One-bath dyeing method for brocade cotton through reactive dyes

A technology of reactive dyes and dyeing methods, applied in dyeing methods, textiles and papermaking, etc., can solve the problems of long dyeing process time, high power consumption, high steam consumption, poor washing fastness, etc., to save dyeing time and improve efficiency. , the effect of good dyeing rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

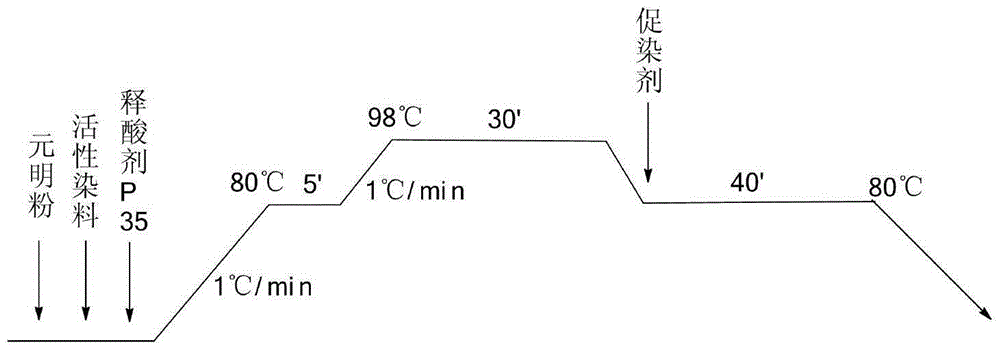

Embodiment 1

[0070] Step (1): Add 250 kg of brocade cotton cloth to the dye vat, and add dye liquor into the dye vat, the bath ratio is 1:4; the steps of adding the dye liquor are: first weigh the required amount of sodium sulfate, pH sliding agent P35 (Shangyu Lide Auxiliary Co., Ltd.) and reactive dyes (CNS black, Jinguang Industrial Co., Ltd.); then fully dissolve them in water at 40-50°C, and the sum of the water used for each component is less than the total of the liquor ratio. water volume. After the components of each dye solution are fully dissolved, pour them into the dyeing vat, and then add hot water to the dyeing vat to the volume required by the bath ratio. In the dye liquor, the concentration of sodium sulfate is 100g / L, the concentration of P35 is 2% (based on the weight of the dye liquor), and the concentration of reactive dye black is 7owf%. After the feeding is completed, keep warm for 20 minutes.

[0071] Step (2): Gradient heating: the temperature rise gradient is 1°...

Embodiment 2

[0074] Step (1): Add 250kg of brocade cotton cloth to the dyeing vat, and add dye liquor into the dye vat, the bath ratio is 1:6; the steps of adding the dye liquor are: first weigh the required amount of sodium sulfate and pH sliding agent P35 (Shangyu Lide Auxiliary Co., Ltd.) and reactive dyes (CNS black, Jinguang Industrial Co., Ltd.); then fully dissolve them in water at 40-50°C, and the sum of the water used for each component is less than the total of the liquor ratio. water volume. After the components of each dye solution are fully dissolved, pour them into the dyeing vat, and then add hot water to the dyeing vat to the volume required by the bath ratio. In the dye liquor, the concentration of sodium sulfate is 100g / L, the concentration of P35 is 1% (based on the weight of the dye liquor), and the concentration of reactive dye black is 8owf%. After the feeding is completed, keep warm for 20 minutes.

[0075] Step (2): Gradient temperature rise: The temperature rise ...

Embodiment 3

[0078] Step (1): Add 250kg of brocade cotton cloth to the dyeing vat, and add dye liquor into the dye vat, the bath ratio is 1:6; the steps of adding the dye liquor are: first weigh the required amount of sodium sulfate and pH sliding agent P35 (Shangyu Lide Auxiliary Co., Ltd.) and reactive dyes (CNS black, Jinguang Industrial Co., Ltd.); then fully dissolve them in water at 40-50°C, and the sum of the water used for each component is less than the total of the liquor ratio. water volume. After the components of each dye solution are fully dissolved, pour them into the dyeing vat, and then add hot water to the dyeing vat to the volume required by the bath ratio. In the dye liquor, the concentration of sodium sulfate is 100g / L, the concentration of P35 is 2% (based on the weight of the dye liquor), and the concentration of reactive dye black is 7owf%. After the feeding is completed, keep warm for 20 minutes.

[0079] Step (2): Gradient heating: the temperature gradient is 1°...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com