Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

30results about How to "Pigment removal" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method used for high-efficient purification of pneumocandins B0

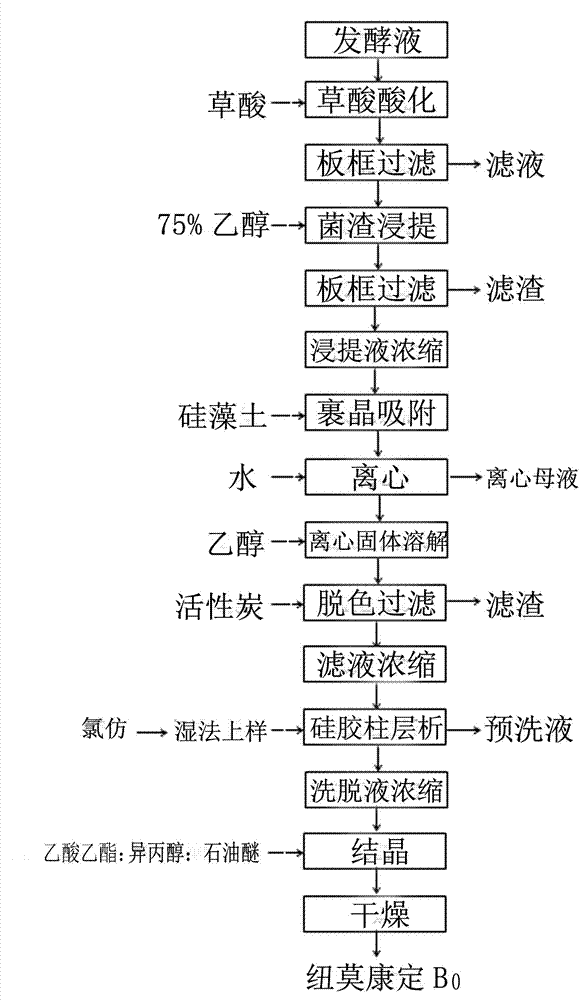

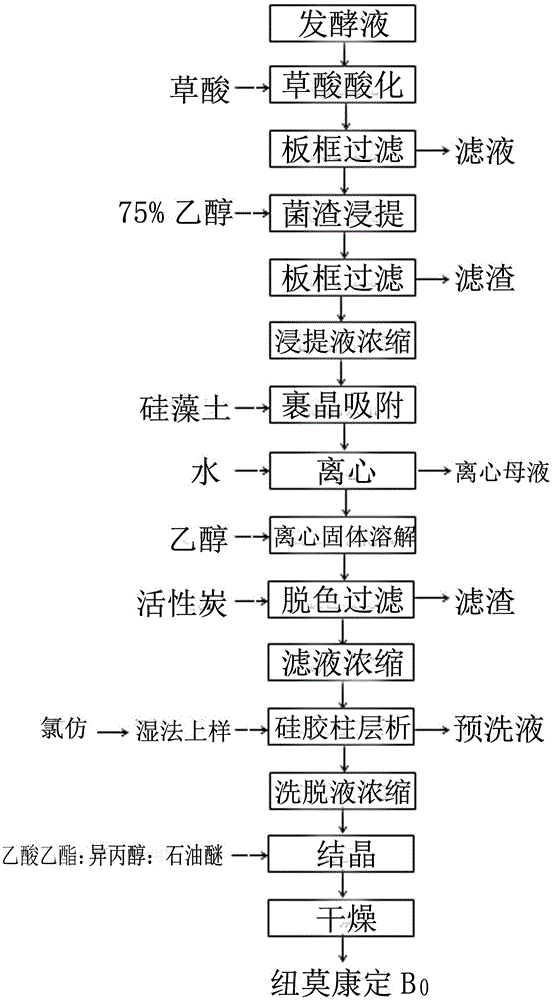

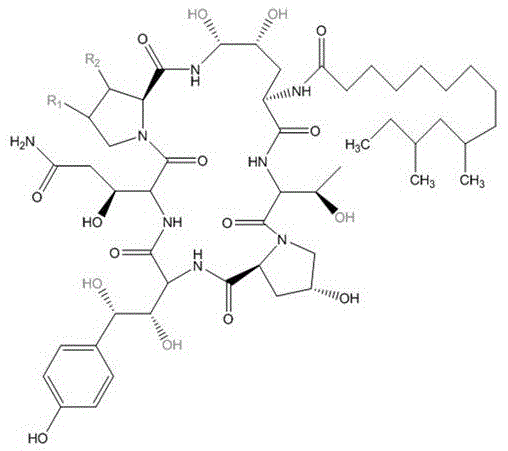

The invention discloses a method used for high-efficient purification of pneumocandins B0. The method comprises following steps: (1) pH value of a fermentation broth containing pneumocandins B0 is adjusted to 2.0 to 4.0, the fermentation broth is filtered, and a pneumocandins B0 extract liquid is obtained via extraction; (2) the extract liquid is condensed, diatomite is added for crystal packaging, water is added, and an obtained mixture is stirred and is subjected to centrifugation; (3) a solid material obtained via centrifugation is dissolved in ethanol, active carbon is added for decolouring, and an obtained mixed material is filtered; (4) an obtained filtrate is condensed, chloroform is added, an obtained solution is delivered through a silica gel column, and a pneumocandins B0 eluant is collected; and (5) the pneumocandins B0 eluant is condensed to be dry, and crystallization is carried out in a multiphase solvent system so as to obtain pneumocandins B0. The method is capable of avoiding application of resin columns and reducing amount of solvents used for elution greatly; active carbon can be used for removing pigments effectively; silica gel column chromatography is capable of removing related substances C0; and extraction purity can be as high as 99%. The method is simple and convenient; cost is reduced greatly; and industrialized production can be easily realized.

Owner:JIANGSU SENRAN CHEM

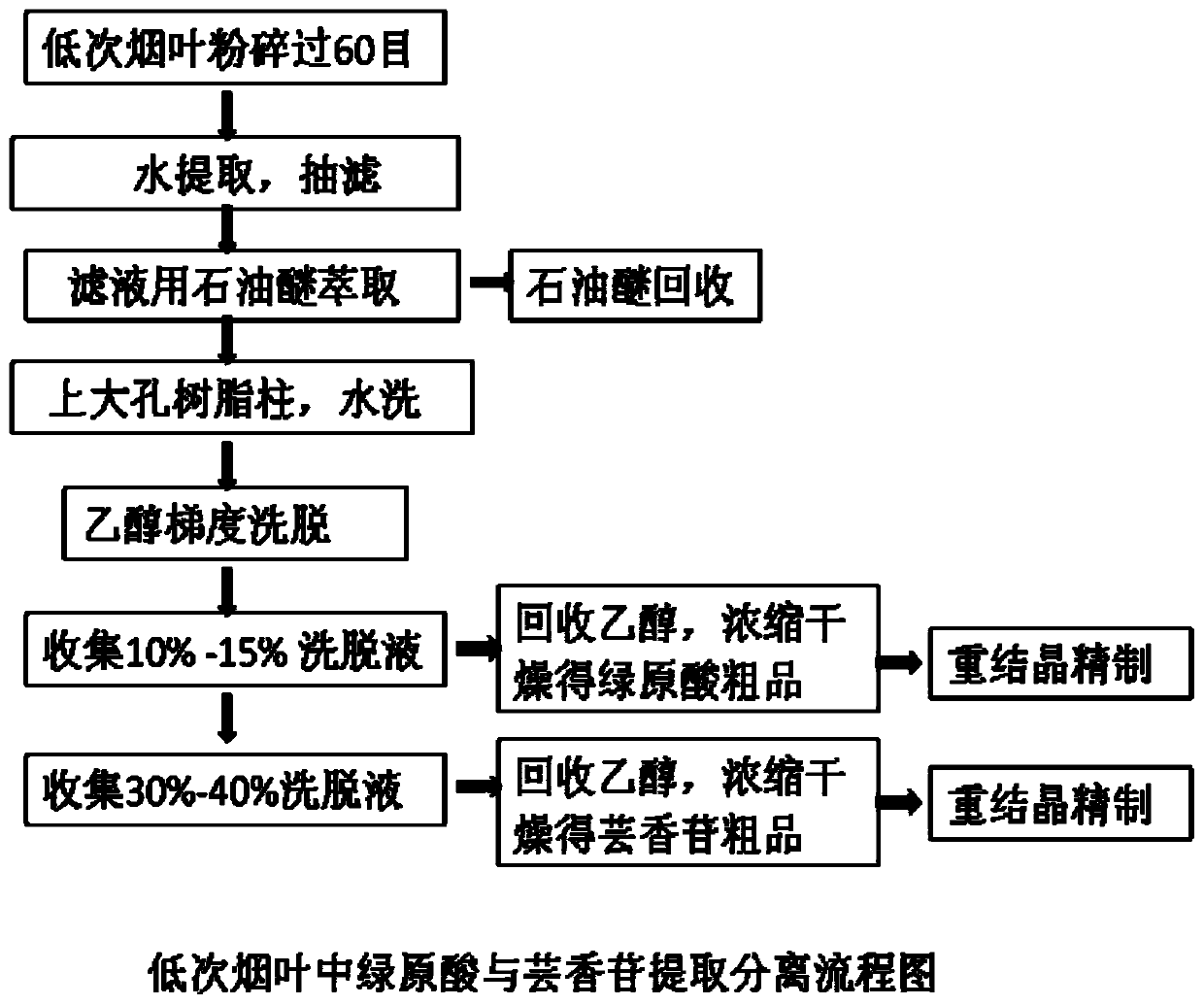

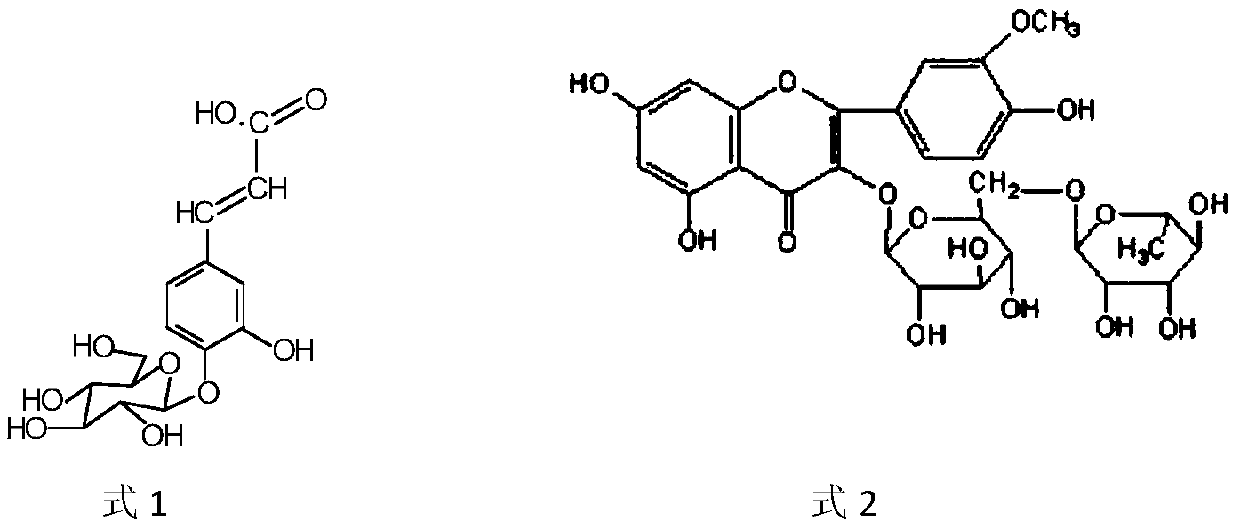

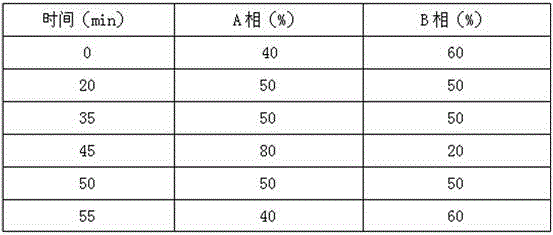

Method for simultaneously separating chlorogenic acid and rutin from tobacco leaves

ActiveCN106496034AReduce extraction costsReduce formationSugar derivativesOrganic compound preparationChlorogenic acidGradient elution

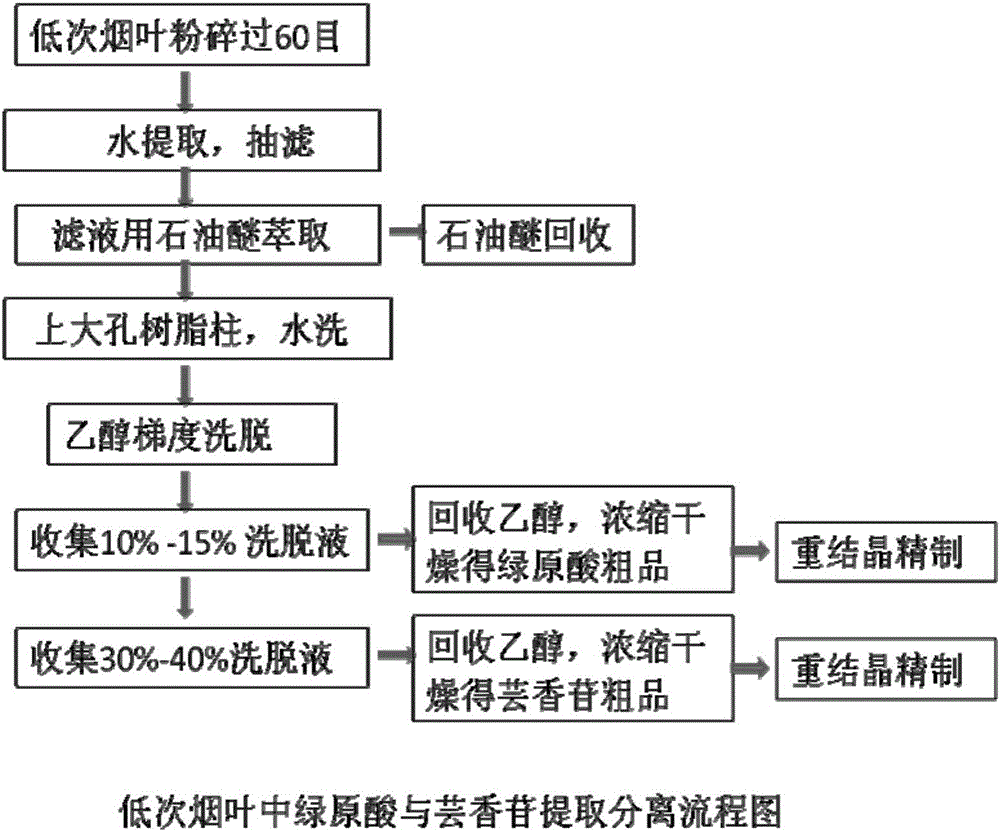

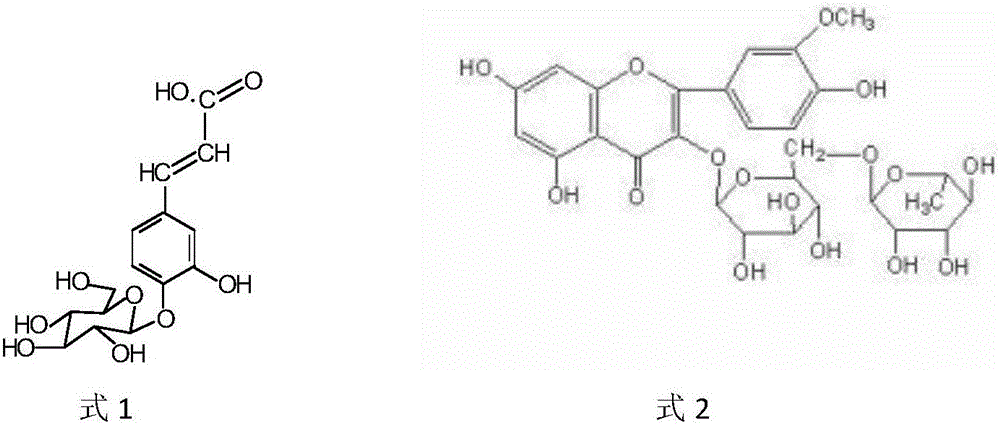

The invention discloses a method for simultaneously separating chlorogenic acid and rutin from tobacco leaves. The method includes: weighting 200g of tobacco leave powder sieved through a 60 mesh sieve, dissolving the tobacco leave powder in water according to a material-liquid ratio of 1:20, setting temperature as 50 DEG C, and stirring and extracting the chlorogenic acid and the rutin for 120min. Petroleum ether is used for extraction and removal of oil-soluble impurities for collected filtrate, and then a chlorogenic acid and rutin extracting solution is obtained. Column chromatography isolation of the chlorogenic acid and the rutin is performed on the upper column of the extracting solution. Water of 5 times of the extracting solution in volume is first used for elution until no sugar can be detected in eluate. After the water is used for the elution, different concentration of ethanol replaces the used eluate for gradient elution. Two types of ethanol eluate 10-15% and 30-40% in concentration are respectively collected so as to obtain a chlorogenic acid solution and a rutin solution. The method for simultaneously separating the chlorogenic acid and the rutin from the tobacco leaves saves raw material and reagents, reduces development cost, and achieves good separating effects.

Owner:CHINA TOBACCO CENTRAL SOUTH AGRICULTURAL EXPERIMENTAL STATION +1

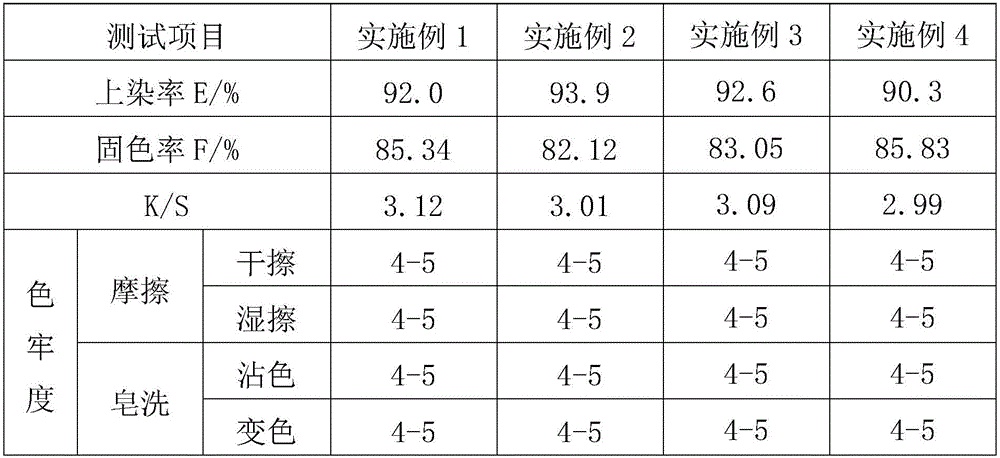

Nylon-cotton fabric one-bath dyeing method with activated dye

InactiveCN106758374ASoft touchImprove the finishDyeing processMicroballoon preparationRare earthSurface-active agents

The invention discloses a nylon-cotton fabric one-bath dyeing method with an activated dye. The method comprises the steps that a nylon-cotton fabric is soaked into a activated dye liquor, dyeing is conducted under the conditions that the bath ratio is adjusted to be 1:(5-20) and the temperature is 20-30 DEG C, the temperature is raised to 55-75 DEG C, heat preservation is conducted for 5-15 min, then the temperature is raised to 105-125 DEG C, heat preservation is conducted for 30-40 min, 1-5 g / L sodium carbonate is added, and heat preservation is conducted for 5-25 min at the fixing temperature of 60-90 DEG C, wherein the activated dye liquor comprises 1-5% owf of rare earth coordinated microencapsulated activated dye, 5-15 g / L of anhydrous sodium sulphate, 0.5-10 g / L of pH lubricating agent, 0.1-0.3 g / L of hydrozybenzene halogenide and 0.01-0.1 g / L of organic fluoride surface active agent. The dyeing method has the advantages of being high in fixation rate and good in leveling property and is simple in technology and short in dyeing time, the consumption of salt in the activated dye is greatly reduced, and environmental protection is achieved.

Owner:无为竟成服饰有限公司

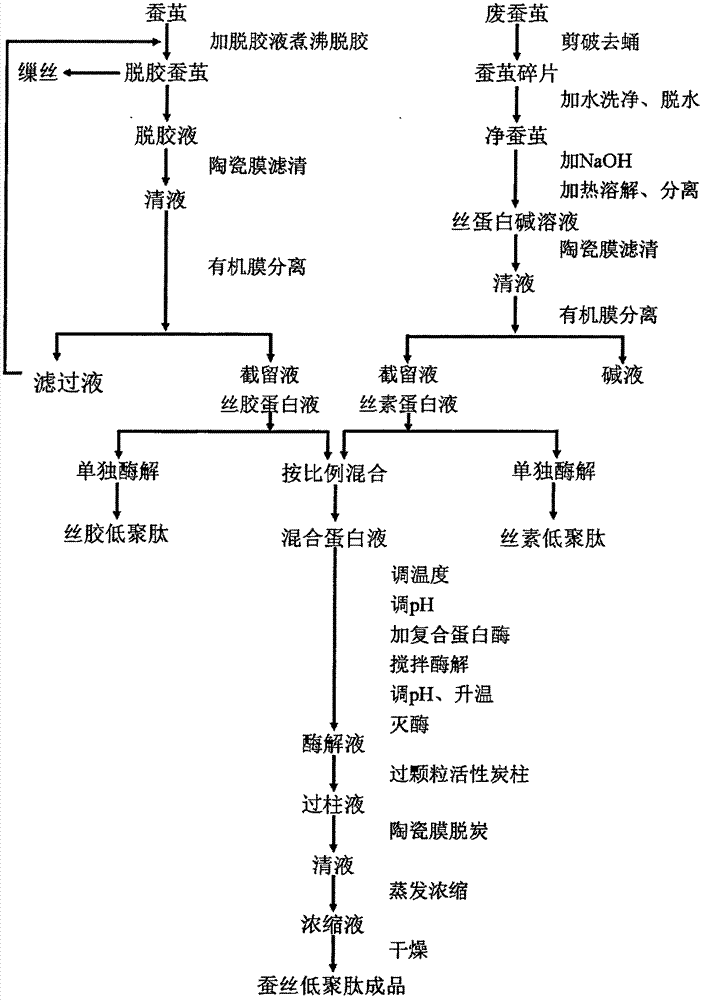

Method for producing oligopeptide by using silkworm cocoon degumming solution and waste silkworm cocoons as raw materials

InactiveCN106905424ALow costEmission reductionPeptide preparation methodsFermentationEnvironmental resistanceHydrolysate

The invention discloses a method for producing oligopeptide by using a silkworm cocoon degumming solution and waste silkworm cocoons as raw materials, and relates to the technical field of biotechnology. The method for producing oligopeptide by using the silkworm cocoon degumming solution and the waste silkworm cocoons comprises the following steps: step one, preparation of a sericin solution; step two, preparation of a silk fibroin solution; step three, mixed enzymolysis of the silk fibroin solution and the sericin solution; step four, decarburization evaporation and concentration of an enzymatic hydrolysate. A permeate liquid can be repeatedly used, so that the cost is reduced, the emission is reduced, and the product color and luster are improved. Clean cocoon shells are heated and dissolved with dilute alkaline, and the using amount of the alkaline is greatly lower than a concentration reported in the literature, so that the production cost can be reduced, and the requirements for equipment, environmental protection and labor protection are reduced. A small quantity of undissolved cocoon silk can be dissolved with the same alkaline liquor again, so that the raw materials are sufficiently utilized. Directionally filtered compound protease is adopted in silk-fibroin liquid enzymolysis, the enzymolysis yield reaches 90%, the product molecular weight is small, the digestive absorption is facilitated, and the product taste is good.

Owner:大连平岛天然产物科技有限公司

Preparation of longan peel oligosaccharides

InactiveCN101463052AReduced loss of oligosaccharidesHigh yield and purityOligosaccharidesFunctional foodAnti oxidative

The invention provides a preparation method of longan peel oligosaccharide. The method comprises the steps of selecting materials, drying, pulverizing, degreasing, lixiviating, removing polysaccharide and protein, decoloring, drying and the like. In the preparation method, the oligosaccharide is lixiviated from the longan peel by a scientific process, and the preparation efficiency of the longan peel oligosaccharide is improved on the premise of keeping bioactivity. Macroporous absorbent resin is used for decoloring, which can effectively remove pigment interference. The prepared longan peel oligosaccharide has high yield, obvious anti-oxidative activity and probiotic bacteria proliferation activity, and is applicable to the functional food development field.

Owner:SOUTH CHINA BOTANICAL GARDEN CHINESE ACADEMY OF SCI

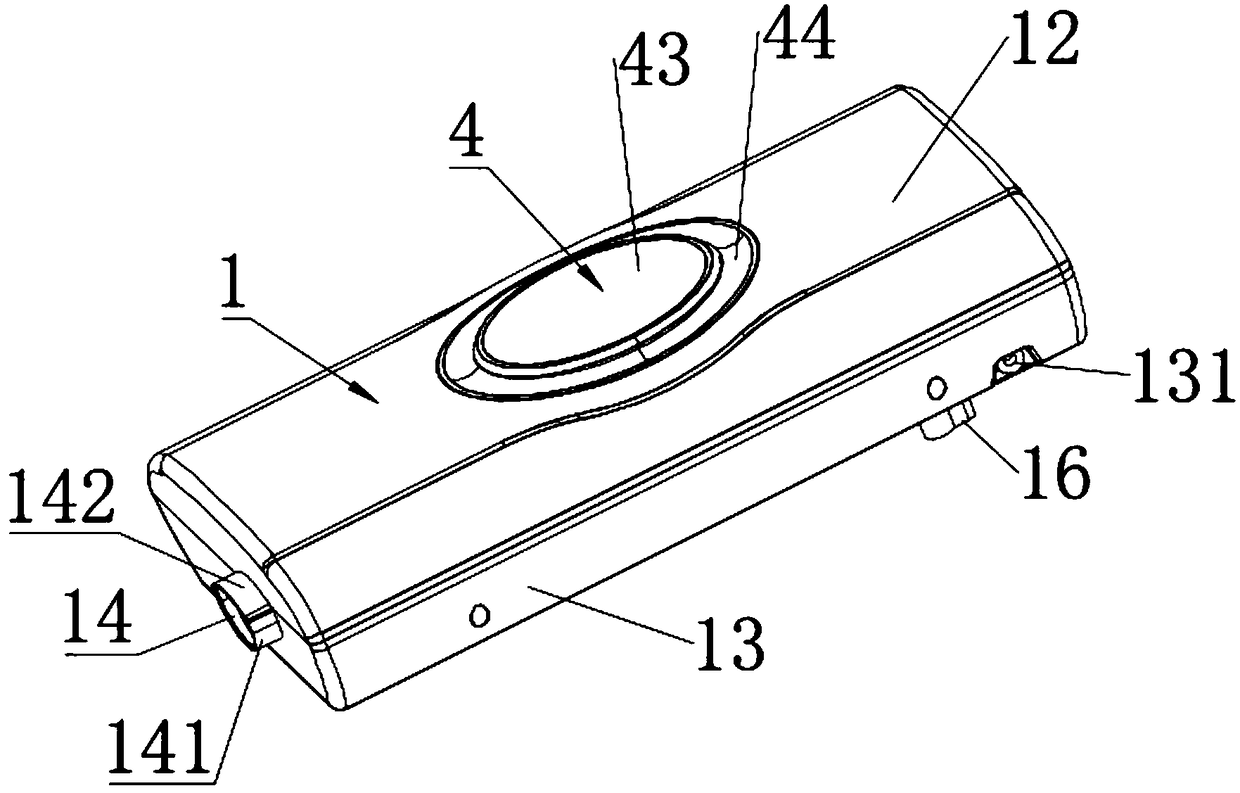

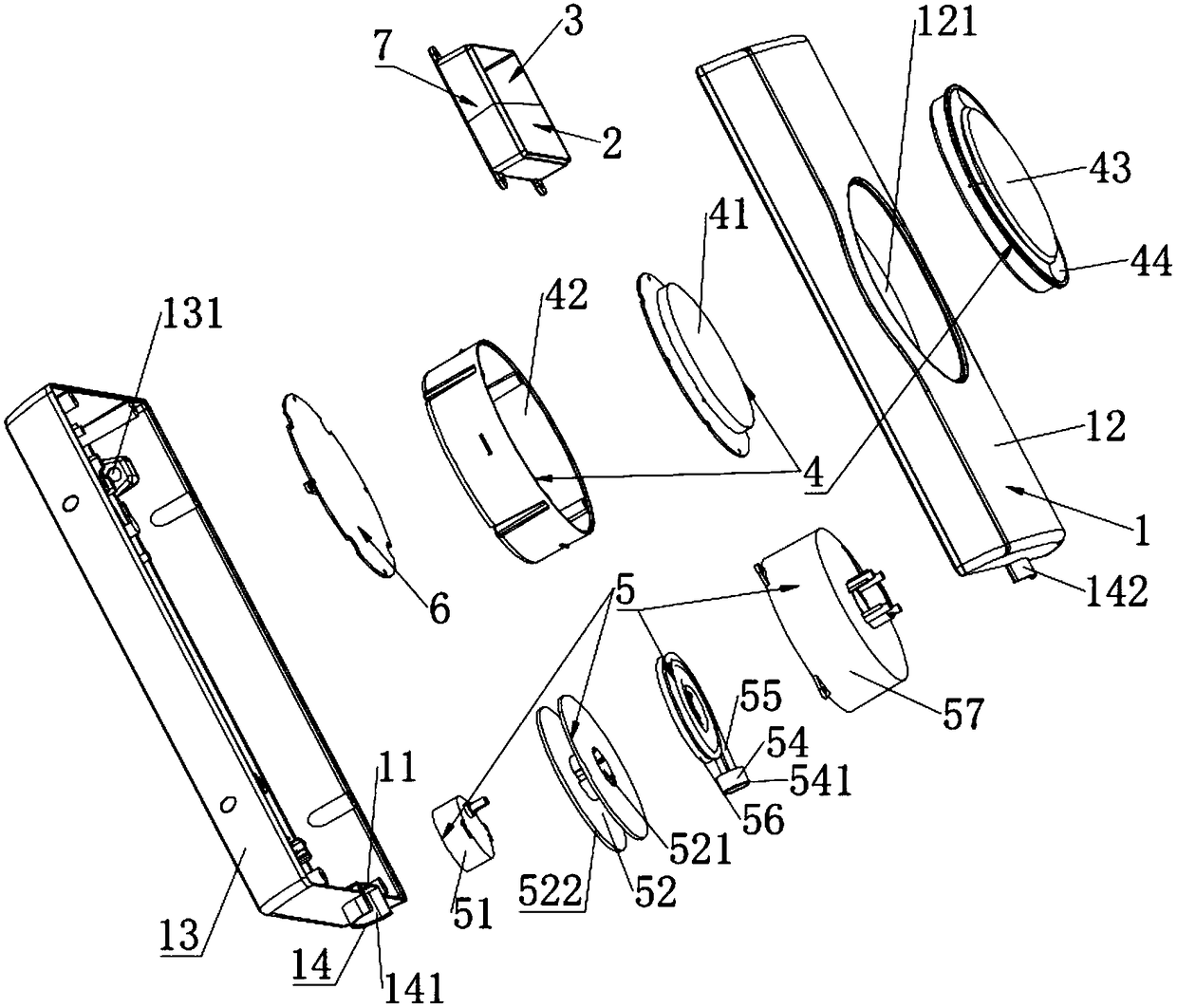

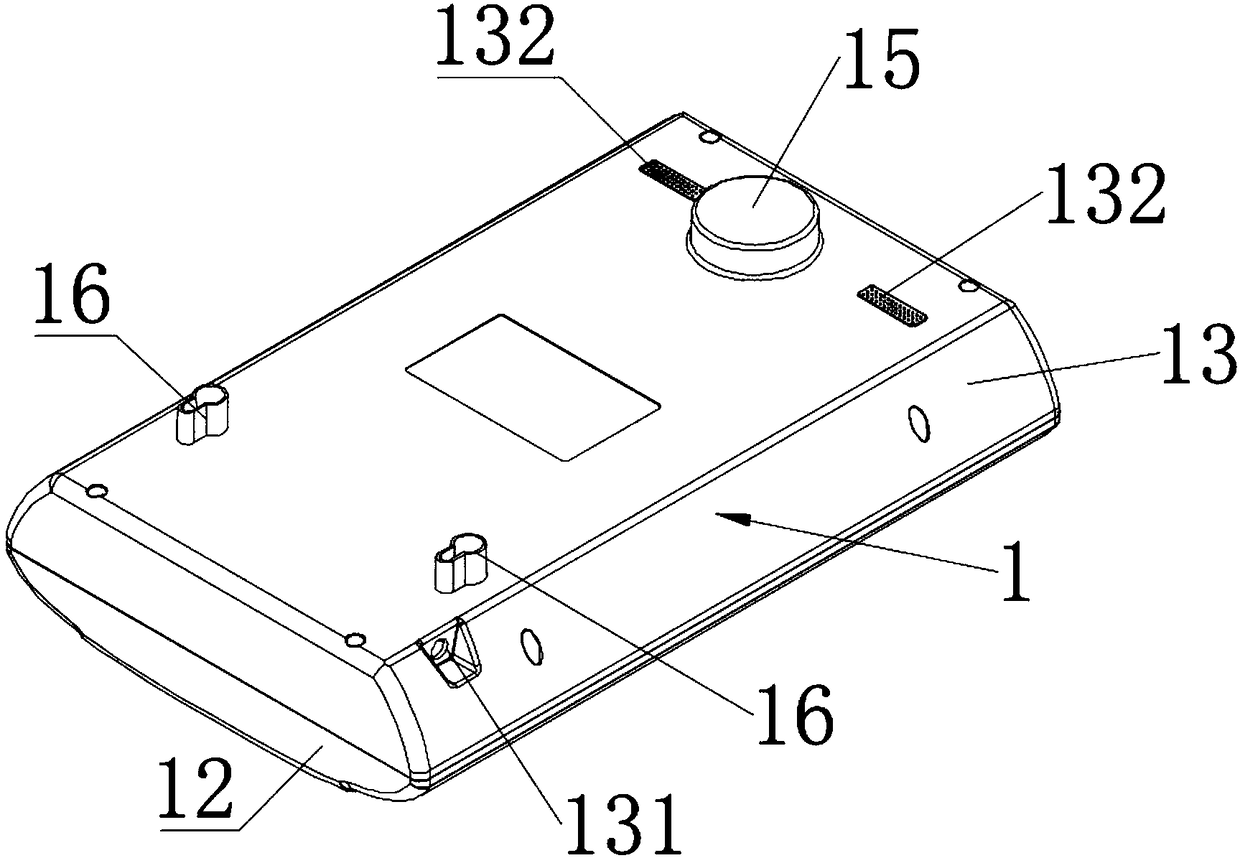

Fruit and vegetable sterilization machine

PendingCN108354196AFlexible sterilizationEfficient and complete pesticide residueFood treatmentOzone generatorPesticide residue

The invention discloses a fruit and vegetable sterilization machine. The machine includes a shell which is provided with a through hole; the machine comprises an ozone generator, an ultrasonic generator, a control piece and a coil pipe output piece which are arranged inside the shell; the control piece is separately connected to the ozone generator, the ultrasonic generator and the coil pipe output piece; the ozone generator and the ultrasonic generator are separately connected to the input end of the coil pipe output piece; the output end of the coil pipe output piece is over against the through hole; the control part controls the output end of the coil pipe output piece, and performs reciprocating motion inside and outside the shell; and a power supply piece is separately connected to the ozone generator, the ultrasonic generator, the control piece and the coil pipe output piece. According to the machine of the application, the coil pipe output piece can flexibly sterilize fruits andvegetables in various volumes, and ozone generated by the ozone generator and ultrasonic generated by the ultrasonic generator are used for performing double sterilization, so that the pesticide residues and pigments on the fruits and vegetables can be efficiently and completely removed.

Owner:佛山市顺德区远熠模塑电器有限公司

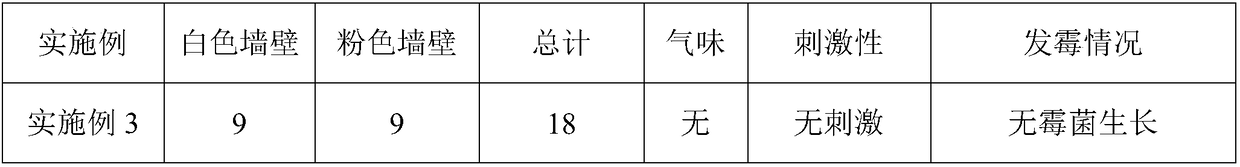

Mildew removal agent and preparation method thereof

The invention discloses a mildew removal agent and a preparation method thereof. The mildew removal agent comprises the following raw materials in percentages by weight: 1% to 10% of an oxidizing agent, 0.05% to 5% of a surface active agent, 0.3% to 1% of a mildew preventive, 0.02% to 0.5% of a penetrating agent, 0.02% to 2% of an assistant agent and the balance of deionized water, wherein the oxidizing agent is selected from at least one of sodium chlorite, sodium dichloro isocyanurate, sodium benzoate and hydrogen peroxide; the surface active agent is selected from at least one of sodium dodecyl benzene sulfonate, dodecyl sulfopropyl betaine and quaternary ammonium salt; and the mildew preventive is selected from at least one of tebuconazole, didecyl dimethyl ammonium chloride, di-octadecyl dimethyl ammonium chloride and pyrithione urea. The mildew preventive has the effects of mildew prevention and mildew removal, is lasting in effect, free of harm for human health or stimulation for skin, is applicable for various home environments, and is convenient to use, simple to produce and process and low in power consumption.

Owner:GUANGZHOU JIANISI ANTIBIOSIS MATERIAL CO LTD

Tea soap powder prepared by adopting Yunnan large leaf variety tea seed cake as raw material

InactiveCN104830547APigment removalGood emulsificationNon-ionic surface-active compoundsDetergent compounding agentsSucroseResource utilization

The present invention relates to tea soap powder prepared by adopting Yunnan large leaf variety tea seed cake as a raw material, wherein the tea soap powder is prepared from Yunnan large leaf variety tea seed cake meal, coconut oil, citric acid, sucrose, and hydrogen peroxide. According to the present invention, the main raw material Yunnan large leaf variety tea seed cake meal contains 15-18% of tea saponin and 12-16% of tea protein, and the tea saponin is a natural non-compound surfactant and has effects of good emulsifying, good decomposition, good foaming, good moistening, and good decontamination; the raw materials of the tea soap powder are the natural substances, hydrogen peroxide is used to decolorize so as to remove the pigment from the tea seeds, and the tea soap powder further contains the fresh aroma of the tea seed oil; the tea soap powder has strong detergency strong, easily washes dirt, and is especially suitable for washing of tableware and cooking utensils made from porcelains, enamels, ceramics, plastics, metals and other materials, the ; and the chronic poisoning risk can not be produced, and safety and reliability are provided; and the preparation method has characteristics of simple process, effective waste cake meal utilization, and rational resource utilization achieving.

Owner:LINCANG JIAYUAN FOOD

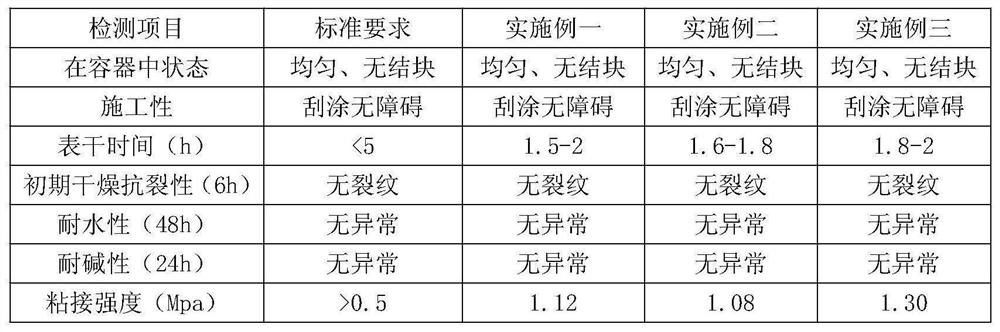

High-strength anti-cracking type external wall elastic putty powder and preparation method thereof

ActiveCN111334113AImproved anti-crack propertiesImprove bindingDrying gas arrangementsFilling pastesCelluloseFiber

The invention relates to the technical field of building materials, and particularly discloses high-strength anti-cracking type external wall elastic putty powder, which is prepared by mixing the following raw materials by weight: 600-700 parts of quartz sand, 300-400 parts of ash cement and 30-50 parts of putty powder adding master batch. The putty powder adding master batch is composed of the following raw materials by weight: 1.5-2.5 parts of palm silk, 25-40 parts of redispersible latex powder, 3-5 parts of hydroxypropyl methyl cellulose, 0.3-0.6 part of starch ether, 1.5-2.5 parts of polypropylene staple fiber, 0.8-1.2 parts of a water repellent agent and 0.3-0.6 part of a water reducing agent. Meanwhile, the invention further discloses a preparation method of the high-strength anti-cracking type external wall elastic putty powder. When the putty powder is used for plastering an external wall, the anti-cracking characteristic of a wall surface coating is obviously improved, the bonding force of the putty coating and a wall surface base layer is higher, and the putty coating is not prone to falling off.

Owner:湖南威邦新材料有限公司

TSN (toosendanin) extraction method

InactiveCN107602656AHigh dissolution rateImprove efficiencySteroidsActivated carbonUltrasonic assisted

The invention discloses a TSN (toosendanin) extraction method. The method comprises the steps as follows: branch bark and bark of chinaberries are crushed and subjected to dynamic countercurrent extraction under ultrasonic assistance, a clarifying agent is added to an obtained extraction solution for impurity removal, decoloration is performed with activated carbon, an extract is obtained throughcondensation and passes macroporous adsorption resin, an obtained eluent is subjected to reduced pressure condensation, a crude extract is obtained, petroleum ether is added for precipitation after the crude extract is dissolved, a precipitate is washed, dried, dissolved and dried again, and TSN is obtained. The TSN is extracted through steps of ultrasonic-assisted dynamic countercurrent extraction, clarification with the clarifying agent, adsorption with the macroporous adsorption resin, petroleum ether precipitation and the like, the purity and extraction rate of the TSN can be effectively increased, and the extracted TSN is high in yield and purity and contains few impurities.

Owner:右江民族医学院

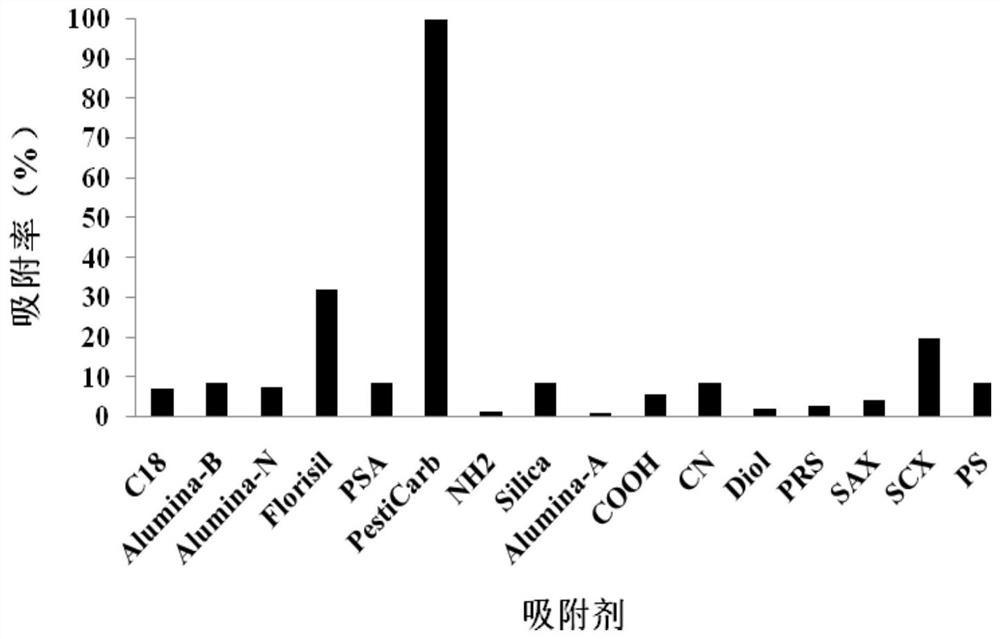

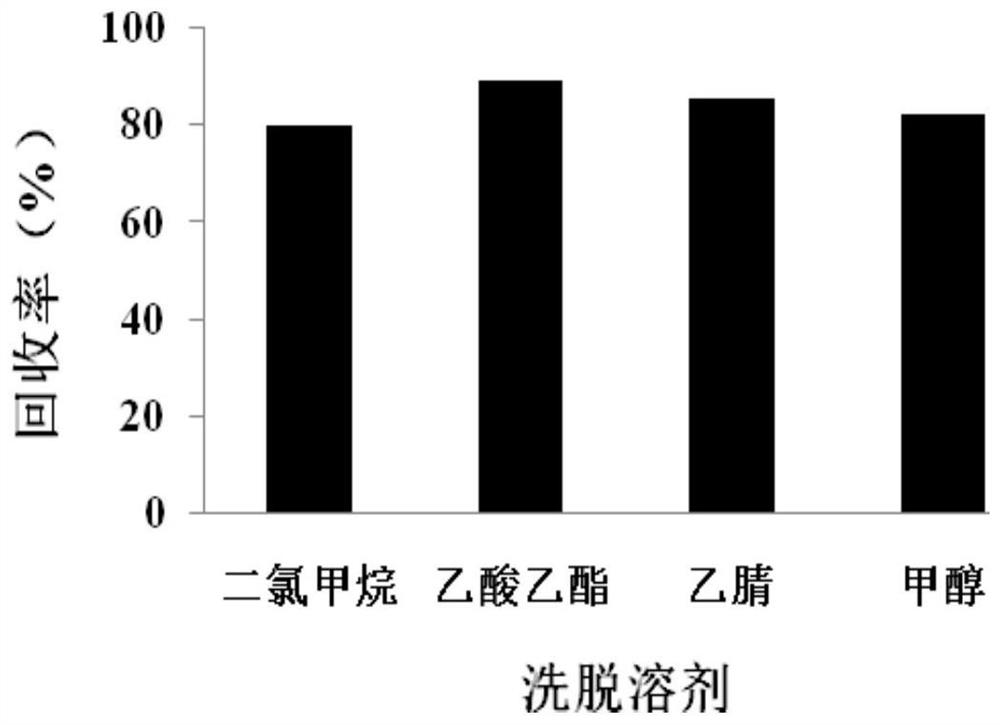

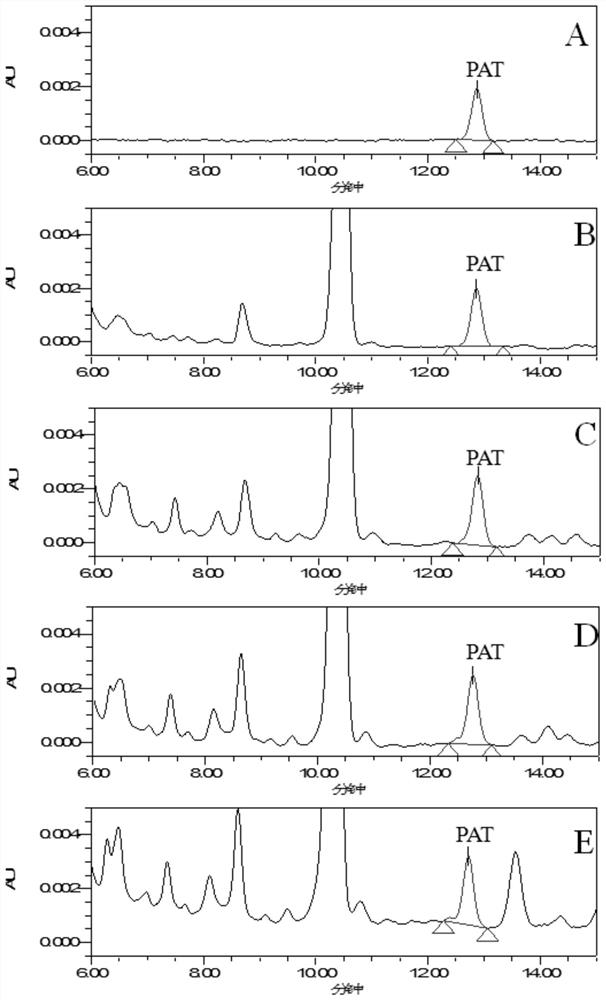

Graphitized carbon SPE column-based rapid detection method for patulin in apple juice

PendingCN113189221ALarge column capacityEasy to makeComponent separationAgainst vector-borne diseasesEnvironmental chemistryBiology

The invention belongs to the field of quality safety detection of fruits, vegetables and products thereof, and particularly discloses a graphitized carbon SPE column-based rapid detection method for patulin in apple juice, which comprises the following specific steps of (1) preparing a graphitized carbon SPE column for purifying patulin by taking graphitized carbon as a filler, (2) enabling the apple juice to be detected to directly pass through the column, and eluting the patulin adsorbed by the apple juice with an organic solvent to obtain a purified solution, and (3) carrying out nitrogen blowing, redissolving and membrane passing on the purified liquid, and then detecting the content of patulin in the apple juice by using HPLC-PDA. The purification column is designed by utilizing the adsorption effect of the graphitized carbon filler on the patulin, the purification column is used only by two steps of sample loading and elution, the steps of sample pretreatment, column activation and leaching are omitted, the purification effect is good, the sample pretreatment efficiency is improved, and the detection cost is reduced.

Owner:ZHEJIANG ACADEMY OF AGRICULTURE SCIENCES

Preparation of longan peel oligosaccharides

The invention provides a preparation method of longan peel oligosaccharide. The method comprises the steps of selecting materials, drying, pulverizing, degreasing, lixiviating, removing polysaccharide and protein, decoloring, drying and the like. In the preparation method, the oligosaccharide is lixiviated from the longan peel by a scientific process, and the preparation efficiency of the longan peel oligosaccharide is improved on the premise of keeping bioactivity. Macroporous absorbent resin is used for decoloring, which can effectively remove pigment interference. The prepared longan peel oligosaccharide has high yield, obvious anti-oxidative activity and probiotic bacteria proliferation activity, and is applicable to the functional food development field.

Owner:SOUTH CHINA BOTANICAL GARDEN CHINESE ACADEMY OF SCI

Extraction and purification method of 10-deacetylbaccatin III

The invention discloses an extraction and purification method of 10-deacetylbaccatin III, which comprises the following steps of treating taxus chinensis branches and leaves, extracting, filtering, concentrating, extracting, washing and concentrating to obtain a crude product A, carrying out freeze suction filtration on the crude product A to obtain a crude product B, and concentrating, freezing, filtering and washing the crude product B to obtain a crude product C, concentrating, freezing and filtering the crude product C to obtain a final extracted and purified 10-deacetylbaccatin III product. After taxus chinensis branches and leaves are extracted, a sodium bicarbonate aqueous solution is used for washing to remove acidic impurities and pigments in the material, so that the content of 10-deacetylbaccatin III in the extract concentrate is greater than or equal to 10%, the standard of acetonitrile washing can be achieved, a chromatographic separation step is omitted in the whole process, the production efficiency is improved, the production time is shortened, and after the crude product B is crystallized, the crude product B is washed with an acetone-n-hexane mixed solvent to remove pigment in the crude product B crystal. The content of the finally obtained 10-deacetylbaccatin III is as high as 99.23%, the purity reaches 99.37%, and the product yield reaches 75.99%.

Owner:CHONGQING ZHENYUAN HONGDOUSHAN DEV CO LTD

Method for dynamic countercurrent extraction of toosendanin

The invention discloses a method for dynamic countercurrent extraction of toosendanin. The method comprises the following steps: crushing branch skin and barks of melia azedarach; pre-treating the crushed branch skin and barks through microwaves; performing dynamic countercurrent extraction; adding a clarifying agent into an obtained extracting solution for impurity removal; decoloring the mixed solution with activated carbon; concentrating the mixed solution to obtain an extract; adsorbing the extract with macroporous adsorption resin, and concentrating obtained eluent through reduced pressure, so as to obtain a crude extract; after the crude extract is dissolved, adding petroleum ether for precipitation, washing precipitation with water, drying and re-dissolving the precipitation, so asto obtain the toosendanin. According to the method, the toosendanin is extracted by the steps of microwave pretreatment, dynamic countercurrent extraction, clarification with the clarifying agent, decoloration with the activated carbon, adsorption with the macroporous adsorption resin, precipitation with the petroleum ether and the like, so that the purity and the extraction efficiency of the toosendanin can be effectively improved, wherein the extraction efficiency is 1.3-1.6mg / g, and the purity is higher than 96%.

Owner:右江民族医学院

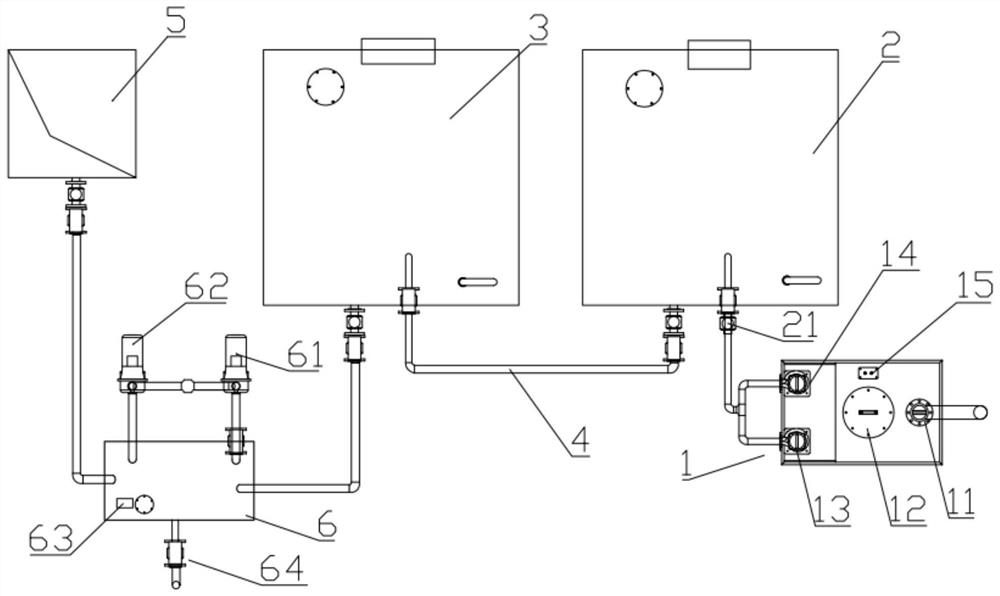

Hospital radioactive wastewater decay tank system and treatment method thereof

InactiveCN114291921AEasy to controlEasy to diluteMultistage water/sewage treatmentRadioactive decontaminationChemical treatmentTap water

The invention discloses a hospital radioactive wastewater decay tank system. The system comprises a water inlet system, a first decay tank, a second decay tank and a water outlet system which are sequentially connected through cast iron pipes, the water outlet system is respectively connected with the second decay tank and the clean water tank, a detector is further arranged on the water outlet system, and tap water in the clean water tank is used for diluting secondary decay liquid treated by the second decay tank; the detector is used for detecting the standard liquid discharged from the water outlet system; meanwhile, the invention further provides a treatment method for radioactive wastewater decay. Rapid coagulation and removal of radionuclides are achieved by adding a chemical treatment agent. The hospital radioactive wastewater conveyed into the decay tank is stored and filtered, after chemical treatment agents are added for treatment, the hospital radioactive wastewater sequentially enters the decay tank to become decay liquid, the decay liquid reaches a water outlet system, reaches the standard through detection and is discharged to a drainage channel from a water outlet control valve, the treatment time is shortened, and meanwhile the complexity of the decay tank system is reduced; and the space is saved.

Owner:JIANGSU SUPERSENSE TECH CO LTD

A high-strength crack-resistant exterior wall elastic putty powder additive masterbatch and its preparation method

ActiveCN111286226BImproved anti-crack propertiesImprove bindingArtificial filament washing/dryingHeating/cooling textile fabricsFiberCellulose

The invention relates to the technical field of building materials, and specifically discloses a high-strength crack-resistant external wall elastic putty powder additive masterbatch, which is composed of the following raw materials in parts by weight: 1.5-2.5 parts of palm silk, 25-40 parts of redispersible latex powder 3-5 parts of hydroxypropyl methylcellulose, 0.3-0.6 parts of starch ether, 1.5-2.5 parts of polypropylene short fiber, 0.8-1.2 parts of hydrophobic agent, and 0.3-0.6 parts of water-reducing agent. At the same time, the invention also discloses a preparation method of the high-strength crack-resistant outer wall elastic putty powder masterbatch. The putty powder masterbatch is applied to the putty powder, and when the outer wall is painted, the wall surface coating is obviously improved. Anti-cracking properties, the putty coating has a stronger bonding force with the base layer of the wall, and it is not easy to fall off.

Owner:湖南威邦新材料有限公司

Functional whitening moisturizer

InactiveCN105853251ANo harmWith health functionCosmetic preparationsToilet preparationsSkin CreamWater soluble

A functional whitening moisturizer is characterized in that a medical amphiphilic resin adsorbent powder is blended into a water-soluble moisturizer, a lotion or a fat-soluble moisturizer.

Owner:于杰

Mineral water and preparation method thereof

PendingCN112806510AIncrease concentrationPigment removalFood ingredient functionsPotable waterNatural mineral

The invention belongs to the technical field of drinking water, and discloses mineral water. The mineral water is prepared from the following components in percentage by mass of 12 to 30 percent of Tibet original ecological natural mineral water, 5 to 20 percent of natural weak base water overseas in Norway, 10 to 20 percent of alkaline natural water from Wangwushan Mountain in a world geological park, 8 to 12 percent of natural mineral water from Chengdu in Sichuan, 8-12 percent of natural mineral water for Shaanxi Ankang, 8-15 percent of natural low-sodium mineral water in Changbai Mountain, 8-12 percent of mineral water in Shaanxi Taibai Mountain and 8-20 percent of natural rock spring water in Guangxi. The mineral water provided by the invention has the characteristics of being soft and cool in mouth feel, slightly sweet in taste, ready to drink at any time and any place, and suitable for all people to drink.

Owner:郭小卫

A kind of maple leaf extract, preparation method and application thereof

ActiveCN108159195BImprove antioxidant capacityImprove cancer resistanceHydroxy compound active ingredientsAntipyreticBiotechnologyPharmacodynamic Study

Owner:GUANGXI INST OF BOTANY THE CHINESE ACAD OF SCI

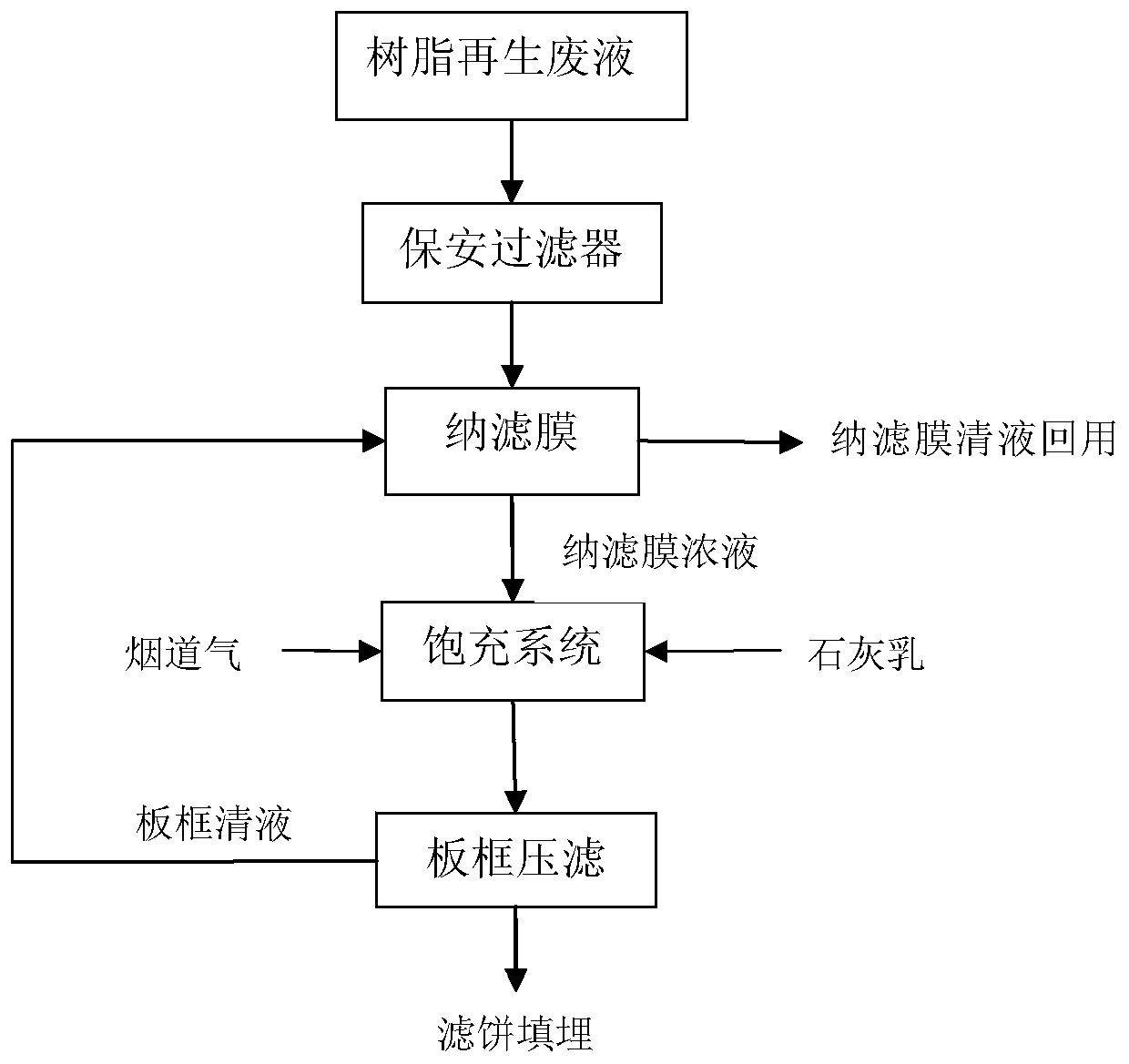

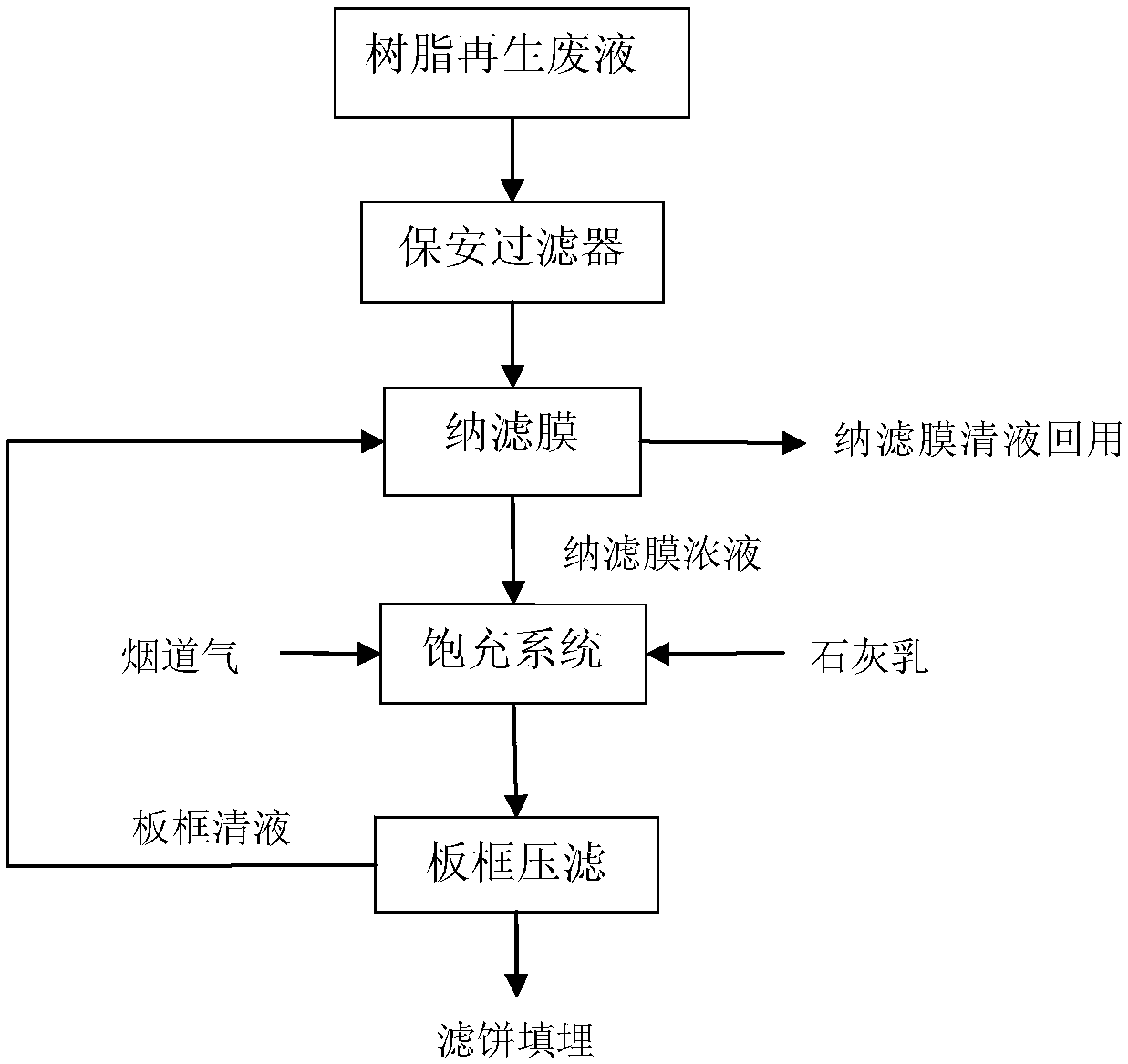

A treatment process for decolorized resin regeneration waste liquid

ActiveCN108503084BPigment removalHigh decolorization rateMultistage water/sewage treatmentLiquid wasteFiltration membrane

The invention discloses a treatment technology of decolorized resin regenerated waste liquid. The treatment technology comprises the following steps: after filtering the decolorized resin regeneratedwaste liquid through a filter, filtering through a nano-filtration membrane; recycling permeated liquid; adding lime milk into obtain intercepted liquid; introducing flue gas and fully filling; aftercarrying out plate and frame filtering on a fully-filled mixing system, recycling permeated liquid and repeating the operation on intercepted liquid. Compared with the prior art, pigments in resin regenerated waste liquid can be effectively removed; the recycling rate of resin regenerated liquid is high and the production cost is low; the treatment technology is simple to operate and has the advantages of high efficiency, energy saving and emission reduction.

Owner:凌国庆

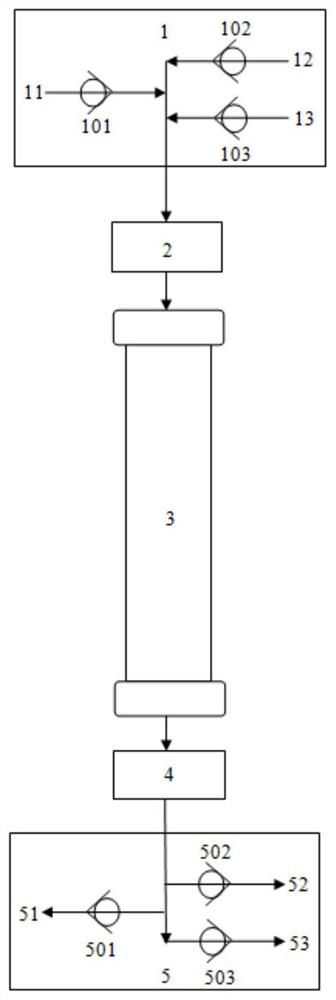

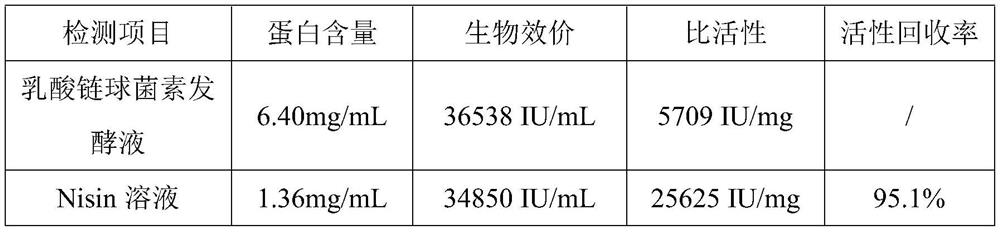

Renewable chromatographic system and method for removing nisin pigment and peculiar smell

PendingCN112957771AEfficient removalReduce processSolid sorbent liquid separationBiotechnologyEngineering

The invention relates to the technical field of separation of natural food preservatives, in particular to a reproducible chromatographic system and method for removing nisin pigment and peculiar smell. The chromatographic system comprises a liquid inlet system, a high-pressure liquid conveying pump, a mixer, a filtering protection column, a chromatographic column, a detector and a liquid outlet system. Separation is realized on the basis of different acting forces between different components and hydrophobic groups in lactic streptococci fermentation liquor, the lactic streptococci fermentation liquor with low ionic strength is adjusted to be acidic, Nisin with weak adsorption acting force rapidly flows out of a chromatographic column by adopting high-flow-rate power, pigment and odor substances are adsorbed on the surface of a medium, and dissociation is carried out through elution of regeneration liquid. The method provided by the invention overcomes the defects of the traditional process, improves the taste and quality of the food-grade nisin, can realize rapid and efficient separation, has no organic solvent residue, is green and environment-friendly, and has long service life of the chromatographic column and low production cost.

Owner:宁波博睿瀚达生物科技有限公司

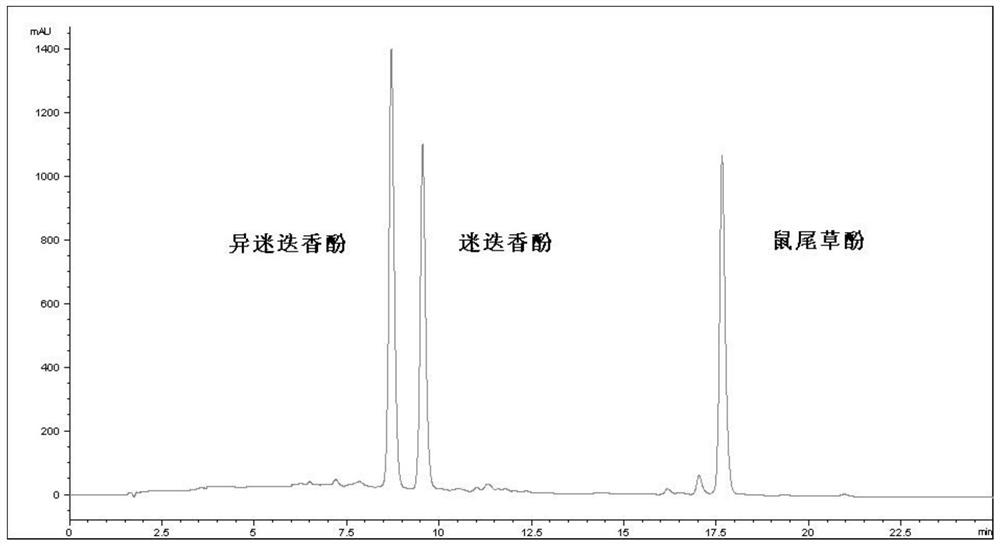

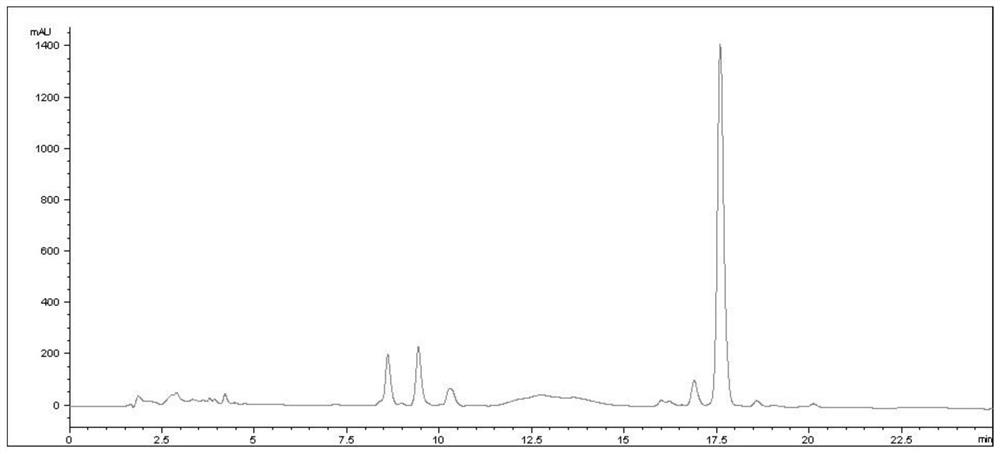

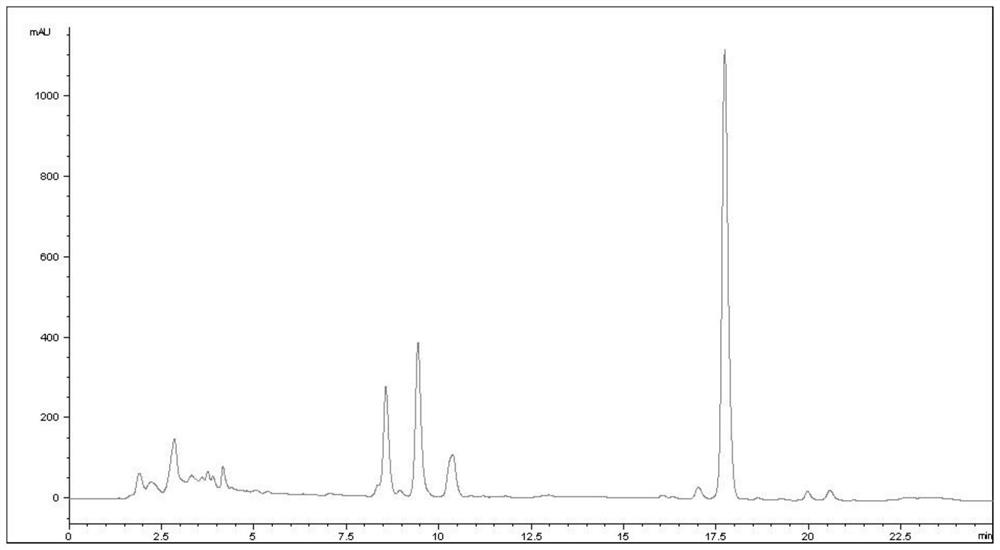

A method for simultaneously extracting and separating chlorogenic acid and rutin from tobacco leaves

ActiveCN106496034BReduce extraction costsReduce formationSugar derivativesOrganic compound preparationChlorogenic acidGradient elution

The invention discloses a method for simultaneously separating chlorogenic acid and rutin from tobacco leaves. The method includes: weighting 200g of tobacco leave powder sieved through a 60 mesh sieve, dissolving the tobacco leave powder in water according to a material-liquid ratio of 1:20, setting temperature as 50 DEG C, and stirring and extracting the chlorogenic acid and the rutin for 120min. Petroleum ether is used for extraction and removal of oil-soluble impurities for collected filtrate, and then a chlorogenic acid and rutin extracting solution is obtained. Column chromatography isolation of the chlorogenic acid and the rutin is performed on the upper column of the extracting solution. Water of 5 times of the extracting solution in volume is first used for elution until no sugar can be detected in eluate. After the water is used for the elution, different concentration of ethanol replaces the used eluate for gradient elution. Two types of ethanol eluate 10-15% and 30-40% in concentration are respectively collected so as to obtain a chlorogenic acid solution and a rutin solution. The method for simultaneously separating the chlorogenic acid and the rutin from the tobacco leaves saves raw material and reagents, reduces development cost, and achieves good separating effects.

Owner:CHINA TOBACCO CENTRAL SOUTH AGRICULTURAL EXPERIMENTAL STATION +1

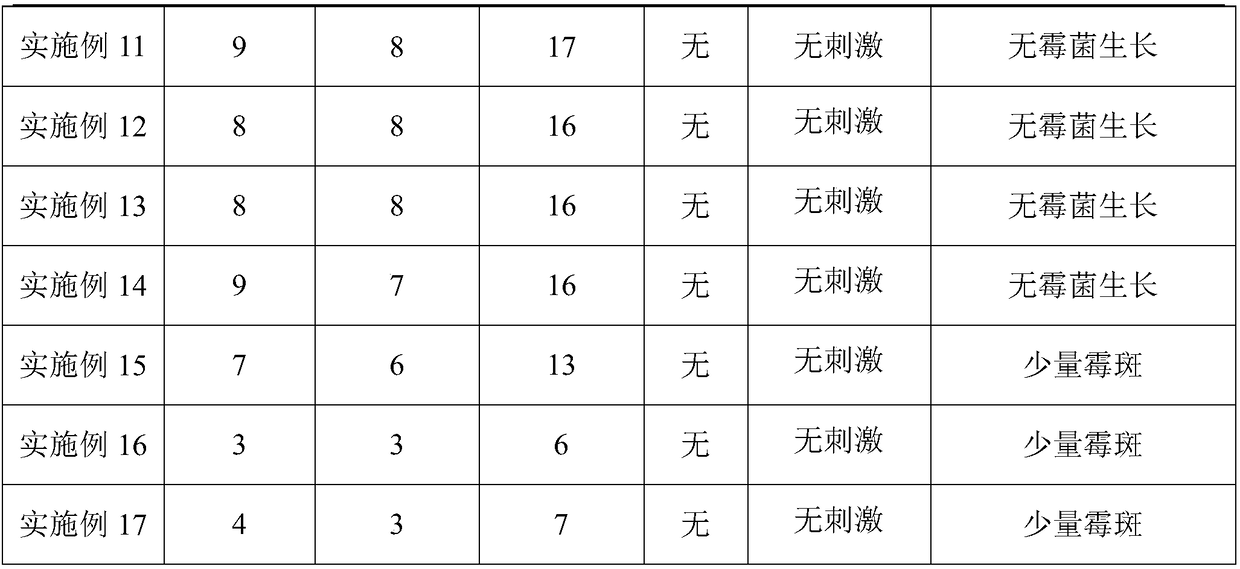

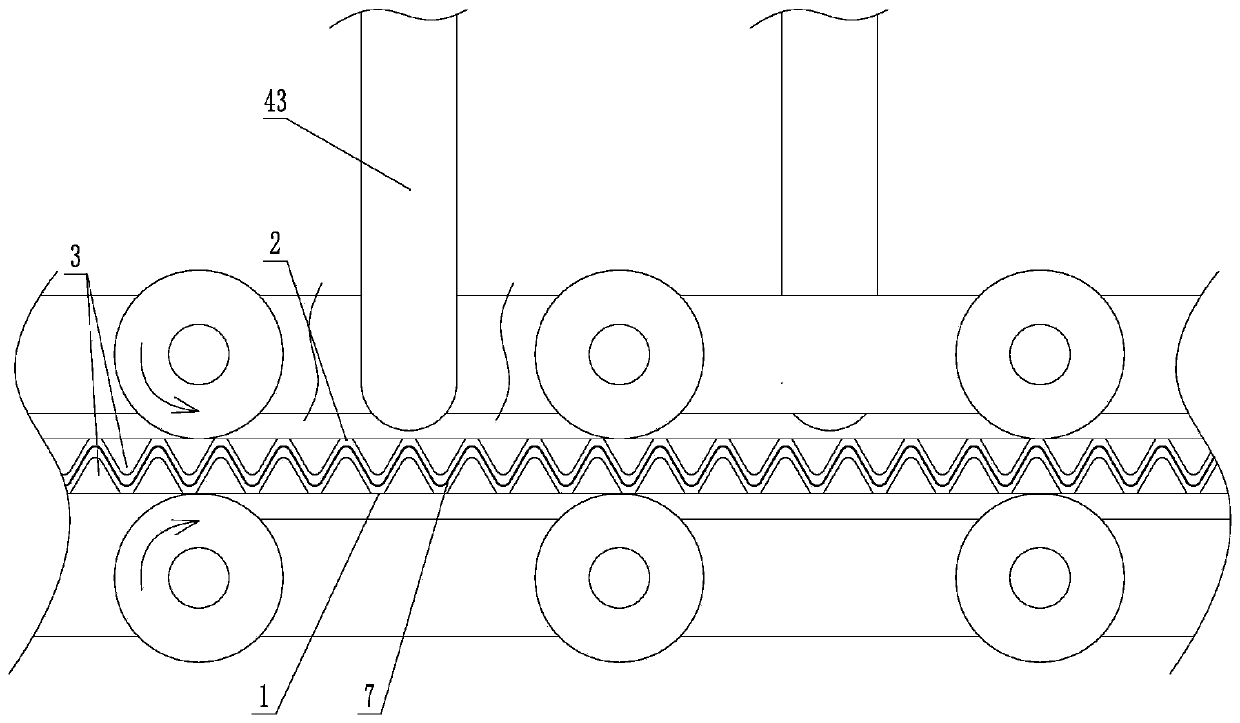

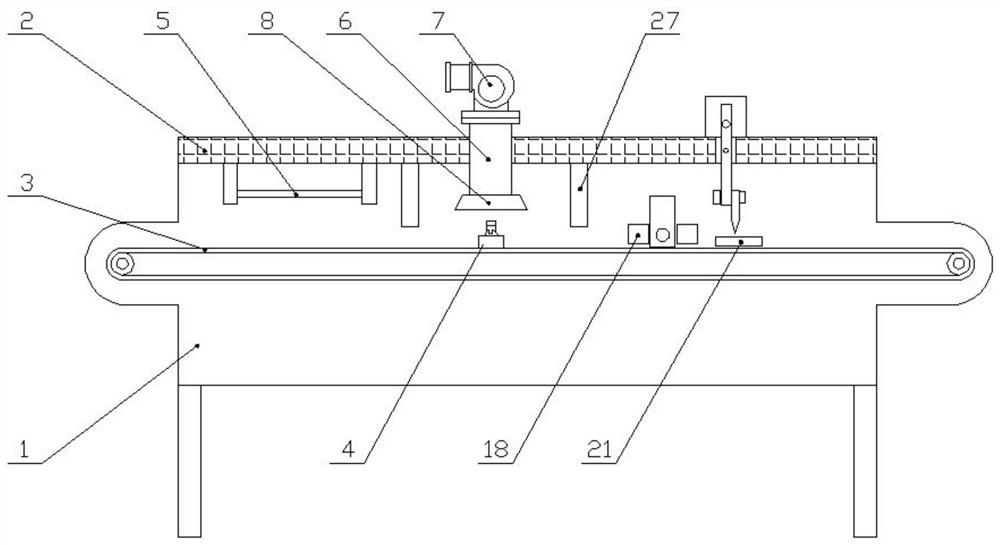

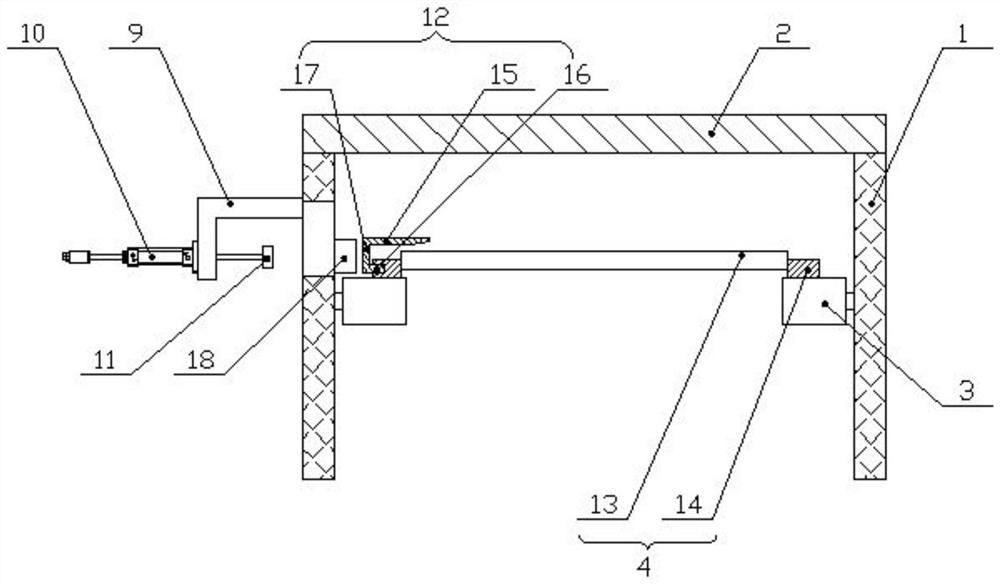

A kind of preparation method and preparation equipment of external wall thermal insulation putty powder

ActiveCN111471343BImprove insulation effectImprove sound absorptionWood treatment detailsReed/straw treatmentThermal insulationEngineering

The invention discloses a preparation method of exterior wall thermal insulation putty powder, which is prepared by stirring and mixing preparation raw materials consisting of base material, cement, vitrified microbeads and masterbatch. The present invention also provides a preparation equipment for external wall thermal insulation putty powder, which includes a frame, and the frame includes side plates arranged at intervals, a top plate is arranged on the top of the side plate, and the inside of the side plate is provided with a A side conveyor belt, a winding frame is placed on the side conveyor belt, and a baking area, a shaping area and a separation area are sequentially arranged on the frame along the conveying direction of the side conveyor belt from front to back; the baking area is provided with an electric heating A support is provided on the outer side of the side plate at the separation area, and a pushing device is provided on the support, and a magnetic device matching the clamping plate on the winding frame is provided on the piston rod of the pushing device. The purpose of the present invention is to improve the anti-crack property of the strong surface and at the same time improve the preparation efficiency of the putty.

Owner:湖南威邦新材料有限公司

A kind of high-strength crack-resistant external wall elastic putty powder and its preparation method

ActiveCN111334113BImproved anti-crack propertiesImprove bindingDrying gas arrangementsFilling pastesFiberCellulose

Owner:湖南威邦新材料有限公司

Treatment technology of decolorized resin regenerated waste liquid

ActiveCN108503084APigment removalHigh decolorization rateMultistage water/sewage treatmentLiquid wasteFiltration membrane

The invention discloses a treatment technology of decolorized resin regenerated waste liquid. The treatment technology comprises the following steps: after filtering the decolorized resin regeneratedwaste liquid through a filter, filtering through a nano-filtration membrane; recycling permeated liquid; adding lime milk into obtain intercepted liquid; introducing flue gas and fully filling; aftercarrying out plate and frame filtering on a fully-filled mixing system, recycling permeated liquid and repeating the operation on intercepted liquid. Compared with the prior art, pigments in resin regenerated waste liquid can be effectively removed; the recycling rate of resin regenerated liquid is high and the production cost is low; the treatment technology is simple to operate and has the advantages of high efficiency, energy saving and emission reduction.

Owner:凌国庆

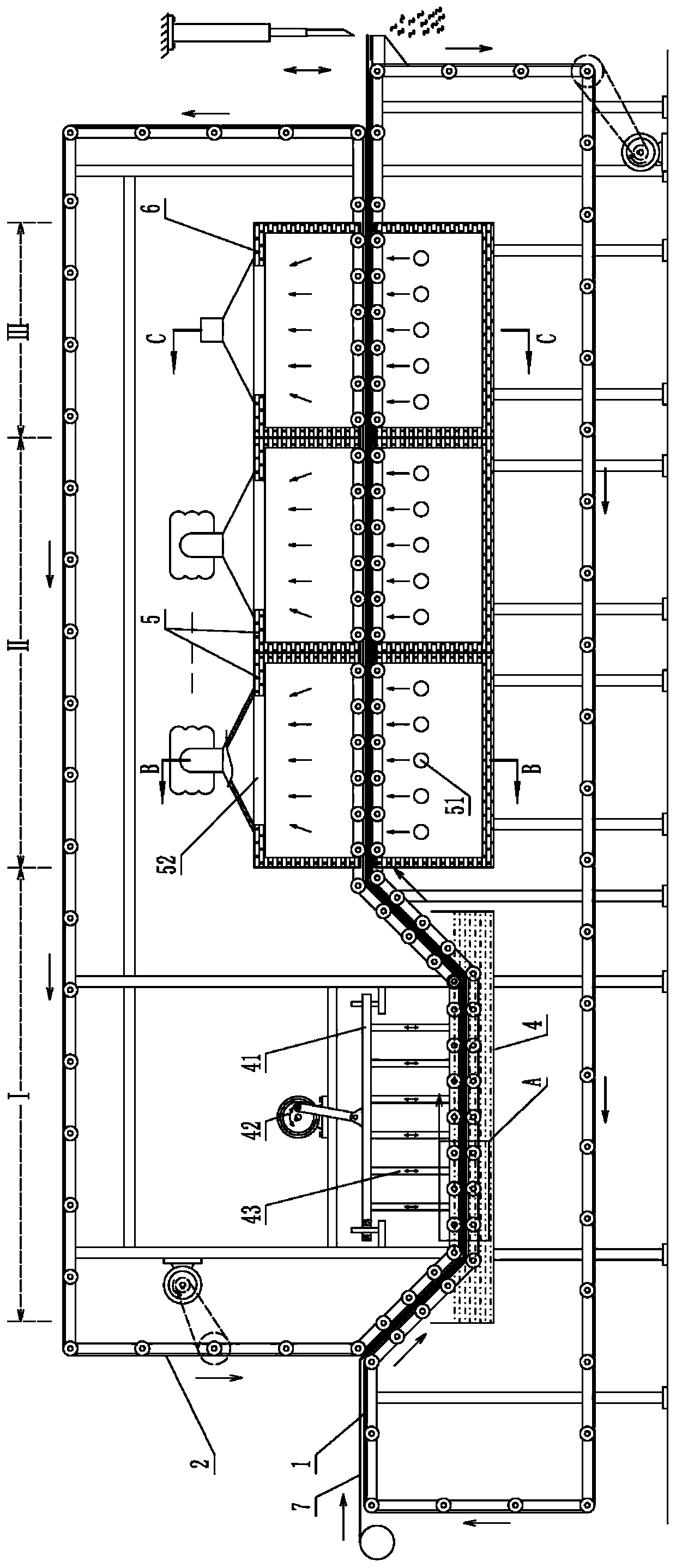

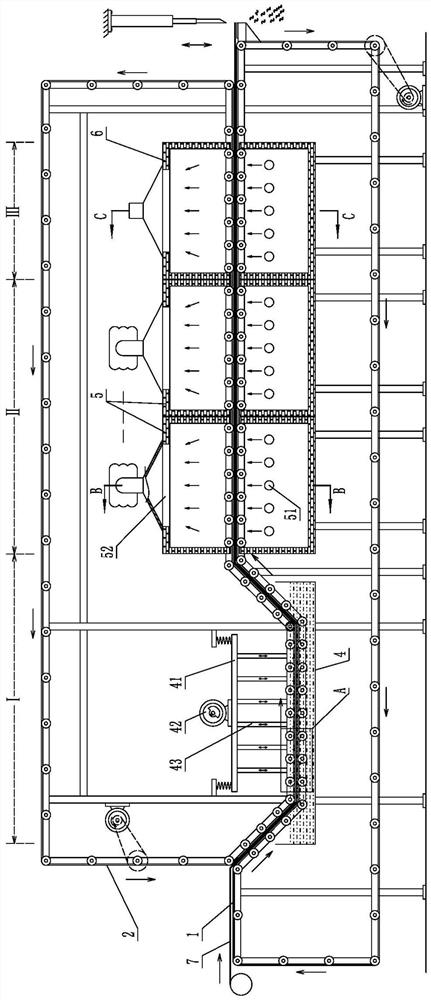

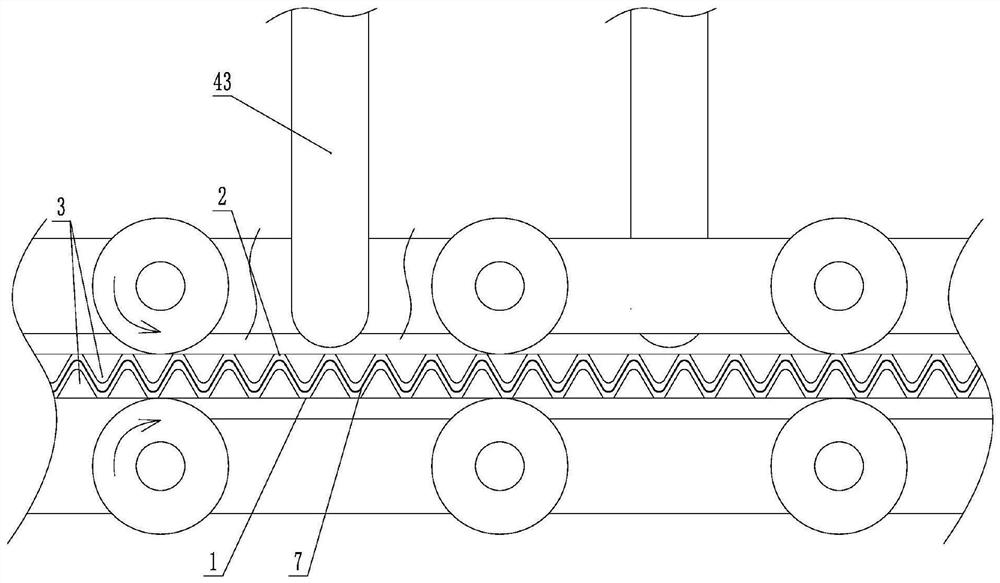

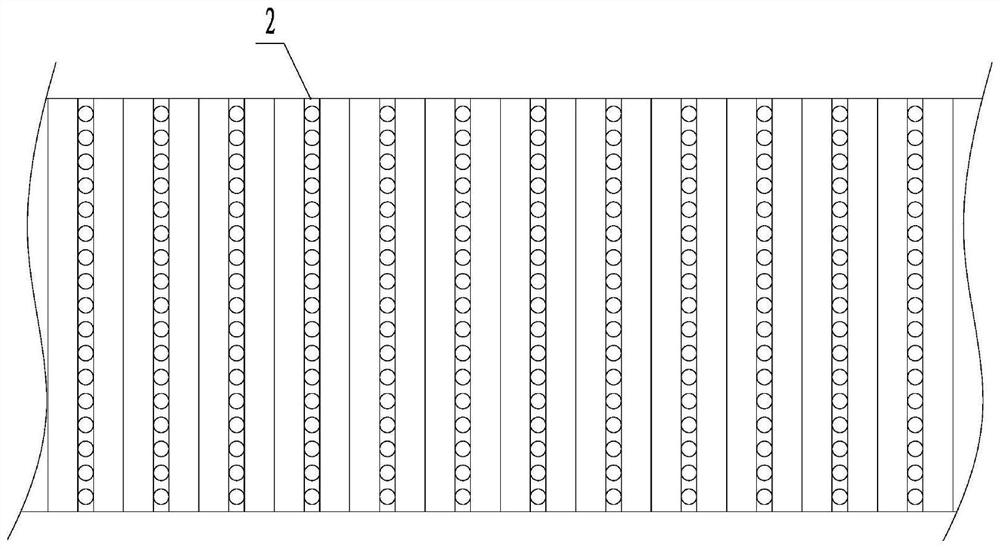

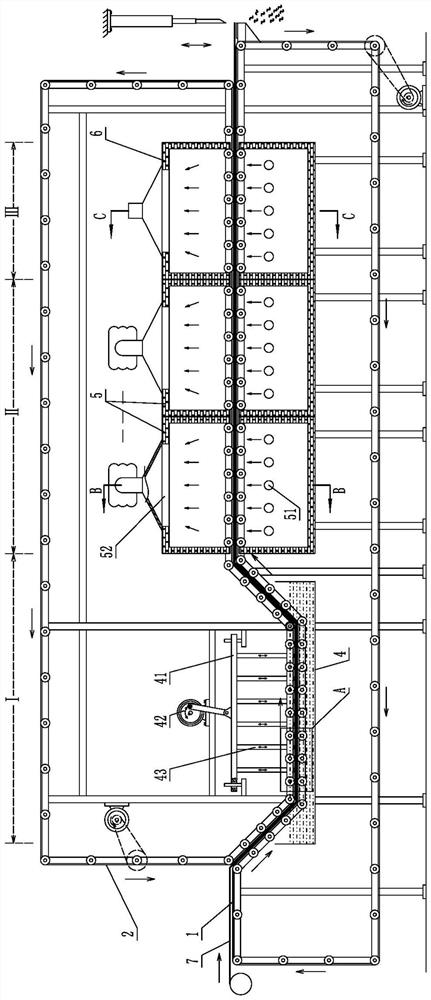

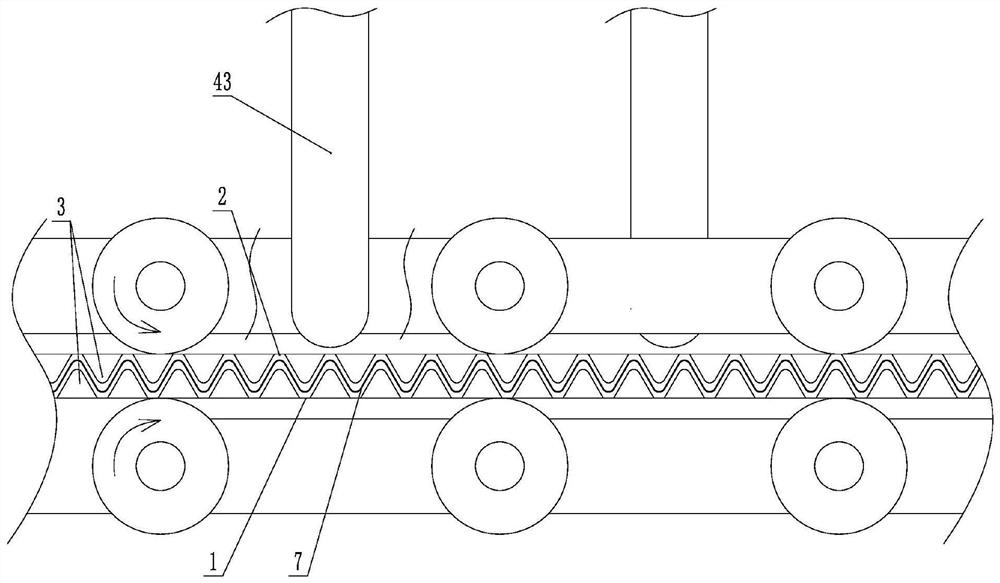

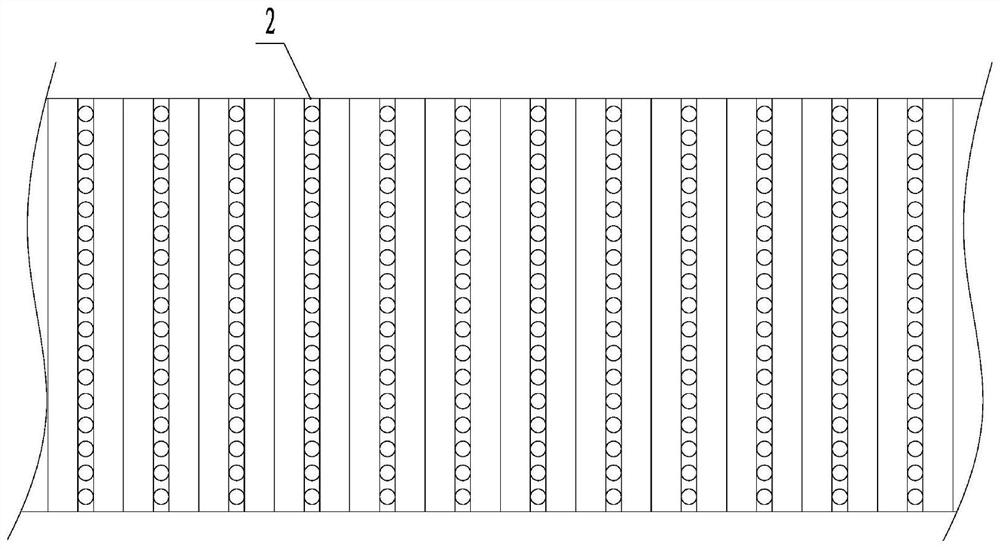

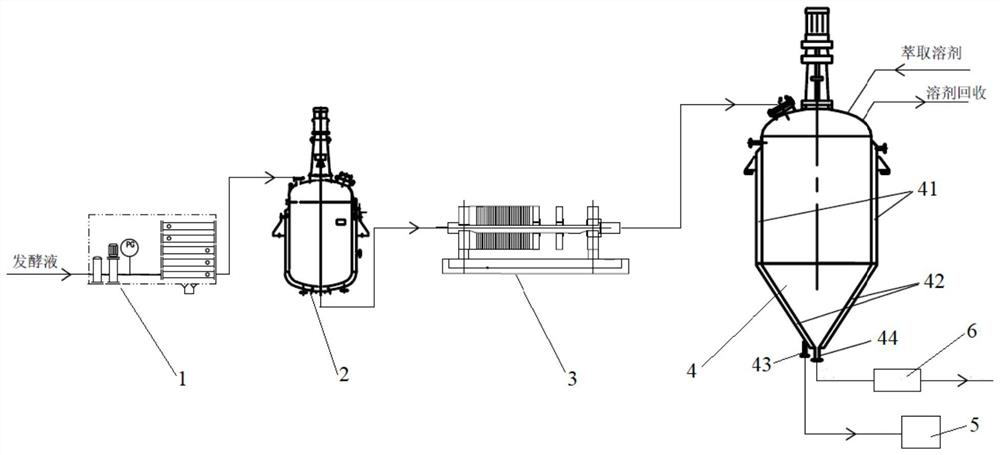

Beta-carotene fermentation liquor filtration and extraction process and equipment

PendingCN113845456AReduce moisture contentHigh extraction yieldOrganic chemistryChemical industryCaroteneFermentation broth

The invention belongs to the technical field of fermentation liquor filtration and extraction, and particularly relates to a beta-carotene fermentation liquor filtration and extraction process and equipment, and the process comprises the following steps: filtering the fermentation liquor with a membrane to obtain a concentrated solution, carrying out top washing into an acidification tank, adding acid, then adding a sodium hydroxide solution to adjust the pH value to obtain an acidified neutralized solution, filtering the acidified neutralized solution with a high-pressure plate frame, and carrying out top washing with water, and discharging to obtain mycelia; and putting into a multifunctional extraction tank, adding an extraction solvent, pumping the extraction liquid into an extraction liquid tank, repeating the extraction operation, finally adding water into the extracted mycelia, recovering the extraction solvent, and conveying and collecting the mycelia. The equipment comprises a membrane filter, an acidification tank, a high-pressure plate frame filter and a multifunctional extraction tank which are sequentially connected, and the multifunctional extraction tank is connected with the extraction liquid tank and a spiral slag extractor. The process and equipment are effectively combined, the water content and impurities of mycelia are reduced after the fermentation liquor is filtered and extracted, efficient solid-liquid extraction is achieved, and the extraction yield and the solvent recovery rate are increased.

Owner:BINZHOU JINLANG BIOTECH

Method for extracting pectin from fresh orange peel

PendingCN114835832AAvoid wastingReduced drying processFood ingredient as gelling agentFood ingredient as emulsifierProcess engineeringPectin

The invention discloses a method for extracting pectin from fresh orange peel. The method comprises the following steps: crushing, extruding and cleaning, extracting pectin, separating, decoloring, concentrating, precipitating and drying. According to the method disclosed by the invention, the fresh citrus peels produced by a citrus tin factory can be fully utilized, resource waste is avoided, the pectin product with high additional value is extracted by adopting the method, and the final product meets the national standard GB25533-2010 and has a very good market prospect.

Owner:浙江丰岛食品股份有限公司

A method for purifying pneumocidine b0

The invention discloses a method used for high-efficient purification of pneumocandins B0. The method comprises following steps: (1) pH value of a fermentation broth containing pneumocandins B0 is adjusted to 2.0 to 4.0, the fermentation broth is filtered, and a pneumocandins B0 extract liquid is obtained via extraction; (2) the extract liquid is condensed, diatomite is added for crystal packaging, water is added, and an obtained mixture is stirred and is subjected to centrifugation; (3) a solid material obtained via centrifugation is dissolved in ethanol, active carbon is added for decolouring, and an obtained mixed material is filtered; (4) an obtained filtrate is condensed, chloroform is added, an obtained solution is delivered through a silica gel column, and a pneumocandins B0 eluant is collected; and (5) the pneumocandins B0 eluant is condensed to be dry, and crystallization is carried out in a multiphase solvent system so as to obtain pneumocandins B0. The method is capable of avoiding application of resin columns and reducing amount of solvents used for elution greatly; active carbon can be used for removing pigments effectively; silica gel column chromatography is capable of removing related substances C0; and extraction purity can be as high as 99%. The method is simple and convenient; cost is reduced greatly; and industrialized production can be easily realized.

Owner:JIANGSU SENRAN CHEM

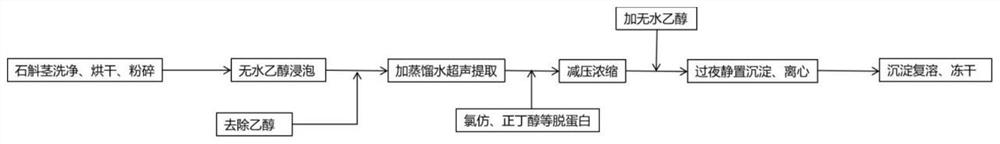

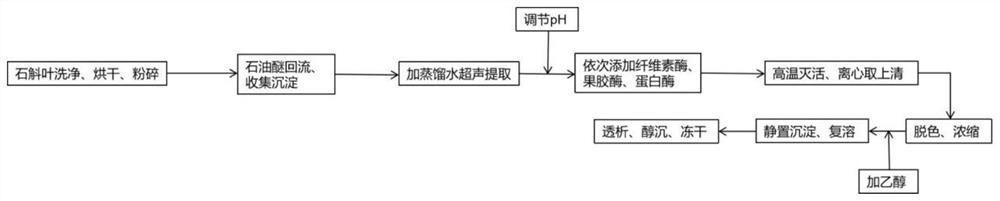

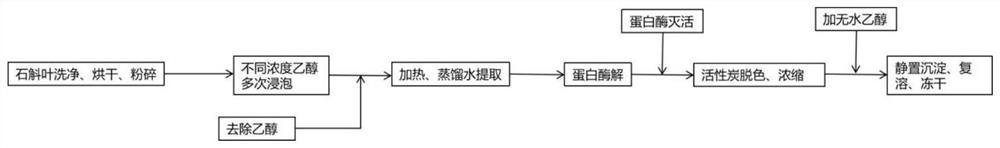

A kind of Dendrobium officinale leaf polysaccharide and its preparation and application

ActiveCN113354748BEnsure complete removalRetain activityOrganic active ingredientsImmunological disordersBiotechnologyActivated carbon

Owner:ZHEJIANG UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com