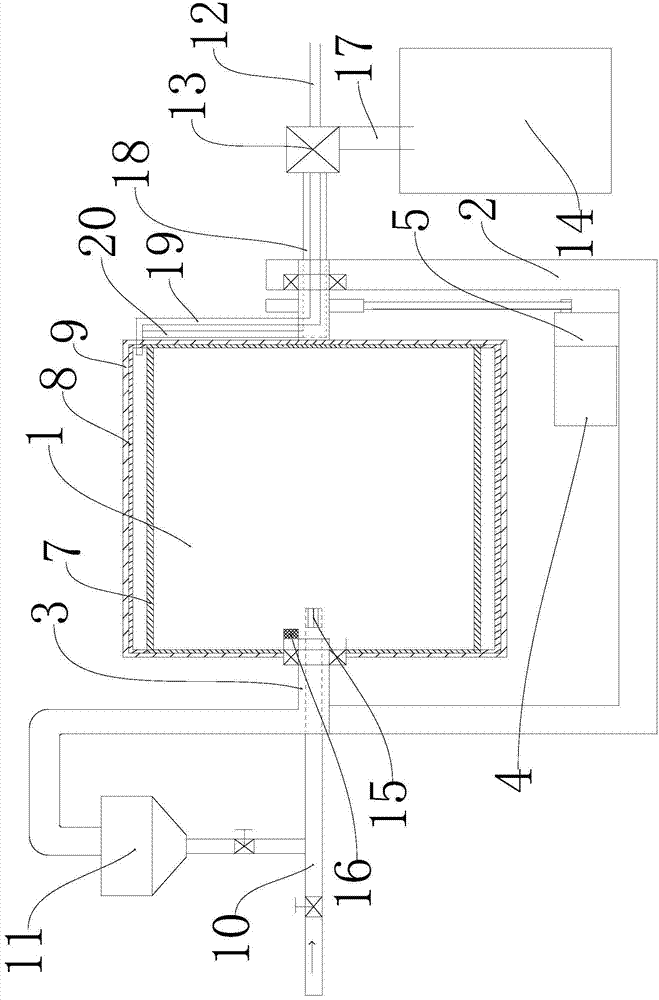

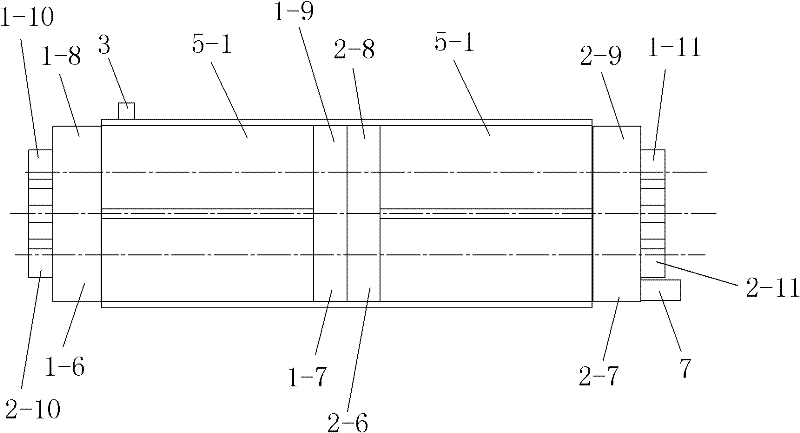

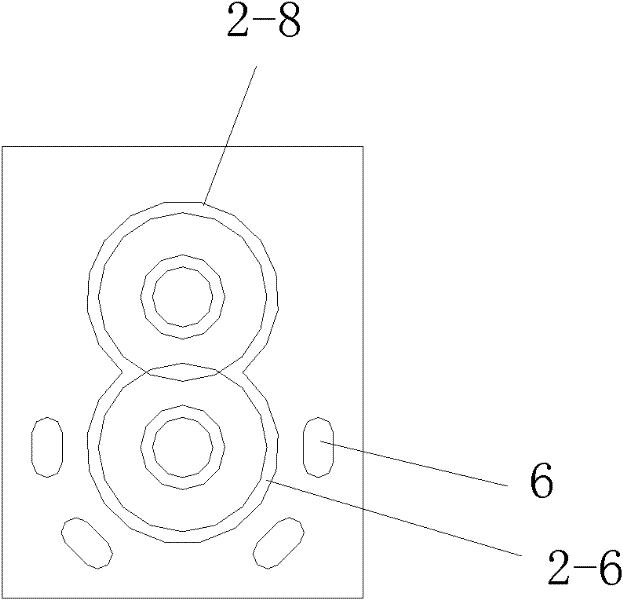

Energy-saving diaphragm type pressure filter

ActiveCN103223269AReduce water contentSave steamFiltration separationPulp and paper industryHigh pressure

The invention discloses an energy-saving diaphragm type pressure filter, comprising a thrust plate, a compressing plate, filter plates and a top press oil cylinder, wherein the thrust plate and the compressing plate are arranged oppositely; the compressing plate is connected to a piston rod of the top press oil cylinder; the filter plates are successively arranged and pressed tightly between the thrust plate and the compressing plate; a filter cloth is clamped between each adjacent filter plates so as to form a filter chamber; an elastic membrane is arranged between each filter plate and corresponding filter cloth; the thrust plate is provided with a material-feeding port communicated with each filter chamber; the material-feeding port is communicated with a slurry pump pipe with a control valve; the thrust plate is also provided with dewatering ports passing through the filter plates and the elastic membranes; the dewatering ports are communicated with a high pressure medium pump pipe with the control valve; and the high pressure medium pump pipe with the control valve and a blow-off pipe are connected to the slurry pump pipe. By adopting two additional processing measures of emptying residual liquid and backflushing air, water content in a filter cake is reduced maximally and steam for the next drying process is saved.

Owner:GUANGXI XINTIANDE ENERGY

Novel technique for dewatering and rinsing medical dressing by one-bath method

InactiveCN101411885AShorten process timeSave on electricity billsBleaching apparatusAbsorbent padsChemistryNovel technique

The invention discloses a new bath bleaching technique for medical dressing, which comprises two steps, namely prewashing and bleaching, wherein the prewashing step is as follows: adding 0.5 to 1 weight percent of cleaning bleacher and 0.1 to 0.5 weight percent of refining agent of the dressing, prewashing the dressing from 10 to 40 minutes in a reaction kettle at a temperature range of between 30 and 90 DEG C, discharging liquid, then pressurizing and rinsing or rinsing the dressing by liquid flow in the reaction kettle for 10 to 25 minutes, and discharging liquid; and after prewashing the dressing, adding bleacher containing sodium hydroxide and oxydol in the reaction kettle, and bleaching the dressing. The technique effectively solves the problems that the prior bleaching technique consumes much time and much energy and produces much sewage, the product becomes yellow and crisp easily, and the like. By adopting the technique, the total cost reduces greatly; and the technique has favorable economic benefit and social benefit.

Owner:宁波米杰纺织材料有限公司 +2

Ramie rapid degumming technique for producing high quality ramie top

InactiveCN101358380AReduced chance of acidic hydrolysisShort processVegetable materialCelluloseSodium acetate

The invention discloses a ramie quick degumming process in the production of high-quality sesame balls. The ramie quick degumming process comprises the following steps: ramie soaking: quick degumming dier boiling agent accounting for 1.0 weight percent to 1.5 weight percent of the ramie is used to soak the ramie for 1.0h to 1.5h at 50 DEG C to 60 DEG C; boiling at normal pressure: under the condition of normal pressure, 6g / l to 10g / l of NaOH aqueous solution is used to cook for 2h to 4h at 95 DEG C to 100 DEG C; the quick degumming dier boiling agent consists of gene improving alkaline pectase, stabilizer sodium acetate and magnesium chloride, penetrative emulsifier peregal O and trimeric sodium phosphate. The process shortens the technological process, and reduces the pickling procedure, so that the cellulose acidic hydrolysis probability is reduced and the degummed ramie forceful injury is small. The obtained degummed ramie has large break length and little hard thread doubling, is tender and applicable in spinning high grade cotton yarn.

Owner:湖南华升洞庭麻业有限公司

High-efficiency steaming production process by two-phase printing process

InactiveCN101608406AFast steam fixationEasy to operateDyeing processLiquid/gas/vapor textile treatmentFiberColour fastness

The invention discloses a high-efficiency steaming production process by a two-phase printing process. The process comprises the following steps: reactive dye is used as a first phase to be printed on a fiber; a second phase is rolled independent of a color fixing liquid alkaline agent, alkali can promote ionization of the fiber and the reaction velocity of the dye, and lead the dye and the fiber to be activated to form covalent bond, and to speed up the completion through a high efficiency steam box. The process comprises the following steps: pretreating openpore, printing and drying single pulp by the dye without fixing agents, such as alkali and the like, rolling the fixing chemical liquid in high efficiency and short steaming efficiently; and washing and drying. The process has the characteristics of high reaction speed, steam usage conservation, high production efficiency, good dye yield and color fastness and high production quality.

Owner:杨安心

Pretreatment process for producing bamboo fibers with bamboos

InactiveCN102373637AReduce dosageShort reaction timePretreatment with alkaline reacting compoundsRaw material divisionPre treatmentLacquer

The invention provides a pretreatment process for producing bamboo fibers with bamboos. The process comprises the following steps: (1) breaking the original bamboos into bamboo chips with maximum diameter being 2-3cm; (2) soaking the bamboo chips obtained in the step (1); and (3) fibrillating the bamboo chips fished out in the step (2) into fine fibers with a devillicate machine, wherein the weight ratio of the water for soaking to the bamboo chips is (4-6):1; NaOH and bio-enzyme are mixed in the water for soaking; the addition of NaOH is 1-4% of the weight of the water for soaking and the addition of the bio-enzyme is 30-70g per ton of bamboos; the bio-enzyme is the mixture of laccase and xylanase in a weight ratio of (90-70):(10-30); the temperature of the water for soaking is 60-80 DEG C; and the soaking time is 4-8 hours. The pretreatment process has the following beneficial effects: the bio-enzyme participates in the reaction while the broken bamboo chips are subjected to hydrolysis treatment, thus effectively overcoming the alkali darkening reaction, reducing the use amount of oxidants in the late bleaching process by more than 40% and shortening the reaction time by more than 30%.

Owner:TIANJIN ZIWEI TAIKE PLANT FIBER TECH

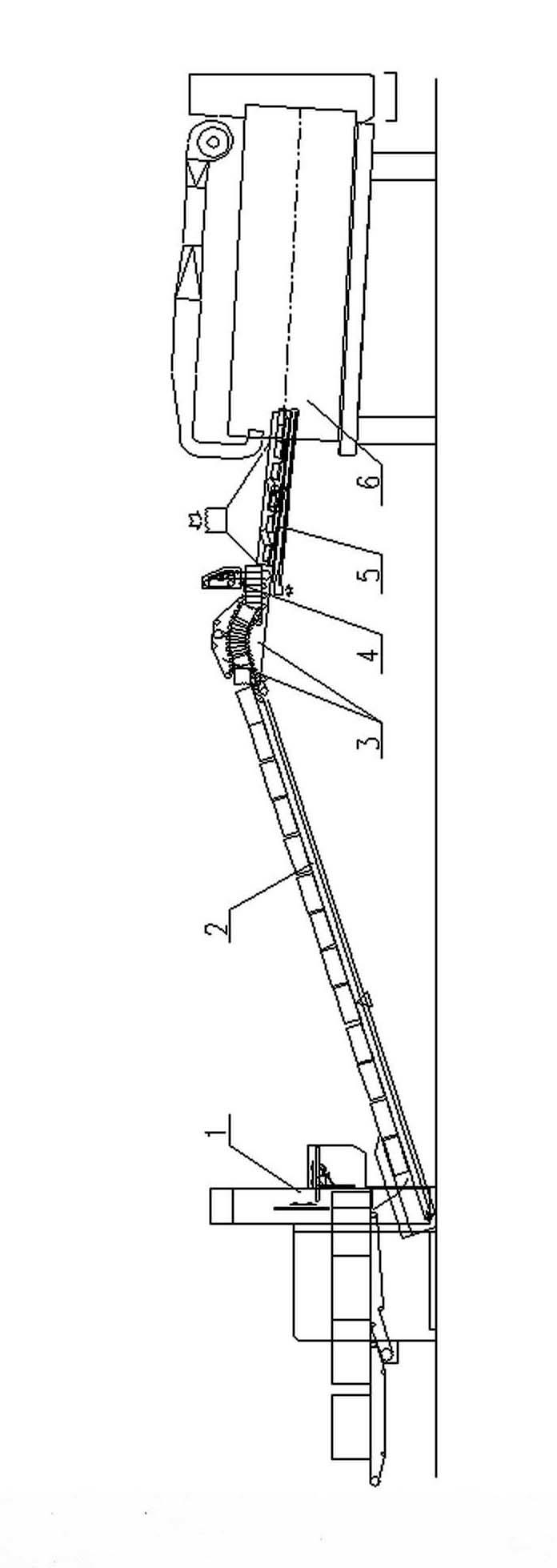

Mechanical continuous extraction process for stevioside and continuous extraction unit

InactiveCN102229630AContinuous extraction process steps are simpleReasonable designSugar derivativesSugar derivatives preparationHelical bladeLow voltage

The invention discloses a mechanical continuous extraction process for stevioside and a continuous extraction unit. The continuous extraction process comprises the following steps of: 1, saturated imbibition immersion; 2, carrying out mechanical continuous extraction by adopting the continuous extraction unit; 3, post-recycling treatment; and 4, follow-up treatment. The continuous extraction unitcomprises a shell, a high-voltage kneading and tearing device and a low-voltage expanding imbibition device which are arranged inside the shell; both the high-voltage kneading and tearing device and the low-voltage expanding imbibition device comprise horizontal thrusters; the horizontal thrusters are of twin-screw extruders and comprise propelling main shafts and propelling countershafts which are synchronous in the rotation and opposite in the rotation direction; and helical blades, which are opposite in the helical direction, are arranged on the propelling main shafts and the propelling countershafts. The process and the continuous extraction unit have the advantages of reasonable design, convenience for implementation, energy saving, environment friendliness, little water consumption,high production efficiency, high extraction efficiency and capability of effectively solving the practical problems, such as larger water consumption, great waste water handling capacity, high investment cost, low production efficiency, low extraction rate and the like when the traditional pot-type steeping tank is used for extraction.

Owner:张付舜 +1

Nylon-cotton fabric one-bath dyeing method with activated dye

InactiveCN106758374ASoft touchImprove the finishDyeing processMicroballoon preparationRare earthSurface-active agents

The invention discloses a nylon-cotton fabric one-bath dyeing method with an activated dye. The method comprises the steps that a nylon-cotton fabric is soaked into a activated dye liquor, dyeing is conducted under the conditions that the bath ratio is adjusted to be 1:(5-20) and the temperature is 20-30 DEG C, the temperature is raised to 55-75 DEG C, heat preservation is conducted for 5-15 min, then the temperature is raised to 105-125 DEG C, heat preservation is conducted for 30-40 min, 1-5 g / L sodium carbonate is added, and heat preservation is conducted for 5-25 min at the fixing temperature of 60-90 DEG C, wherein the activated dye liquor comprises 1-5% owf of rare earth coordinated microencapsulated activated dye, 5-15 g / L of anhydrous sodium sulphate, 0.5-10 g / L of pH lubricating agent, 0.1-0.3 g / L of hydrozybenzene halogenide and 0.01-0.1 g / L of organic fluoride surface active agent. The dyeing method has the advantages of being high in fixation rate and good in leveling property and is simple in technology and short in dyeing time, the consumption of salt in the activated dye is greatly reduced, and environmental protection is achieved.

Owner:无为竟成服饰有限公司

Waste water heat energy utilization method applicable to viscose staple fiber industry

InactiveCN104264255APromote energy saving and consumption reductionTake advantage ofArtificial thread manufacturing machinesTextile/flexible product manufactureFiberSocial benefits

The invention discloses a waste water heat energy utilization method applicable to the viscose staple fiber industry. The waste water heat energy utilization method applicable to the viscose staple fiber industry comprises processes of performing heat exchange and recycling on waste hot water during viscose staple fiber production, wherein the waste hot water comprises plasticizing tank overflow water; the processes comprise utilizing the plasticizing tank overflow water to perform step-by-step heat exchange sequentially on plasticizing tank make-up water, desulfurizing liquid and packaged cooling water, the packaged cooling water is conveyed to a cutting machine after heat exchange is performed, and then utilized by a refiner to obtain green cut water, and the green cut water returns to the cutting machine or is conveyed to a plasticizing tank water supplementing tank to serve as plasticizing tank supplement water. The waste water heat energy utilization method applicable to the viscose staple fiber industry achieves comprehensive recycling and utilization of various types of waste hot water and meanwhile achieves heat exchange treatment on specific mediums requiring heating during the viscose staple fiber production, thereby making full use of waste heat of the waste hot water, promoting energy conservation and consumption reduction for enterprises on the basis of existing process waste water treatment and under the premise of no flow losses, and obtaining high social benefits and economic benefits.

Owner:YIBIN GRACE +2

ADCA (Azodicarbonamide) foaming agent liquid waste disposal process

InactiveCN103043841ALow fluid resistanceReduce running power consumptionMultistage water/sewage treatmentAmmonium halidesLiquid wasteWastewater

The invention relates to an ADCA (Azodicarbonamide) foaming agent waste liquor treatment process which comprises the following steps of: preheating waste liquor to 40-60 DEG C; treating the waste liquor in a vacuum crystallizer under the condition that the temperature is 45-130 DEG C and the vacuum degree is 0-0.1 MPa; separating out sodium sulfate; reducing the temperature of a mother solution obtained after the sodium sulfate is separated to 35-40 DEG C, and crystallizing under the condition that the vacuum degree is 0.080-0.085 MPa; and separating out ammonium chloride. The ADCA foaming agent waste liquor treatment process provided by the invention can recover the sodium sulfate and the ammonium chloride under the precondition of zero sewage discharge and can greatly reduce the treatment cost of waste water.

Owner:ZAOZHUANG ZHONGKE CHEM

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com