Combustion Apparatus

a combustion apparatus and combustion technology, applied in the field of combustion apparatuses, can solve problems such as the total amount of emissions, and achieve the effect of less nox emissions and higher turn down ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

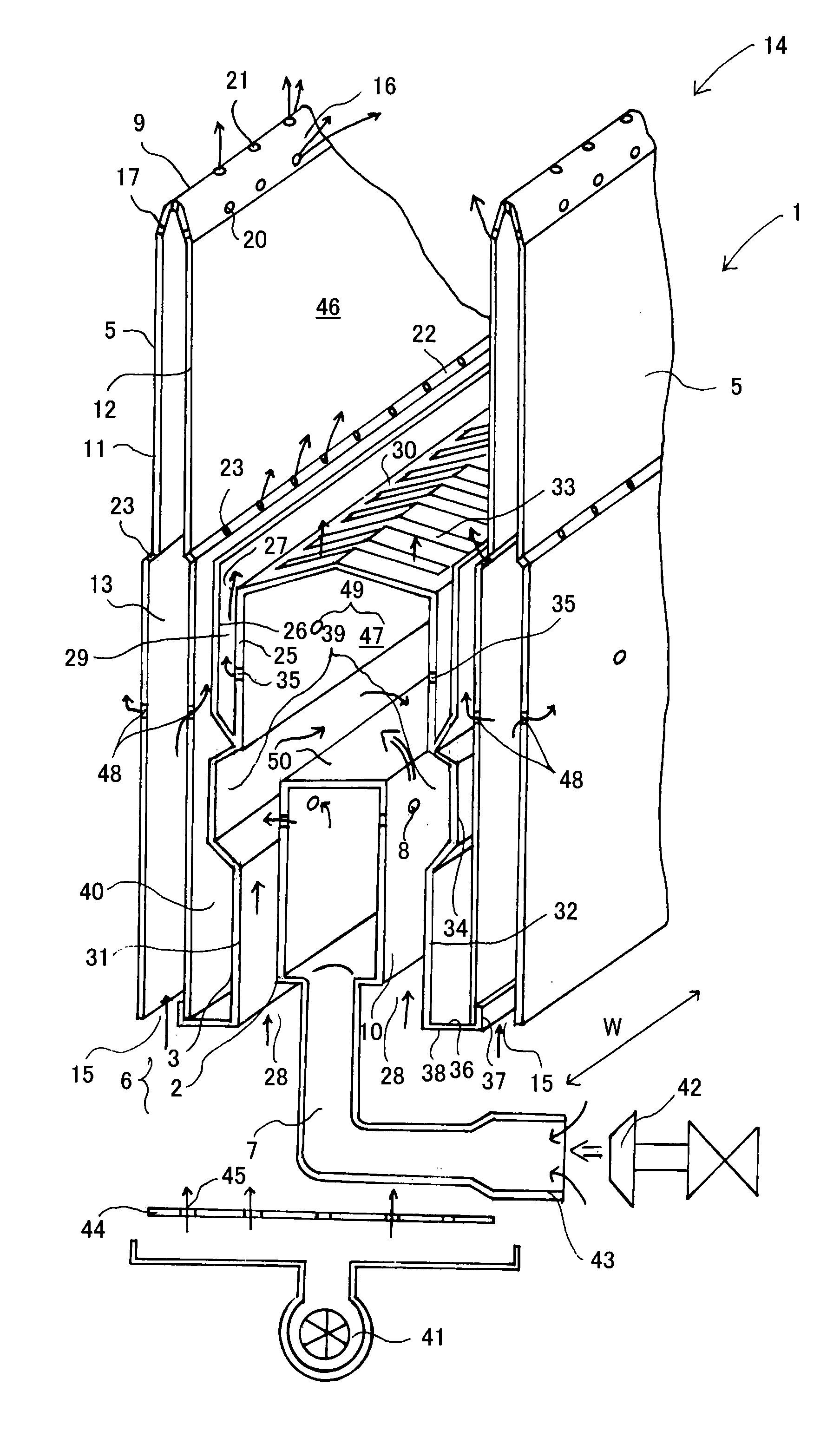

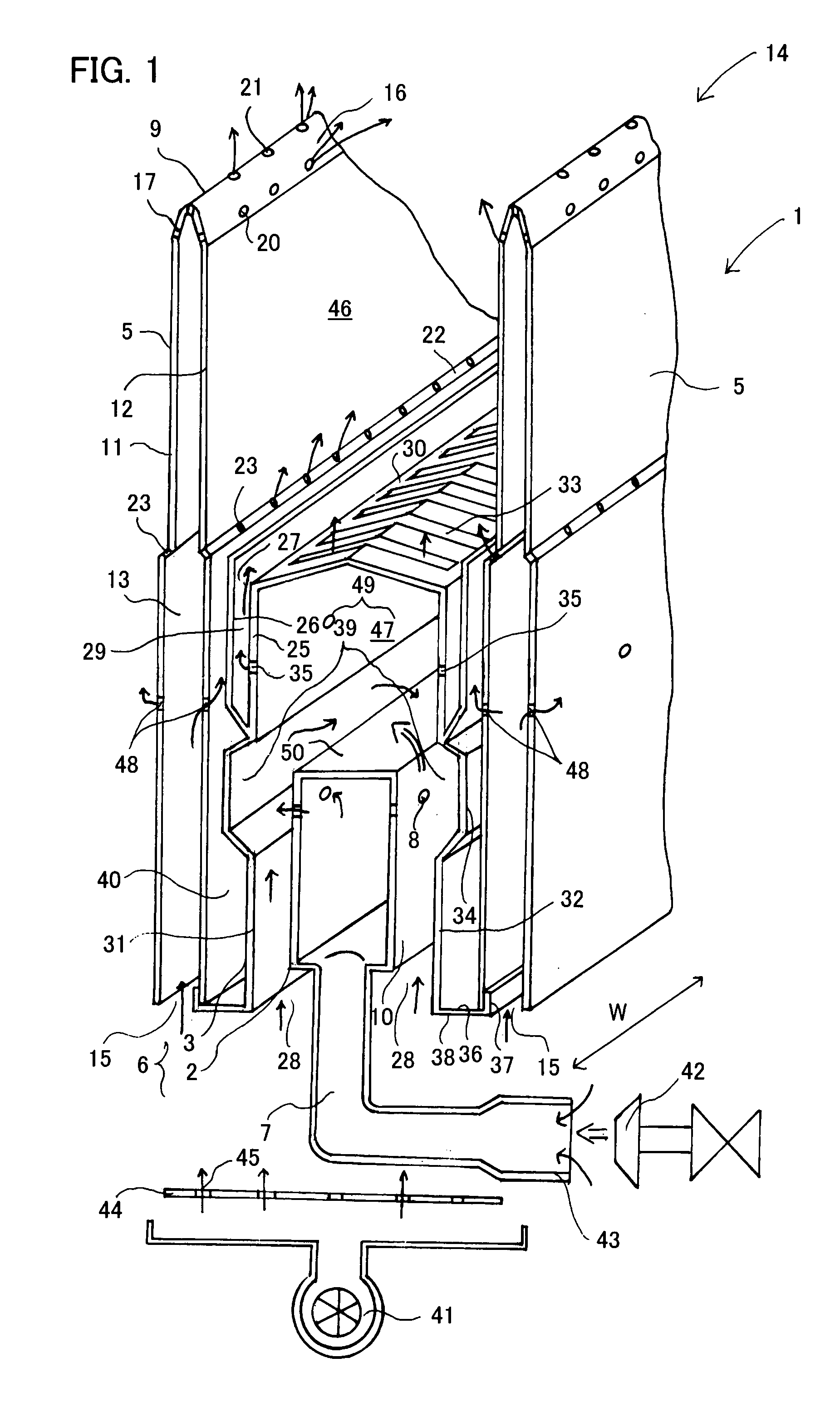

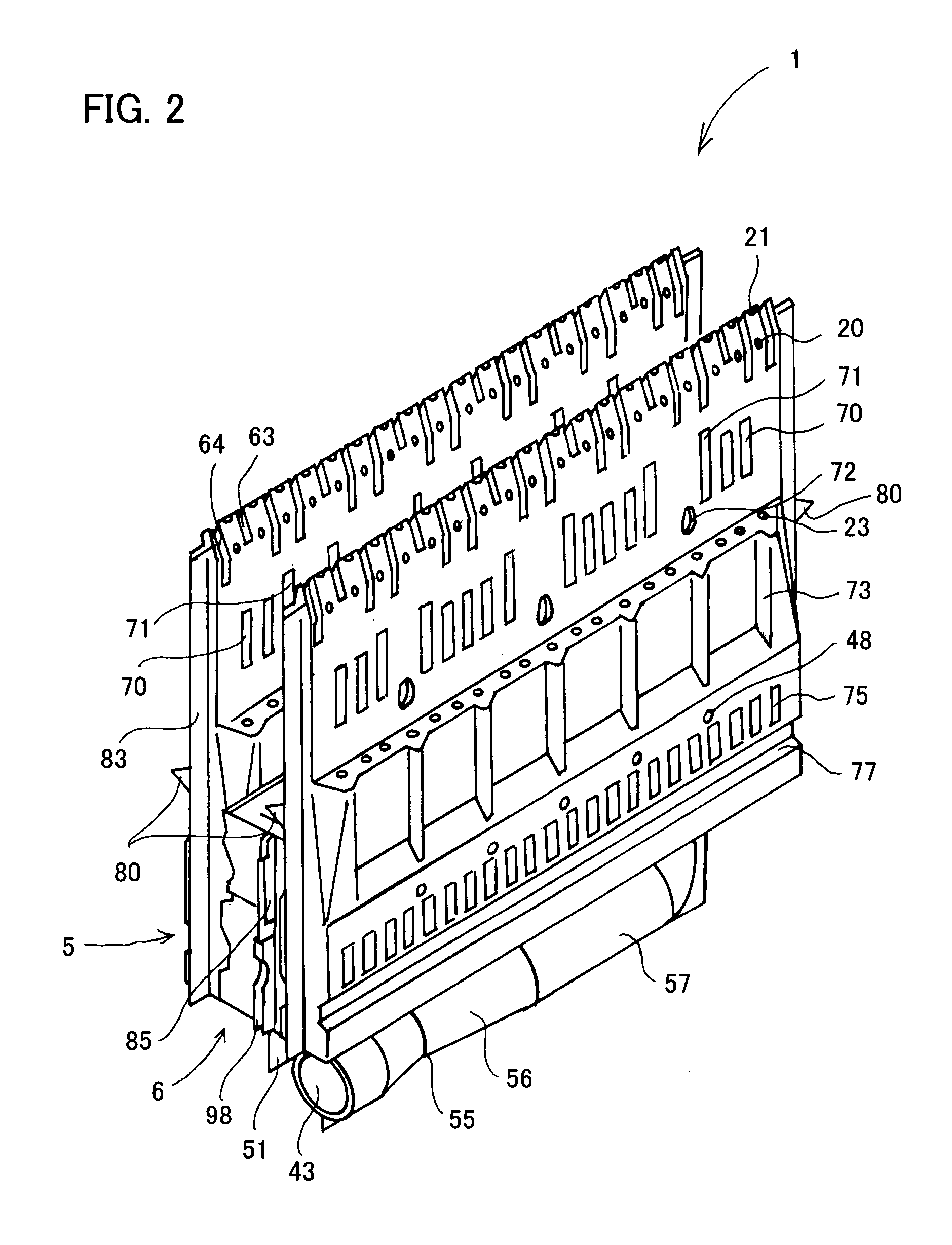

[0077]Now, an embodiment of the present invention will be described below in detail, making reference to the accompanying drawings. First, an outline configuration and basic functions of the present invention will be described, referring to a schematic view of FIG. 1. An embodiment in FIG. 1 conceptually illustrates the present invention.

[0078]In the following descriptions, the vertical positional relationship is based on a combustion apparatus 1 positioned upright and producing flame at an upper part thereof. Terms “upstream” and “downstream” are based on an air or fuel gas flow. A “width direction” denotes a lateral direction (a direction of an arrow “W” in the figure) with a part having the maximal area of the combustion apparatus facing the front.

[0079]The combustion apparatus 1 of the present embodiment is used by accommodating more than one apparatus in a casing or alone. The combustion apparatus 1 includes a premixer 2, a burner port assembly 3, and two air passage members 5....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com