Mildew removal agent and preparation method thereof

A mildew remover and antifungal technology, applied in botanical equipment and methods, biocides, disinfectants, etc., can solve the problems of use, strong odor, poor stability, etc., and achieve low equipment requirements and bactericidal effect. Good, short production cycle effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

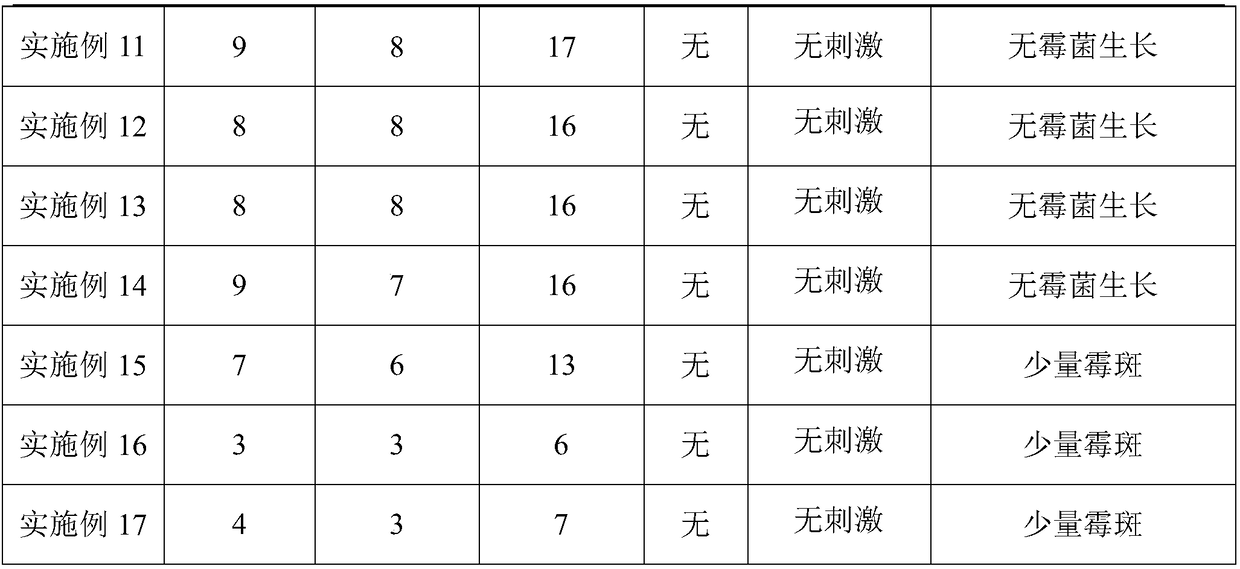

Examples

Embodiment 1

[0048] Mix didecyldimethylammonium chloride, dioctadecyldimethylammonium chloride, and pyrithione urea in a ratio of 3:3:1 to form an antifungal agent, and then take the following raw materials in weight percentages : Sodium chlorite 1%, lauryl sulfopropyl betaine 1%, antifungal agent 0.7%, sodium alkylbenzene sulfonate 0.2%, citric acid buffer 0.5%, deionized water balance. Sodium chlorite, dodecyl sulfopropyl betaine, and deionized water were mixed under the condition of 500r / min for 10 minutes to obtain mixture A, and then sodium alkylbenzenesulfonate and antifungal agent were added to the obtained In the mixture A, the mixture B was obtained after stirring and mixing under the condition of 800r / min for 8 minutes, and then the auxiliary agent was added to the obtained mixture B, and after stirring and mixing under the condition of 1200r / min for 5 minutes, the mildew remover was obtained.

Embodiment 2

[0050] "Sodium chlorite 1%" in Example 1 was replaced with "Sodium chlorite 3%", and the steps of Example 1 were repeated to obtain the mildew remover.

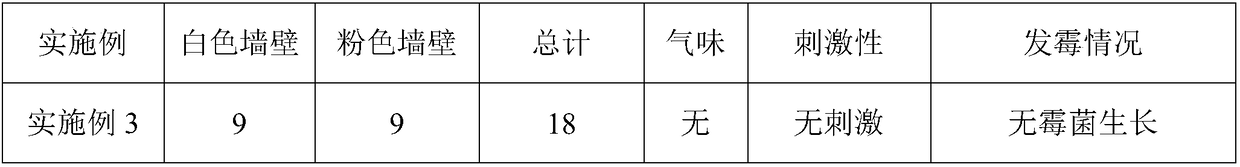

Embodiment 3

[0052]Mix didecyldimethylammonium chloride, dioctadecyldimethylammonium chloride, and pyrithione urea in a ratio of 3:3:1 to form an antifungal agent, and then take the following raw materials in weight percentages : Sodium chlorite 5%, lauryl sulfopropyl betaine 1%, antifungal agent 0.7%, sodium alkylbenzene sulfonate 0.2%, citric acid buffer 0.5%, deionized water balance. Sodium chlorite, dodecyl sulfopropyl betaine, and deionized water were stirred and mixed under the condition of 400r / min for 12min to obtain mixture A, then, sodium alkylbenzenesulfonate and antifungal agent were added to the obtained In the mixture A, the mixture B was obtained after stirring and mixing under the condition of 600r / min for 5 minutes, and then the auxiliary agent was added to the obtained mixture B, and after stirring and mixing under the condition of 1000r / min for 7 minutes, the mildew remover was obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com