Sol gluing system

A glue-coating and sol-coating technology, which is applied in the direction of coating and liquid-coating devices on the surface, can solve the problems of complicated operation procedures, low glue-coating efficiency, and unfavorable mass production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] It should be noted that, in the case of no conflict, the embodiments of the present invention and the features in the embodiments can be combined with each other.

[0021] The invention will be described in detail below with reference to the accompanying drawings and examples.

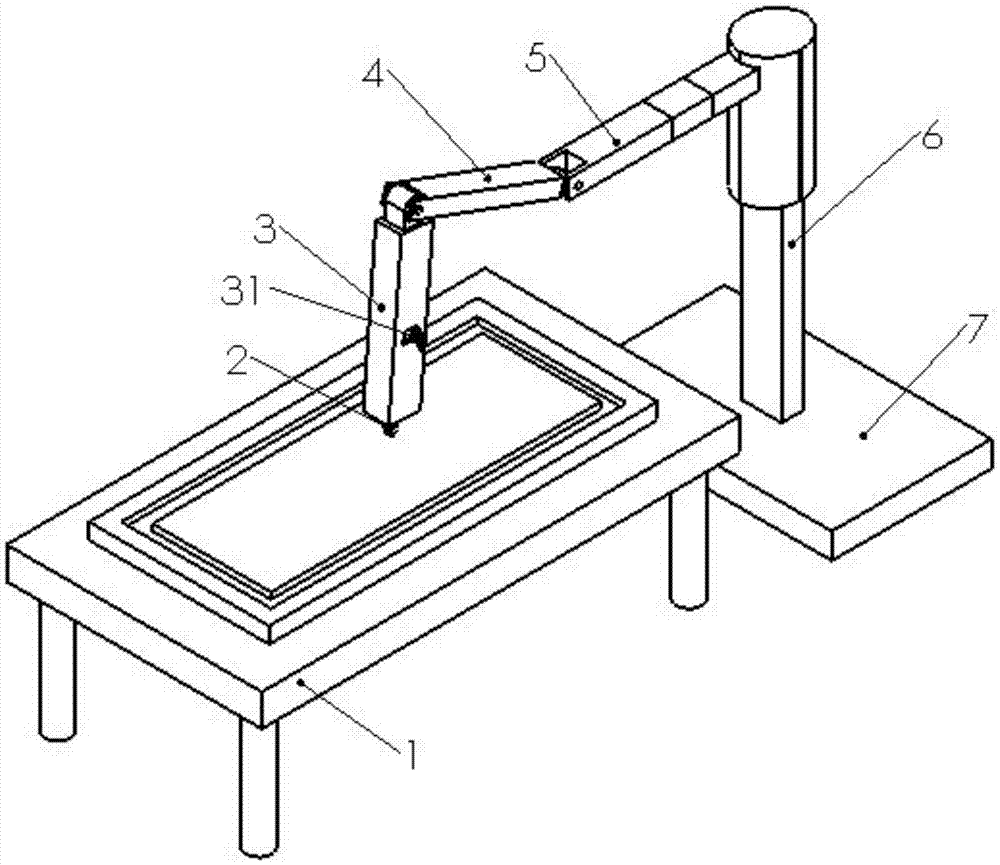

[0022] Such as figure 1 , 2 As shown, a sol gluing system includes an operating table 1, a spraying arm 3, a connecting arm 4, a telescopic arm 5, a pillar 6 and a base 7;

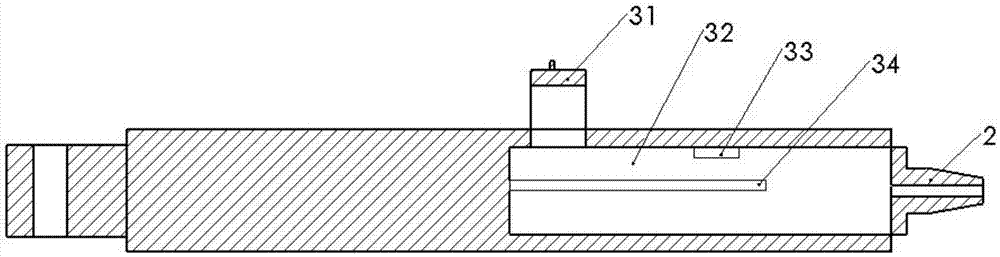

[0023] The spraying arm 3 is provided with an accommodating cavity 32, in which a heating element 34 and a temperature sensor 33 are arranged, and one end of the spraying arm 3 is provided with a spray nozzle 2 communicating with the accommodating cavity 32, and one side of the spraying arm 3 is provided with a The injection port 31 through which the accommodating cavity 32 is connected;

[0024] The two ends of the connecting arm 4 are respectively hinged on the spraying arm 3 and the telescopic arm 5 through a hinge sha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com