Coal liquefied oil boiling bed hydrogenation technique

A technology for coal liquefied oil and hydrogenation treatment, which is applied in the fields of hydrogenation treatment process, petroleum industry, and hydrocarbon oil treatment. It can solve the problems of difficult removal of aromatics and difficulty in hydrogenation saturation of aromatics, and it is easier to control the reaction temperature , Reduce the content of polycyclic aromatic hydrocarbons, the effect of low investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

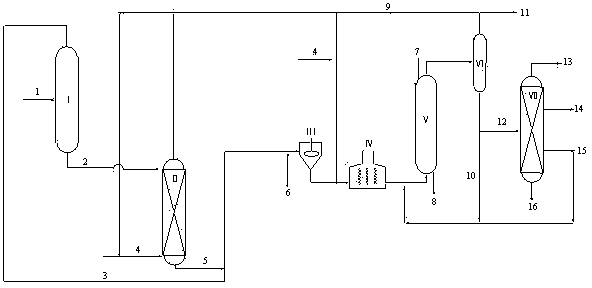

[0056] Example 1 is to divide the filtered decant oil into 350°C fraction with 350°C as the cut point. Among them, the >350°C distillate and hydrogen enter the hydro-upgrading unit in reverse for hydro-upgrading. After hydro-upgrading, the clarified oil, <350°C light fraction and coal liquefied oil (the weight ratio of oil slurry / coal liquefied oil is 1:9) is mixed with the mixing tank and then mixed with hydrogen and enters from the bottom of the reactor. When it flows upwards, it drives the catalyst in the reactor to fluidize, so that the reactor is in a fully mixed flow state. After the reacted material is separated, the catalyst is returned to the reaction zone or discharged, and part of the circulating oil (the circulating ratio is 2:1, that is, the weight ratio of the circulating liquid to the coal liquefied oil) enters the reactor to mix with the raw material to continue the reaction; Enter the hot high fraction for gas-liquid separation. The gas rich in hydrogen is re...

Embodiment 2

[0058] Example 2 is to put the filtered >350°C clarified oil fraction into the hydrogenation unit for hydrotreating, and combine the hydrogenated and upgraded clarified oil, the light fraction <350°C and the coal liquefied oil (oil slurry: coal liquefaction The oil weight ratio is 1:4) and mixed with hydrogen after passing through the mixing tank and enters from the bottom of the reactor. When it flows upwards, it drives the catalyst in the reactor to fluidize, so that the reactor is in a fully mixed flow state. After the reacted material is separated, the catalyst is returned to the reaction zone or discharged, and part of the circulating oil (the circulating ratio is 2:1, that is, the weight ratio of the circulating liquid to the coal liquefied oil) enters the reactor to mix with the raw material to continue the reaction; Enter the hot high fraction for gas-liquid separation. The gas rich in hydrogen is recycled after passing through the scrubber. The resulting oil separate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| dry point | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com