Flat-flamed burner

A plane flame and burner technology, applied in burners, gas fuel burners, combustion methods, etc., can solve the problems of low safety and reliability, inconvenient improvement and maintenance, system errors, etc., and achieve improved safety and stability, good gas The effect of tightness and reducing the interference of flames

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

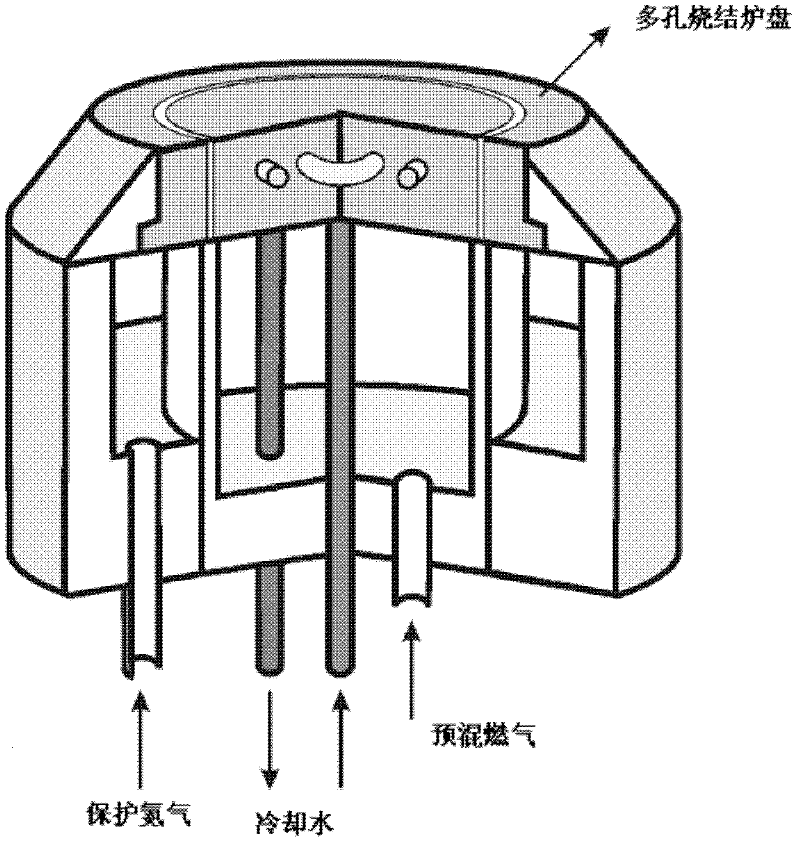

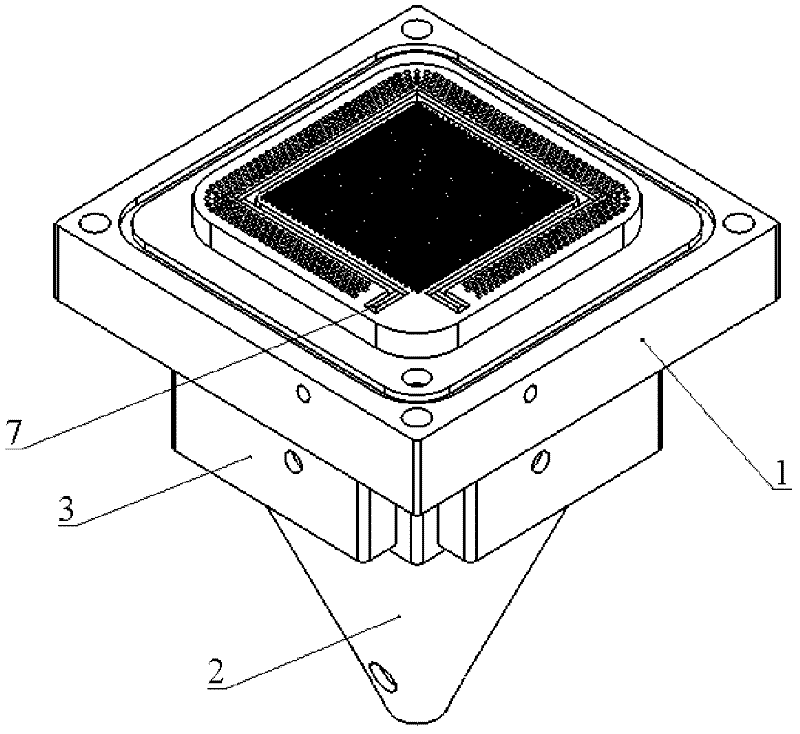

[0104] A flat flame burner, which is composed of a furnace pan 1, a premixed gas chamber 2, and a protective gas chamber 3. The furnace pan 1, the premixed gas chamber 2, and the protective gas chamber 3 are connected coaxially, and the center of the protective gas chamber 3 is inserted The premixed gas chamber 2 is matched with the connection;

[0105] The furnace plate 1 is composed of a base 17 and a test bench 18: the shape of the base 17 is a square when viewed from above, the four top corners are opened with connecting through holes 12, the upper surface is designed with a sealing groove 16, and a cooling liquid hole 24 is designed on each of the two sides A spark plug assembly hole 26 is designed between the seal groove 16 in the top corner area and the test bench 18, the seal groove 16 is located on the periphery of the test bench 18, the groove size is determined according to the mechanical design manual, and one end of the coolant hole 24 is opened on the side of the ...

Embodiment 2

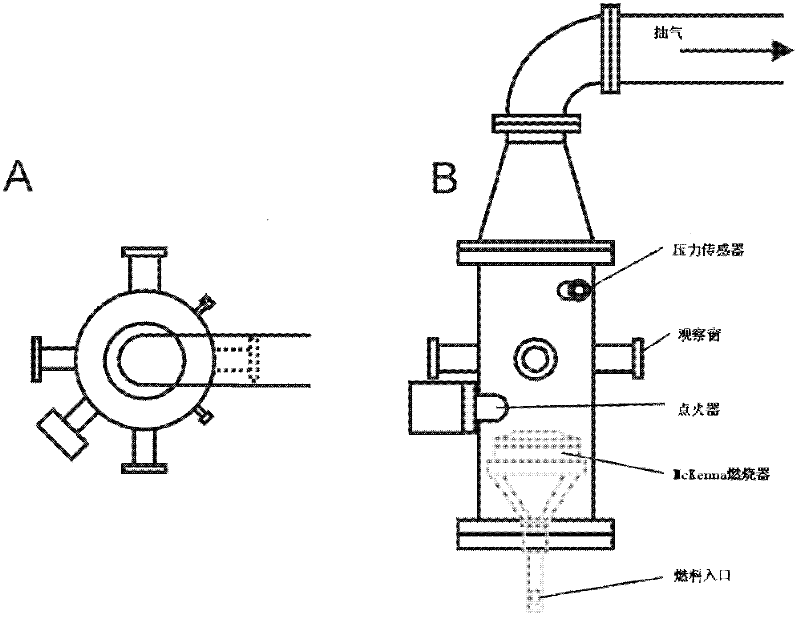

[0109] A flat flame burner, composed of a furnace tray 1, a premixed gas chamber 2, a protective gas chamber 3, an experimental cabin 4, an exhaust cover 5, a pressure regulator 6, an observation window glass 9, and a glass sealing cover 10; 1 is coaxially docked with the premixed air chamber 2, the protective air chamber 3, and the experimental cabin 4, the center of the protective air chamber 3 is inserted into the premixed air chamber 2 and connected, and the experimental cabin 4 is coaxially docked with the exhaust cover 5. The exhaust cover 5 is connected with the pressure regulator 6 through the pipeline, the observation window glass 9 is put into the glass window 38 of the experimental cabin 4, and the glass sealing cover 10 is fixed and sealed;

[0110] Wherein the structure of the stove plate 1, the premixed gas chamber 2, and the protective gas chamber 3 is the same as that of Embodiment 1, only the following parameters are different: the gas nozzle 21 tube diameter i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com