A high-strength crack-resistant exterior wall elastic putty powder additive masterbatch and its preparation method

A technology of putty powder and exterior walls, which can be used in filling slurry, heating/cooling fabrics, textiles and papermaking, etc. It can solve the problems of non-fireproof, water-resistant, cost-effective, poor weather resistance, and environmental protection, and improve the state of micro-elastic deformation , Improve the anti-cracking properties, the effect of good bonding performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

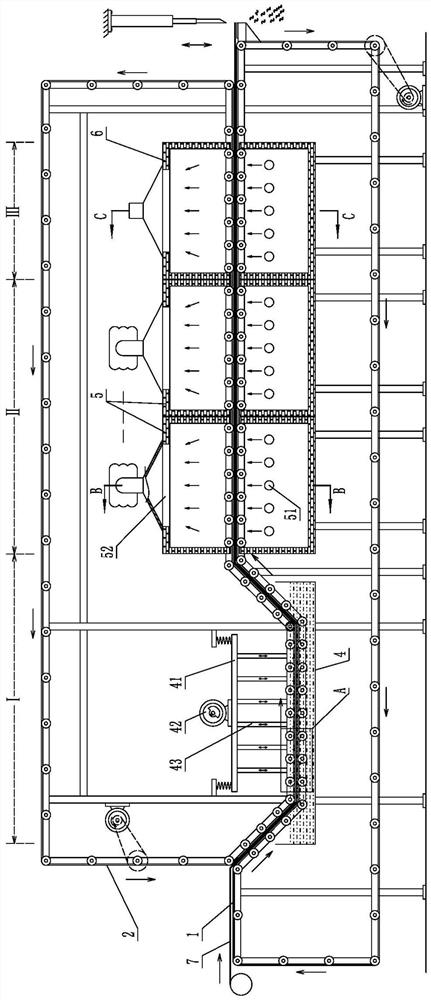

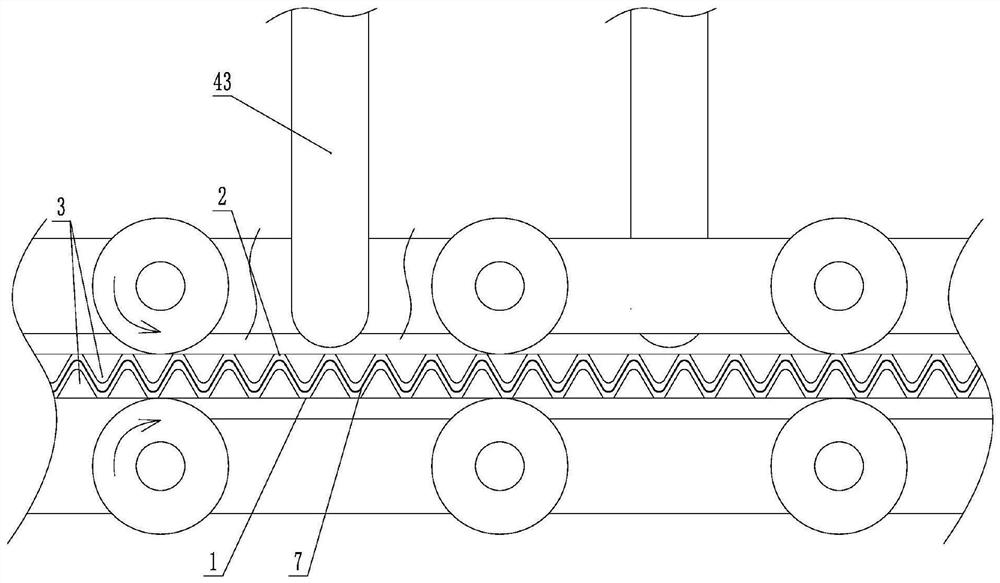

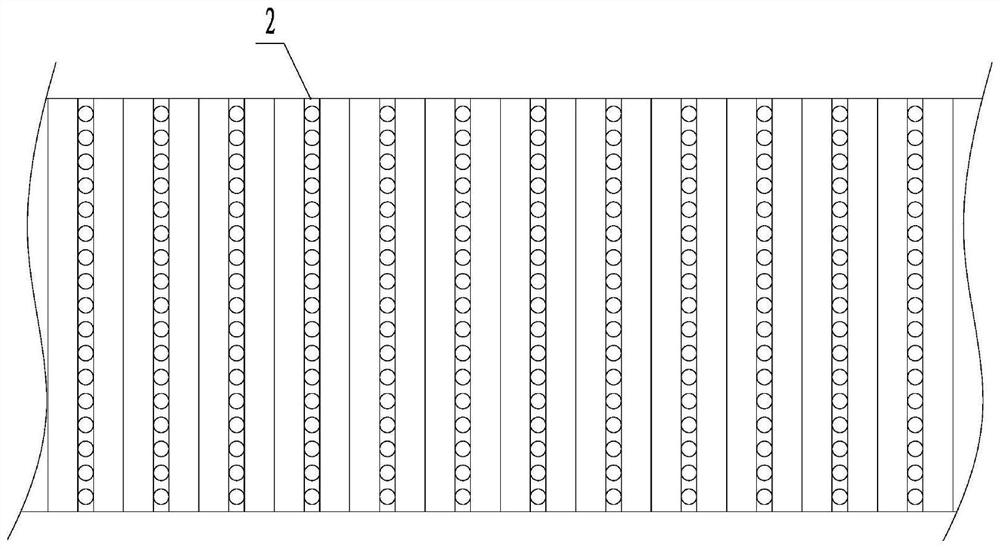

Image

Examples

Embodiment 1

[0054] A masterbatch of high-strength crack-resistant elastic putty powder for exterior walls, consisting of the following raw materials in parts by weight: 2 parts of palm fiber, 30 parts of redispersible latex powder, 4 parts of hydroxypropyl methylcellulose, hydroxypropyl 0.5 parts of starch ether, 2 parts of polypropylene short fiber, 1 part of silicone hydrophobic agent, and 0.5 part of melamine superplasticizer.

[0055] The preparation method of the above-mentioned high-strength anti-cracking type elastic putty powder for external walls added to the masterbatch comprises the following steps:

[0056] S1: Palm fiber deoiling treatment

[0057] It is divided into the following two steps: a. Put the dry palm fiber into the reaction tank containing pentane for soaking, adjust the pH to 3.5 by 0.12mol / L sulfuric acid, and the reaction temperature is 80°C for 18 minutes. At the same time, the reaction tank continuously Pass in oxygen and stir at a constant speed, the oxygen ...

Embodiment 2

[0065] A masterbatch of high-strength crack-resistant elastic putty powder for external walls, consisting of the following raw materials in parts by weight: 1.5 parts of palm fiber, 25 parts of redispersible latex powder, 3 parts of hydroxypropyl methylcellulose, hydroxypropyl 0.3 parts of starch ether, 1.5 parts of polypropylene short fiber, 0.8 parts of silicone hydrophobic agent, and 0.3 parts of melamine superplasticizer.

[0066] The preparation method of the above-mentioned high-strength anti-cracking type elastic putty powder for external walls added to the masterbatch comprises the following steps:

[0067] S1: Palm fiber deoiling treatment

[0068] It is divided into the following two steps: a. Put the dry palm fiber into the reaction tank containing pentane for soaking, adjust the pH to 3.5 by 0.12mol / L sulfuric acid, and the reaction temperature is 80°C for 18 minutes. At the same time, the reaction tank continuously Pass in oxygen and stir at a constant speed, the...

Embodiment 3

[0076] A masterbatch of high-strength crack-resistant elastic putty powder for external walls, consisting of the following raw materials in parts by weight: 2.5 parts of palm fiber, 40 parts of redispersible latex powder, 5 parts of hydroxypropyl methylcellulose, hydroxypropyl 0.6 parts of starch ether, 2.5 parts of polypropylene short fiber, 1.2 parts of silicone hydrophobic agent, and 0.6 parts of melamine superplasticizer.

[0077] The preparation method of the above-mentioned high-strength anti-cracking type elastic putty powder for external walls added to the masterbatch comprises the following steps:

[0078] S1: Palm fiber deoiling treatment

[0079] It is divided into the following two steps: a. Put the dry palm fiber into the reaction tank containing pentane for soaking, adjust the pH to 3.5 by 0.12mol / L sulfuric acid, and the reaction temperature is 80°C for 18 minutes. At the same time, the reaction tank continuously Pass in oxygen and stir at a constant speed, the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com