Loading and unloading integration machine for water drilling grinder group

A technology for grinding machines and rhinestones, which is applied to grinding machines, machine tools suitable for grinding workpiece edges, grinding/polishing equipment, etc., can solve the problems of high labor intensity, and achieve the effect of reducing labor intensity, saving production costs and saving institutions.

Inactive Publication Date: 2010-12-01

杭州亿恒科技有限公司

View PDF0 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Both the loading machine and the unloading machine need to be operated by one person; this requires two people to complete the loading and unloading process, and each movement process is completed by the operator continuously controlling the air valve, which is labor-intensive

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

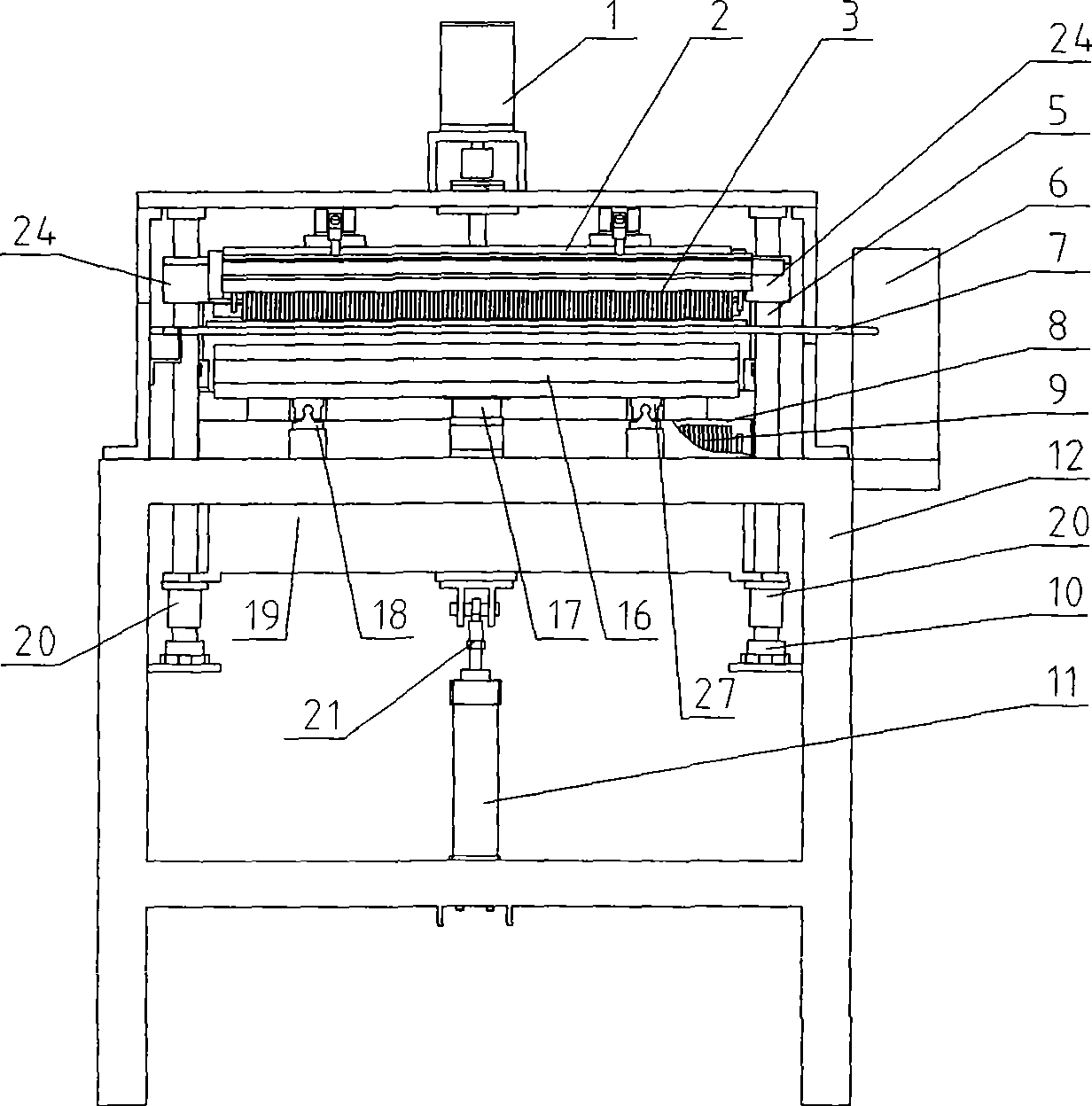

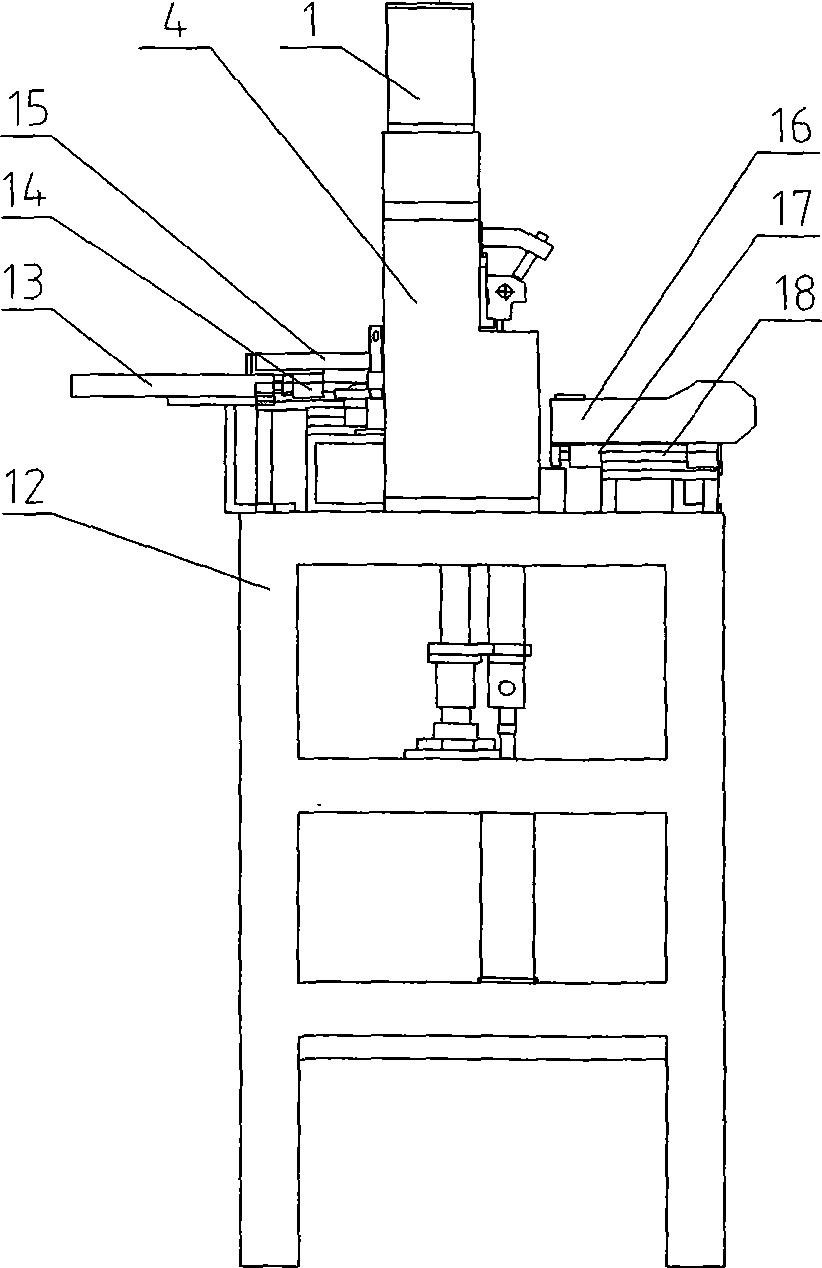

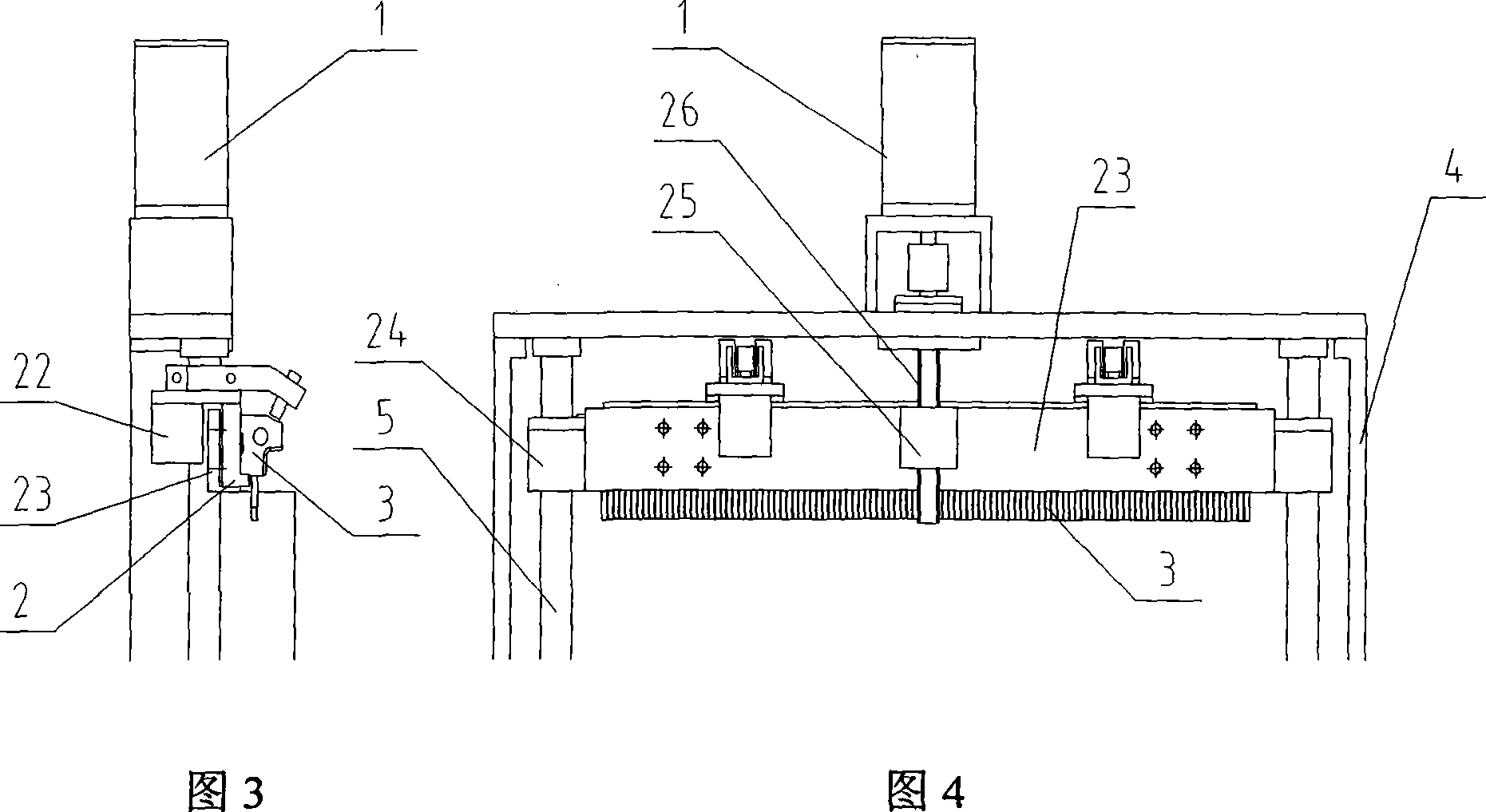

The invention discloses a loading and unloading integrated machine of a water diamond grinder unit. A loading die feeding mechanism is respectively connected at the lower part of the vertical guide rails through a first rectilinear motion ball bearing and a second rectilinear motion ball bearing, a fixture motion mechanism is respectively connected at the upper part of the vertical guide rails through a third rectilinear motion ball bearing and a fourth rectilinear motion ball bearing, the two vertical guide rails are respectively installed on the guide rail seats, the guide rail seats are fixed on the frame body of a workbench, supporting brackets are installed on the table boards on both sides of the workbench, the heating pipe of a fixture heating system is installed at the middle partof the supporting brackets, and an unloading box motion mechanism and a rubber powder box motion mechanism are respectively installed on the workbench on both sides of the supporting brackets. The motion process is unitedly and automatically controlled through a controller, the fixture after the grinding and the polishing is installed on the machine, and the process of automatic loading after theunloading can be realized by the machine. The work flow is simplified, the middle switching process is reduced, and the safety and pollution problems caused by using coal gas are avoided through electric heating. The machine is suitable for the loading and unloading process of the processing industry of water diamond or relevant jewelry.

Description

Rhinestone grinder group integrated loading and unloading machinery technical field The invention relates to a machine for loading and unloading raw materials and finished products in the production process of rhinestones, in particular to an integrated machine for loading and unloading a rhinestone grinder group. It belongs to the field of machinery manufacturing and is mainly used in the production of rhinestones, ironing diamonds and other accessories. Background technique At present, the domestic rhinestone grinding machine group is composed of a feeding machine, a grinding machine, a throwing machine, a surface changing machine, and a blanking machine. The feeding machine ejects the feeding mold by the cylinder (the glass beads are laid on the feeding mold), the fixture to be loaded is heated first, after the rubber powder is glued, it is docked with the feeding mold, and then the top of the fixture is heated. After heating for a few seconds and cooling down, the fix...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): B24B9/16

Inventor 房旺

Owner 杭州亿恒科技有限公司

Features

- Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com