Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

190 results about "Bypass ratio" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

The bypass ratio (BPR) of a turbofan engine is the ratio between the mass flow rate of the bypass stream to the mass flow rate entering the core. A 10:1 bypass ratio, for example, means that 10 kg of air passes through the bypass duct for every 1 kg of air passing through the core.

Turbofan engine including fans with reduced speed

InactiveUS6209311B1Shorten speedIncrease the outer diameterGas turbine plantsEfficient propulsion technologiesImpellerFluid coupling

An impeller is directly driven by an output shaft of a core engine. The airflow produced by the impeller rotates an air turbine and a fan disposed integrally with the air turbine. The impeller and the air turbine form a fluid coupling which serves also as a speed reducing mechanism. The rotational speed of the fan can be reduced to be lower than that of the output shaft while retaining efficiency of the core engine. The outer diameter of the fan can be increased, raising a bypass ratio.

Owner:NIKKISO COMPANY

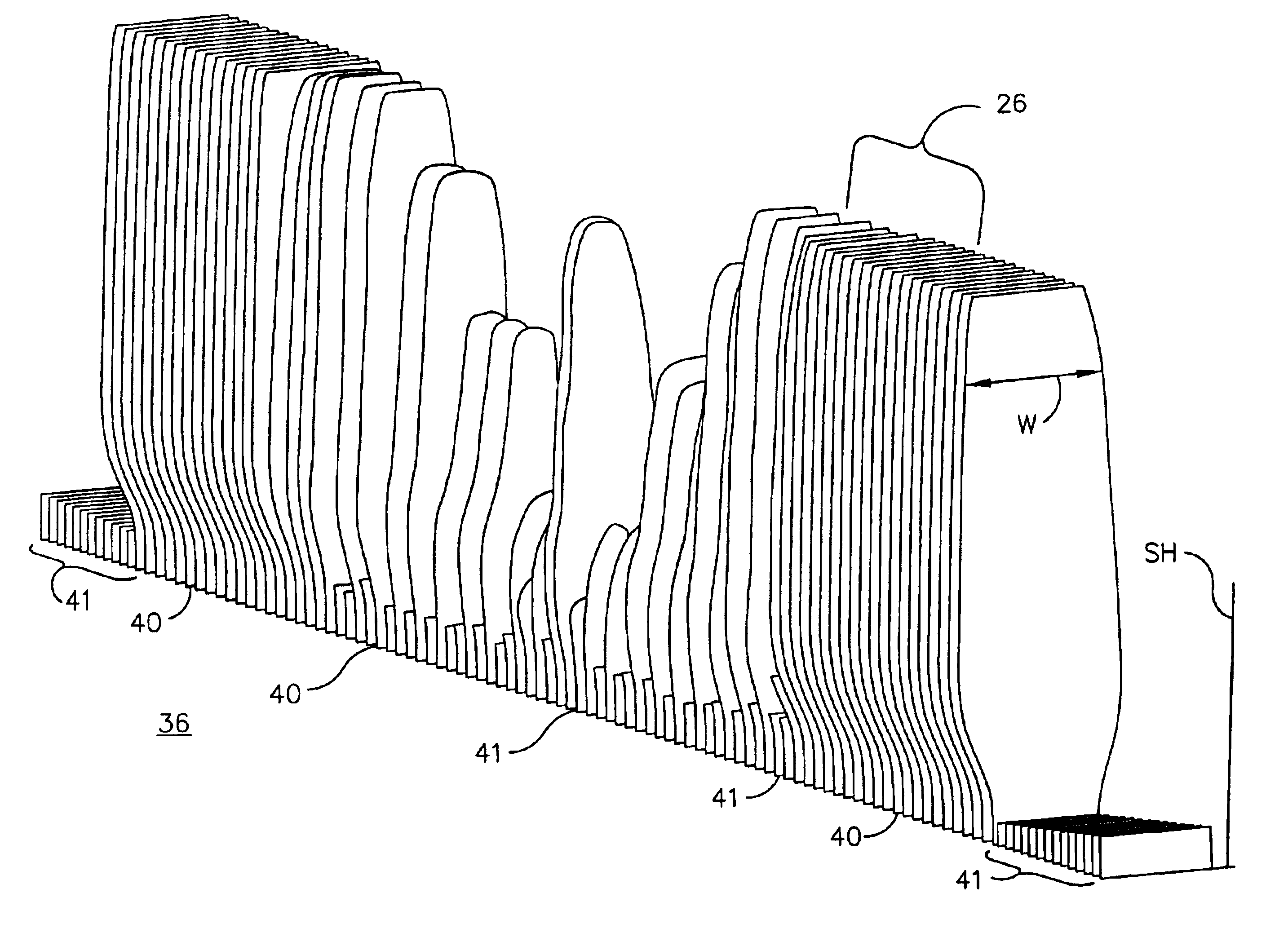

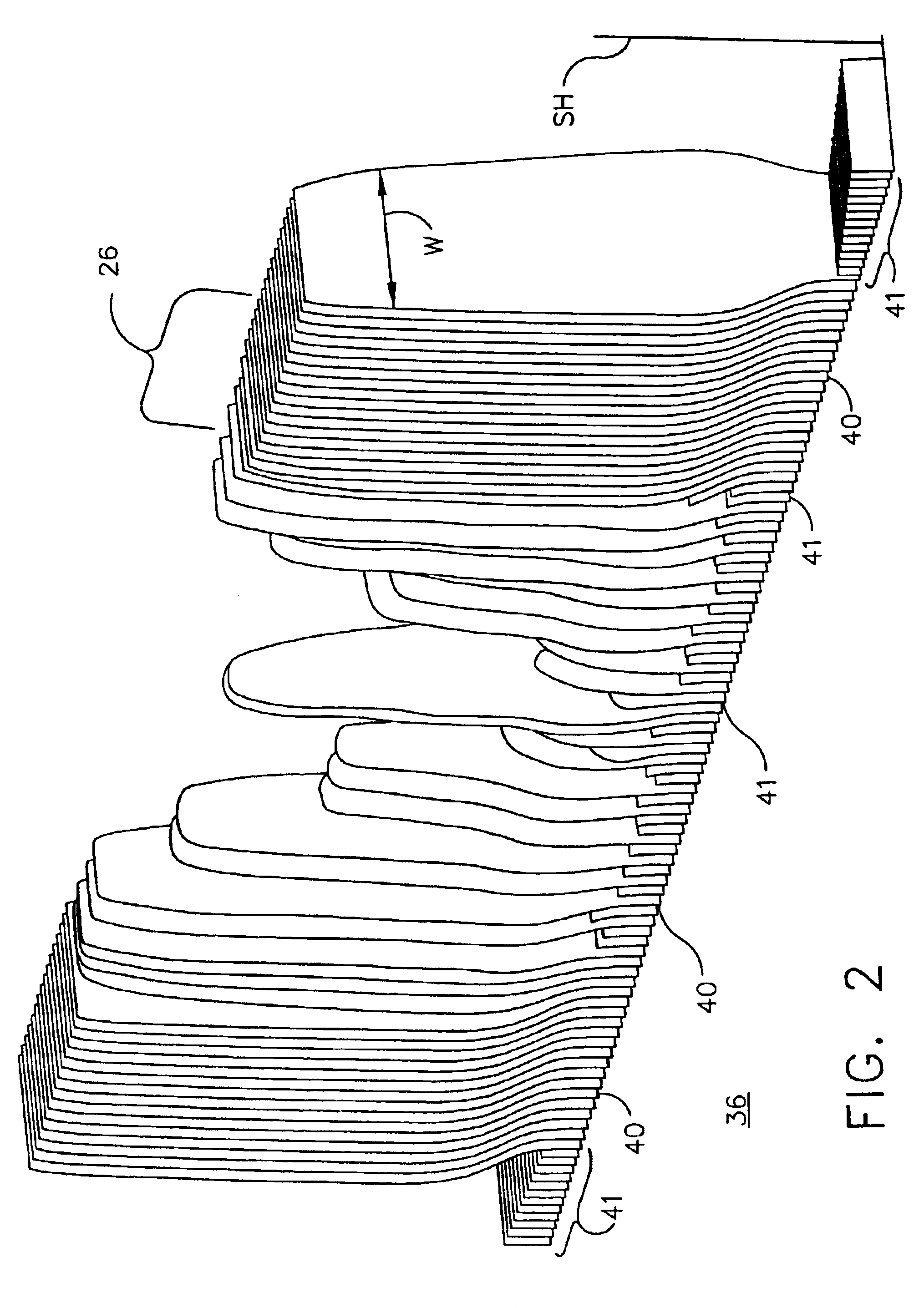

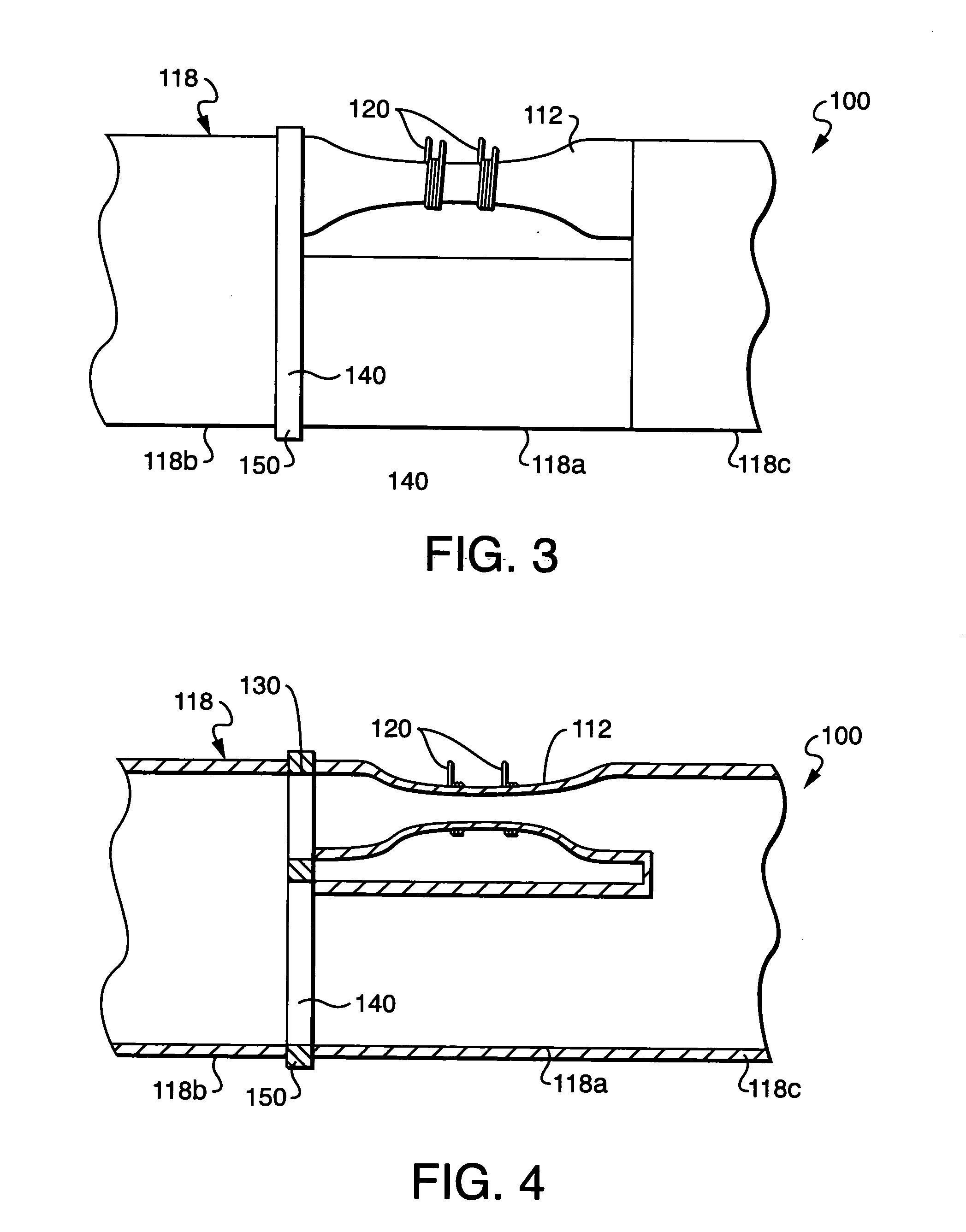

Laser projection system to facilitate layup of complex composite shapes

InactiveUS6843565B2Increased ply lay-up speedReduce morbidityBlade accessoriesProjectorsData setComposite laminates

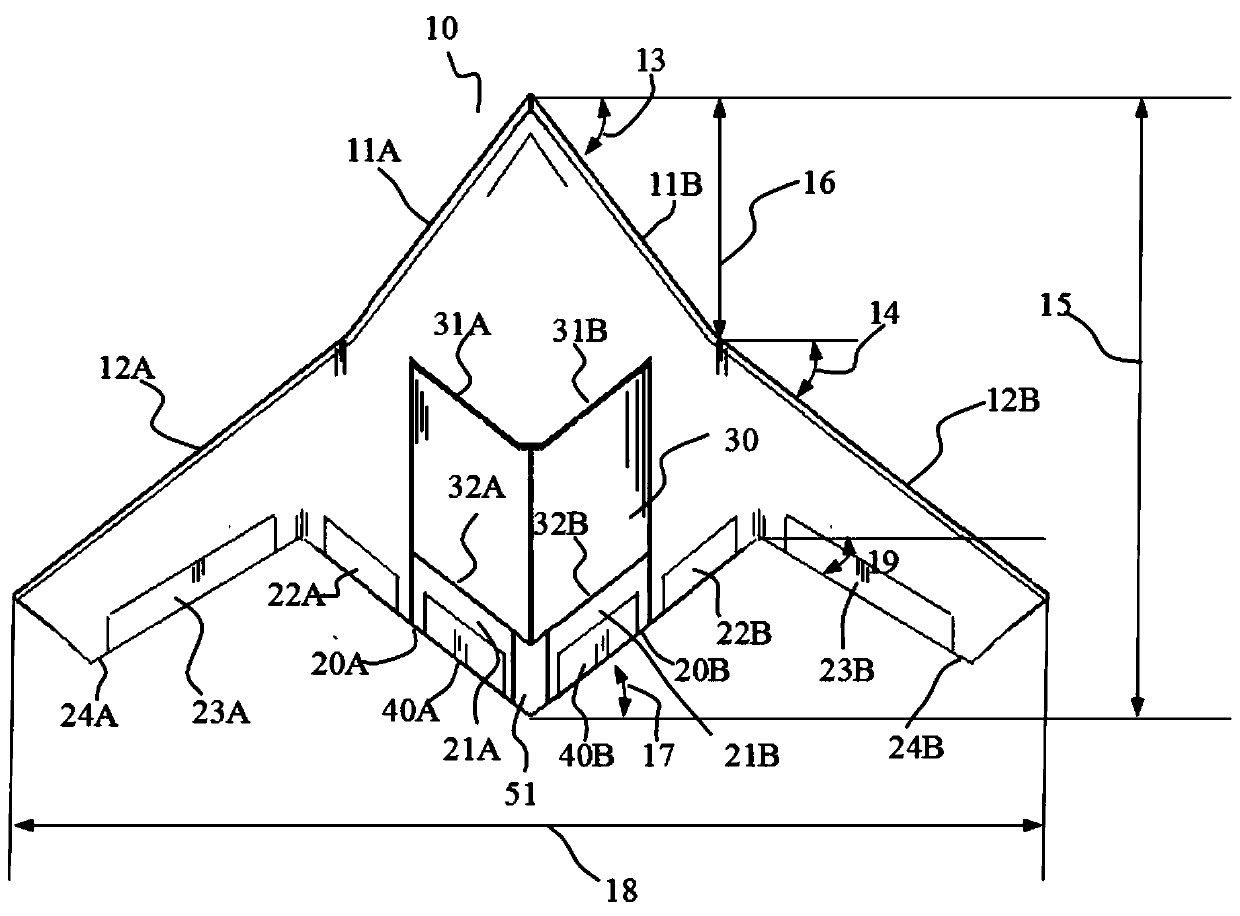

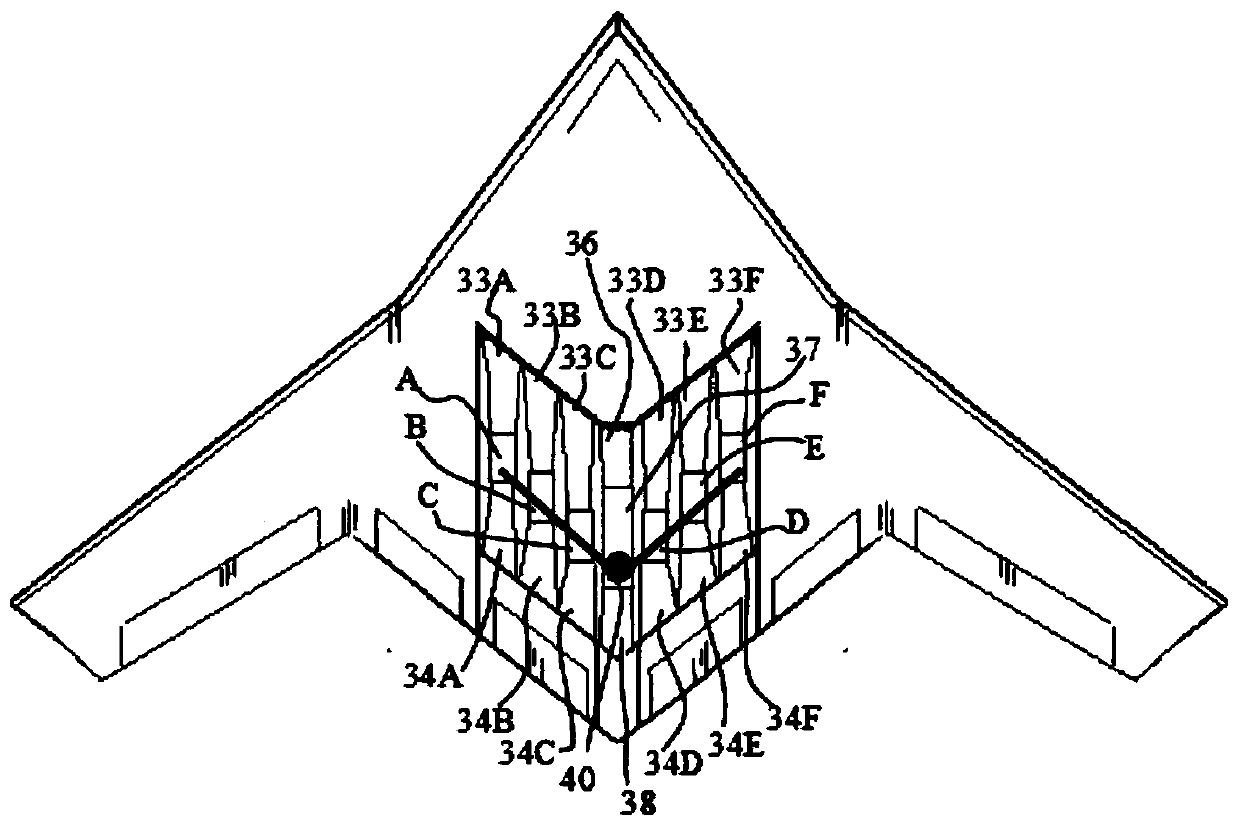

The present invention provides a process for the lay-up of a composite laminate article, the article produced by this process, and the apparatus used to produce the composite laminate article. The composite laminate article may be, for example, an airfoil, particularly useful as a fan blade in a large high bypass ratio turbofan engine, wherein the blade is generally regarded as large and having a high degree of twist. In a preferred embodiment, the present invention provides a process for laying up a composite laminate article comprising a) reading a data set to enable the projection of an image of a ply section onto a work surface, the image indicating a ply section target point; b) laying up a ply section of composite laminating material within the image, wherein the ply section first contacts the work surface at the target point; and c) repeating steps (a)-(b) until the composite laminate article is complete. In a second preferred embodiment, the present invention provides for a lamination apparatus for use in making a composite laminate article comprising a work surface for receiving, in a predetermined sequence, a plurality of ply sections of composite laminating material; a laser projection system using predetermined projection points for outlining an image of a ply section onto the work surface, the image further indicating a ply section target point for making first contact of the ply section with the work surface; and a data set for providing the predetermined projection points to the laser projection system.

Owner:GENERAL ELECTRIC CO

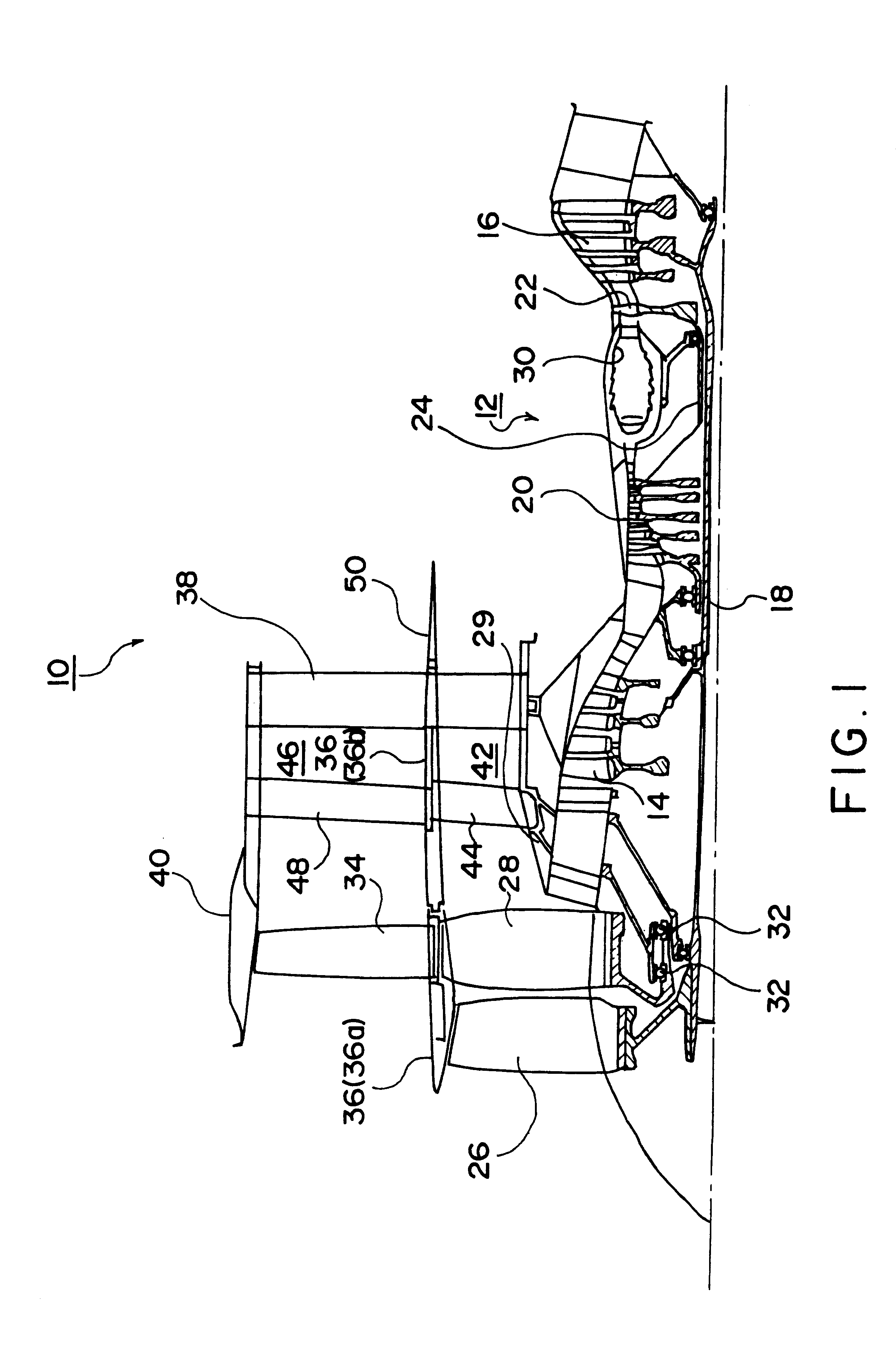

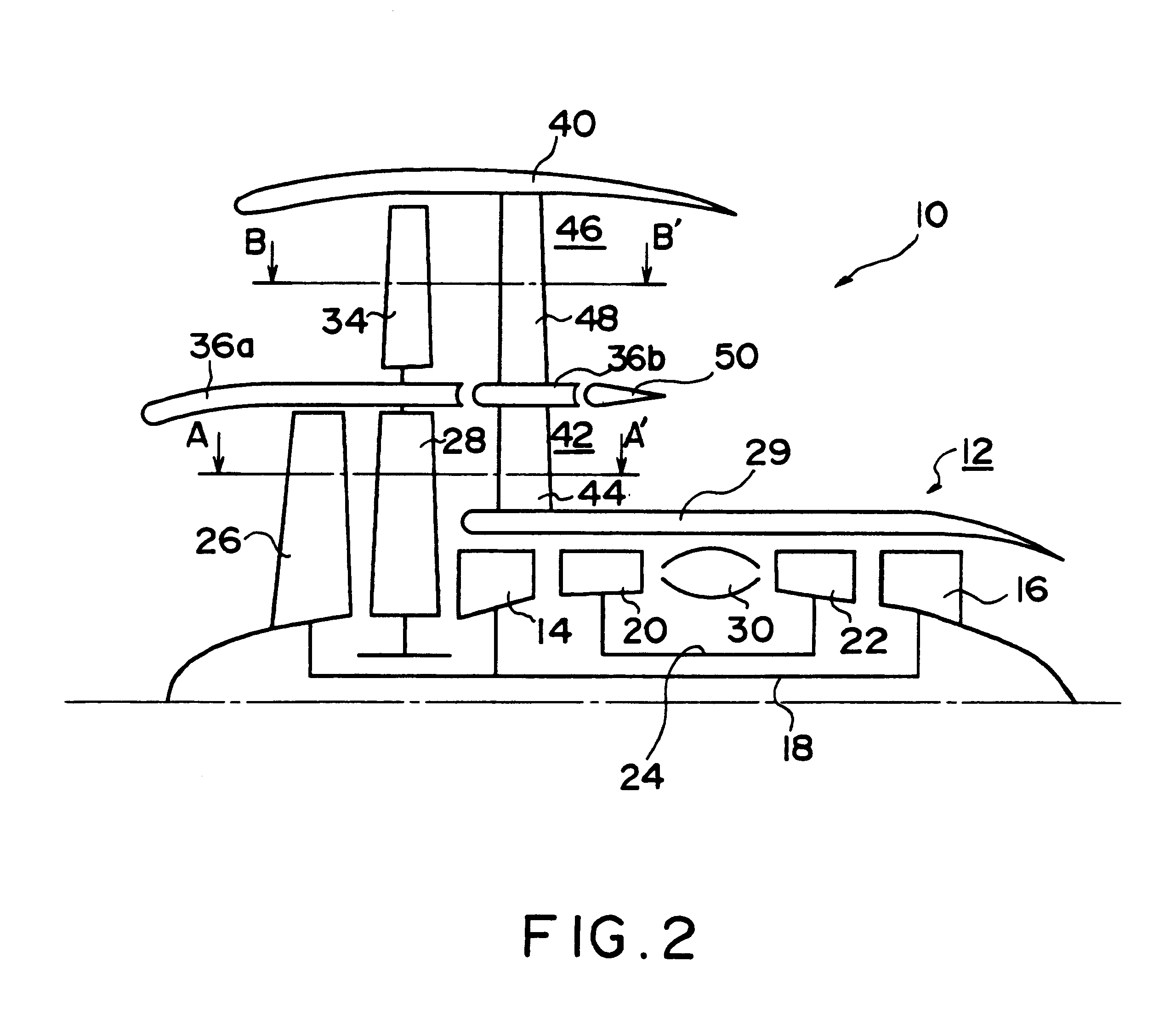

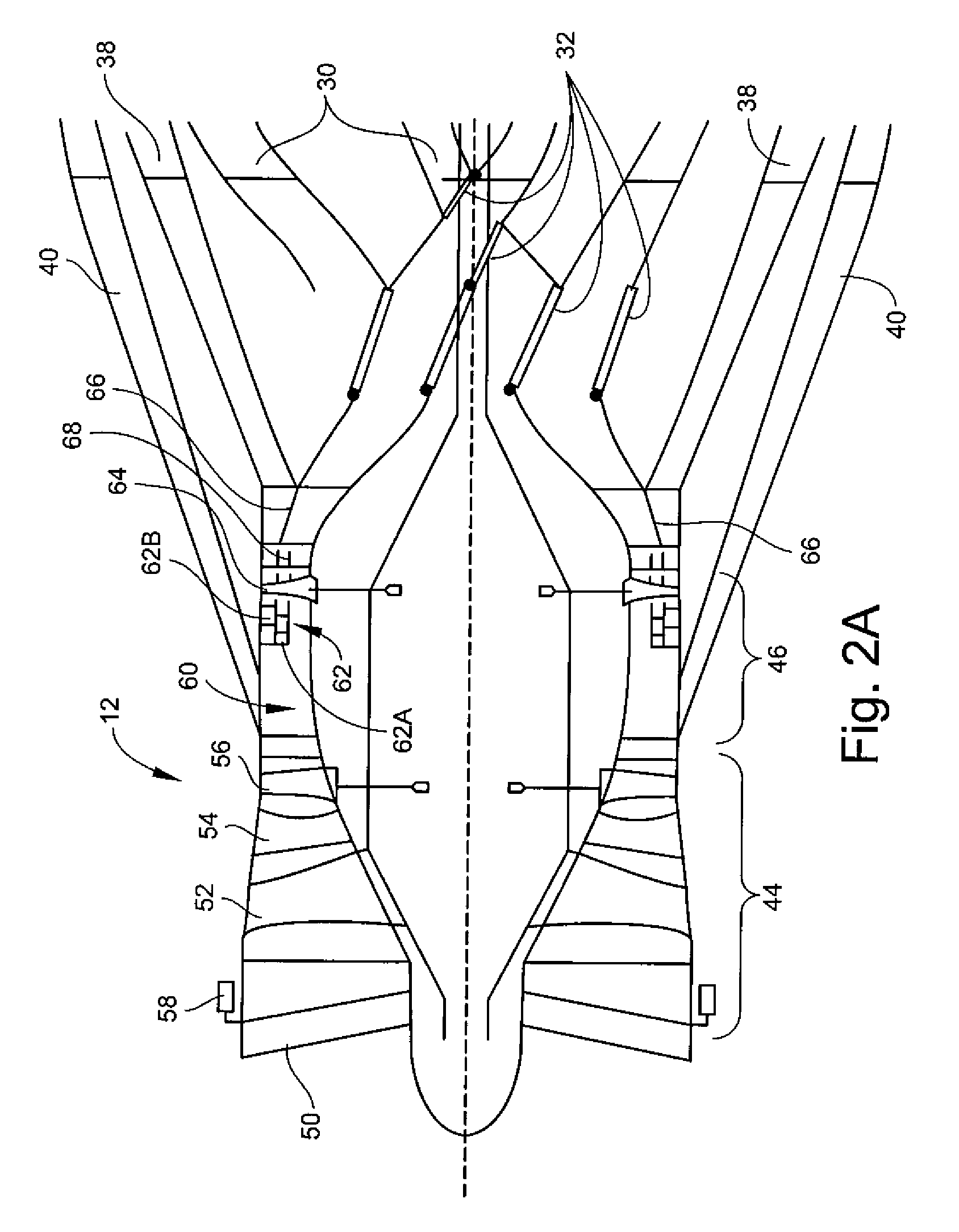

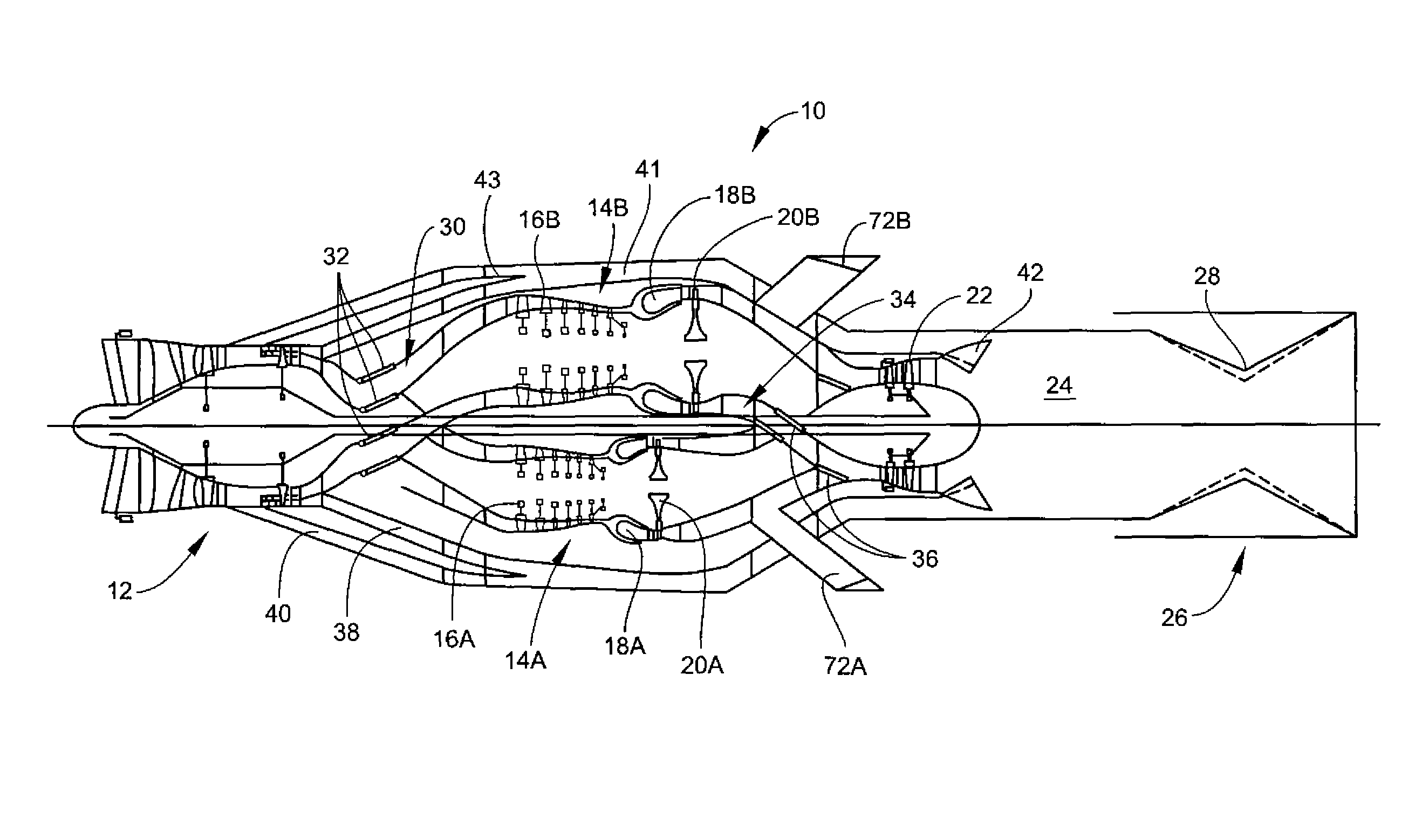

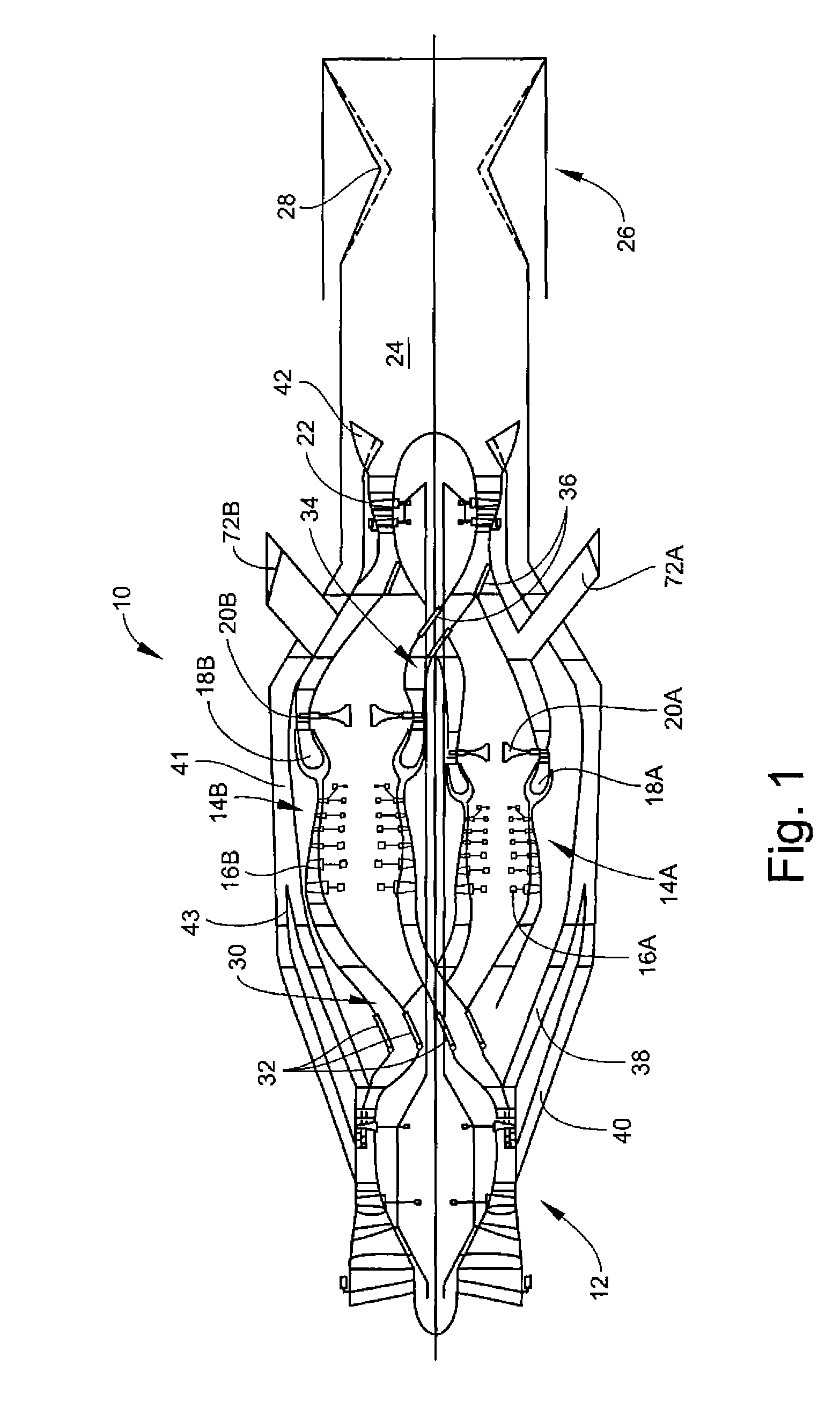

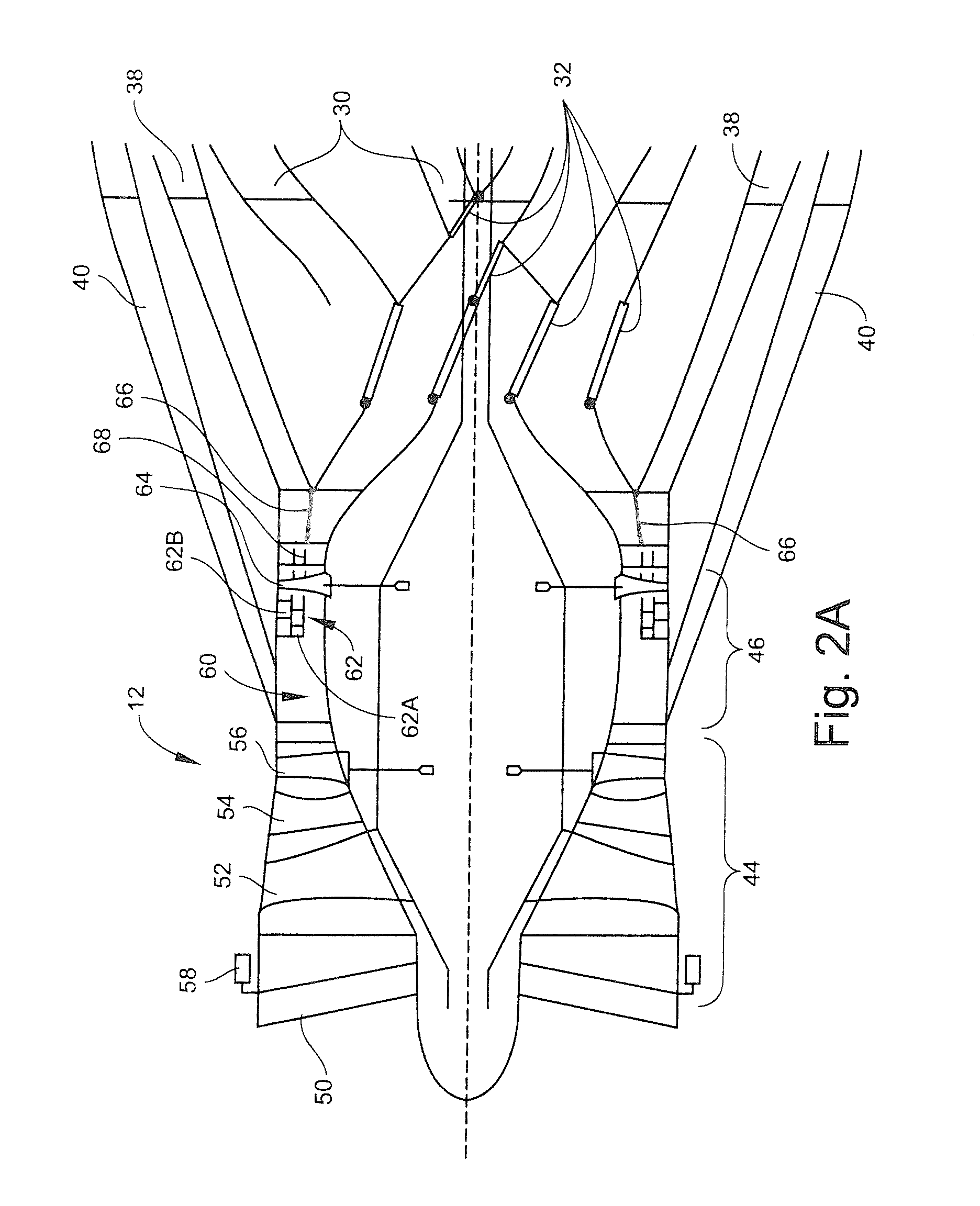

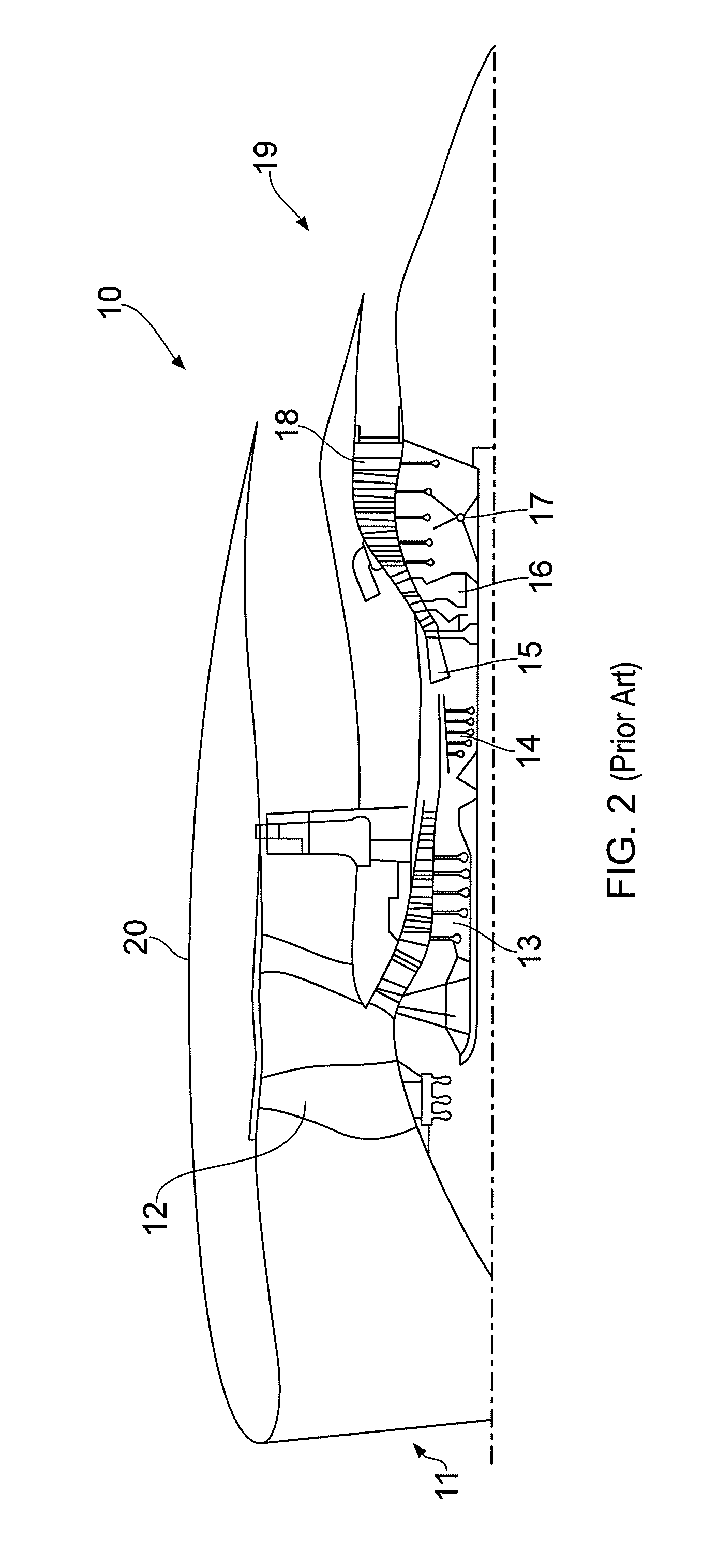

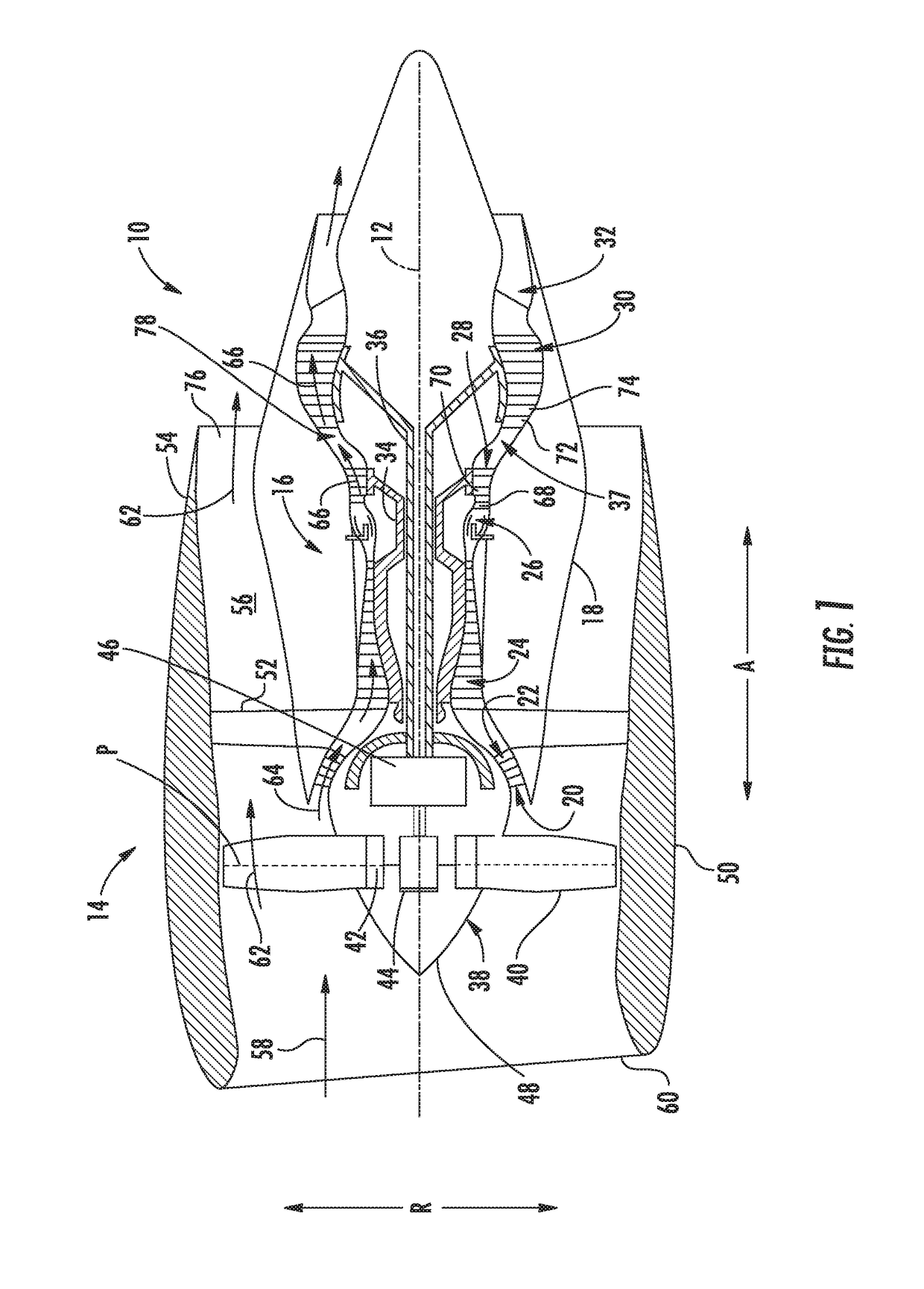

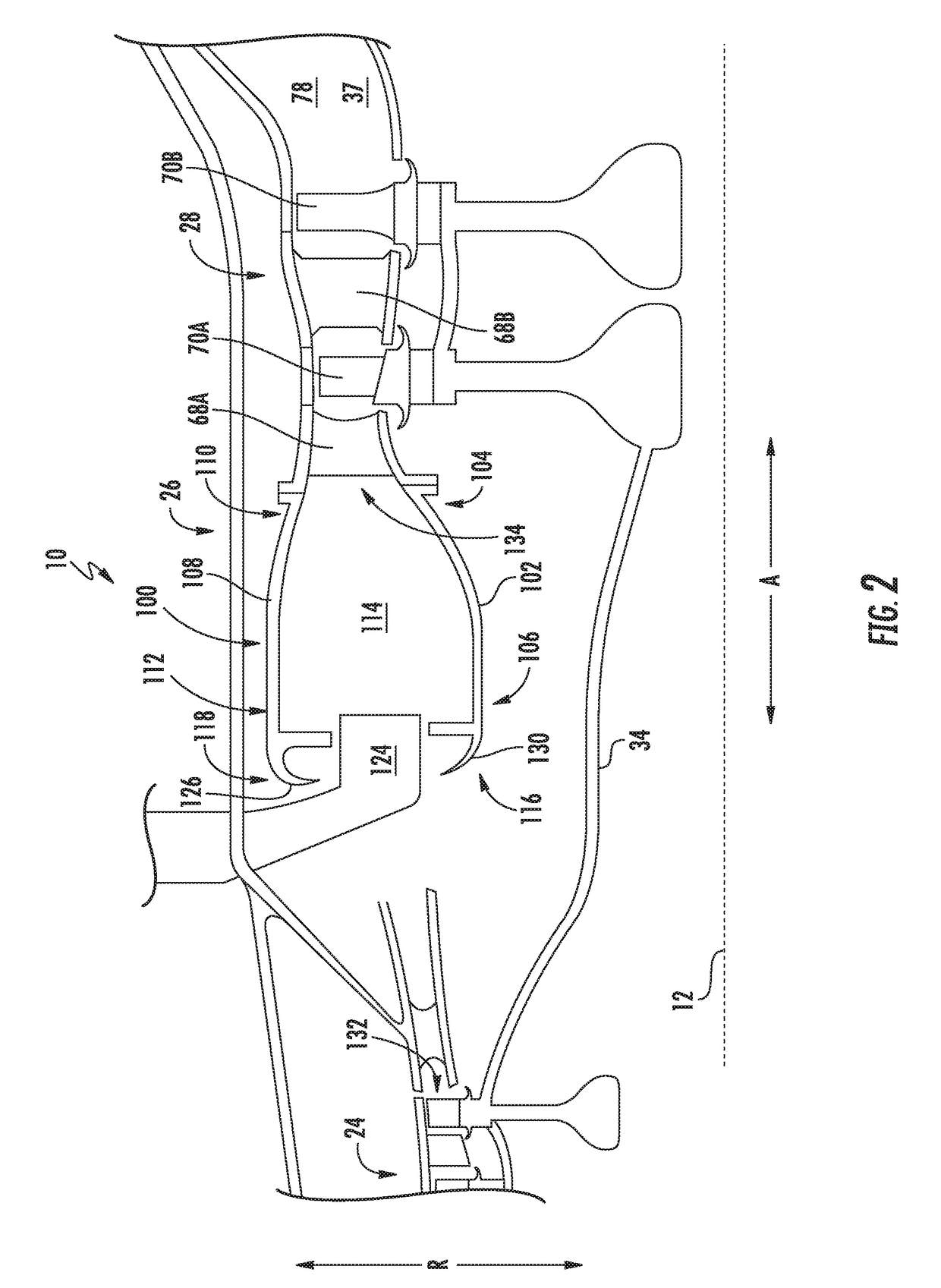

Convertible gas turbine engine

A gas turbine engine includes a turbomachinery core operable to generate a flow of pressurized combustion gases at a variable flow rate, while maintaining a substantially constant core pressure ratio; a rotating fan disposed upstream of the core, the fan adapted to extract energy from the core and generate a first flow of air which is compressed at a first pressure ratio; and at least a first bypass duct surrounding the core downstream of the fan adapted to selectively receive at least a first selected portion of the first flow which is compressed at a second pressure ratio lower than the first pressure ratio, and to bypass the first selected portion around the core, thereby varying a bypass ratio of the engine. The fan is adapted to maintain a flow rate of the first flow substantially constant, independent of the bypass ratio.

Owner:GENERAL ELECTRIC CO

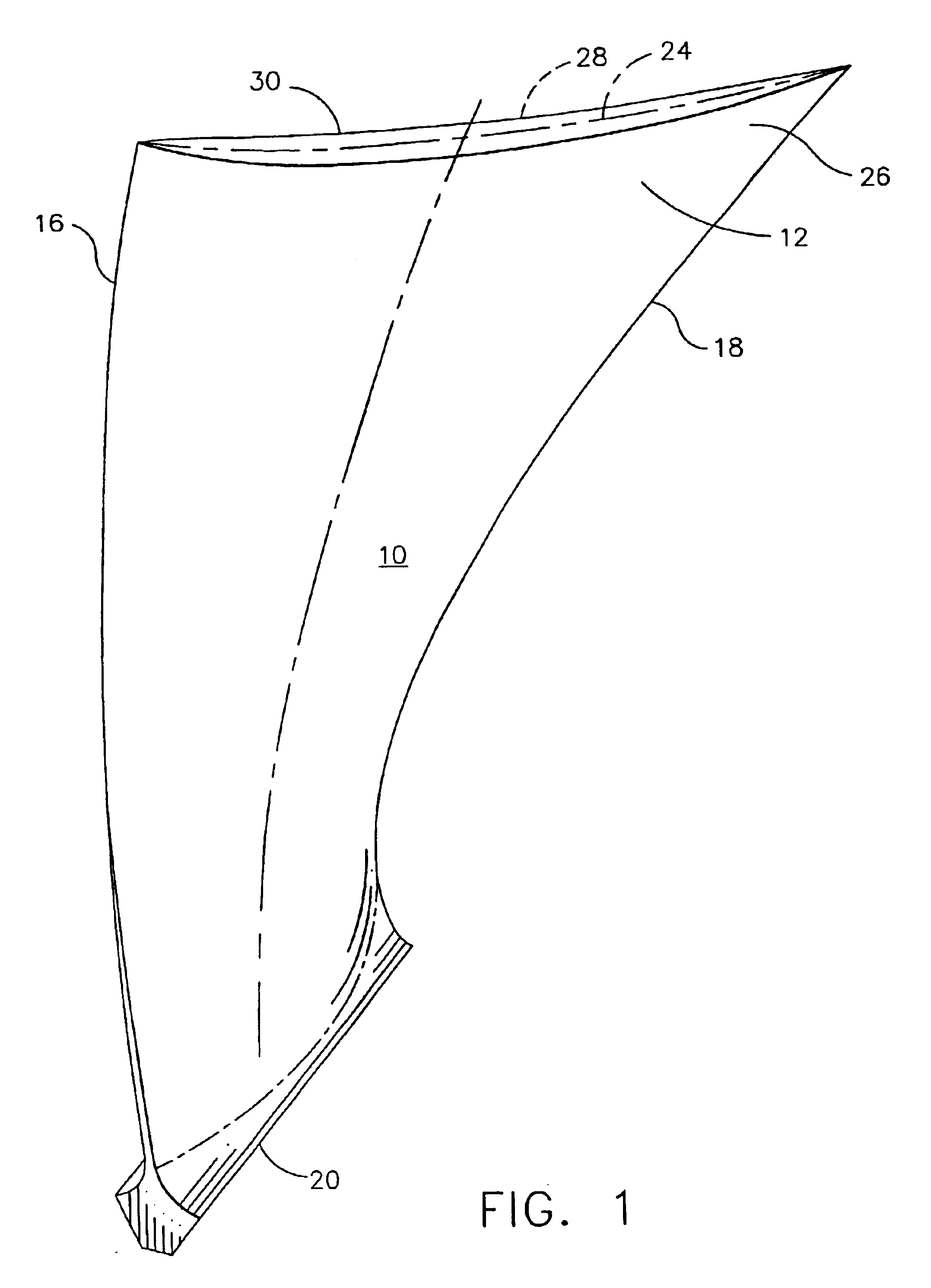

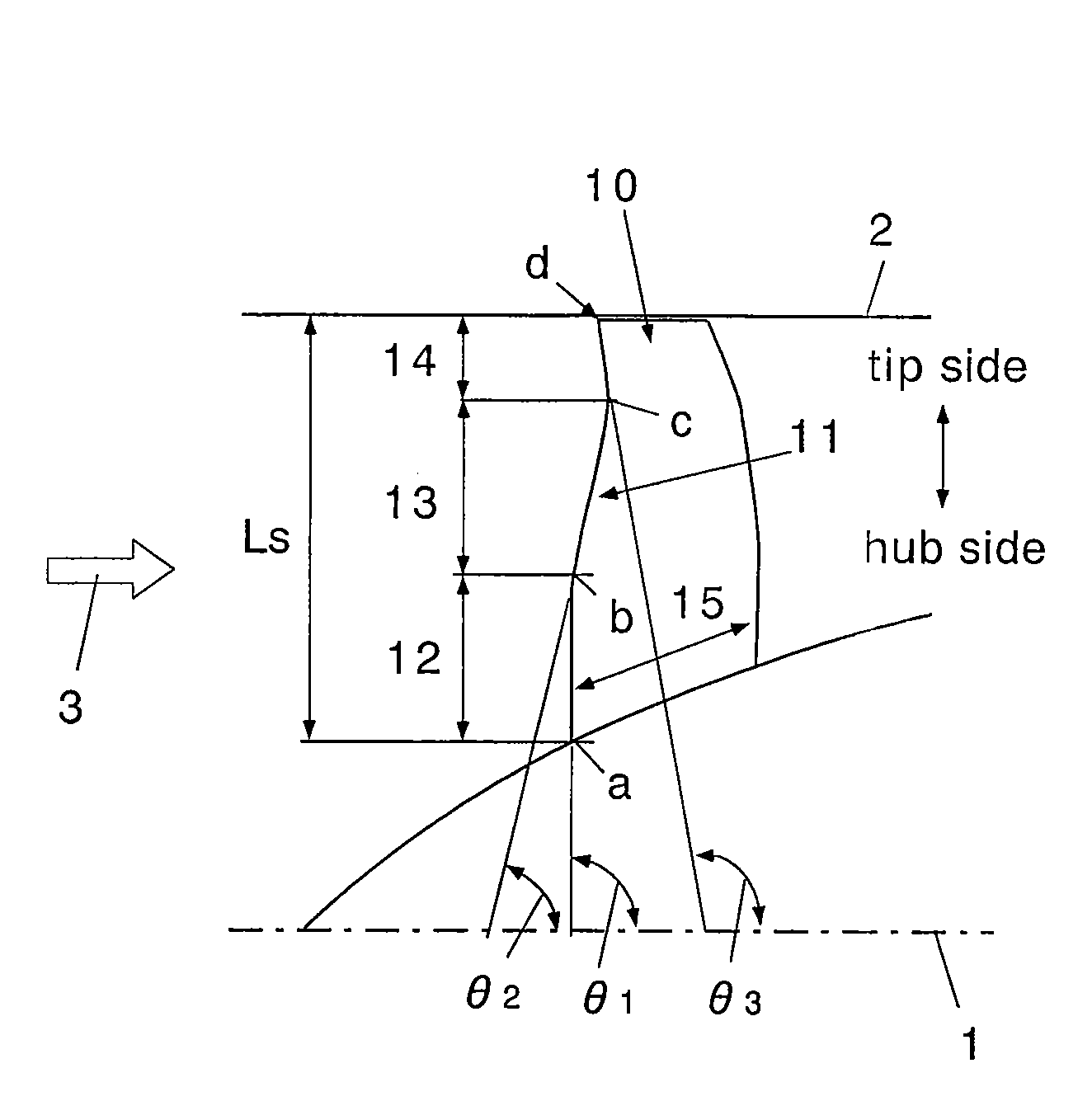

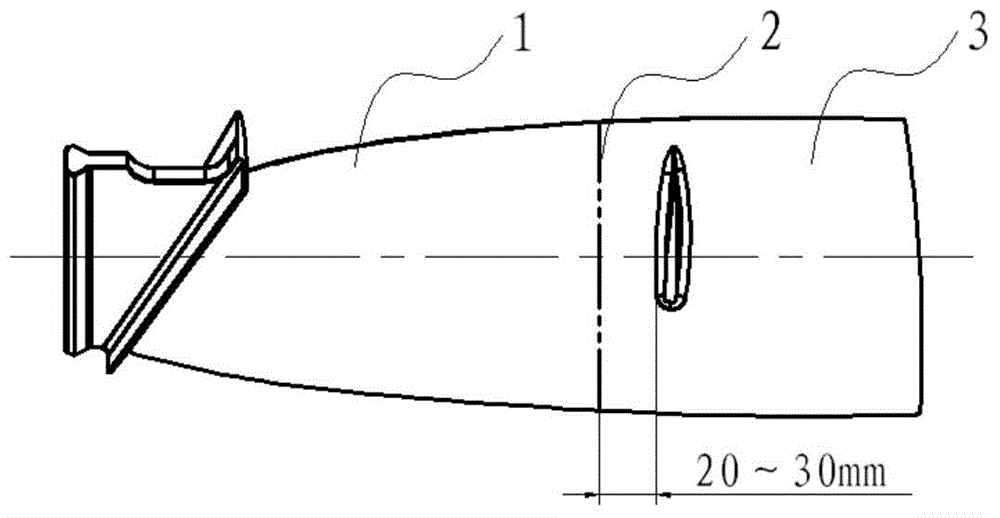

Fan rotating blade for turbofan engine

ActiveUS20100232970A1Relieve pressureIncrease pressure ratioPump componentsBlade accessoriesLeading edgeEngineering

[Object]An object of the invention is to provide a fan rotating blade for a turbofan engine capable of increasing a bypass ratio by increasing an intake air flow rate without enlarging a diameter of a fan and an inner diameter of a casing and of realizing a decrease in weight of an engine as well as a decrease in fuel consumption and noise.[Means for Solving the Problems]A leading edge part 11 of a fan rotating blade 10 for taking air thereinto is provided with a vertical hub portion 12 positioned on the hub side so as to be substantially perpendicular to a fan rotary shaft, a backward mid-span portion 13 inclined toward the downstream side from the hub side to the mid-span portion, and a forward inclined tip portion 14 inclined toward the upstream side from the mid-span side to the tip portion.

Owner:IHI CORP

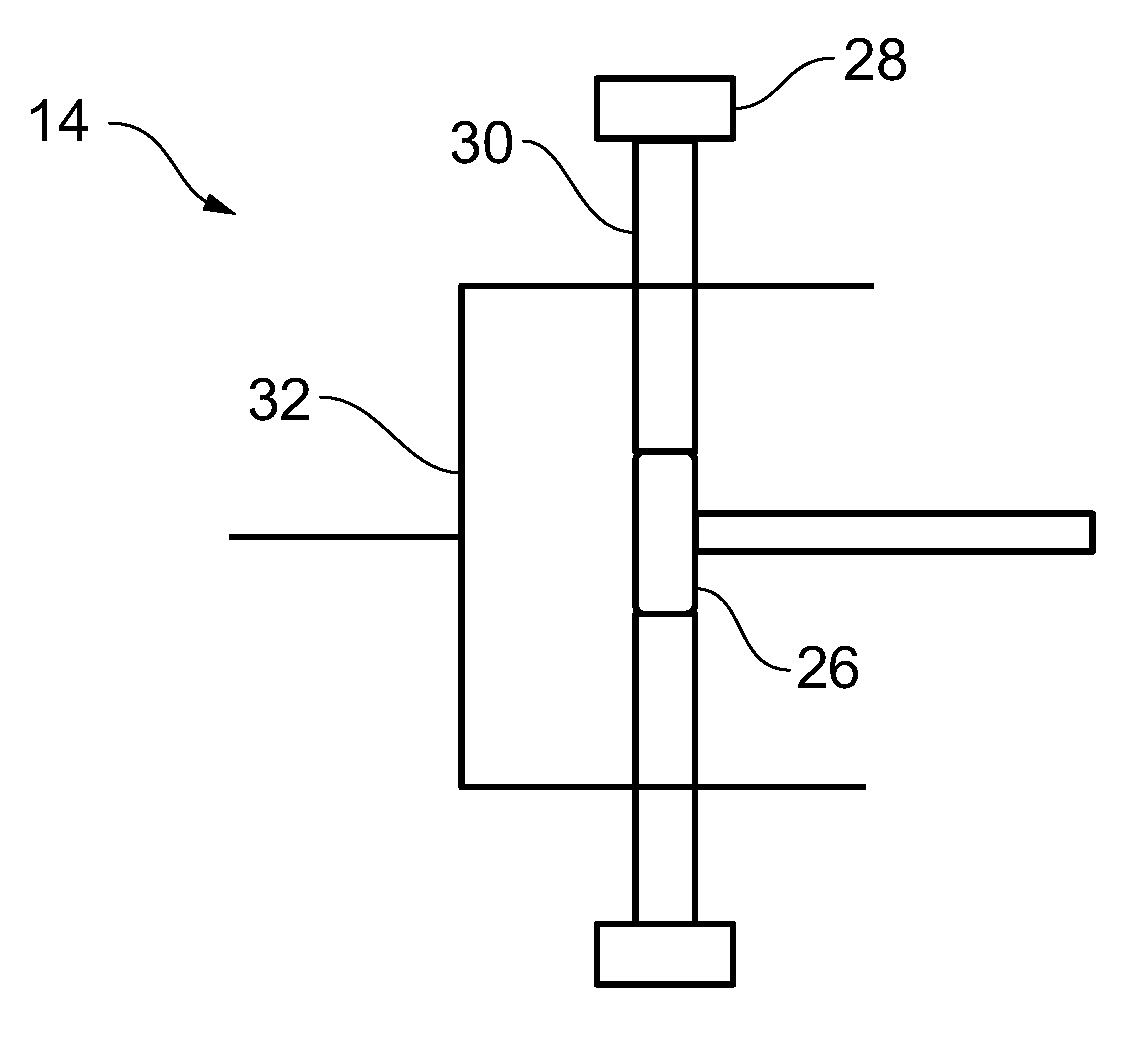

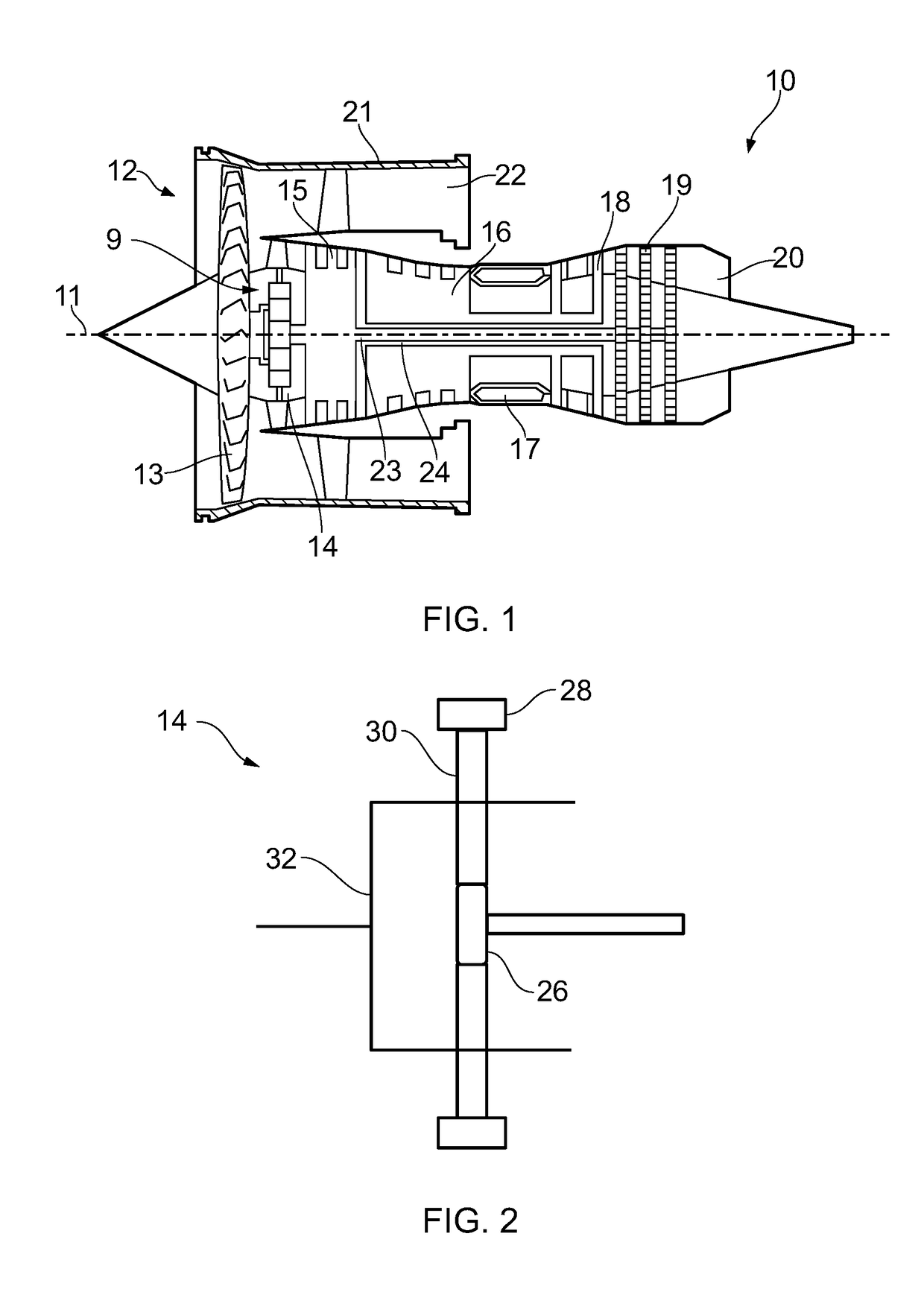

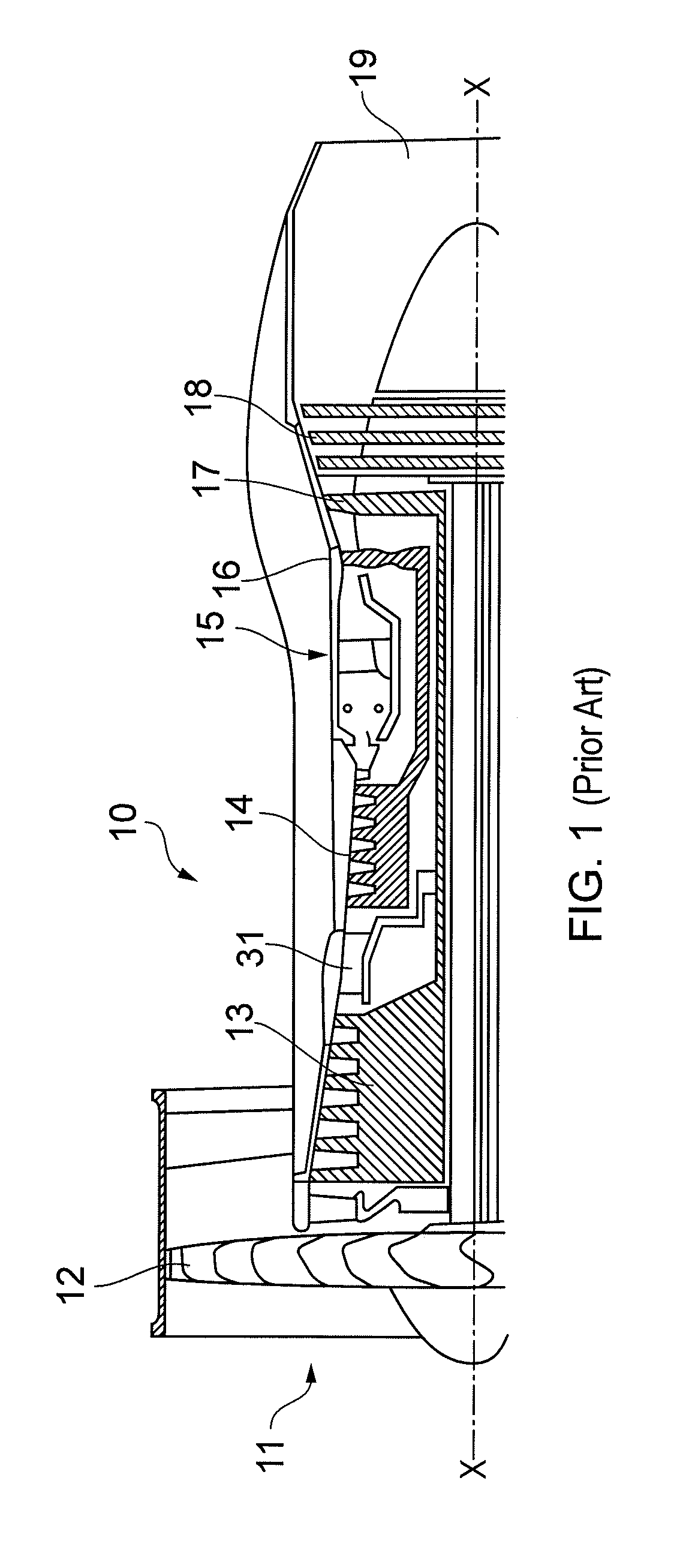

Geared turbofan

PendingUS20180252166A1Low efficiencyReduce fuel consumptionEngine fuctionsToothed gearingsEngineeringHigh pressure

A gas turbine engine (10) comprising: a low pressure turbine (19); a fan (13) drivable by the low pressure turbine. A high pressure turbine (18) and a high pressure compressor (16) coupled by a high pressure shaft (24). An epicyclic gearbox (14) in planetary configuration coupled between a low pressure shaft (23) and the fan. The engine having a bypass ratio greater than or equal to 13. Or the fan having a diameter greater than or equal to 85 inches and less than or equal to 170 inches. Or the engine arranged to generate thrust in the range 35,000 lbf to 130,000 lbf.

Owner:ROLLS ROYCE PLC

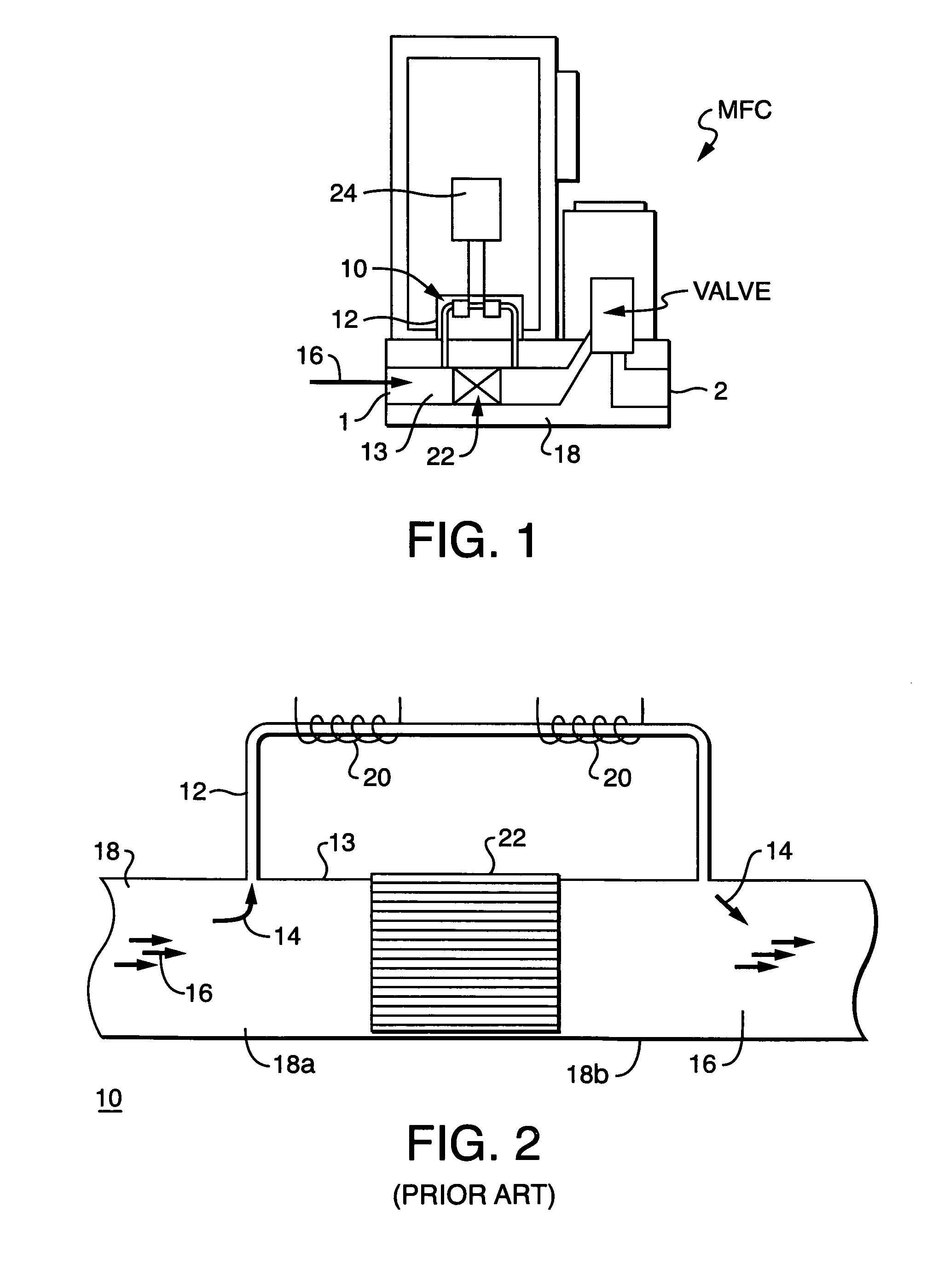

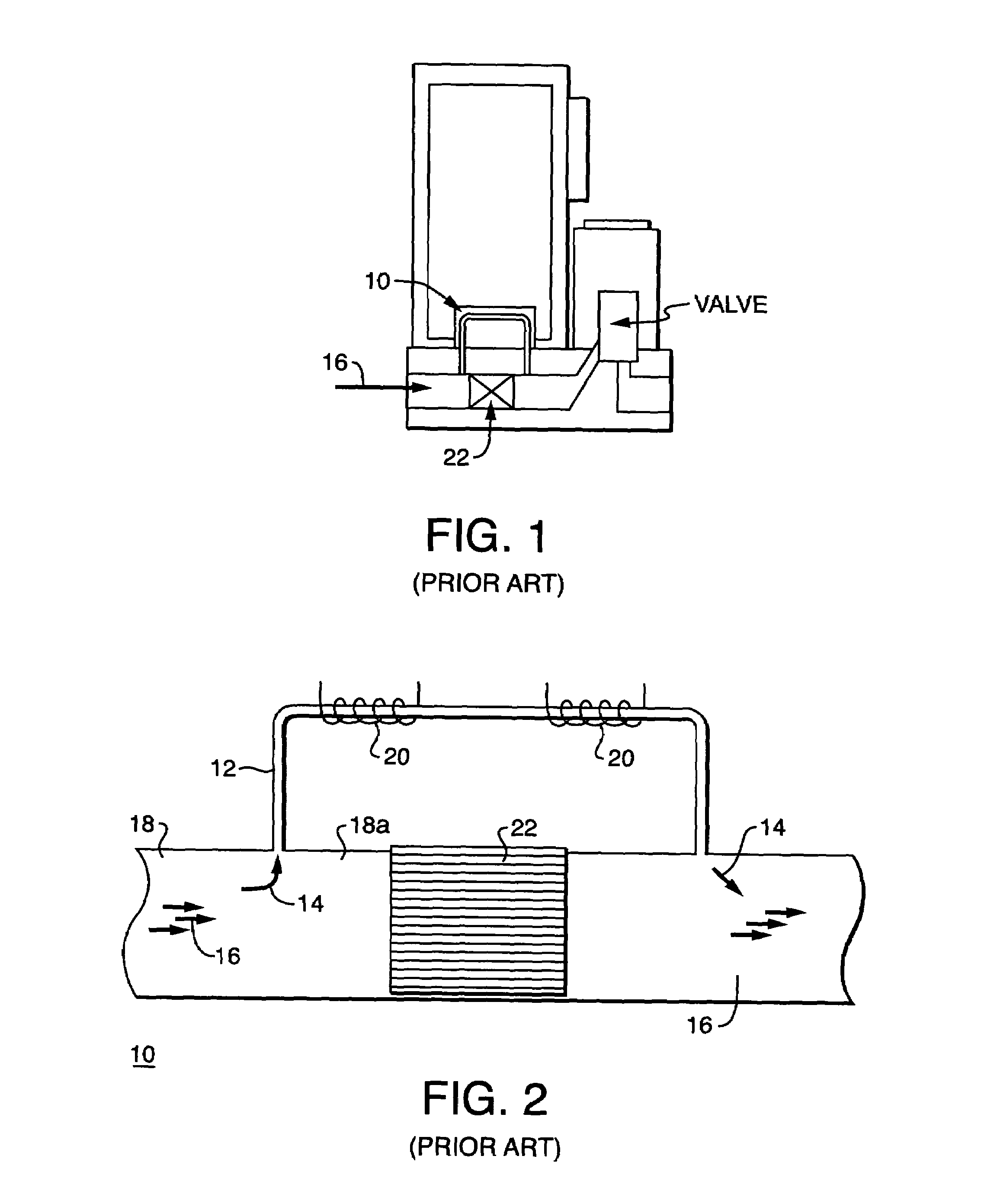

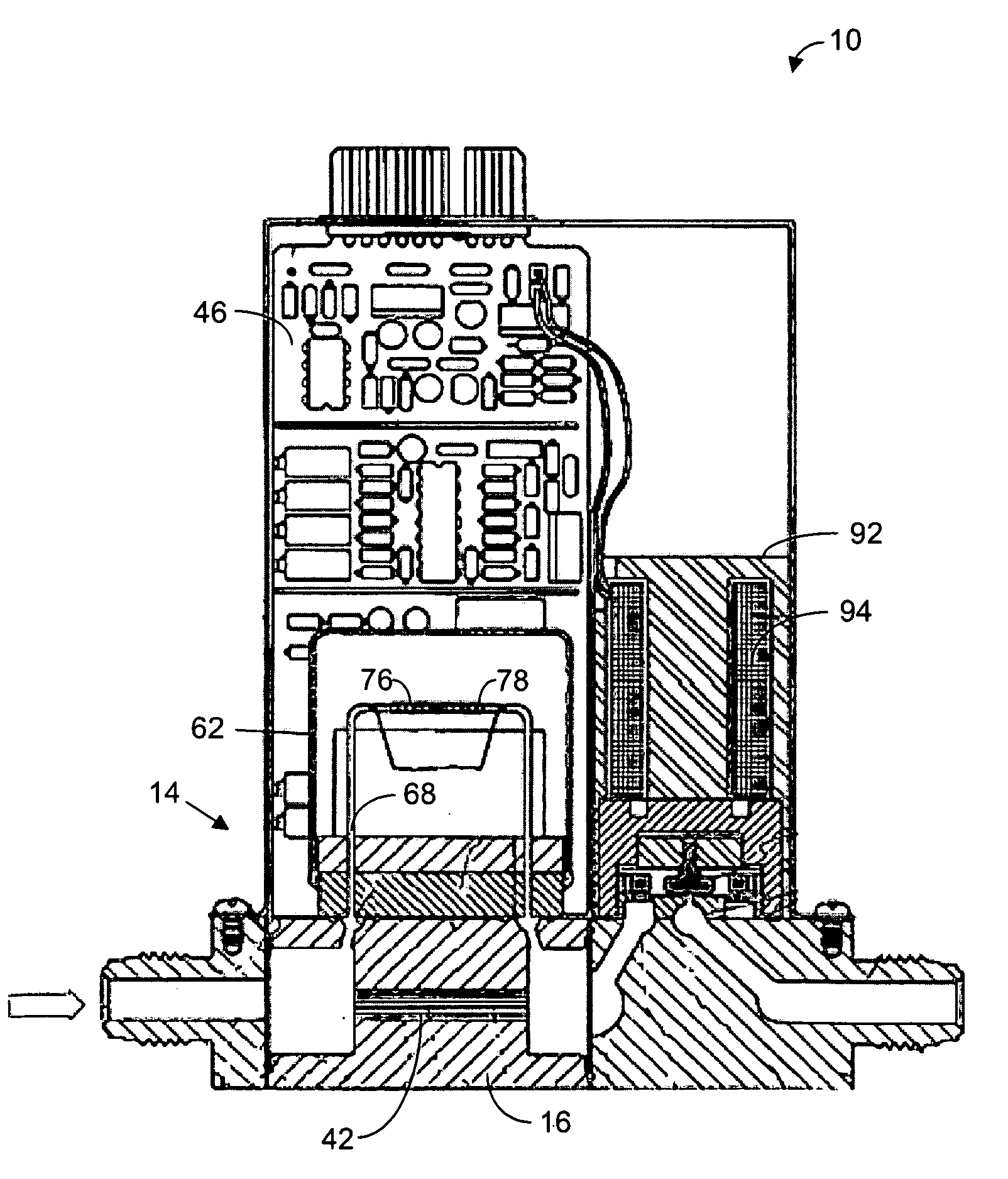

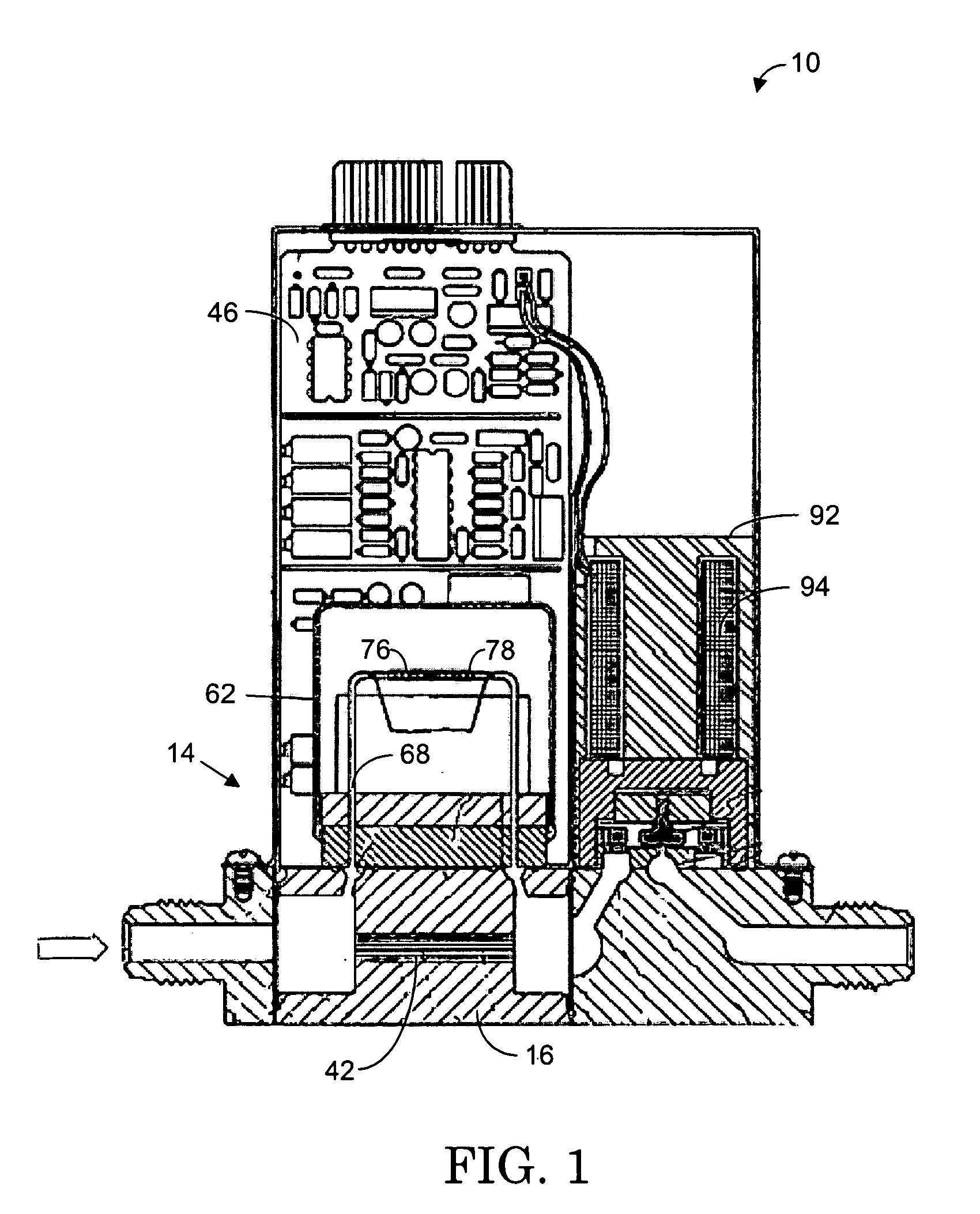

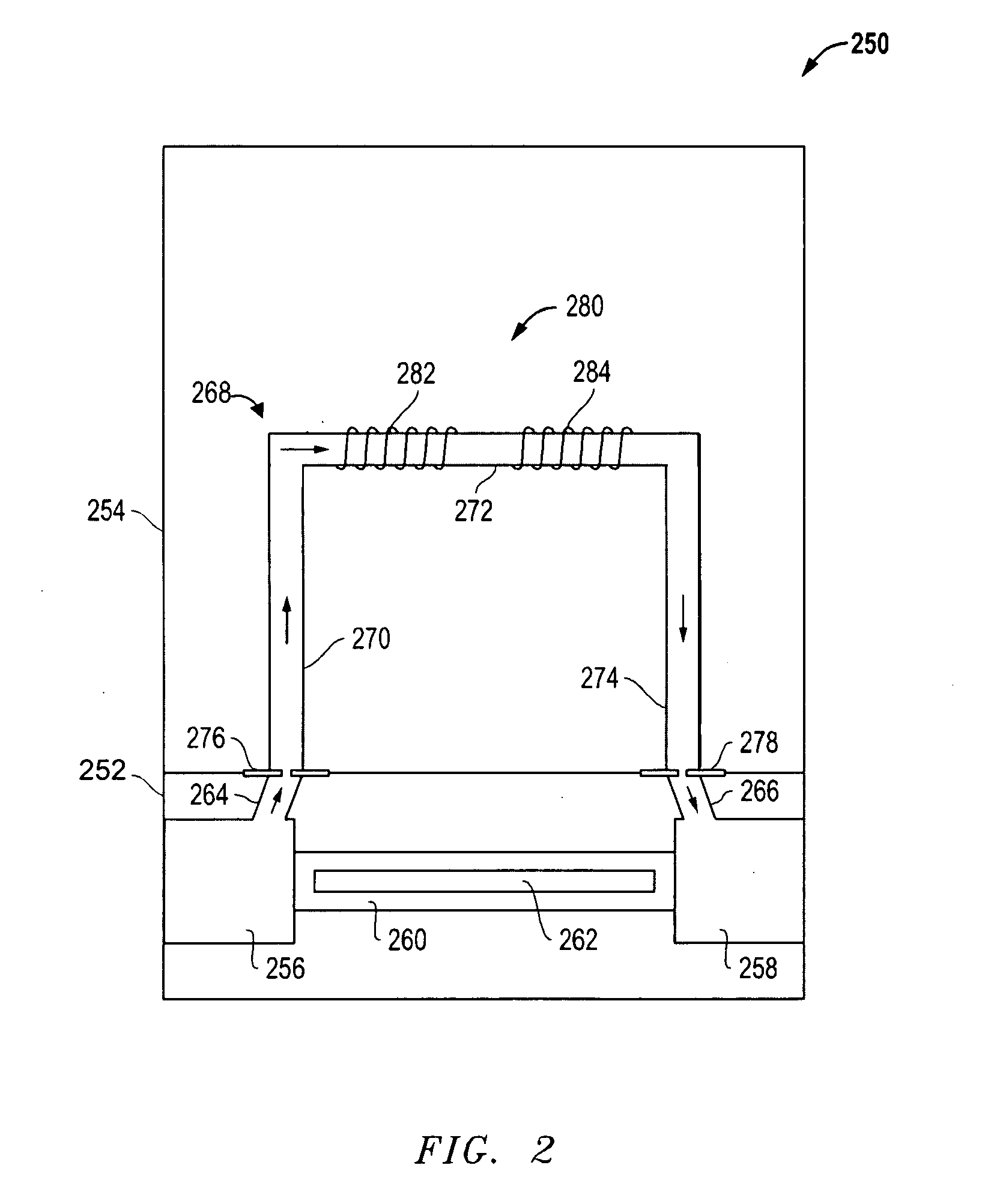

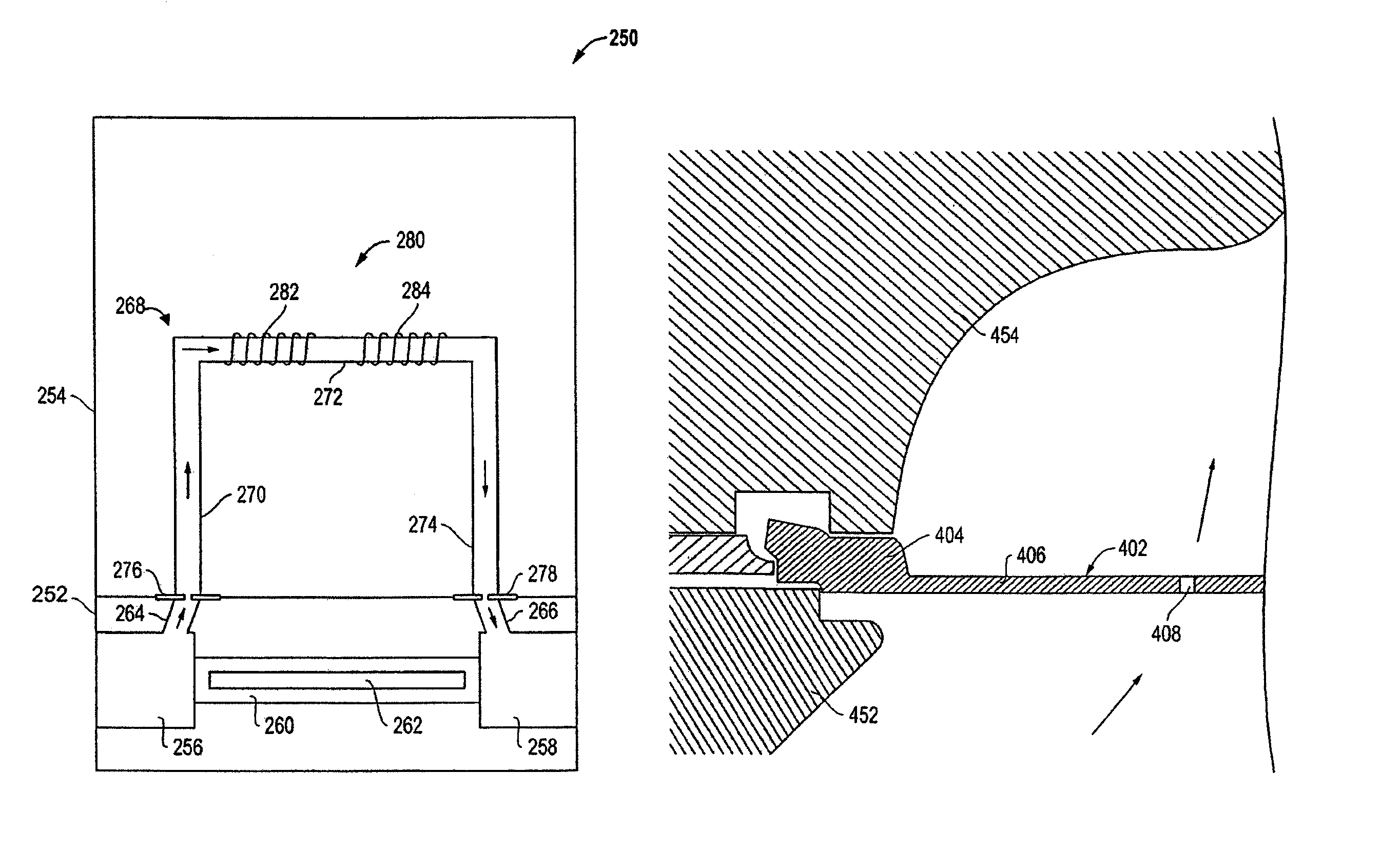

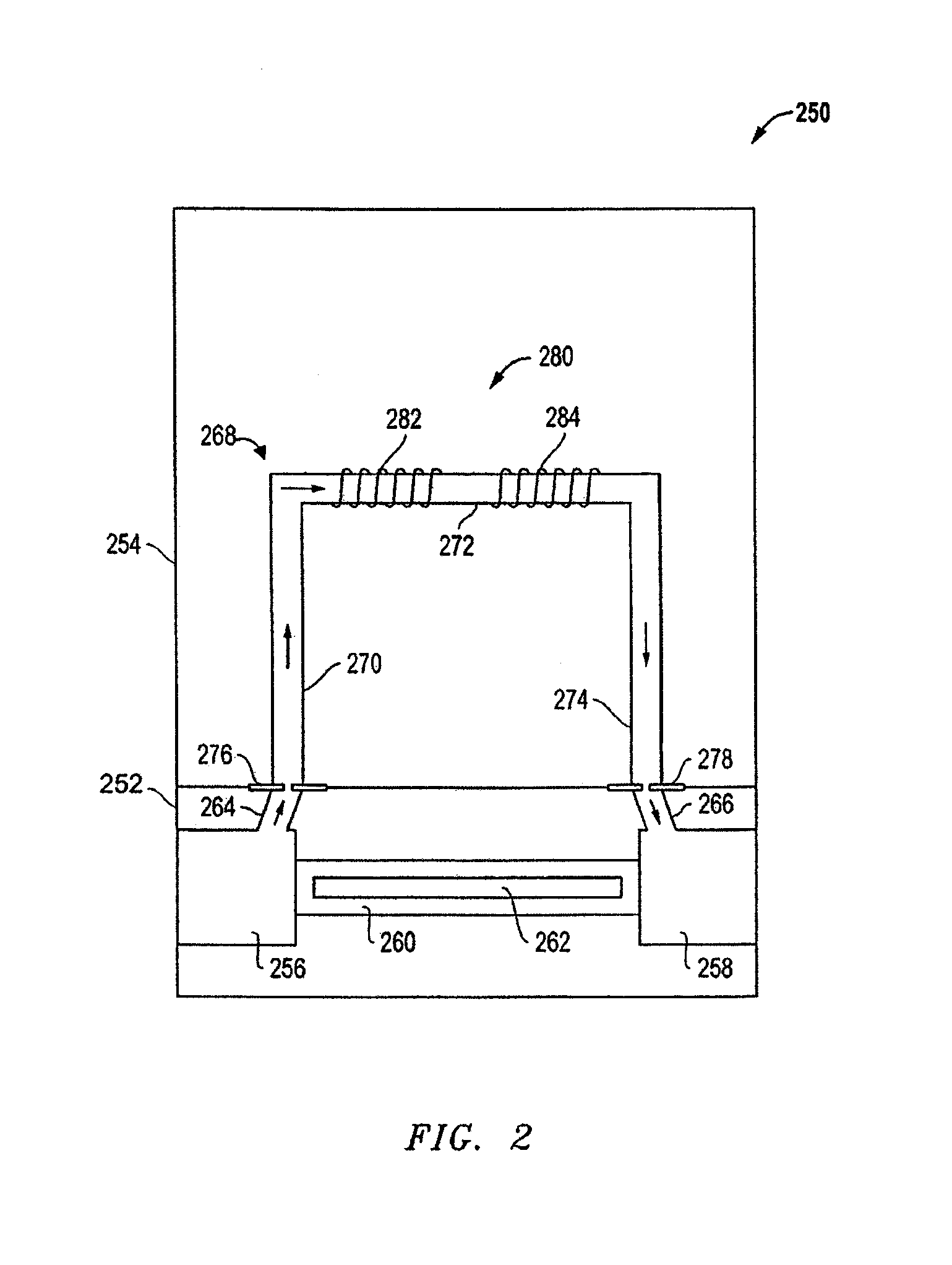

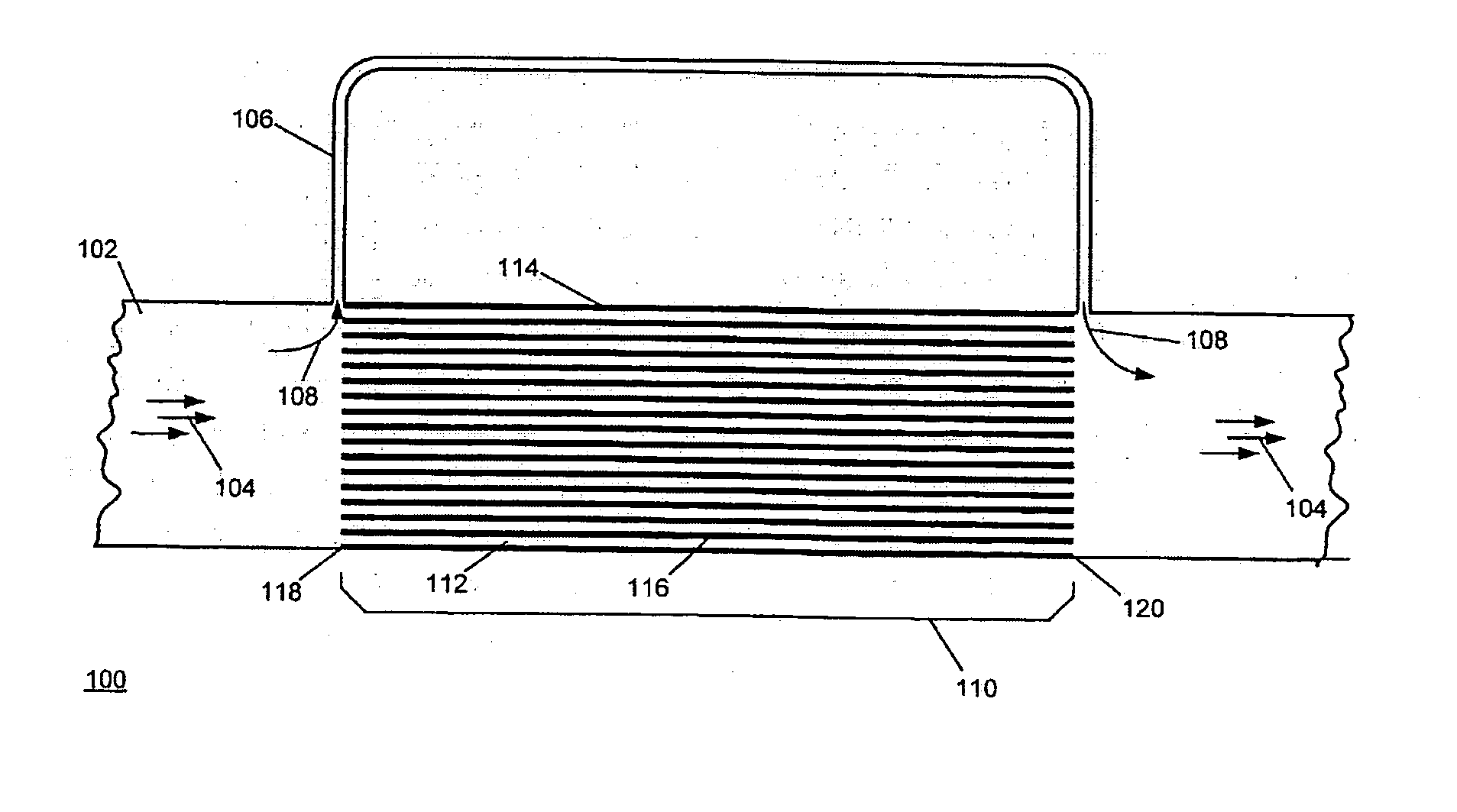

Thermal mass flow rate sensor including bypass passageways and a sensor passageway having similar entrance effects

ActiveUS7107834B2Type accurateCalibrationVolume/mass flow by thermal effectsVolume flow proportion measurementEngineeringBypass ratio

A sensing apparatus for use in a mass flow rate sensor for measuring a fluid flow rate includes a main conduit for containing a fluid flow, and a sensor passageway for tapping a portion of the fluid flow from the main conduit at a first location, and returning the portion of the fluid flow to the conduit at a second location. At least one bypass passageway, which may be provided in the form of a tube, is positioned in the main conduit between the first and second locations, and the bypass passageway is provided with non-negligible entrance effects that are substantially equal to entrance effects of the sensor passageway, so that a bypass ratio of the apparatus remains constant. A mass flow rate sensor of the present disclosure accurately measures any type of gas but only requires calibration in only one reference gas.

Owner:MKS INSTR INC

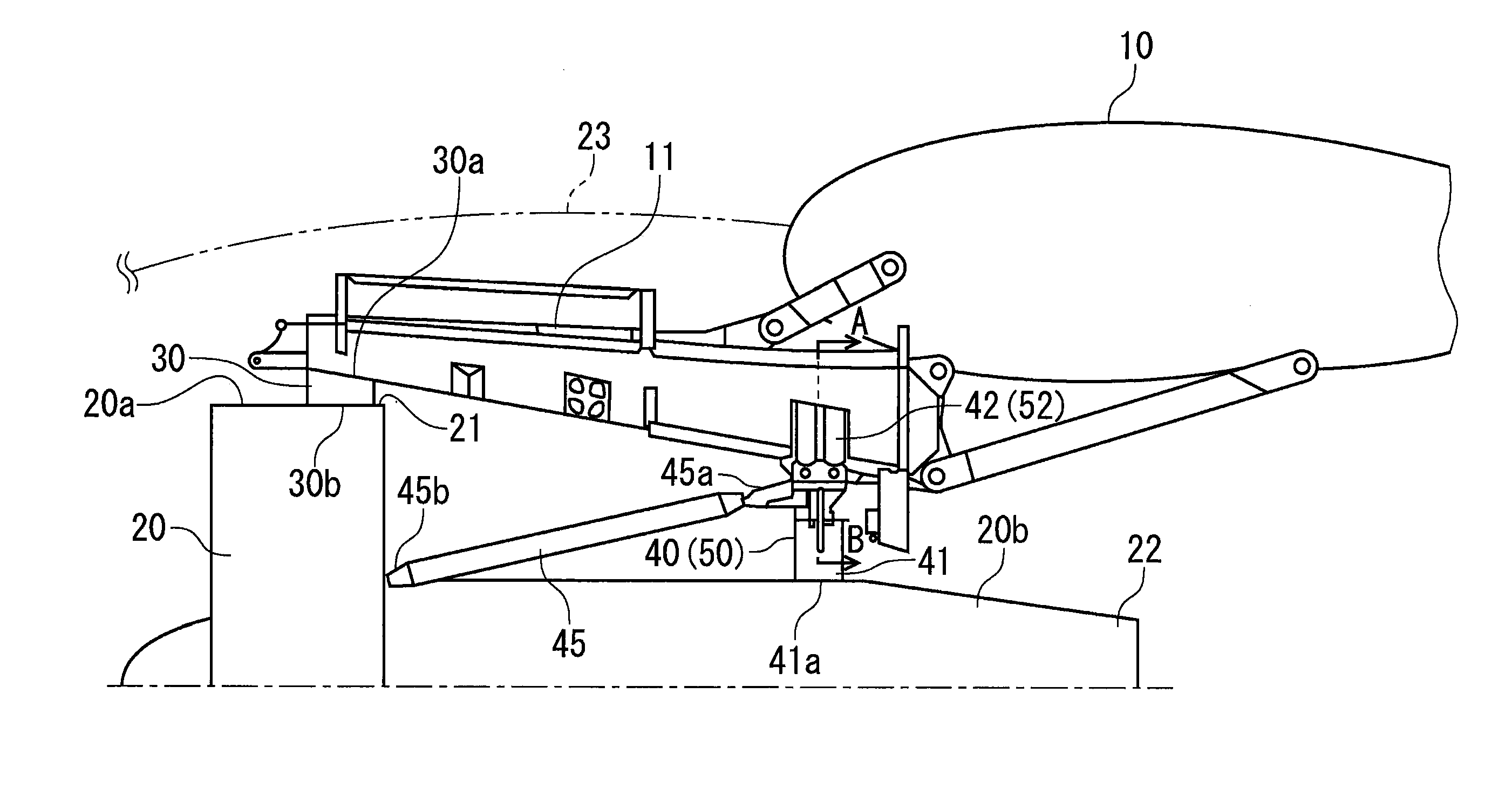

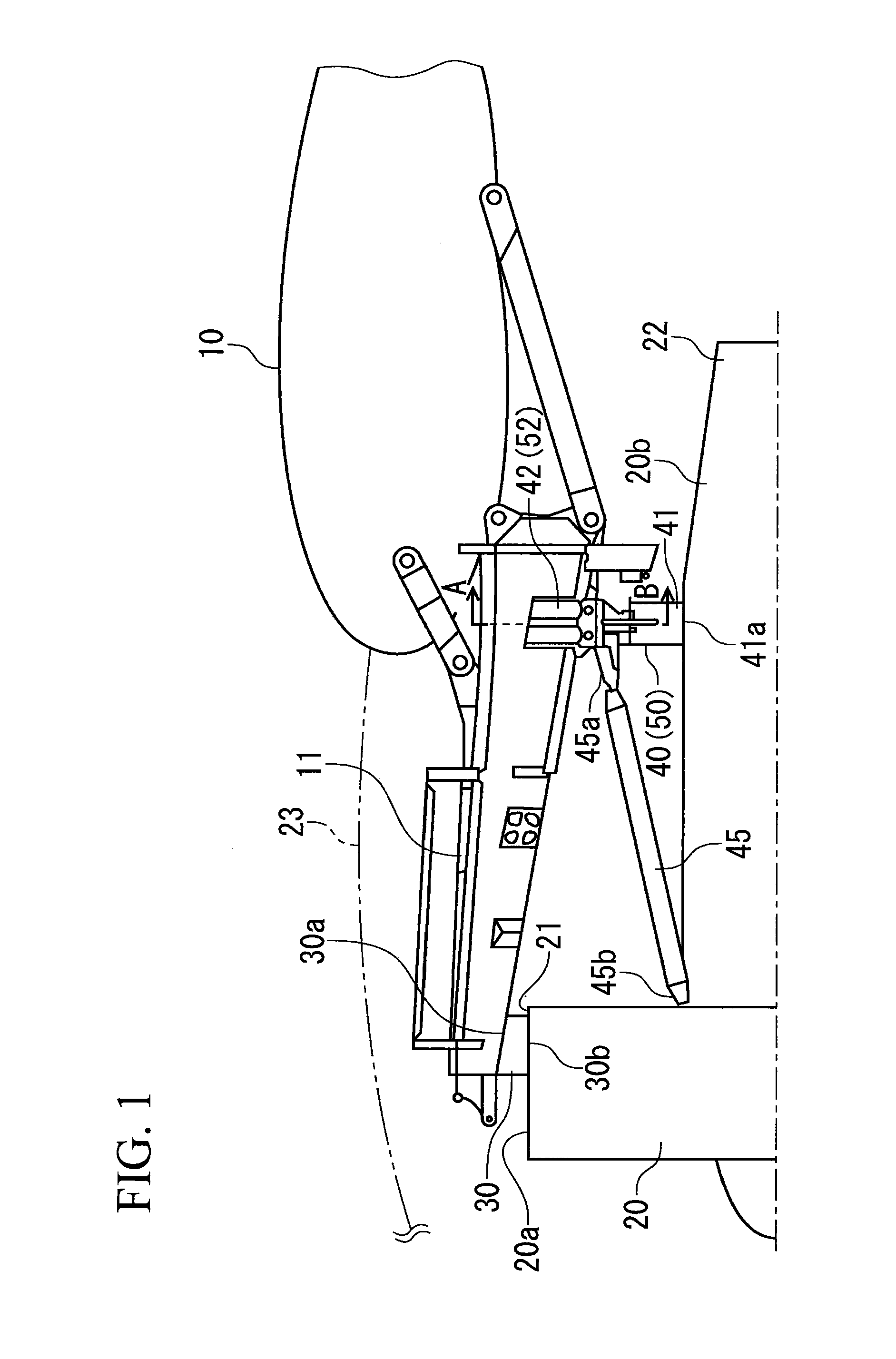

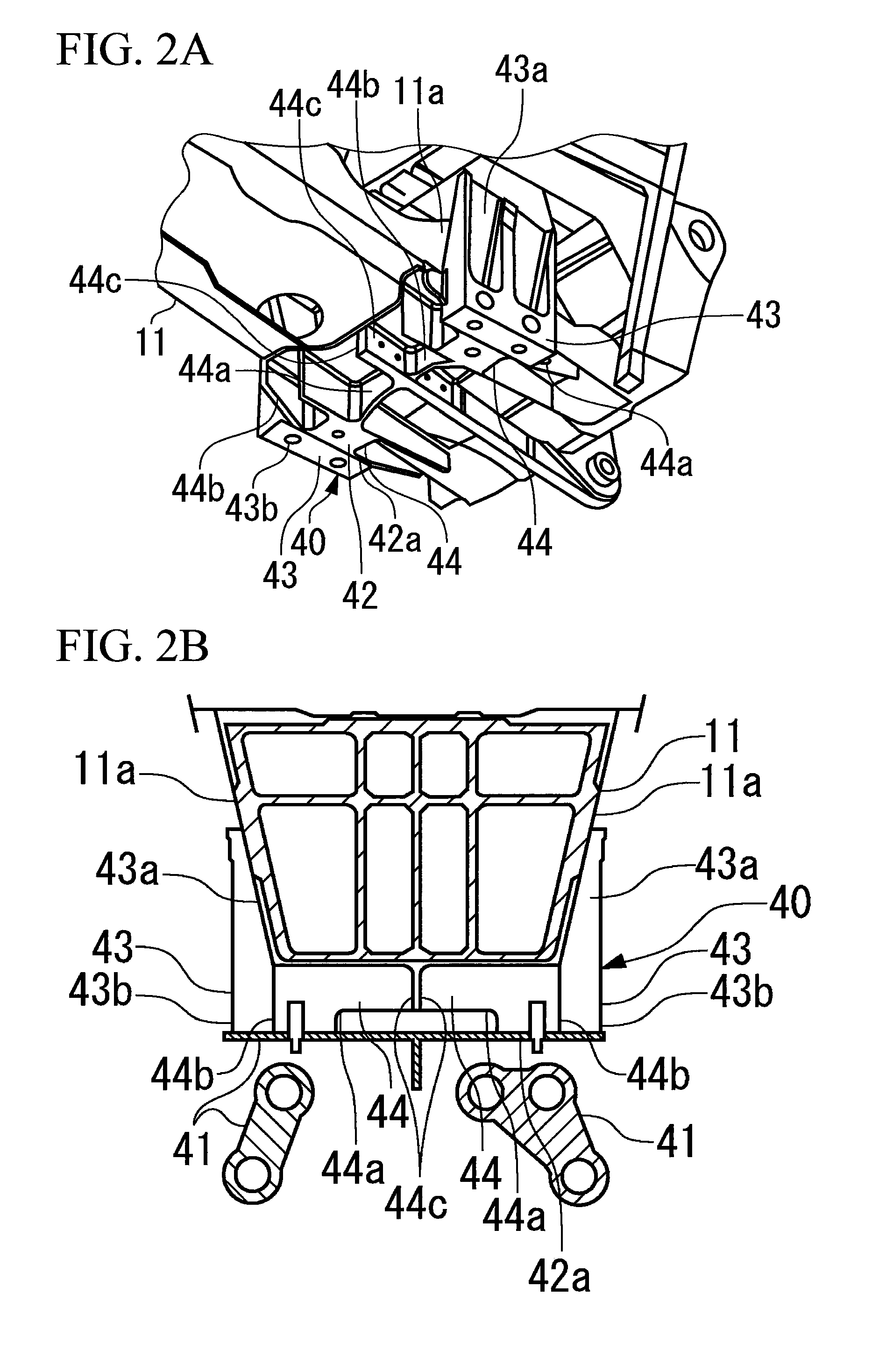

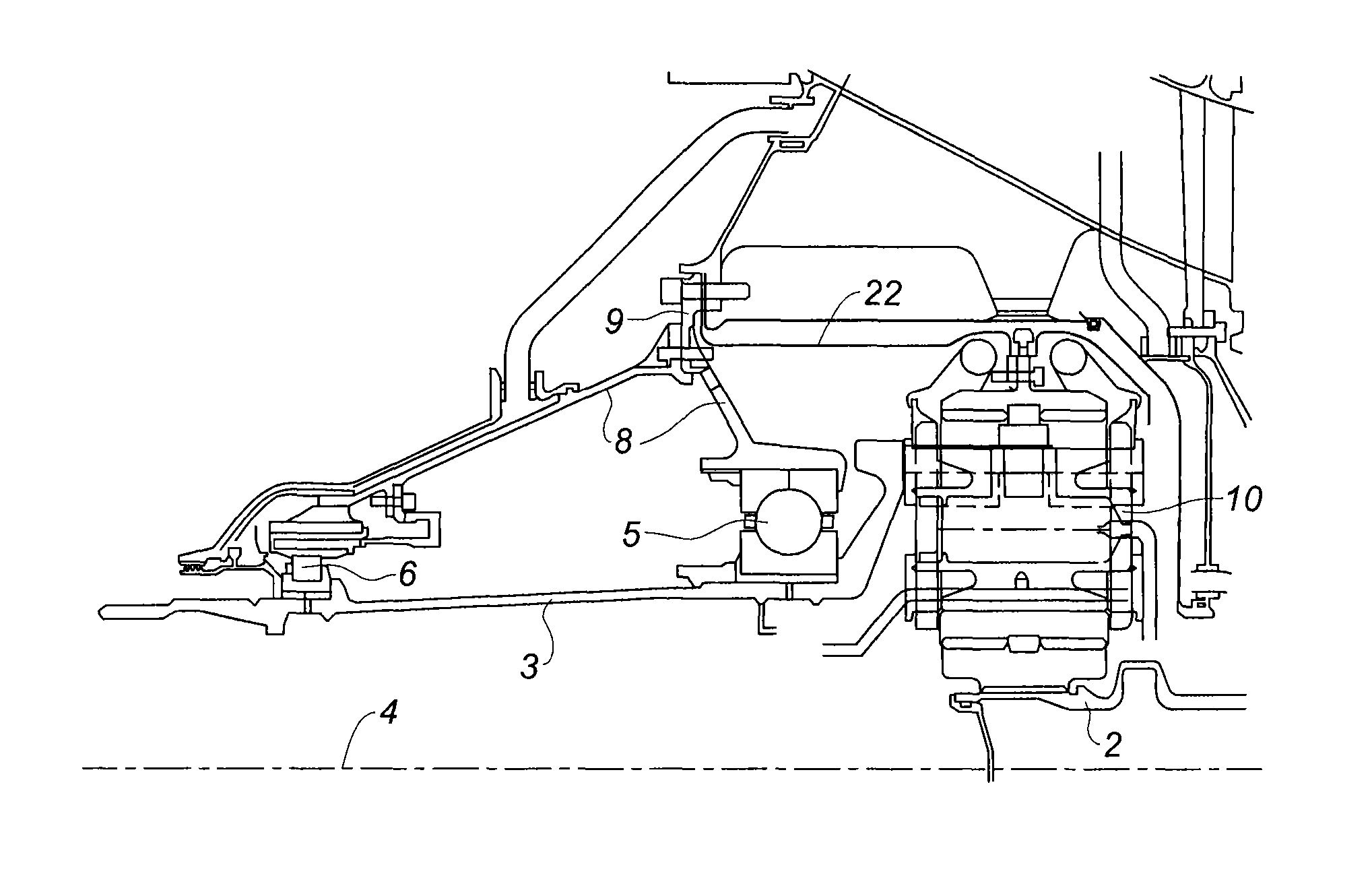

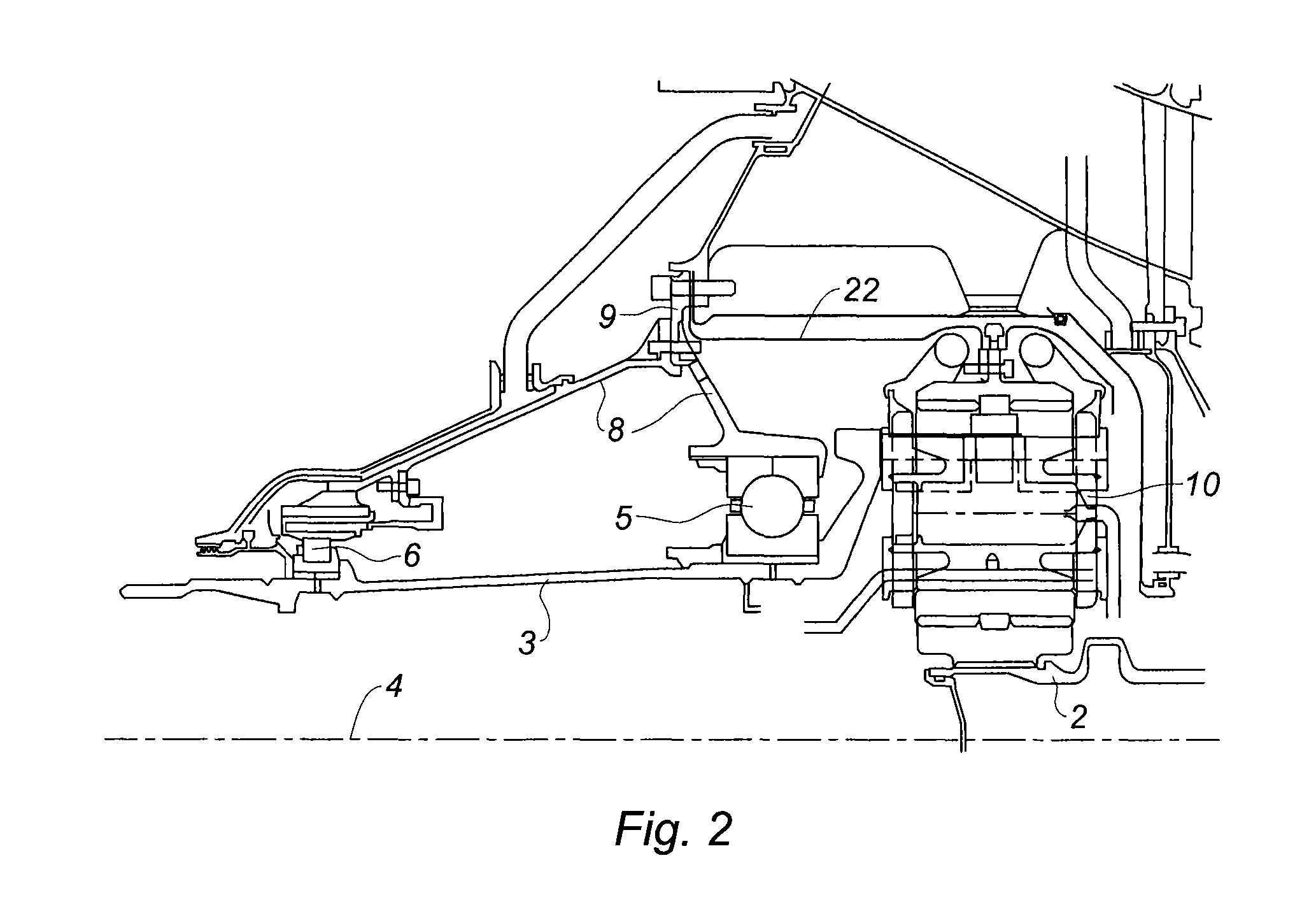

Engine mount of aircraft and aircraft

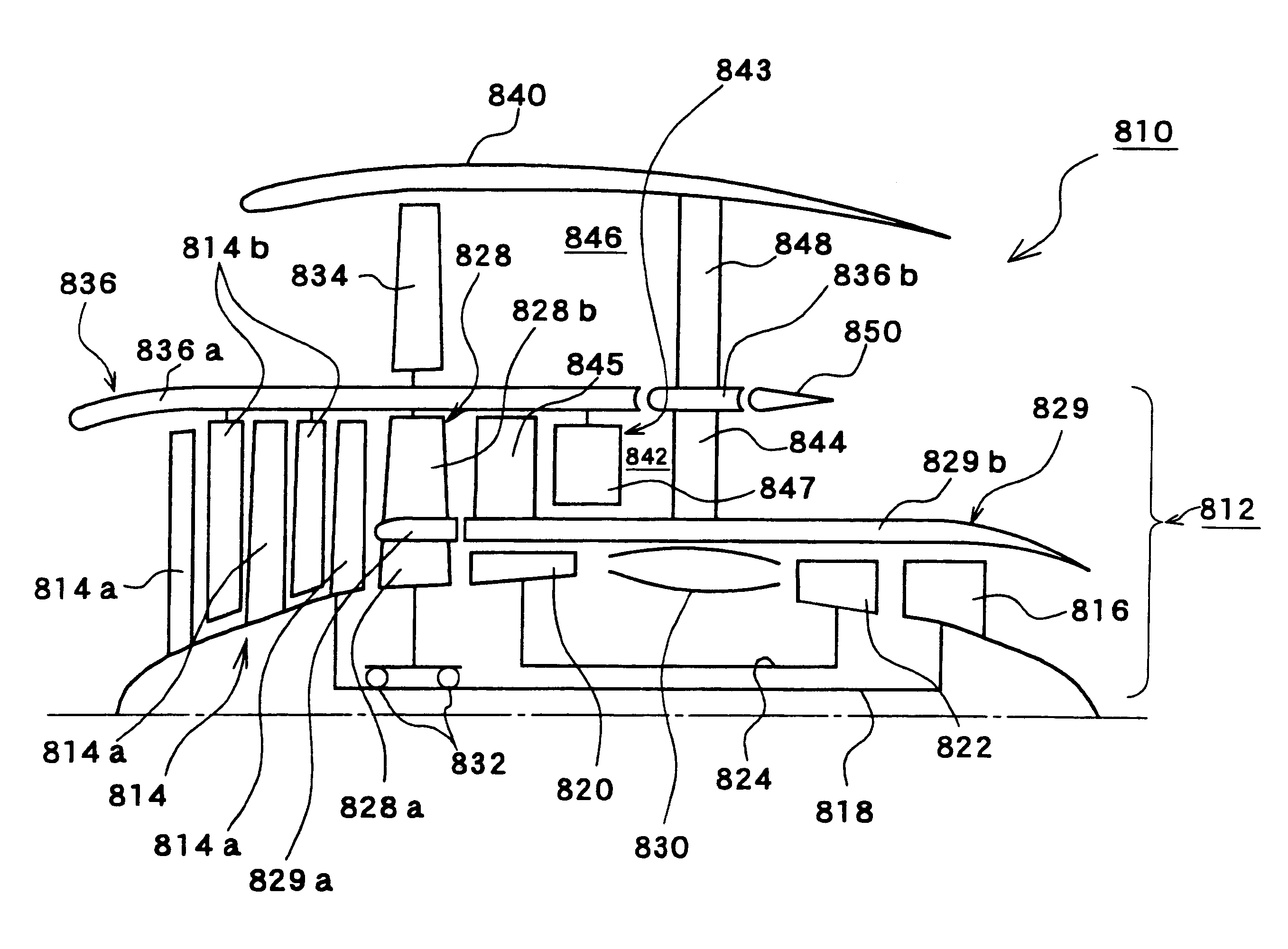

ActiveUS20110127371A1Small sizeIncrease the use of spacePower plant constructionJet type power plantsNacelleBypass ratio

An engine mount of an aircraft and an aircraft are provided, which can reduce a size of an engine mount and can effectively use a space in an engine nacelle even in an engine with a high bypass ratio. An engine core section 20b at a rear of an engine 20 is supported by a rear engine mount 40 comprising an engine side mount member 41 fixed to a side of the engine 20 and a strut side mount member 42 fixed to a side of a pylon strut 11. The rear engine mount 40 is divided into the engine side mount member 41 and the strut side mount member 42, and thereby, even in the engine 20 with a high bypass ratio in which an outside diameter of the fan section 20a and the outside diameter of the engine core section 20b significantly differ, the lengths in the vertical direction of the engine side mount member 41 and the strut side mount member 42 are suppressed.

Owner:MITSUBISHI AIRCRAFT

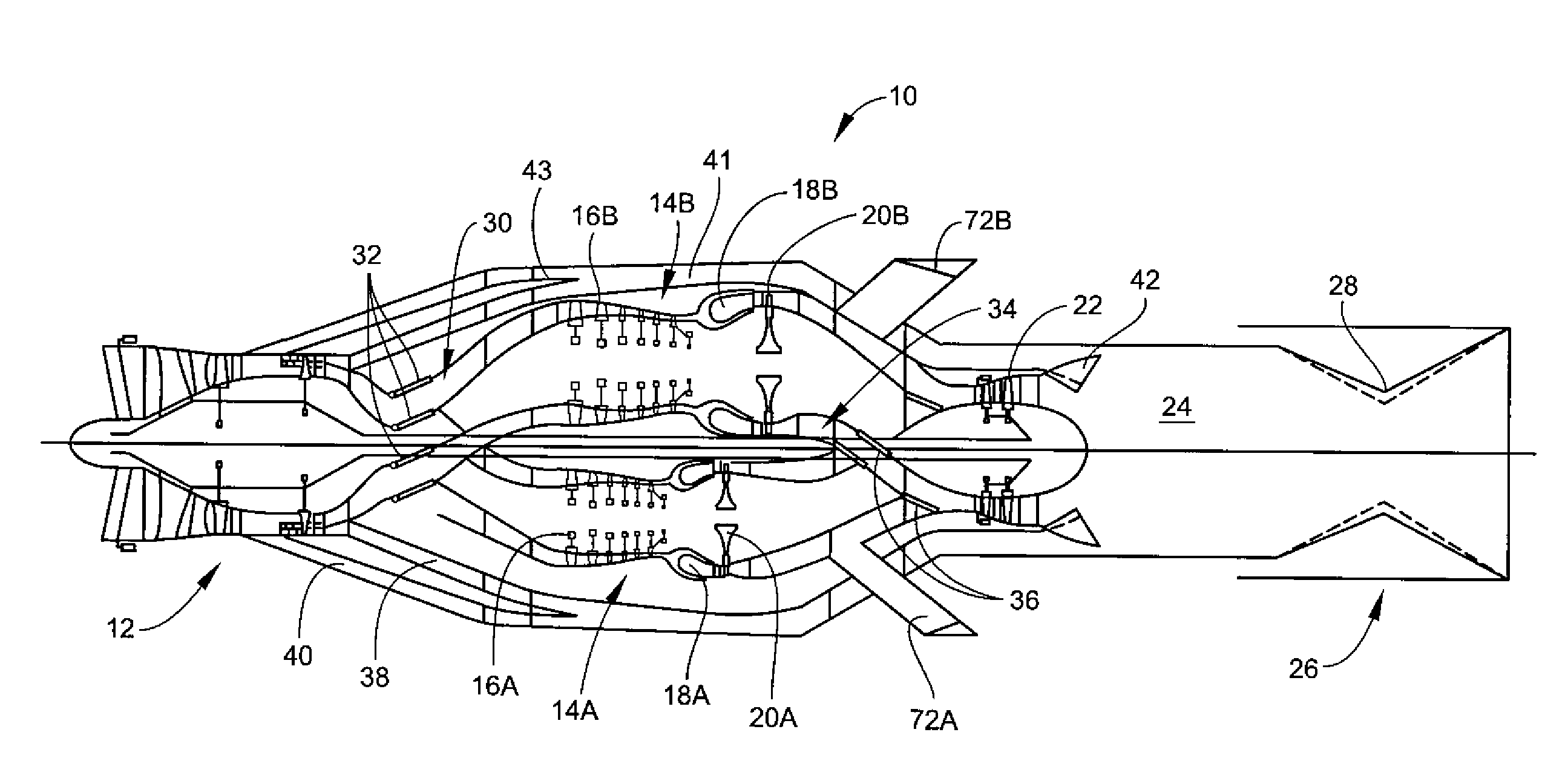

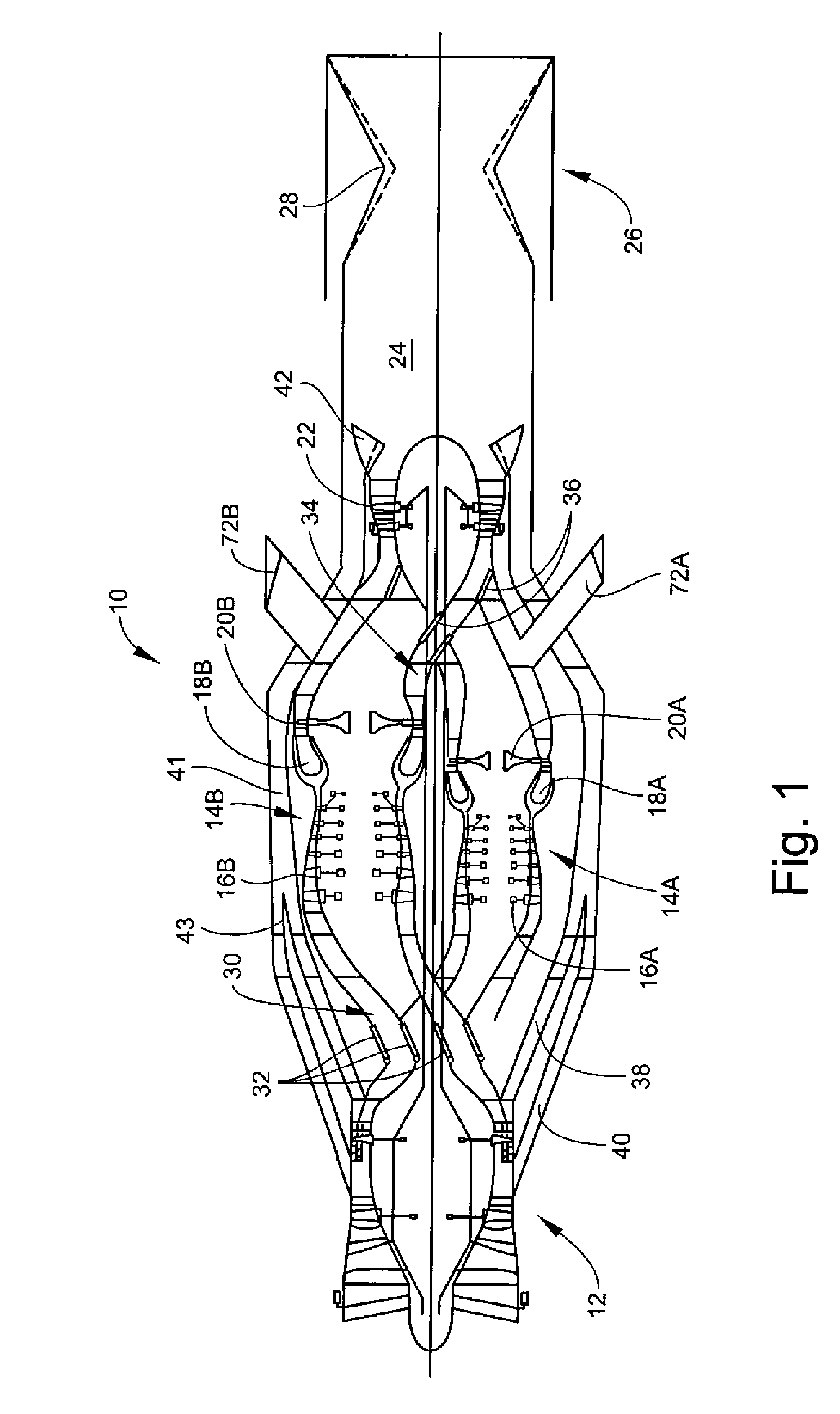

Convertible gas turbine engine

A gas turbine engine includes a turbomachinery core operable to generate a flow of pressurized combustion gases at a variable flow rate, while maintaining a substantially constant core pressure ratio; a rotating fan disposed upstream of the core, the fan adapted to extract energy from the core and generate a first flow of air which is compressed at a first pressure ratio; and at least a first bypass duct surrounding the core downstream of the fan adapted to selectively receive at least a first selected portion of the first flow which is compressed at a second pressure ratio lower than the first pressure ratio, and to bypass the first selected portion around the core, thereby varying a bypass ratio of the engine. The fan is adapted to maintain a flow rate of the first flow substantially constant, independent of the bypass ratio.

Owner:GENERAL ELECTRIC CO

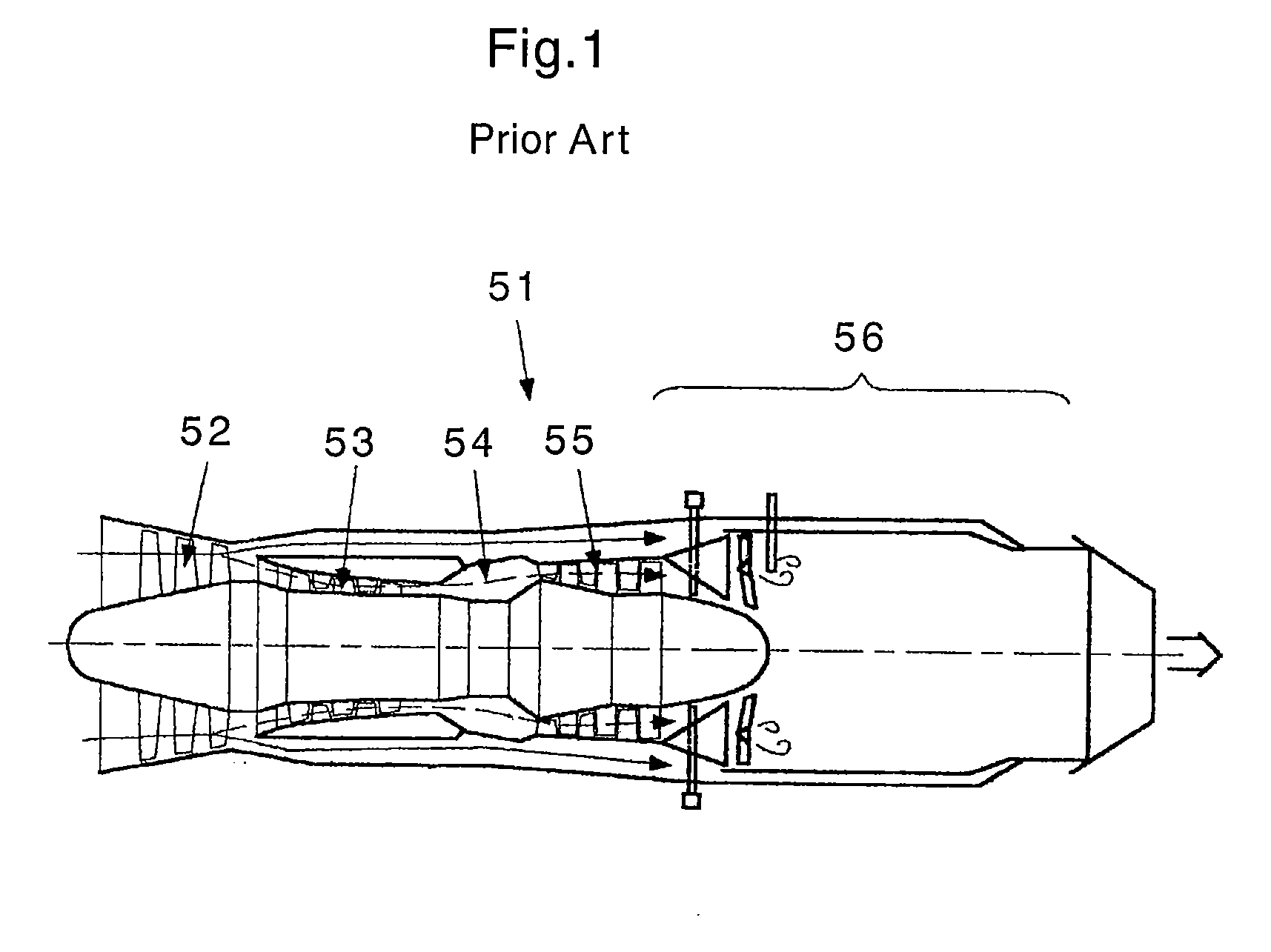

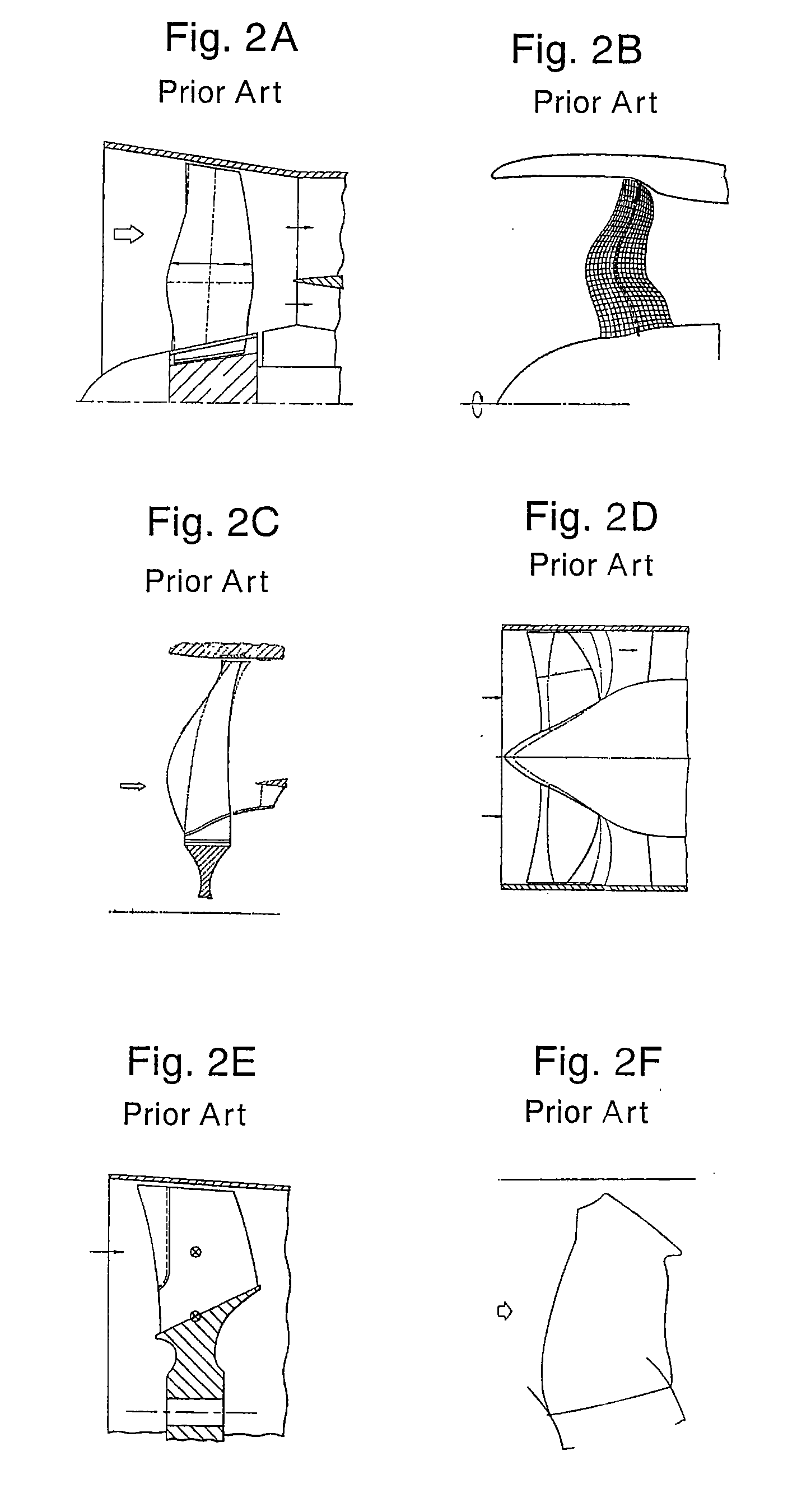

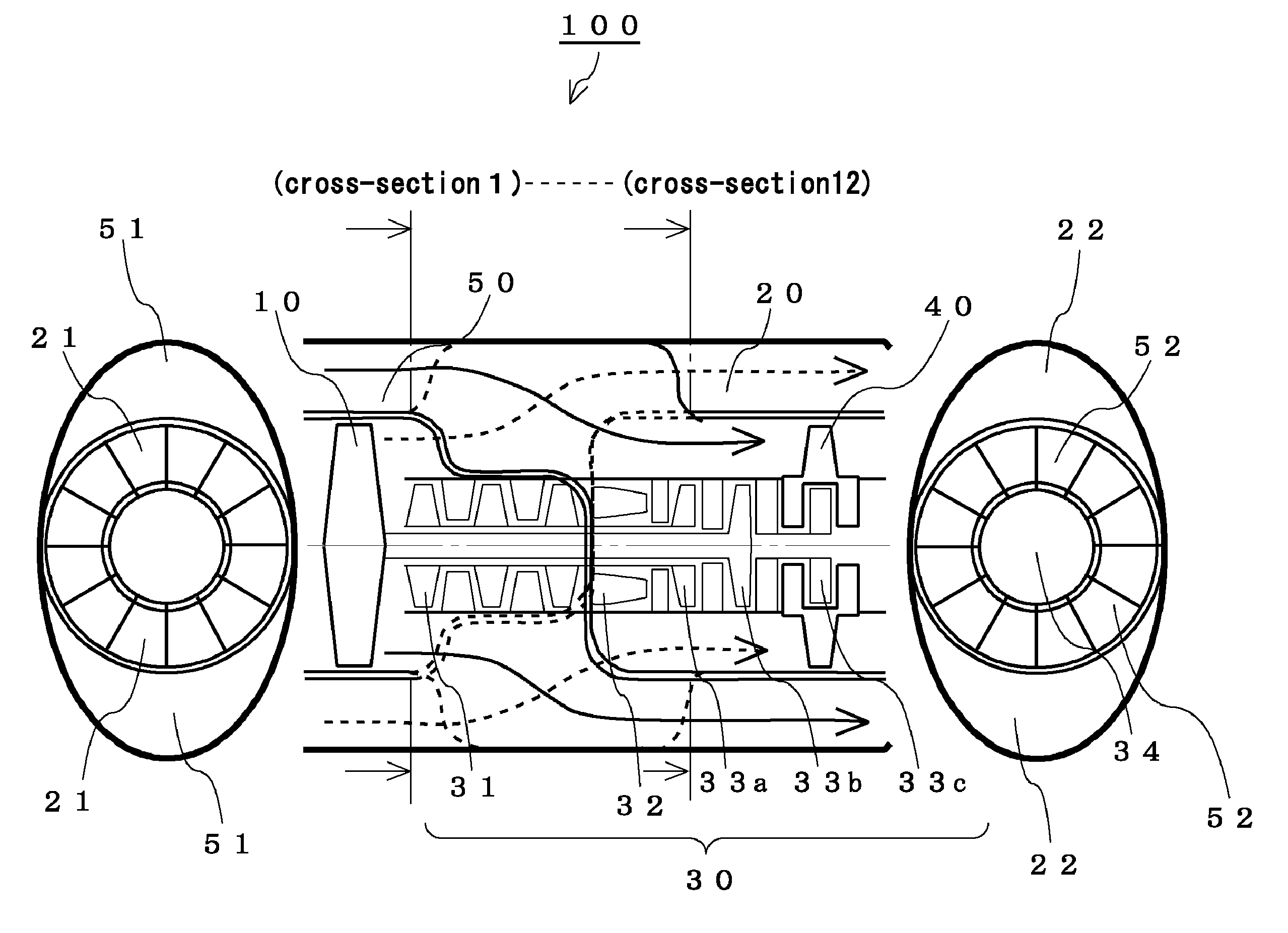

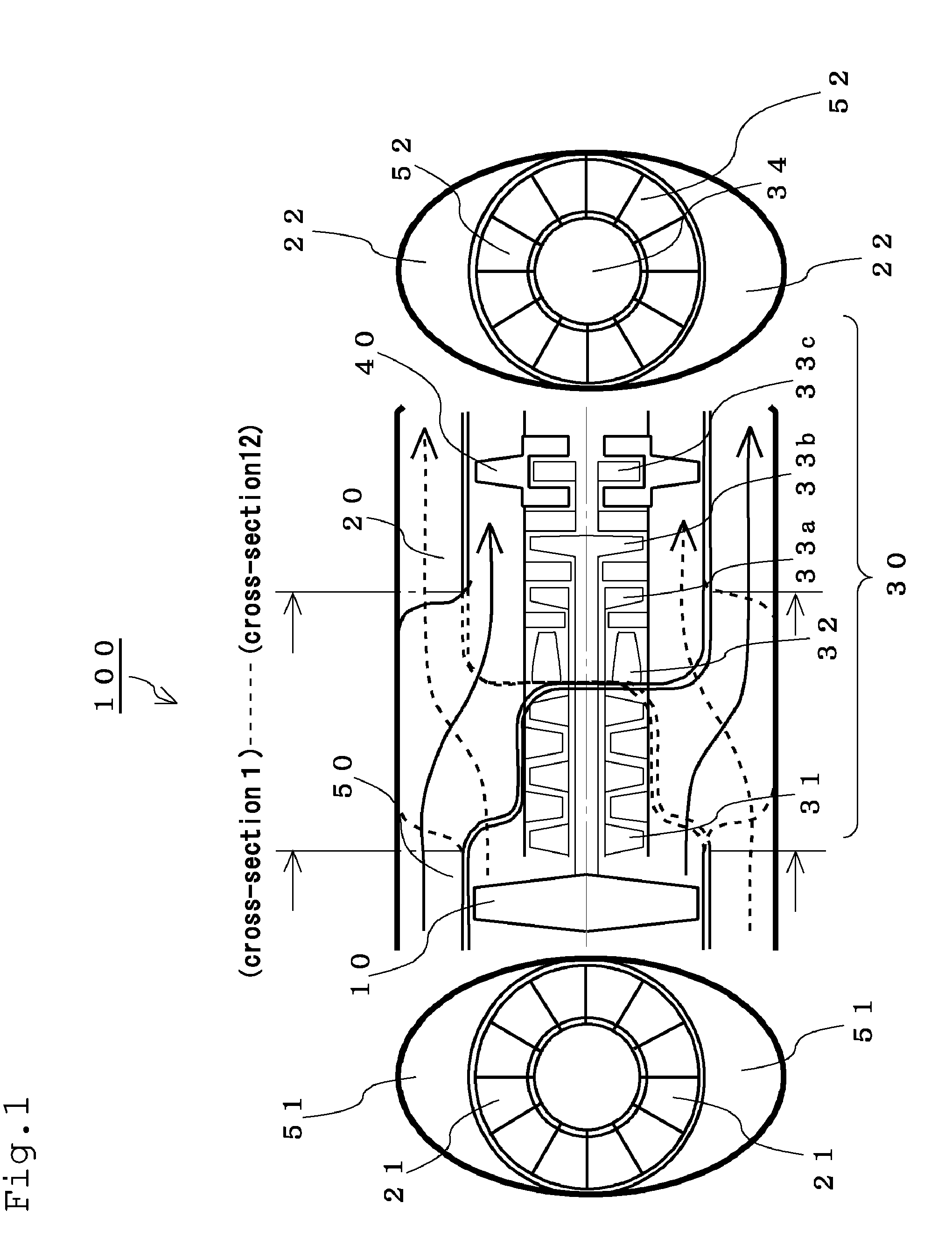

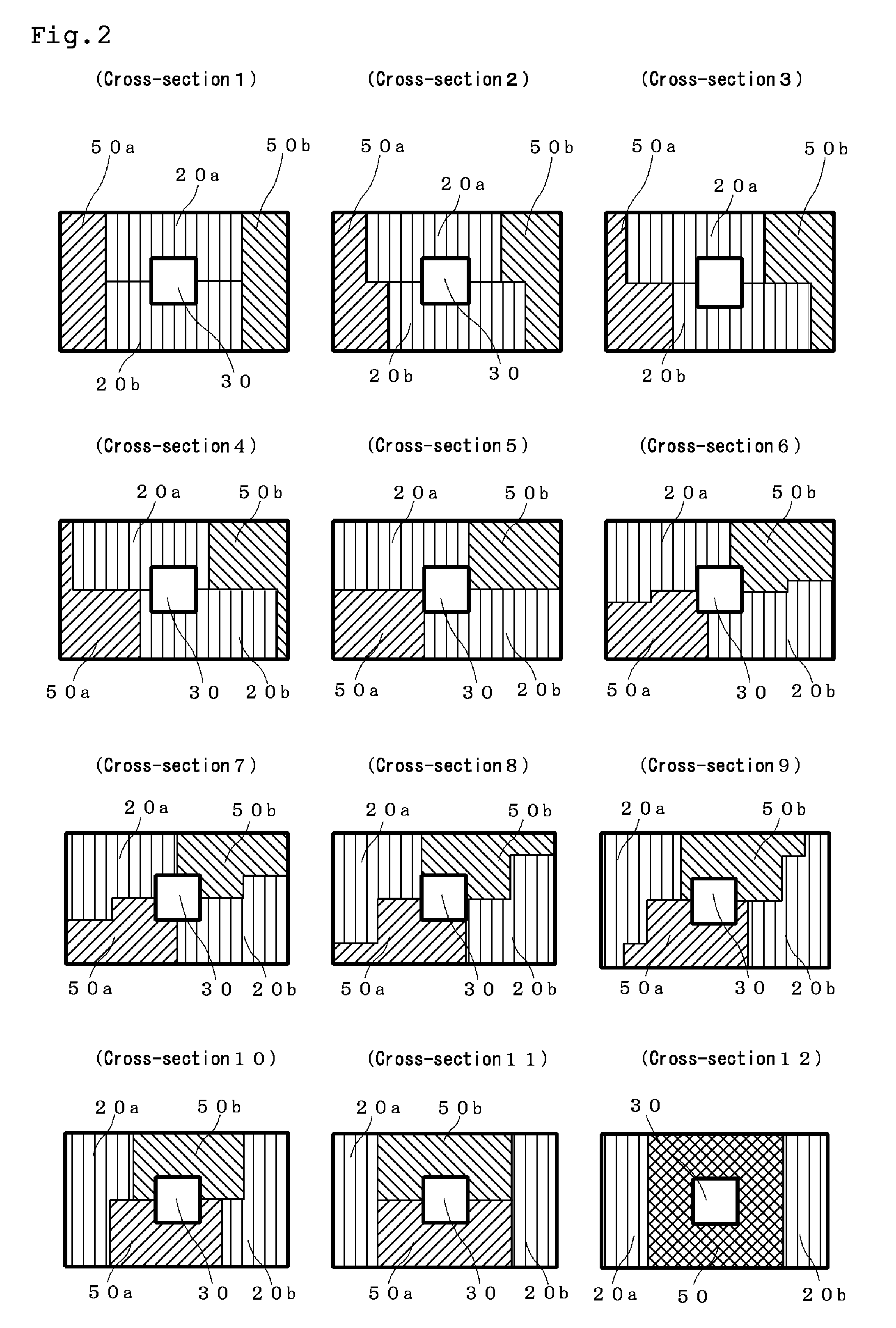

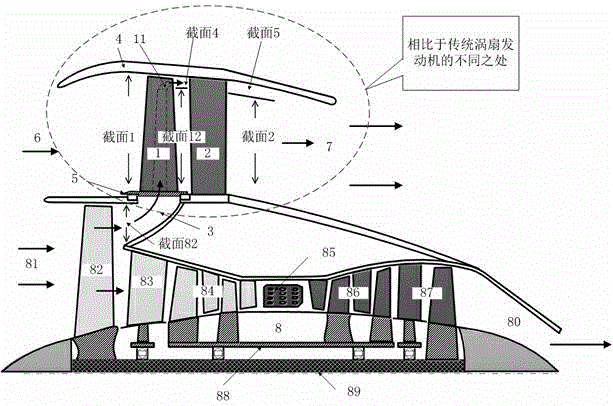

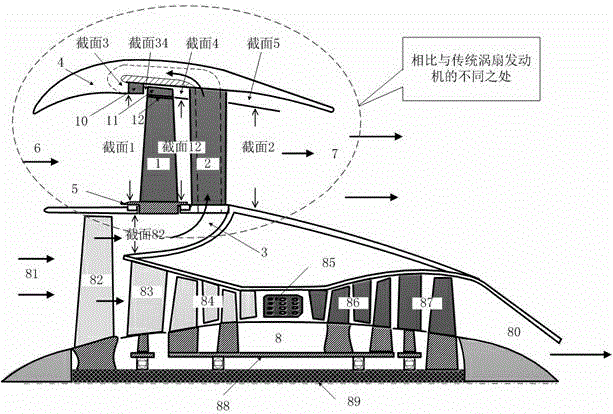

High bypass-ratio turbofan jet engine

InactiveUS20090226297A1Reduce air resistanceReduce the overall diameterEngine manufactureWind motor controlAerodynamic dragJet engine

To provide a turbofan jet engine which is capable of increasing the bypass ratio without increasing the fan diameter, and of reducing air resistance acting on the engine, a front fan duct that discharges air compressed by a front fan to the atmosphere and an aft fan duct that introduces air into an aft fan are disposed such as to change cross-sectional shapes thereof by rotating around a core engine in a counterclockwise direction, so that the cross-sectional geometric relationship between the front fan duct and the aft fan duct at a position immediately posterior to the front fan and a cross-sectional geometric relationship between the front fan duct and the aft fan duct at a position immediately anterior to the aft fan are inverted.

Owner:JAPAN AEROSPACE EXPLORATION AGENCY

Reynolds number correction function for mass flow rate sensor

ActiveUS7000463B1Volume/mass flow by thermal effectsVolume flow proportion measurementBypass ratioMass flow sensor

A mass flow rate sensor uses a Reynolds number correction function to compensate for errors in a bypass ratio of the sensor for all gases, based on the fact that all bypass errors are functions of Reynolds number. The sensor includes a sensor tube and a bypass tube dividing flow, wherein a bypass ratio of the sensor equals a total flow rate through the sensor divided by a flow rate through just the sensor tube. Heater elements heat an upstream portion and a downstream portion of the sensor tube, and a circuit is connected to the heater elements for producing a voltage based upon a difference in resistance between the heater elements. The voltage is calibrated based on known flow rates of a reference gas, and the flow rate through the sensor is based upon the calibrated voltage multiplied by a multi-gas correction function and a Reynolds number correction function.

Owner:MKS INSTR INC

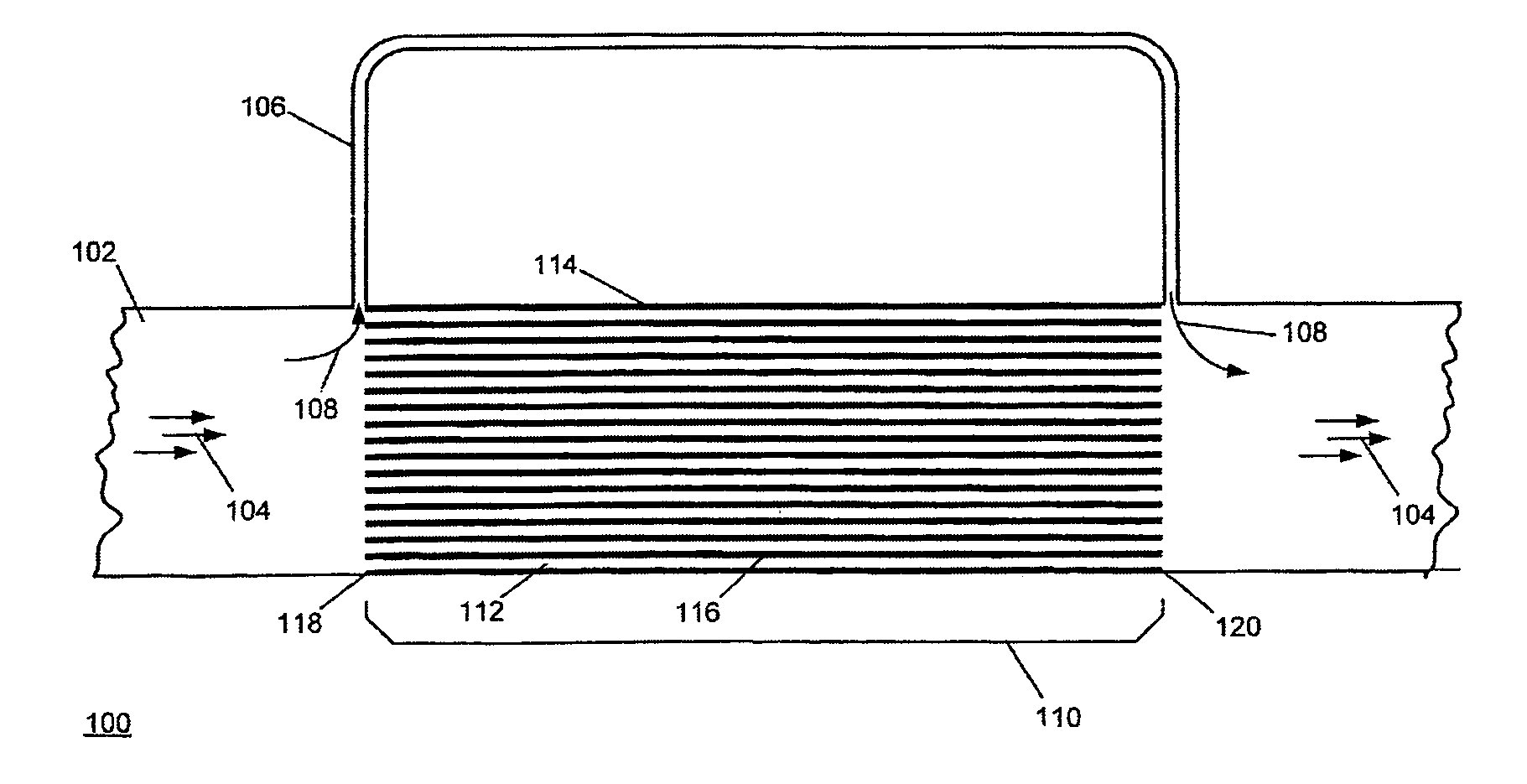

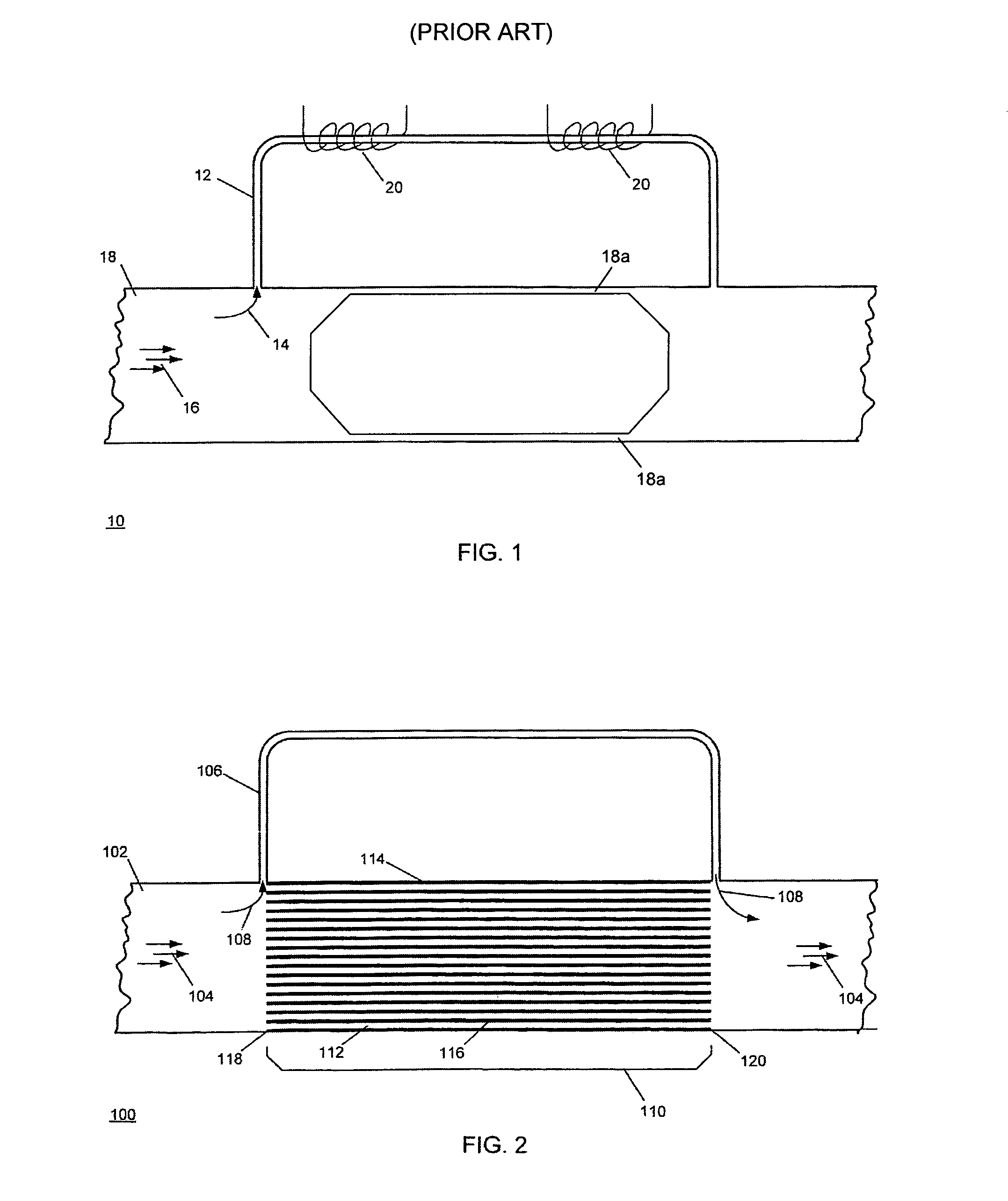

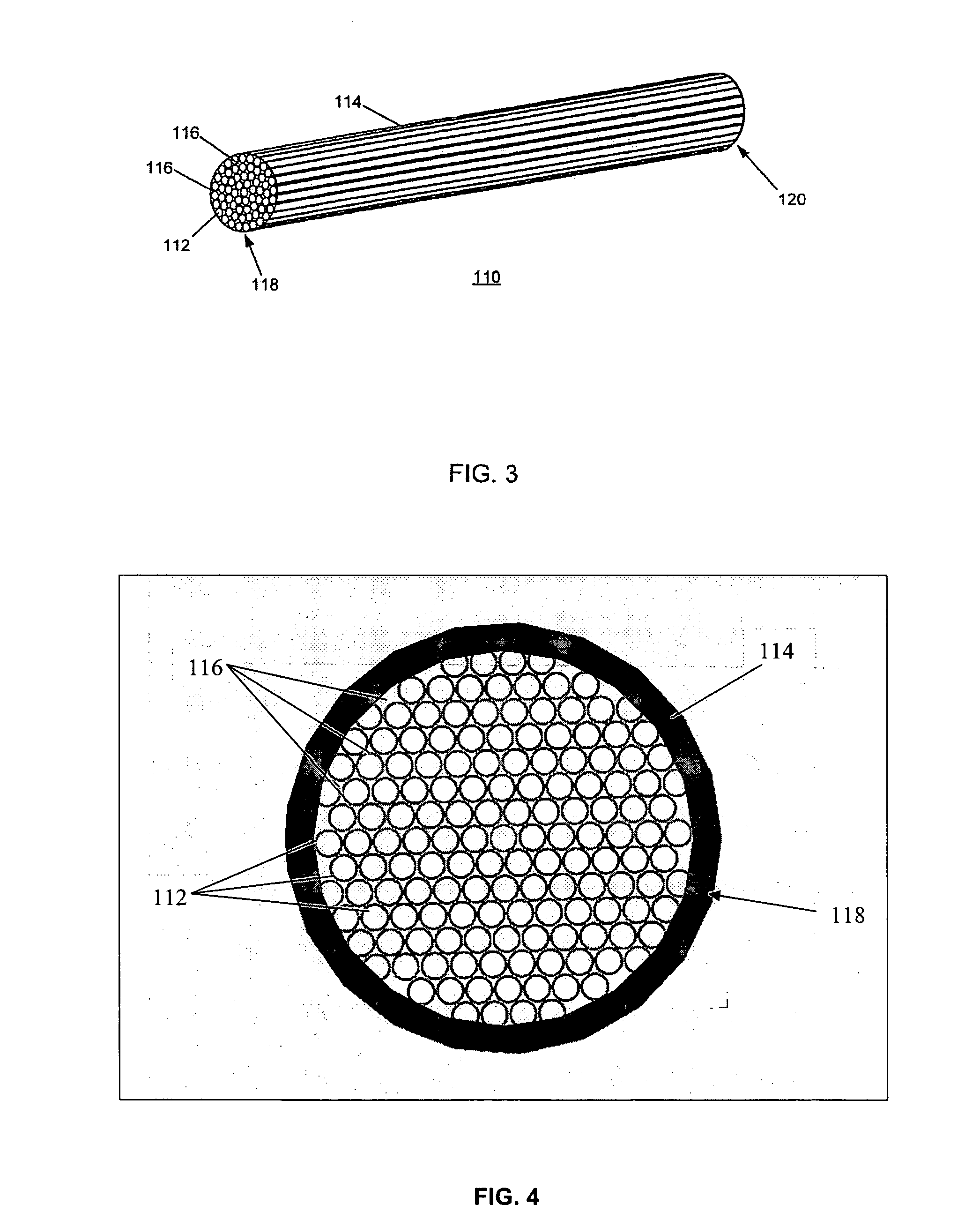

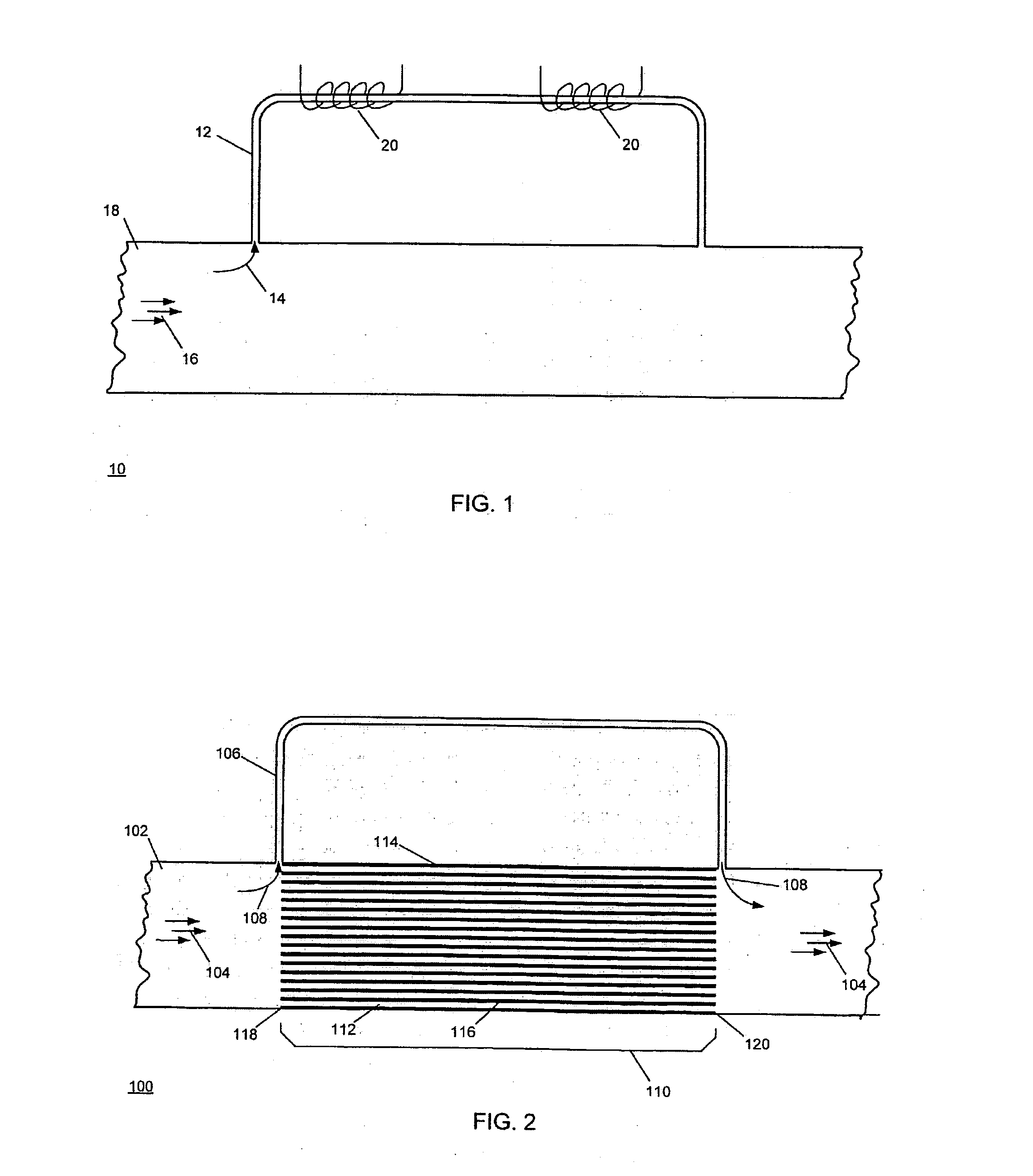

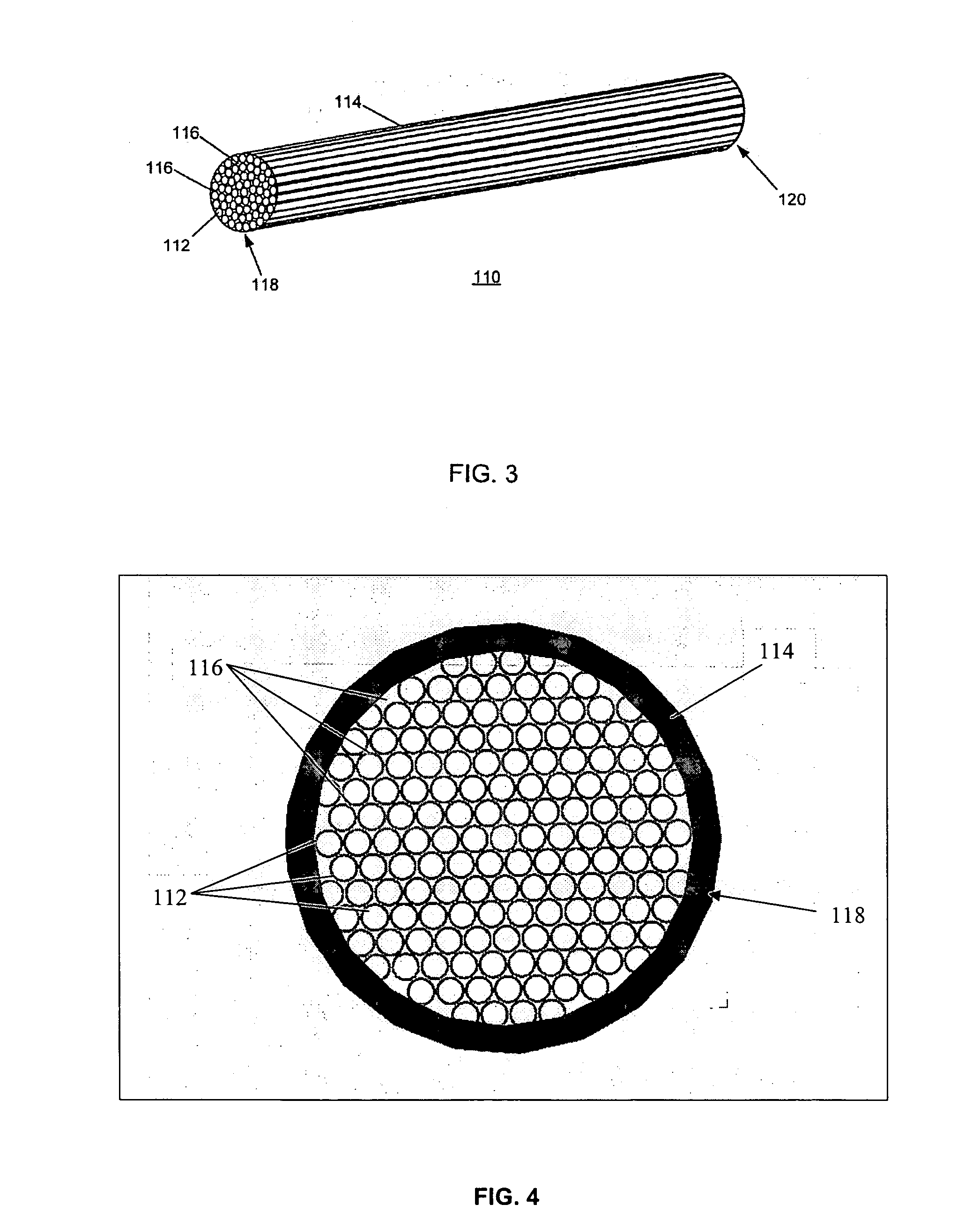

Thermal mass flow rate sensor having fixed bypass ratio

ActiveUS7121139B2Simple designReduce manufacturing costVolume/mass flow by thermal effectsVolume flow proportion measurementFlow transducerPorous medium

A flow rate sensor includes a main conduit, a sensor tube and a bypass tube connecting an upstream portion of the main conduit to a downstream portion of the main conduit such that flow through the main conduit is divided through the sensor tube and the bypass tube, and at least one heater element for heating the sensor tube. A first flow restrictor of porous media is positioned between the upstream portion of the main conduit and the sensor tube, and a second flow restrictor of porous media is positioned between the upstream portion of the main conduit and the bypass tube. The flow restrictors provide the flow rate sensor with a fixed bypass ratio so that the sensor can operate independently of the type of gas being measured.

Owner:MKS INSTR INC

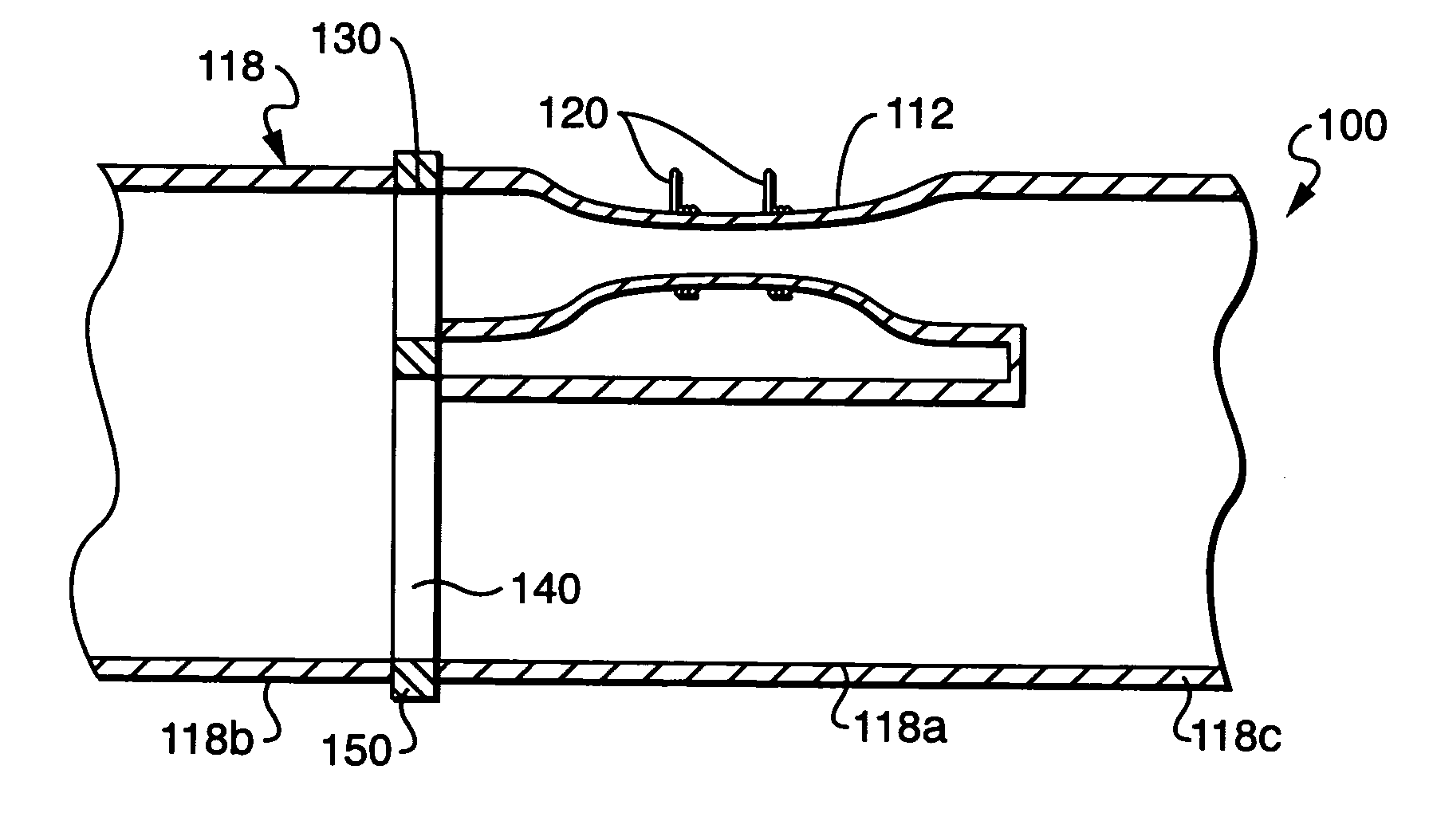

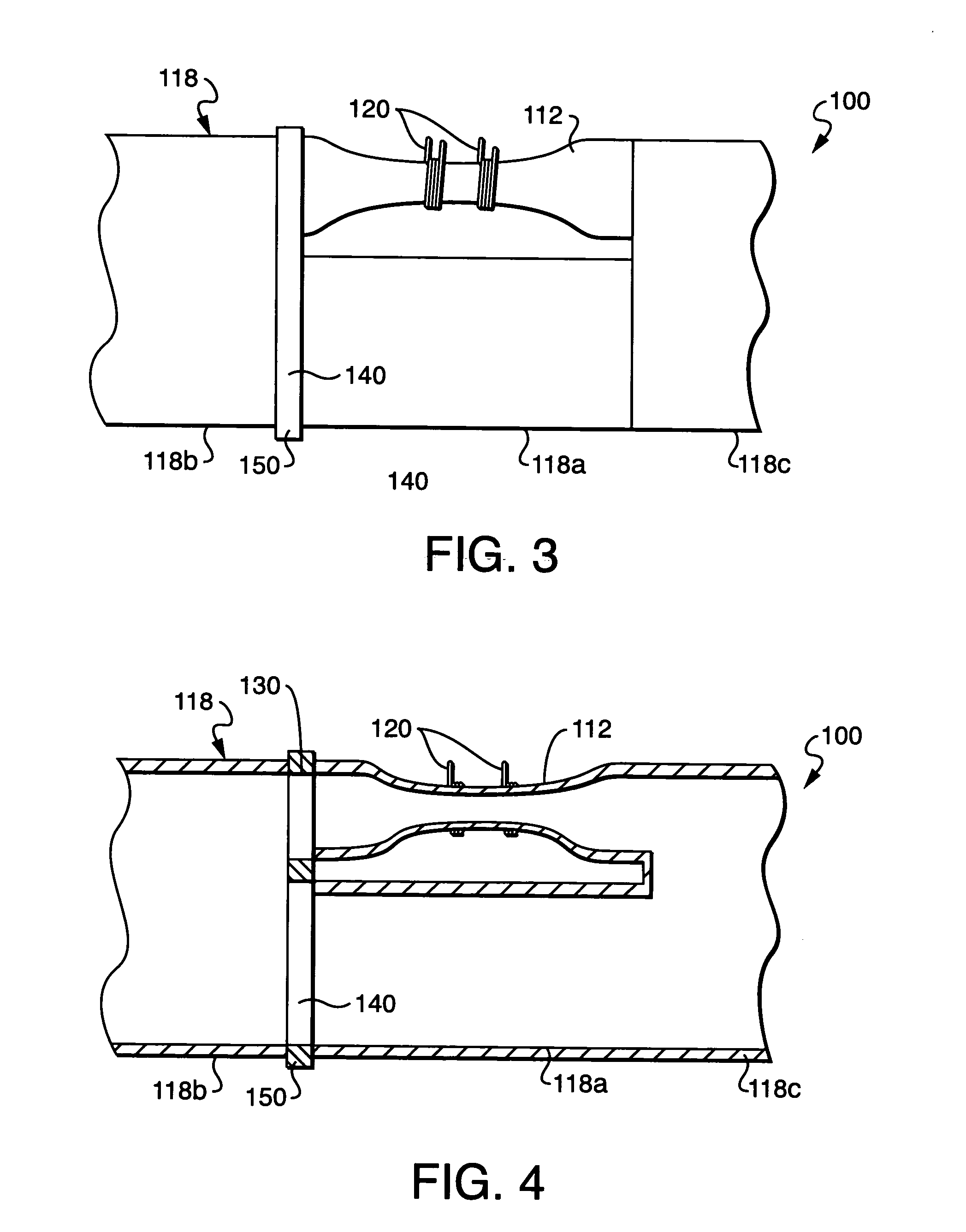

System for and method of providing a wide-range flow controller

ActiveUS20090095068A1Improve signal-to-noise ratioLow set-pointsVolume/mass flow by thermal effectsVolume flow proportion measurementLinear relationshipEngineering

An improved flow measuring device, such as a mass flow meter or mass flow controller, providing a high turn-down ratio as compared to prior art devices. In accordance with various embodiments of the invention, a flow sensor includes a sensor flow path that includes one or more restrictions configured to provide the sensor flow path with a non-linear relationship between a pressure drop across the sensor flow path and the flow of fluid through the flow sensor conduit. Such a flow sensor preferably achieves a high turn-down ratio by way of a variable bypass ratio that is directly proportional to the sensor tube mass flow rate so that the turn-down ratio of the mass flow controller will be ideally proportional to the square of the turndown achievable by the flow sensor conduit fluid sensing portion alone. In some embodiments, the restriction can be employed as a part of a fluid seal having an orifice and disposed between a flow sensor portion of a flow meter and a bypass portion of the flow meter.

Owner:BROOKS INSTRUMENT

System for and method of providing a wide-range flow controller

ActiveUS7874208B2Improve signal-to-noise ratioIncrease the turndown ratioVolume/mass flow by thermal effectsVolume flow proportion measurementLinear relationshipDischarge measurements

An improved flow measuring device, such as a mass flow meter or mass flow controller, providing a high turn-down ratio as compared to prior art devices. In accordance with various embodiments of the invention, a flow sensor includes a sensor flow path that includes one or more restrictions configured to provide the sensor flow path with a non-linear relationship between a pressure drop across the sensor flow path and the flow of fluid through the flow sensor conduit. Such a flow sensor preferably achieves a high turn-down ratio by way of a variable bypass ratio that is directly proportional to the sensor tube mass flow rate so that the turn-down ratio of the mass flow controller will be ideally proportional to the square of the turndown achievable by the flow sensor conduit fluid sensing portion alone. In some embodiments, the restriction can be employed as a part of a fluid seal having an orifice and disposed between a flow sensor portion of a flow meter and a bypass portion of the flow meter.

Owner:BROOKS INSTRUMENT

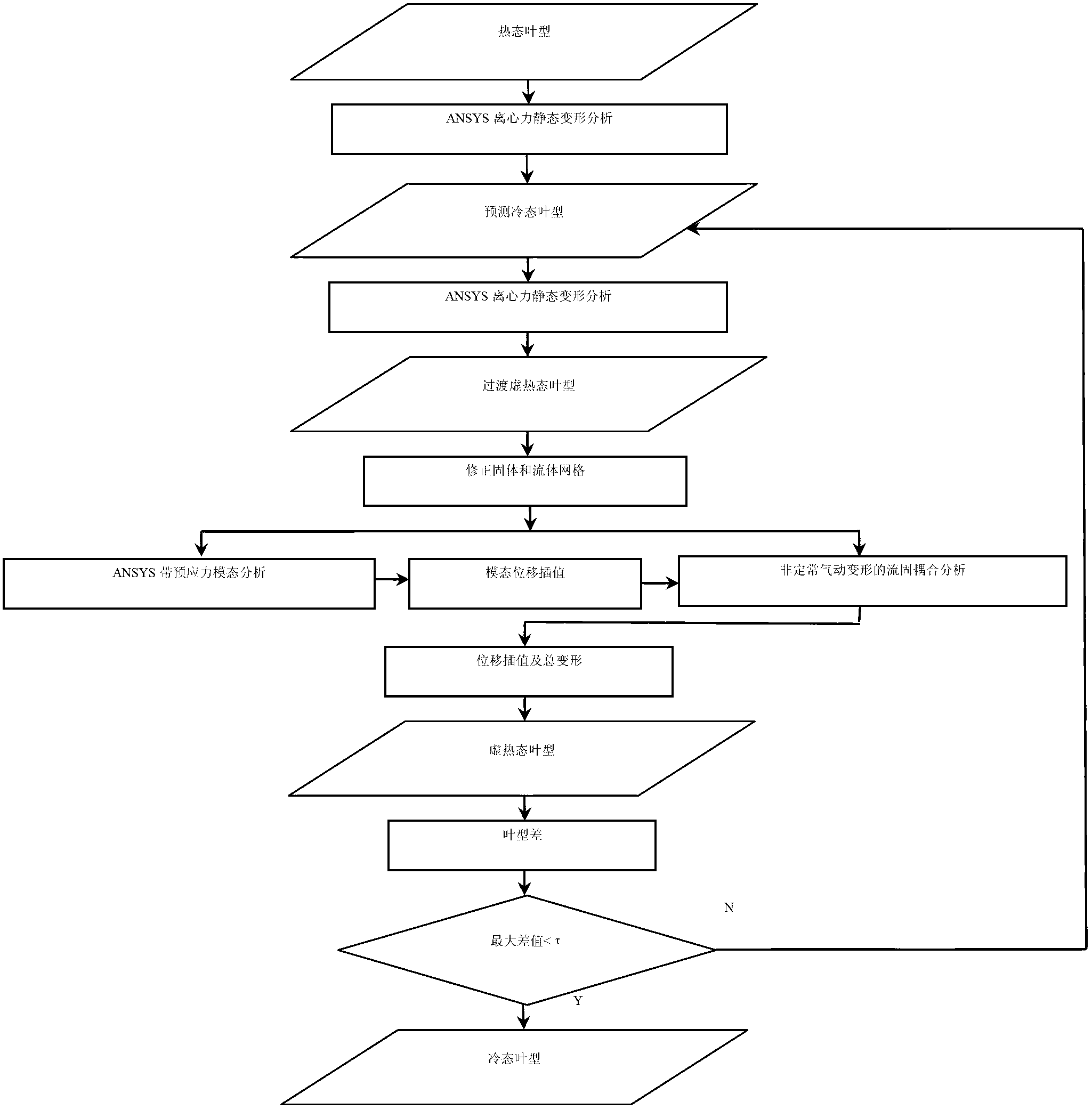

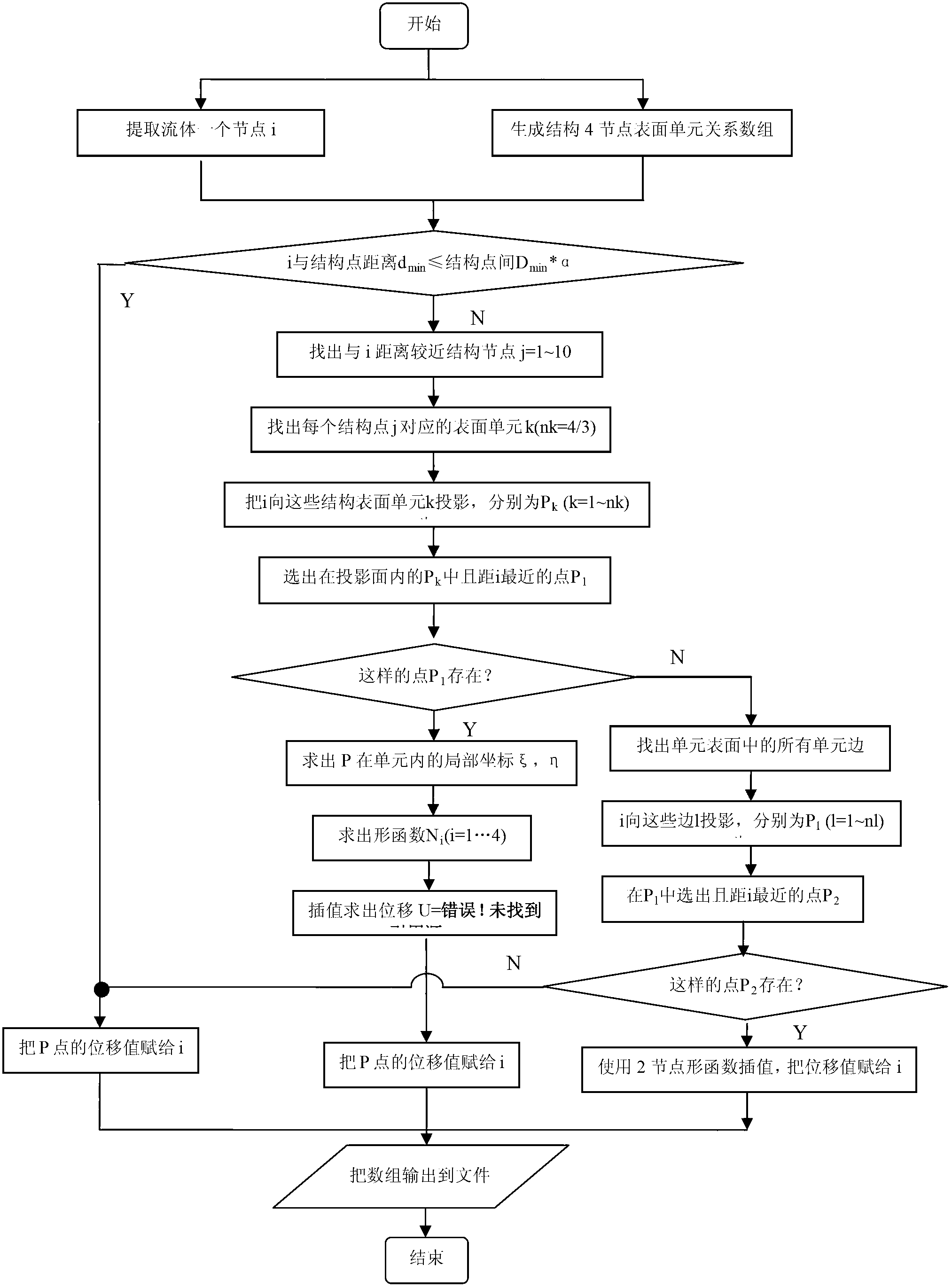

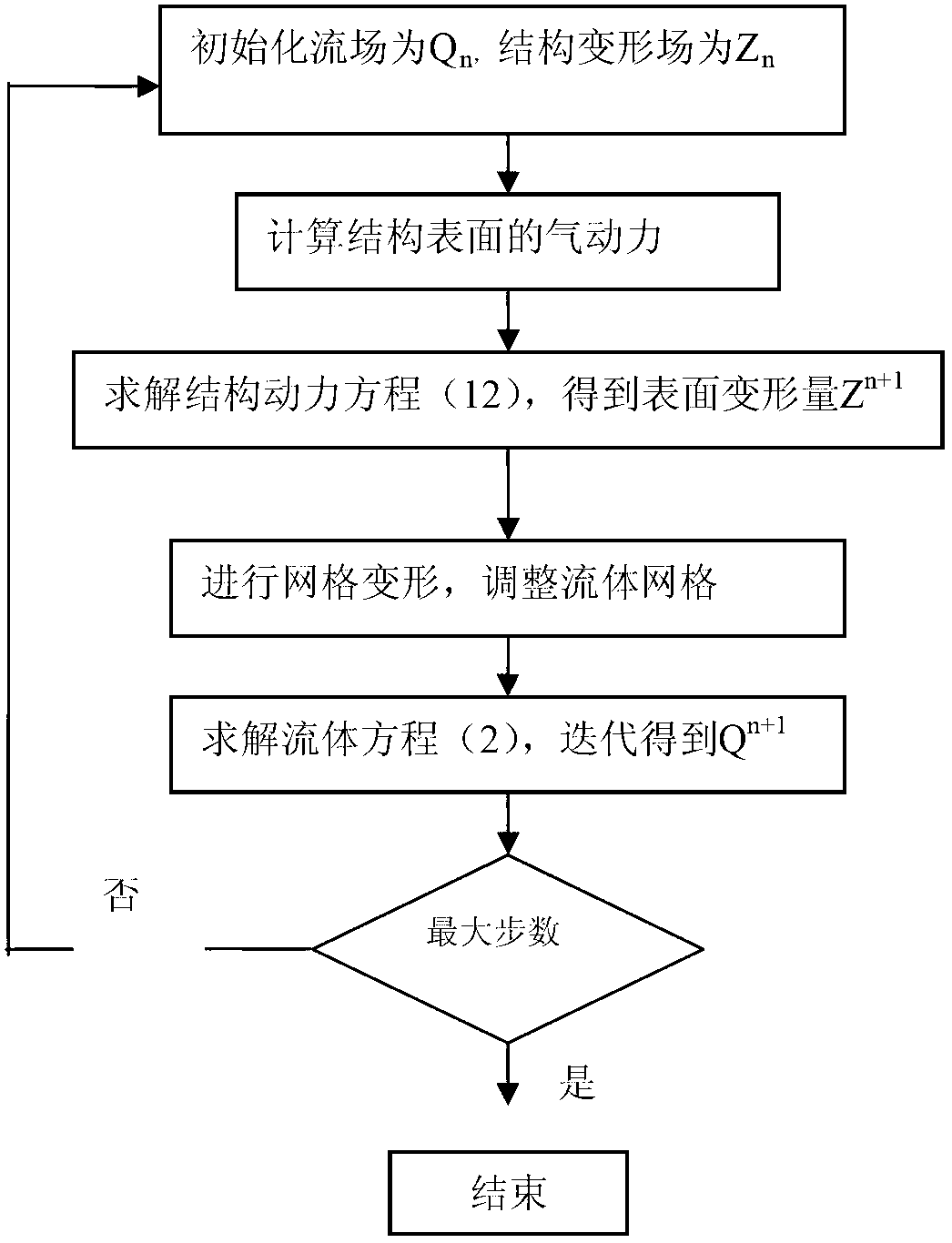

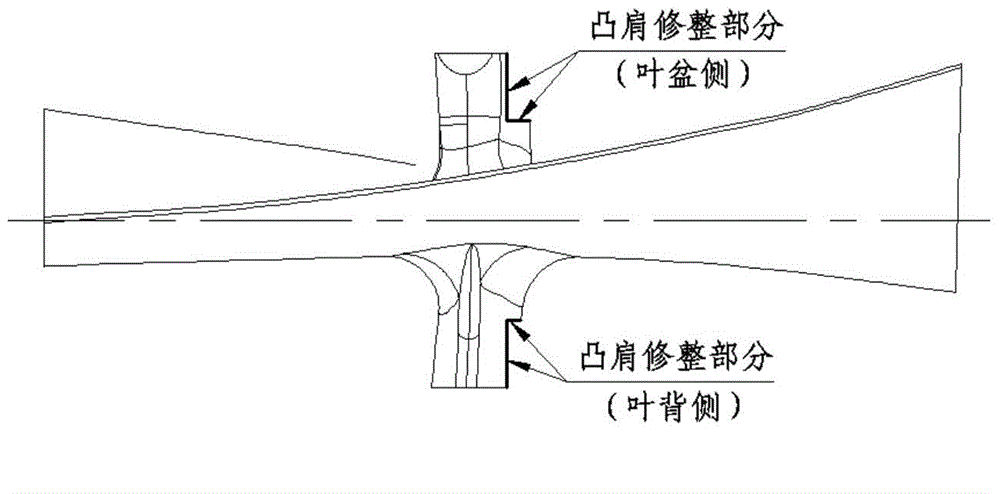

Method for estimating reverse twisting process of fan blade of gas turbine

InactiveCN102799730AImprove calculation accuracyOptimizing Manufacturing AirfoilsSpecial data processing applicationsThermal stateEngineering

The invention provides a method for estimating a reverse twisting process of a fan blade of a gas turbine, and aims to solve the problem that the conventional gas turbine fan blade reverse twisting design method is incomplete. According to the method, a cold state blade profile can be finally obtained by steps of performing analysis software (ANSYS) centrifugal force static deformation analysis on a thermal state blade profile, forecasting the cold state blade profile, then performing ANSYS centrifugal force static deformation analysis on the forecast cold state blade profile, transitioning a virtual thermal state blade profile, correcting a solid and liquid grid, performing aerodynamic force deformation fluid-solid coupling analysis and the like. The method has great significance for implementing consistency between the forecast thermal state blade profile and an actual working state blade profile of the blade under each pneumatic working condition and researching a method for precisely estimating the reverse twisting process of the fan blade of the gas turbine; and particularly, the method has important engineering application value in developing transonic speed fans with large bypass ratios.

Owner:BEIHANG UNIV

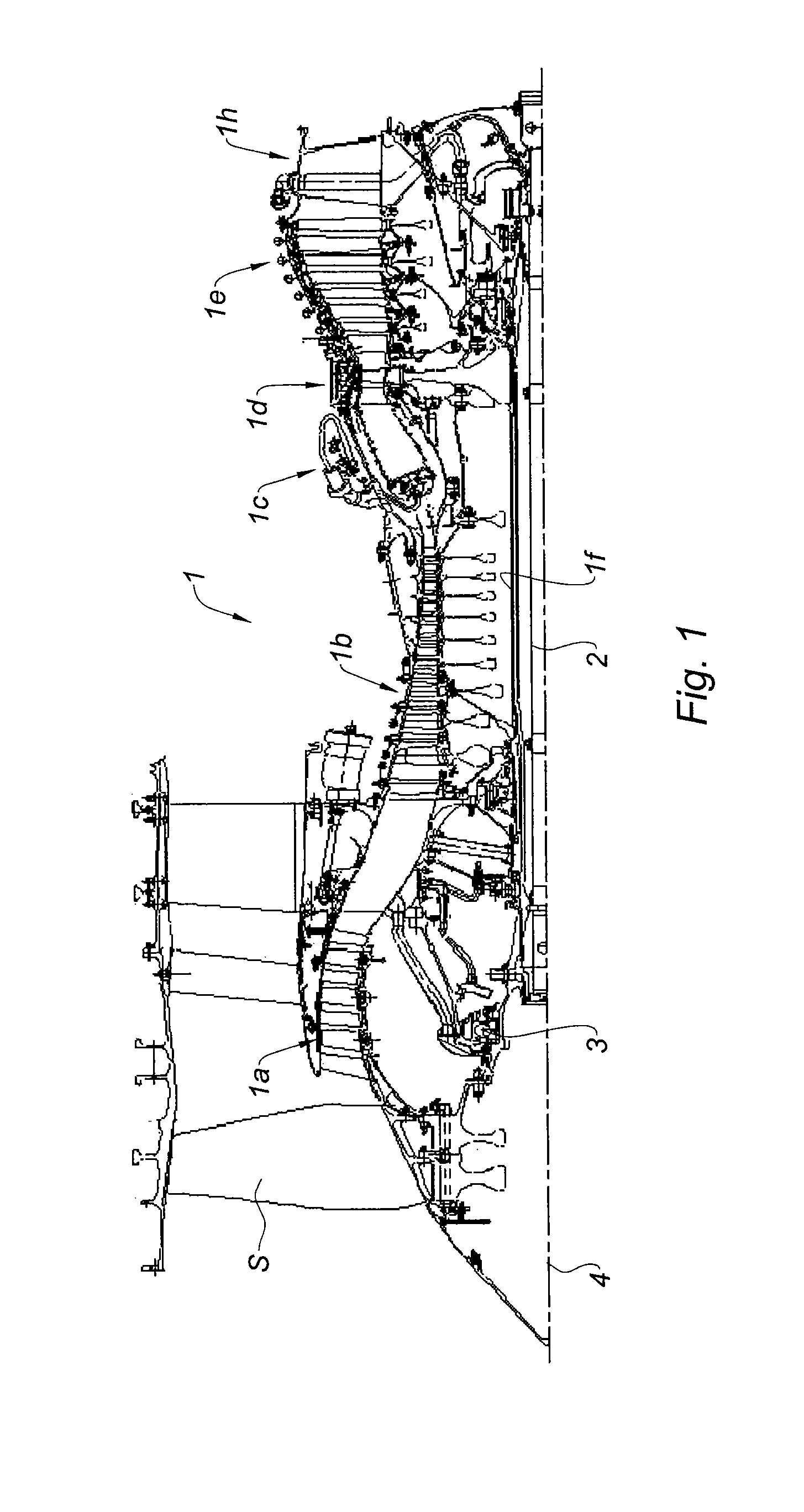

Turbofan comprising a low-supercritical-pressure shaft

A turbofan engine including: a turbine shaft; a fan shaft; and a reduction mechanism coupling the turbine shaft and the fan shaft, is provided. The turbofan engine has a bypass ratio greater than or equal to 10, and the turbine shaft is supported by four bearings such that the flexural deformation modes of the turbine shaft are positioned in transient phase or outside the operating range of the turbofan engine.

Owner:SN DETUDE & DE CONSTR DE MOTEURS DAVIATION S N E C M A

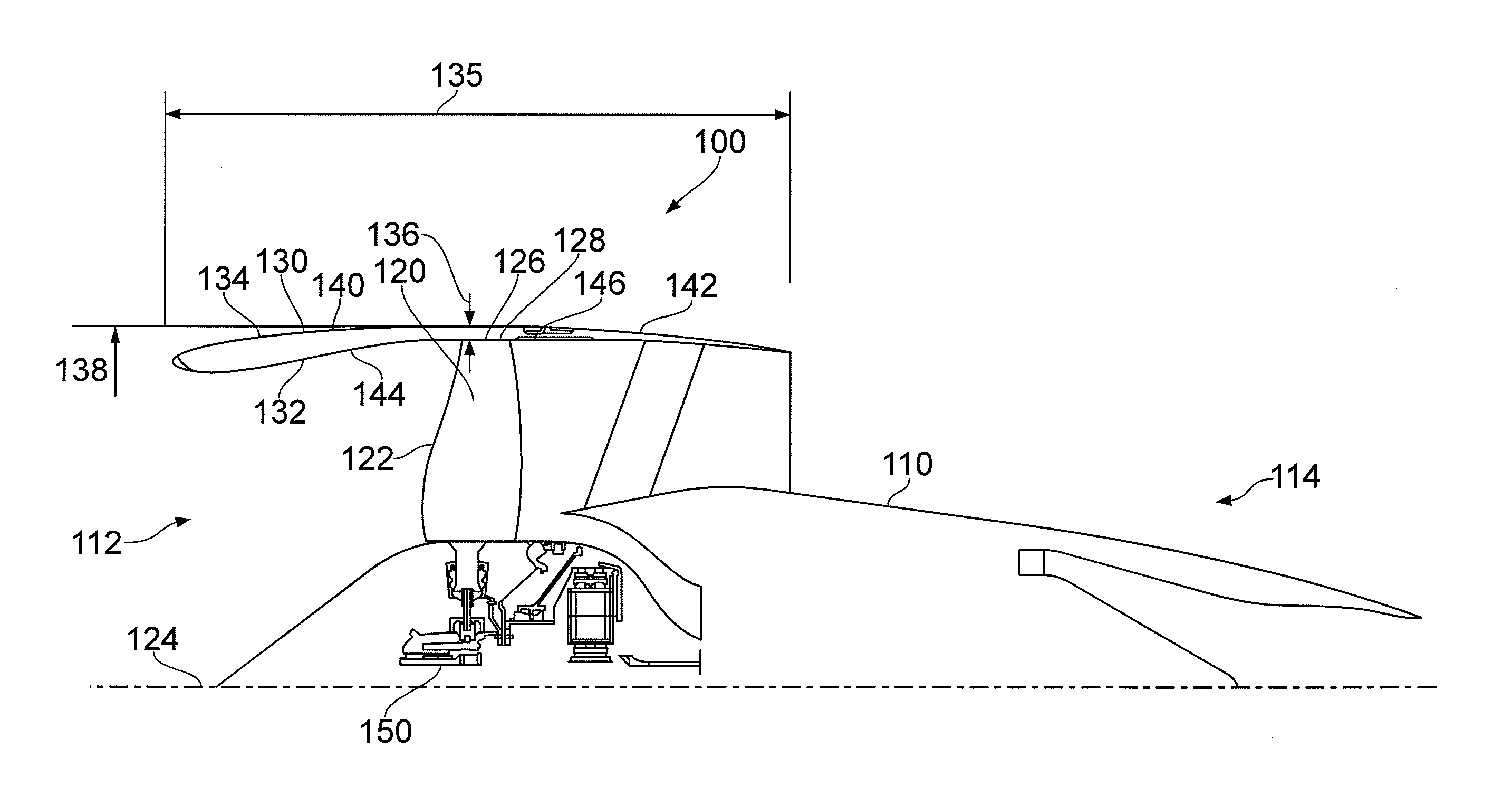

Aircraft propulsion system nacelle

ActiveUS20130216364A1Power plant arrangements/mountingPump componentsJet aeroplaneSpacecraft propulsion

An aircraft propulsion system has an engine assembly having an axis of rotation, a fan assembly operatively connected to the engine assembly and comprising a plurality of fan blades arranged circumferentially around the axis of rotation and a monolithic nacelle assembly which circumferentially encloses the fan assembly. The propulsion system has a ratio of fan assembly outer diameter to nacelle assembly outer diameter of at least 0.87. As a result, the propulsion system provides for a significantly larger fan assembly outer diameter for a given nacelle assembly outer diameter than a conventional prior art turbofan engine, thereby increasing the specific power output or the bypass ratio of the propulsion system, which will result in improved propulsive efficiency without an increase in nacelle drag.

Owner:ROLLS ROYCE PLC

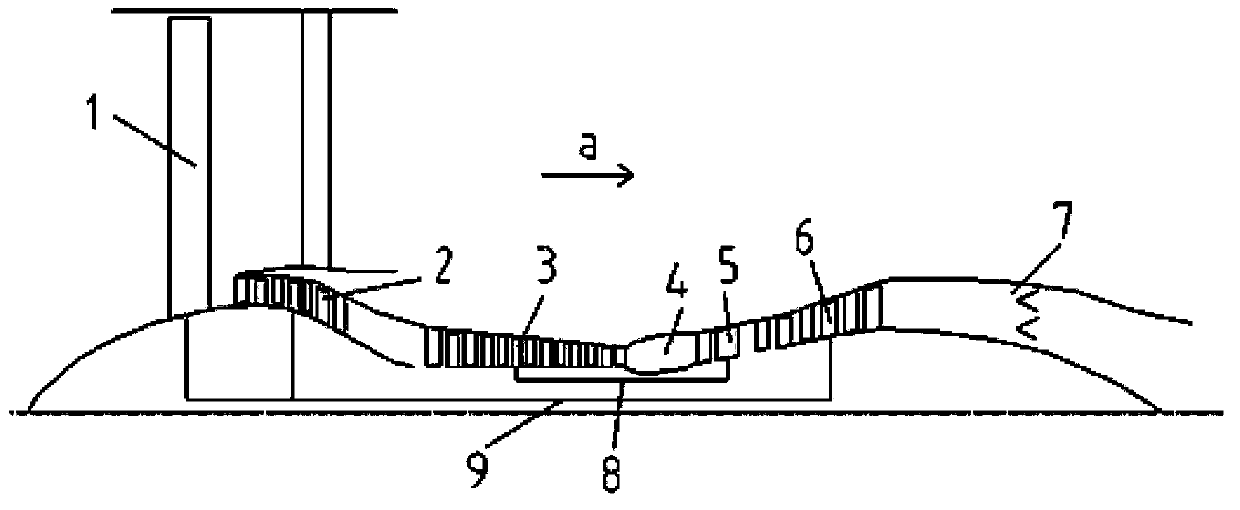

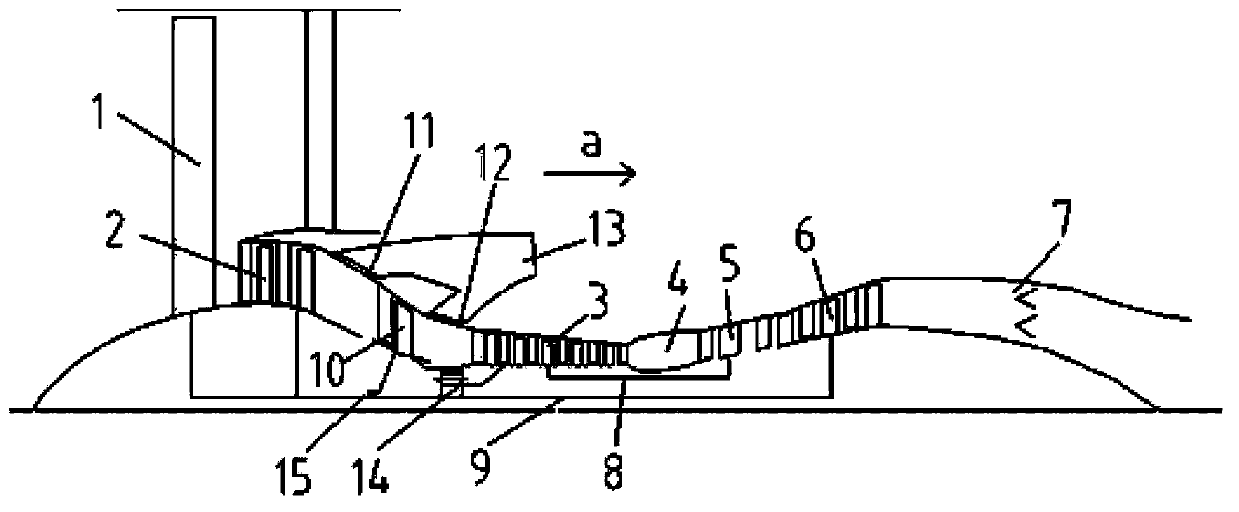

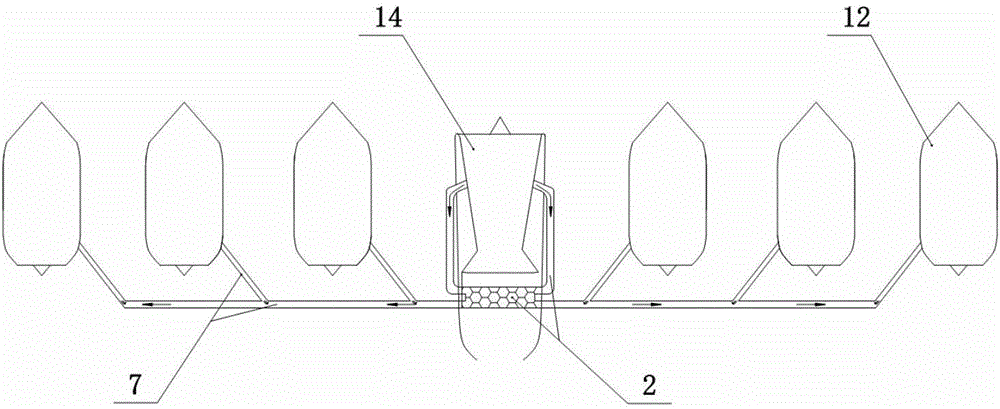

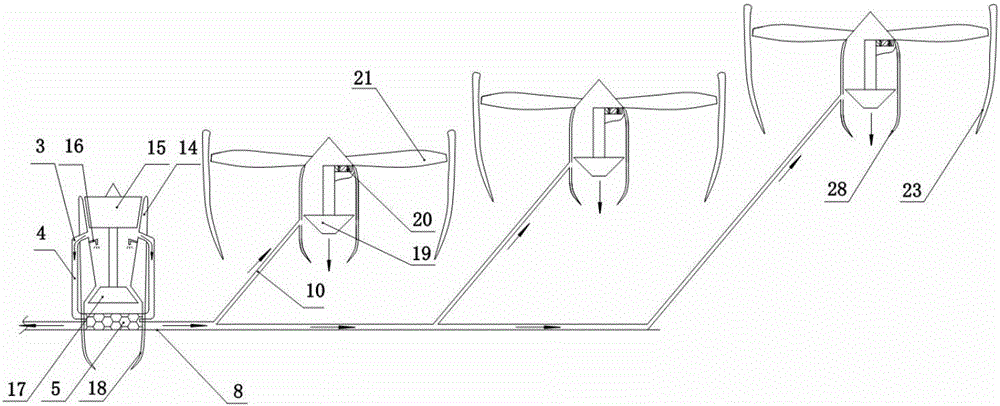

Large-bypass-ratio turbofan engine of vane tip jet driven fan

ActiveCN104675556AIncrease bypass ratioRealize boost boost and reduce consumptionJet propulsion plantsTorque transmissionBypass ratio

The invention provides a large-bypass-ratio turbofan engine of a vane tip jet driven fan and a designing method. A large-bypass-ratio fan rotor driven by vane tip jet is arranged on an external duct portion and comprises an additional ducted fan rotor, a vane tip driving portion and a rotary additional duct rotor hub; an additional duct stator is arranged on a downstream portion of the additional ducted fan rotor and a downstream portion of a vane tip driving portion; and air is led to vane tips of the additional ducted fan rotor from an external duct of the original double-rotor turbofan engine by an air leading channel. The large-bypass-ratio turbofan engine of the vane tip jet driven fan has the advantages that the bypass ratio is increased, torque transmission is implemented by an aerodynamic force, and the problem that the rotation speed of the fan is not matched with that of the driving component; the peripheral speed is greatly improved, and the improvement potential of the bypass ratio is high; compared with the prior art, the large-bypass-ratio turbofan engine is simple in structure; and the large-bypass-ratio turbofan engine is improved on the basis of the existing double-rotor turbofan engine, development risk and the development cost of the large-bypass-ratio turbofan engine of the vane tip jet driven fan are reduced, and the development cycle is shortened.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

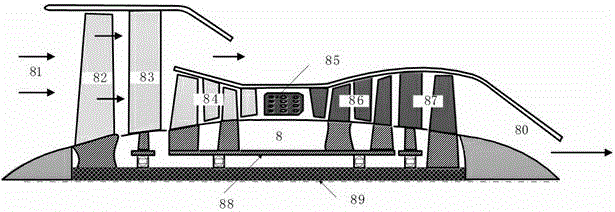

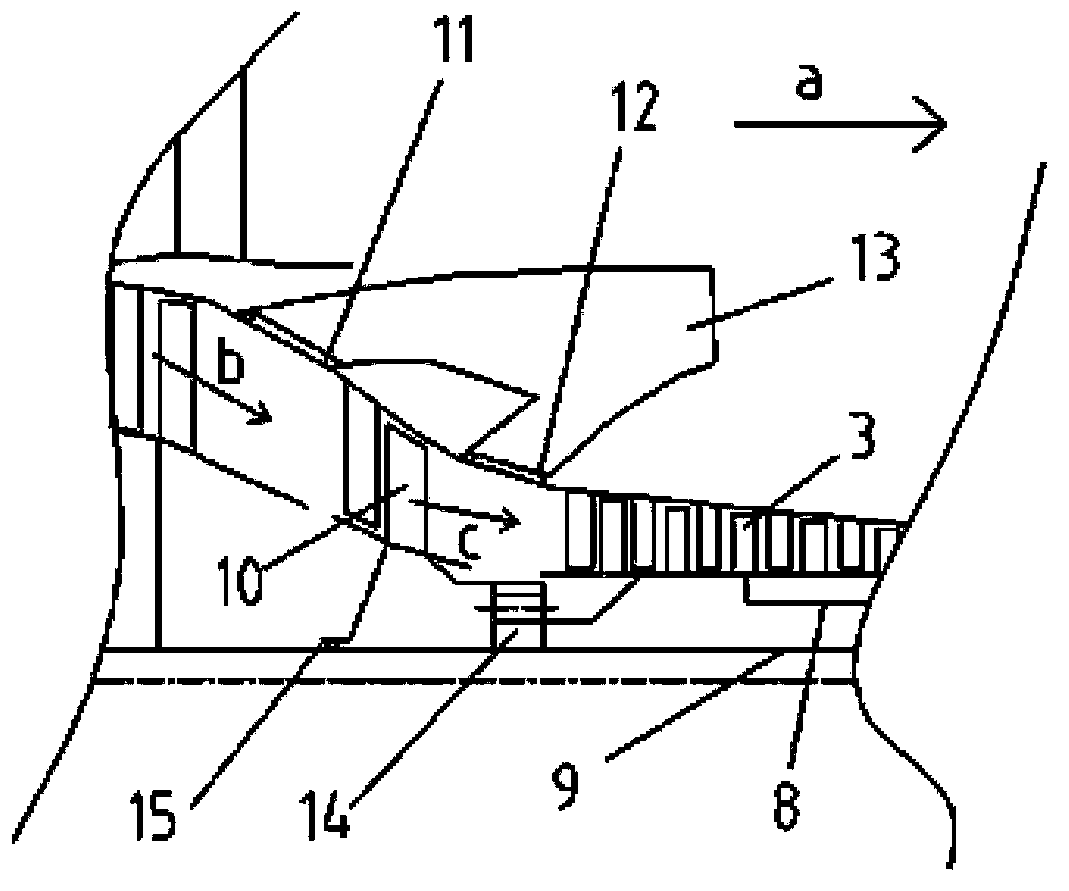

Variable cycle engine with high bypass ratio

ActiveCN103867337AImproved airflow matchingImprove surge marginJet propulsion plantsCombustorBypass ratio

The invention relates to a variable cycle engine with a high bypass ratio. The variable cycle engine comprises a front fan (1), a booster stage (2), a high-pressure compressor (3), a combustor (4), a high pressure turbine (5), a low-pressure turbine (6) and a tail pipe nozzle (9), wherein the high-pressure compressor (3) and the booster stage (2) are respectively driven by the high pressure turbine (5), the low-pressure turbine (6) and the exhaust nozzle (9) through a high pressure shaft (8) and a low pressure shaft (9); a rear fan (10) is arranged between the booster stage (2) and the high-pressure compressor (3), the revolving speed of the rear fan (10) is between the revolving speed of the booster stage (2) and the revolving speed of the high-pressure compressor (3), and a plurality of first bypass valves (12) and corresponding bypass channels are arranged on the outlet of the rear fan (10). The air current matching of engine parts can be improved by additionally setting the rear fan between the booster stage and the high-pressure compressor, and bypass valves capable of being opened or closed are arranged on the outlet of the rear fan, so that the bypass ratio of the engine can be changed so as to be applied to the requirements of different power states.

Owner:AECC COMML AIRCRAFT ENGINE CO LTD

Thermal mass flow rate sensor including bypass passageways and a sensor passageway having similar entrance effects

ActiveUS20060101908A1Type accurateCalibrationVolume/mass flow by thermal effectsVolume flow proportion measurementEngineeringCatheter

A sensing apparatus for use in a mass flow rate sensor for measuring a fluid flow rate includes a main conduit for containing a fluid flow, and a sensor passageway for tapping a portion of the fluid flow from the main conduit at a first location, and returning the portion of the fluid flow to the conduit at a second location. At least one bypass passageway, which may be provided in the form of a tube, is positioned in the main conduit between the first and second locations, and the bypass passageway is provided with non-negligible entrance effects that are substantially equal to entrance effects of the sensor passageway, so that a bypass ratio of the apparatus remains constant. A mass flow rate sensor of the present disclosure accurately measures any type of gas but only requires calibration in only one reference gas.

Owner:MKS INSTR INC

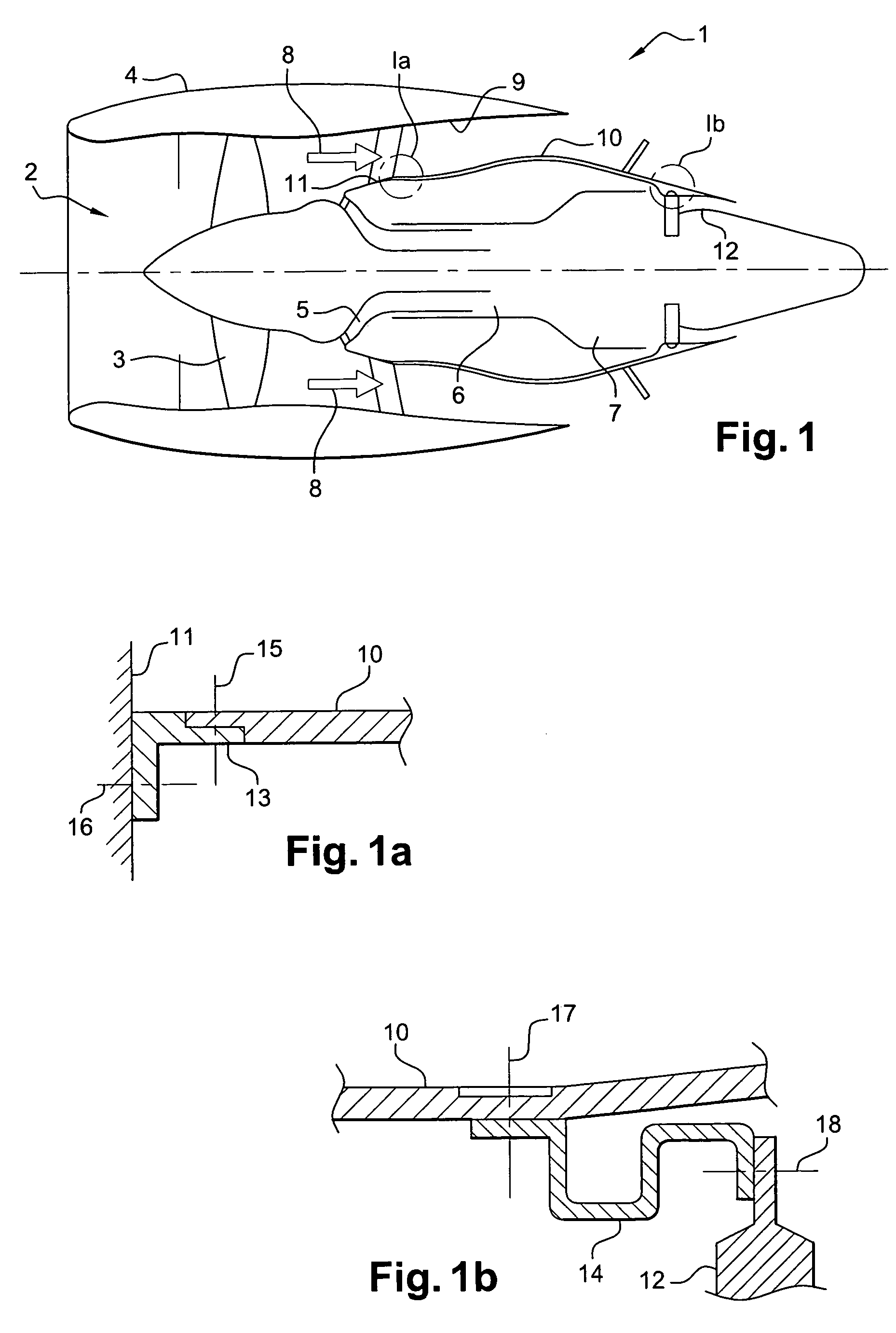

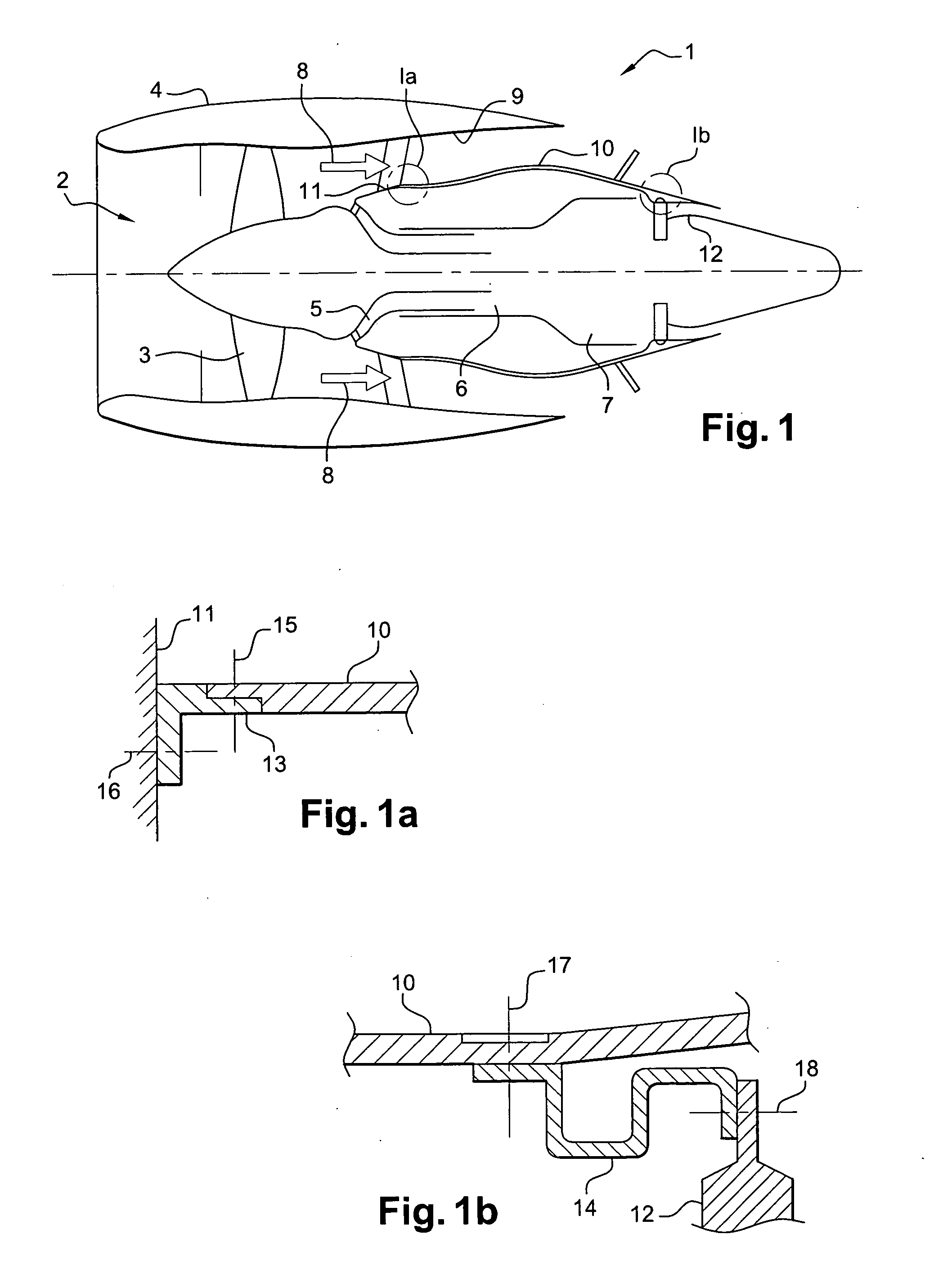

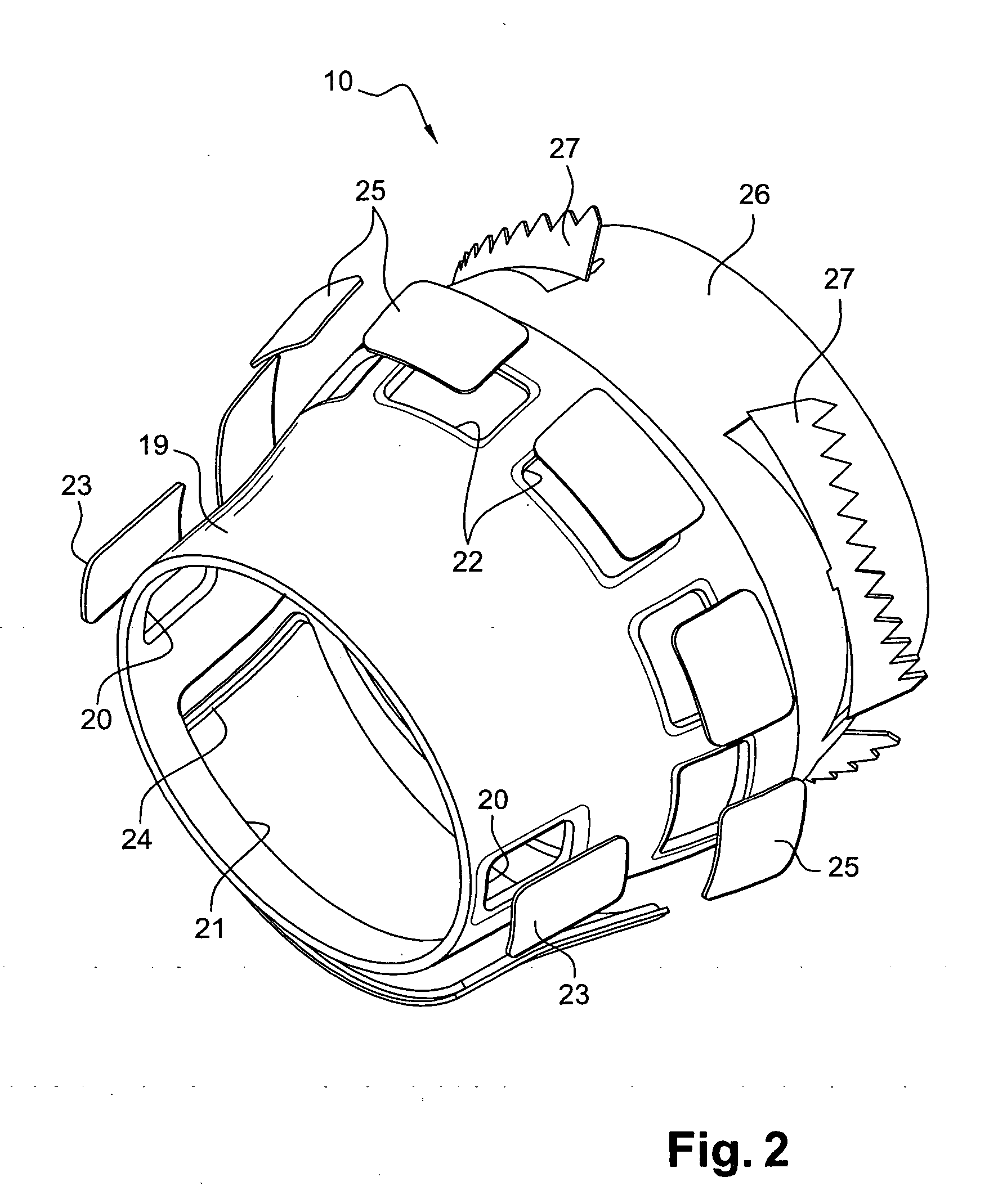

Turbojet having a large bypass ratio

ActiveUS7430852B2Simple and effective and inexpensiveBig ratioSpraying apparatusBlade accessoriesCombustion chamberBypass ratio

A turbojet comprises at least a fan, a compressor, a combustion chamber, a turbine, and a rigid substantially-cylindrical jacket fastened at its upstream end to an intermediate casing and at its downstream end to an exhaust casing, the jacket serving to transmit forces between the intermediate casing and the exhaust casing.

Owner:SN DETUDE & DE CONSTR DE MOTEURS DAVIATION S N E C M A

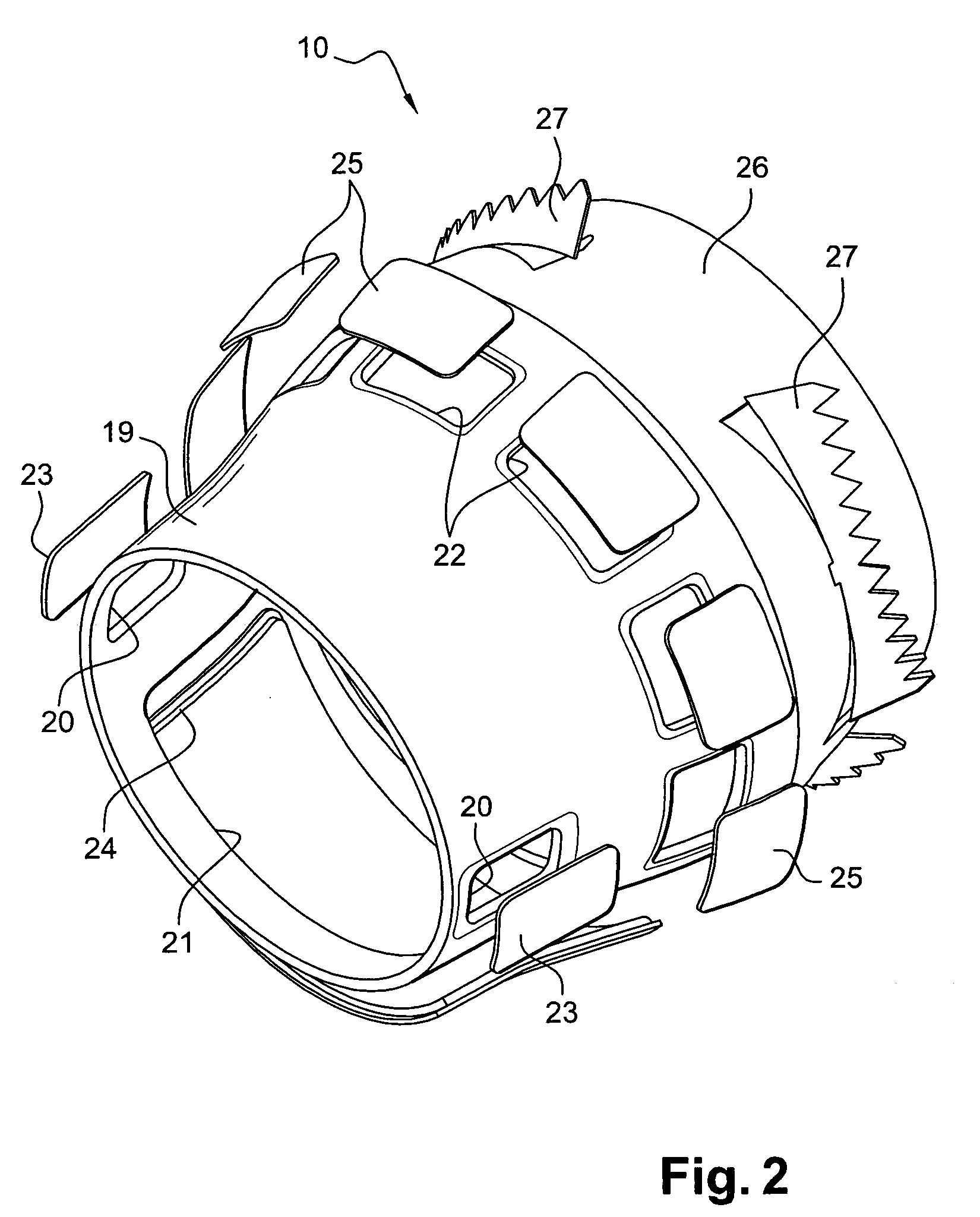

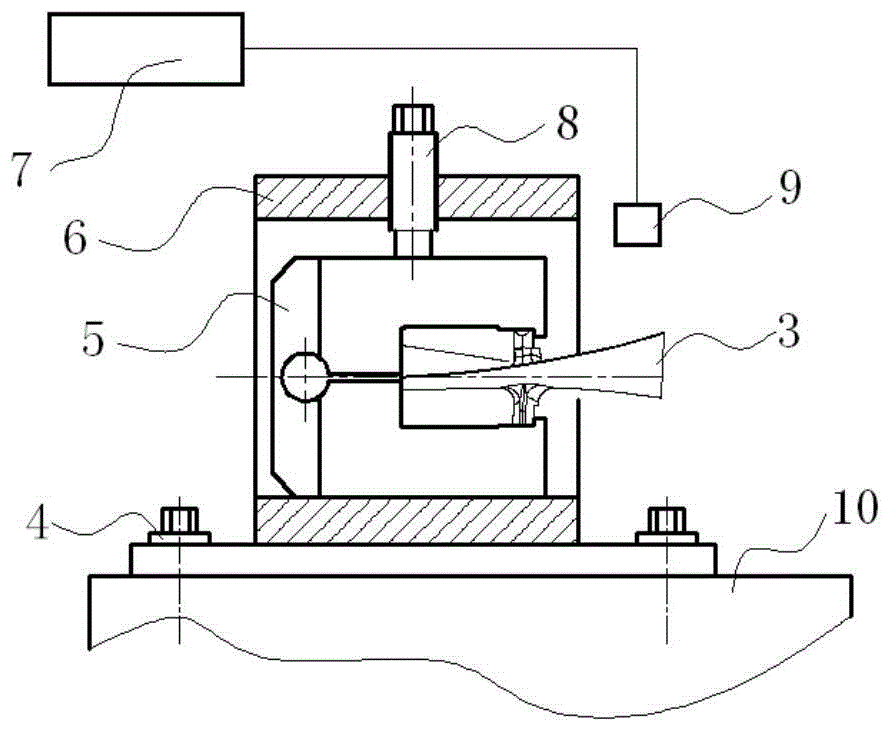

Vibration fatigue testing method for large-bypass-ratio engine fan blade with shoulder

The invention belongs to the technology of aviation engine blade testing, and provides a vibration fatigue testing method for a large-bypass-ratio engine fan blade with a shoulder. The method comprises the steps: (1) laterally cutting the fan blade with the shoulder; (2) machining the top of the shoulder into two parallel platforms; (3) enabling a clamp pedestal to be fixedly connected with a vibrating platform; (4) binding strain gages on the blade body; (5) enabling a testing blade with the strain gages to be placed on an inner clamping surface of a dedicated clamping block; (6) enabling the dedicated clamping block with the testing blade to be placed into a frame of the clamp pedestal for compression; (7) enabling the lead of each strain gage on the testing piece to be connected with a corresponding channel of a deformeter; (8) controlling the vibration sweep frequency of a small load of the vibration platform, and finding a first-order bending resonance frequency of the blade; (9) recording the strain value of each channel and the amplitude of a blade tip through the deformeter, determining the maximum stress position, and carrying out the fitting of the relation between the maximum stress and the amplitude of the blade tip; (10) solving a required testing load value, and completing the vibration fatigue testing.

Owner:AECC AVIATION POWER CO LTD

Thermal mass flow rate sensor having fixed bypass ratio

ActiveUS20060101907A1Simple designReduce manufacturing costVolume/mass flow by thermal effectsVolume flow proportion measurementPorous mediumEngineering

A flow rate sensor includes a main conduit, a sensor tube and a bypass tube connecting an upstream portion of the main conduit to a downstream portion of the main conduit such that flow through the main conduit is divided through the sensor tube and the bypass tube, and at least one heater element for heating the sensor tube. A first flow restrictor of porous media is positioned between the upstream portion of the main conduit and the sensor tube, and a second flow restrictor of porous media is positioned between the upstream portion of the main conduit and the bypass tube. The flow restrictors provide the flow rate sensor with a fixed bypass ratio so that the sensor can operate independently of the type of gas being measured.

Owner:MKS INSTR INC

Reduction gear with epicyclic gear train having roller-bearing-mounted planet spindles

A reduction gear with epicyclic gear train including an annulus gear, and at least one planet gear rolling on the annulus gear and able to rotate about a planet spindle borne by a planet carrier is provided. The planet spindle is mounted such that it can itself rotate about its axis relative to the planet carrier. The reduction gear is suitable for mounting in a high bypass ratio jet engine for driving the fan thereof.

Owner:SN DETUDE & DE CONSTR DE MOTEURS DAVIATION S N E C M A

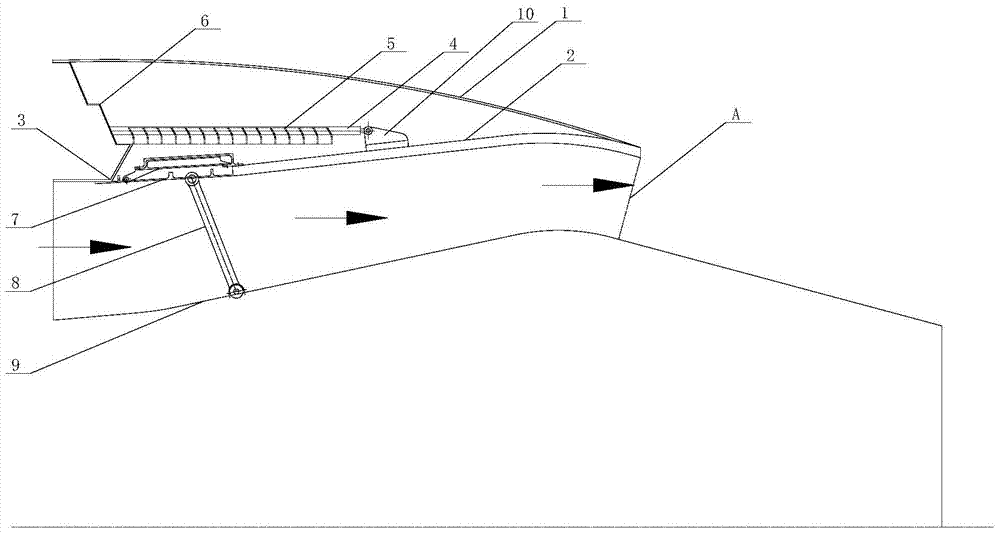

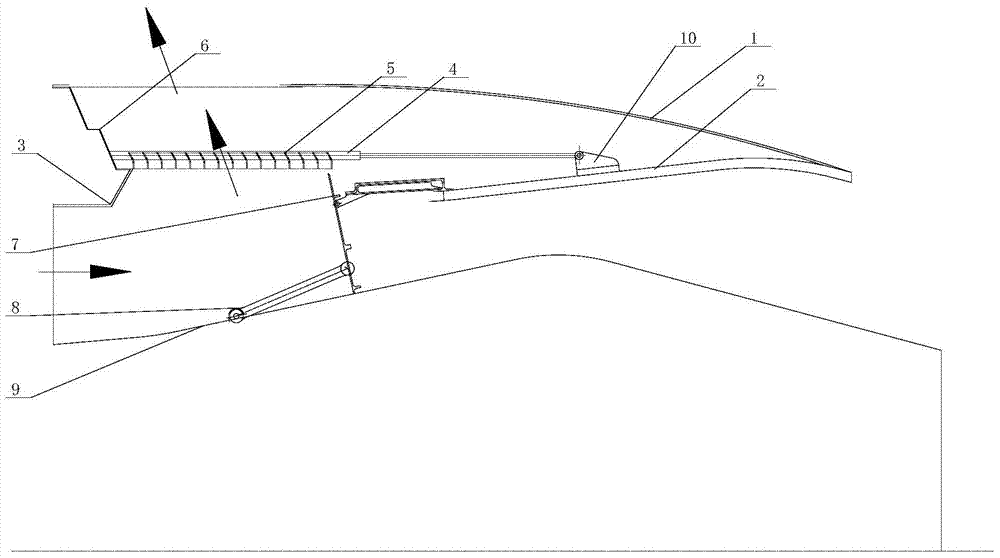

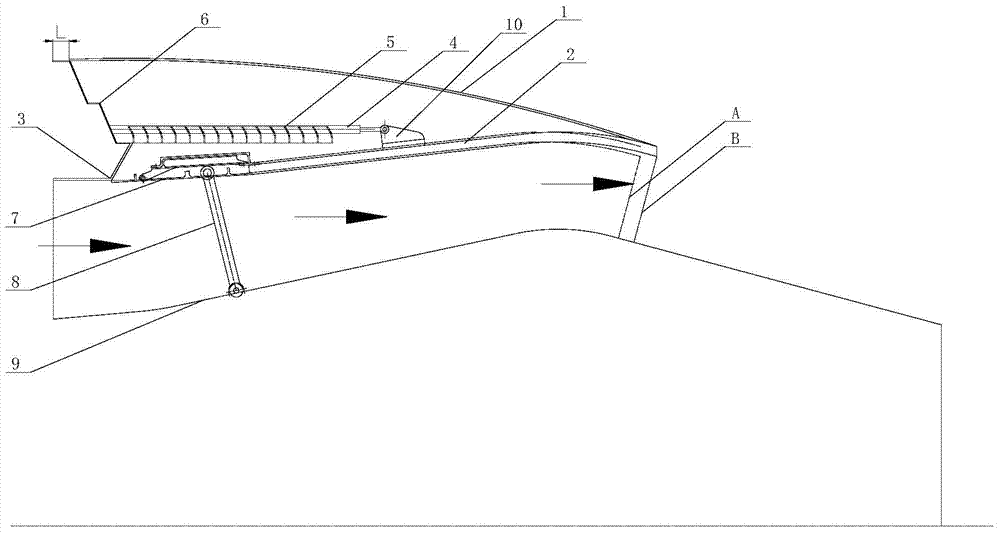

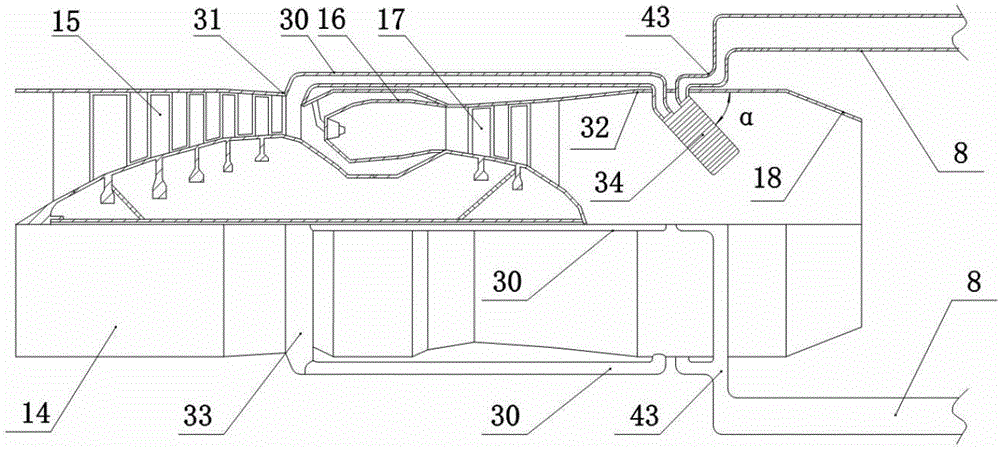

Reverse thrusting device with capacity of adjusting area of spray pipe

InactiveCN103696877AFulfilling Regulatory NeedsJet propulsion plantsMechanical engineeringBypass ratio

The invention discloses a reverse thrusting device with the capacity of adjusting the area of a spray pipe. The reverse thrusting device comprises a motion part and a fixed part, and a motion mechanism is used for realizing the adjustment on the area of an outer culvert spray pipe and the opening and closing of the reverse thrusting device when the reverse thrusting device is in a closing state; an outer culvert spray pipe throat area A can be formed together by an outer culvert spray pipe outer wall surface and an outer culvert spray pipe inner wall surface when an actuating cylinder is in a retracting position, an outer culvert spray pipe throat area B is formed together by the outer culvert spray pipe outer wall surface and the outer culvert spray pipe inner wall surface, an outer culvert spray pipe throat area is positioned between A and B when the stretching length of the actuating cylinder is positioned between 0 and L, and thus the adjustment on the area of the outer culvert spray pipe throat area can be realized. The reverse thrusting device disclosed by the invention has the advantages that the structure form of an existing reverse thrusting device is not changed, only an existing structure is adaptively changed, and thus the adjustment requirement on the area of the outer culvert spray pipe throat area of a large-bypass-ratio engine can be realized on the premise that an original reverse thrusting function is ensured.

Owner:AECC SHENYANG ENGINE RES INST

Distributed propulsion system

ActiveCN106742075AImprove efficiencyImprove realizabilityCosmonautic propulsion system apparatusRegenerative designGas compressor

The invention discloses a distributed propulsion system. The distributed propulsion system is characterized in that input ends of gas collecting devices of a high-energy working medium collecting device are communicated with an output end of a core machine gas compressor of a turbine engine core machine; output ends of the high-energy working medium collecting device are communicated with inlets of efficient working medium transmission devices; output ends of transmission branched pipes of the efficient working medium transmission devices are respectively communicated with input ends of propeller turbine volute casings of various distributed propellers; input ends of the transmission branched pipes are communicated with transmission header pipes of the efficient working medium transmission devices; the six distributed propellers are uniformly distributed on two sides of the turbine engine core machine. The distributed propulsion system has the advantages that the shortcoming of dependence of distributed propulsion systems on the basis of electric power distribution on energy storage equipment with high energy density and super-power motors can be overcome, and the implementability of the distributed propulsion system can be enhanced; mechanical restraint between gas generators and propellers in a distributed propulsion system on the basis of mechanical transmission can be dispensed, bypass ratio limit on turbo fan engines and the traditional distributed power can be broken through, the distributed propulsion system is in a heat regenerative design, and the propulsion efficiency can be improved.

Owner:西安觉天动力科技有限责任公司

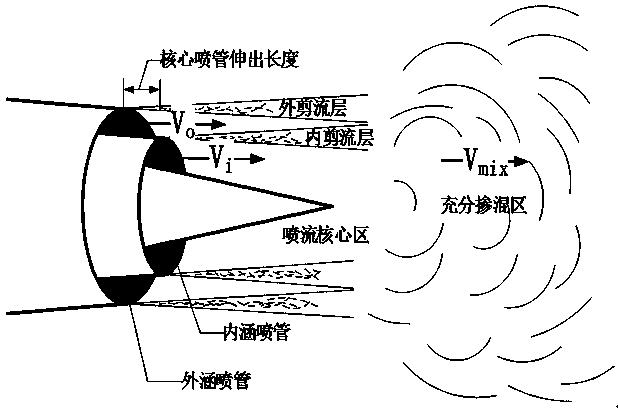

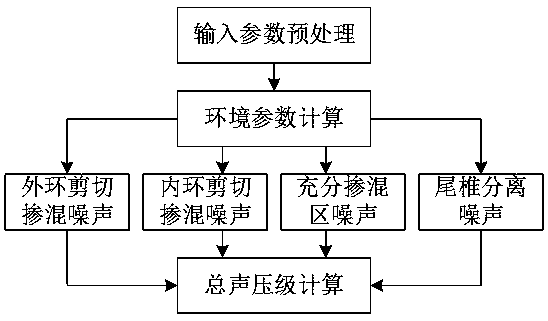

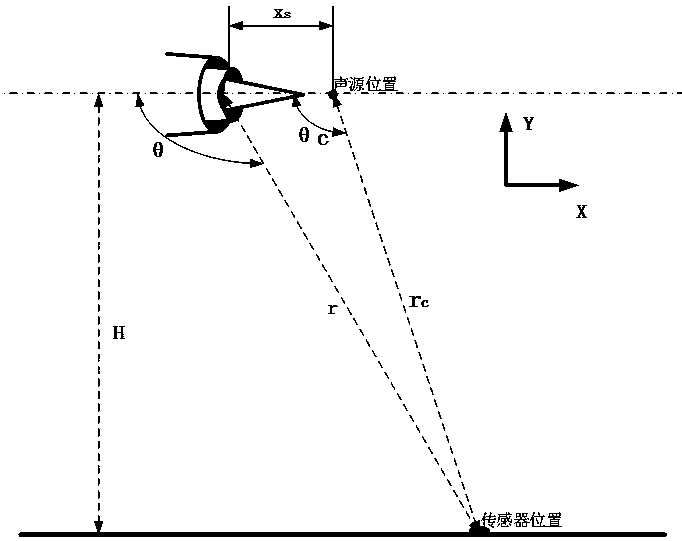

Flight/propulsion system/jet flow noise comprehensive real-time model modeling method

ActiveCN110991017AMeet real-time simulation requirementsMeet application requirementsGeometric CADDesign optimisation/simulationNonlinear modelBypass ratio

The invention relates to a modeling method for a flight / propulsion system / jet flow noise comprehensive real-time model. The modeling method comprises the following steps: establishing a jet flow noisereal-time prediction model; establishing a component-level model of the turbofan engine with the large bypass ratio; establishing a kinetic model and a kinematics model of the double-engine transporter; and synthesizing and correcting a flight / engine / jet noise model. The invention discloses a noise reduction method for an aircraft. According to a traditional method, a flight system, a propulsionsystem and noise calculation are generally carried out separately; the inter-system coupling relationship is difficult to fully consider; the problem that the noise condition in the whole flight process cannot be covered is solved. According to the method, the problems that the calculation amount is large, and the jet flow noise cannot be calculated in real time according to flight and engine states are solved, a jet flow noise real-time prediction model is established and combined with a flight model and an engine nonlinear model, and real-time simulation of the flight state, the engine performance and the jet flow noise is achieved.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

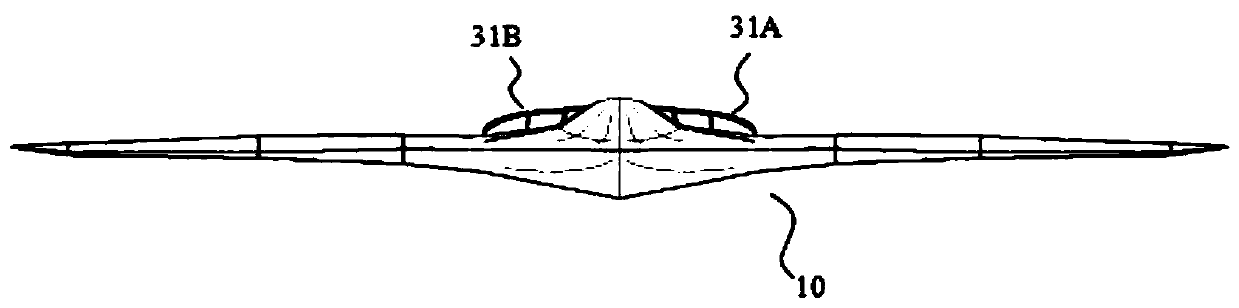

Distributed propulsion flying wing aircraft

ActiveCN111332464AReduce fuel consumptionShorten speedGas turbine type power plantsRotocraftFlight vehicleBypass ratio

The invention is applicable to the technical field of aircrafts. The invention provides a distributed propulsion flying wing aircraft. The flying wing comprises a flying wing body and a distributed propelling system, the distributed propulsion system is arranged in the flying wing body and comprises a ducted fan system, a turbine engine system and a shaft power transmission system, and the shaft power transmission system transmits shaft power output by the turbine engine system to the ducted fan system. The distributed propelling system integrates a ducted fan system and a turbine engine system, the effect of a large-bypass-ratio engine is achieved, and the oil consumption rate of the flying-wing aircraft can be reduced by 25% or above.

Owner:INST OF HIGH SPEED AERODYNAMICS OF CHINA AERODYNAMICS RES & DEV CENT

Turbojet having a large bypass ratio

ActiveUS20050172609A1Increase in-flight idling speedSimple and effective and inexpensiveSpraying apparatusBlade accessoriesCombustion chamberEngineering

A turbojet comprises at least a fan, a compressor, a combustion chamber, a turbine, and a rigid substantially-cylindrical jacket fastened at its upstream end to an intermediate casing and at its downstream end to an exhaust casing, the jacket serving to transmit forces between the intermediate casing and the exhaust casing.

Owner:SN DETUDE & DE CONSTR DE MOTEURS DAVIATION S N E C M A

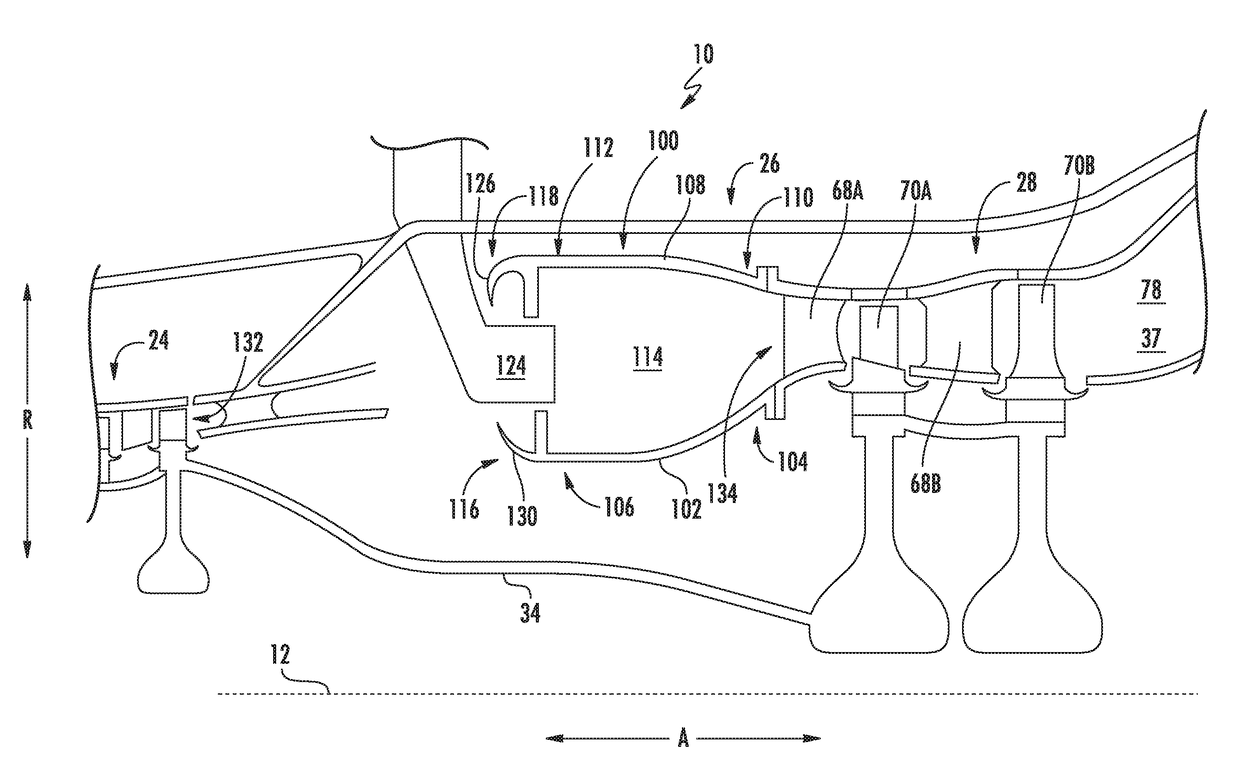

Cool core gas turbine engine

InactiveUS20180216575A1Turbine/propulsion engine coolingEfficient propulsion technologiesCombustionNacelle

A turbofan engine is provided including a fan having a plurality of rotatable fan blades and defining a fan pressure ratio during operation of the turbofan engine. The turbofan engine also includes a turbomachine operably coupled to the fan for driving the fan, the turbomachine including a compressor section, a combustion section, and a turbine section in serial flow order and together defining a core air flowpath. The turbofan also includes an outer nacelle at least partially surrounding the fan and the turbomachine, the outer nacelle defining a bypass passage with the turbomachine. A bypass ratio of an amount of airflow through the bypass passage to an amount of airflow through the core air flowpath during operation of the turbofan is less than or equal to about 11 and wherein the fan pressure ratio is less than or equal to about 1.5.

Owner:GENERAL ELECTRIC CO

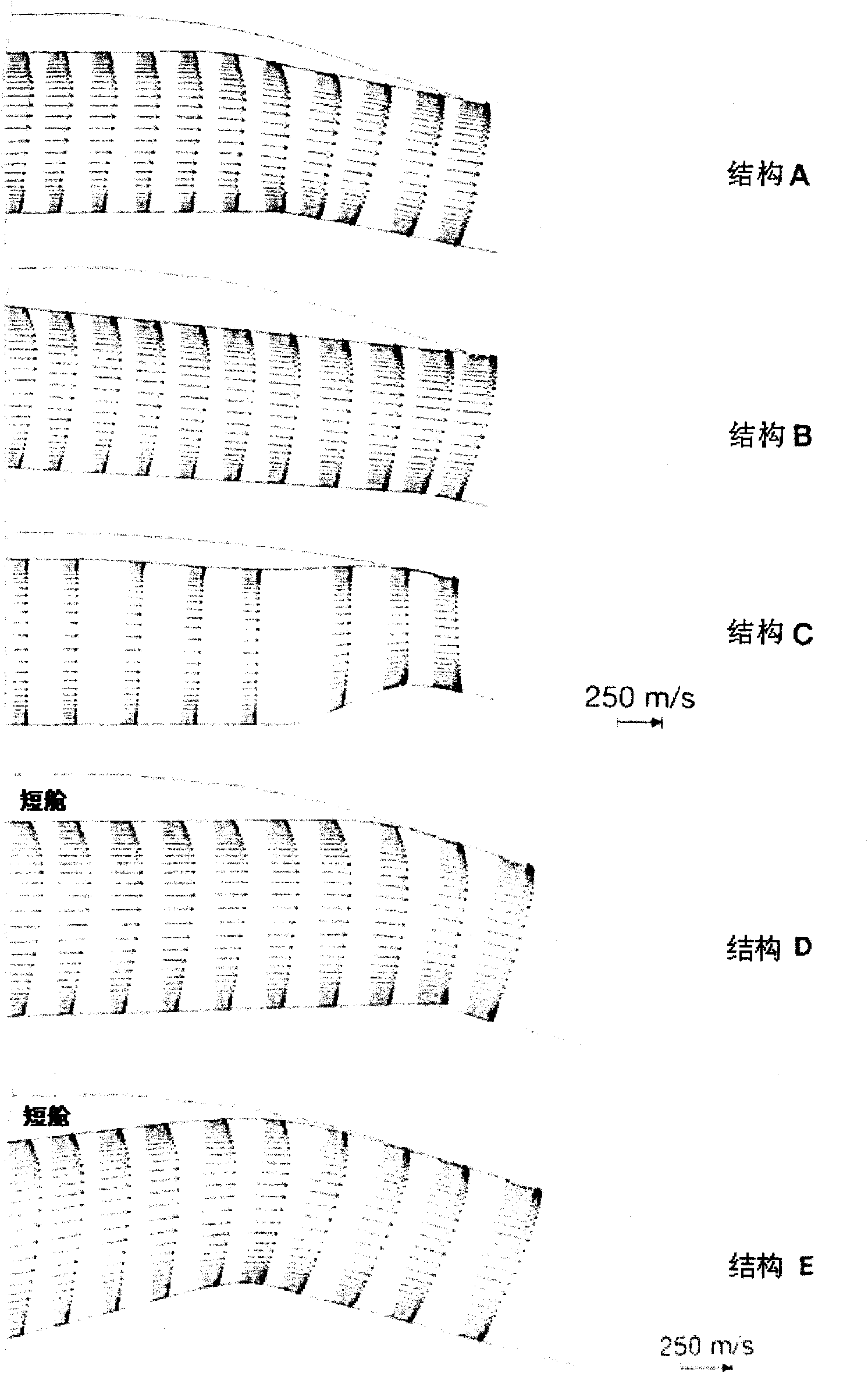

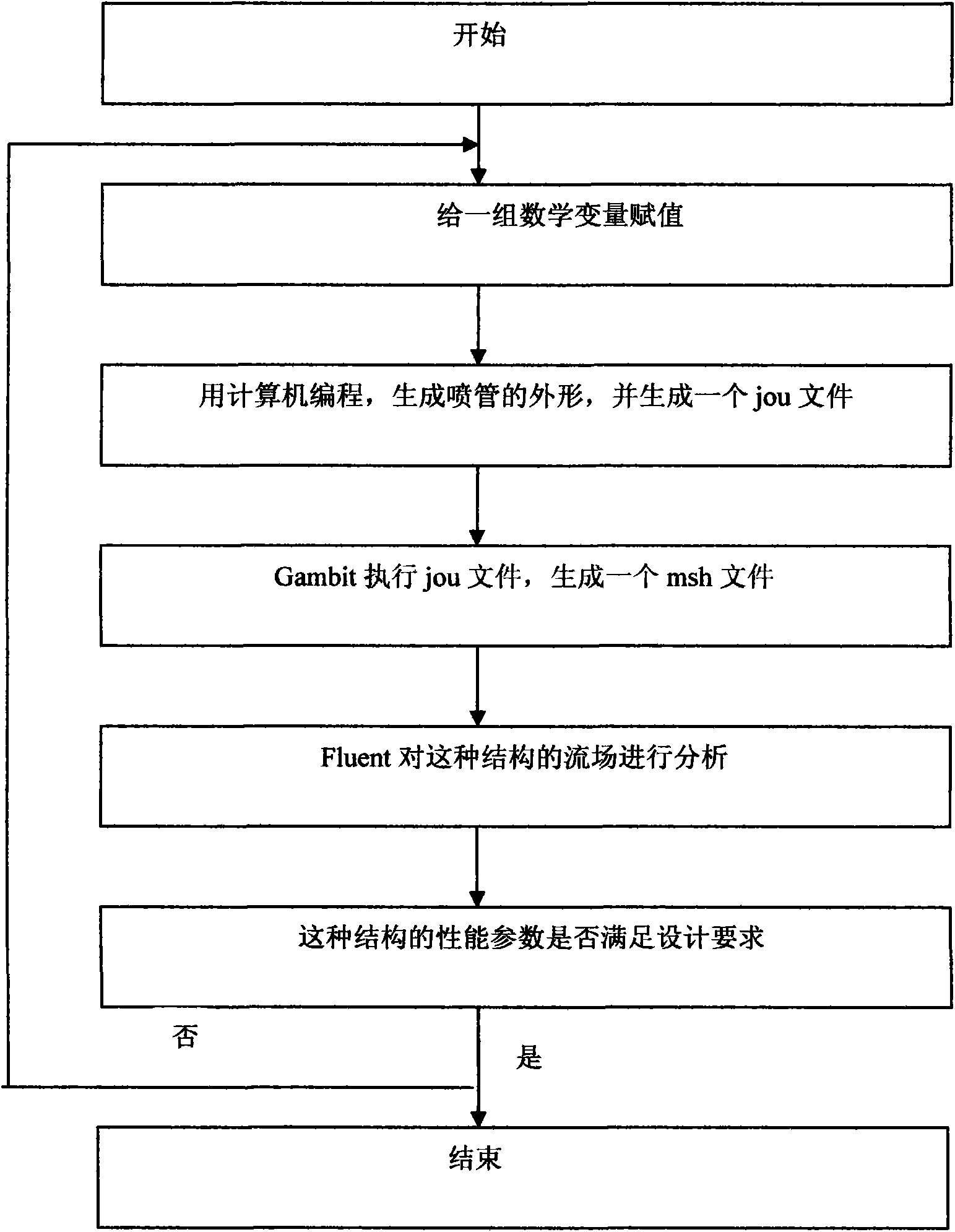

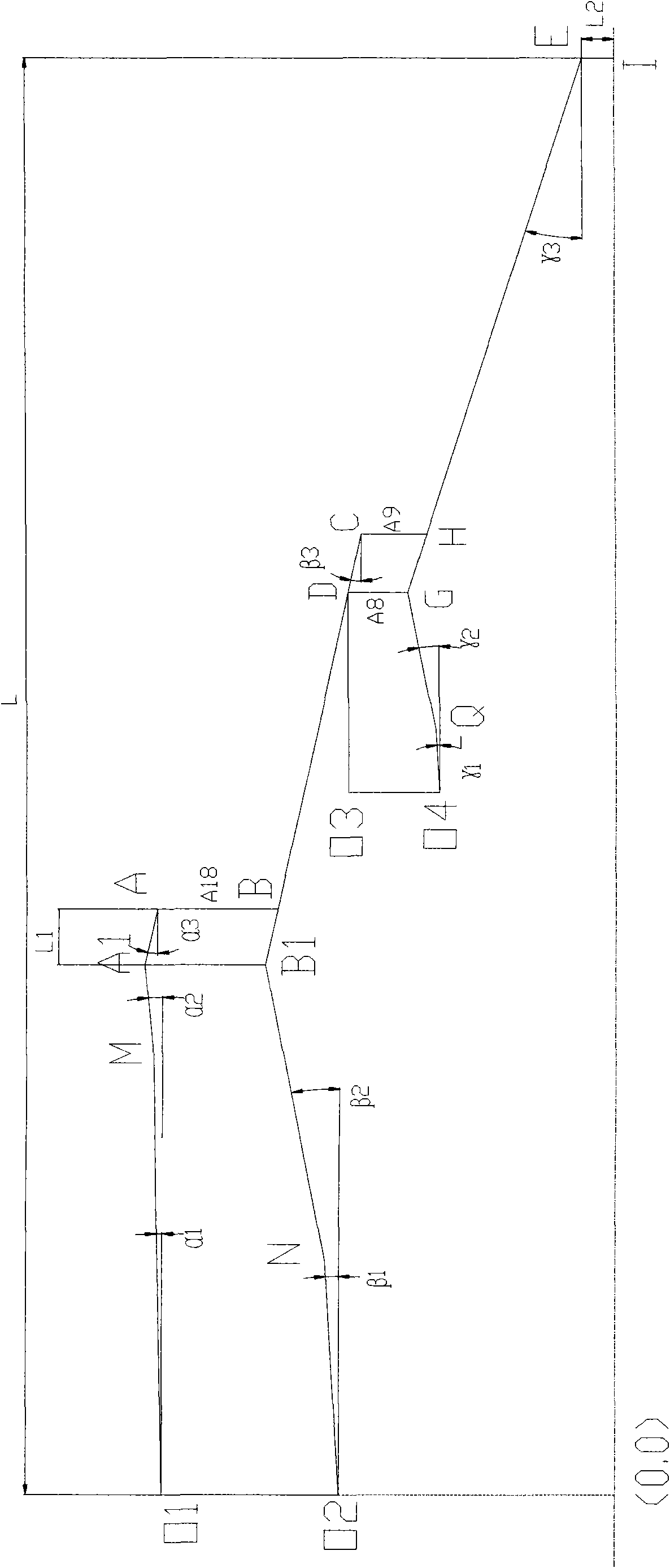

Pneumatic design method for separation type exhaust jet pipe of high bypass ratio engine

InactiveCN101676918ARapid designShorten the design cycleSpecial data processing applicationsGeometric relationsBypass ratio

Pneumatic design method for separation type exhaust jet pipe of high bypass ratio engine, which is characterized in that: the method adopts parametrization design, a straight line segment form composes a pneumatic shape of the jet pipe, circular arcs are used for smoothly connecting among the straight line segments. A concrete flow is that: step 1, defining an initial parameter of the pneumatic design of the jet pipe, and assigning; step 2, solving the other parameter according with a geometric relation of the jet pipe shape and establishing a mathematics model; step 3, generating the jet pipe shape controlled by the step 1 and the step 2; step 4, examining the pneumatic shape whether reaching to a required pneumatic performance - if yes, finishing the design flow; if no, returning to thestep 1 and restarting the flow. The design method can design an inner-outer bypass jet-pipe flow scheme rapidly, check the scheme whether practicably reduce the design period obviously, and ensure a simple processing method.

Owner:SHENYANG ENGINE DESIGN RES INST CHINA AVIATION IND CORP I

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com