Method for producing oligopeptide by using silkworm cocoon degumming solution and waste silkworm cocoons as raw materials

An oligopeptide and silkworm cocoon technology, applied in the field of biotechnology, can solve the problems of no molecular weight determination of enzymatic hydrolysis products, no systematic screening of enzymes for enzymatic hydrolysis, and high production costs, so as to improve product color, facilitate digestion and absorption, and reduce equipment requirements. and environmental effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

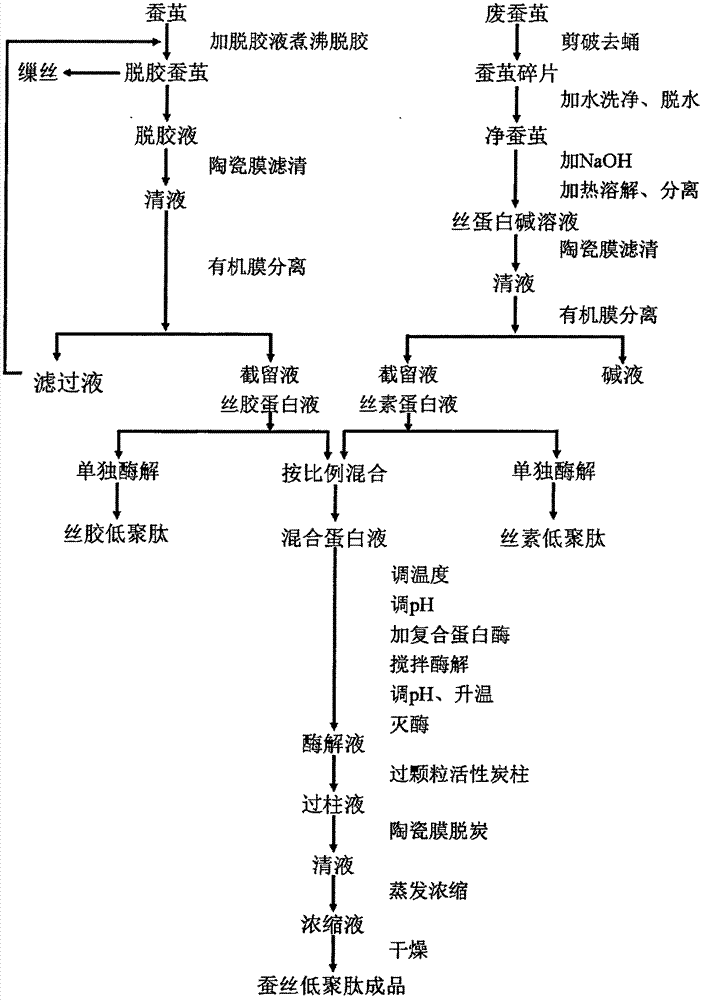

Image

Examples

preparation example Construction

[0030] Step 2. Preparation of silk fibroin protein liquid: cut the waste silkworm cocoon and remove the cocoon fragments, filter and dehydrate the excrement of the pupae in the cocoon in an industrial washing machine to obtain a clean silkworm cocoon, put the clean silkworm cocoon into the boiling concentration of 0.8% Stir and dissolve in -1.5% NaOH solution for 1-3 hours, cool down the solution properly, and centrifuge. If there is any precipitate, it can be heated and dissolved with the same concentration of lye, and the solution is combined into a silk protein solution; after the silk protein solution is filtered with a ceramic membrane , through an alkaline organic membrane with a molecular weight cut-off of 0.1ku-5ku, the permeate is lye, which can be reused for dissolving the next batch of cocoon shells, and the retentate is silk fibroin liquid, which can be enzymatically hydrolyzed alone. Or the silk fibroin solution can also be enzymatically hydrolyzed together with th...

Embodiment 1

[0034] Example 1: The waste silkworm cocoon and degumming solution used in the research of this example were provided by a silk reeling factory in Anhui, Anhui Province. It was verified that the protein content of the waste silkworm cocoon shell was 98.17%, and the protein content of the degumming solution was 2.69%.

[0035] The method for producing oligopeptides in this embodiment is: the degumming solution is filtered through a ceramic membrane to obtain a clear solution, and the clear solution is filtered through a 10ku organic membrane, and the permeate is a degumming solution without gelatin, which can be repeatedly used for degumming. The intercepted liquid is sericin, add 3-4 times of pure water to dilute, wash the degummed liquid in the sericin as much as possible, make the pH of the sericin liquid around 8.0, take the sericin liquid, adjust it with pure water The substrate concentration is about 5%; warm the feed solution to 47°C±1°C, use NaOH solution to season the p...

Embodiment 2

[0036] Example 2: The waste silkworm cocoon and degumming solution used in the research of this example were provided by a silk reeling factory in Anhui, Anhui Province. It was verified that the protein content of the waste silkworm cocoon shell was 98.17%, and the protein content of the degumming solution was 2.69%.

[0037] The method for producing oligopeptides in this example is: add the washed silkworm cocoon fragments into a boiling 1.1% NaOH solution, stir and dissolve for 2 hours, centrifuge the silkworm cocoon solution to obtain a liquid phase, and add an appropriate amount of 1.1% NaOH if there is a small amount of precipitation The solution is heated to dissolve, and after centrifugation, it is merged into the liquid phase of the first centrifugation, and the liquid phase passes through the ceramic membrane to obtain the filtrate. The clear liquid is filtered with an alkaline organic membrane with a molecular weight cut-off of 0.5ku, and the permeate is lye, which ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com