A kind of preparation method and preparation equipment of external wall thermal insulation putty powder

An external wall insulation and putty powder technology, applied in the field of putty powder, can solve the problems of unsatisfactory anti-cracking performance and unsatisfactory effect, achieve better bonding performance, improve the state of micro elastic deformation, and improve anti-cracking properties Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

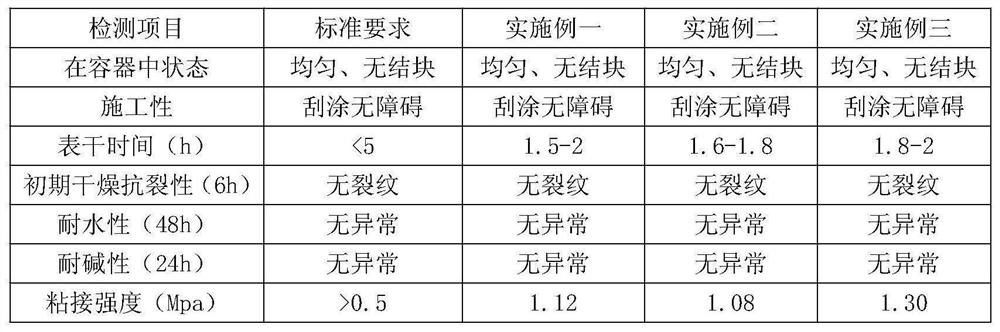

[0034] Embodiment 1: A method for preparing external wall thermal insulation putty powder. The raw materials are composed of base material, cement, vitrified beads, and masterbatch; the above components are in parts by weight: 300 parts of base material, vitrified 150 parts of microbeads, 20 parts of masterbatch, and 350 parts of cement; said masterbatch is composed of the following raw materials in parts by weight: 10 parts of redispersible latex powder, 2 parts of hydroxypropyl methylcellulose, and 0.2 part of starch ether , 0.5 parts of hydrophobic agent, 0.2 parts of water reducing agent, 1.5 parts of polypropylene short fiber, and 1.5 parts of palm fiber; the preparation method comprises the following steps: stirring the base material and vitrified microbeads evenly, then adding the masterbatch and continuing to stir evenly, Then add cement and stir to make the prepared raw materials evenly mixed; finally, sieve the evenly mixed raw materials and pack them.

[0035] Prefe...

Embodiment 2

[0043] Embodiment 2: The preparation method of the putty and the preparation method of the masterbatch are the same as in Example 1, but the components of the putty raw materials are respectively in parts by weight: 550 parts of base material, 230 parts of vitrified microbeads, and 50 parts of masterbatch , 550 parts of cement; the masterbatch is composed of the following raw materials in parts by weight: 25 parts of redispersible latex powder, 7 parts of hydroxypropyl methylcellulose, 0.7 part of starch ether, 1.2 parts of hydrophobic agent, and 0.7 part of water reducing agent , 2.3 parts of polypropylene staple fiber, 2.5 parts of palm fiber.

[0044] Preferably, the palm fiber is arc-shaped.

Embodiment 3

[0045] Embodiment 3: The preparation method of the putty and the preparation method of the masterbatch are the same as in Example 1, but the components of the putty raw materials are respectively in parts by weight: 400 parts of base material, 200 parts of vitrified microbeads, and 30 parts of masterbatch , 400 parts of cement; the masterbatch is made up of the following raw materials in parts by weight: each component of the masterbatch is in parts by weight: 20 parts of redispersible latex powder, 4 parts of hydroxypropyl methylcellulose, 0.5 parts of starch ether, 1 part of hydrophobic agent, 0.5 parts of water reducing agent, 2 parts of polypropylene short fiber, 2 parts of palm fiber.

[0046] Preferably, the palm fiber is arc-shaped.

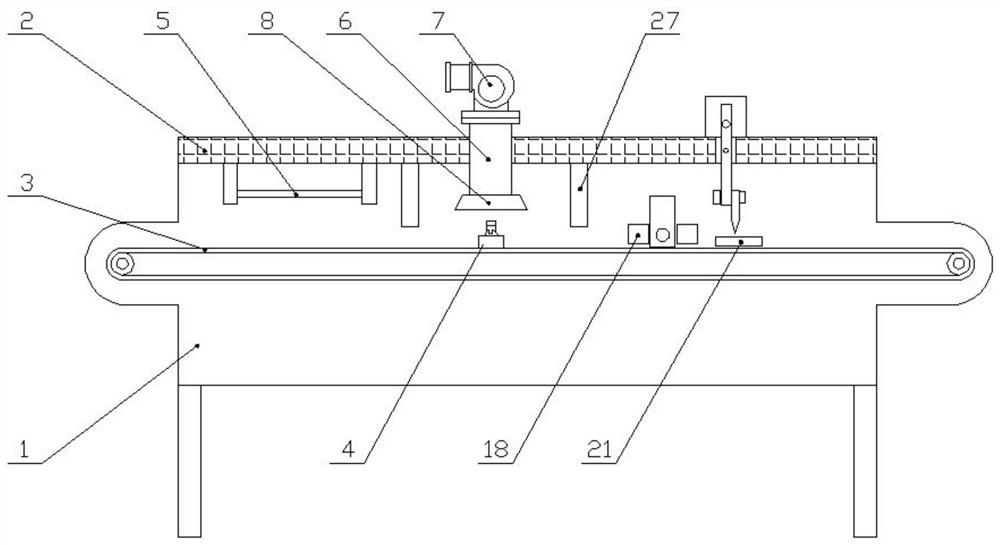

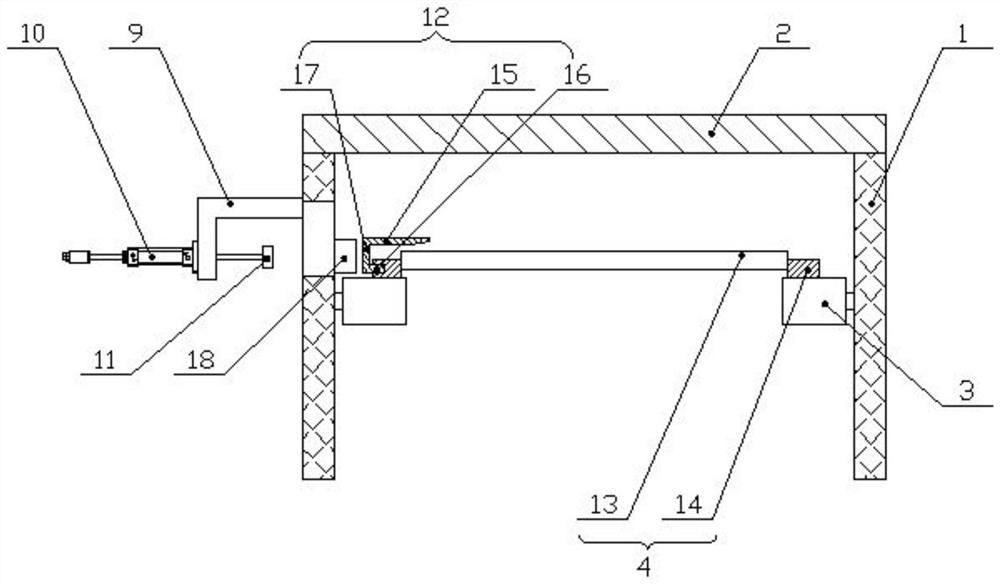

[0047] In order to shape the palm fiber into an arc, a method such as Figure 2-Figure 5 A kind of external wall thermal insulation putty powder preparation equipment is shown, it comprises frame, and described frame comprises the side pl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com