Methanation furnace for producing methane from coal synthesis gas and production method of methanation furnace

A coal-to-synthesis gas and methanation technology, which is applied to chemical instruments and methods, gas fuels, and hydrocarbon production from carbon oxides, etc., can solve the problem of process parameters and reaction devices that need to be improved, thick pressure shells, metal High temperature and other problems, to achieve the effect of high industrial application value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

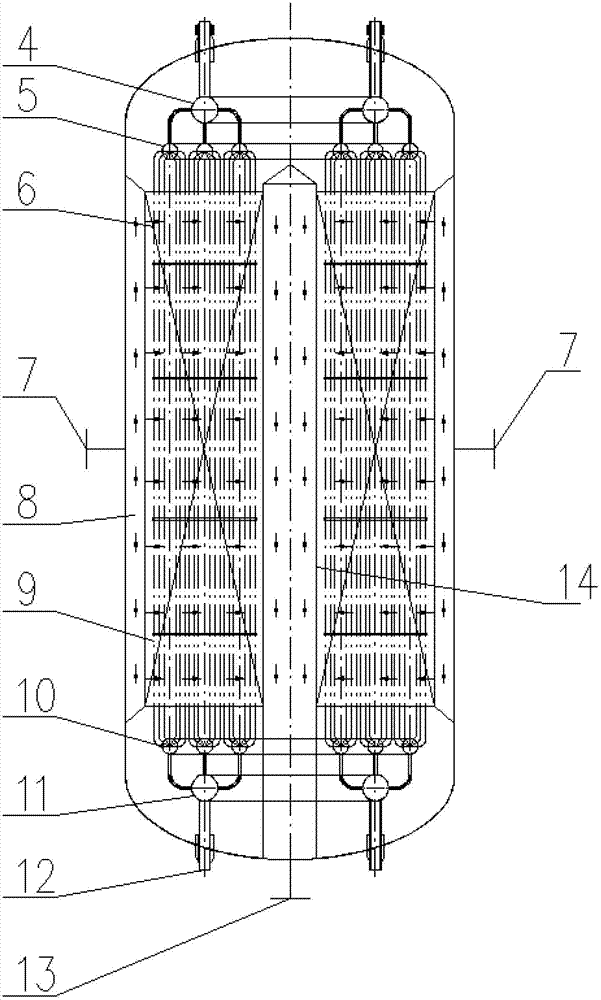

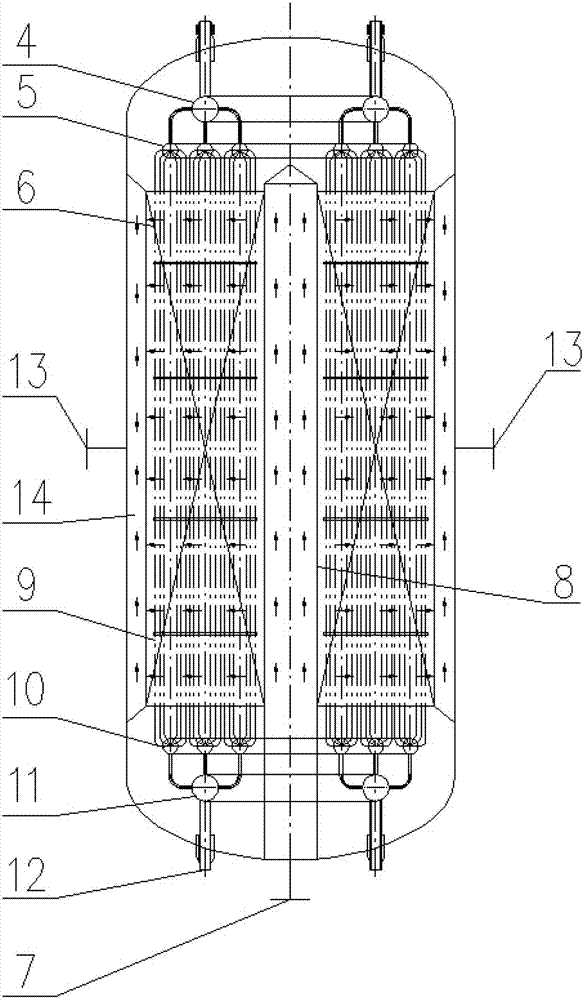

[0033] In order to make the technical solution proposed by the present invention easier to understand, the present invention will be further described in conjunction with the accompanying drawings, and its equipment structure and production process are clear and achievable to those skilled in the art.

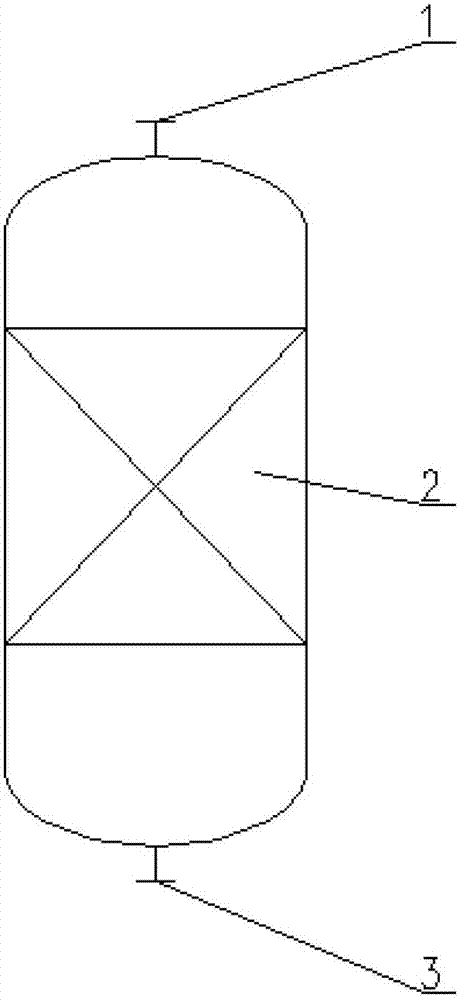

[0034] The present invention has made two kinds of improved schemes to the structure of the key equipment methanation furnace of synthesis gas to natural gas, just therefore obtained the methanation furnace of two kinds of structures and production method thereof:

[0035] Option One

[0036] The structure of the methanation furnace in this scheme is as follows figure 2 As shown, it includes a synthesis gas inlet 7, a catalyst bed 6 and a methane gas outlet 13. It is characterized in that the bottom of the methanation furnace is provided with a methane gas outlet 13, the left and right sides of the methanation furnace are provided with a synthesis gas inlet 7, and the middle p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com