Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

110results about How to "Increase the turndown ratio" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

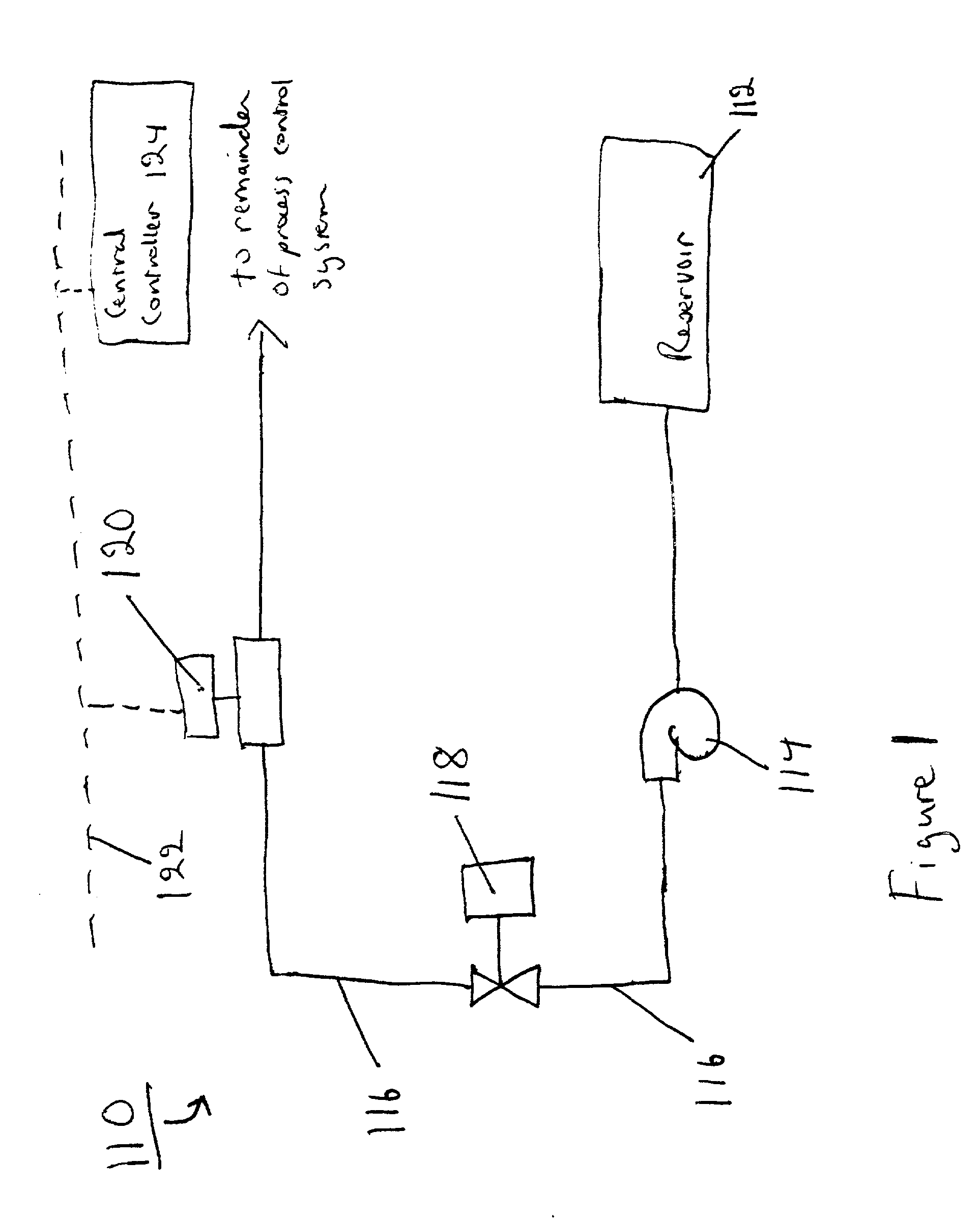

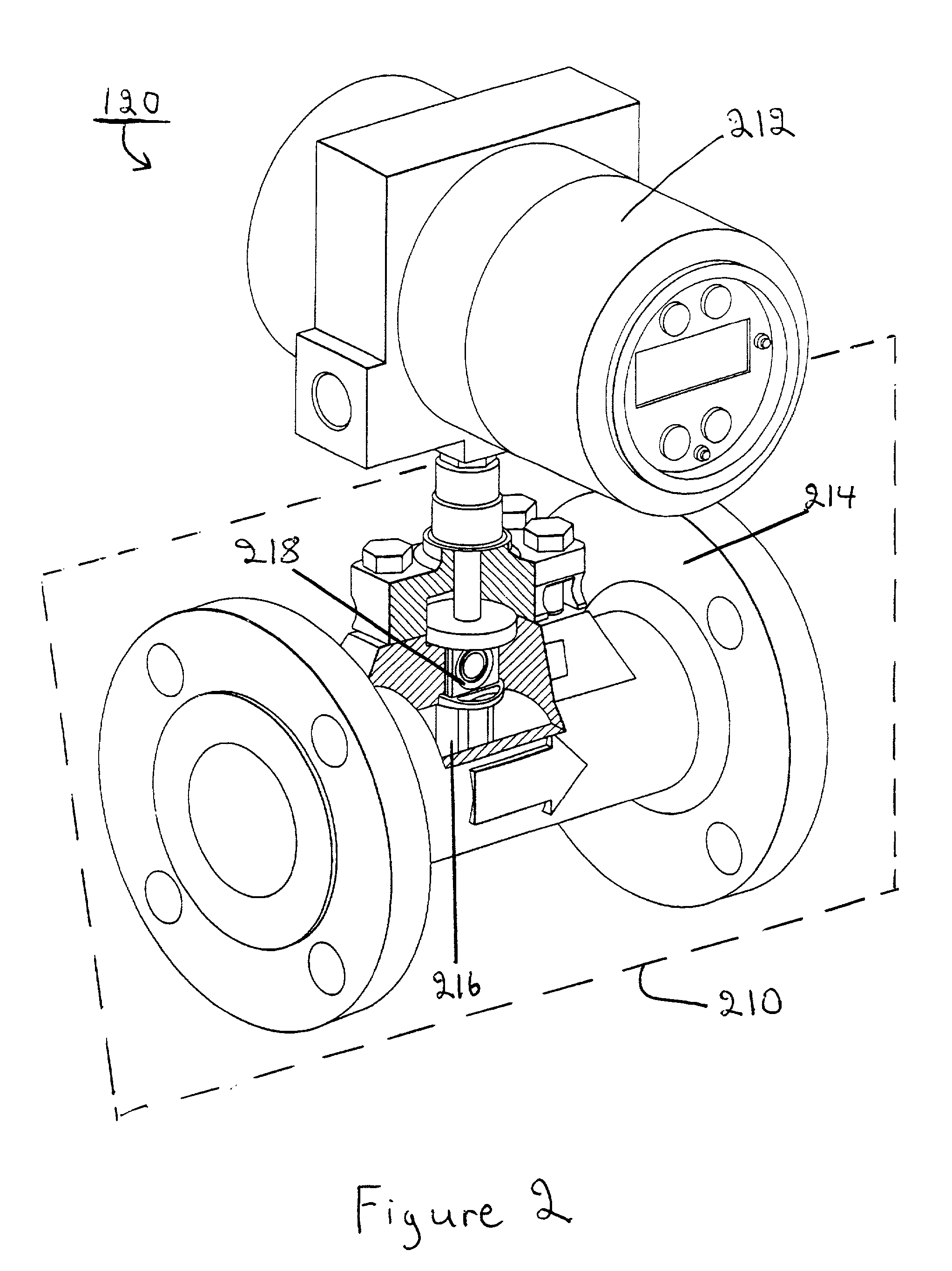

Vortex flowmeter

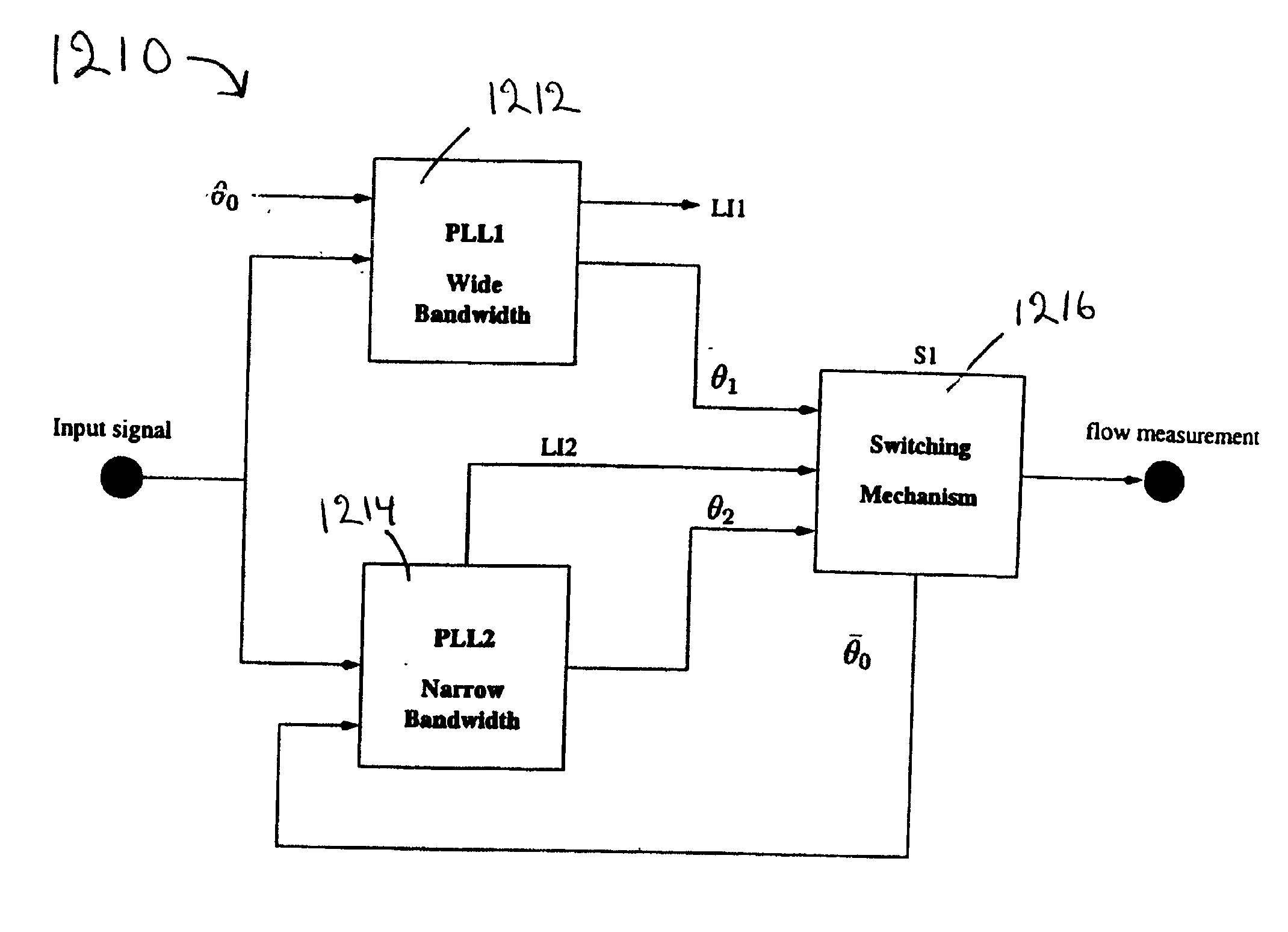

InactiveUS20020129661A1Improve accuracyIncrease speedElectrical measurementsVolume/mass flow by dynamic fluid flow effectEngineeringBand width

A process variable transmitter, implemented in a dual PLL structure, includes a first PLL having a first bandwidth producing a first output signal, and a second PLL having a second bandwidth narrower than the first bandwidth of the first PLL. The first and second PLLs are operable to lock into a frequency of an input signal and produce first and second output signals, respectively. The second PLL is operable to lock into the frequency of the input signal with greater accuracy and greater immunity to noise than the first PLL. A switch is operable to switch an output signal of the process variable transmitter between the first output signal and the second output signal.

Owner:SCHNEIDER ELECTRIC SYST USA INC

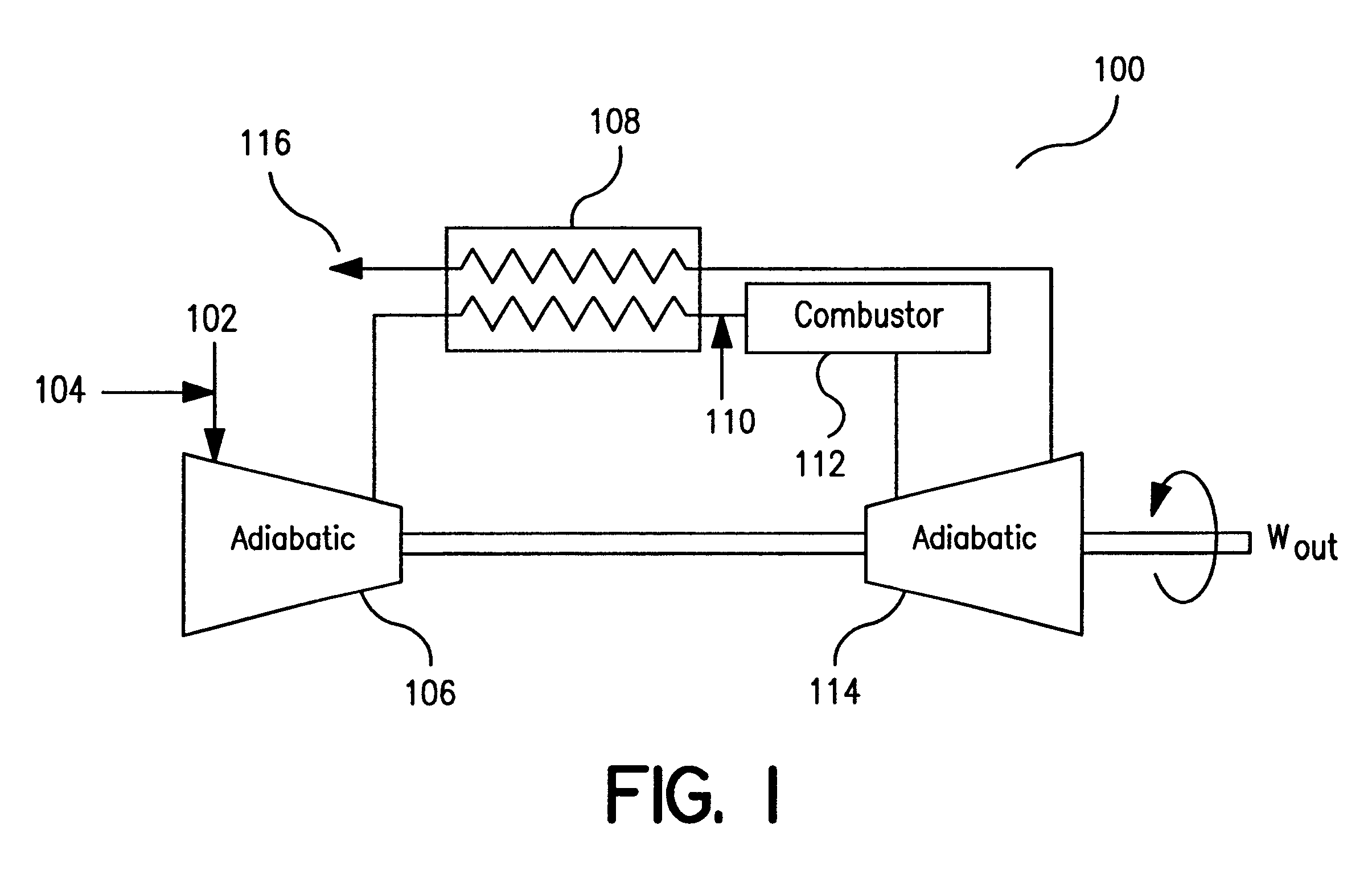

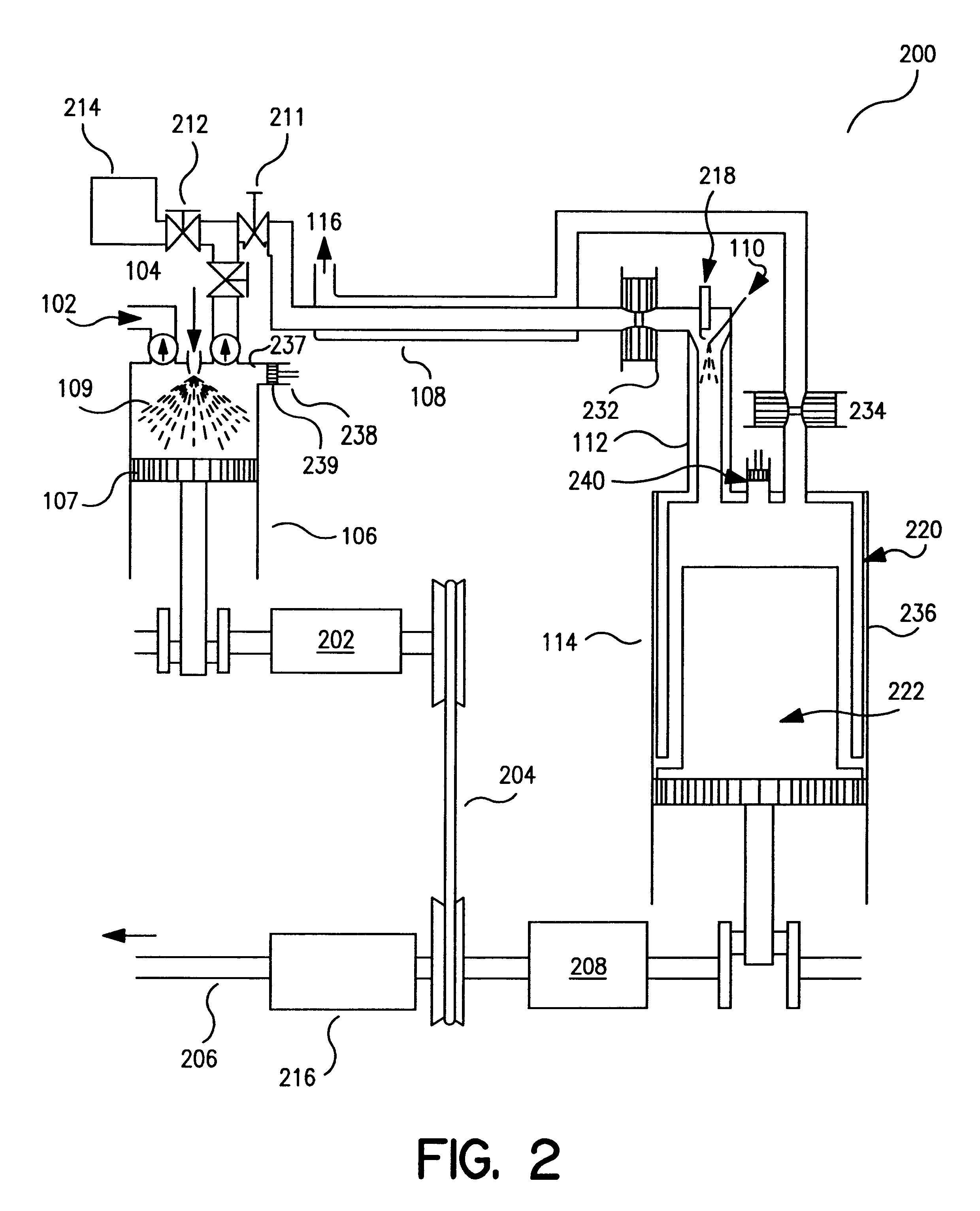

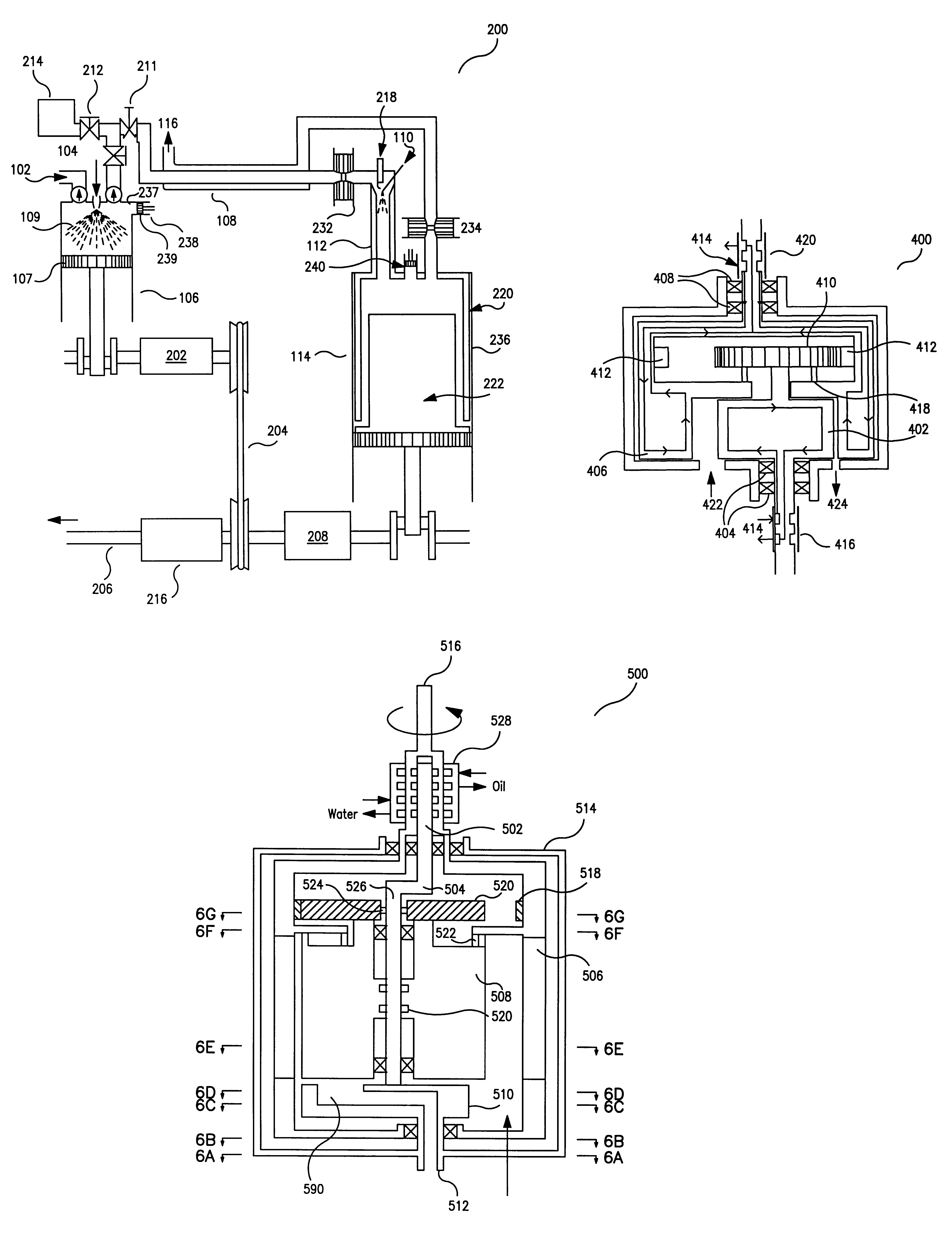

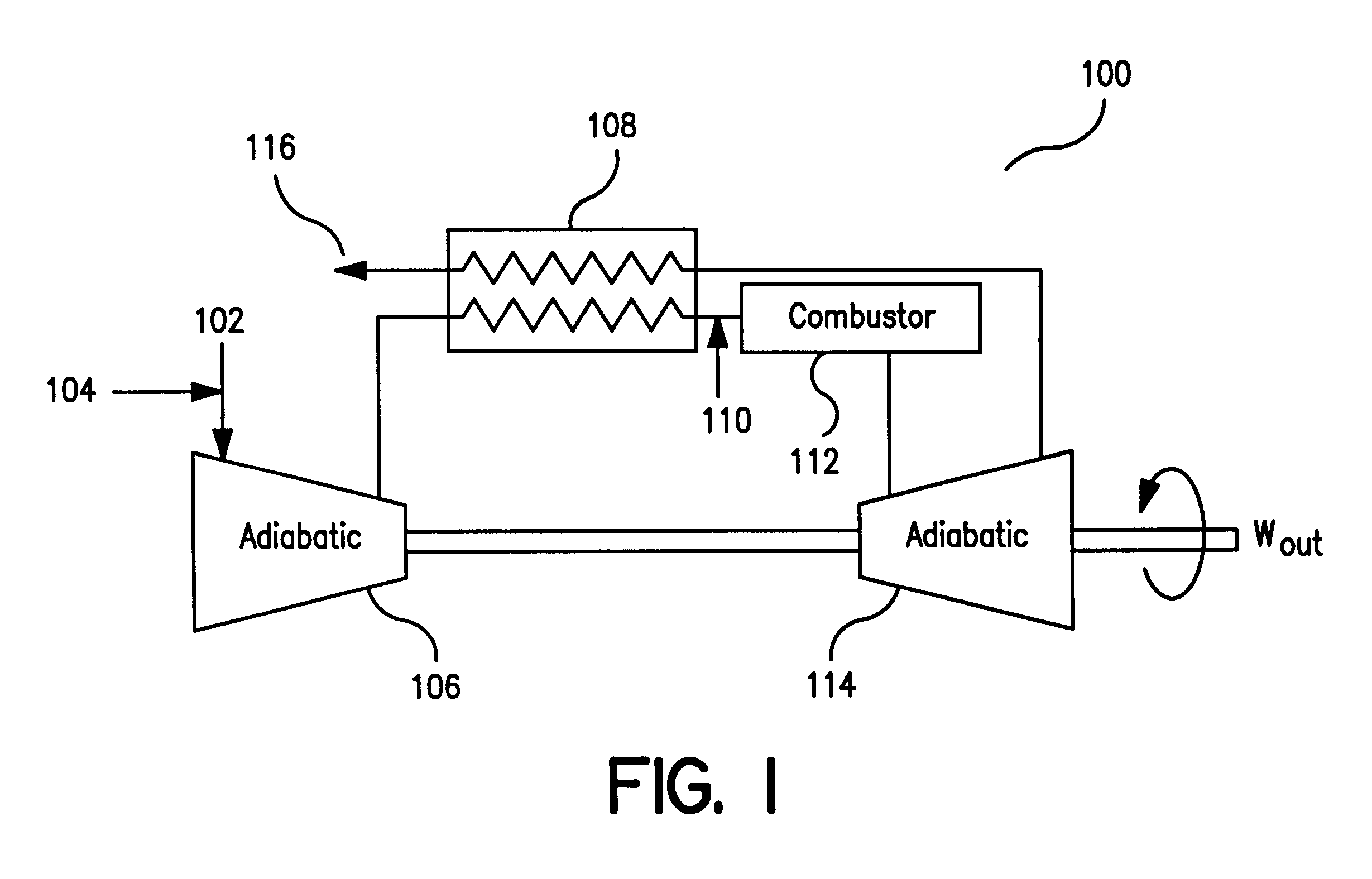

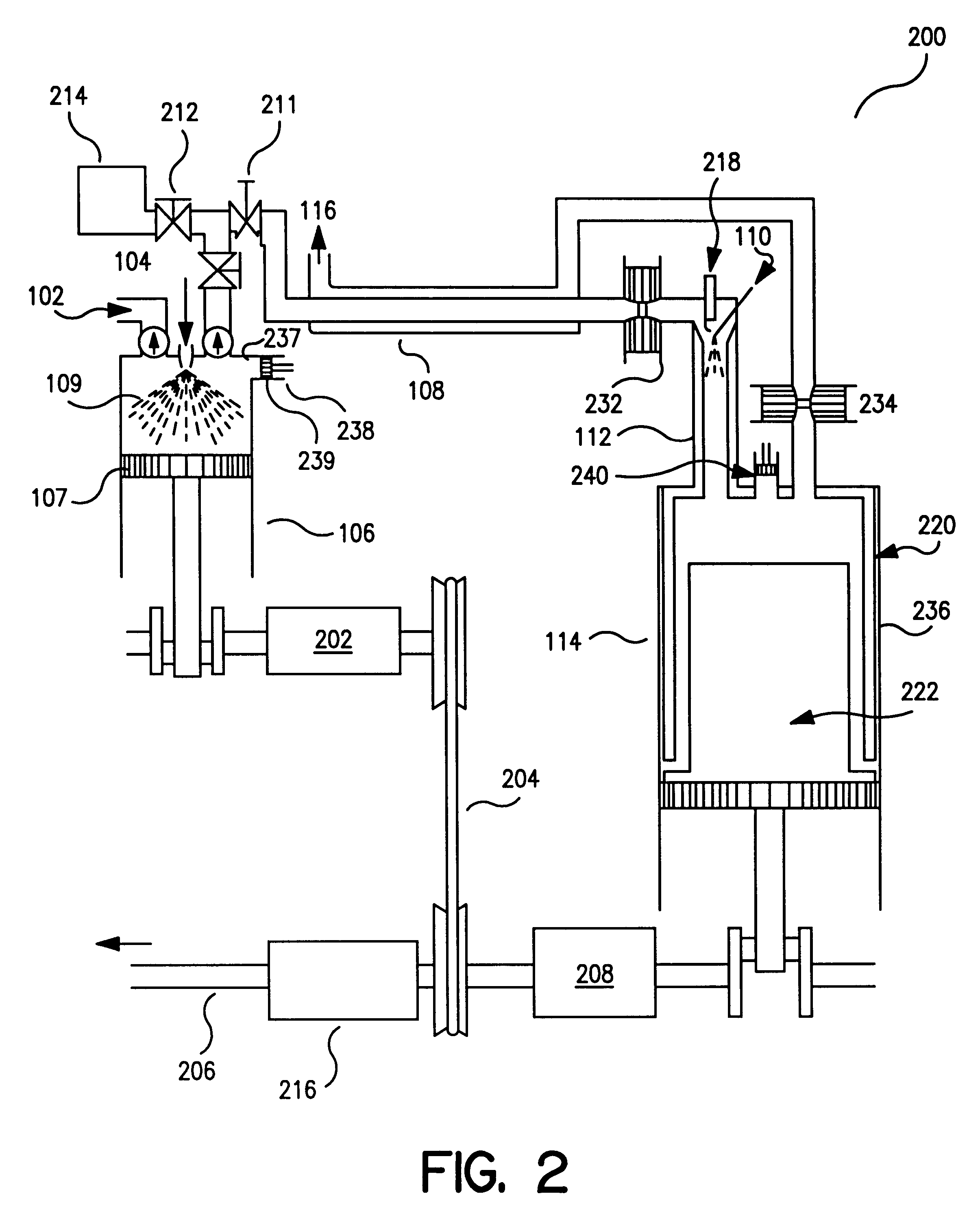

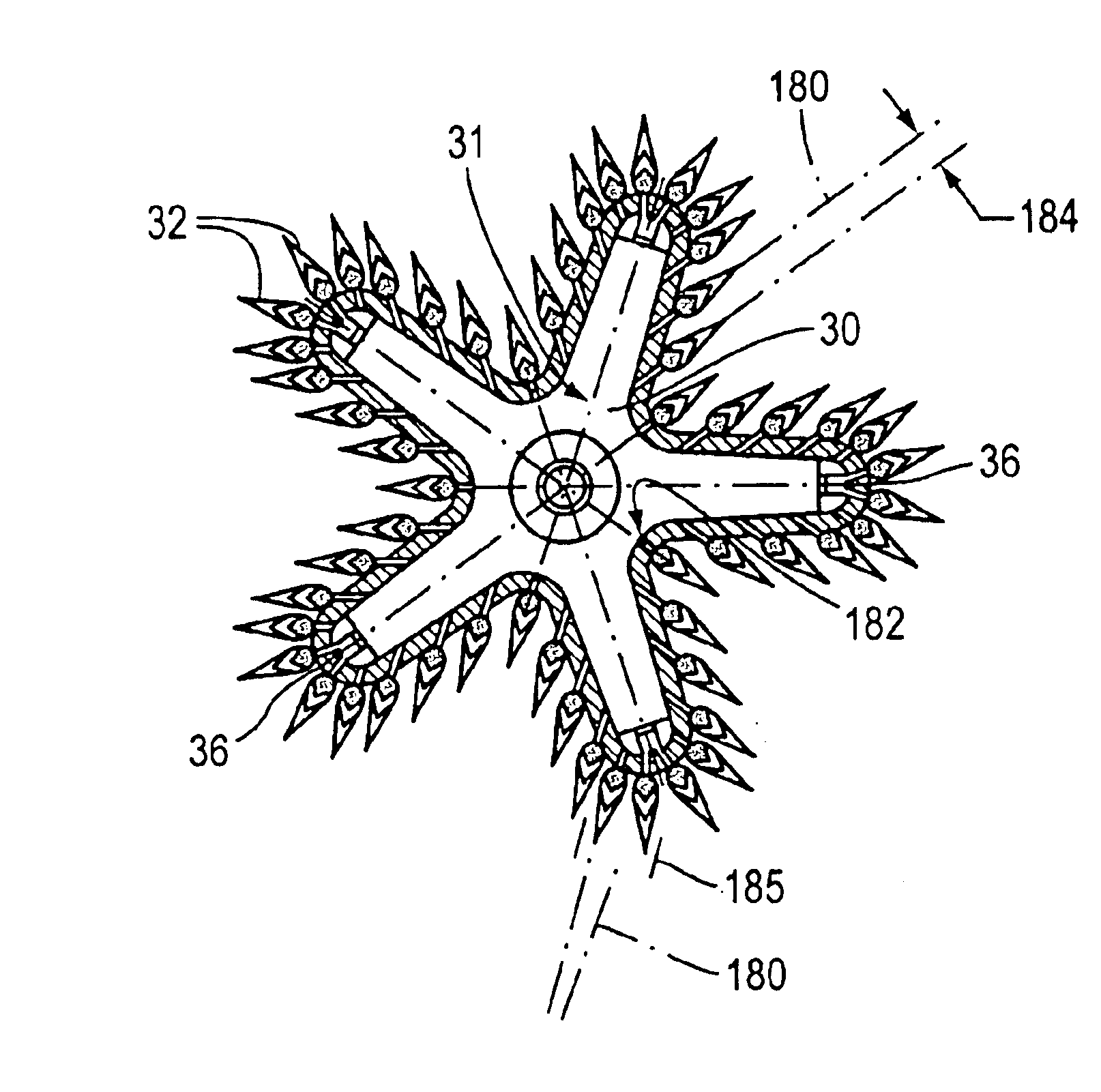

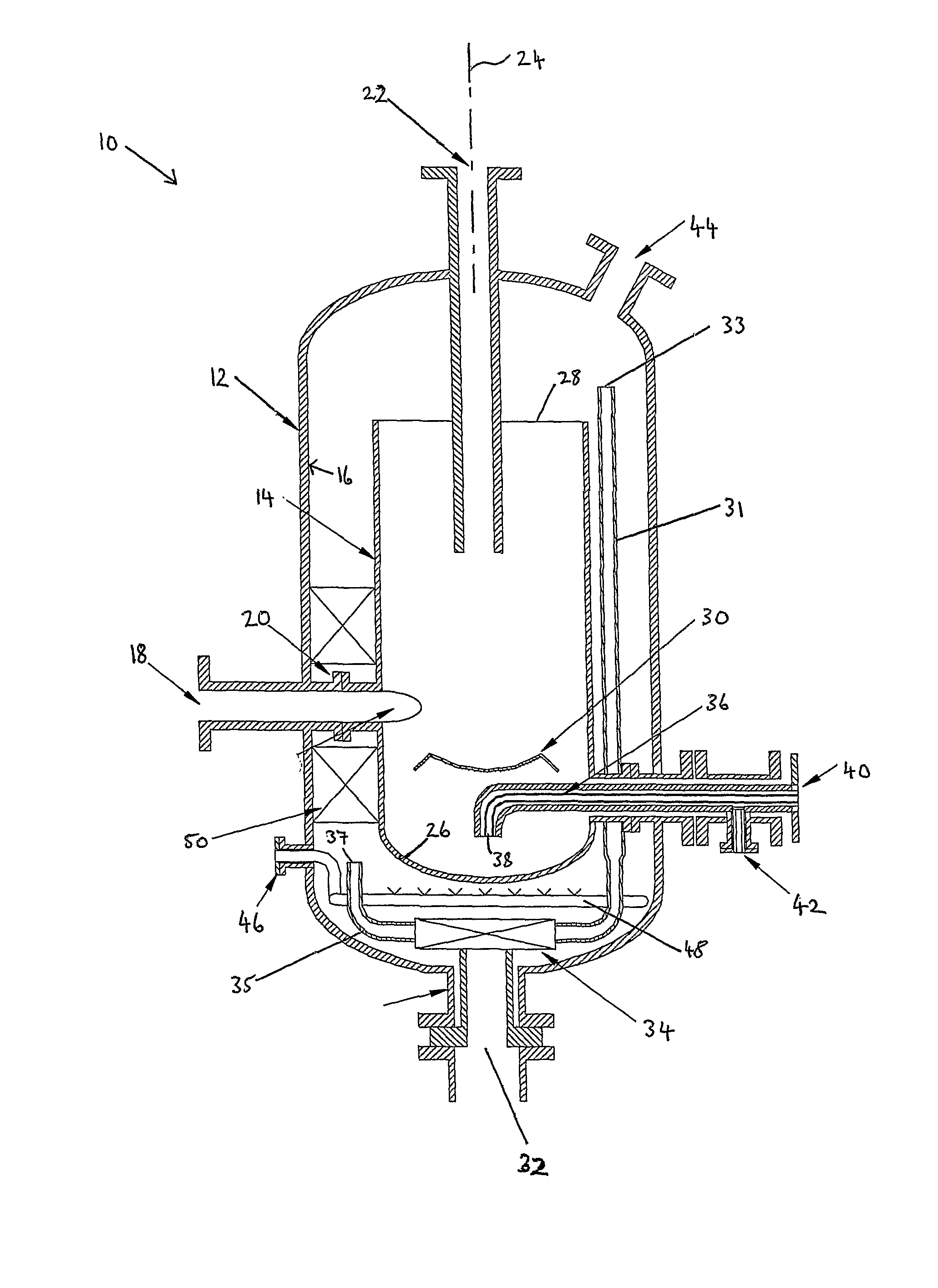

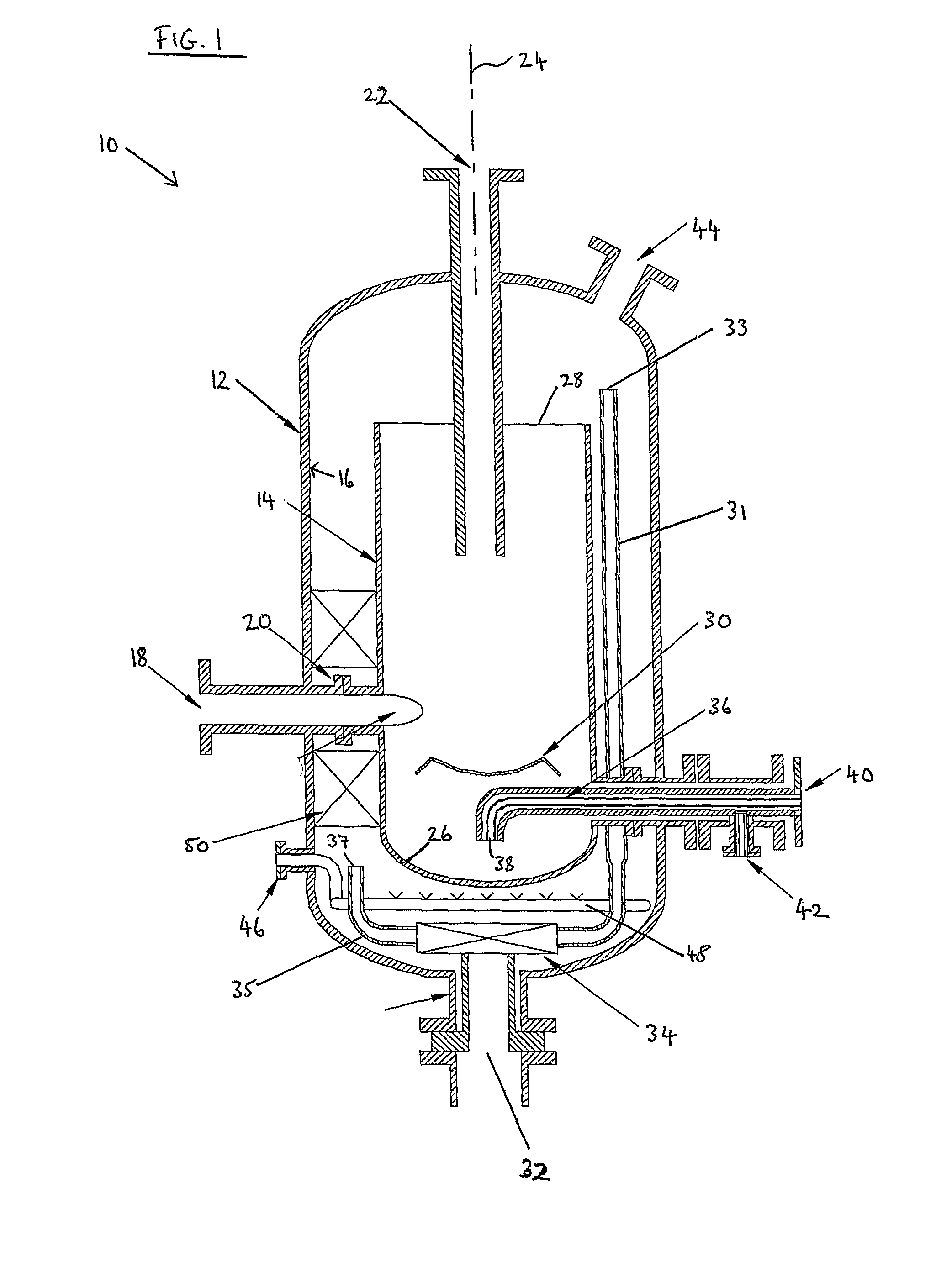

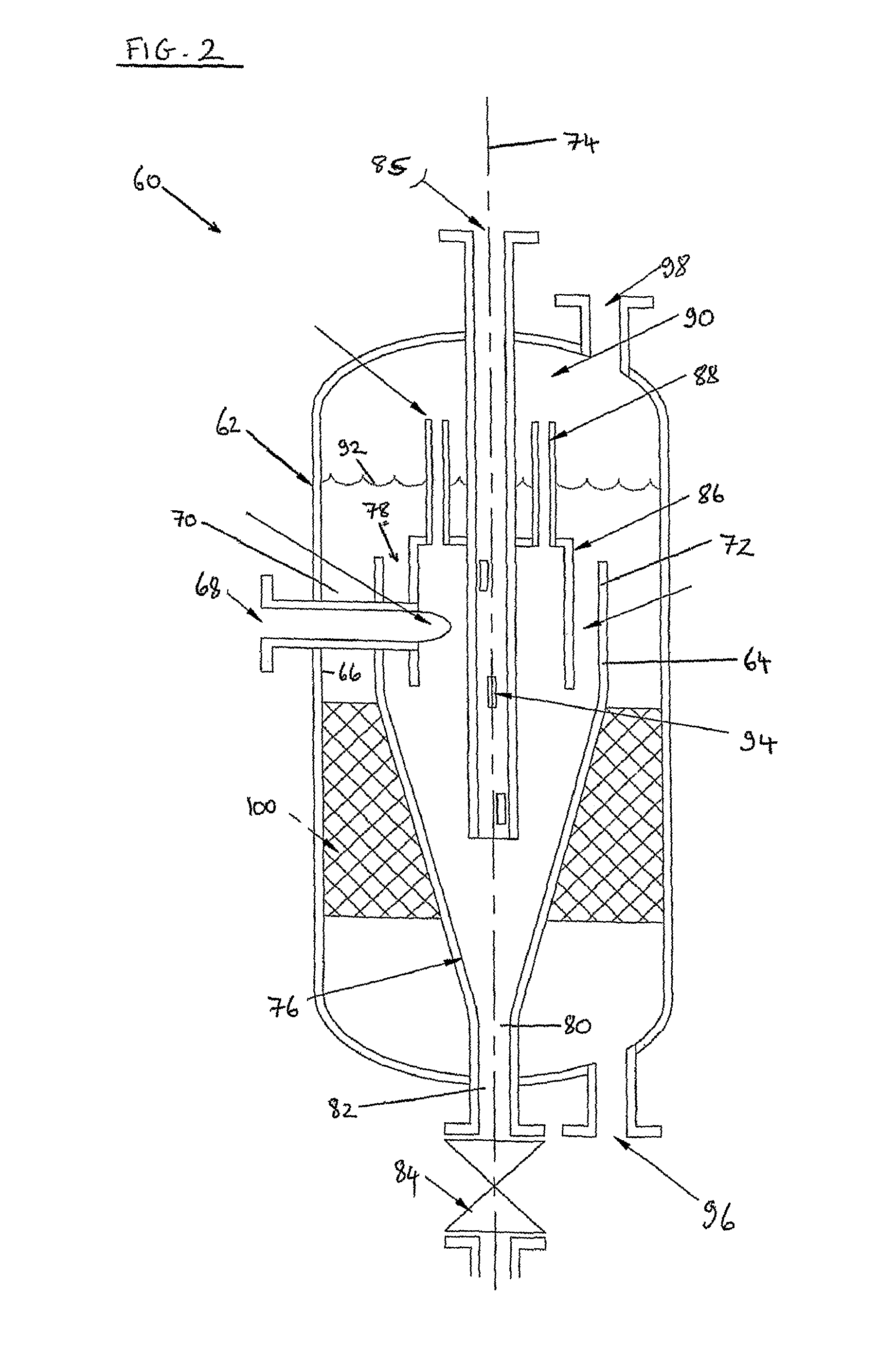

Quasi-isothermal Brayton Cycle engine

InactiveUS6530211B2Increase the turndown ratioHigh operating requirementsInternal combustion piston enginesEngine of arcuate-engagement typeBrayton cycleCombustor

Owner:HOLTZAPPLE MARK T +1

Quasi-isothermal Brayton cycle engine

InactiveUS6336317B1Increase the turndown ratioHigh operating requirementsInternal combustion piston enginesCombination enginesBrayton cycleCombustor

An engine is disclosed. According to one embodiment of the present invention, the engine comprises a compressor, and combustor, and an expander. The compressor compresses ambient air. The combustor burns the compressed air, and produces exhaust gasses. The expander receives the exhaust gases from the combustor, and expands the exhaust gasses. The compressor may be a gerotor compressor or a piston compressor having variable-dead-volume control. The expander may be a gerotor expander or a piston expander having variable-dead-volume control. In another embodiment, an engine comprises a piston compressor, a combustor, a piston expander, and a pressure tank. The piston compressor compresses ambient air. The combustor burns the compressed air, and produces exhaust gasses. The piston expander receives the exhaust gasses from the combustor, and expands the exhaust gasses. The pressure tank receives and stores the compressed air from the compressor. In another embodiment, a gerotor compressor or a gerotor expander comprises an inner gerotor, and an outer gerotor. The inner gerotor and the outer gerotor are driven so that they do not touch. The gerotors may be cantilevered or non-cantilevered.

Owner:TEXAS A&M UNIVERSITY

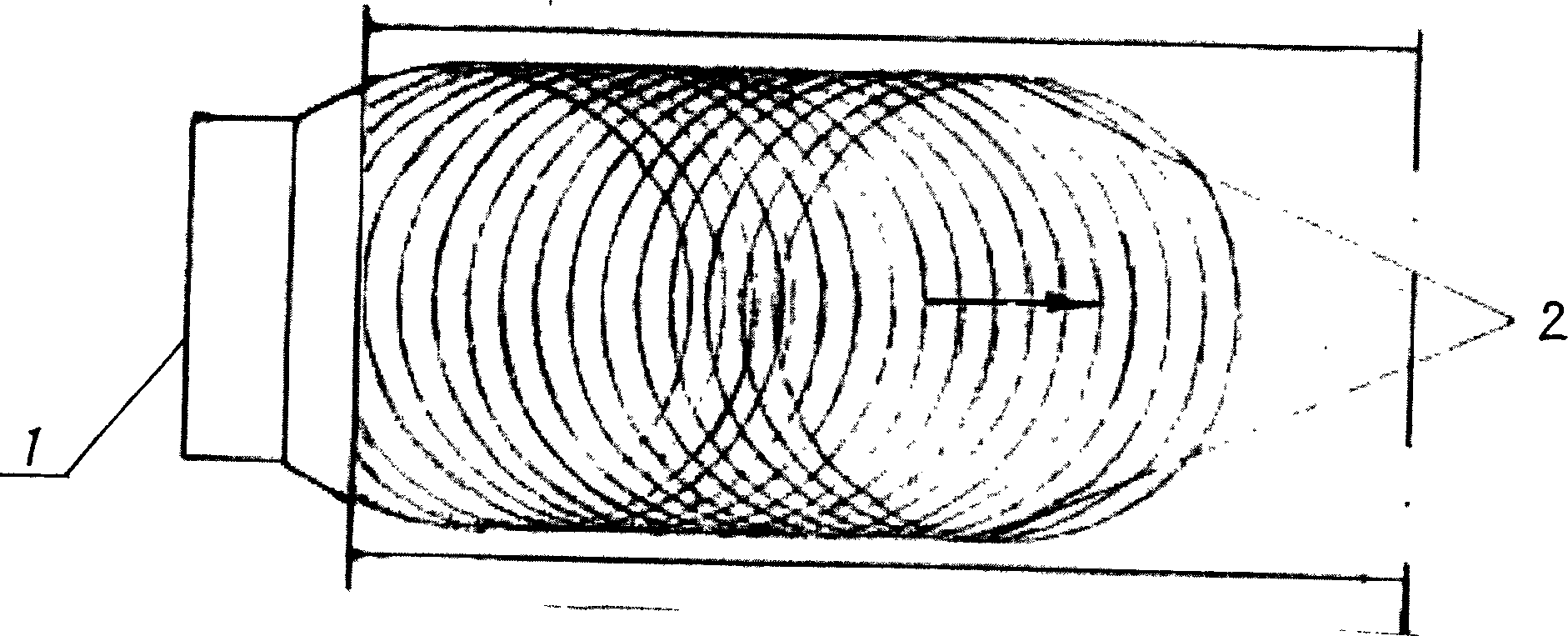

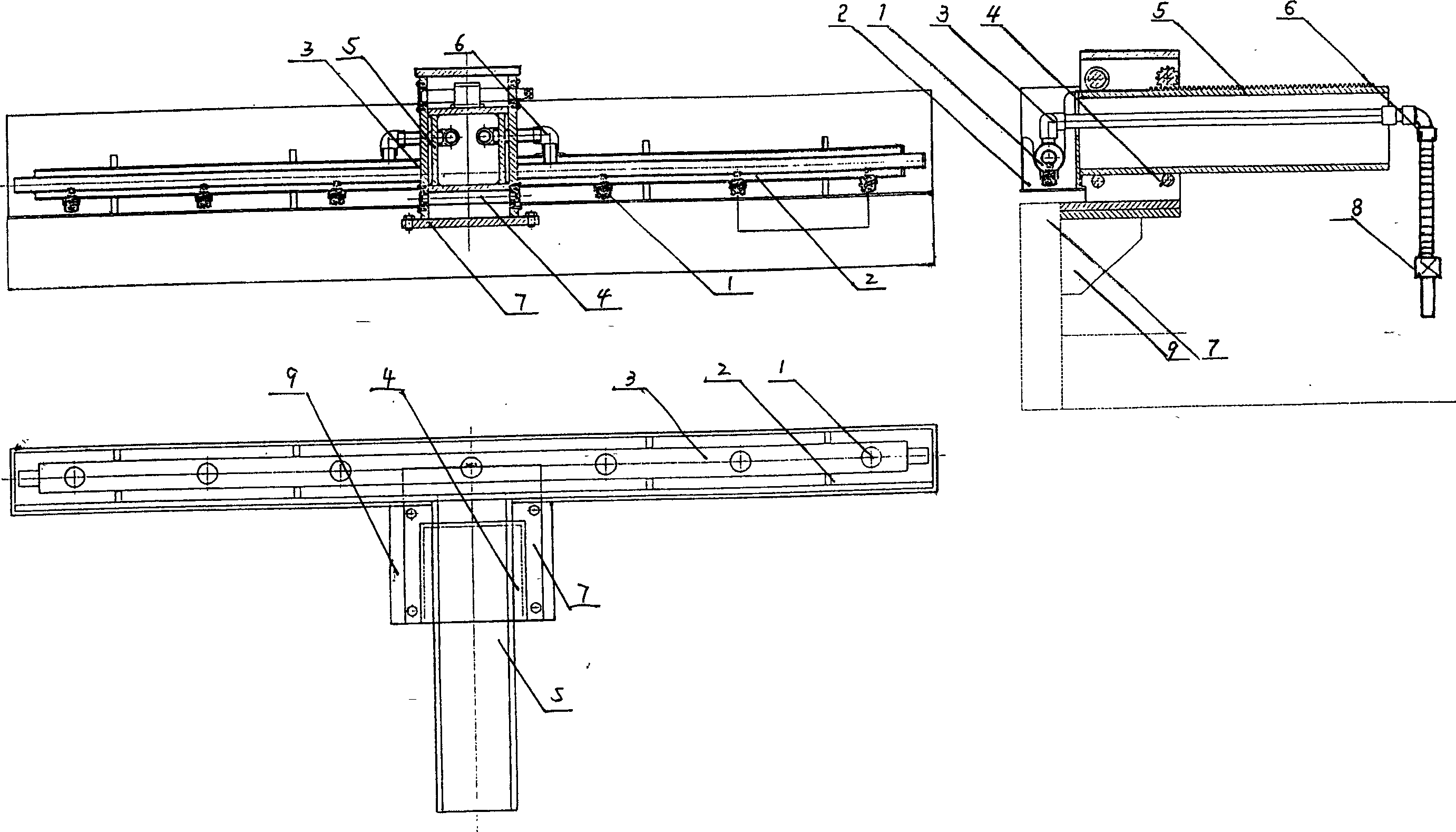

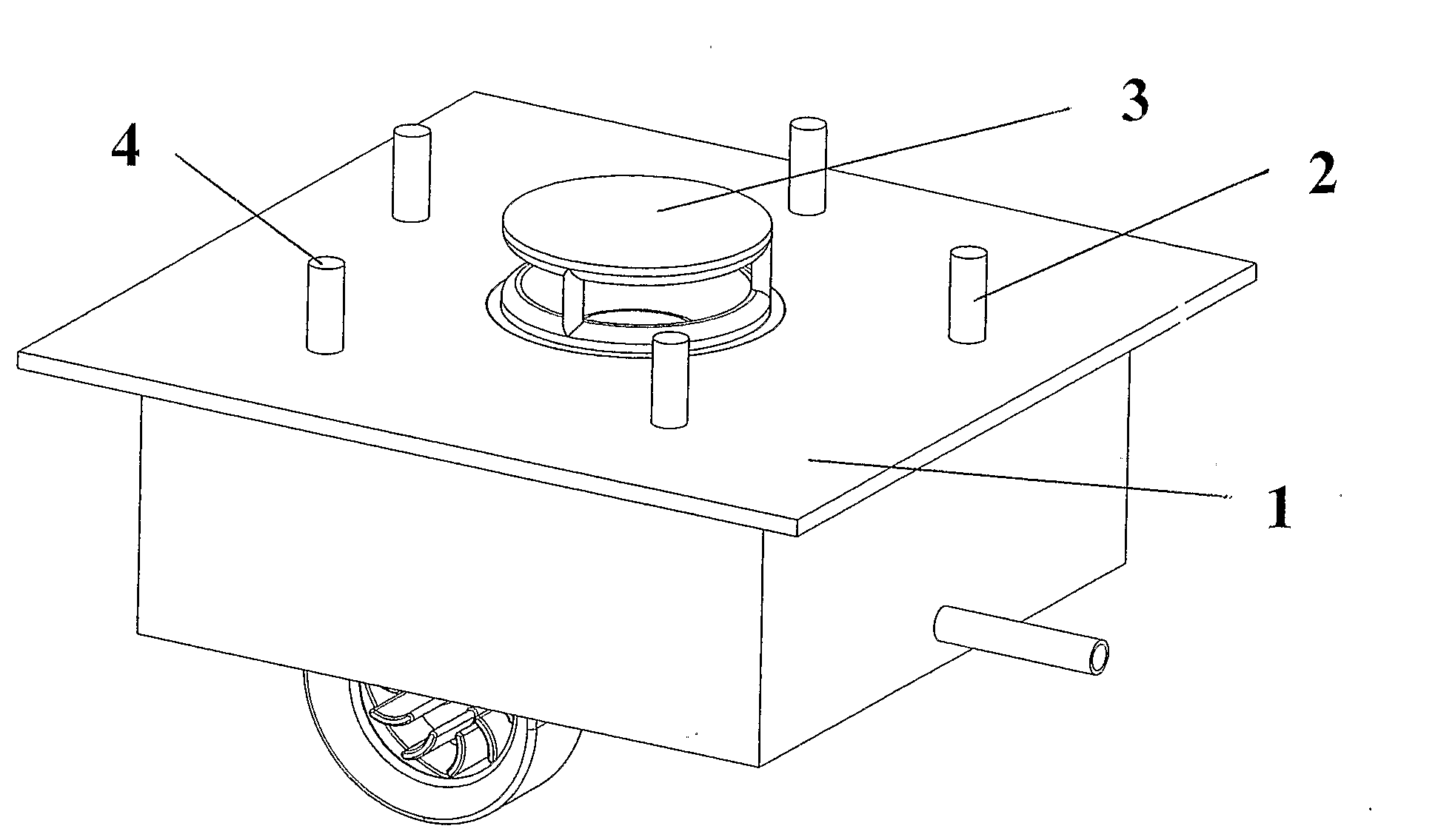

Stelmo line gas spray cooling device and method for high-speed wire rod mill

InactiveCN1603021AControllable water volumeWater pressure adjustableWork treatment devicesMetal rolling arrangementsForced-airEngineering

The invention simultaneously solves building the contact organization, the performance is uneven question. The invention has provides a kind of gas spray cooling system and the method, namely after the spinning machine, style touches in front of the air blower a section of air cooled table place above, two sides symmetrical establishes the gas spray chiller, first builds above the contact from the coil, key to builds the contact to leave the atomization to cool, then style touches the forced-air cooling line again from the underneath forced-air cooling, and uses the' good spirit installment concentratly blowing the contact place. The intensity difference between the line material build contact through the gas spray cooling system and the no build contact is fall to 5~7MPa; The overall intensity of the line material may enhance 20~25MPa; Improves the surface quality; Simultaneously decreases the ambient temperature, improves the operating environment.

Owner:UNIV OF SCI & TECH LIAONING

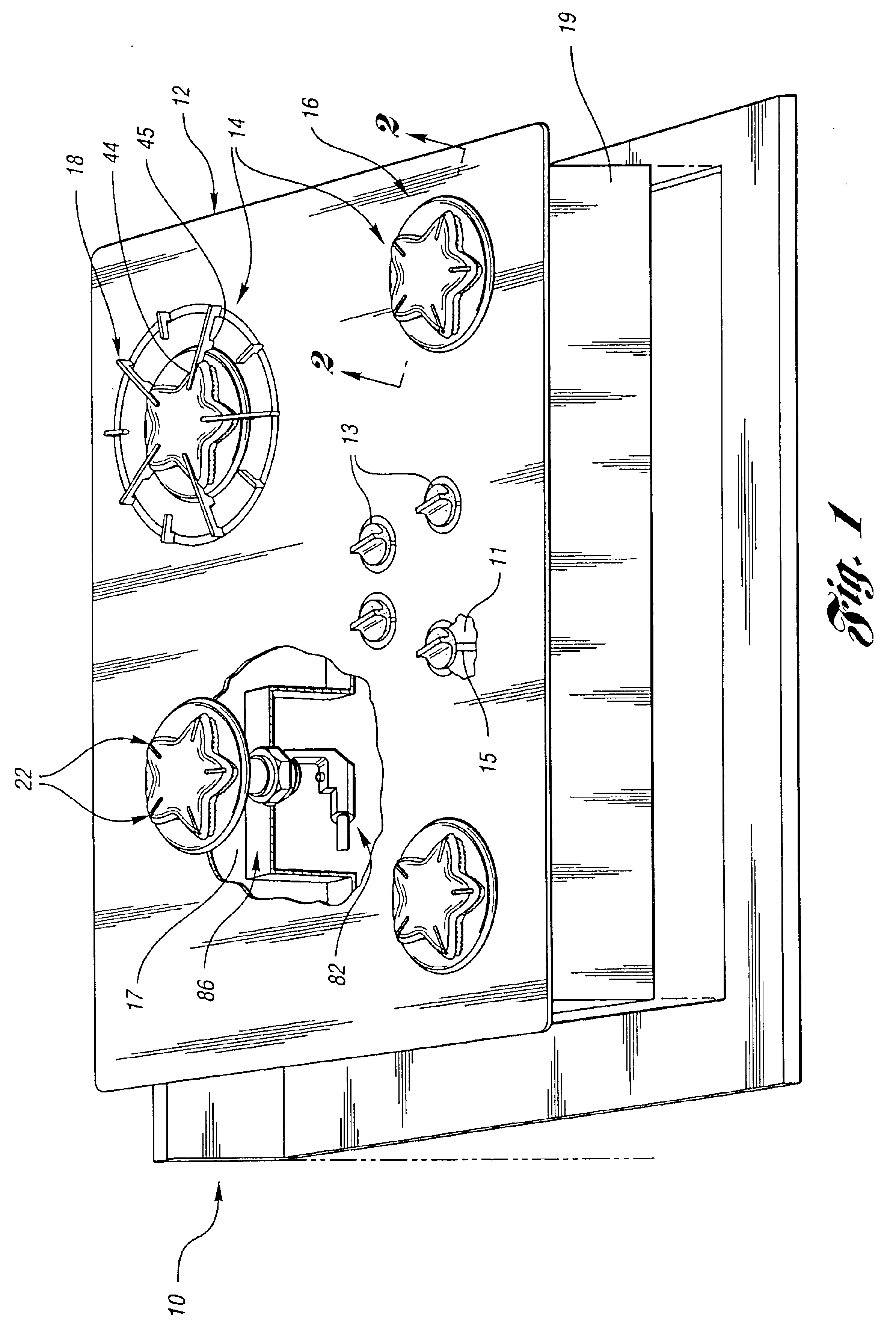

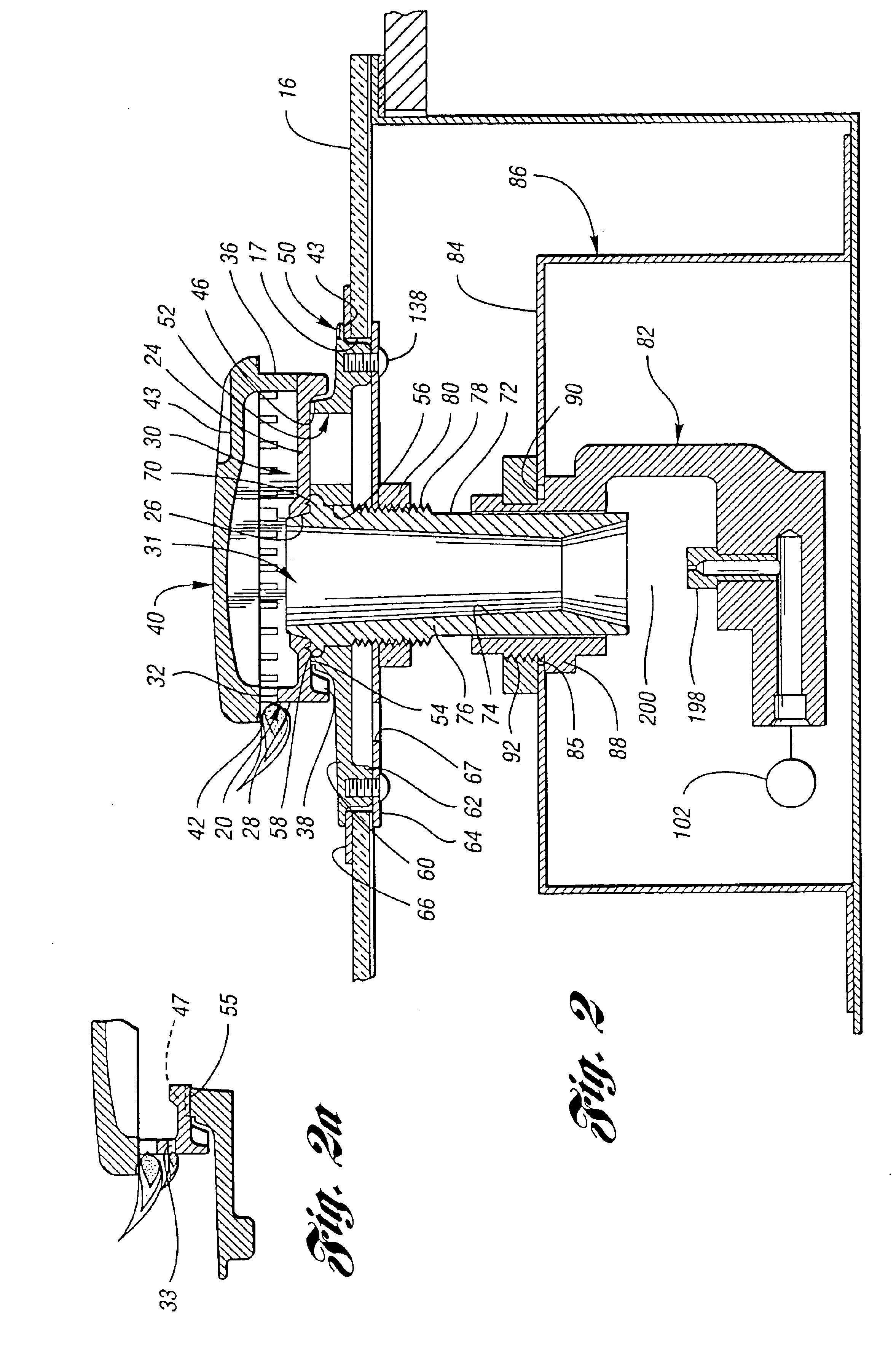

Burner with piloting ports

InactiveUS6851420B2Increase the turndown ratioImprove efficiencyDomestic stoves or rangesGaseous fuel burnerCombustorEngineering

A cooking appliance includes burners having ports that are aligned in a defined alignment with respect to an adjacent structure of a burner body or the cooking appliance within a piloting zone so that the adjacent structure guides the formation of a flame kernel at an outlet of the port. The adjacent structure may be ports which also form flame kernels withing the piloting zone of the burner port outlet, a structural portion of the burner body such as an extended lip protruding beyond the burner port or a separate structure such as a flame rod or other target that stabilizes the flame kernels at the burner port outlet. Such structures provide a method for improving the turndown ratio of burners by preventing lifting or backlash of the flame kernels generated at the burner port outlets by aligning the ports in conjunction with an adjacent structure within a piloting zone.

Owner:BSH HOME APPLIANCES CORP

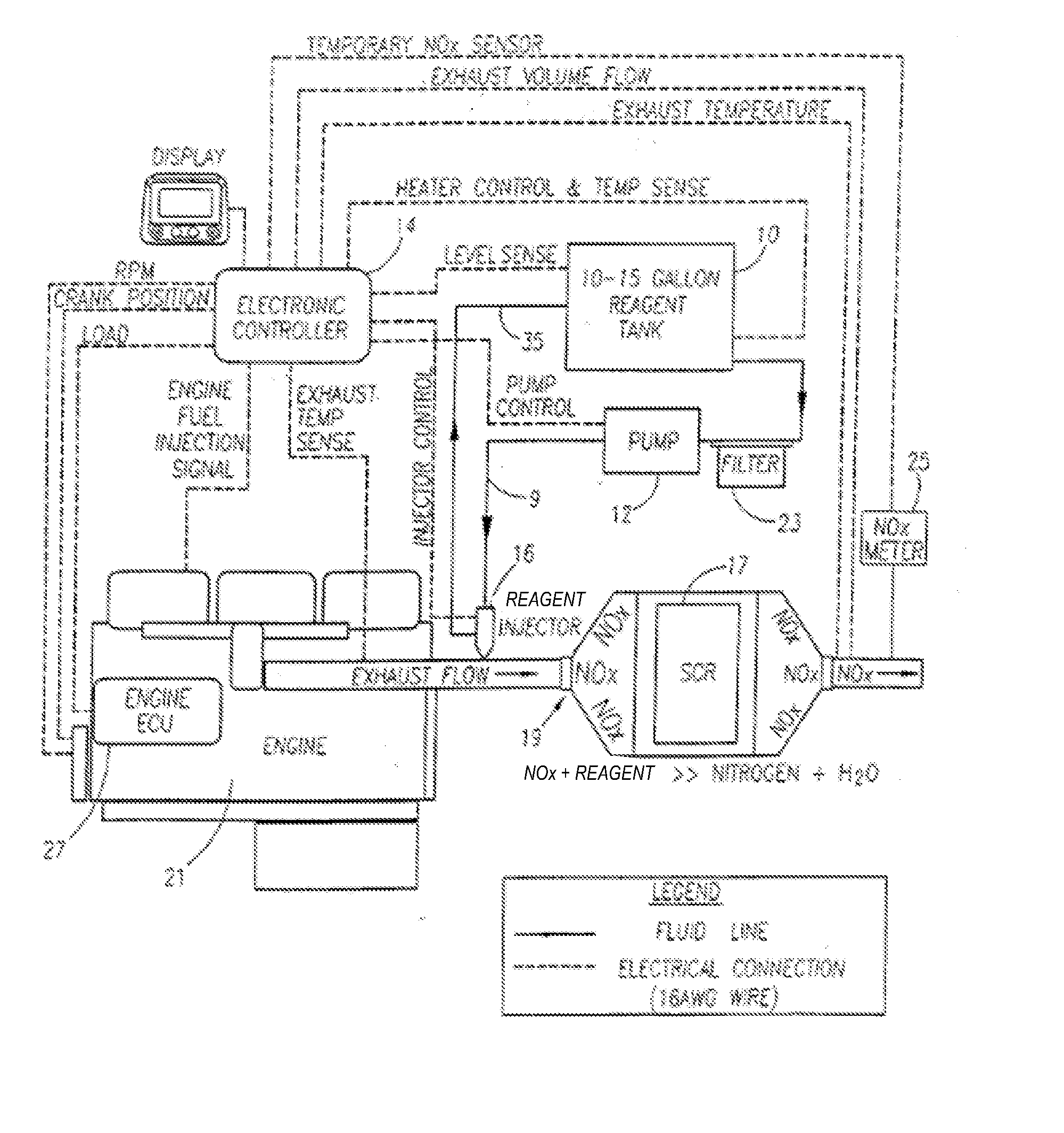

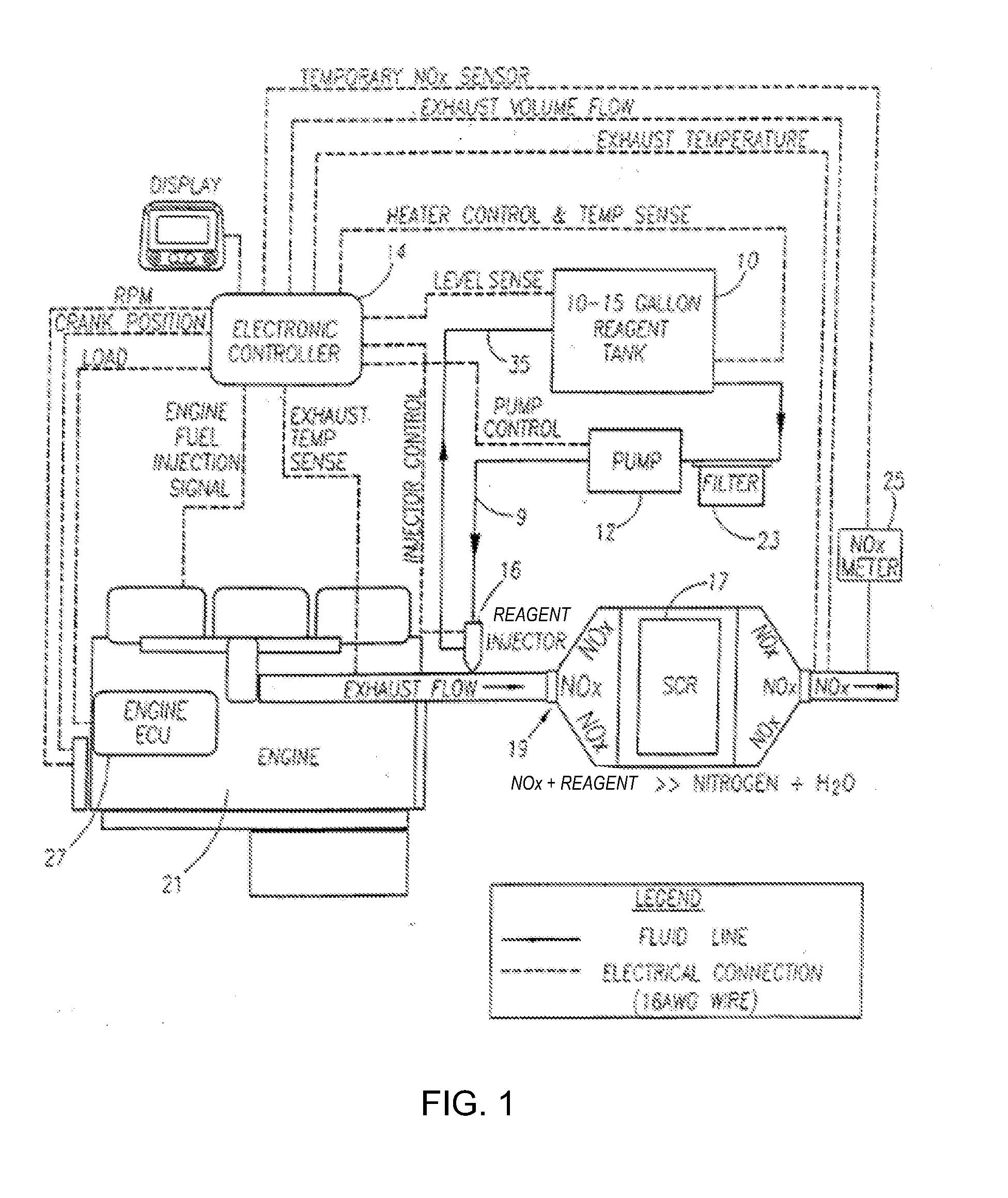

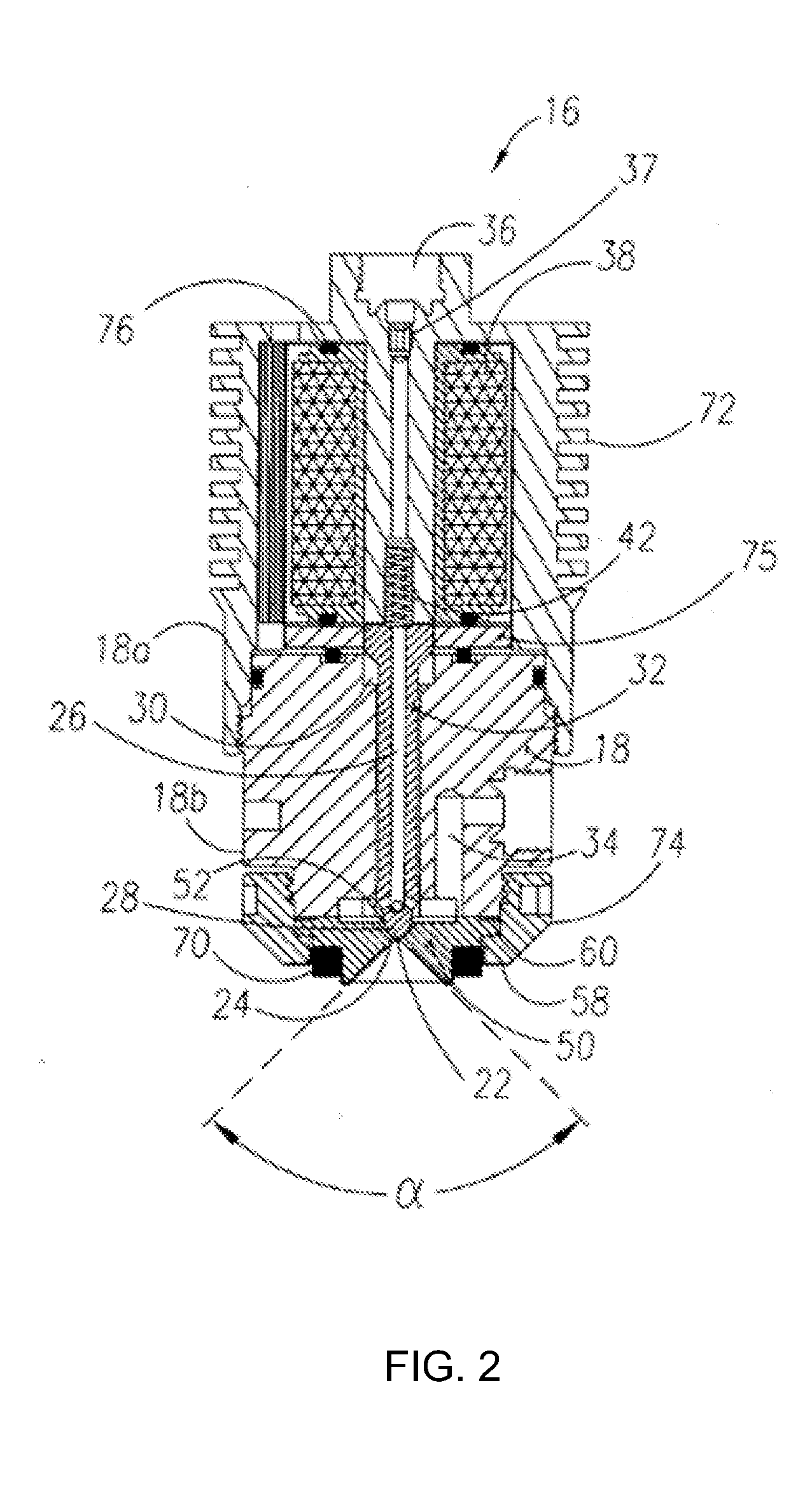

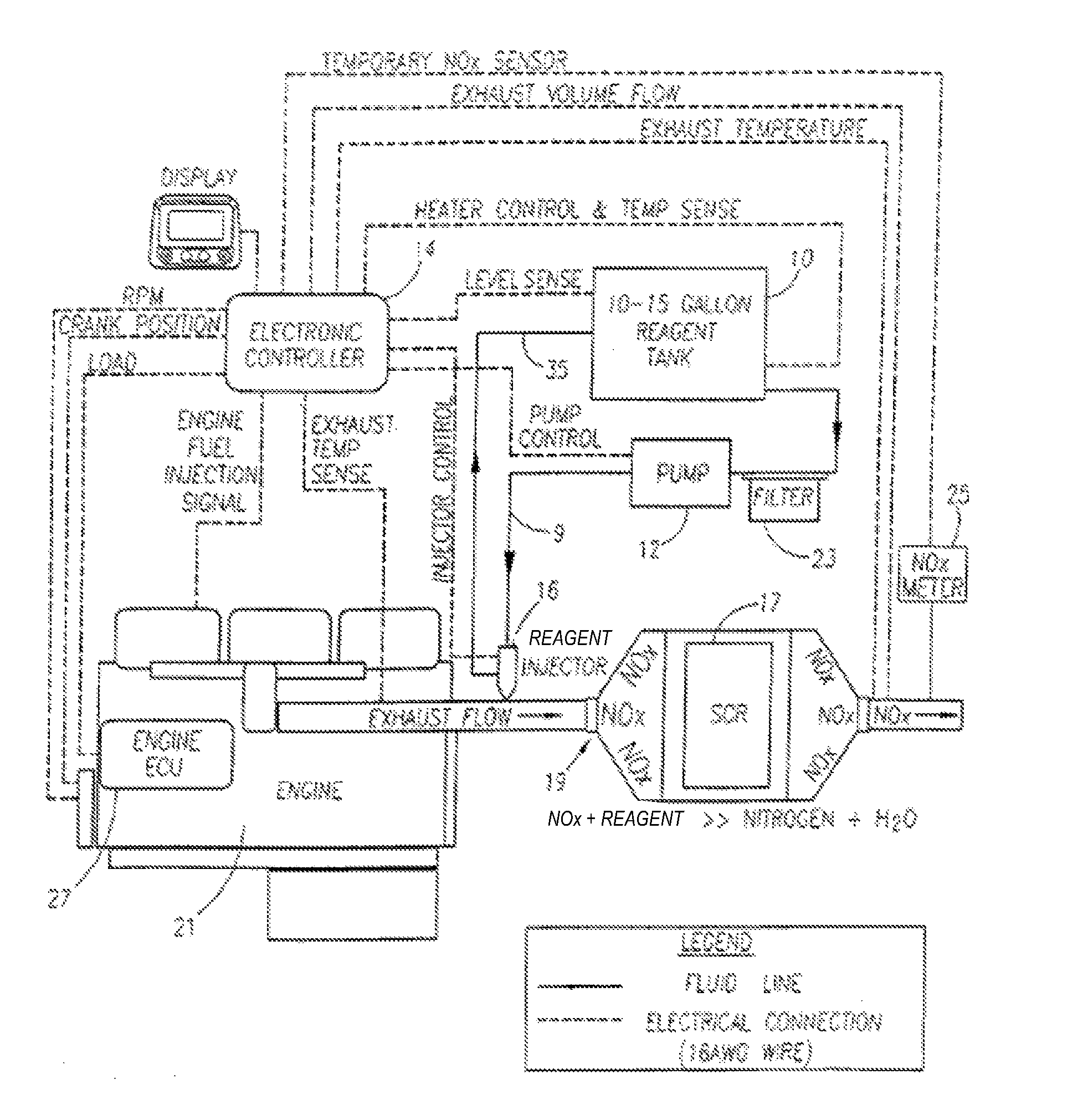

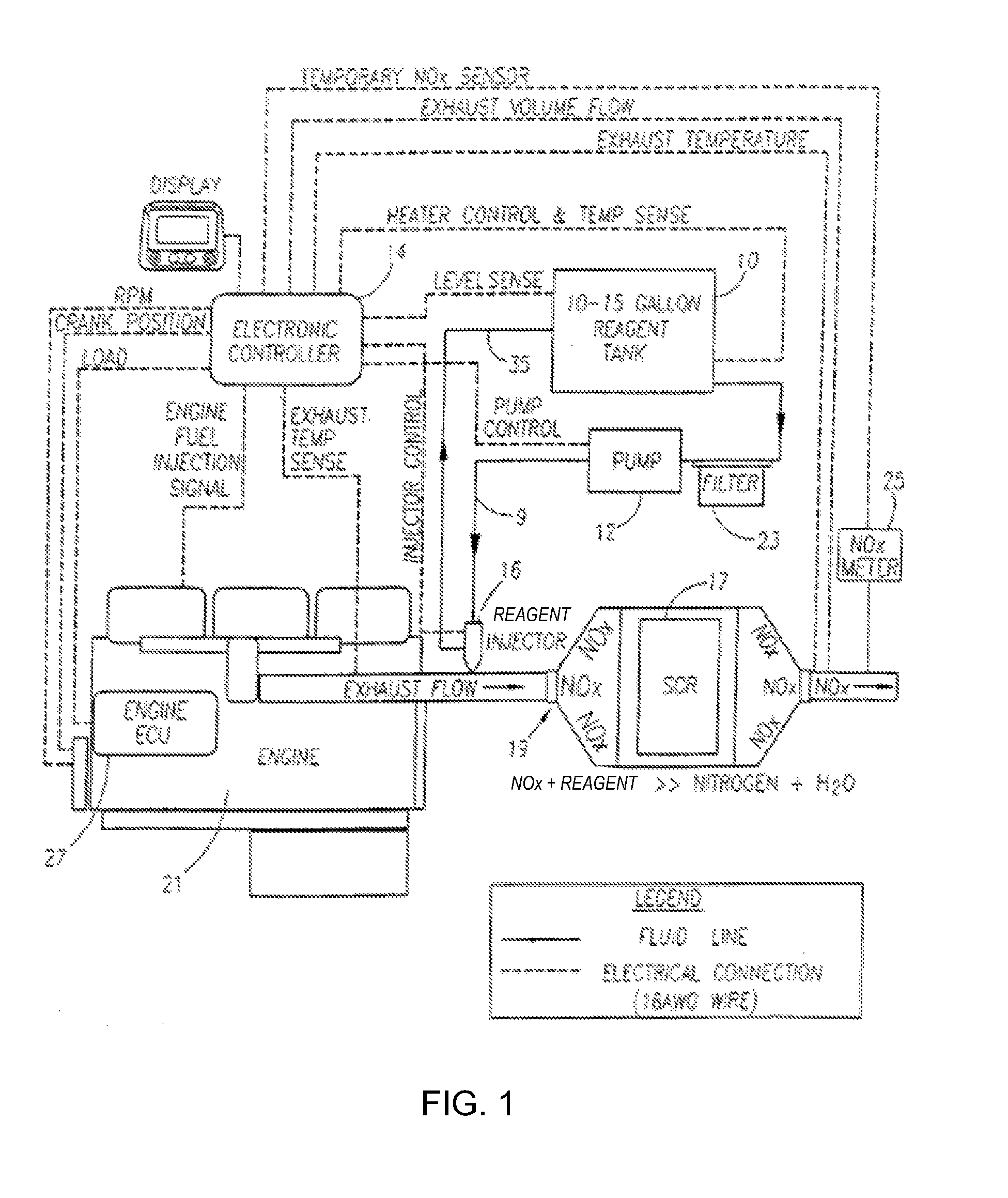

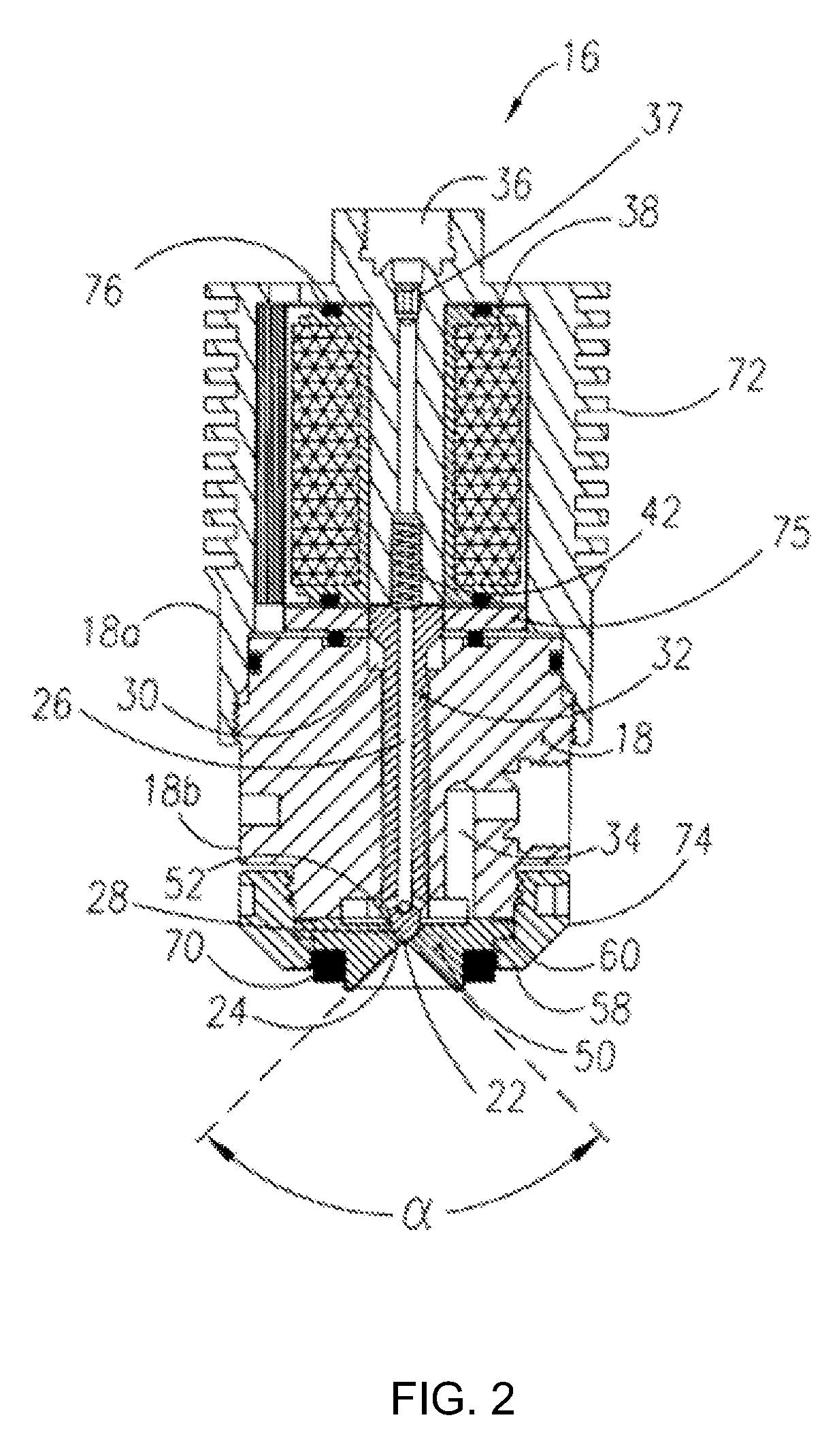

Method And Apparatus For Reducing Emissions In Diesel Engines

InactiveUS20080022654A1Emission reductionReduce flow rateInternal combustion piston enginesExhaust apparatusEngineeringInlet pressure

A method of reducing emissions from a diesel engine including the steps of providing an injector to an exhaust outlet of the diesel engine, the injector having an orifice with a diameter of about 0.006 inch or less, providing a reagent to the injector at an inlet pressure between about 120 psi and about 60 psi, actuating the injector on and off at a frequency between about 10 Hz and about 1 Hz with an on-time of about 1% or more, injecting the reagent via the orifice into the exhaust outlet at an injection rate, and wherein varying of at least two of the inlet pressure, the frequency, and the on-time achieves a turn-down ratio of a maximum injection rate to a minimum injection rate of at least about 31:1.

Owner:TENNECO AUTOMOTIVE OPERATING CO INC

Compact low NOx gas burner apparatus and methods

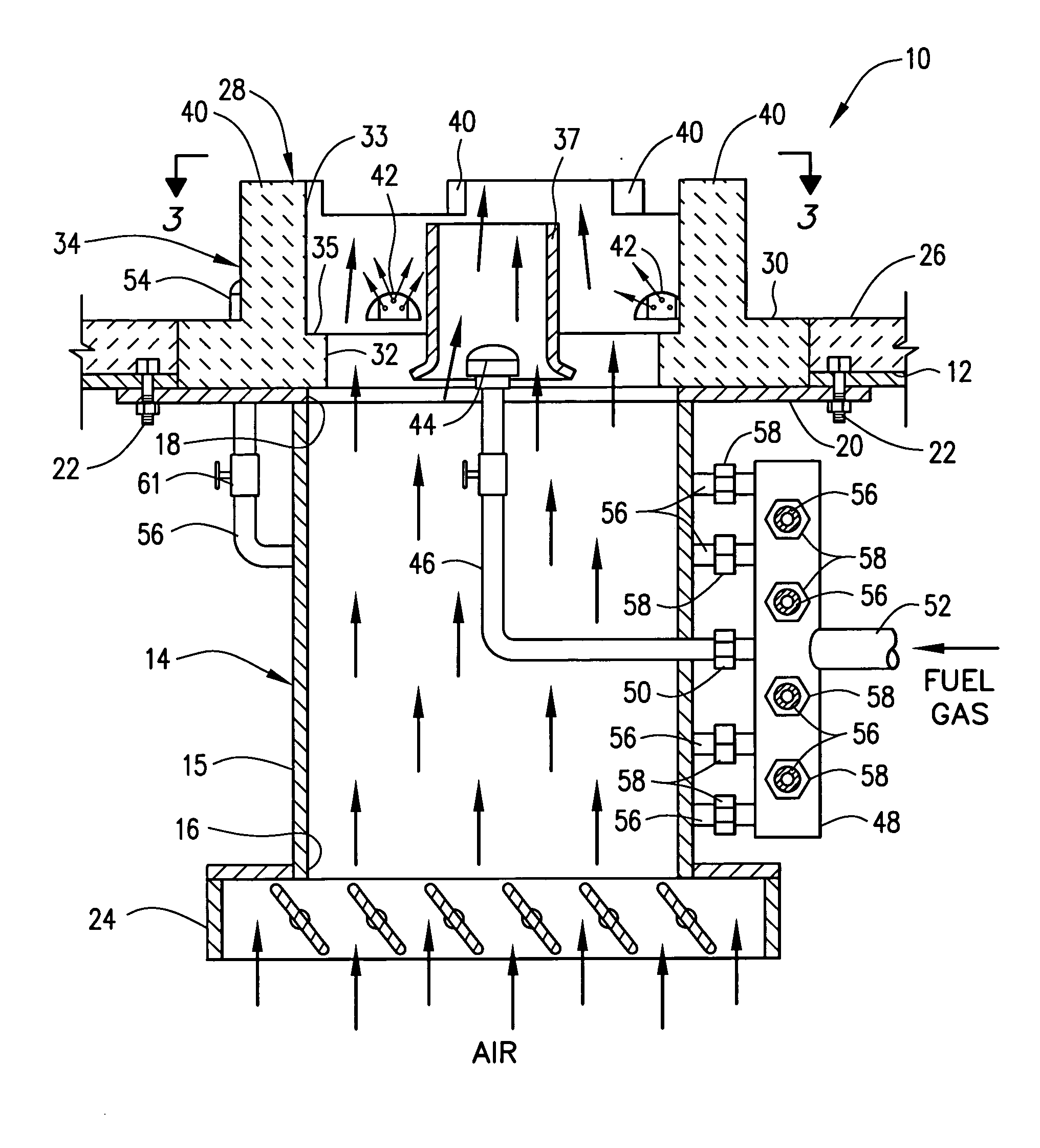

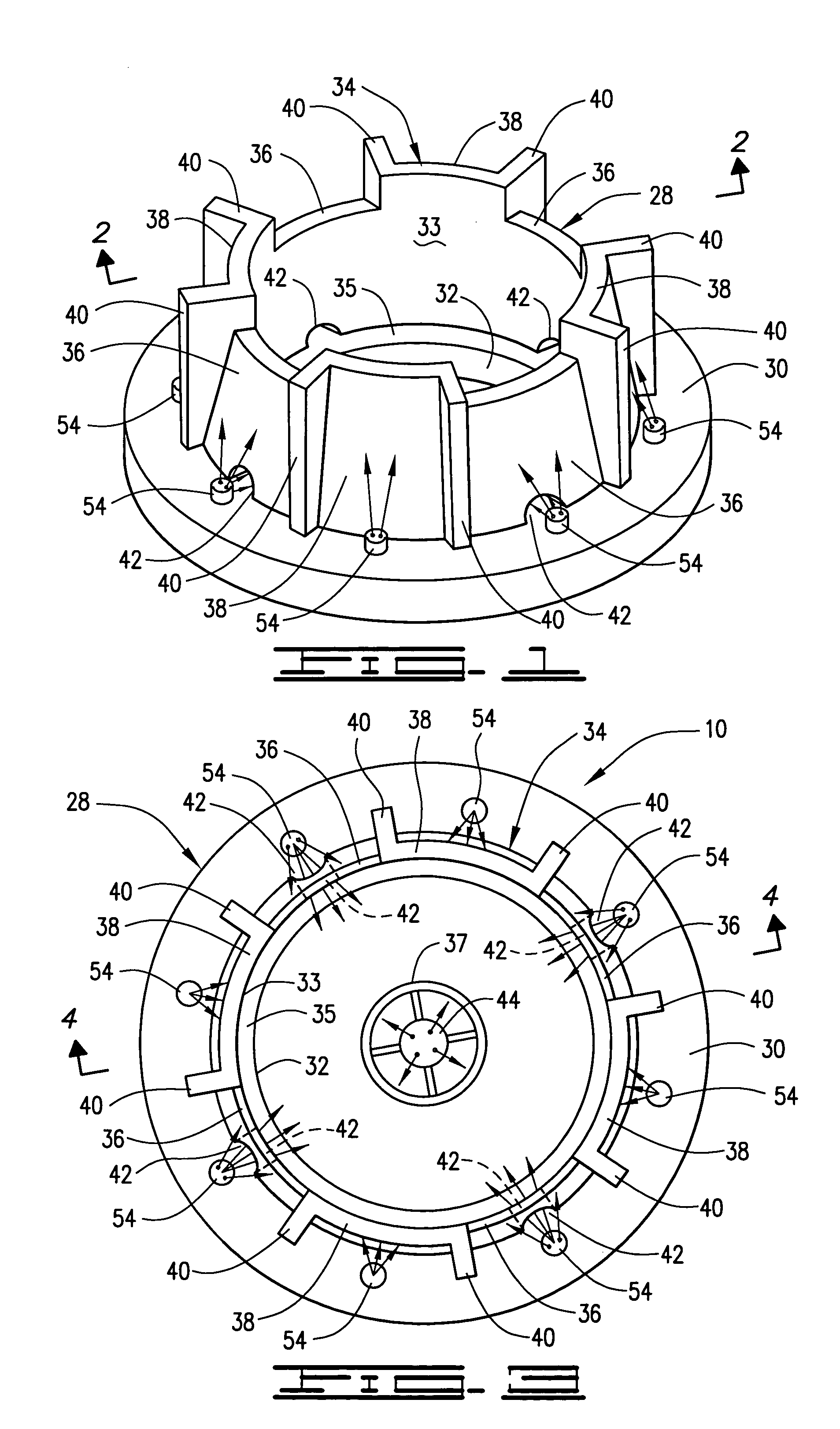

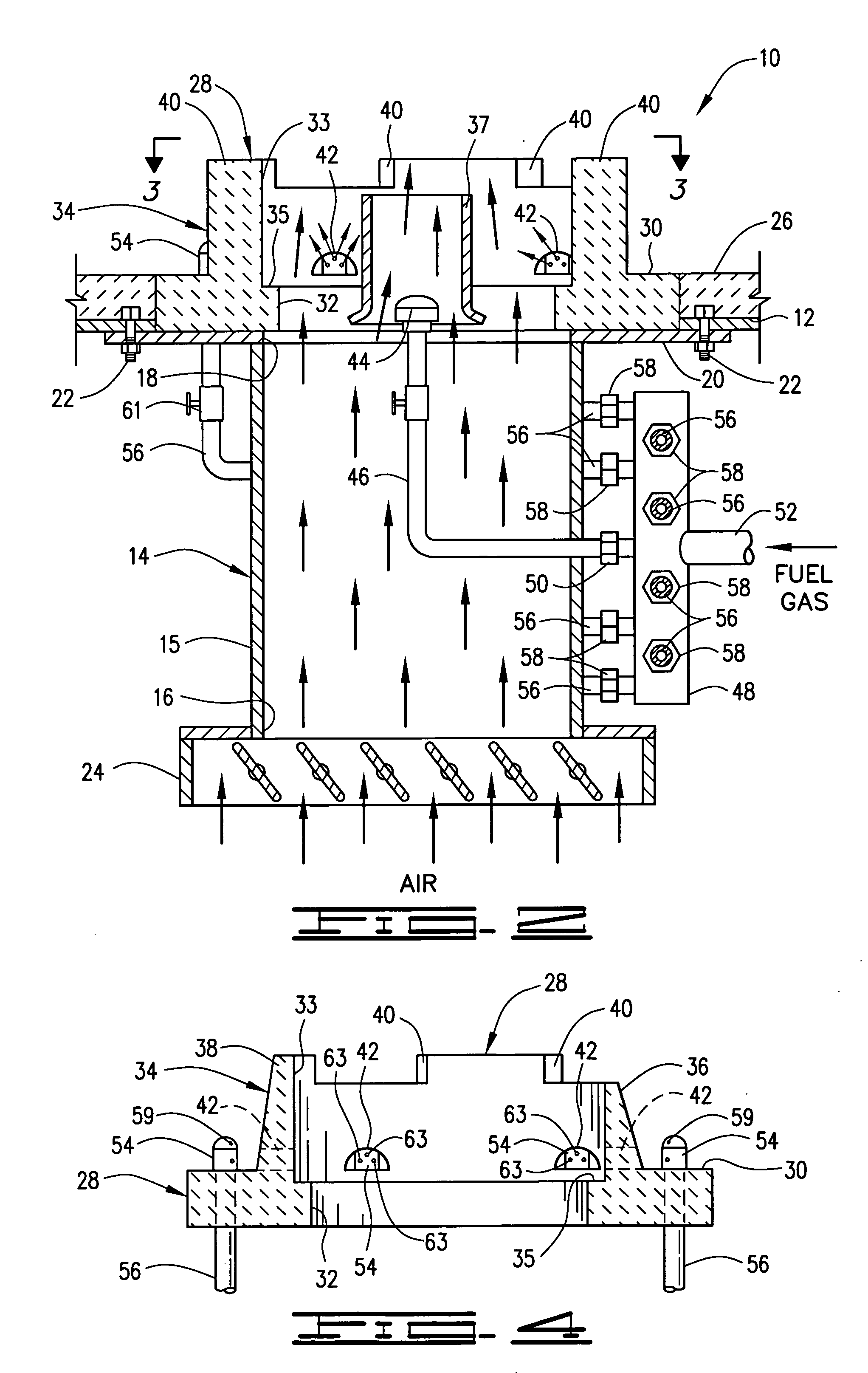

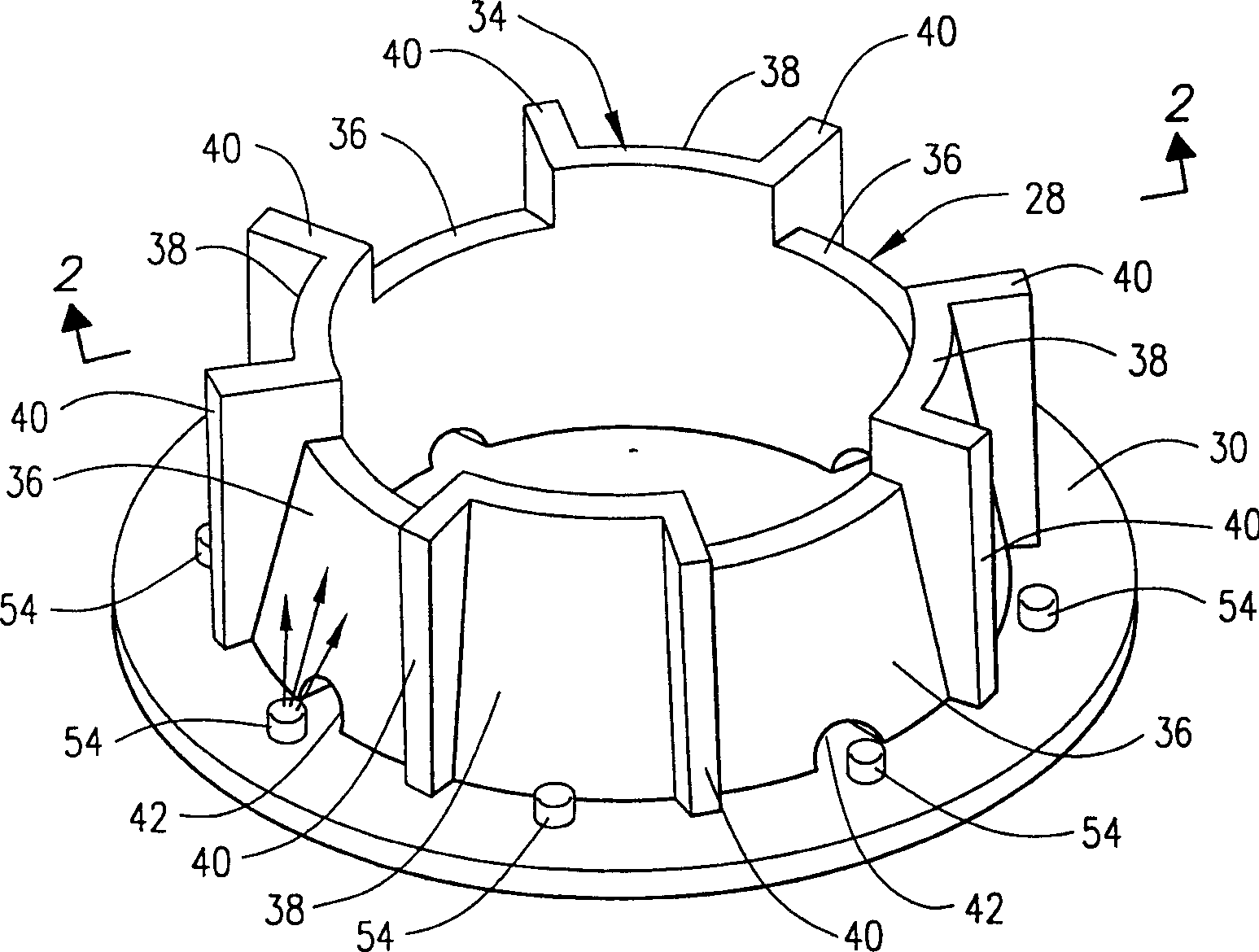

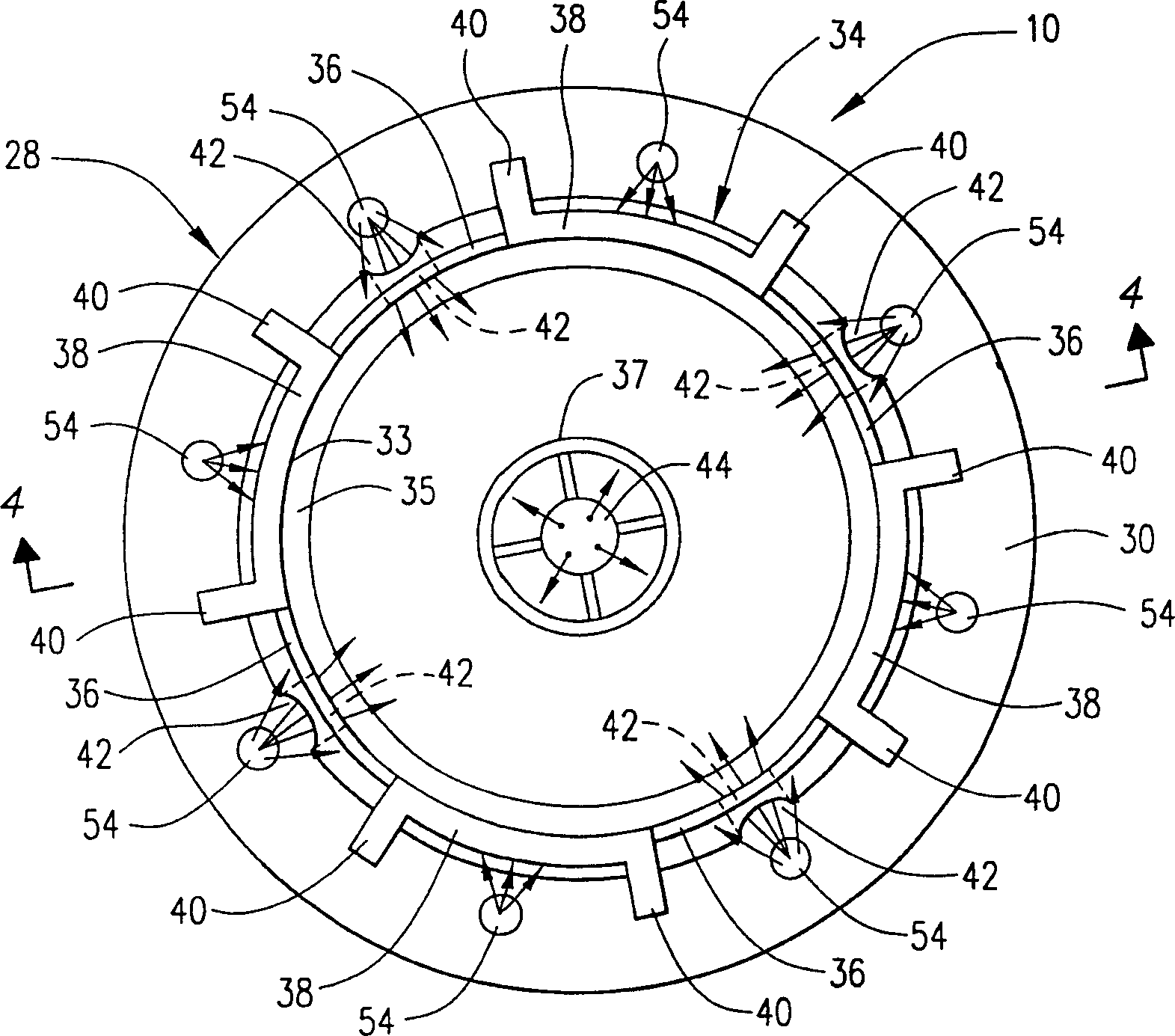

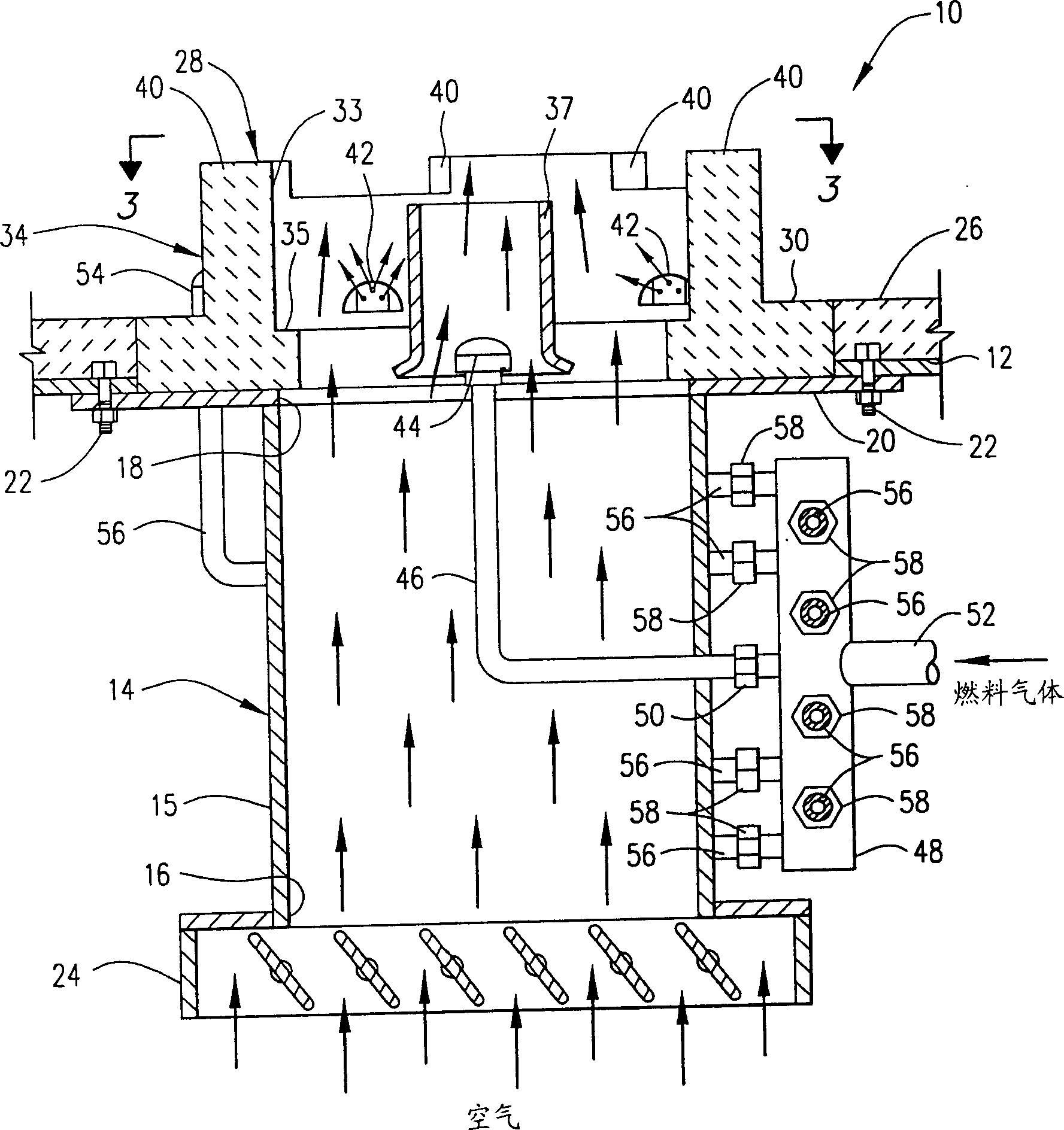

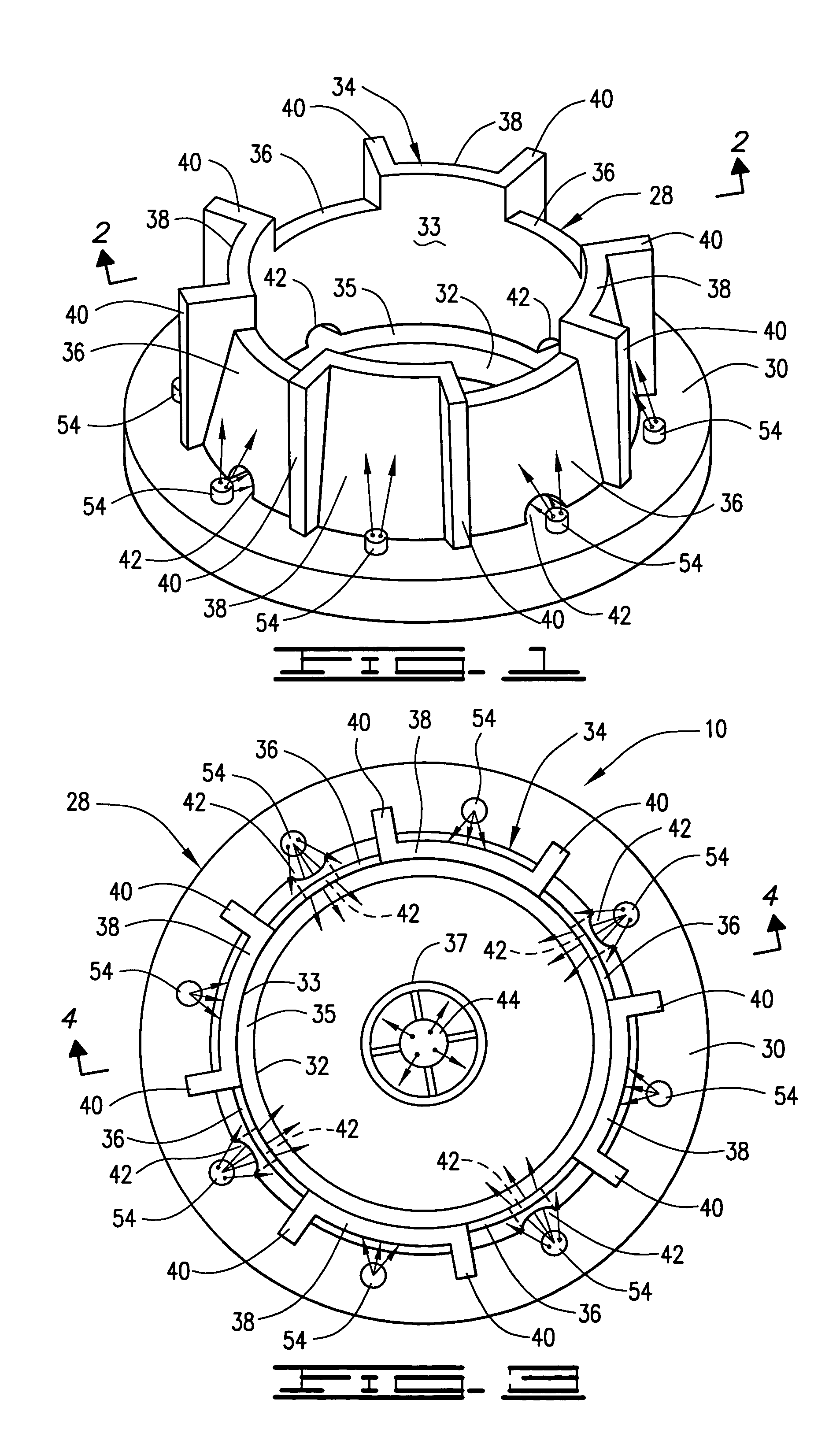

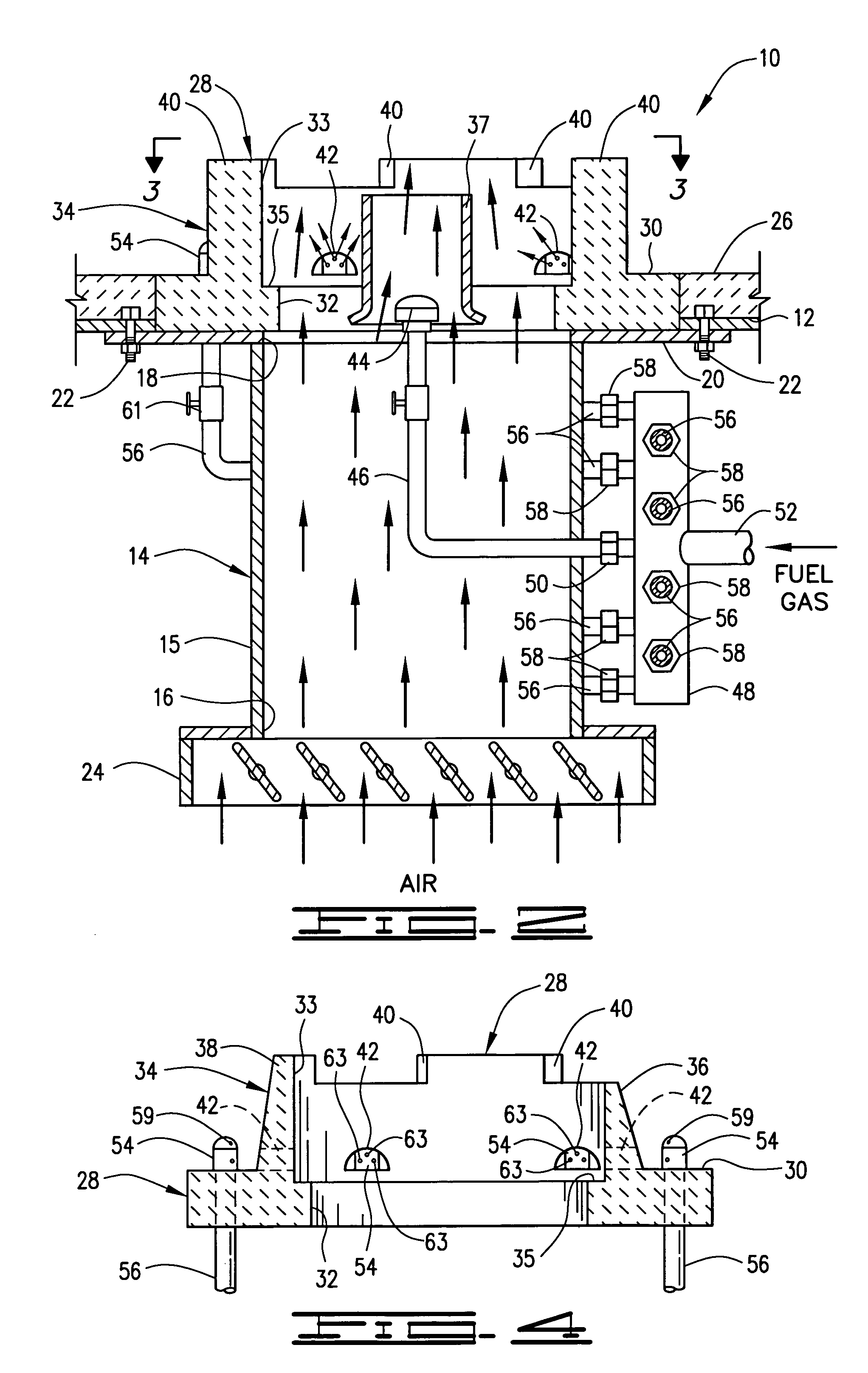

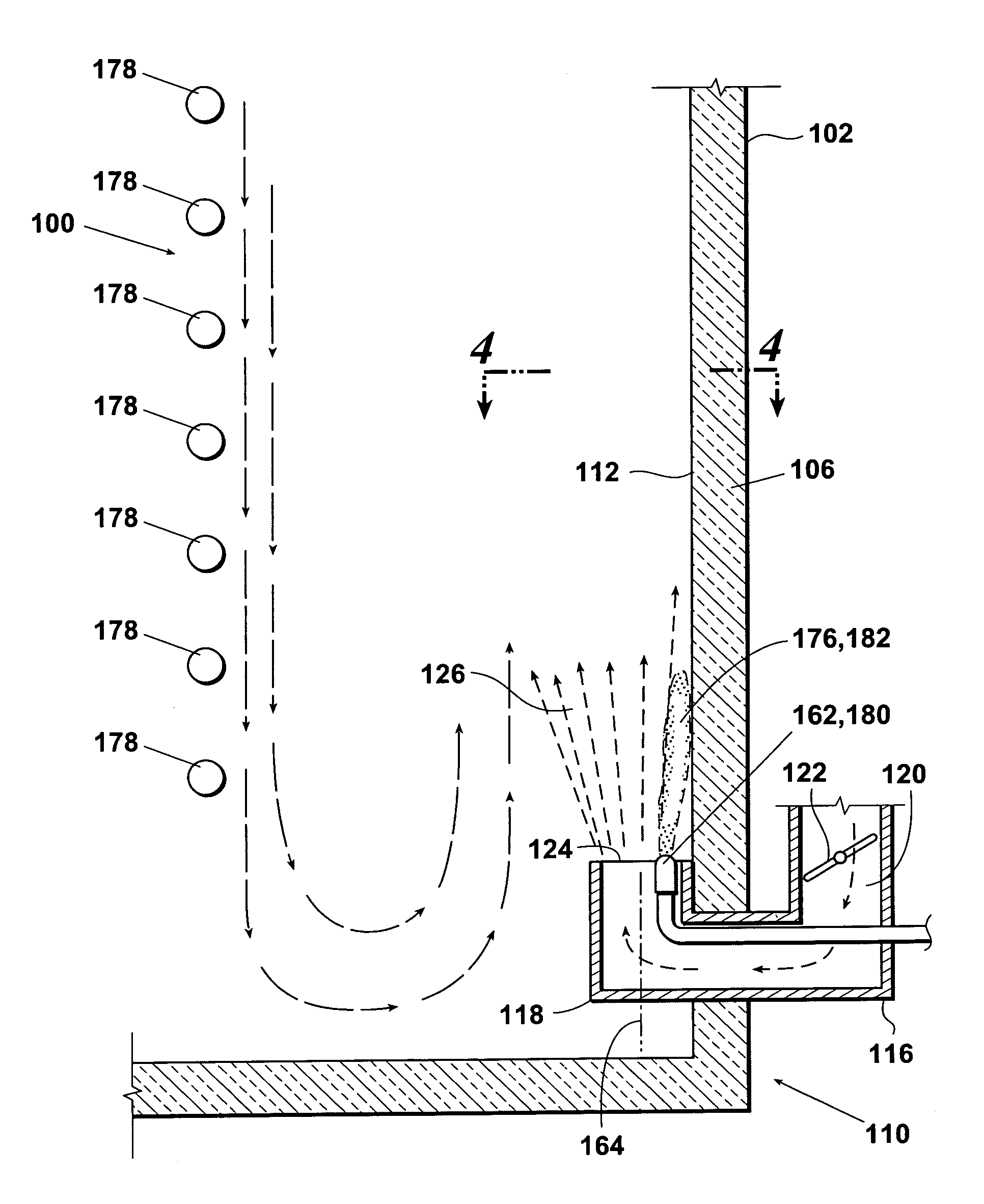

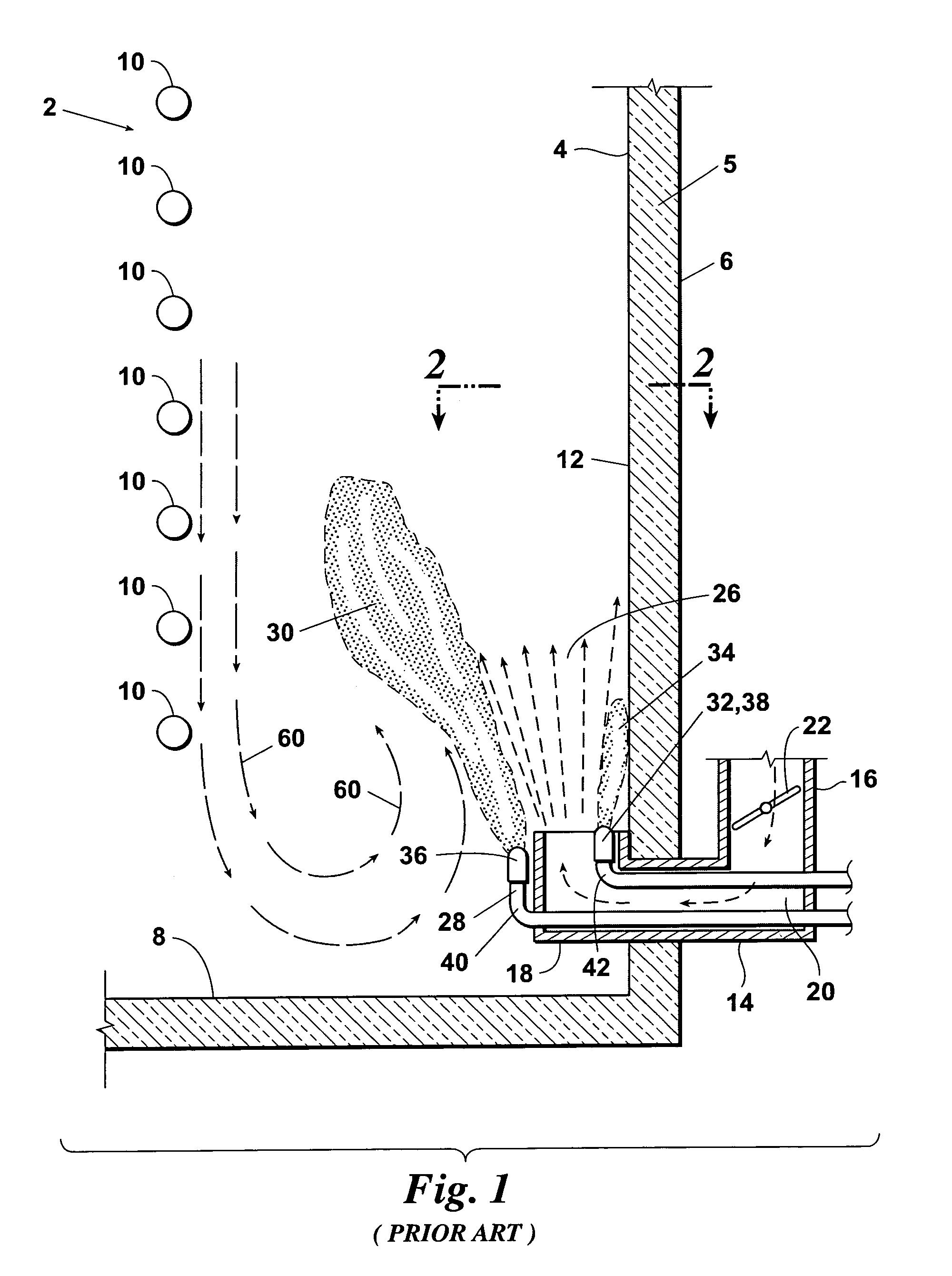

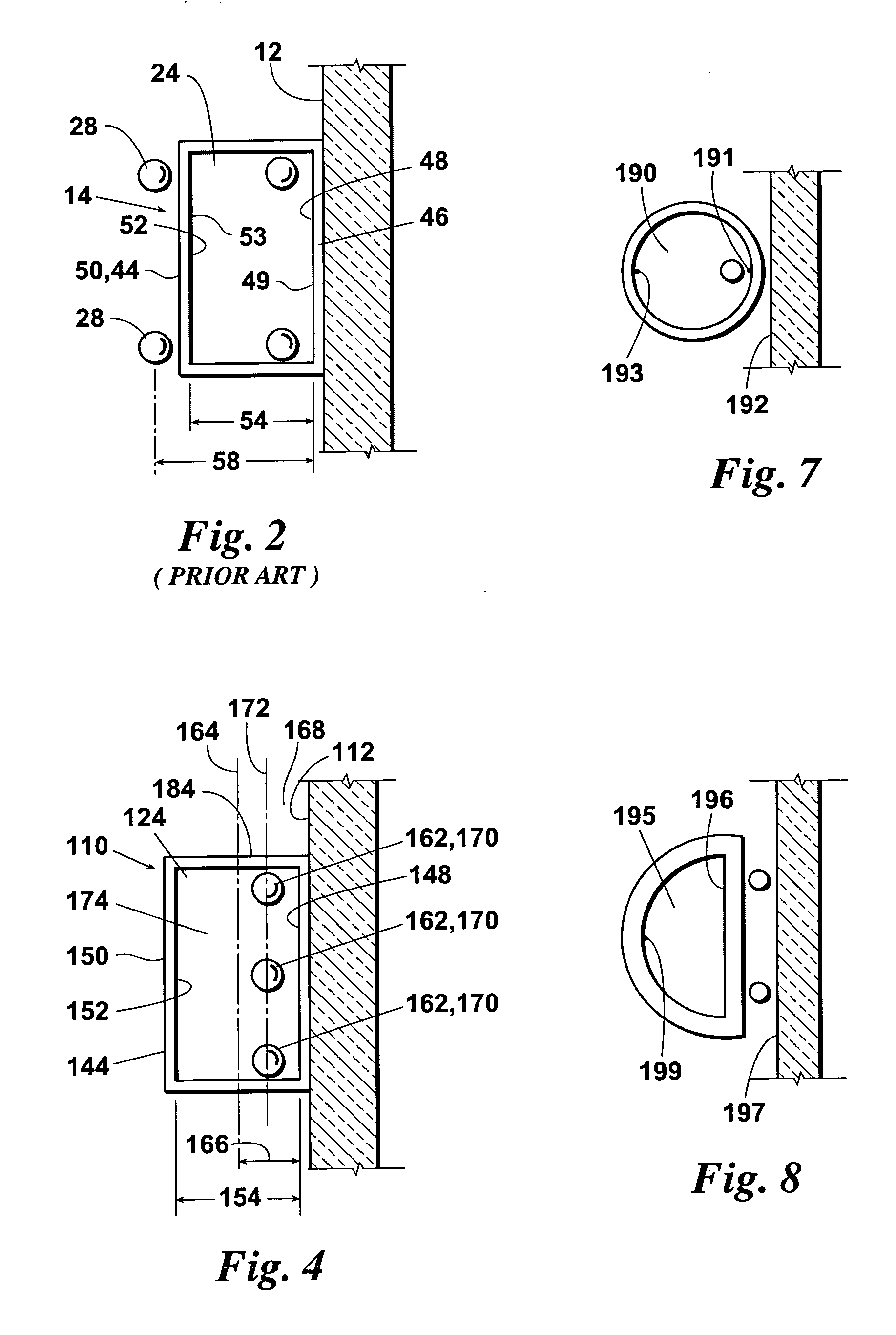

ActiveUS20050175945A1Increase the turndown ratioShort flame lengthCombustion using gaseous and pulverulent fuelCombustion using liquid and pulverulent fuelFlue gasEngineering

Compact low NOx gas burner apparatus and methods for discharging fuel gas and air mixtures into furnace spaces wherein the mixture is burned in folded flame patterns and flue gases having low NOx content are formed are provided. A burner apparatus of the invention is basically comprised of a housing having a burner tile attached thereto and means for introducing air therein. The burner tile has an opening therein with a wall surrounding the opening which extends into a furnace space. The exterior sides of the wall are divided into sections by radially positioned baffles with alternate sections having the same or different heights and slanting towards the opening at the same or different angles. Primary fuel gas mixed with flue gases and air is discharged through the burner tile. Secondary fuel gas is discharged adjacent to the external slanted wall sections whereby the secondary fuel gas mixes with flue gases in the furnace space. The resulting fuel gas-flue gases streams mix with the fuel gas-flue gases-air mixture discharged through the burner tile and the resulting mixture is burned in the furnace space.

Owner:JOHN ZINK CO LLC

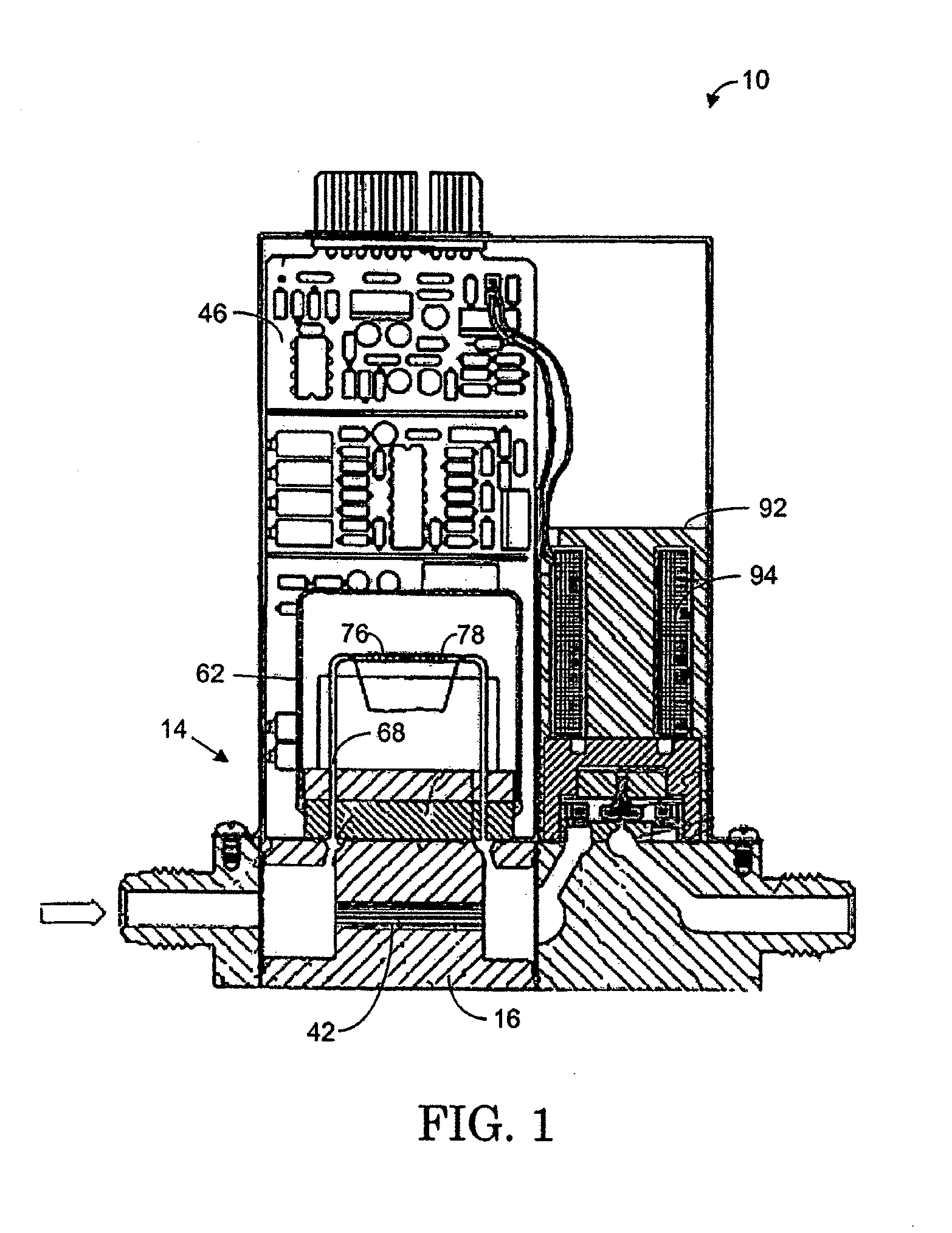

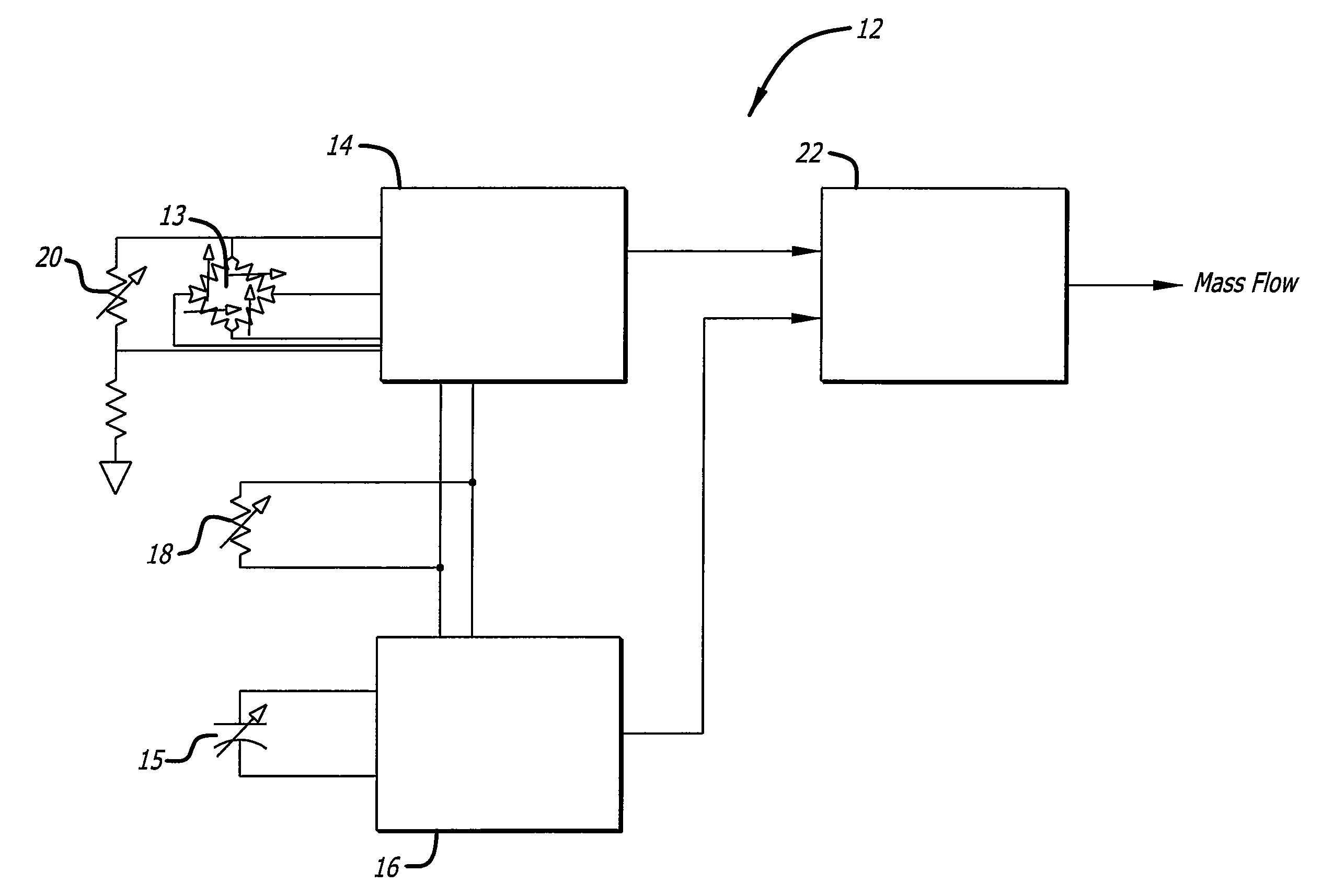

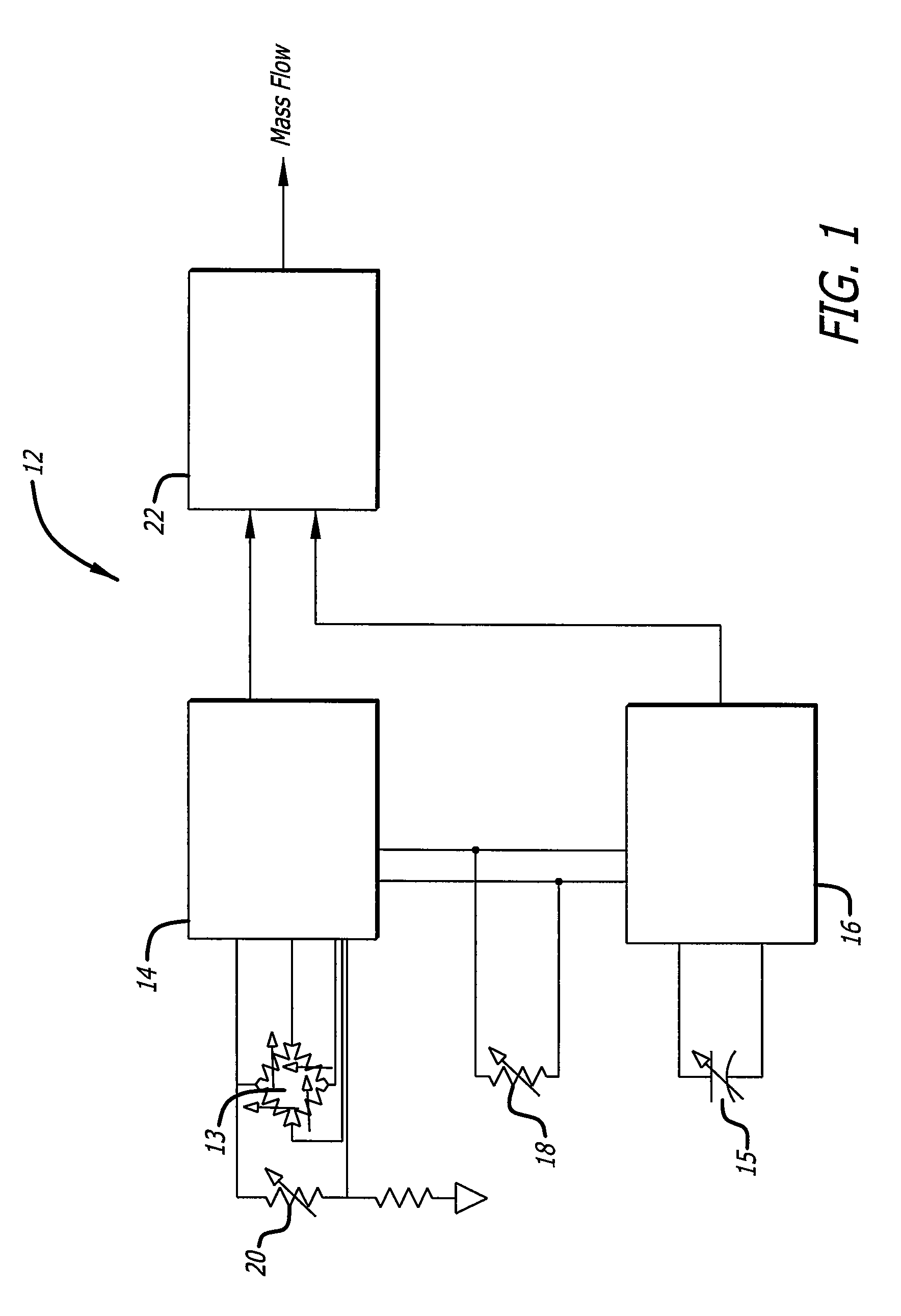

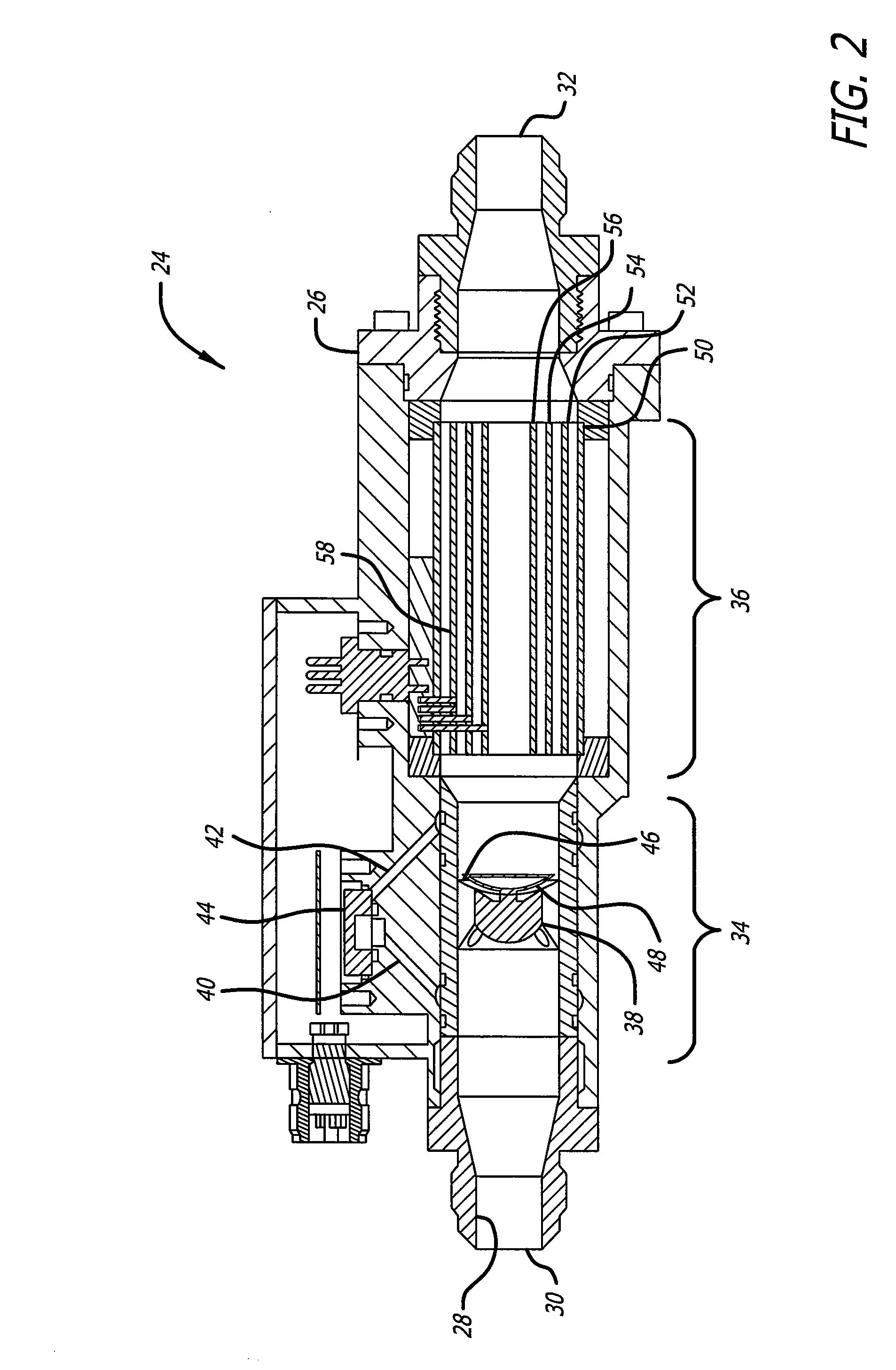

System for and method of providing a wide-range flow controller

ActiveUS7874208B2Improve signal-to-noise ratioIncrease the turndown ratioVolume/mass flow by thermal effectsVolume flow proportion measurementLinear relationshipDischarge measurements

An improved flow measuring device, such as a mass flow meter or mass flow controller, providing a high turn-down ratio as compared to prior art devices. In accordance with various embodiments of the invention, a flow sensor includes a sensor flow path that includes one or more restrictions configured to provide the sensor flow path with a non-linear relationship between a pressure drop across the sensor flow path and the flow of fluid through the flow sensor conduit. Such a flow sensor preferably achieves a high turn-down ratio by way of a variable bypass ratio that is directly proportional to the sensor tube mass flow rate so that the turn-down ratio of the mass flow controller will be ideally proportional to the square of the turndown achievable by the flow sensor conduit fluid sensing portion alone. In some embodiments, the restriction can be employed as a part of a fluid seal having an orifice and disposed between a flow sensor portion of a flow meter and a bypass portion of the flow meter.

Owner:BROOKS INSTRUMENT

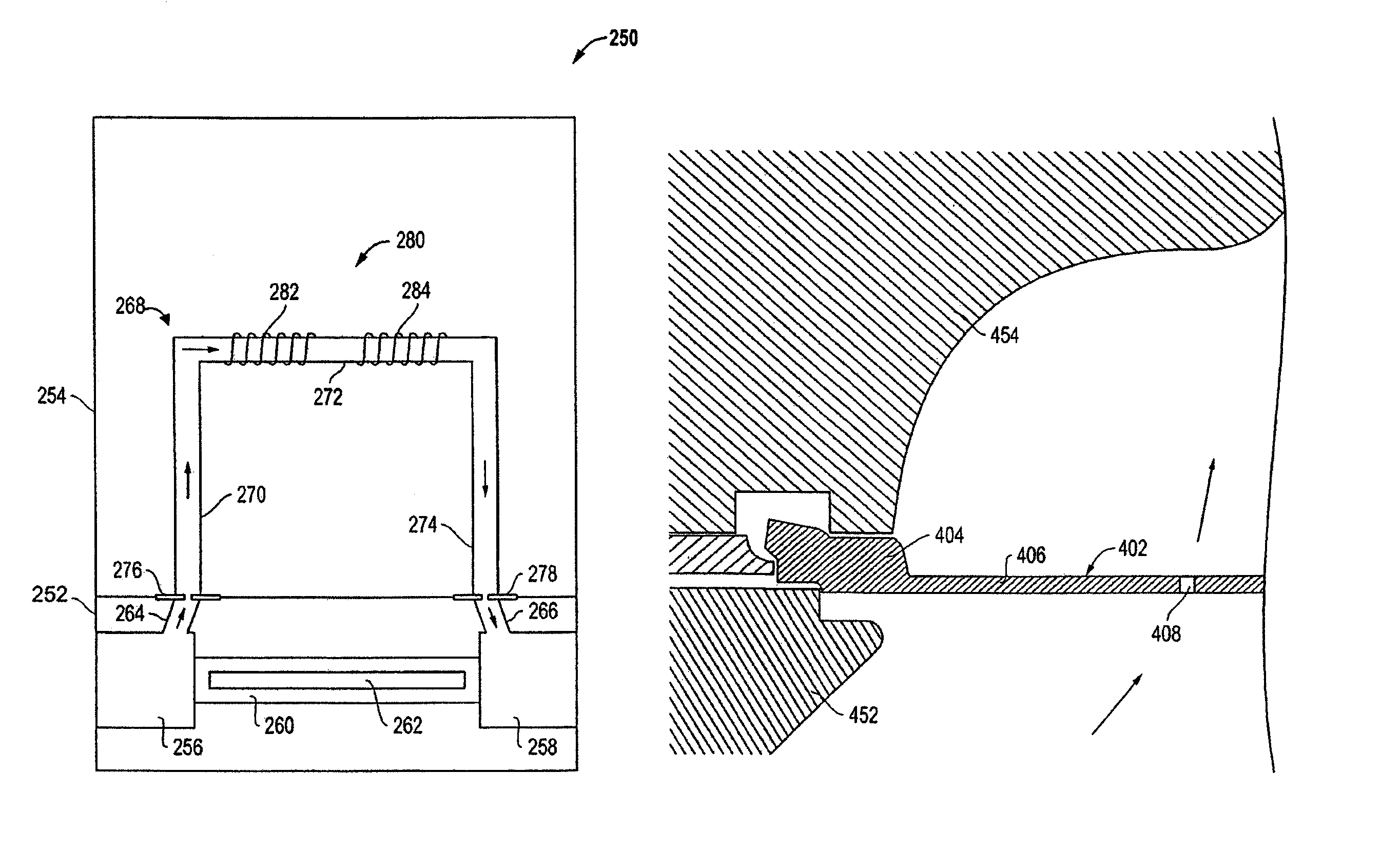

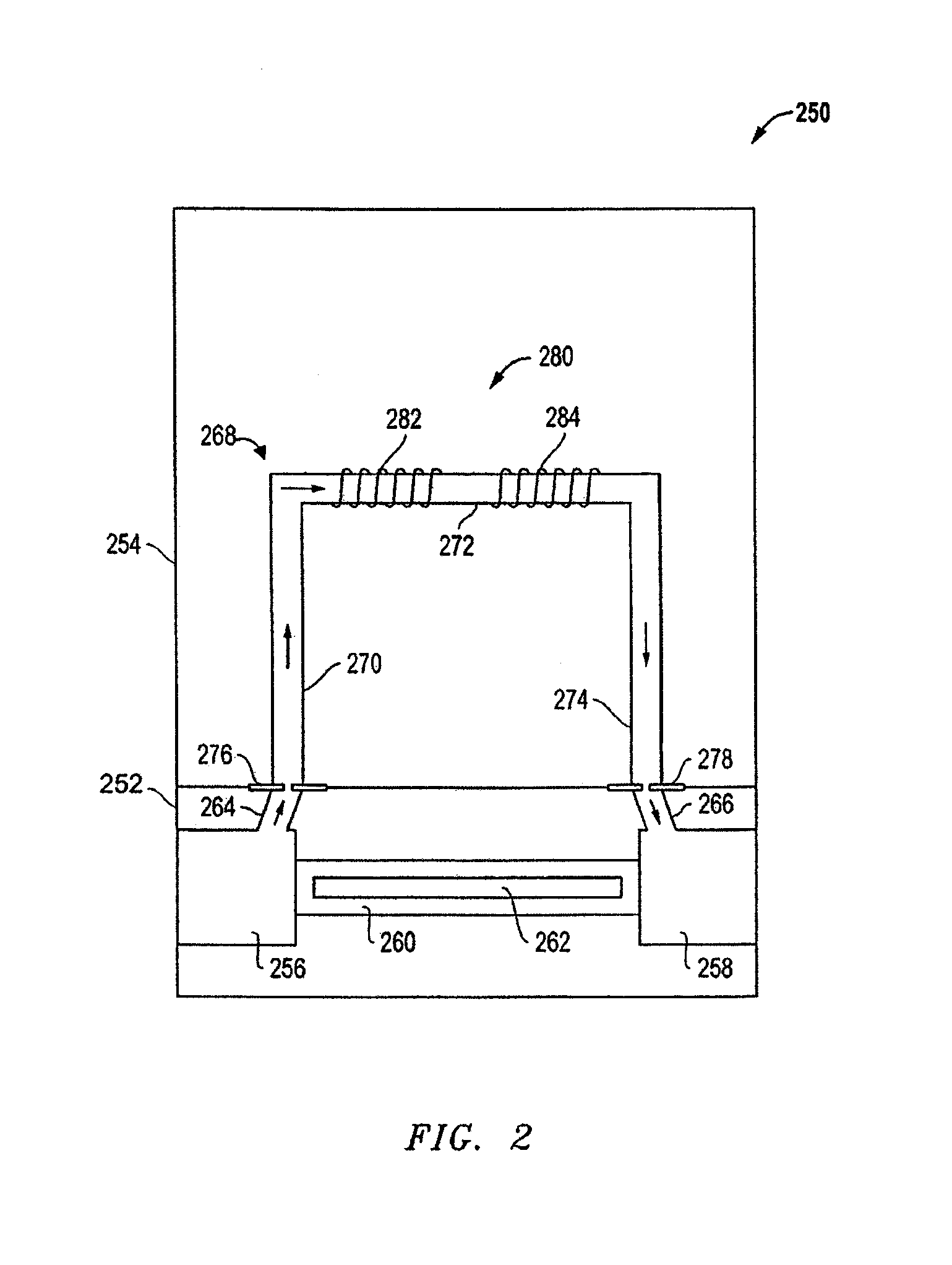

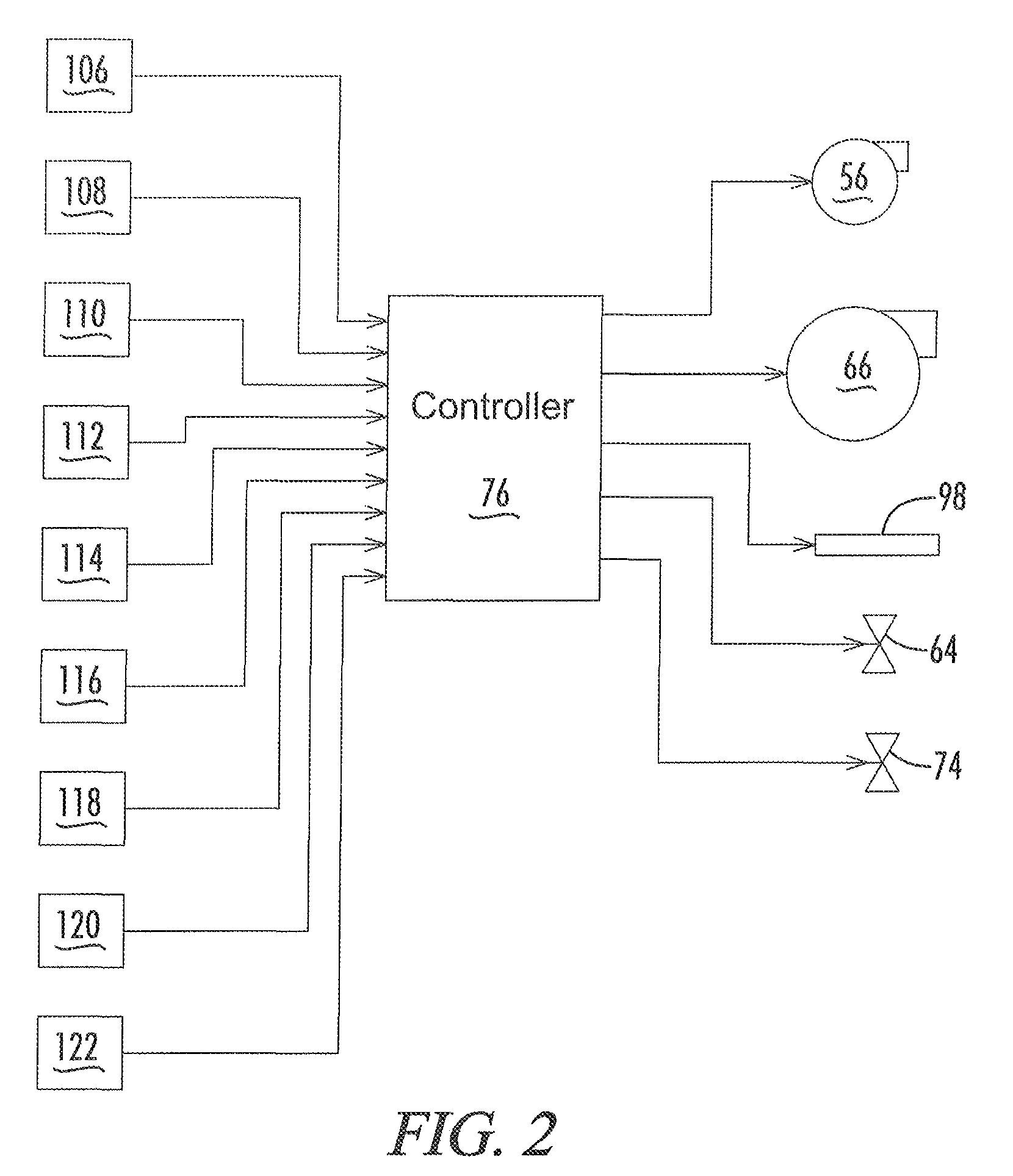

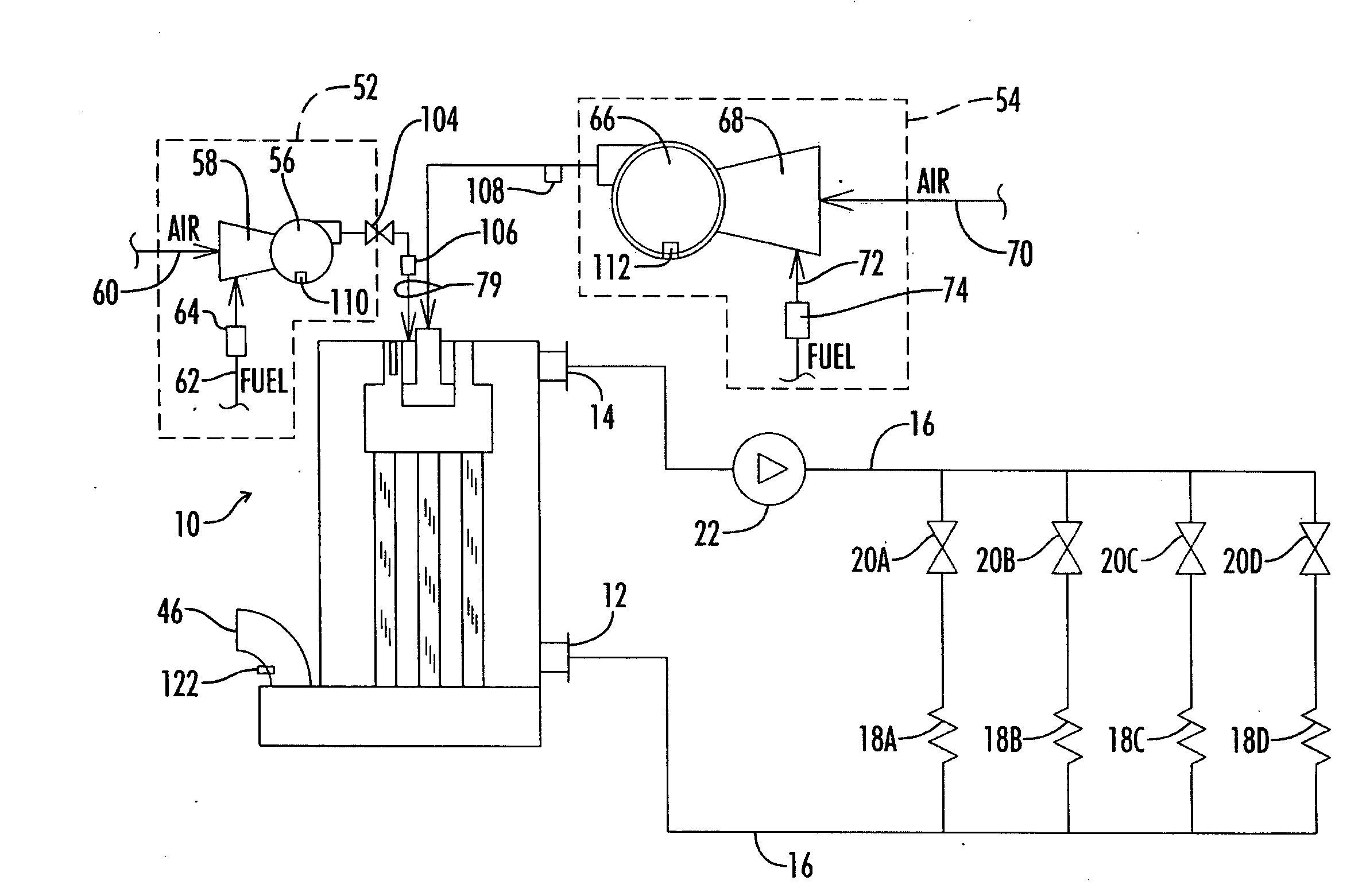

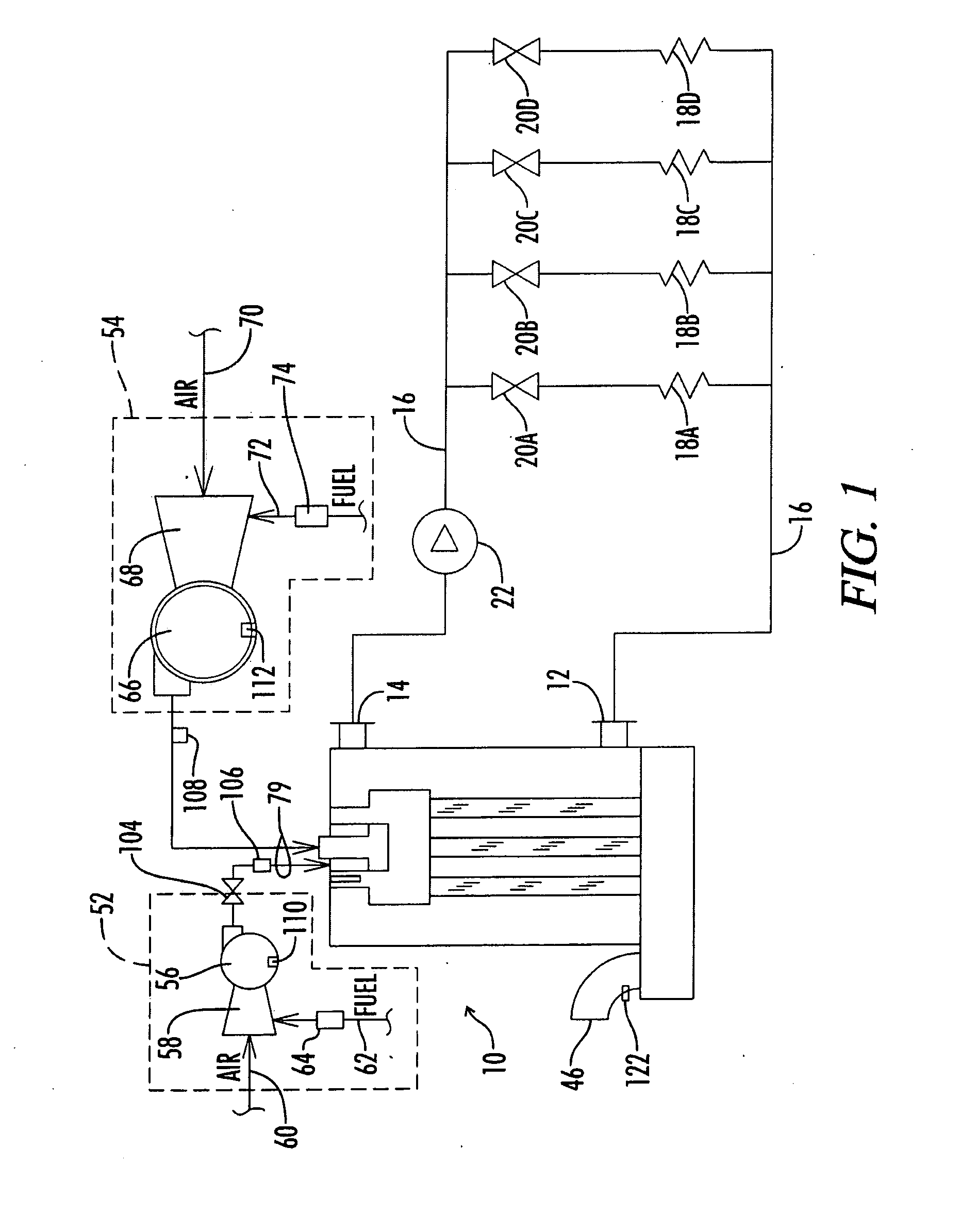

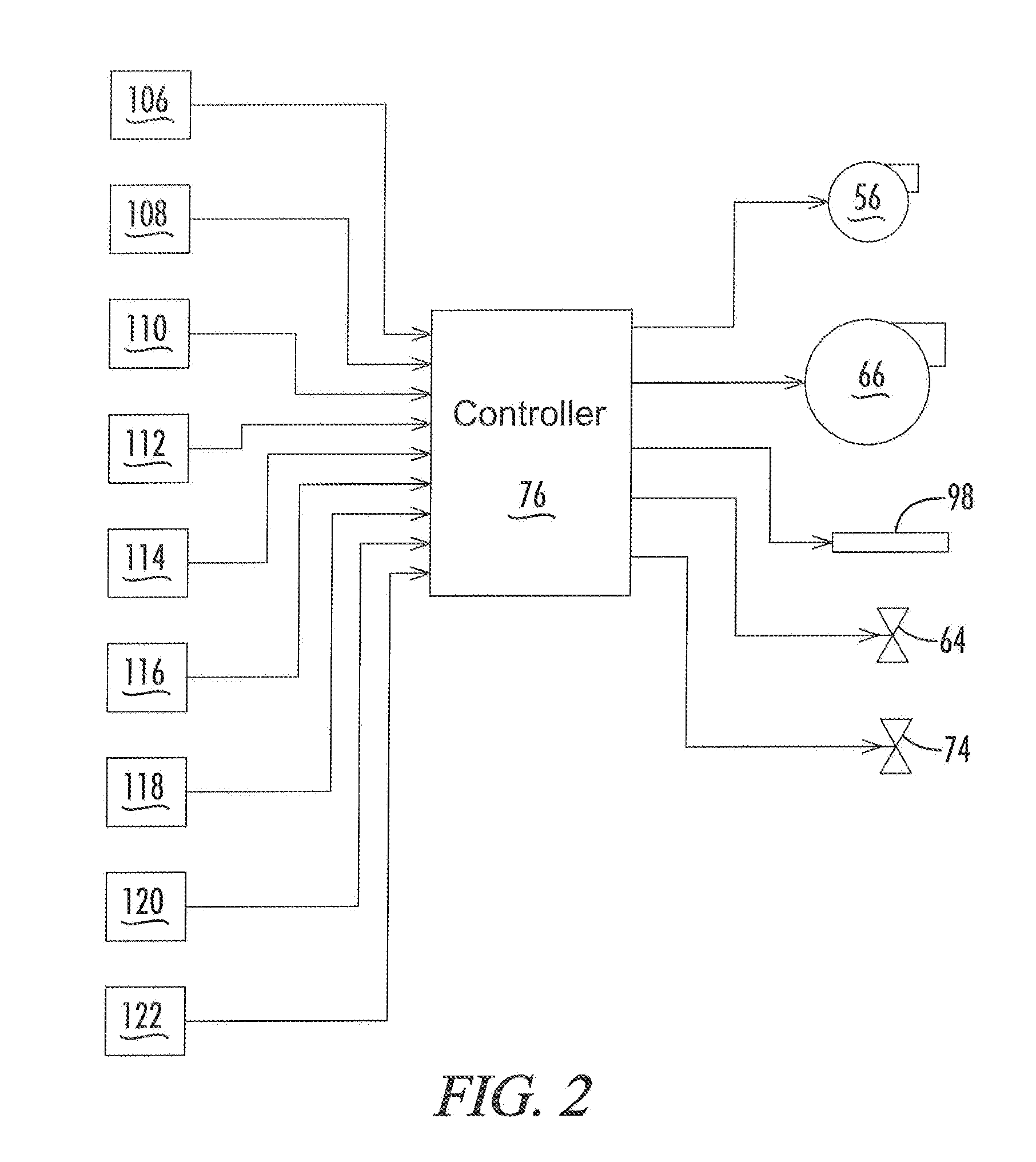

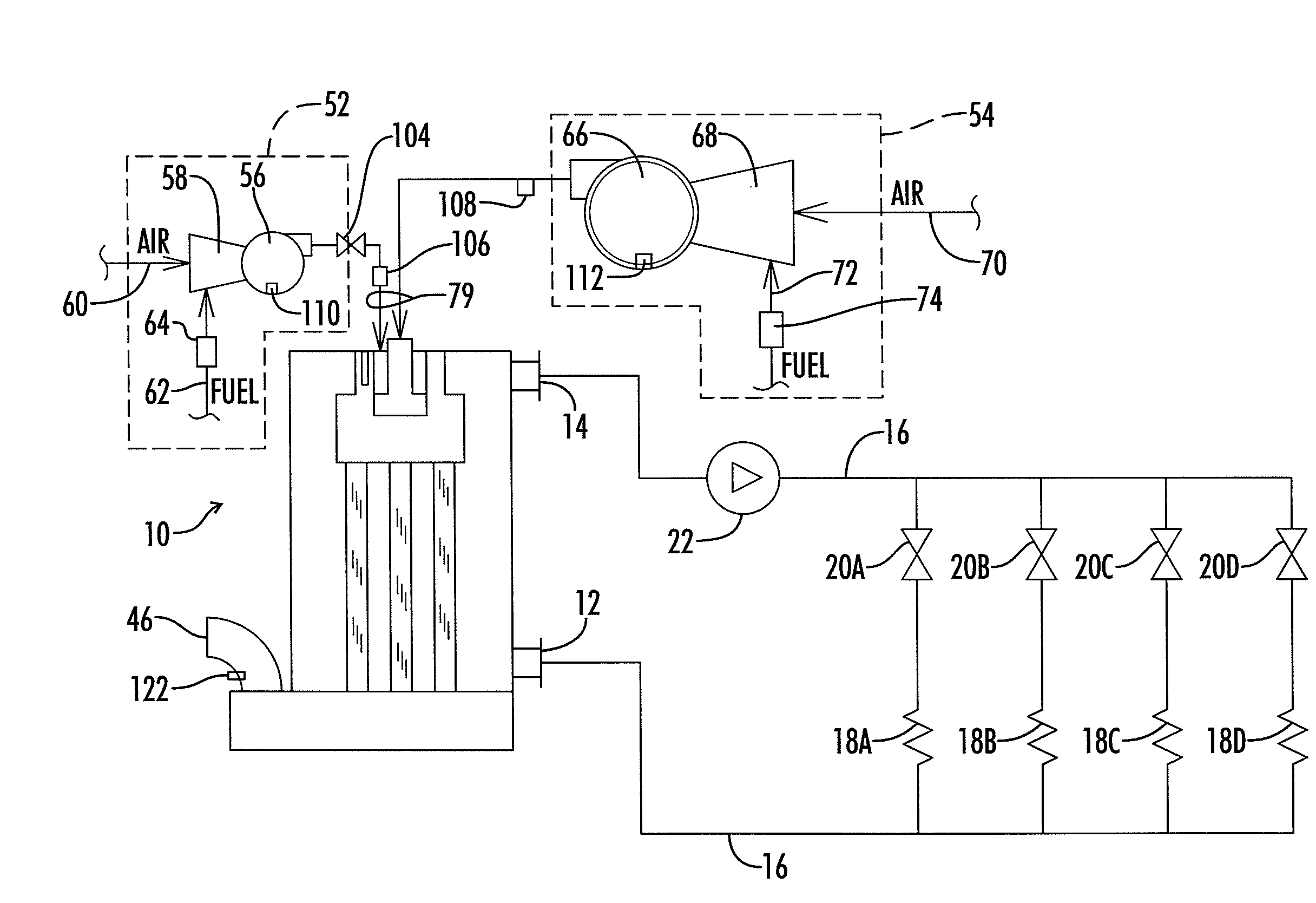

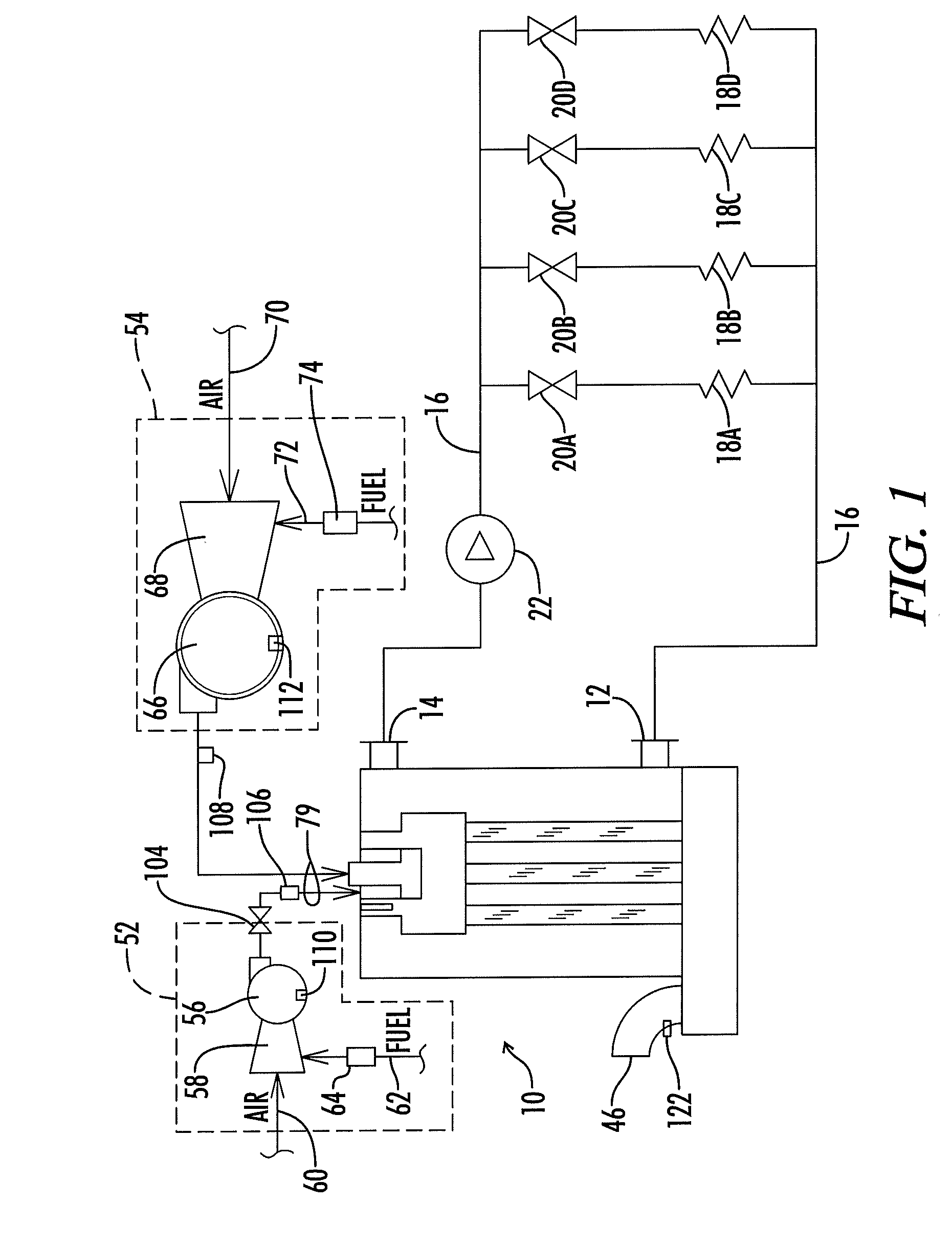

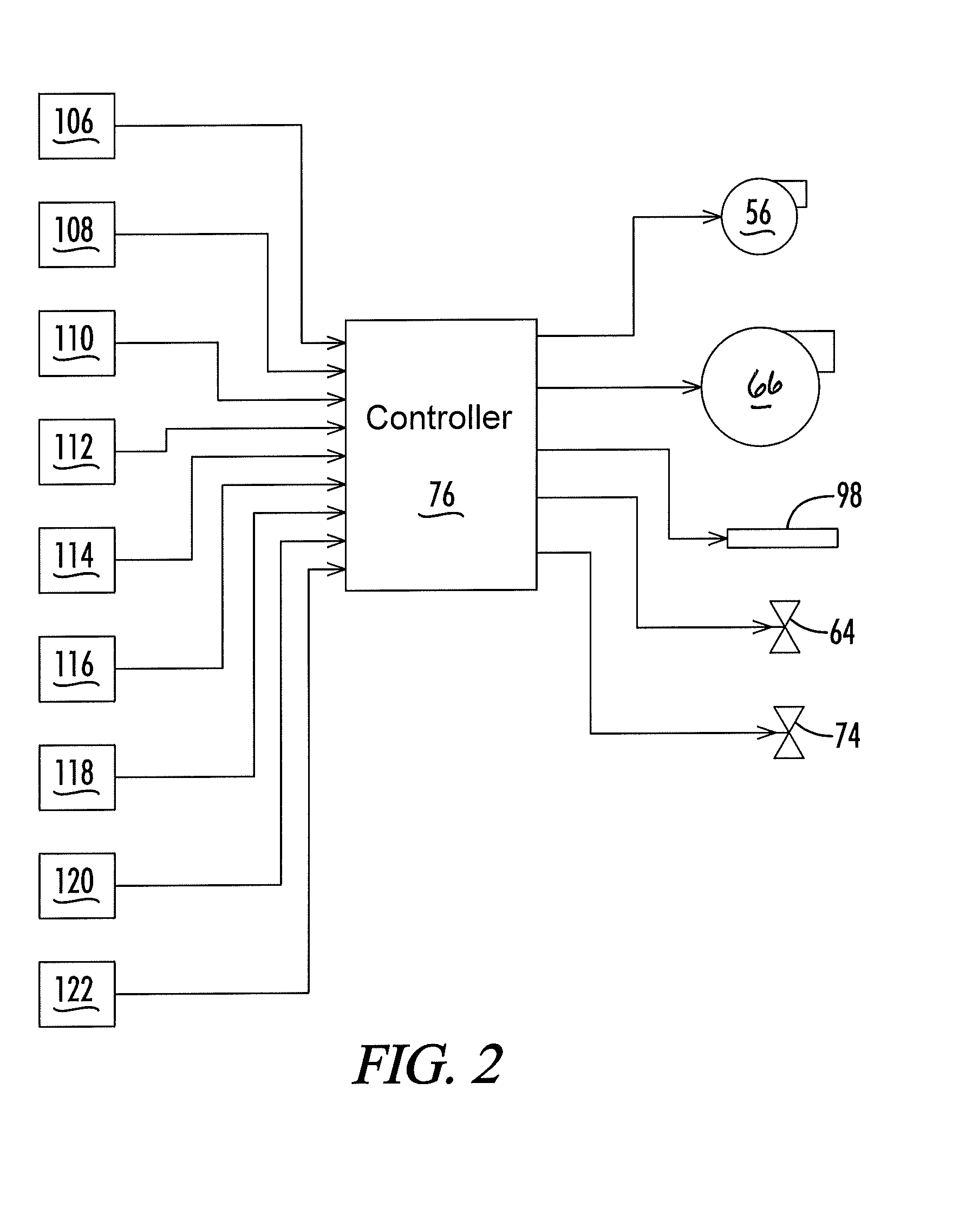

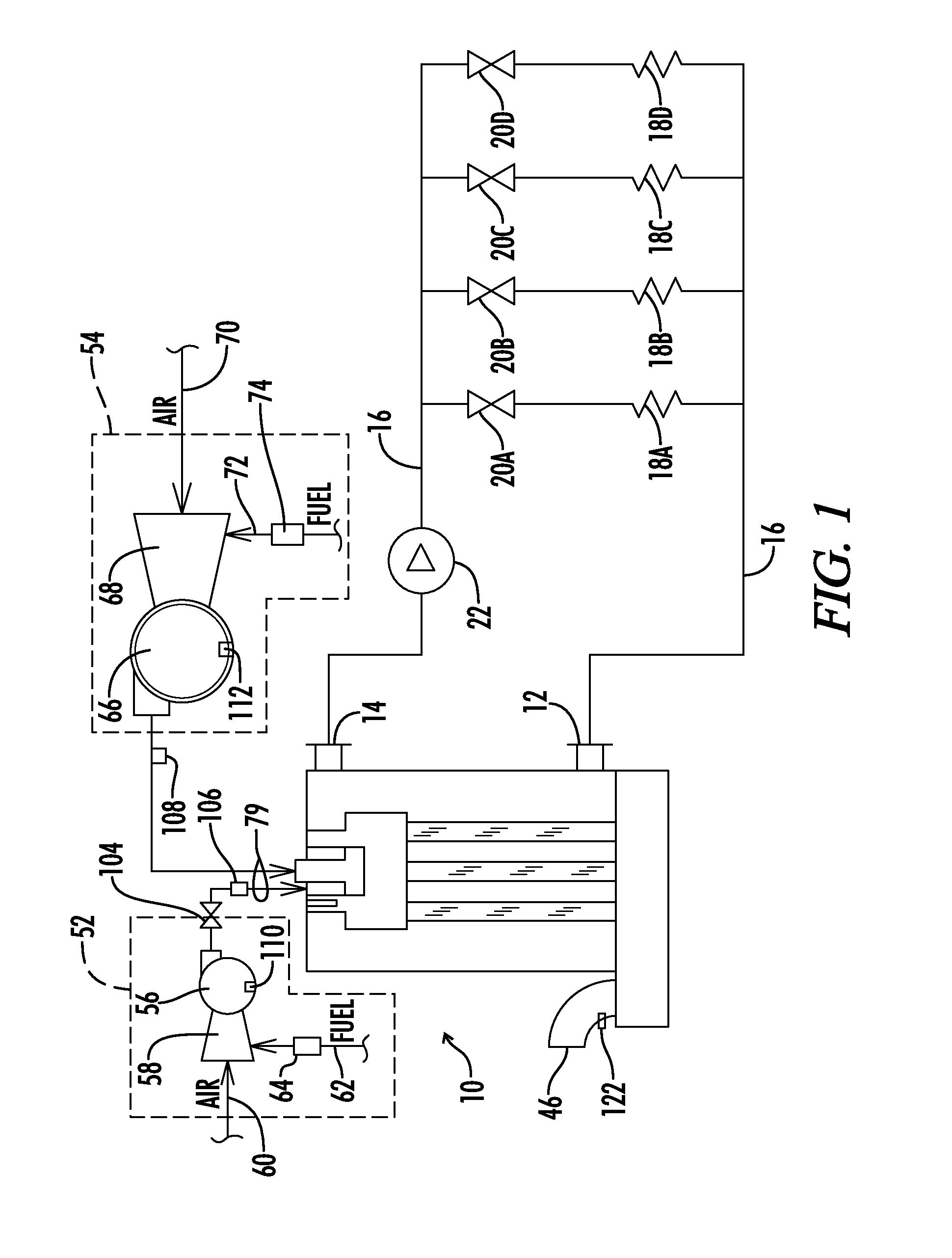

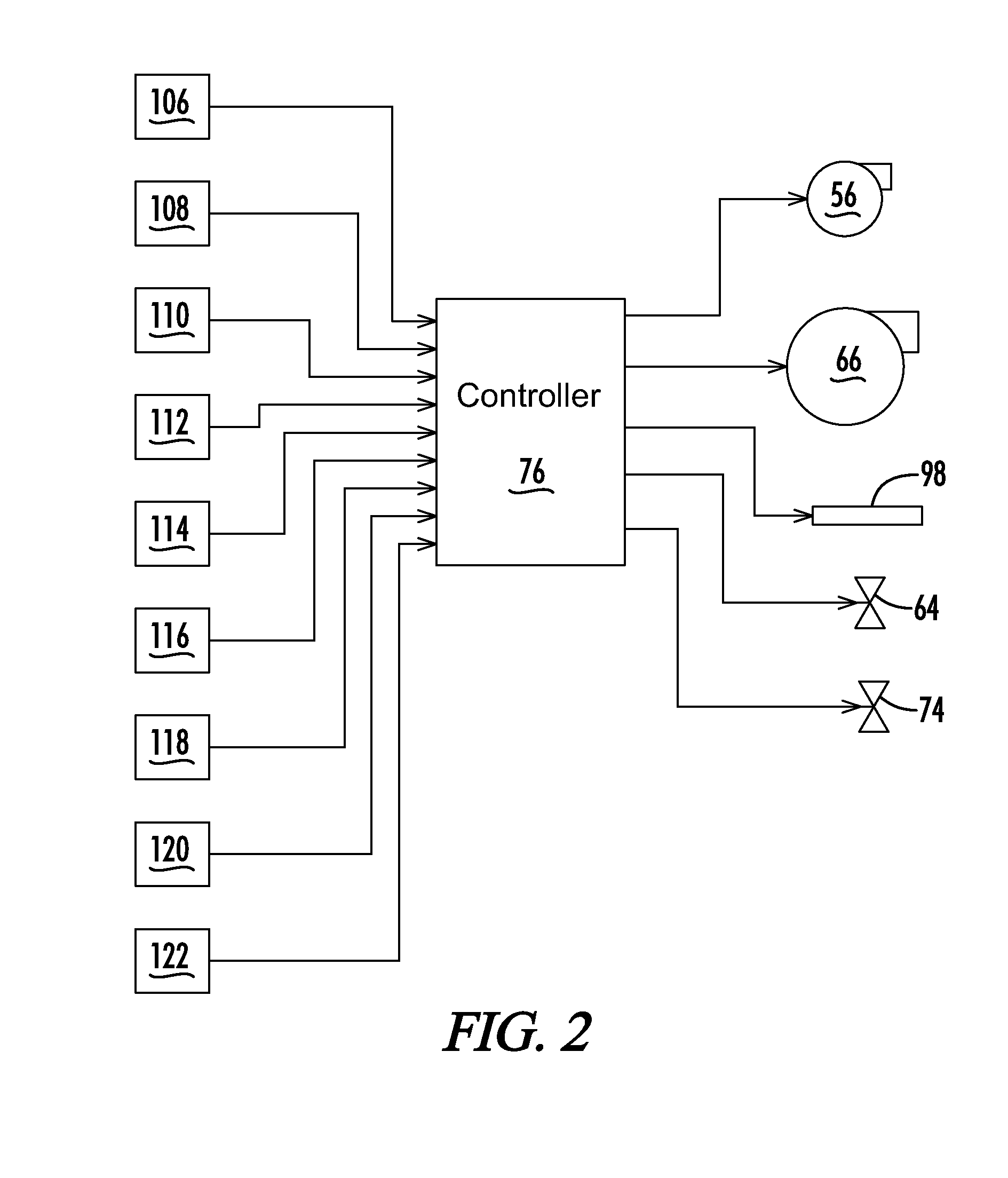

Gas fired modulating water heating appliance with dual combustion air premix blowers

ActiveUS8286594B2Avoid condensationIncrease the turndown ratioWater circulationEnergy efficient heating/coolingCombustorEngineering

A water heating apparatus uses a low range blower assembly and a high range blower assembly, each providing a variable flow of premixed fuel and air to a burner assembly. Appropriate choice of the operating ranges of the blower assemblies can provide a high turndown ratio approximately equal to the product of the turndown ratios of each of the individual blower assemblies. Turndown ratios as high as 25:1 are achievable.

Owner:LOCHINVAR

Method and apparatus for reducing emissions in diesel engines

InactiveUS7861520B2Emission reductionReduce flow rateInternal combustion piston enginesExhaust apparatusInlet pressureEngineering

Owner:TENNECO AUTOMOTIVE OPERATING CO INC

Gas Fired Modulating Water Heating Appliance With Dual Combustion Air Premix Blowers

ActiveUS20100095905A1Avoid condensationPrevent backflowFuel supply regulationEnergy efficient heating/coolingCombustorEngineering

A water heating apparatus uses a low range blower assembly and a high range blower assembly, each providing a variable flow of premixed fuel and air to a burner assembly. Appropriate choice of the operating ranges of the blower assemblies can provide a high turndown ratio approximately equal to the product of the turndown ratios of each of the individual blower assemblies. Turndown ratios as high as 25:1 are achievable.

Owner:LOCHINVAR

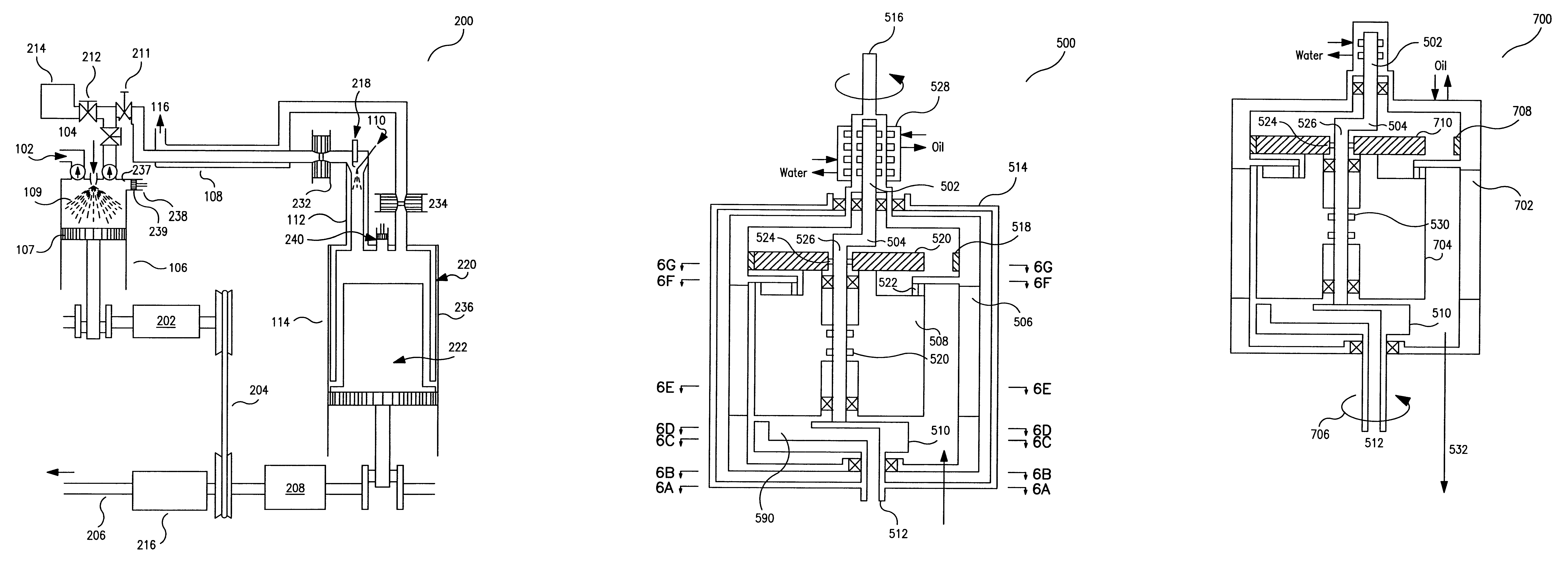

Separator to separate a liquid/liquid/gas/solid mixture

ActiveUS8114283B2Reliable methodIncrease productionLiquid degasificationReversed direction vortexCycloneProduct gas

A separator for separating or partially separating oil, water, gas and solids from hydrocarbon production well fluids comprises a vessel and a cyclone contained within the vessel. An inlet passage passes through a wall of the vessel and into the cyclone, the inlet passage having means for causing the flow to rotate within the cyclone. A first outlet passage for an oil rich phase extends from a position within the cyclone and substantially on a central axis of the cyclone; a second outlet passage for a water phase extends from a base of the vessel; and a third outlet passage for the solids extends from a lower end of the cyclone.

Owner:DPS BRISTOL HOLDINGS LTD

Quasi-Isothermal brayton cycle engine

InactiveUS20020014069A1Increase the turndown ratioHigh operating requirementsInternal combustion piston enginesCombination enginesBrayton cycleCombustor

An engine is disclosed. According to one embodiment of the present invention, the engine comprises a compressor, and combustor, and an expander. The compressor compresses ambient air. The combustor bums the compressed air, and produces exhaust gasses. The expander receives the exhaust gases from the combustor, and expands the exhaust gasses. The compressor may be a gerotor compressor or a piston compressor having variable-dead-volume control. The expander may be a gerotor expander or a piston expander having variable-dead-volume control. In another embodiment, an engine comprises a piston compressor, a combustor, a piston expander, and a pressure tank. The piston compressor compresses ambient air. The combustor bums the compressed air, and produces exhaust gasses. The piston expander receives the exhaust gasses from the combustor, and expands the exhaust gasses. The pressure tank receives and stores the compressed air from the compressor. In another embodiment, a gerotor compressor or a gerotor expander comprises an inner gerotor, and an outer gerotor. The inner gerotor and the outer gerotor are driven so that they do not touch. The gerotors may be cantilevered or non-cantilevered.

Owner:HOLTZAPPLE MARK T +1

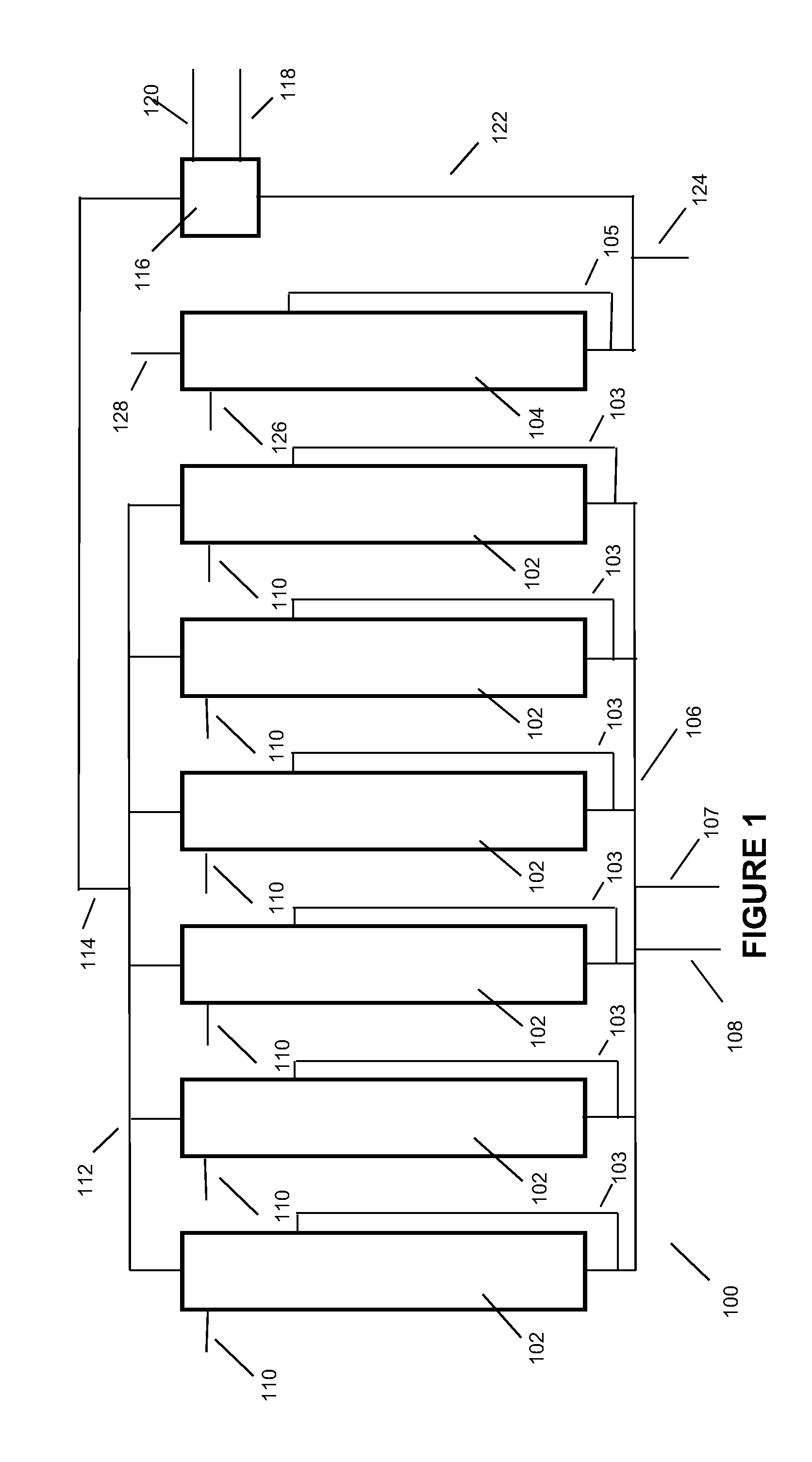

Low energy, high substrate efficiency, anaerobic, deep, bubble column fermentation processes

ActiveUS20130078688A1High conversion of carbon monoxideRisk minimizationBiofuelsChemical recyclingSimple Organic CompoundsHydrogen

Bioconversion processes are disclosed that enable high conversion efficiencies of gas substrate containing both carbon monoxide and hydrogen to oxygenated organic compounds via the carbon monoxide and hydrogen pathways using anaerobic, deep, bubble column fermentation in a cost effective manner. The high conversion efficiency processes of this invention comprise the combination of using at least two deep, bubble column reactors in flow series and using certain feed gas compositions and microbubbles while avoiding carbon monoxide inhibition.

Owner:SYNATA BIO INC

Small size Low Nox gas burner equipment and method

InactiveCN1506609AIncrease the turndown ratioShort flame lengthCombustion using gaseous and pulverulent fuelCombustion using liquid and pulverulent fuelFlue gasExhaust fumes

Compact low NOx gas burner apparatus and methods for discharging fuel gas and air mixtures into furnace spaces wherein the mixture is burned in folded flame patterns and flue gases having low NOx content are formed are provided. A burner apparatus of the invention is basically comprised of a housing having a burner tile attached thereto and means for introducing air therein. The burner tile has an opening therein with a wall surrounding the opening which extends into a furnace space. The exterior sides of the wall are divided into sections by radially positioned baffles with alternate sections having the same or different heights and slanting towards the opening at the same or different angles. Primary fuel gas mixed with flue gases and air is discharged through the burner tile. Secondary fuel gas is discharged adjacent to the external slanted wall sections whereby the secondary fuel gas mixes with flue gases in the furnace space. The resulting fuel gas-flue gases streams mix with the fuel gas-flue gases-air mixture discharged through the burner tile and the resulting mixture is burned in the furnace space.

Owner:JOHN ZINK CO LLC

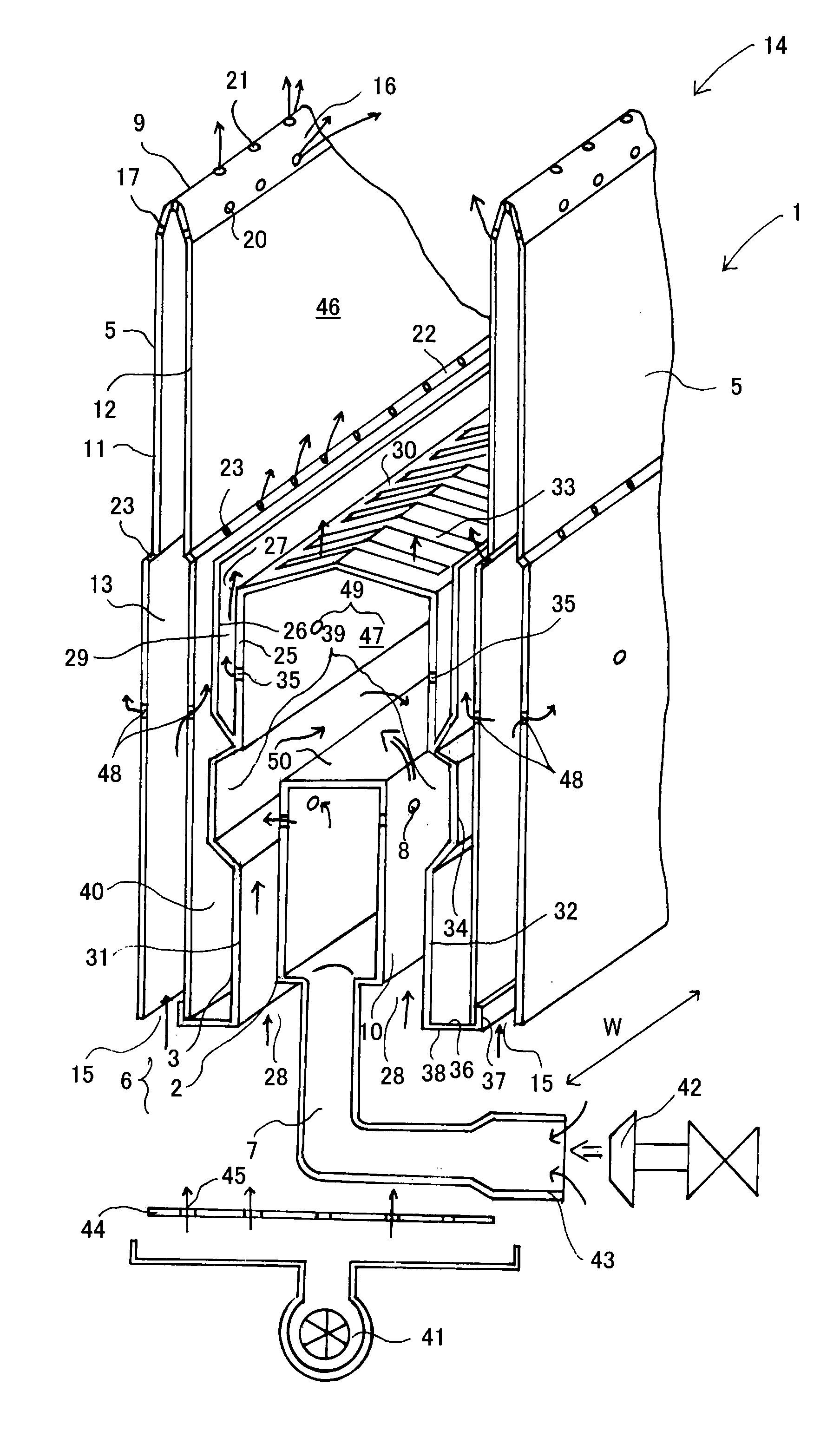

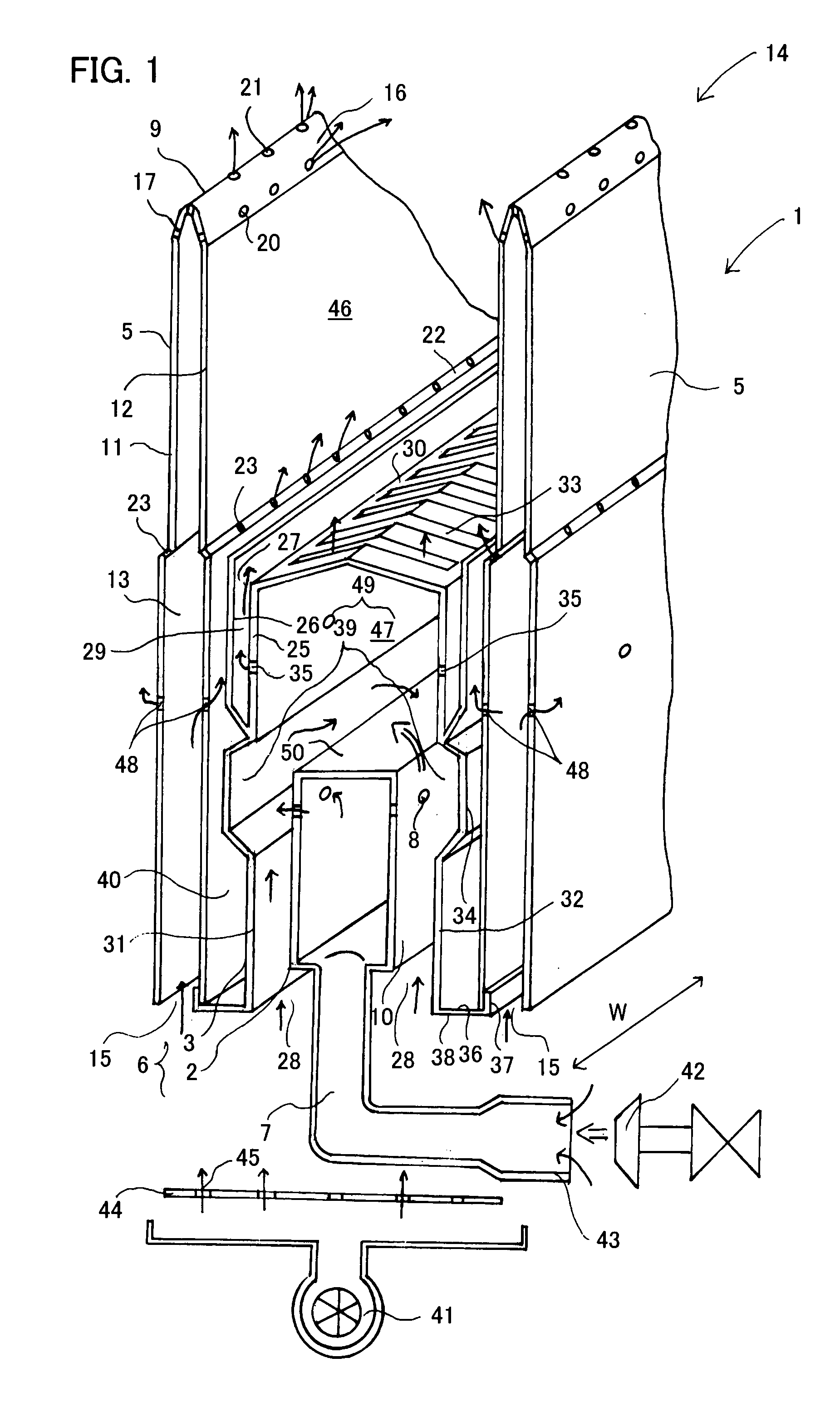

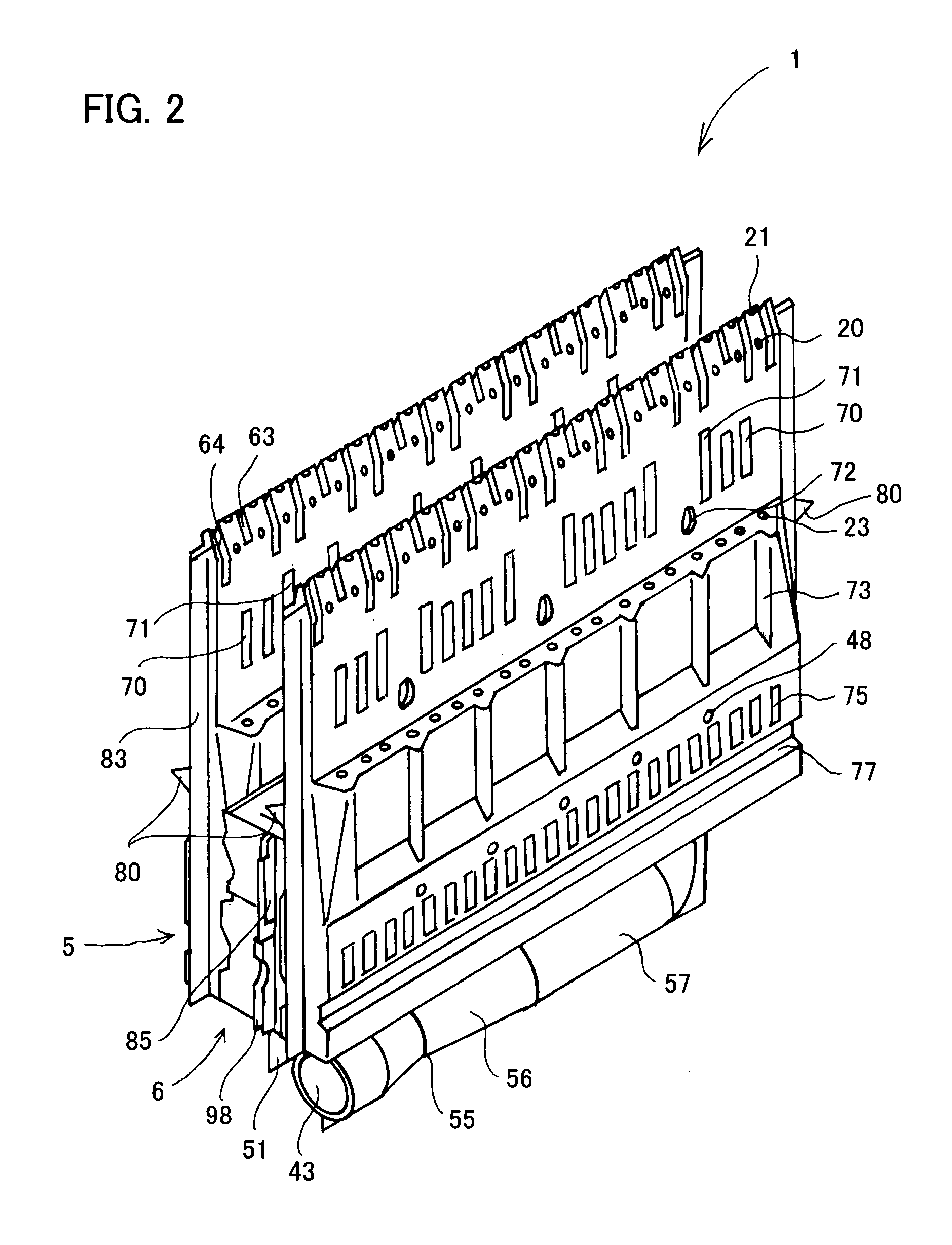

Combustion Apparatus

InactiveUS20080160467A1Evenly distributedLess amountCombustion using gaseous and pulverulent fuelCombustion using liquid and pulverulent fuelCombustorEngineering

A combustion apparatus 1 includes an intermediate member 6 constituted by a premixer 2 and a burner port assembly 3 and an air passage member 5, the intermediate member 6 being interposed between two air passage members 5. Fuel gas flows into an opening row part 10. The opening row part 10 has a number of openings 8 arranged linearly, so that the fuel gas introduced into the row part 10 is uniformly discharged through each of the openings 8. The fuel gas discharged through the openings 8 of the row part 10 bumps into air at mixing spaces 39. Fuel gas discharged through slots is homogenous and uniform in flow rate. Fuel gas produces a primary flame in a first combustion part 46 to perform a primary combustion. Unburned combustible components are discharged outside through openings of the first combustion part 46 and produce a secondary flame with air supplied through the distal end portion of the air passage member 5.

Owner:NORITZ CORP

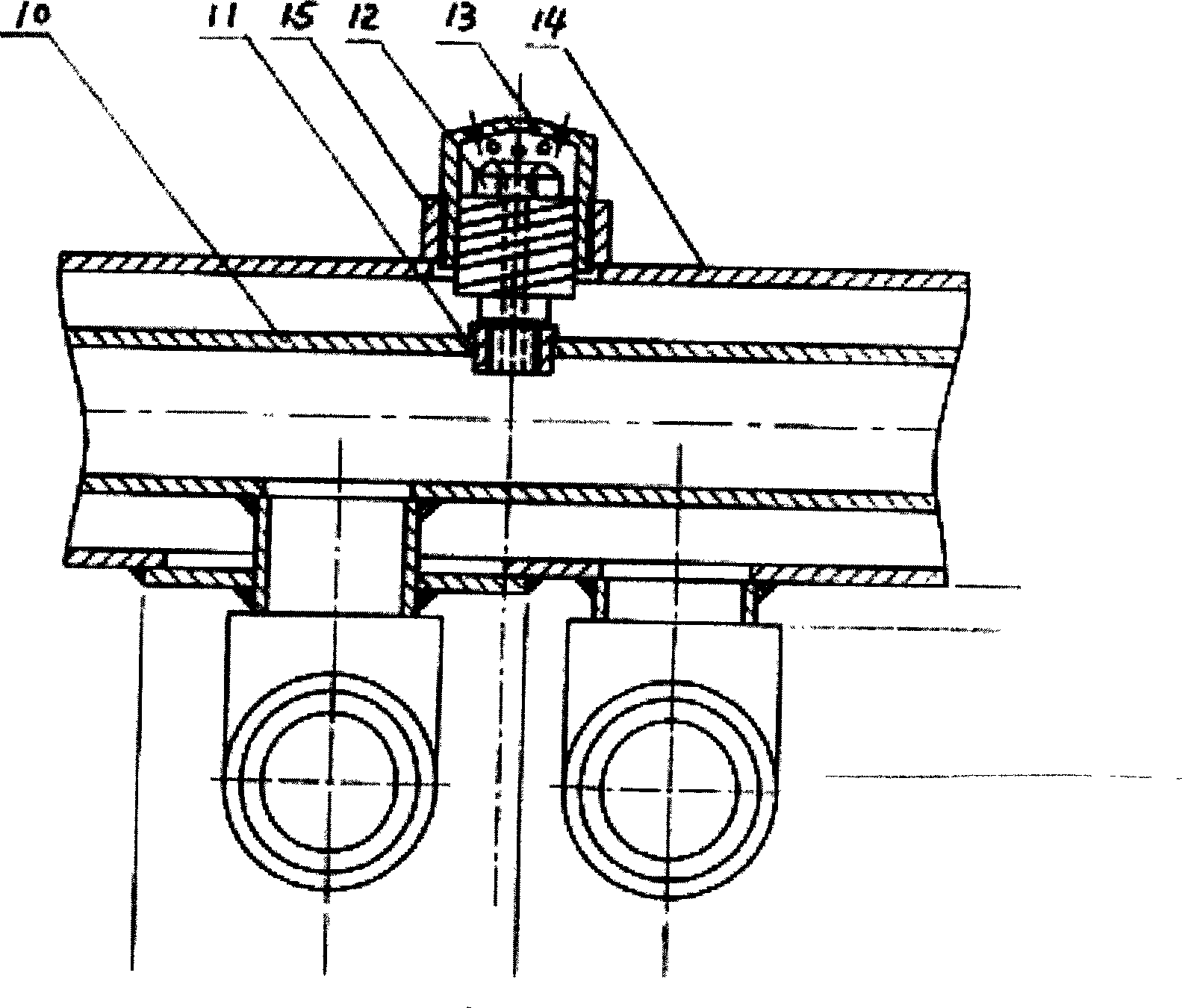

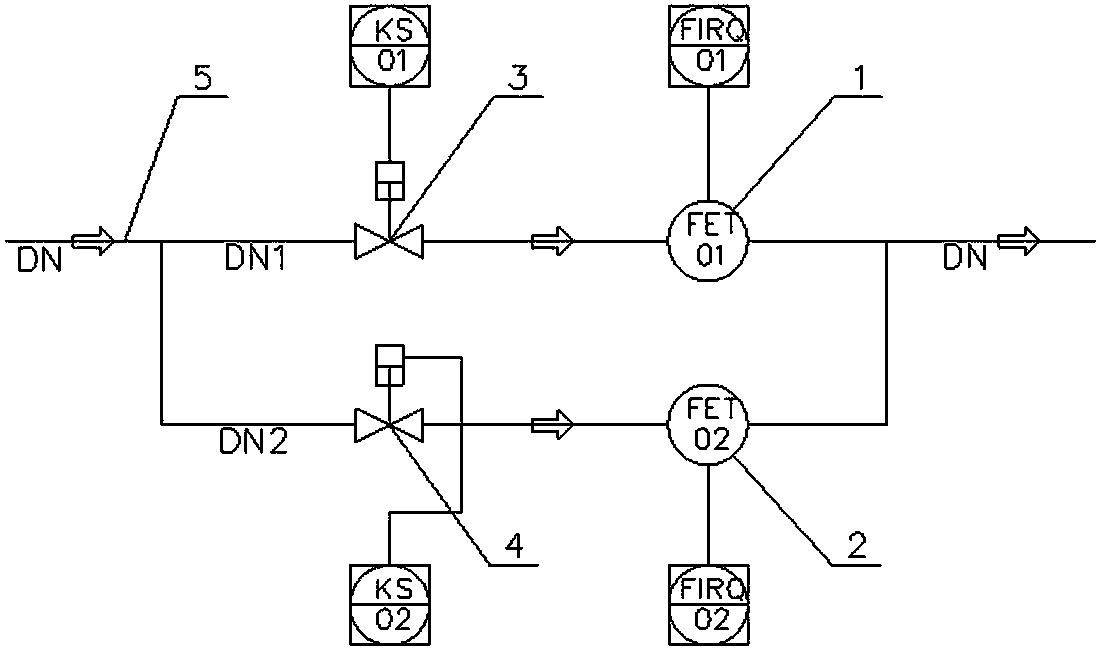

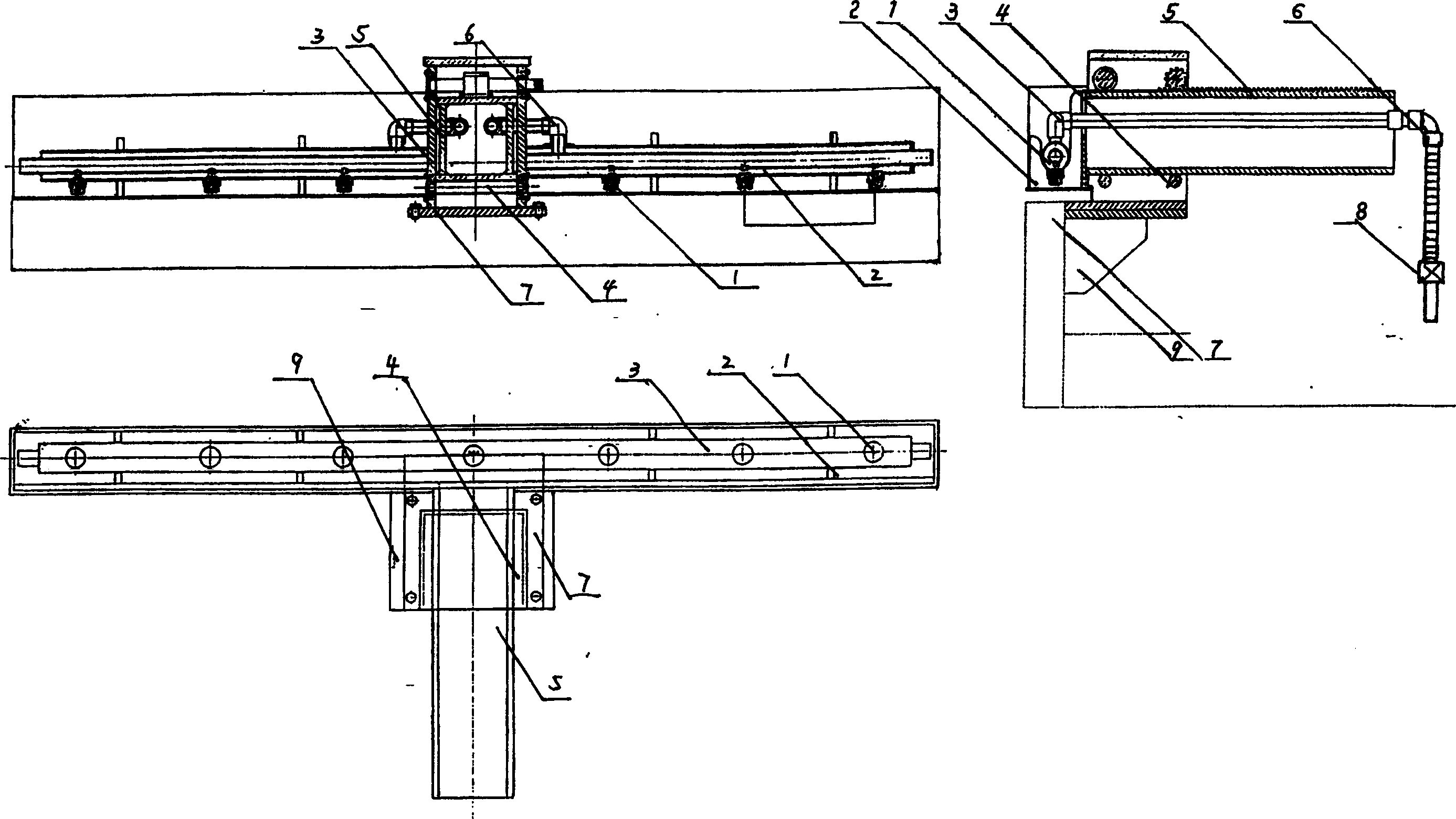

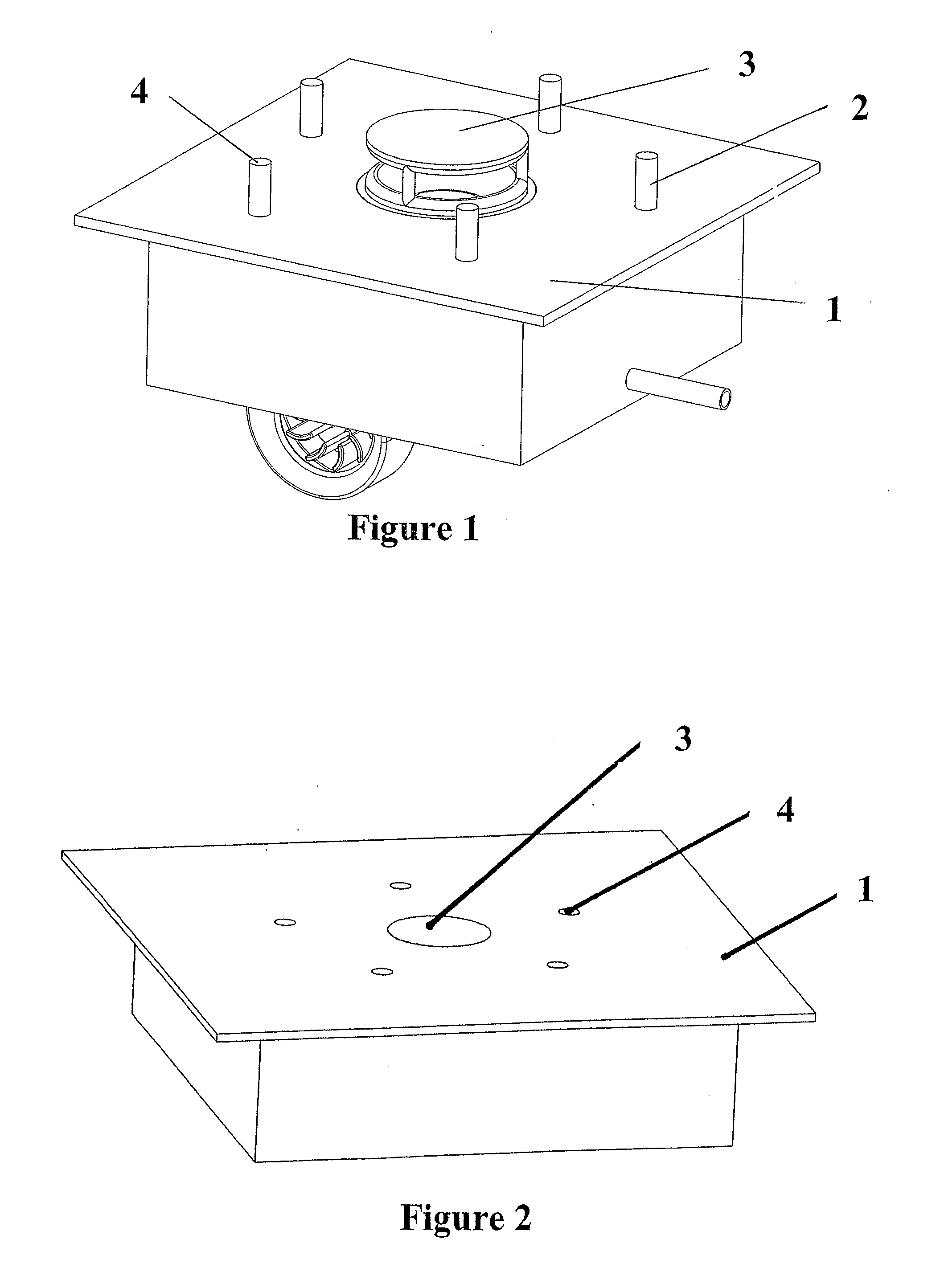

Parallel installation and segmental measurement flow measurement method with large measurement range ratio and device thereof

InactiveCN103868559AIncrease the turndown ratioImprove measurement accuracyVolume flow measuring devicesLower limitEngineering

The invention discloses a parallel installation and segmental measurement flow measurement method with a large measurement range ratio and a device of the method. The device comprises a process pipeline, a first flow meter and a second flow meter, wherein the first flow meter and the second flow meter are arranged on the process pipeline in parallel. A normally-open first stop valve and a normally-closed second stop valve which correspond to each other and have the same caliber are arranged at the front end of the first stop valve and the front end of the second stop valve respectively. The measurement range lower limit of the second flow meter is slightly lower than the measurement range upper limit of the first flow meter. A PLC automatically detects the flow of liquid flowing through the process pipeline and carries out interlocking control on the first stop valve and the second stop valve in the manner that the first flow meter is adopted under a small flow and the second flow meter is adopted under a large flow. The method and device have the advantages that the measurement range ratio of the flow measurement device is effectively improved, measurement accuracy is high, and the method and device are suitable for energy medium measurement in a large measurement range; the device is easy and convenient to use, practical, reliable and high in operating control feasibility.

Owner:WISDRI ENG & RES INC LTD

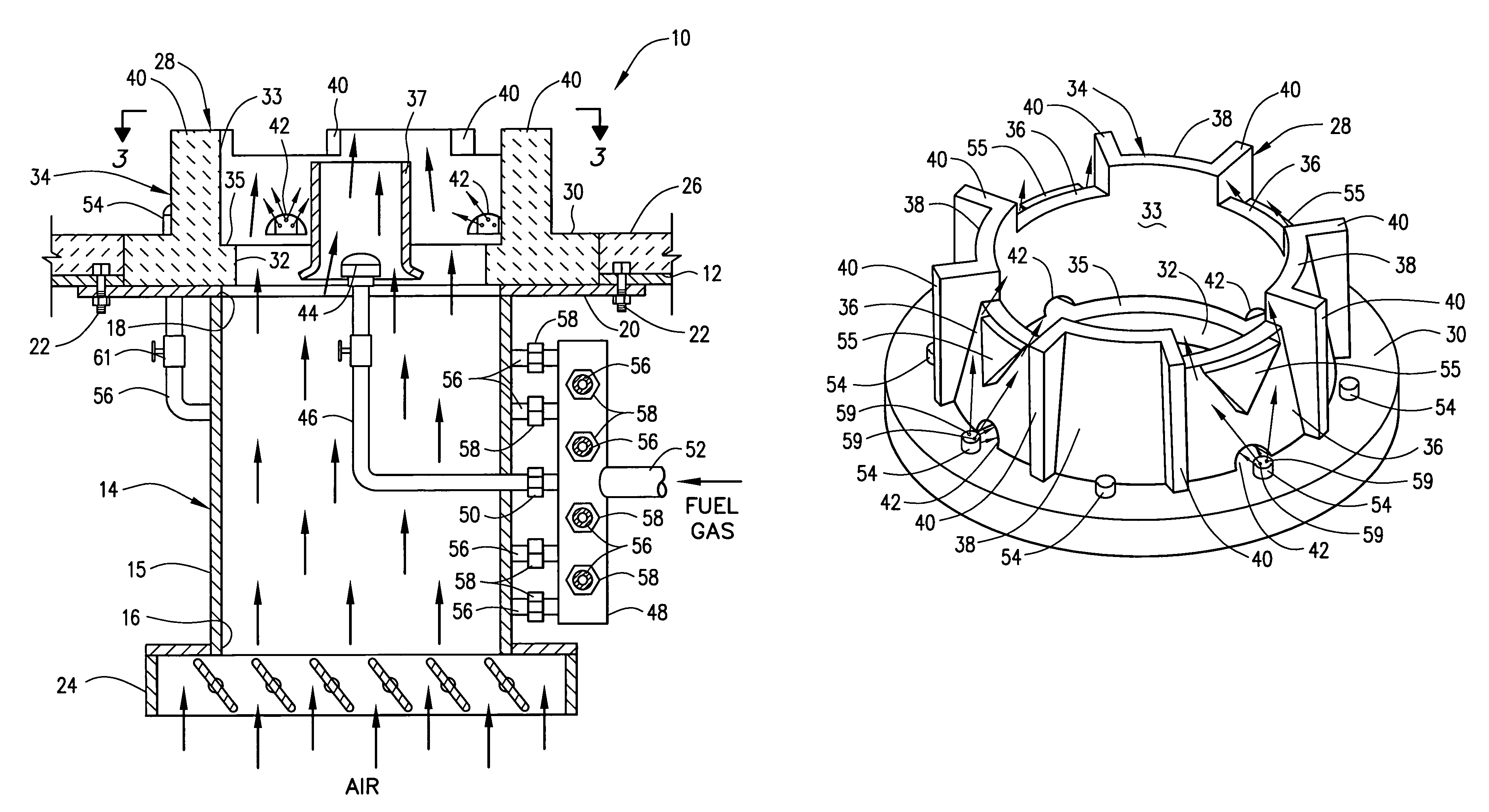

Compact low NOx gas burner apparatus and methods

ActiveUS7198482B2Increase the turndown ratioShorten the lengthCombustion using gaseous and pulverulent fuelCombustion using liquid and pulverulent fuelThermodynamicsFlue gas

Compact low NOx gas burner apparatus and methods for discharging fuel gas and air mixtures into furnace spaces wherein the mixture is burned in folded flame patterns and flue gases having low NOx content are formed are provided. A burner apparatus of the invention is basically comprised of a housing having a burner tile attached thereto and means for introducing air therein. The burner tile has an opening therein with a wall surrounding the opening which extends into a furnace space. The exterior sides of the wall are divided into sections by radially positioned baffles with alternate sections having the same or different heights and slanting towards the opening at the same or different angles. Primary fuel gas mixed with flue gases and air is discharged through the burner tile. Secondary fuel gas is discharged adjacent to the external slanted wall sections whereby the secondary fuel gas mixes with flue gases in the furnace space. The resulting fuel gas-flue gases streams mix with the fuel gas-flue gases-air mixture discharged through the burner tile and the resulting mixture is burned in the furnace space.

Owner:JOHN ZINK CO LLC

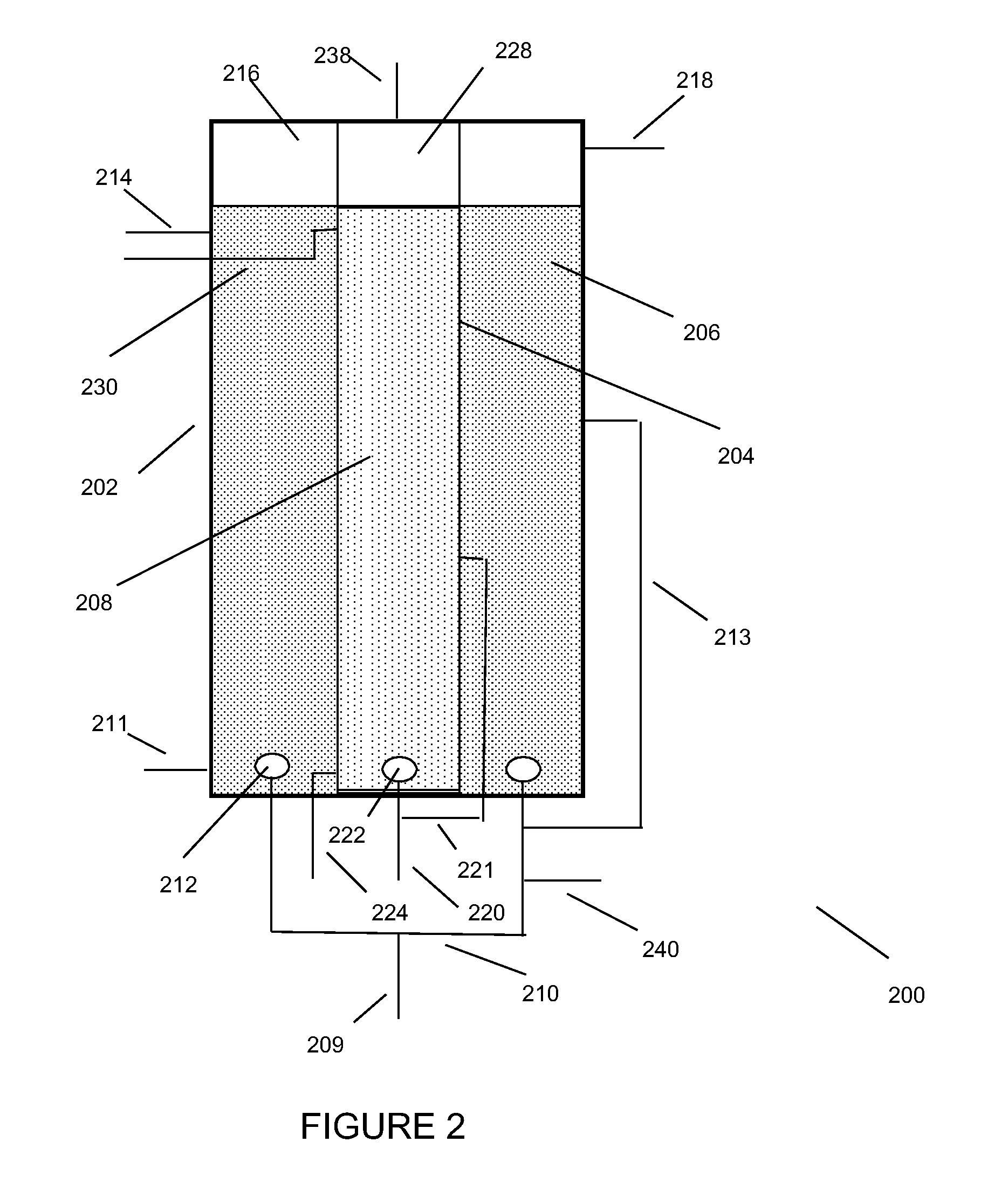

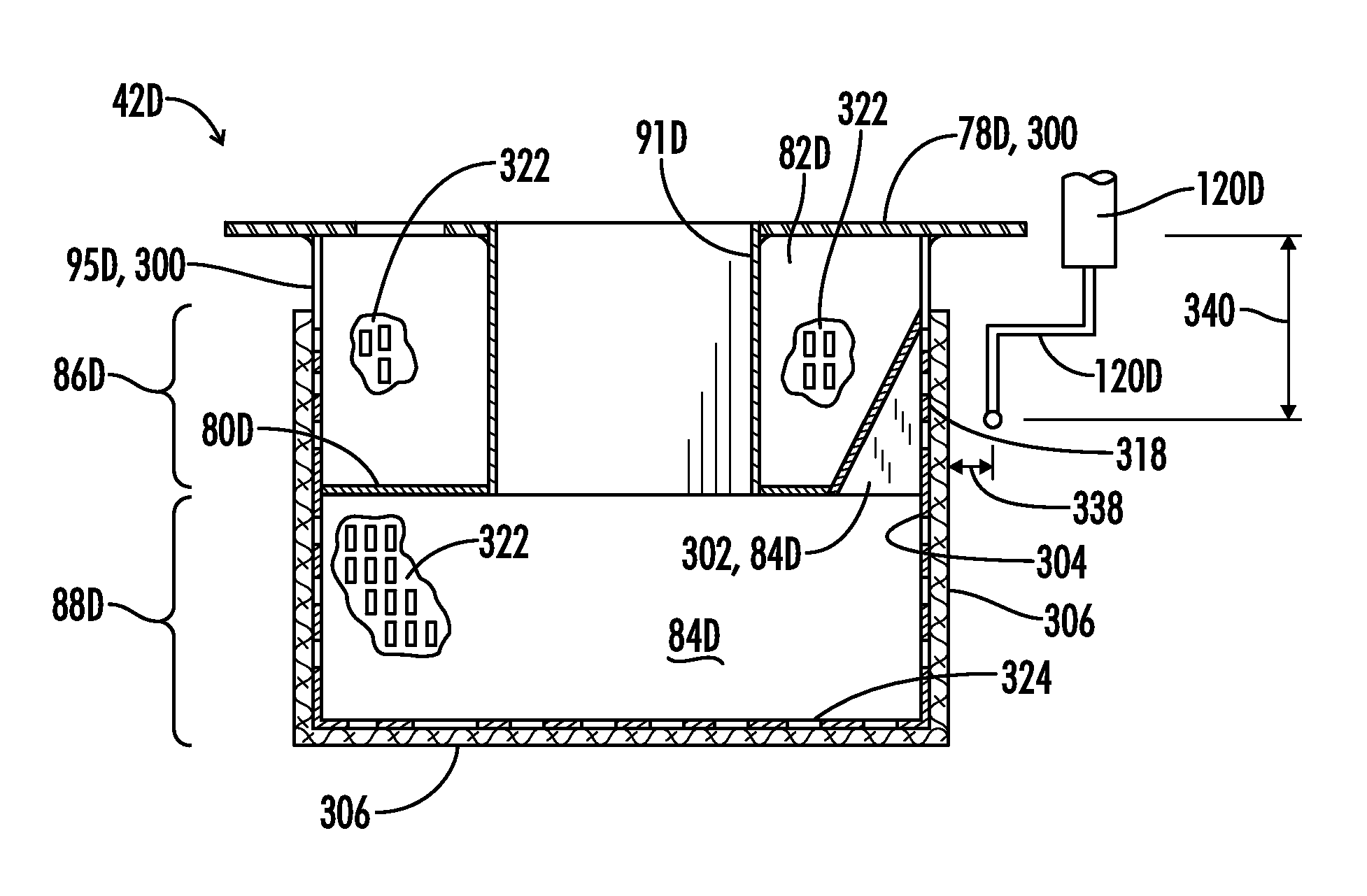

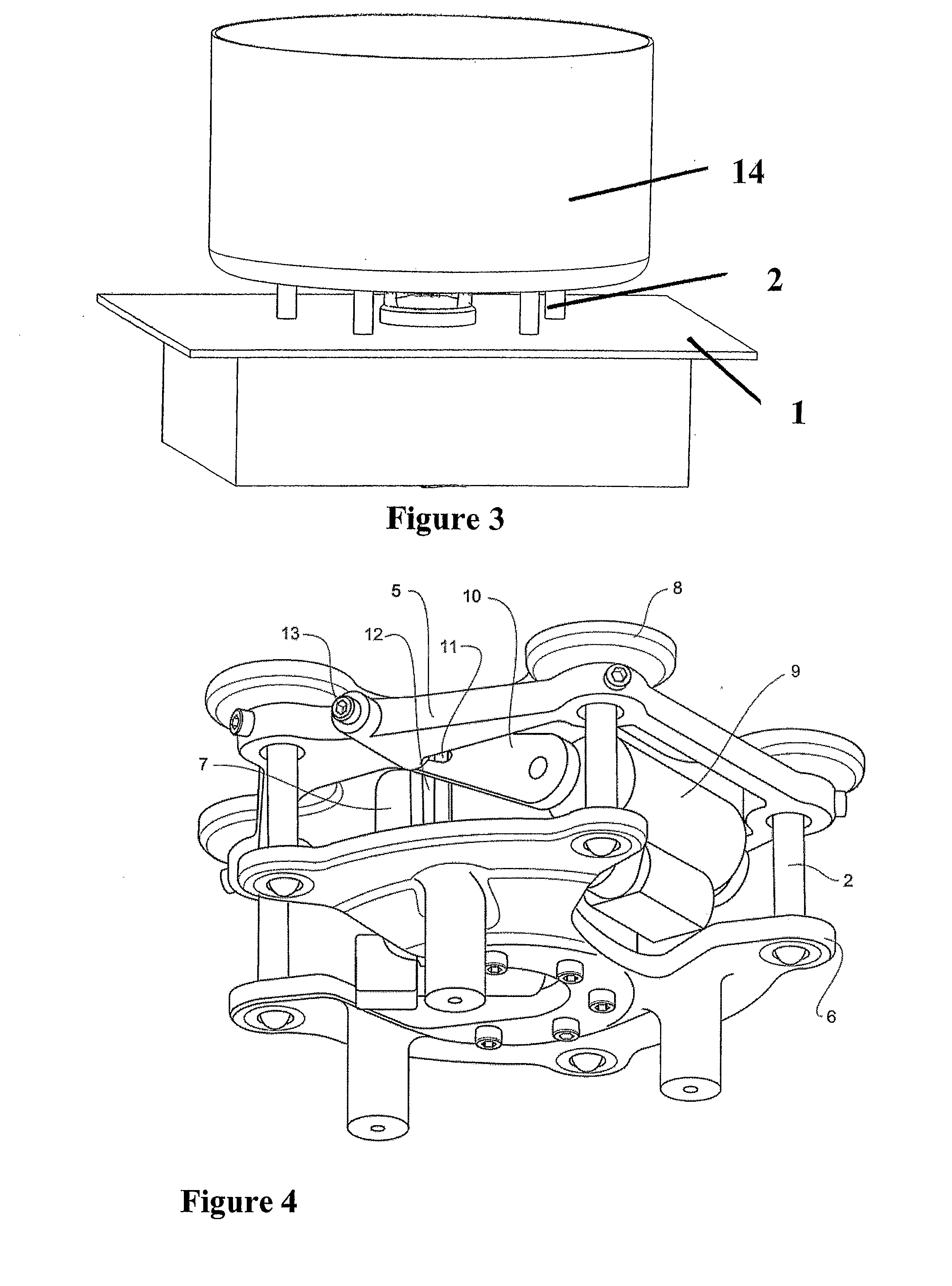

Integrated Dual Chamber Burner

ActiveUS20100116225A1Avoid condensationPrevent backflowCombustion using gaseous and pulverulent fuelCombustion using liquid and pulverulent fuelCombustorEngineering

A dual chamber burner assembly is provided for use with a heater apparatus having dual combustion air premix blowers. The burner assembly includes first and second interior zones communicated with first and second foraminous outer wall portions. First and second fuel and air inlet passages are communicated with the first and second interior zones, respectively.

Owner:LOCHINVAR

Anti-flashback nozzle and combustion device with the same

ActiveCN101315187AIncrease the turndown ratioPrevent backfireCombustion using gaseous and pulverulent fuelCombustion using liquid and pulverulent fuelCombustionBack-fire

The invention relates to an anti-backfire nozzle for a gas burner and a burning device by adopting the nozzle. The nozzle particularly comprises a shell. A fuel passage, a combustion supporting gas passage, a mixing chamber positioned at the downstream of the fuel passage and the combustion supporting gas passage and a spout are arranged in the shell; the mixing chamber has N-stage mutually-communicating cavities. On the radial section of the nozzle, the cross-sectional area of the cavity positioned at the upstream is smaller than that of the adjacent cavity at the downstream. When little circulating gas enters the cavity at the downstream, the mixed gas is burned in the cavity at the downstream and the adjacent cavity at the upstream. With the sharp increase of pressure of combustion products, the combustion products are instantly jet out of the nozzle, thereby preventing the flame from being blown off by the circulating gas flow. Since the nozzle is specially provided with the anti-backfire structure, the burning device with the nozzle is adaptable to reversal convection blowing, provides good working hot gas flow and ensures good stability and high regulation rate of the nozzle flame.

Owner:ECLIPSE COMBUSTION EQUIP SUZHOU CO LTD

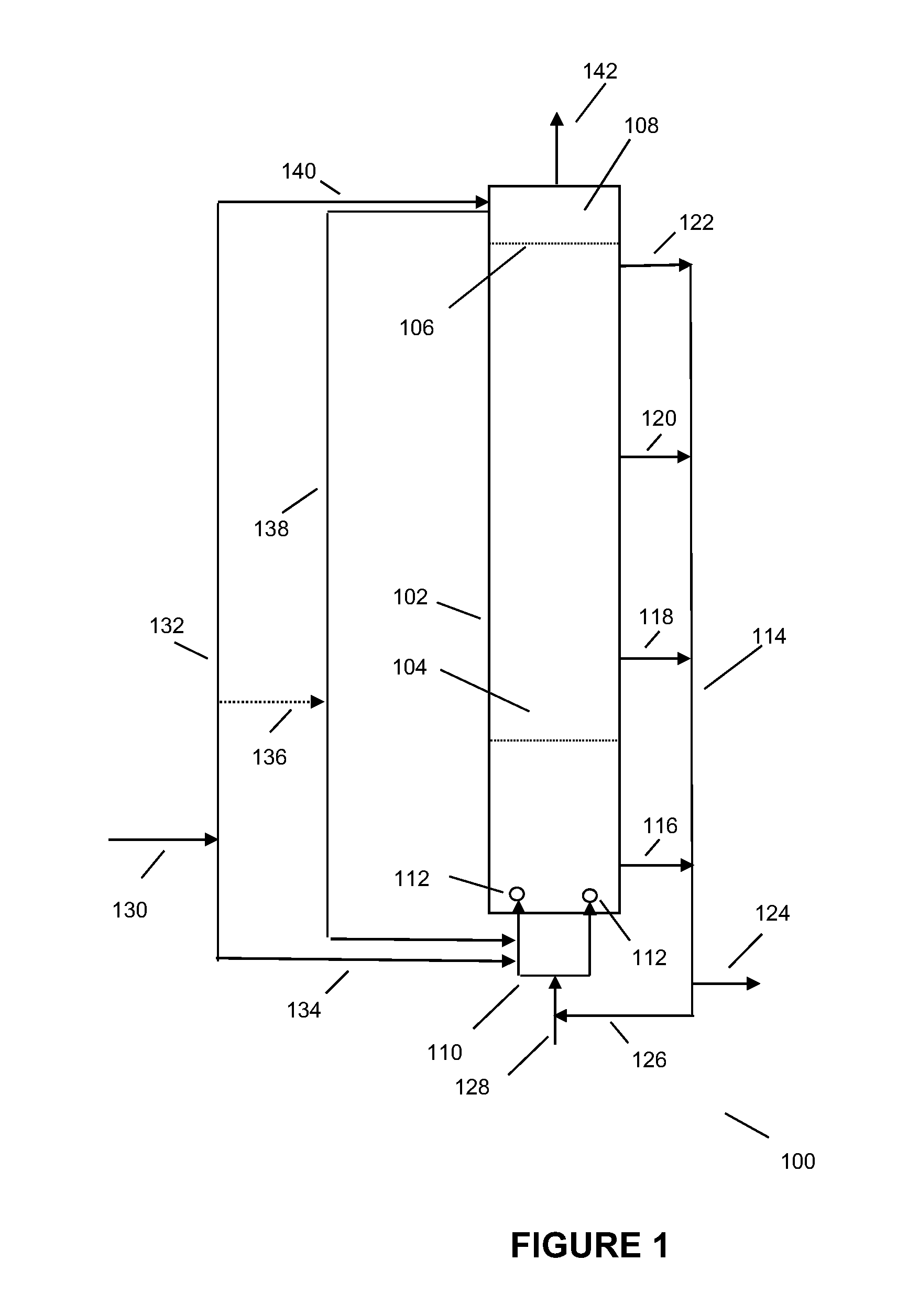

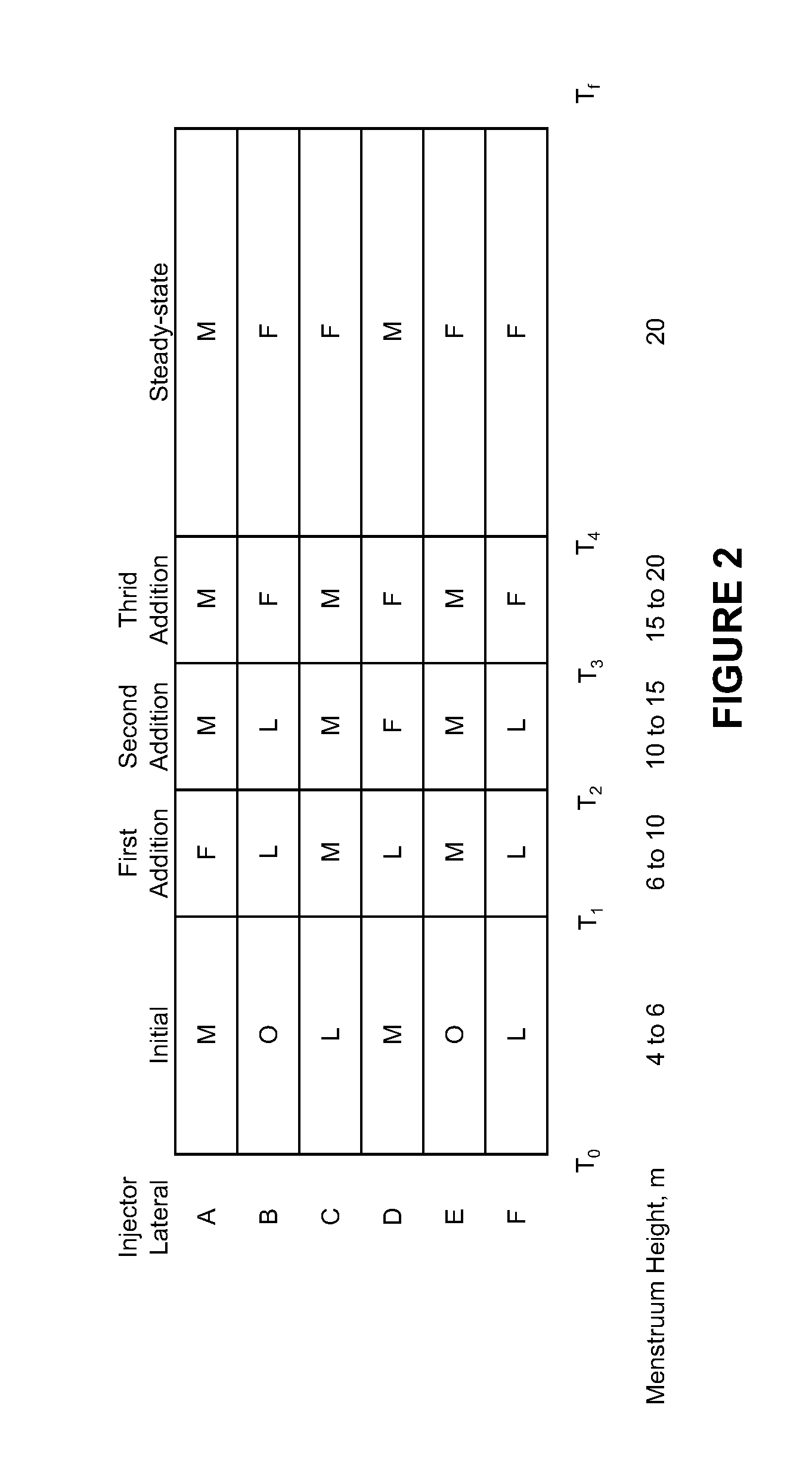

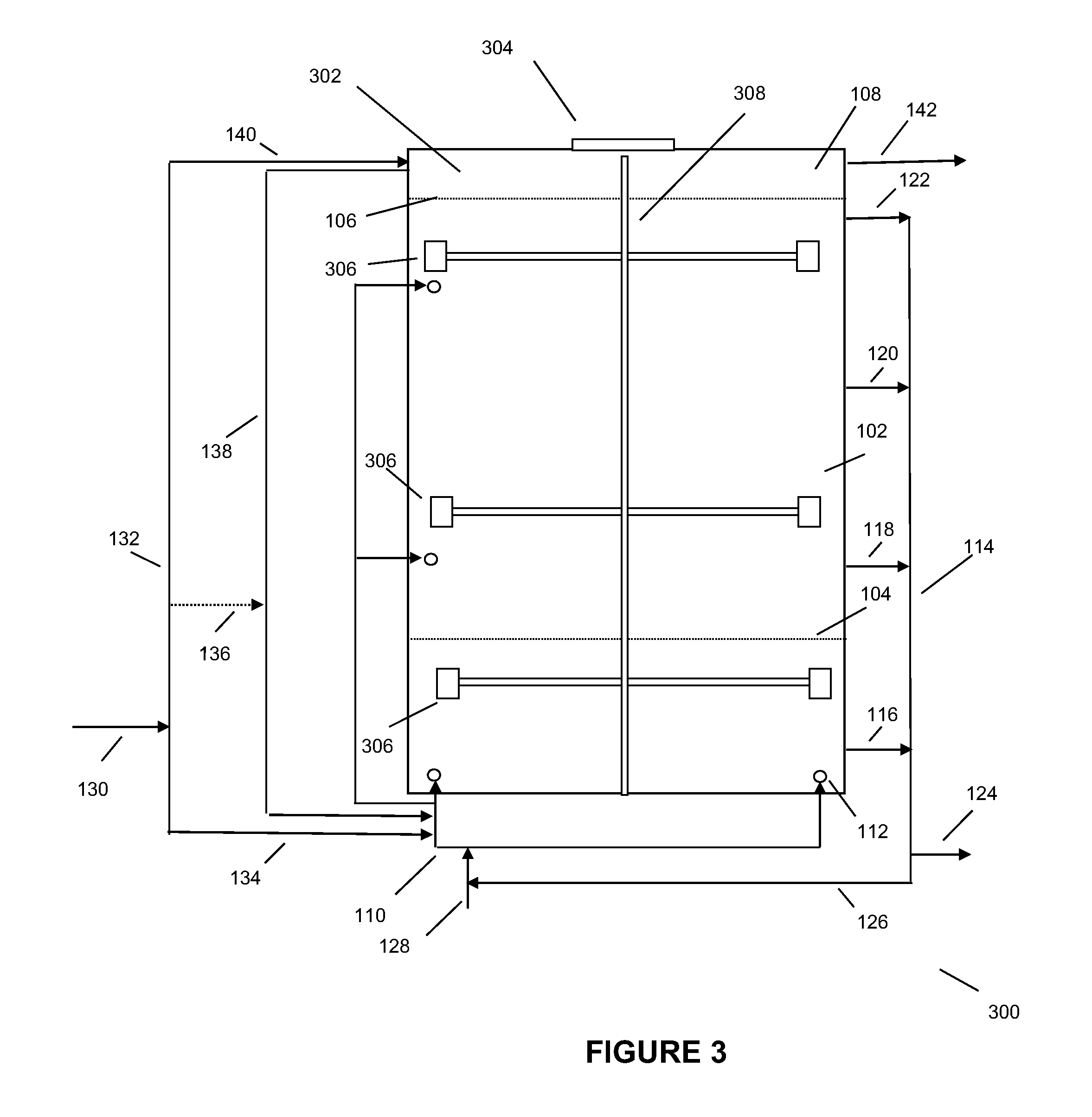

Processes for starting up deep tank anaerobic fermentation reactors for making oxygenated organic compound from carbon monoxide and hydrogen

ActiveUS20130078693A1Reduce riskPromotes robust growthBiochemistry apparatusBiofuelsOxygenOrganic compound

Processes are provided for starting up of anaerobic, deep tank fermentation systems used in the anaerobic bioconversion of hydrogen and carbon monoxide in a gaseous substrate stream to oxygenated organic compounds such as ethanol. In the processes injectors using a motive liquid are used to introduce gas substrate into the deep tank fermentation reactor where at least one of:(i) adjusting the gas to liquid flow ratio through an injector,(ii) changing the rate of liquid flow through an injector, and(iii) adjusting the carbon monoxide mole fraction in the gas feed by admixture with at least one other gas,wherein the mass transfer of carbon monoxide to an aqueous menstruum in the reactor is controlled to obtain the robust growth of the microorganism while maintaining the carbon monoxide concentration below that amount which is unduly adverse to the microorganism. In preferred aspects of the invention, recycled gas from the head space of the reactor is used to modulate the supply of carbon monoxide to the aqueous menstruum.

Owner:SYNATA BIO INC

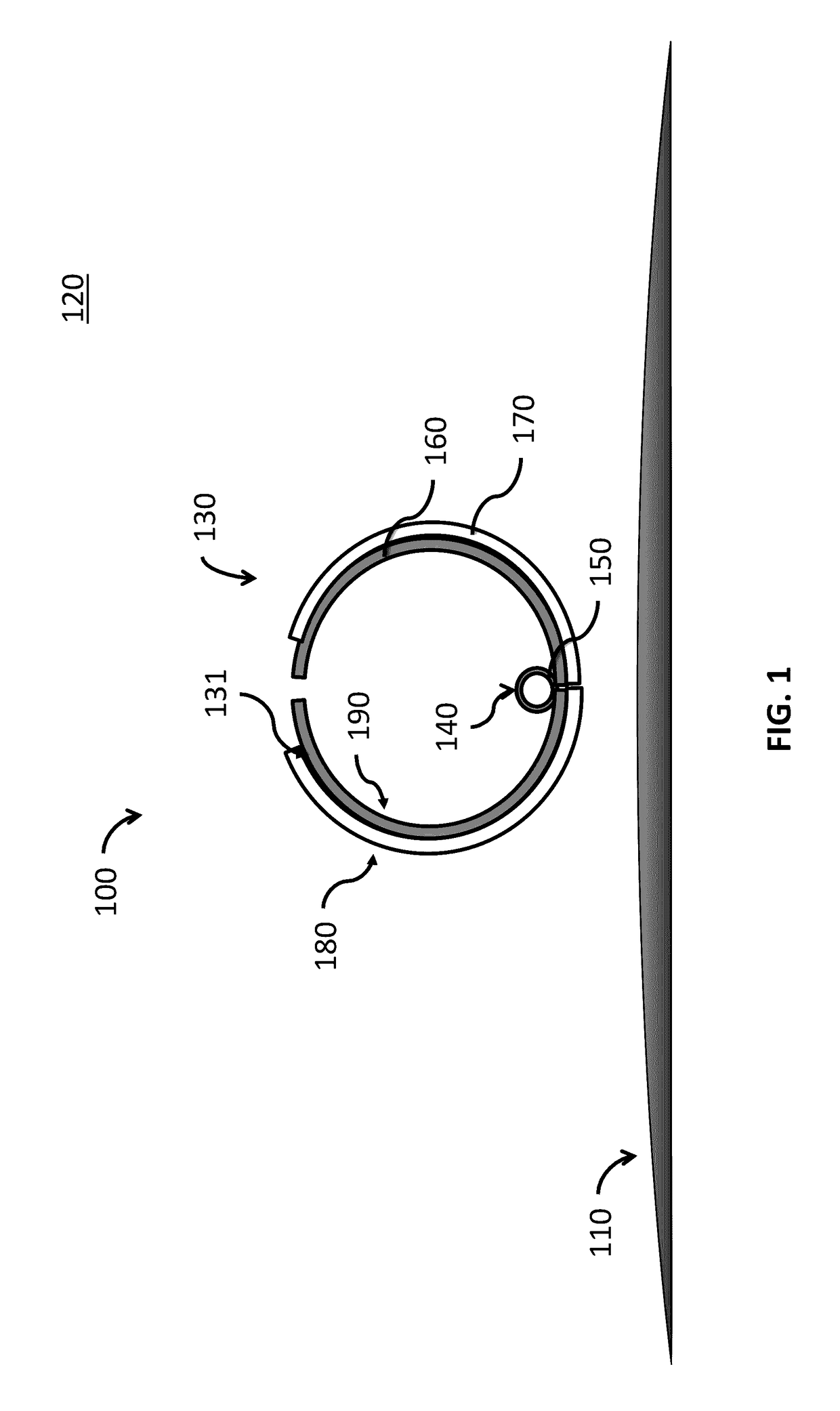

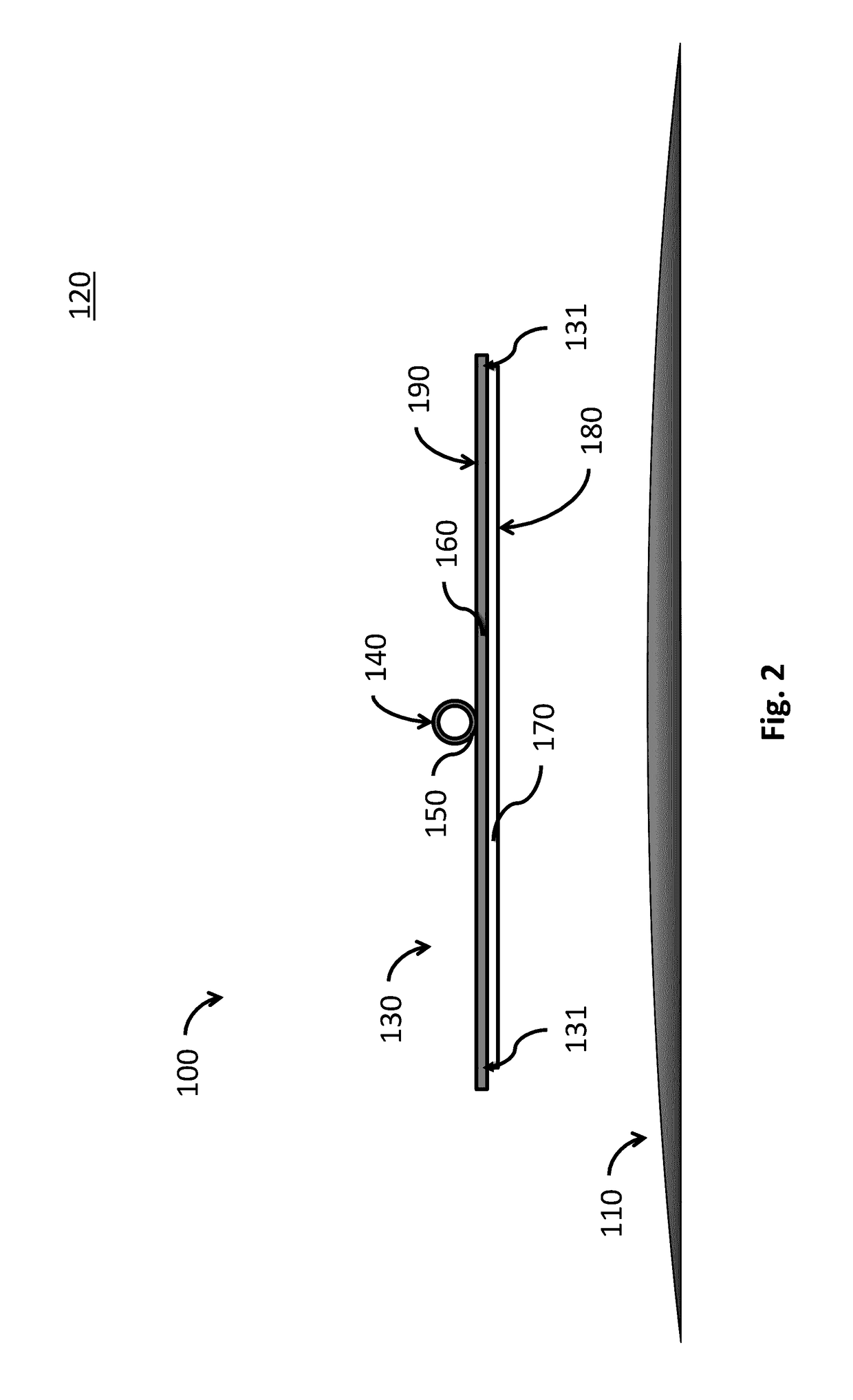

Variable Heat Rejection Device

ActiveUS20170160021A1Increase the turndown ratioCosmonautic environmental control arrangementCosmonautic vehiclesWorking fluidControl system

A heat rejection system that employs temperature sensitive shape memory materials to control the heat rejection capacity of a vehicle to maintain a safe vehicle temperature. The technology provides for a wide range of heat rejection rates by varying the shape and thus effective properties of the heat rejection system in response to temperature. When employed as a radiator for crewed spacecraft thermal control this permits the use of higher freezing point, non-toxic thermal working fluids in single-loop thermal control systems for crewed vehicles in space and other extraterrestrial environments.

Owner:COGNATA THOMAS JASPERO +3

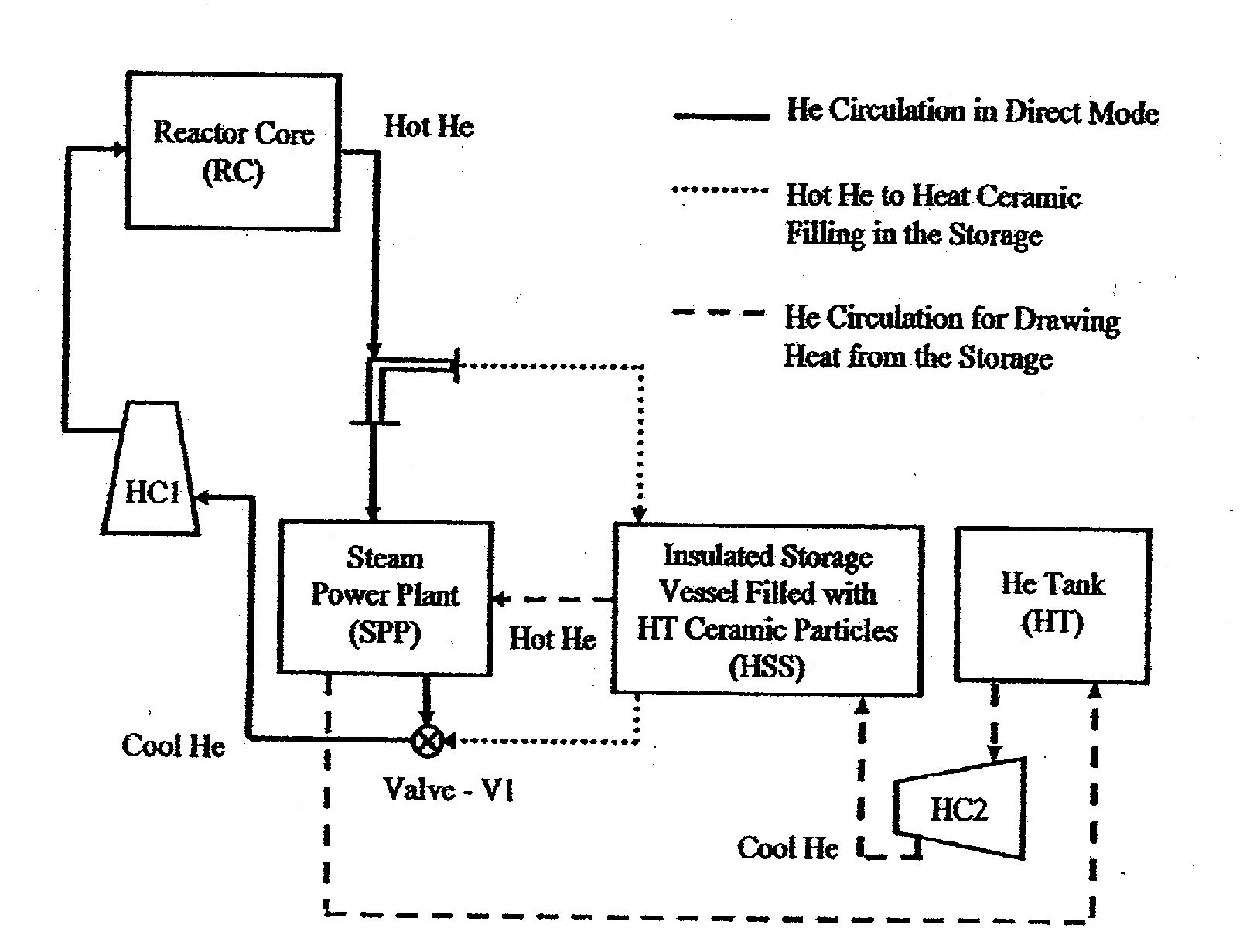

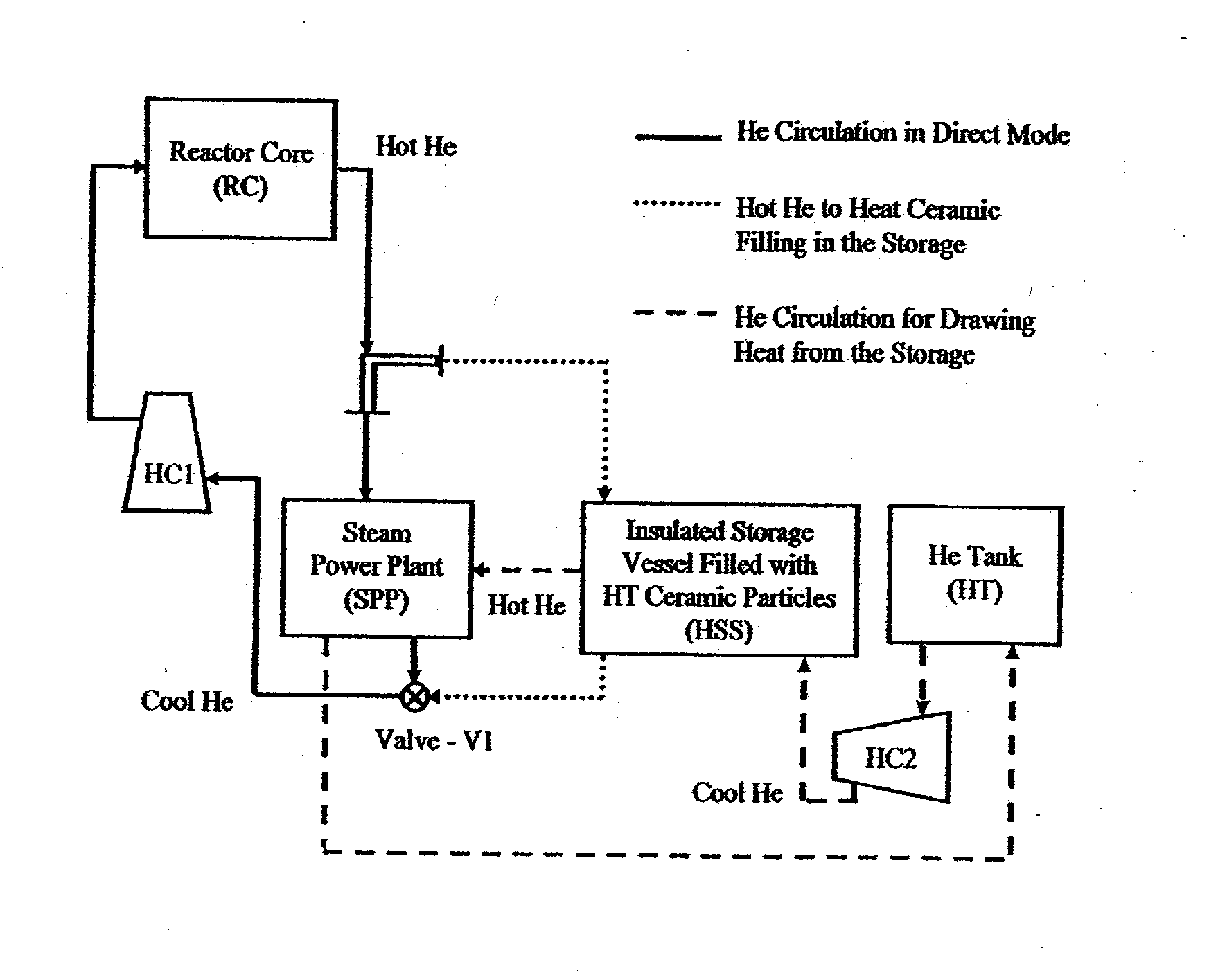

System and method for storing energy in a nuclear power plant

ActiveUS20100202582A1Increase the turndown ratioRapid responseSteam generation heating methodsNuclear energy generationNuclear plantPower station

A method of storing heat includes moving a portion of a heated fluid from at least one reactor core to at least one tank having solid media, storing heat from the portion of the heated fluid in the solid media, and transferring the stored heat from the solid media to a fluid that can be used by a power plant to generate electrical energy. A system for storing heat in a nuclear power plant includes at least one tank comprising solid media structured and arranged to store heat and an arrangement structured and arranged to pass a first fluid through the at least one tank, transfer heat from the first fluid to the solid media, store the heat in the solid media, and transfer the heat from the solid media to a second fluid. This Abstract is not intended to define the invention disclosed in the specification, nor intended to limit the scope of the invention in any way.

Owner:RES FOUND THE CITY UNIV OF NEW YORK

Flow meter

InactiveUS20090099794A1Increase the turndown ratioHighly accurate and precise mass flow computationVibration measurement in solidsAnalysing solids using sonic/ultrasonic/infrasonic wavesDifferential pressureEngineering

A simple, passive and rugged device for measuring the flow rate of liquid. A variable area obstruction valve, a differential pressure sensor and a densitometer are combined in a single housing to provide for a highly accurate and precise measure of mass flow.

Owner:ELDEC CORP

Combustion apparatus and method for radiating wall heating system

ActiveUS6979191B1Reduce decreaseHigher available turn-down ratioCombustion using gaseous and pulverulent fuelCombustion using liquid and pulverulent fuelCombustorHeating system

A burner and combustion method for a radiant wall heating system wherein each burner fuel ejector is positioned such that at least a substantial portion of the burner combustion air is discharged from an area beyond the ejector located the greatest distance from the radiant wall.

Owner:ZEECO

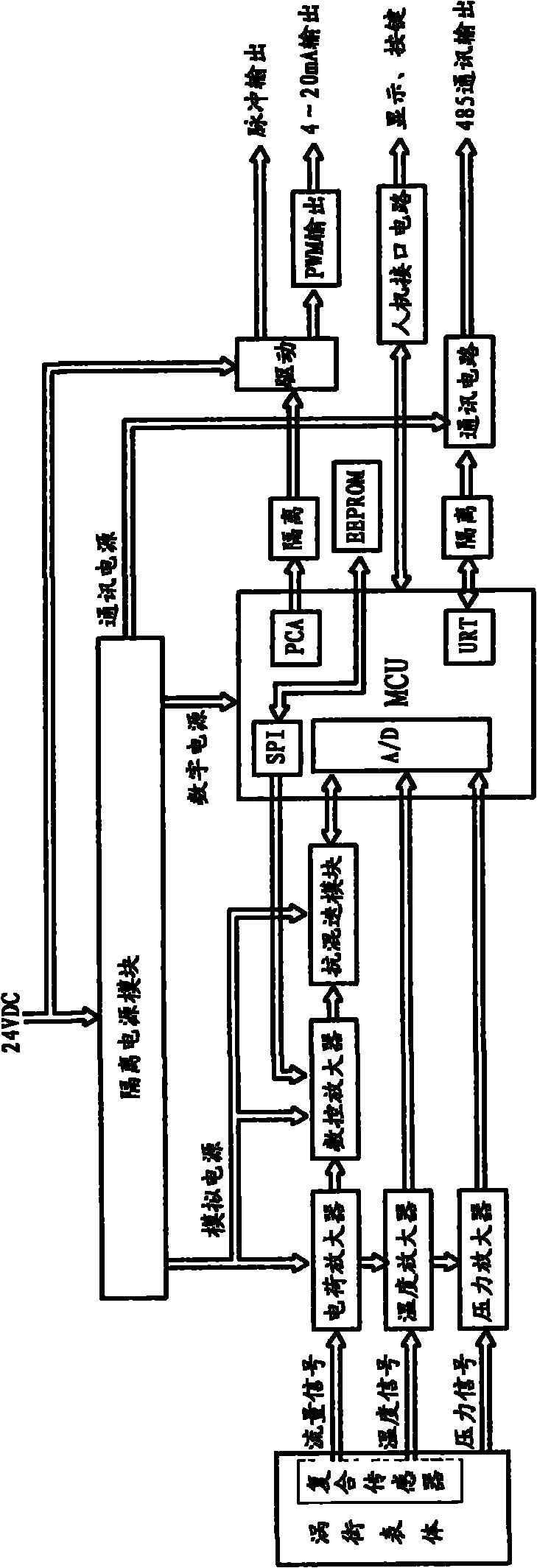

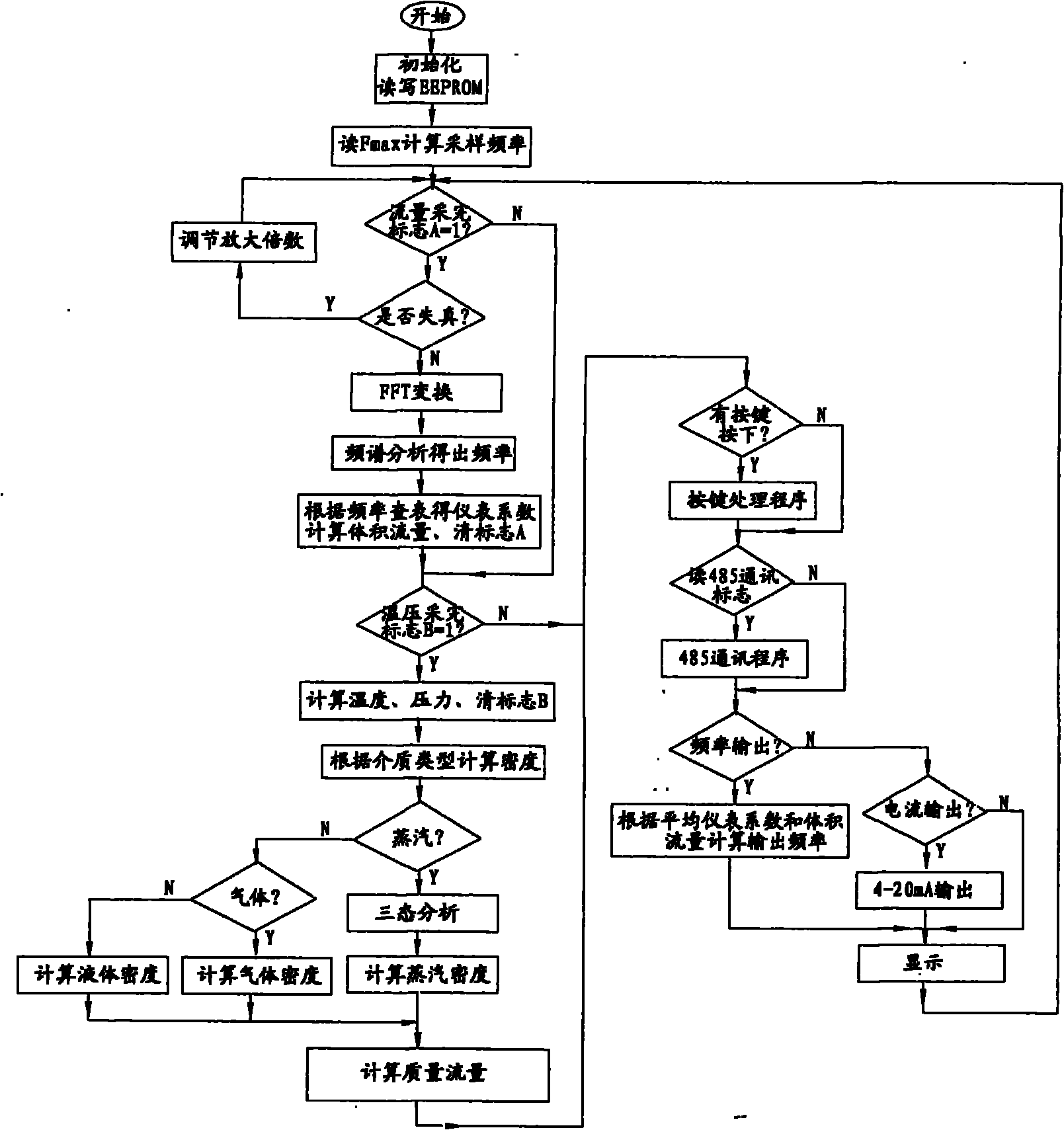

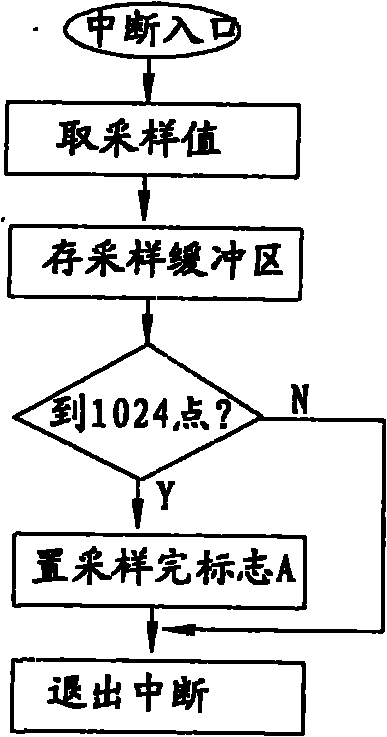

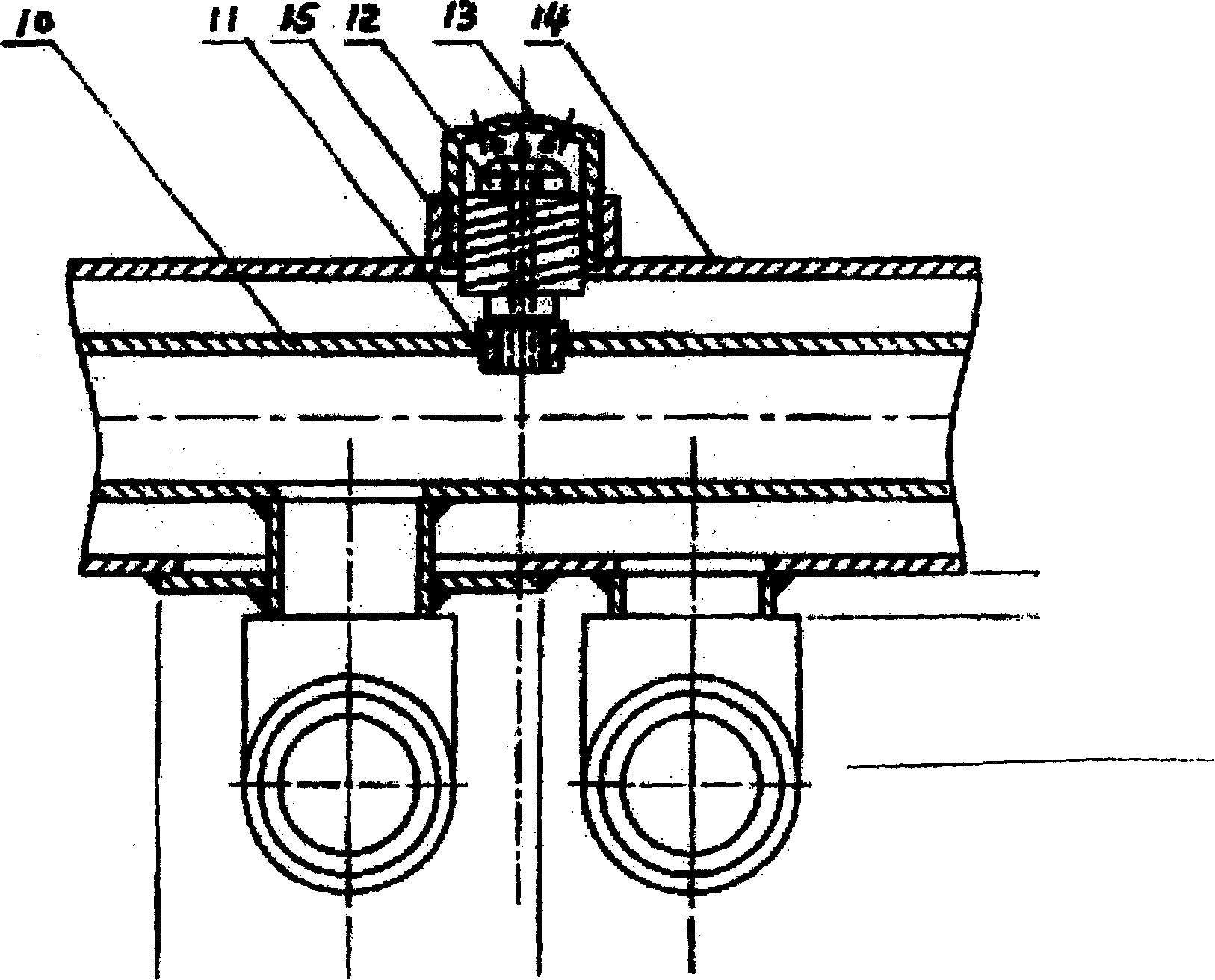

Digital integrated mass vortex-shedding meter

InactiveCN101769773AReduce the starting flow rateIncrease the turndown ratioIndirect mass flowmetersDisplay deviceDischarge measurements

The invention discloses a digital integrated mass vortex-shedding meter, which comprises a meter body, a sensor, amplifiers, output circuits and a display device. The digital integrated mass vortex-shedding meter is characterized in that: 1, amplitude-frequency characteristic identification technology is adopted to identify Fourier spectrum according to an amplitude-frequency characteristic model to further improve the lower limit of measurement capacity; 2, linear correction technology is adopted to calculate flow in sections and inversely calculate frequency output with the flow to improve accuracy; 3, a compound sensor is adopted to integrally measure temperature and pressure to provide data for steam state identification and mass flow calculation; 4, steam state identification technology is adopted to judge a steam state and calculate density with the temperature and the pressure; and 5, on the basis of improving volume flow measurement and the steam state identification, integrated mass flow measurement is realized by flow compensation technology. In an actual measurement process, the digital integrated mass vortex-shedding meter completely eliminates the shortcomings of the poor resistance to shock, low disturbance resisting capacity, large measurement dead zone, poor linearity and the like of the conventional vortex-shedding meter and can greatly reduce measurement starting flow velocity and simultaneously improve the radio of measuring range and accuracy.

Owner:NORTHEASTERN UNIV ENG & RES INST CO LTD +1

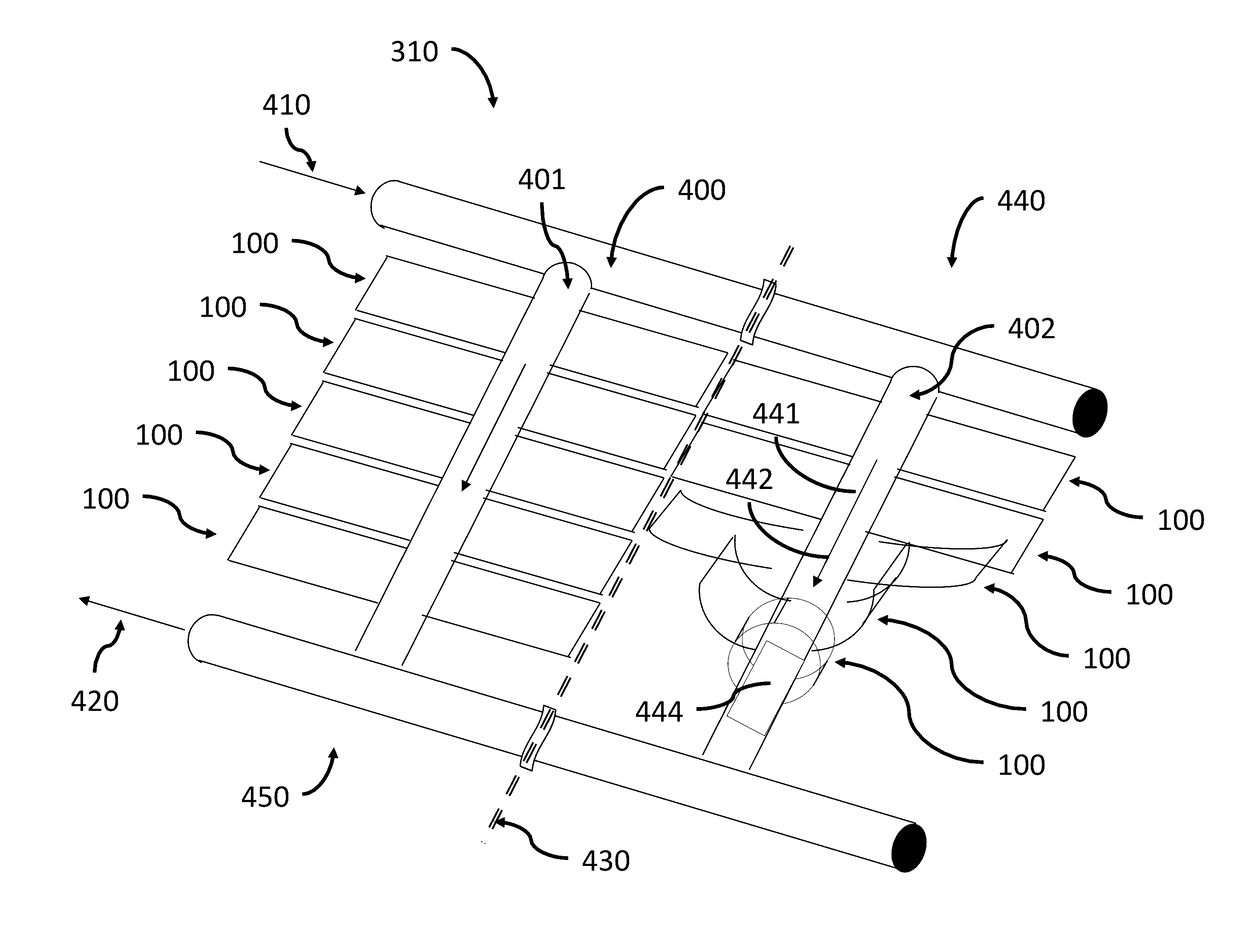

Integrated dual chamber burner with remote communicating flame strip

ActiveUS9097436B1Improved carry-over lightingElimination/reduction of resonant burner noiseFuel supply regulationAir supply regulationCombustion chamberCombustor

A dual chamber burner assembly provides a header, a first burner chamber adjacent the header, and a second burner chamber on an opposite side of the first burner chamber from the header. The second burner chamber is provided with a flame sensor portion extending back through the first burner chamber toward the header so that first and second flame sensors may be utilized to detect flame in the first and second chambers, respectively.

Owner:LOCHINVAR

Stelmo line gas spray cooling device and method for high-speed wire rod mill

InactiveCN1287921CControllable water volumeWater pressure adjustableWork treatment devicesMetal rolling arrangementsWire rodAerosol Mist

Owner:UNIV OF SCI & TECH LIAONING

Gas Heating Appliance

ActiveUS20080289617A1Increase the turndown ratioDomestic stoves or rangesWater supply tanksEngineeringProduct gas

In one aspect the invention discloses an improved gas burner with a high turn-down ratio. The improved burner includes first and second gas flow passages (44, 47), a flame front locator (49) in one of the passages of the burner head. Fuel gas is injected into an end of one of one of the passages (47) and is ignited to establish a flame at the flame front locator (49). Secondary combustion air is provided through the other of the passages (44) which on a high setting enables secondary combustion and on a low setting may mix with the hot gases and cool them resulting in a lower temperature at the cooking vessel.

Owner:FISHER & PAYKEL APPLIANCES LTD

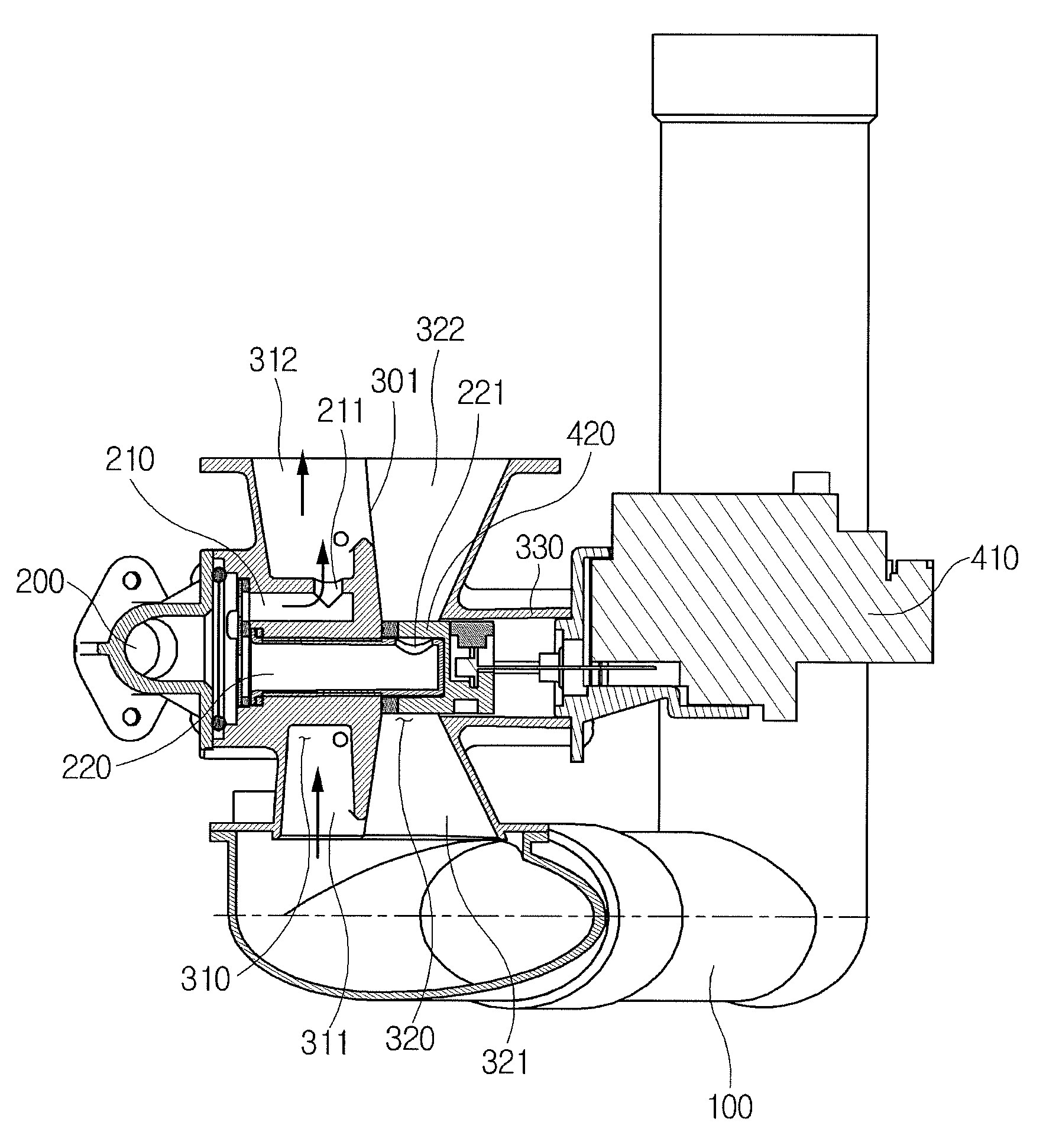

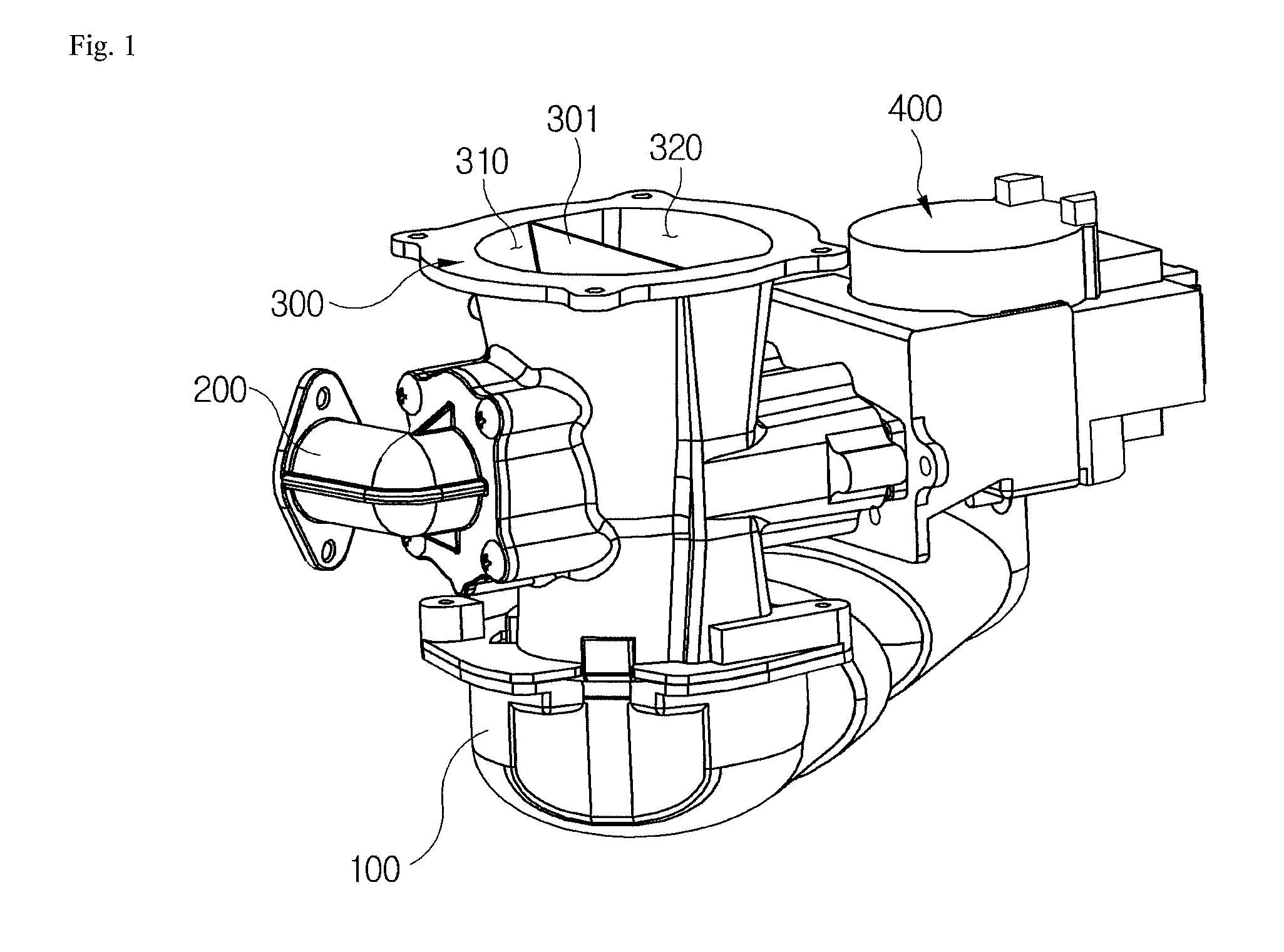

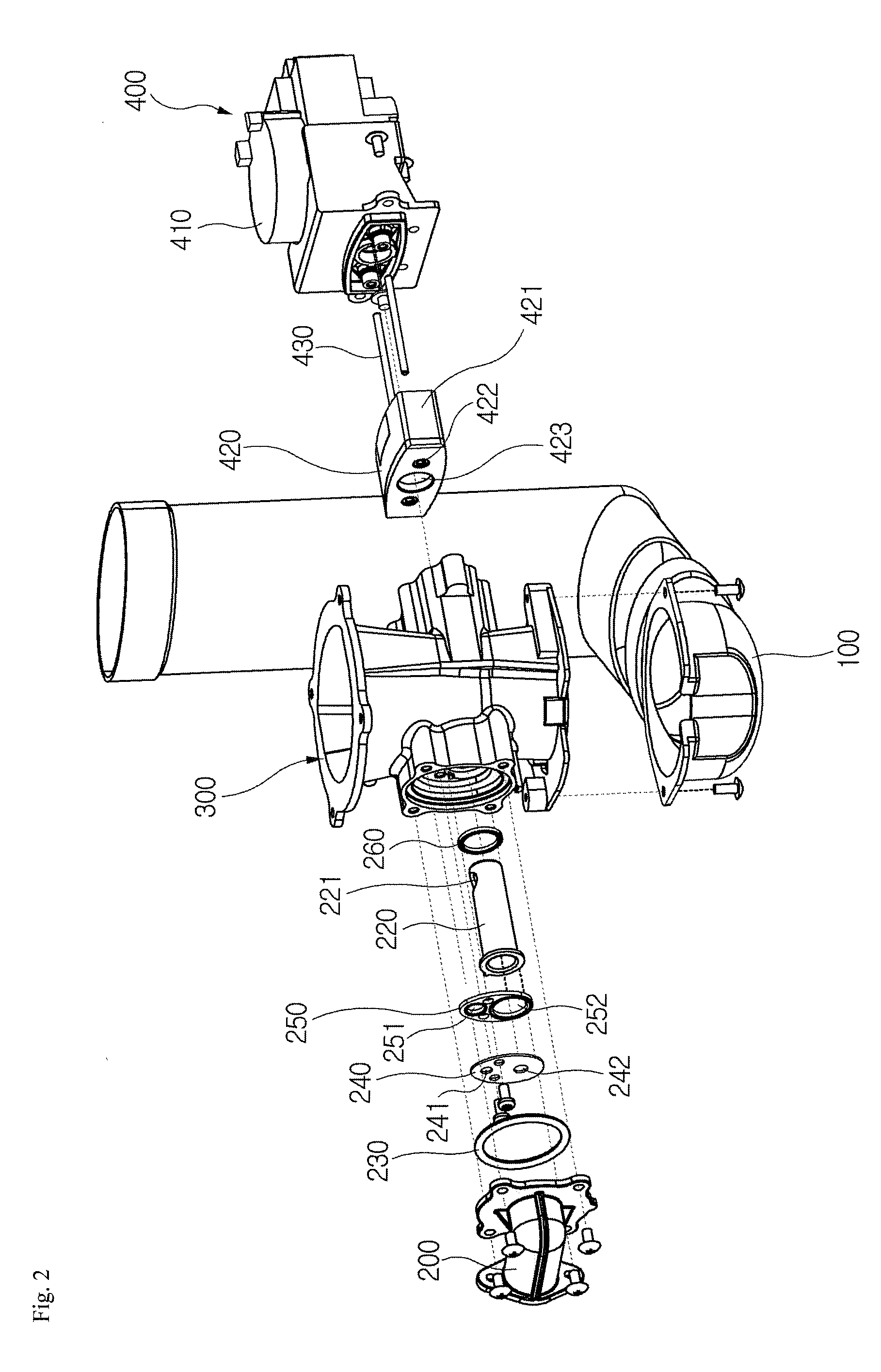

Combustion device for improving turndown ratio

ActiveUS20150086931A1Combustion state is stableImprove combustion efficiencyCombustion using gaseous and pulverulent fuelFuel supply regulationCombustorProcess engineering

The purpose of the present invention is to provide a combustion device for improving a turndown ratio, which is capable of stably implementing a combusted state in a low-output load region by improving a turndown ratio of a burner. To this end, the present invention provides the combustion device having a premixing chamber (300) which is connected to an air supply tube (100) and a gas supply tube (200), and which has a space for premixing air and gas provided therein, wherein the space for premixing the air and gas supplied from the air supply tube (100) and the gas supply tube (200) is divided into multiple stages of a venturi structure in the premixing chamber (300), and the discharging direction of the gas discharged inside the premixing chamber (300) through the gas supply tube (200) is formed in parallel to the flow direction of the gas supplied inside the premixing chamber (300) through the air supply tube (100).

Owner:KYUNGDONG NAVIEN

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com