Preparation system and preparation method for polyisobutylene

A polyisobutene and preparation system technology, applied in the field of chemical technology and equipment, can solve the problems of uncontrollable molecular weight of product polyisobutene, affecting product quality and use, large molecular weight distribution index, etc., and achieving uniform, stable and adjustable reaction temperature and structure. Simple, molecular weight controllable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

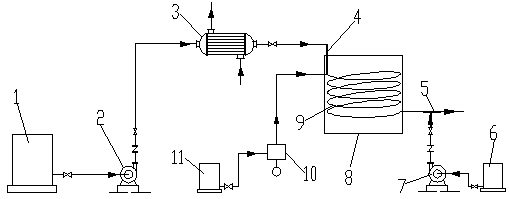

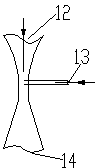

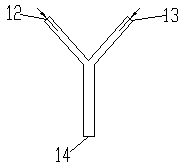

[0042] The static mixing tubular polymerization reactor 9 described in the preparation system of this polyisobutylene is Figure 4 The several layers shown are arranged in a horizontal serpentine form from bottom to top or Figure 5 The tubular structure shown in several rows of vertical serpentine arrangements is made of ordinary carbon steel; the diameter and length of the tube are adjusted and determined according to the residence time and output required for the reaction. The inner diameter of the tube ranges from 20mm to 150mm and the length ranges from 100m ~800m, the wall thickness is 2.5mm, so that the residence time of the reaction material in the tubular reactor is 1min~35min. The inside of the static mixing tubular polymerization reactor 9 adopts a static mixer mixing unit structure, and the specific form can be any one of SK type, ISG type, LPD type and SV type; the static mixer mixing unit structure makes the reaction fluid Cutting, shearing, rotating and re-mixi...

Embodiment 1

[0051] Embodiment 1: The preparation method of the present polyisobutylene The specific process is as follows.

[0052] use figure 1 The preparation system of polyisobutylene shown in the reaction, the constant temperature brine bath is a square storage tank, the size is: length 1m, width 1m, height 2m, the static mixing tubular polymerization reactor immersed in the constant temperature brine bath is a horizontal coil , The material is Teflon tube (teflon tube), the inner diameter of the coil is 20mm, the length of the tube is 800m, and the coiling method is a multi-layer circular spiral rise.

[0053] At 200kPa, add brine solution into the constant temperature brine bath 8, and start an external refrigerator to cool the brine, so as to control the reaction temperature to 0°C. Into the isobutylene cooler 3, feed the brine cooled by an external freezer, start the raw material delivery pump 2, 3 The flow rate of / h is from the isobutene storage tank 1 to the tube side of the ...

Embodiment 2

[0055] Embodiment 2: The preparation method of the present polyisobutylene The specific process is as follows.

[0056] In the preparation system of polyisobutylene, the constant temperature brine bath is a square storage tank with a size of 1.5m in length, 1.5m in width and 2m in height. The static mixing tubular polymerization reactor submerged in the constant temperature brine bath is a horizontal surrounding coil, and the material is Teflon tube (teflon tube), the inner diameter of the coil is 20mm, the length of the total pipe is 800m, the coiling method is a multi-layer circular spiral rise, and the number of parallels is 2.

[0057] At 200kPa, a saline solution was added to the thermostatic brine bath 8, and an external refrigerator was started to cool the brine, so as to control the reaction temperature to -5°C. Into the isobutylene cooler 3, feed the brine cooled by an external freezer, start the raw material delivery pump 2, 3 The flow rate of / h is from the isobute...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The inside diameter of | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Wall thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com