High-strength anti-cracking type external wall elastic putty powder and preparation method thereof

An elastic putty and putty powder technology, which is applied in the field of building materials, can solve the problems of non-fire and water resistance, low cost performance, poor weather resistance and environmental protection, so as to improve the state of micro elastic deformation, improve the anti-cracking characteristics and good bonding performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

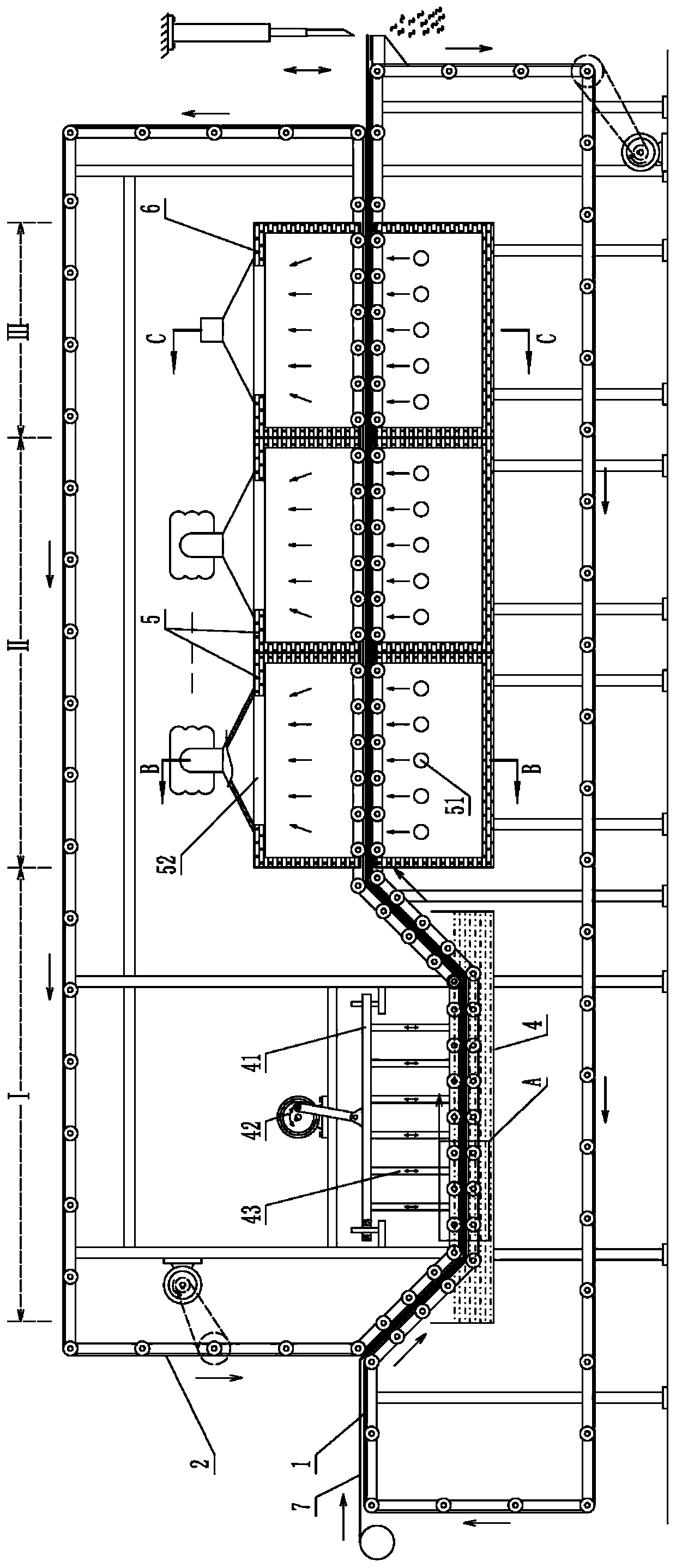

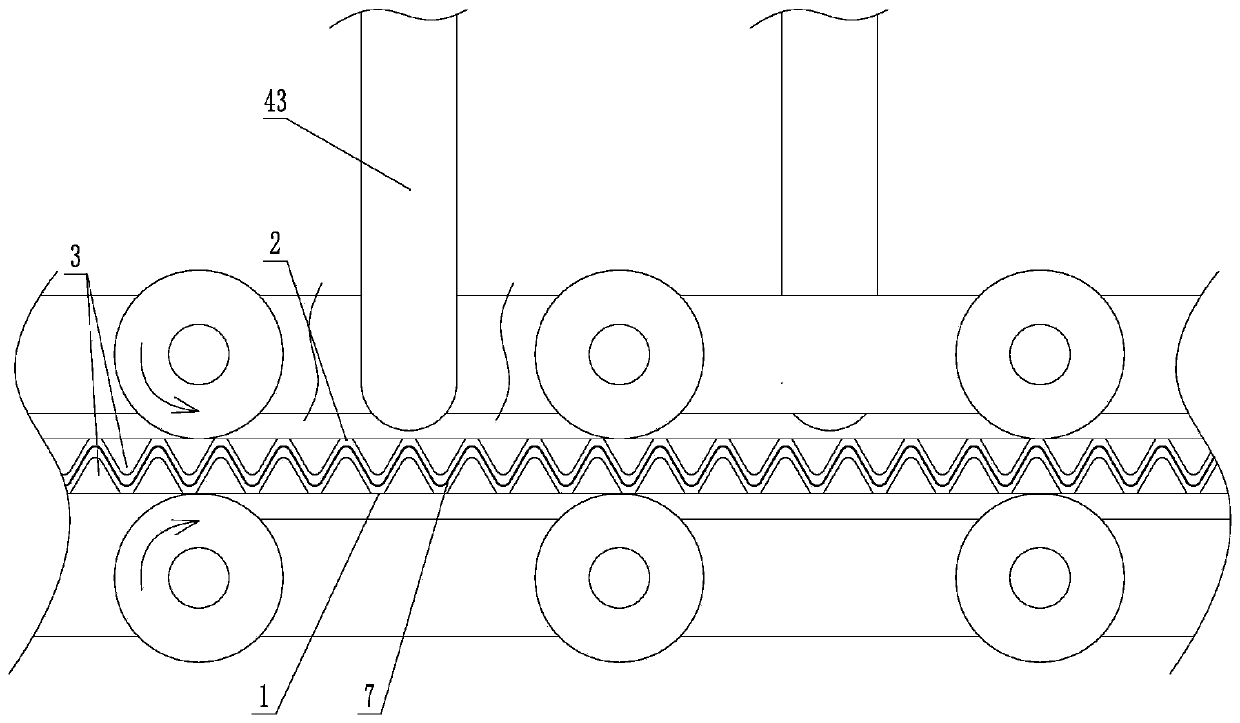

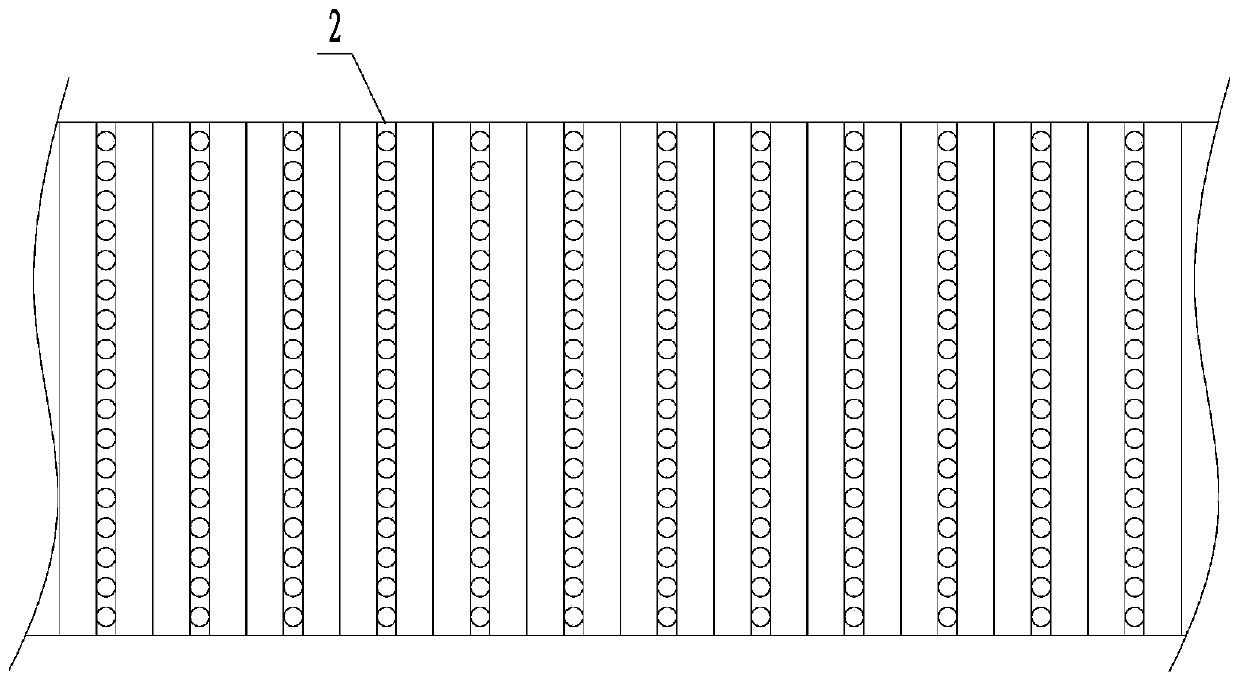

Image

Examples

Embodiment 1

[0059] A high-strength crack-resistant elastic putty powder for external walls, which is made by mixing the following raw materials in parts by weight: 650 parts of quartz sand, 350 parts of No. 42.5 gray cement, and 40 parts of putty powder masterbatch; wherein, the putty powder is added The masterbatch is composed of the following raw materials in parts by weight: 2 parts of palm fiber, 30 parts of redispersible latex powder, 4 parts of hydroxypropyl methylcellulose, 0.5 part of hydroxypropyl starch ether, 2 parts of polypropylene short fiber, organic 1 part of silicon hydrophobic agent, 0.5 part of melamine superplasticizer.

[0060] The preparation method of the above-mentioned high-strength crack-resistant external wall elastic putty powder is as follows: weigh 650kg of quartz sand, 350kg of gray cement, and 40kg of masterbatch to the putty powder, mix them, mix them evenly, pass through a 100-mesh sieve, and pack them to get the product; among them, the putty The prepara...

Embodiment 2

[0070] A high-strength anti-crack type elastic putty powder for external walls, which is made by mixing the following raw materials in parts by weight: 600 parts of quartz sand, 300 parts of No. 42.5 gray cement, and 30 parts of putty powder masterbatch; wherein, the putty powder is added The masterbatch is composed of the following raw materials in parts by weight: 1.5 parts of palm silk, 25 parts of redispersible latex powder, 3 parts of hydroxypropyl methylcellulose, 0.3 parts of hydroxypropyl starch ether, 1.5 parts of polypropylene short fiber, organic 0.8 parts of silicon hydrophobic agent, 0.3 parts of melamine water reducing agent.

[0071] The preparation method of the above-mentioned high-strength crack-resistant external wall elastic putty powder is as follows: weigh 600kg of quartz sand, 400kg of No. 42.5 gray cement, and add 40kg of masterbatch to the putty powder to mix, stir evenly, pass through a 100-mesh sieve, and pack to obtain the product; , the preparation...

Embodiment 3

[0081] A high-strength crack-resistant elastic putty powder for external walls, which is made by mixing the following raw materials in parts by weight: 700 parts of quartz sand, 400 parts of No. 42.5 gray cement, and 50 parts of putty powder masterbatch; wherein, the putty powder is added The masterbatch is composed of the following raw materials in parts by weight: 2.5 parts of palm fiber, 40 parts of redispersible latex powder, 5 parts of hydroxypropyl methylcellulose, 0.6 part of hydroxypropyl starch ether, 2.5 parts of polypropylene short fiber, organic 1.2 parts of silicon hydrophobic agent, 0.6 parts of melamine water reducing agent.

[0082] The preparation method of the above-mentioned high-strength crack-resistant external wall elastic putty powder is as follows: weigh 700 kg of quartz sand, 400 kg of No. 42.5 gray cement, and add 40 kg of masterbatch to the putty powder to mix, mix evenly, pass through a 100-mesh sieve, and pack it to obtain; , the preparation method...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com