Nylon-cotton fabric one-bath dyeing method with activated dye

A technology of reactive dyes and dyeing methods, applied in dyeing methods, textiles and papermaking, microcapsule preparations, etc., can solve the problems of increased labor intensity, low utilization rate of reactive dyes, poor dyeing effect, etc., and achieve soft overall fabric feel, Excellent slow-release function, good leveling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

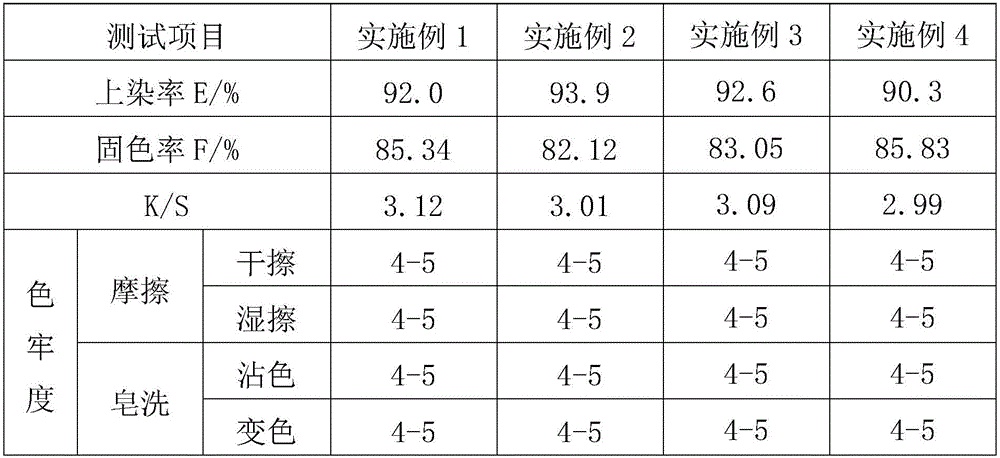

Examples

Embodiment 1

[0019] In the present embodiment, a reactive dye one-bath dyeing method of nylon cotton fabric comprises: immersing nylon cotton fabric in reactive dye solution, adjusting the bath ratio to be 1:15, entering dyeing at 25°C, and dyeing at 2.5°C / min Raise the temperature to 65°C at a rate of 10 minutes, then raise the temperature to 115°C at a rate of 1.5°C / min, keep it for 35 minutes, add 3g / L of soda ash according to the volume of the reactive dye solution, and keep it at a fixing temperature of 75°C for 15 minutes , after cooling down to room temperature, wash in cold water, soap, hot water, and dry;

[0020] The reactive dye liquor comprises: 3% owf of rare earth complexed microencapsulated reactive dye, 10 g / L of sodium sulfate, 5 g / L of pH sliding agent, 0.2 g / L of organic phenol halide, and 0.05 g of organic fluorine surfactant / L.

Embodiment 2

[0022] In this embodiment, a reactive dye one-bath dyeing method for nylon cotton fabrics comprises: immersing nylon cotton fabrics in the reactive dye solution, adjusting the bath ratio to 1:5, entering dyeing at 30°C, and dyeing at 2°C / min Raise the temperature to 75°C at a certain rate, keep it warm for 5 minutes, then raise the temperature to 105°C at a rate of 2°C / min, keep it warm for 40 minutes, add 1g / L of soda ash according to the volume of the reactive dye solution, and keep it warm at a fixing temperature of 90°C for 5 minutes , after cooling down to room temperature, wash with water at 20°C for 5min, then soap at 100°C for 5min, the amount of soaping agent used for soaping is 3g / L, and the soaping agent is made of dodecane with a weight ratio of 1:0.3 Sodium phenylsulfonate and NP-10 are compounded, then washed with water at 80°C for 5 minutes, and dried in the air;

[0023] The reactive dye solution includes: 1% owf of rare earth complexed microencapsulated reacti...

Embodiment 3

[0027]In this embodiment, a reactive dye one-bath dyeing method for nylon cotton fabrics comprises: immersing nylon cotton fabrics in the reactive dye solution, adjusting the bath ratio to 1:20, entering dyeing at 20°C, and dyeing at 3°C / min Raise the temperature to 55°C at a certain rate, keep it warm for 15 minutes, then raise the temperature to 125°C at a rate of 1°C / min, keep it warm for 30 minutes, add 5g / L of soda ash according to the volume of the reactive dye solution, and keep it warm at a fixing temperature of 60°C for 25 minutes After cooling down to room temperature, wash with water at 5°C for 15min, then soap at 90°C for 25min, the amount of soaping agent used for soaping is 1g / L, and the soaping agent is made of dodecane with a weight ratio of 1:0.6 Sodium phenylsulfonate and NP-10 are compounded, then washed with water at 60°C for 15 minutes, and dried in the air;

[0028] The reactive dye solution includes: 5% owf of rare earth complexed microencapsulated react...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com