Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1738results about How to "Improve stability and security" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Wave, wind and light comprehensive electricity generation ship on sea

ActiveCN103523181AImprove stability and securityAvoid direct erosionWaterborne vesselsEnergy industryMechanical energyEngineering

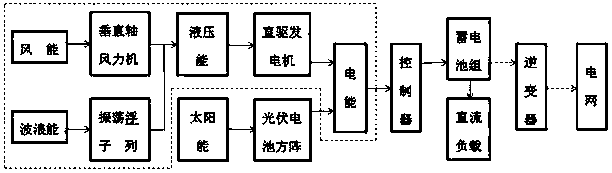

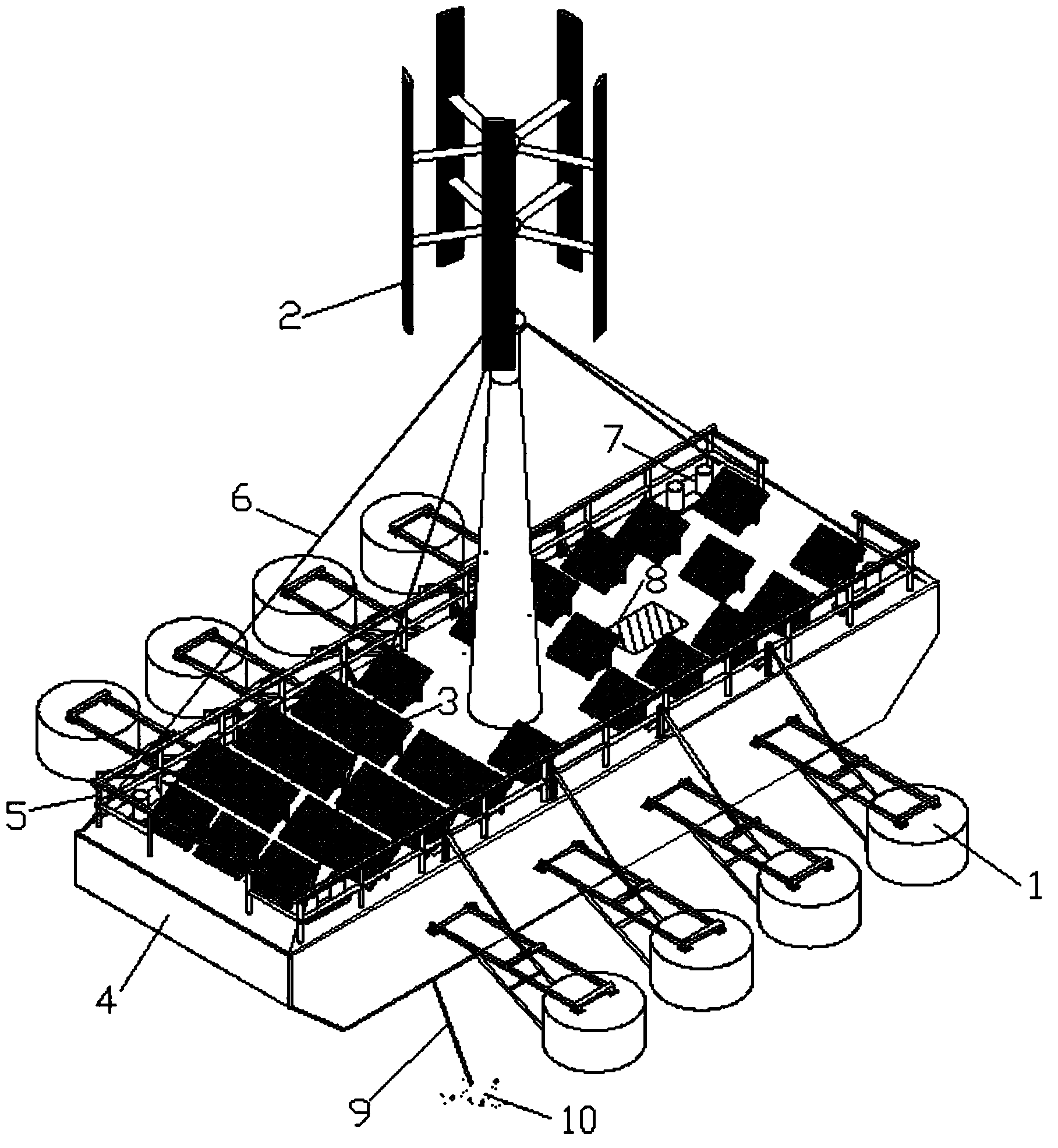

The invention discloses a wave, wind and light comprehensive electricity generation ship on the sea in the technical field of development and utilization of ocean renewable energy sources. Floaters are installed on the two sides of a hull respectively, the floaters vibrate up and down under the action of waves, and wave energy is firstly translated into mechanical energy and then translated into high-pressure energy of hydraulic oil through a hydraulic transition system; a perpendicular shaft wind machine is installed on a deck of the hull, wind rotors rotate under the action of blown wind, and wind energy is firstly translated into mechanical energy and then translated into high-pressure energy of the hydraulic oil through the hydraulic transition system; the hydraulic oil carrying the high-pressure energy works through impacting a hydraulic motor and drives a direct driven electric generator to generate electricity; a photovoltaic cell square matrix is installed on the deck of the hull to absorb solar energy and translate the solar energy into electric energy. The wave, wind and light comprehensive electricity generation ship solves the problems that electricity generation with ocean energy resources is high in unit cost, poor in stability and the like, and greatly improves competitive power of the development and utilization of the ocean renewable energy sources due to the high flexibility of a system.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

Pressure-control type electric pressure cooker

ActiveCN105286498AImprove stability and securitySimple structurePressure-cookersEngineeringPressure controlled ventilation

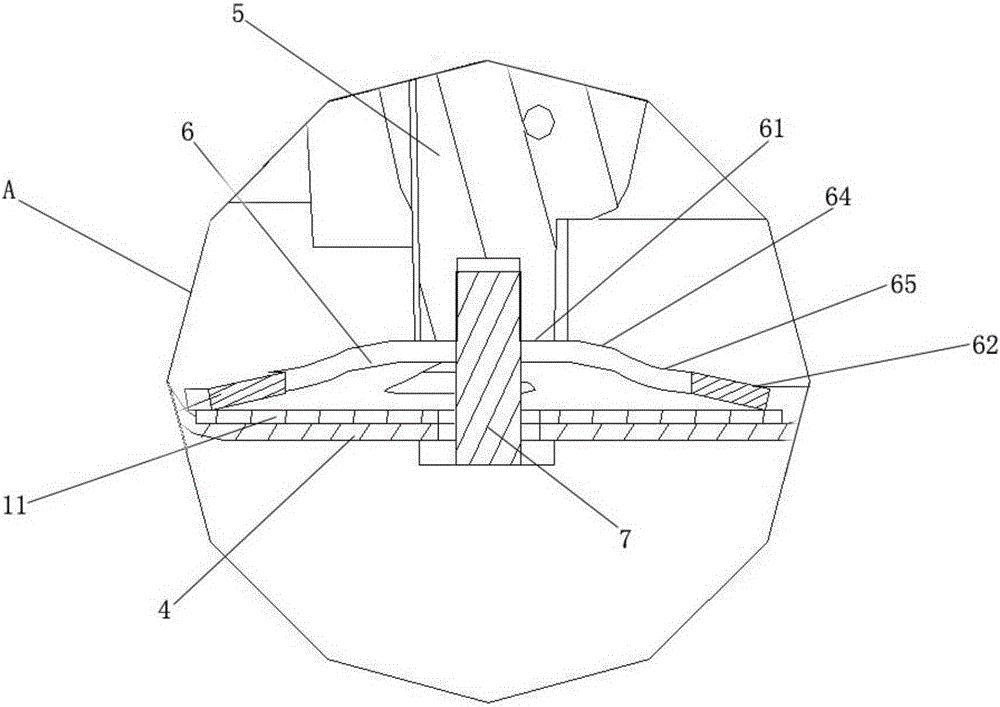

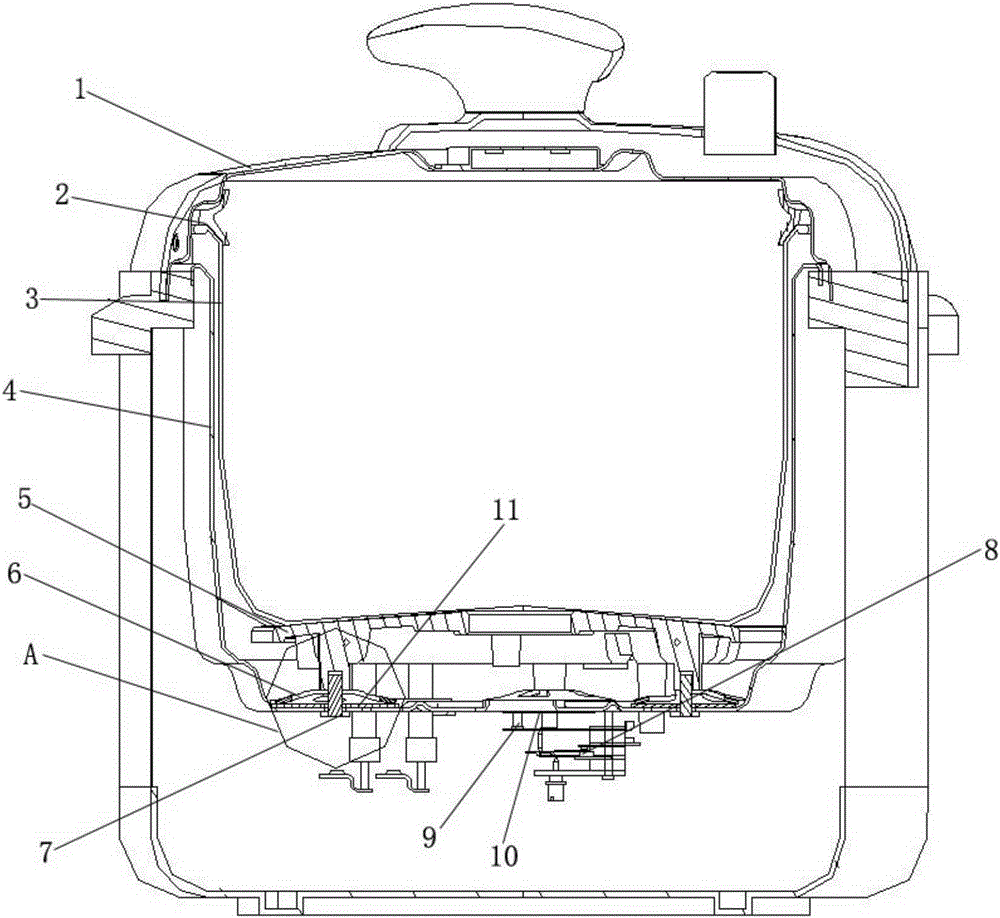

The invention discloses a pressure-control type electric pressure cooker. A sealed body is formed by sequentially connecting a pot cover, a seal ring, an inner pot and an outer pot; a plurality of belleville springs, which are provided with opening grooves, are arranged between a heating plate and the outer pot; upper supporting rings are formed by horizontally flanging the small-diameter ends of the belleville springs towards inner sides, and lower supporting rings are formed by the big-diameter ends of the belleville springs; an elastic deformation area is formed by a conical wall parts between each of the upper supporting rings and each of the lower supporting rings; the elastic deformation areas penetrate through the upper supporting rings in a radial direction and extend to conical body parts, and the opening grooves that contour lines projected on a horizontal plane are in a cross form are formed; the opening grooves are of gradually expanded structures with upsides smaller than downsides from openings to bottoms; the lower supporting rings are supported on the bottom of the outer pot; the upper supporting rings are propped against supporting legs of the heating plate; and the supporting legs and the belleville springs are integrally positioned with and connected to the outer pot by virtue of fixed screws. The amount of elastic deformation of the electric pressure cooker is effectively improved by virtue of the belleville springs, and the change in induction pressure of a pressure detection device is more conveniently to be detected, so that the precision and the safety stability of pressure control are improved.

Owner:HANGZHOU YONGYAO TECH

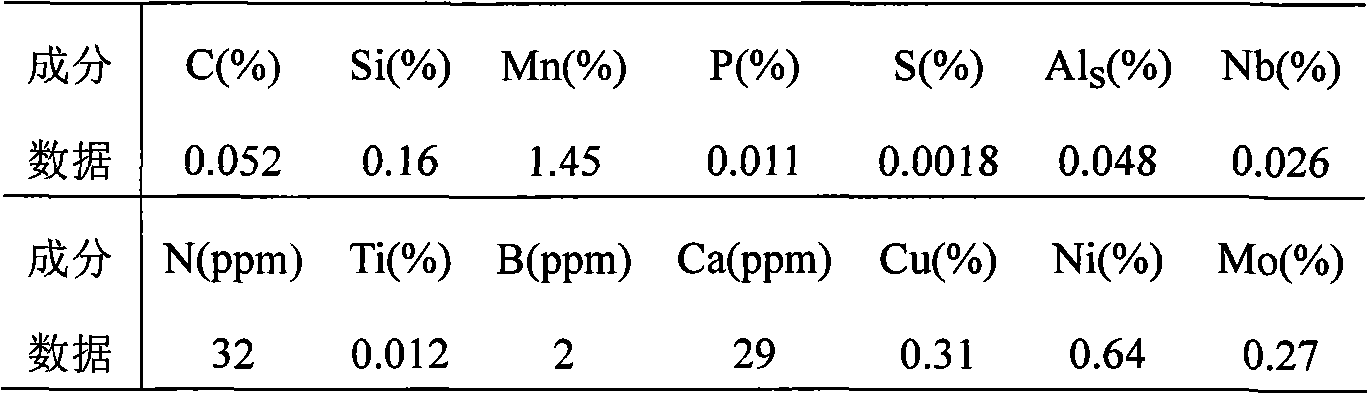

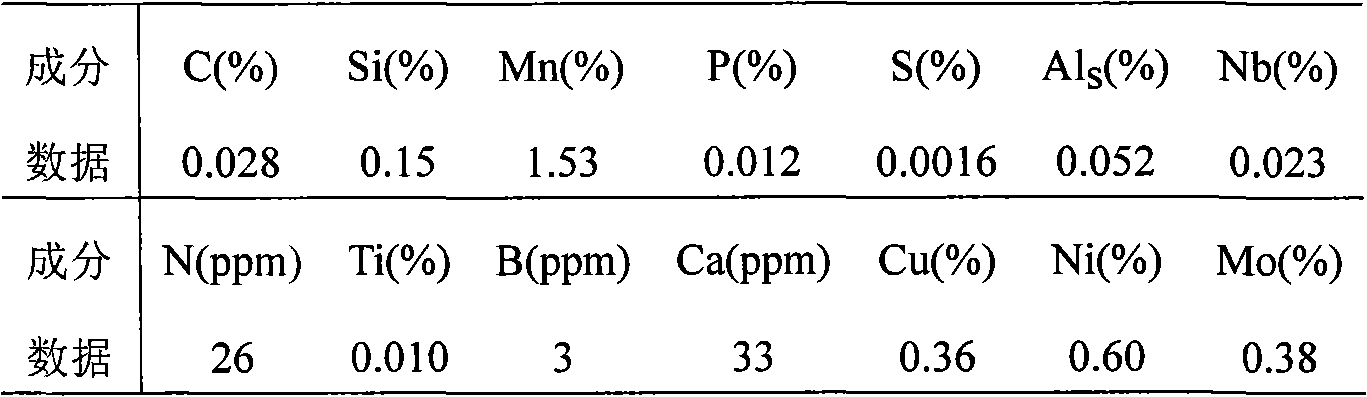

Low-yield ratio, high heat input welding, high-strength and high ductility steel plate and method of manufacture

ActiveCN101289728AIncrease contentSimple processTemperature control deviceAlloy elementOil production

The invention provides a steel plate having low-temperature toughness, high tensile strength and low yield ratio, as well as a method for making the same. By combining simple combination design of alloying elements with optimized TMCP process, the method successfully solves the problem that low-temperature impact toughness and low yield ratio are in mutual conflict and difficult to reconcile in composition design and process design, which reduces the amount of steel material, saves cost, lightens the dead weight of a steel structure, increases stability and safety, and more importantly, improves the safety, stability and seismic damage resistance of the steel structure. The steel plate can be widely applied to large-scale high-rise building structures, bridge structures, offshore oil production platform structures, low temperature pressure vessels and large-scale ship structures.

Owner:BAOSHAN IRON & STEEL CO LTD

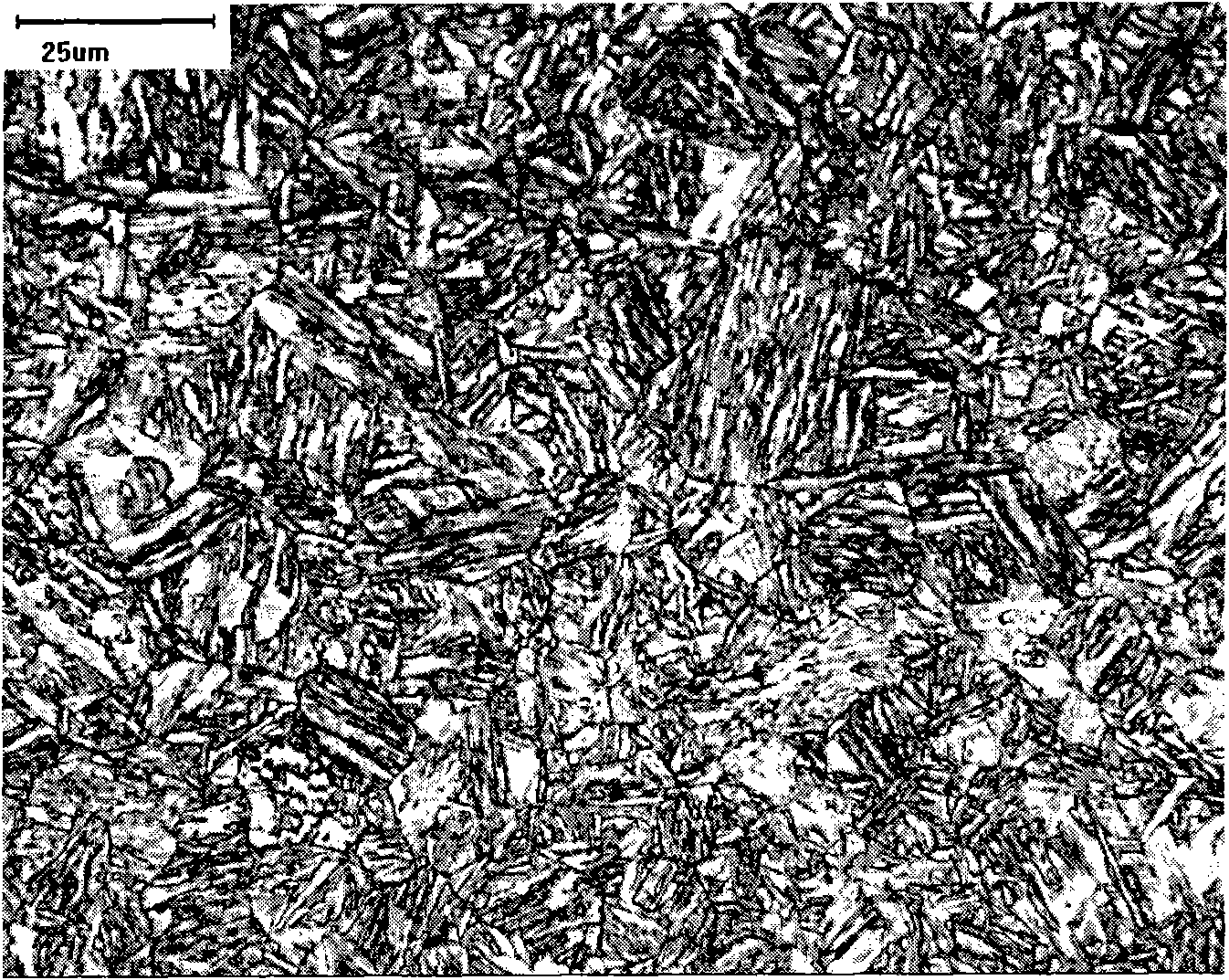

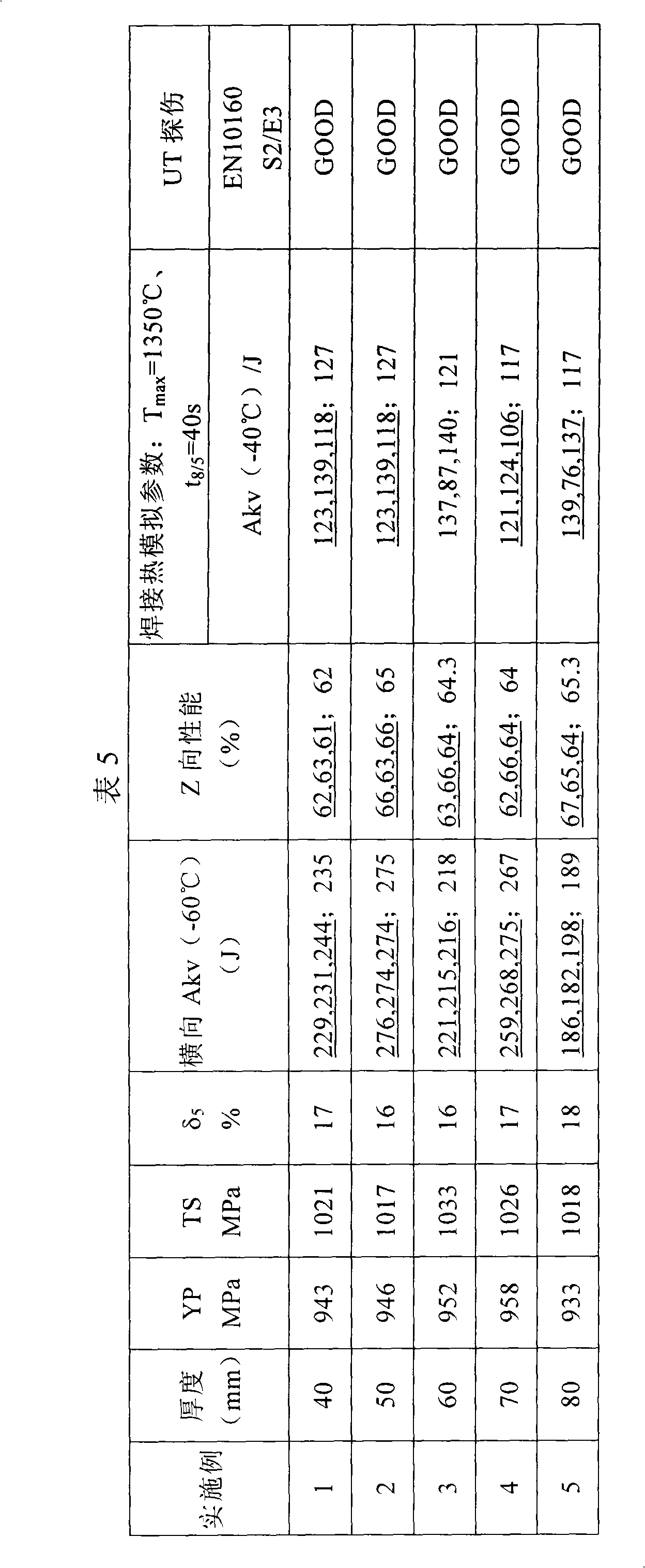

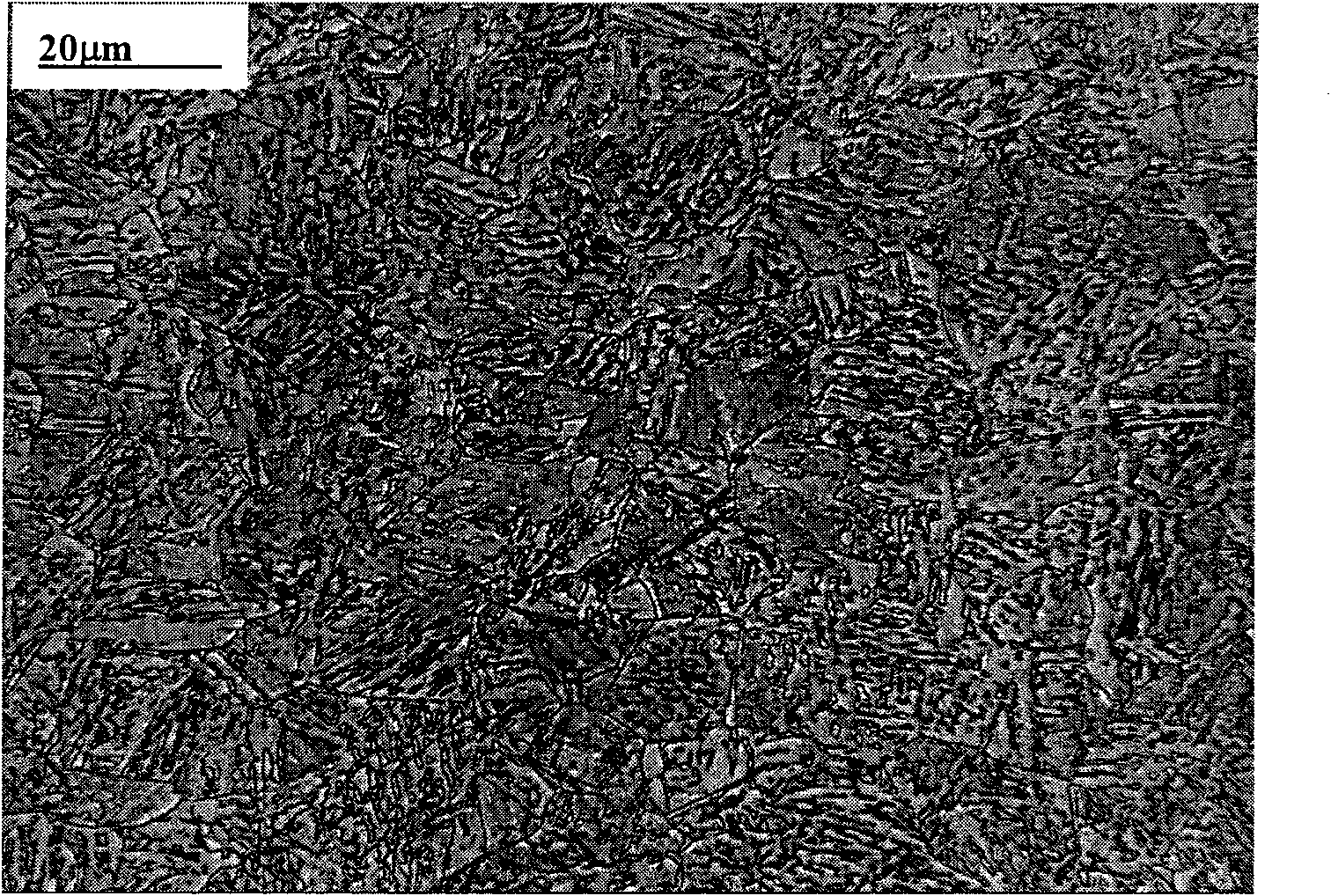

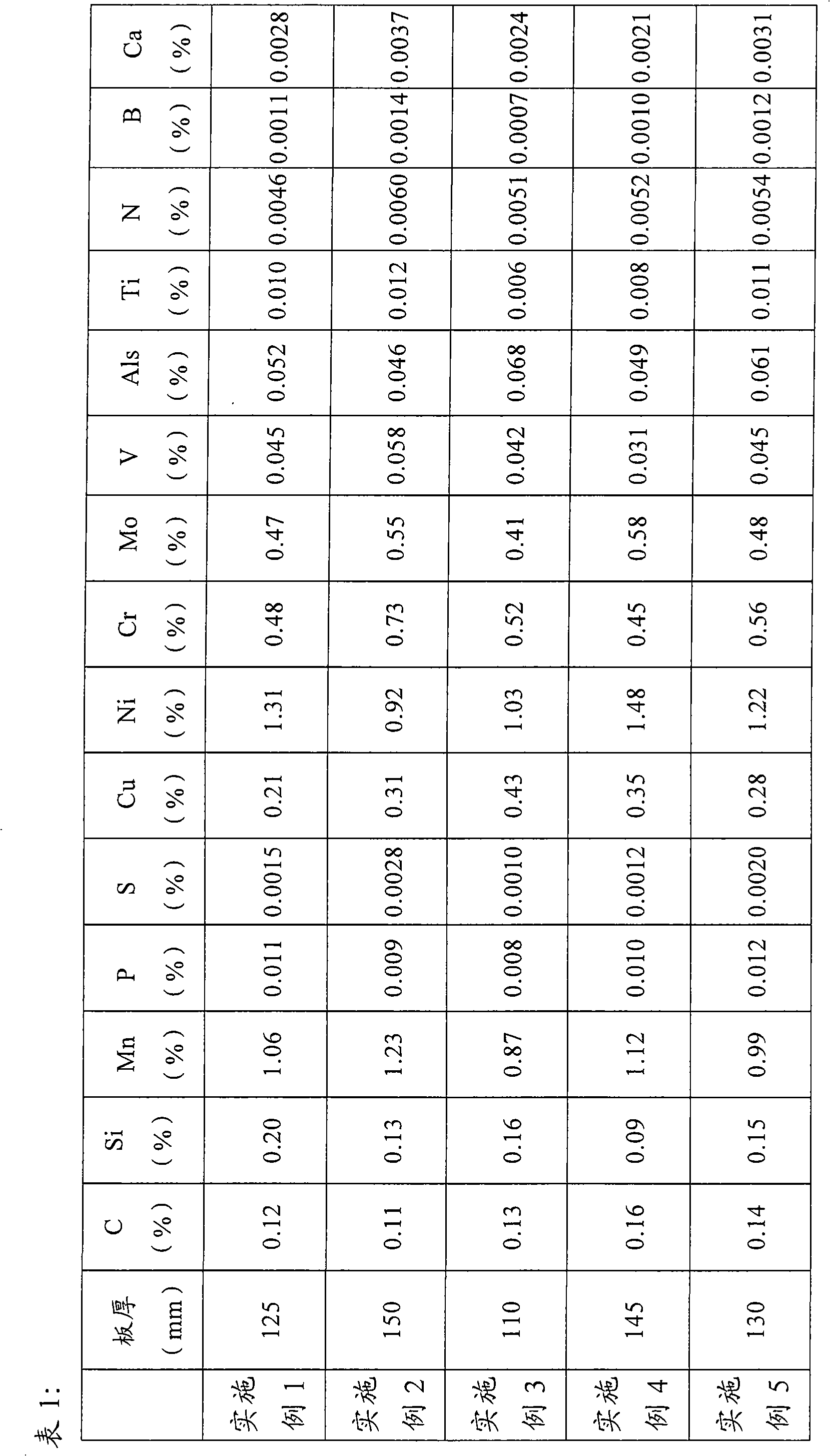

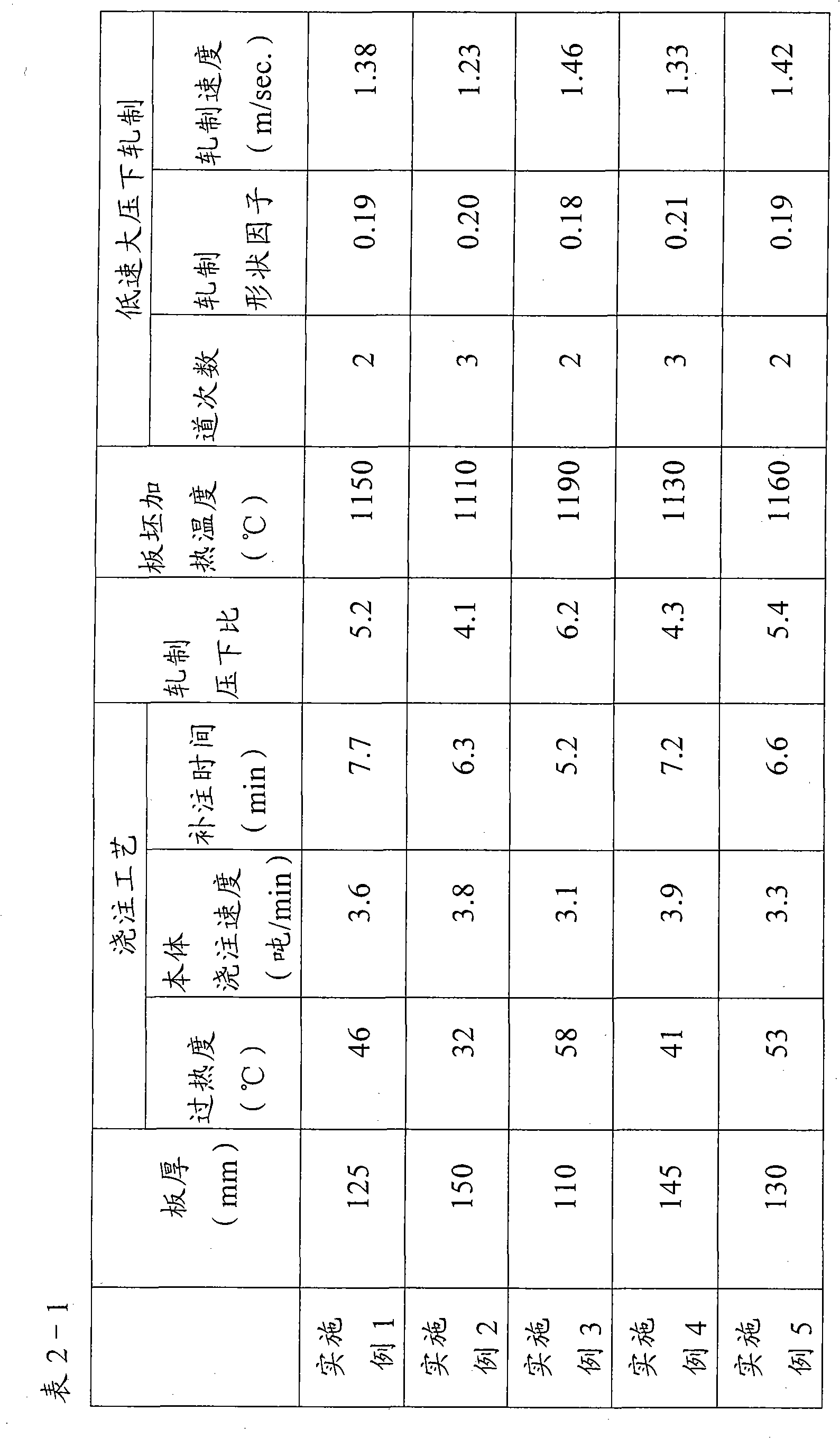

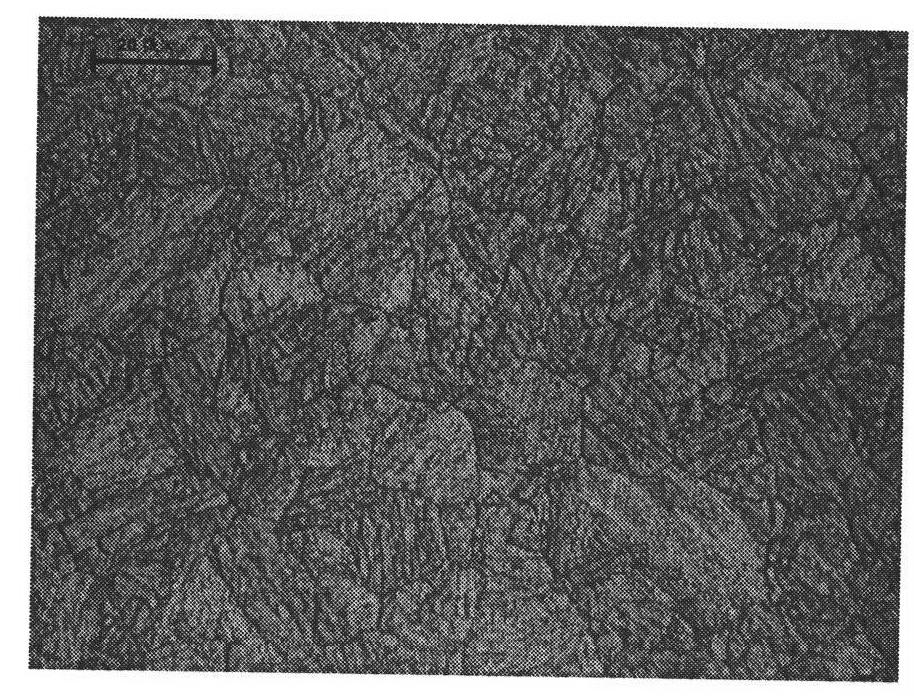

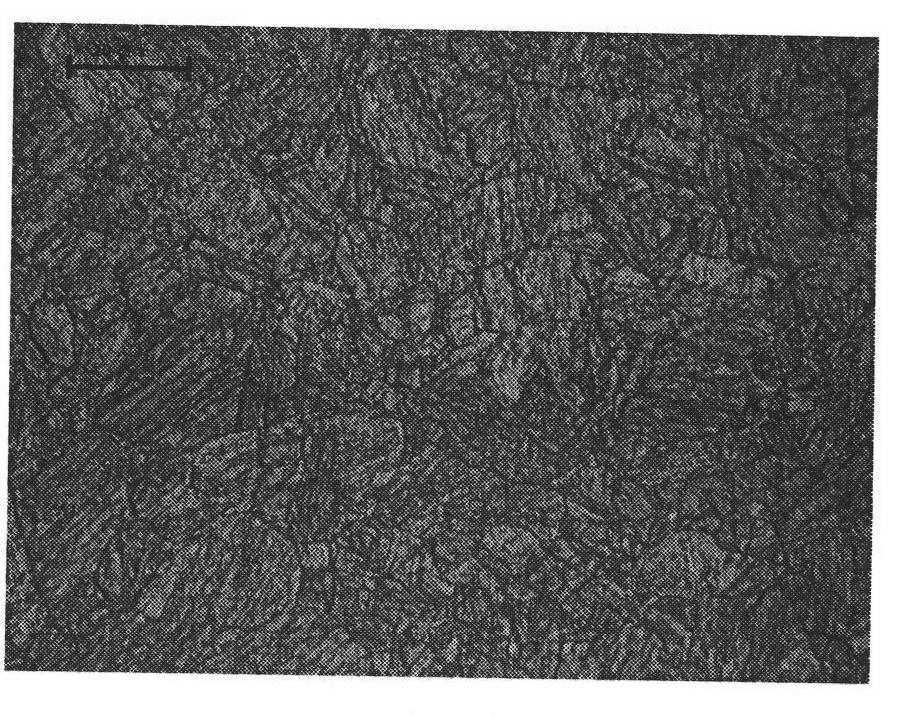

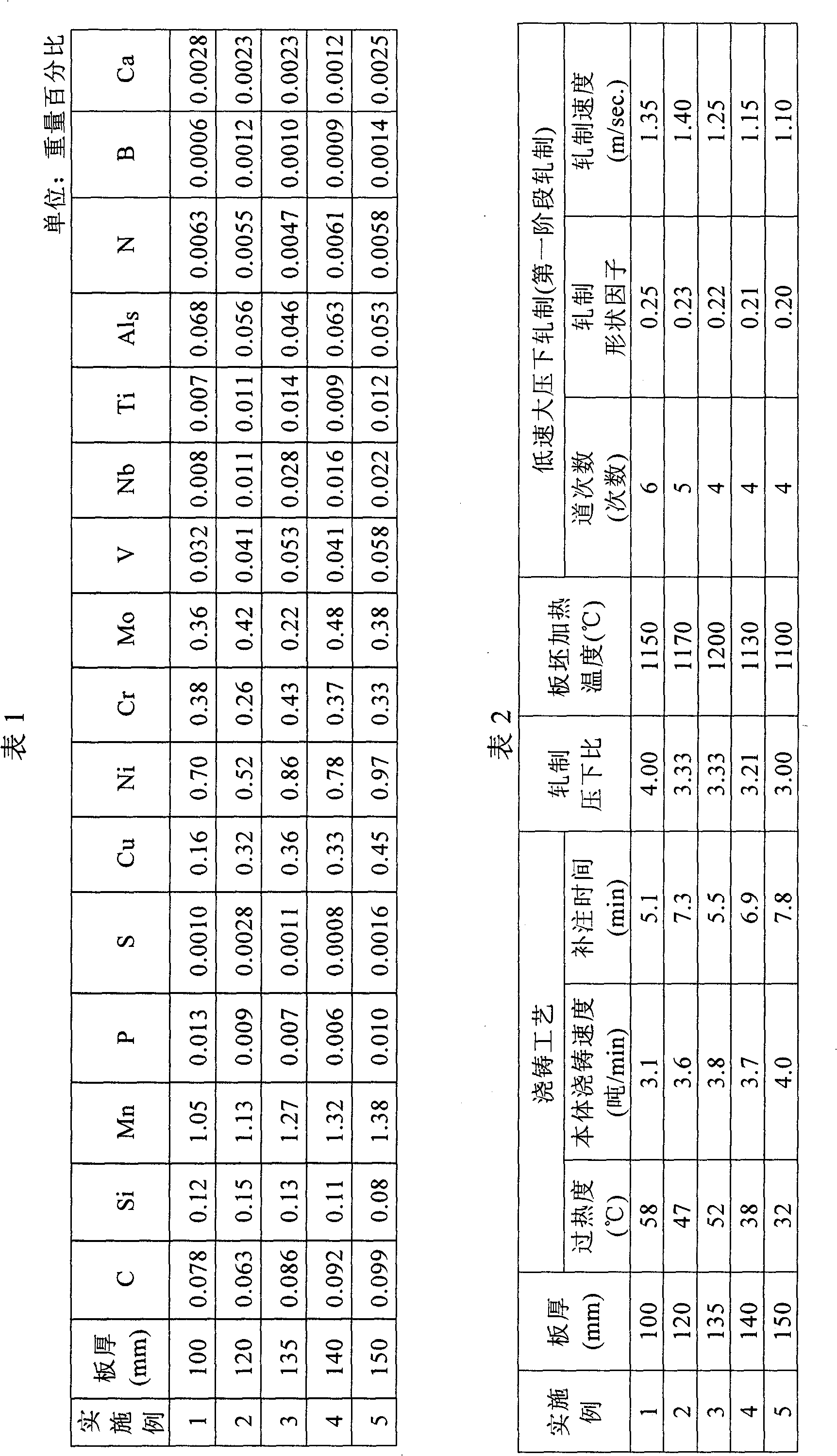

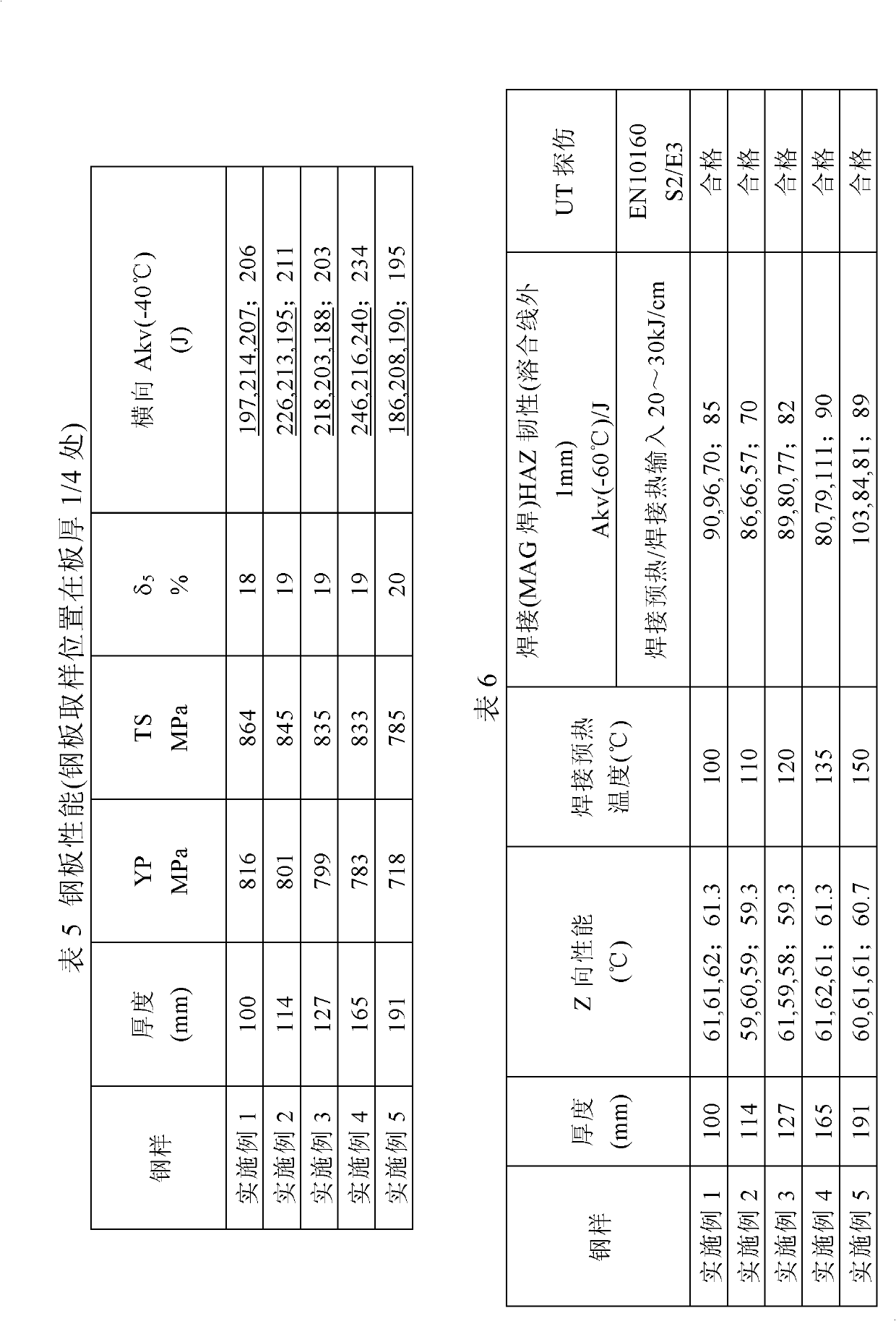

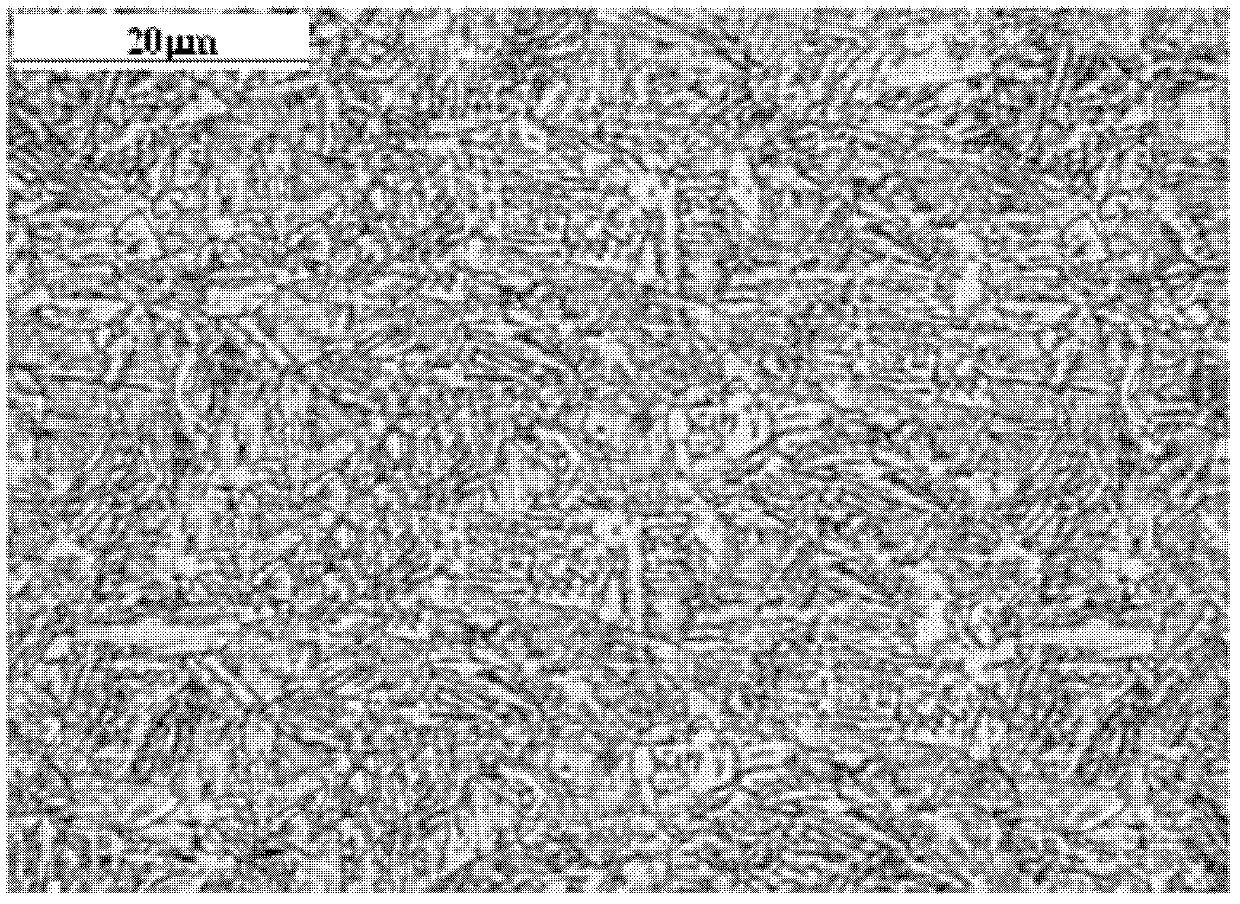

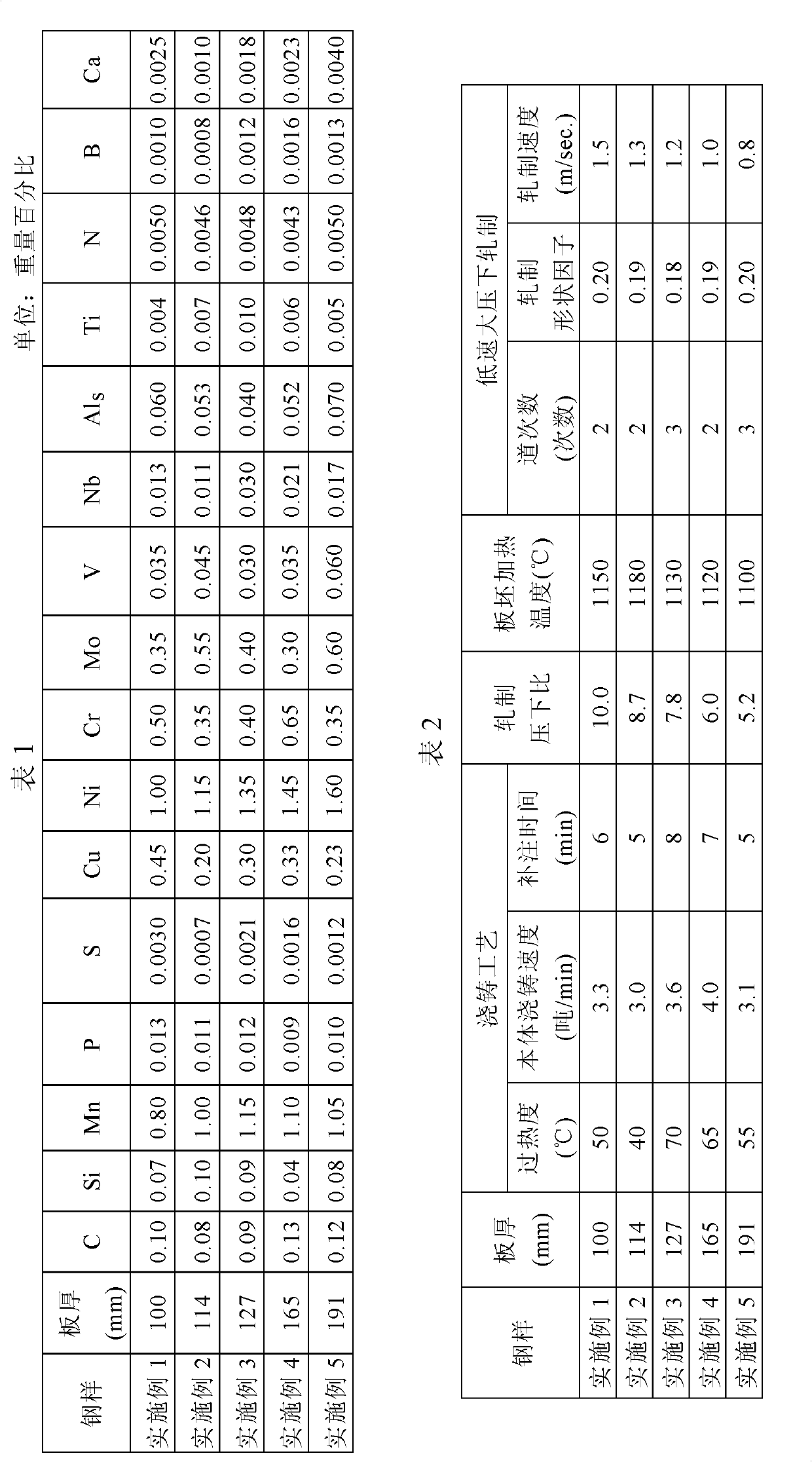

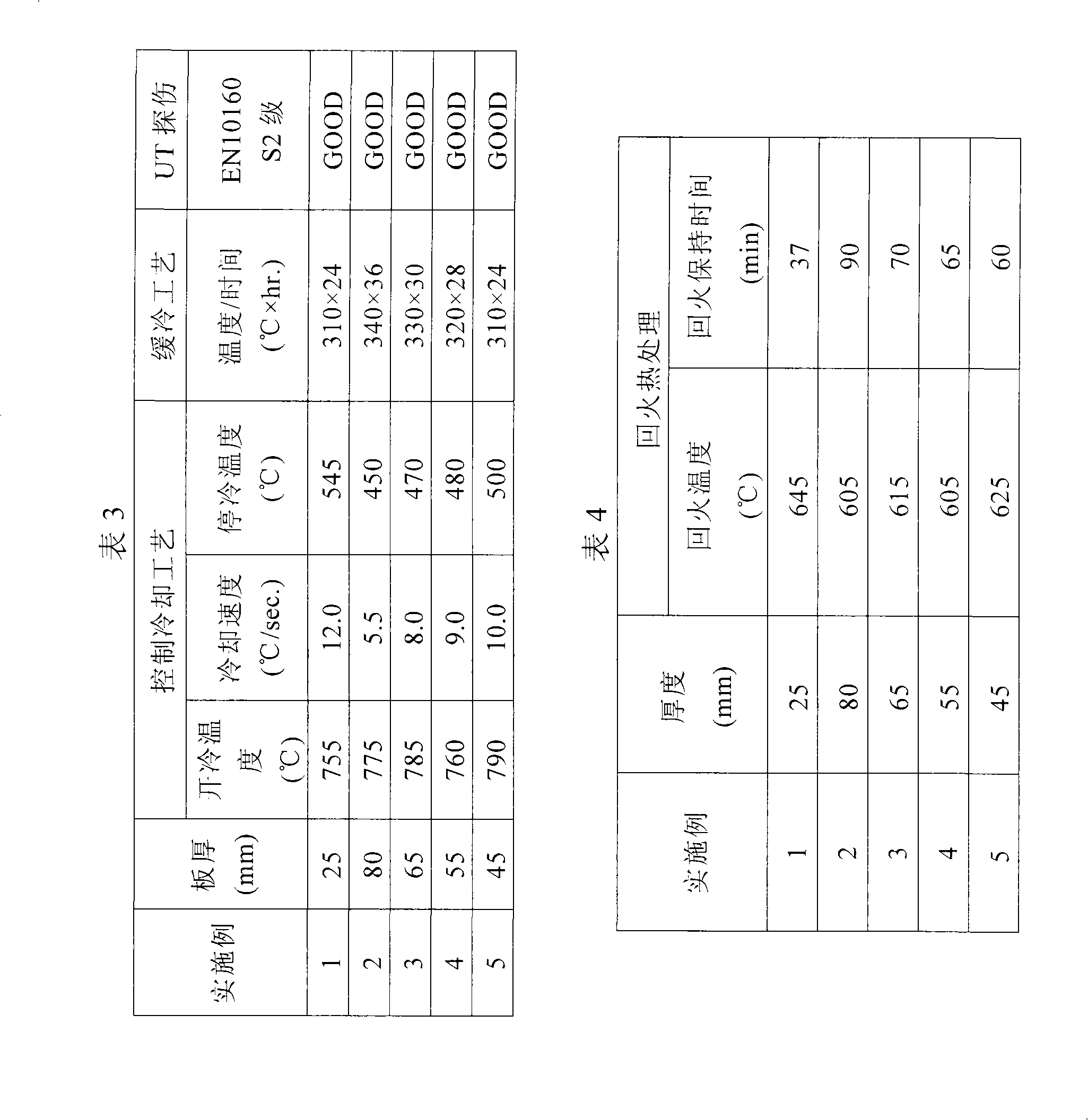

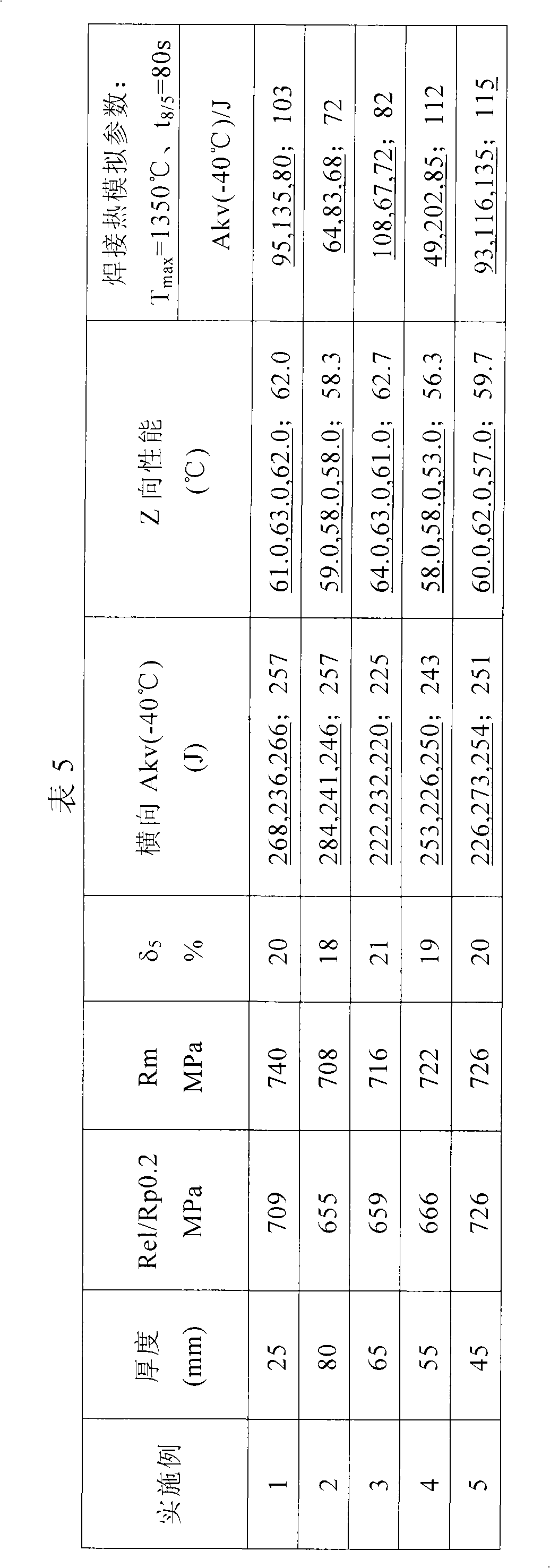

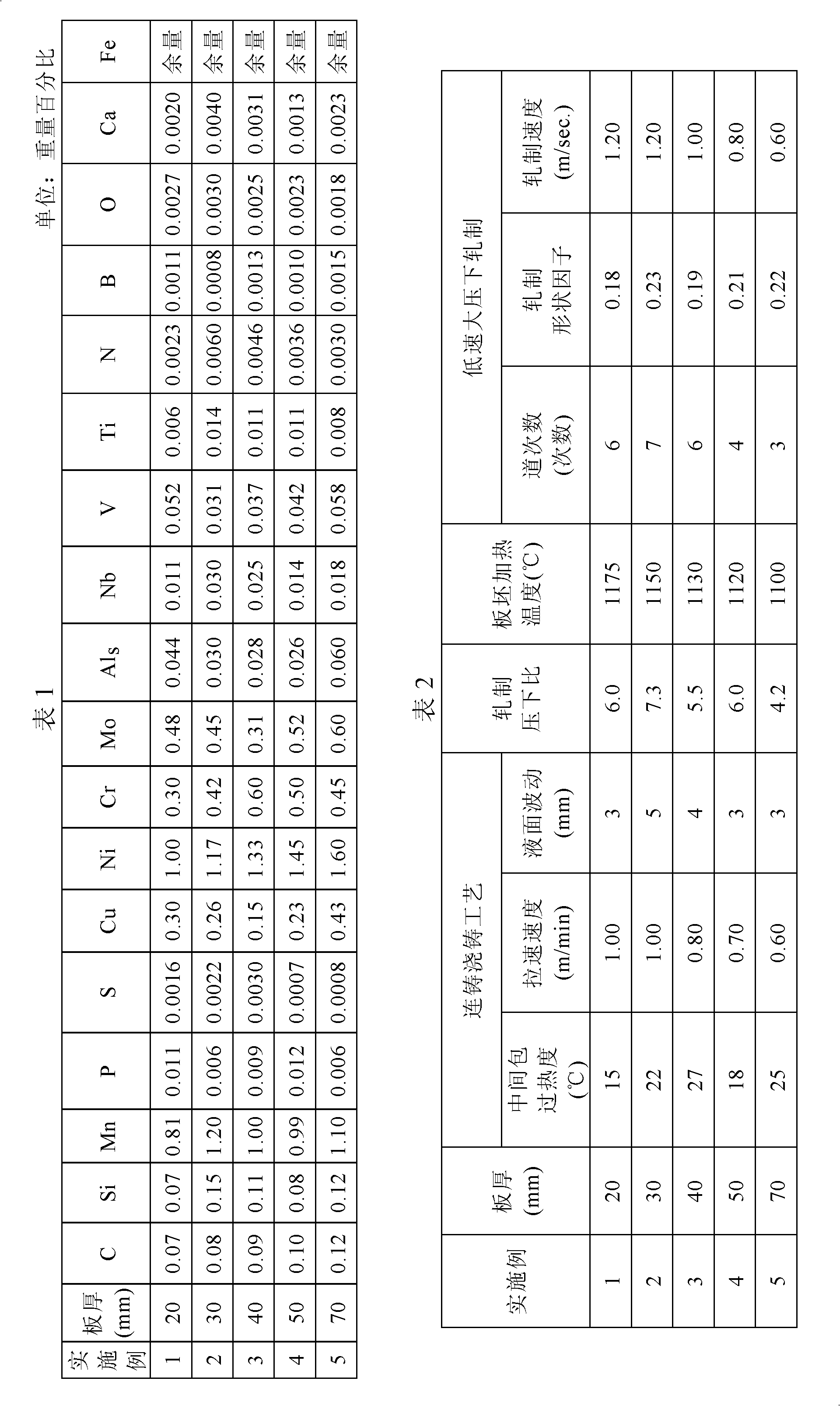

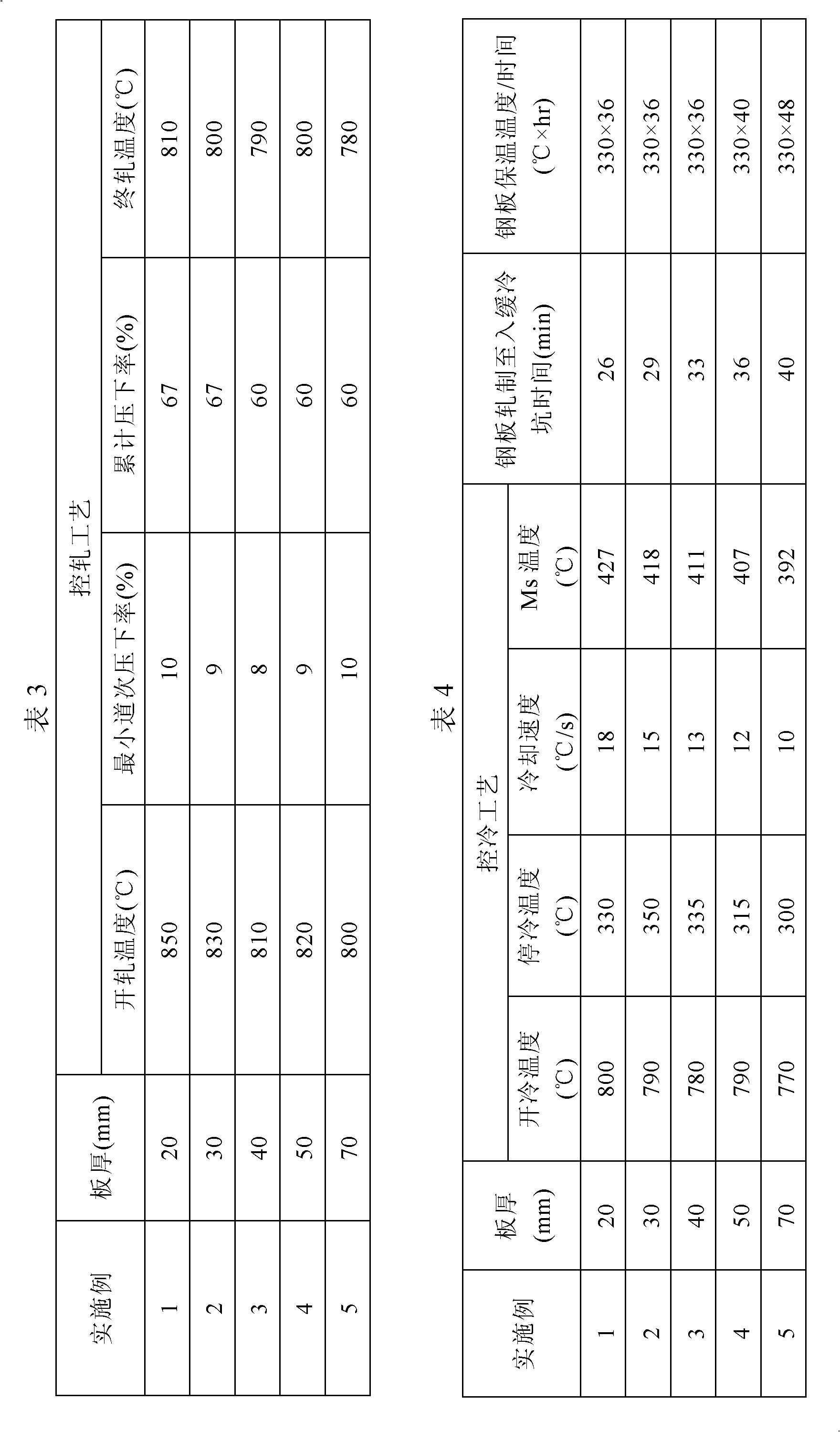

Excellent 100 kg-grade quenched and tempered steel plate with strong toughness and plasticity, and manufacturing method thereof

ActiveCN102337478ASimple welding processImprove stability and securityUltimate tensile strengthQuenching

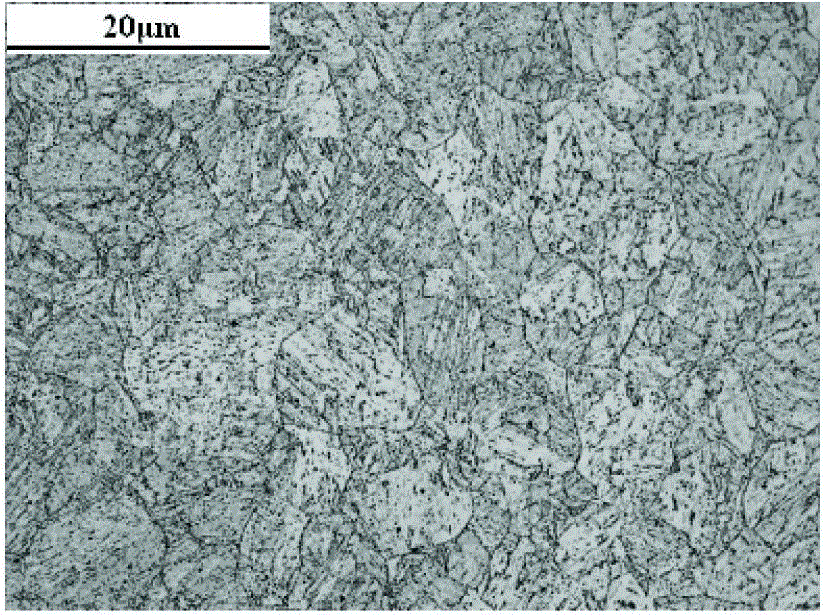

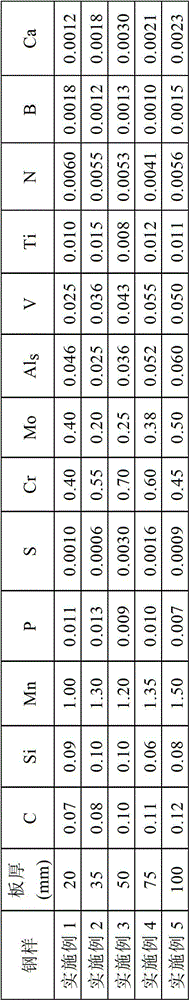

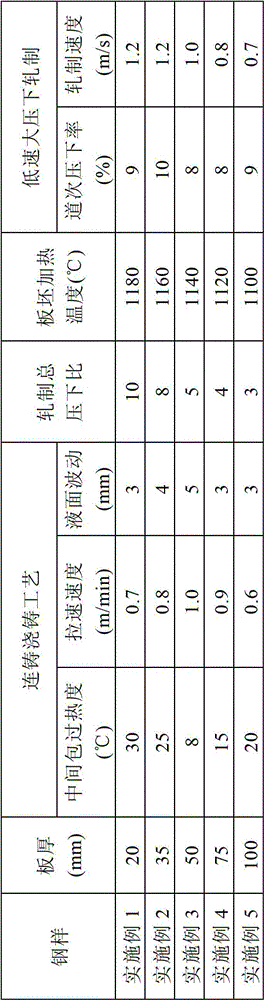

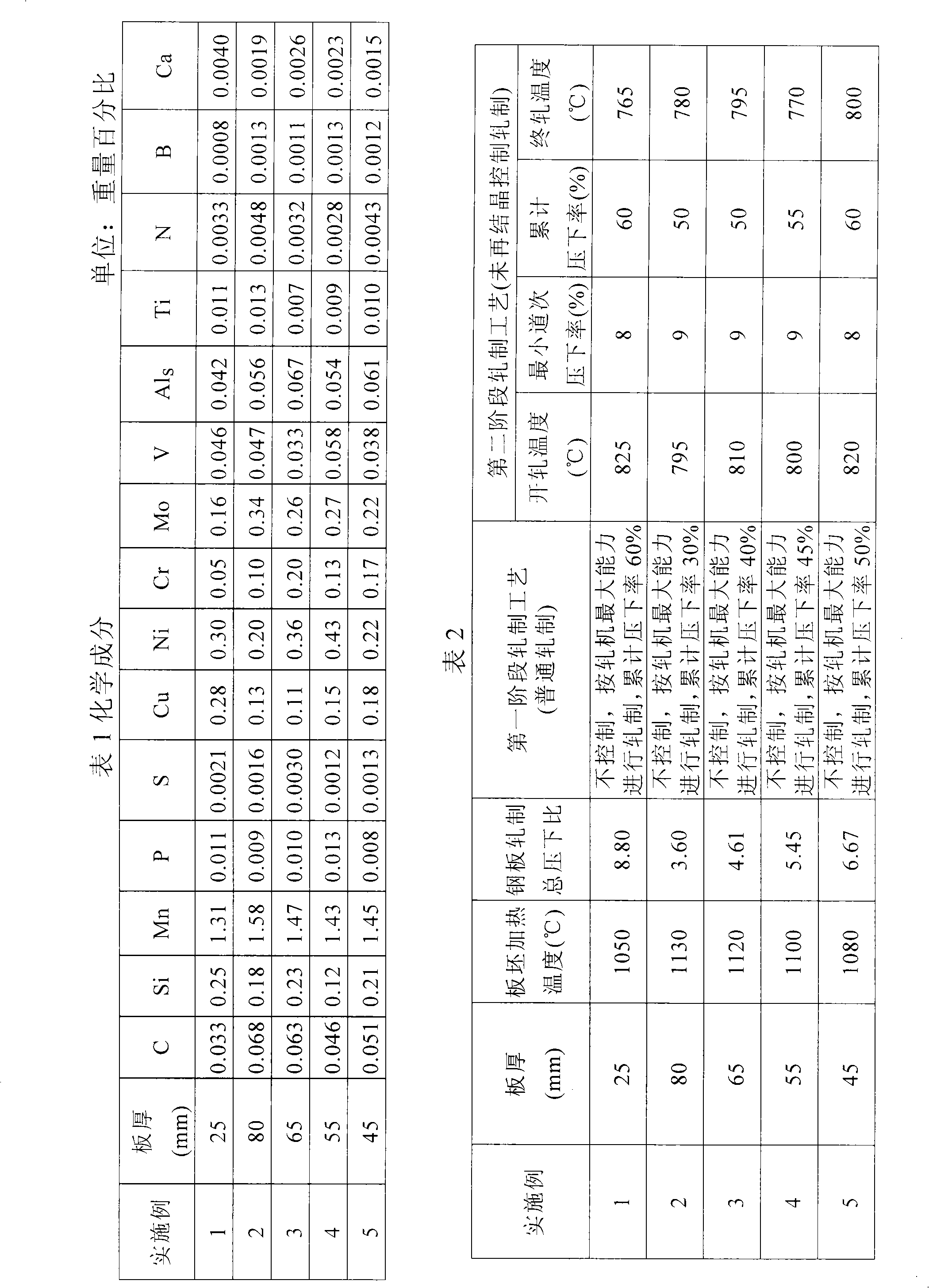

The invention discloses an excellent 100 kg-grade quenched and tempered steel plate with strong toughness and plasticity, and a manufacturing method thereof. The excellent 100 kg-grade quenched and tempered steel plate with strong toughness and plasticity comprises: by weight, 0.09 to 0.15% of C, less than or equal to 0.10% of Si, 0.70 to 1.10% of Mn, less than or equal to 0.013% of P, less than or equal to 0.0030% of S, 0.20 to 0.45% of Cu, 1.30 to 2.00% of Ni, 0.45 to 0.85% of Cr, 0.45 to 0.75% of Mo, 0.045 to 0.070% of Als, 0.008 to 0.025% of Nb, 0.030 to 0.060% of V, 0.004 to 0.010% of Ti, less than or equal to 0.0060% of N, 0.001 to 0.005% of Ca, 0.0006 to 0.0014% of B, and the balance Fe and unavoidable impurities. Through a technology (RQ+RQ+T) combining optimally controlled rolling and offline special conditioning, the excellent 100 kg-grade quenched and tempered steel plate with strong toughness and plasticity forms a microstructure composed of a fine tempered lower bainite and a tempered martensite, wherein an average size of druses is below 20 micrometers; tensile strength is great than or equal to 980MPa; yield strength is great than or equal to 890MPa; and single transverse Charpy impact energy (-60 DEG C) is great than or equal to 47J. Therefore, the excellent 100 kg-grade quenched and tempered steel plate with strong toughness and plasticity has excellent weldability and can solve the problem of over-quenching of a surface of a steel plate with ultra-high strength.

Owner:BAOSHAN IRON & STEEL CO LTD

HT550 steel plate with ultrahigh toughness and excellent weldability and manufacture method thereof

ActiveCN103320692AImprove performanceShorten the manufacturing cycleFurnace typesQuenching agentsSheet steelYield ratio

Owner:BAOSHAN IRON & STEEL CO LTD

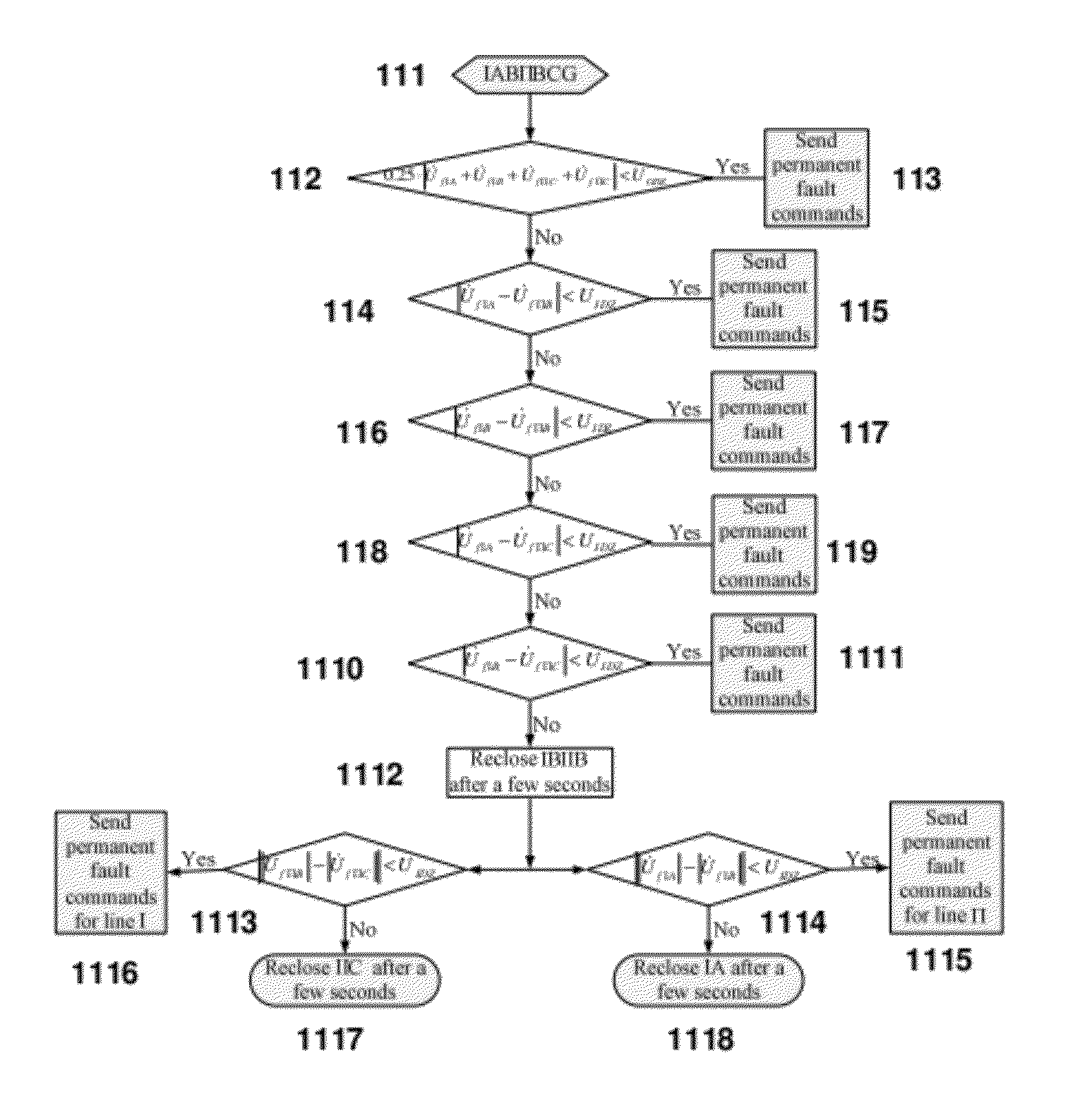

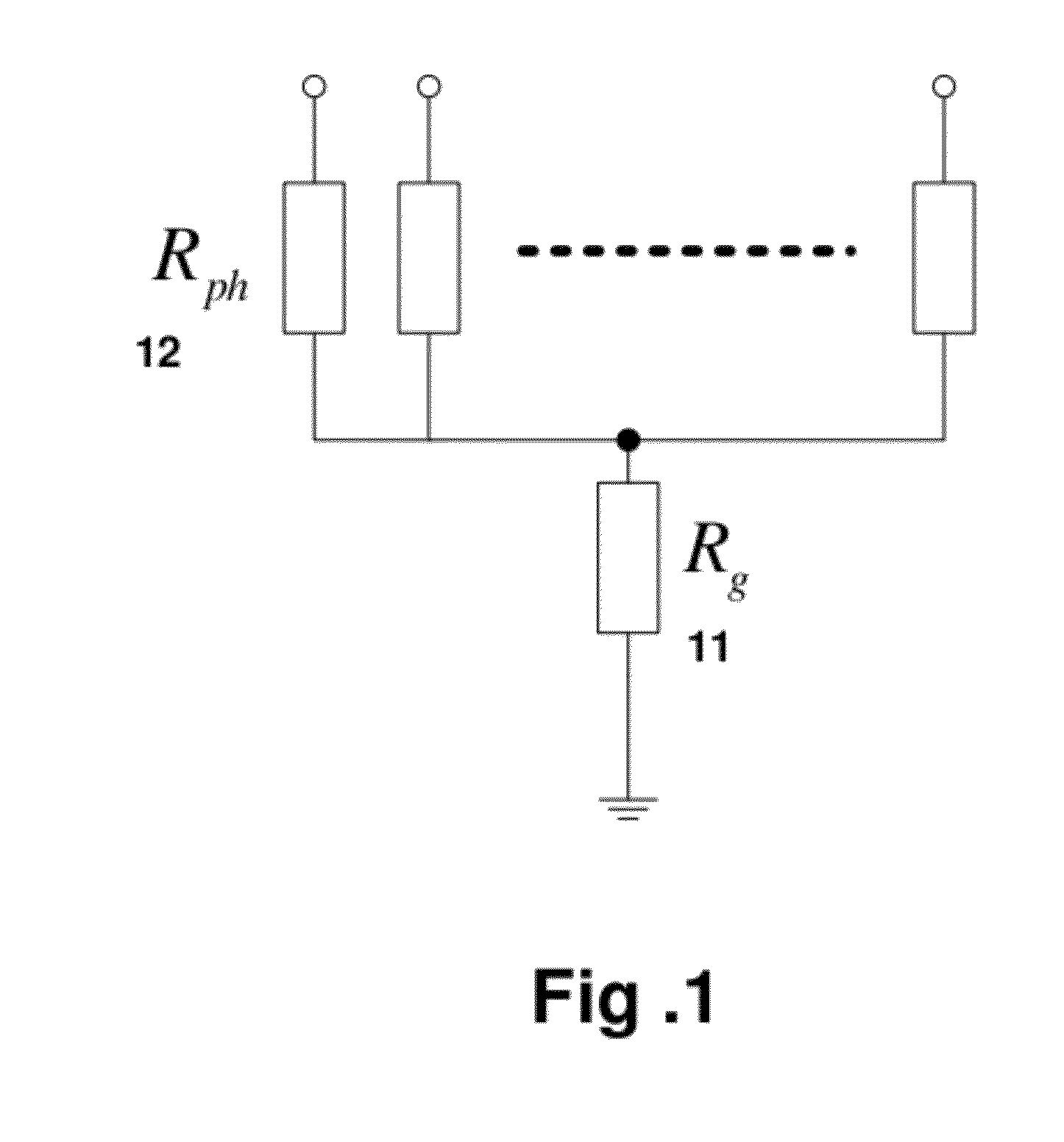

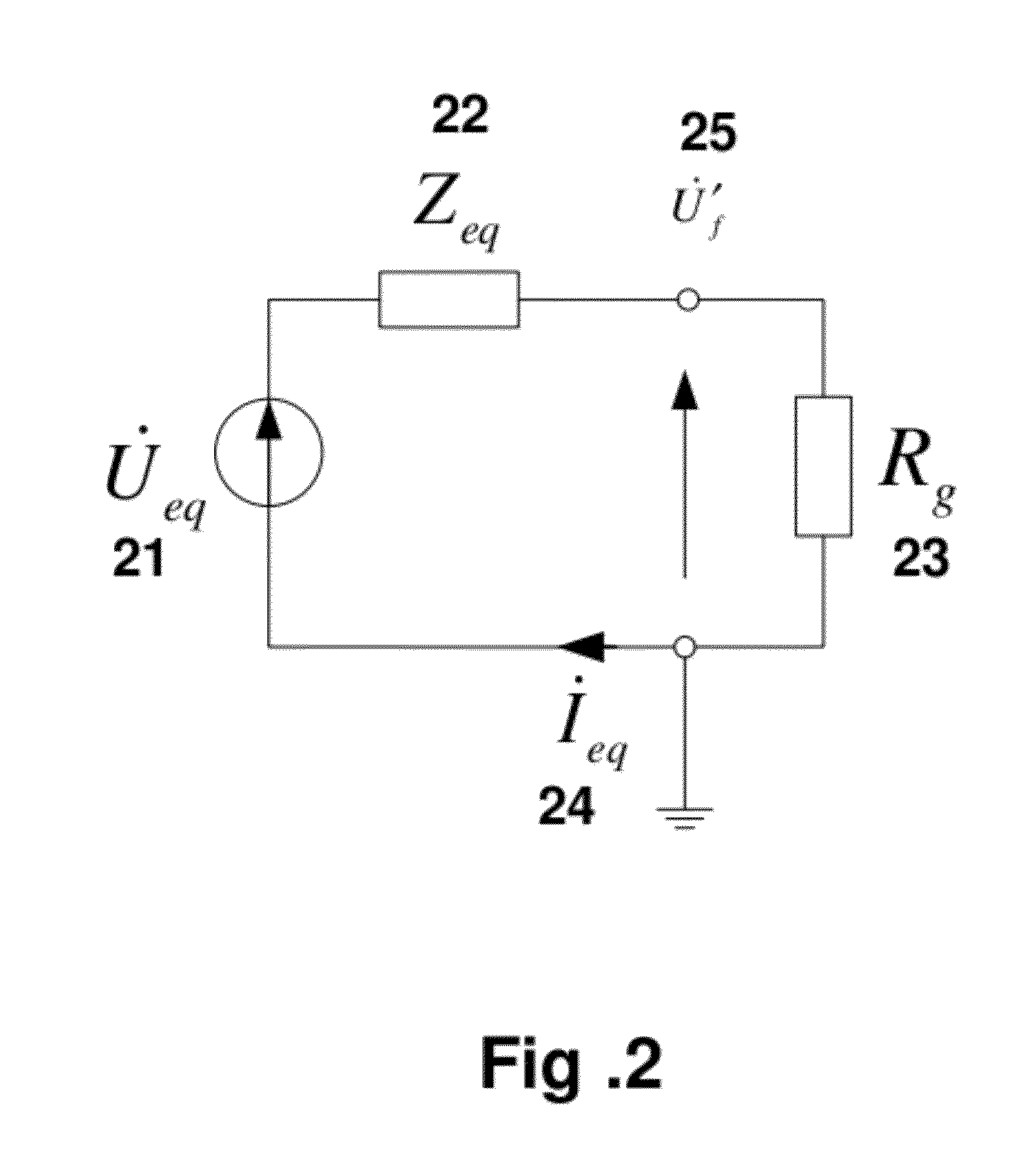

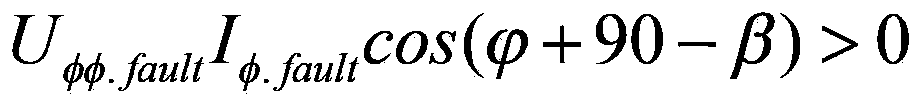

Method for Identifying Type of Fault on Power Line

ActiveUS20120095707A1Improve accuracyIncreasing confidence coefficientEmergency protective arrangement detailsFault location by conductor typesElectrical resistance and conductanceTerminal voltage

A method for identifying the type of faults occurred on a power line, characterized in that it comprises: calculating a fault point voltage on fault points based on terminal voltage and fault locations of the power line; adopting the fault point voltage corresponding to a maximum transition resistance as a setting value; comparing the fault point voltage on fault points with the setting value; and identifying the type of fault as a permanent type or a transient type based on the result of the comparison.

Owner:HITACHI ENERGY SWITZERLAND AG

Quenched and tempered steel sheet and manufacturing method thereof

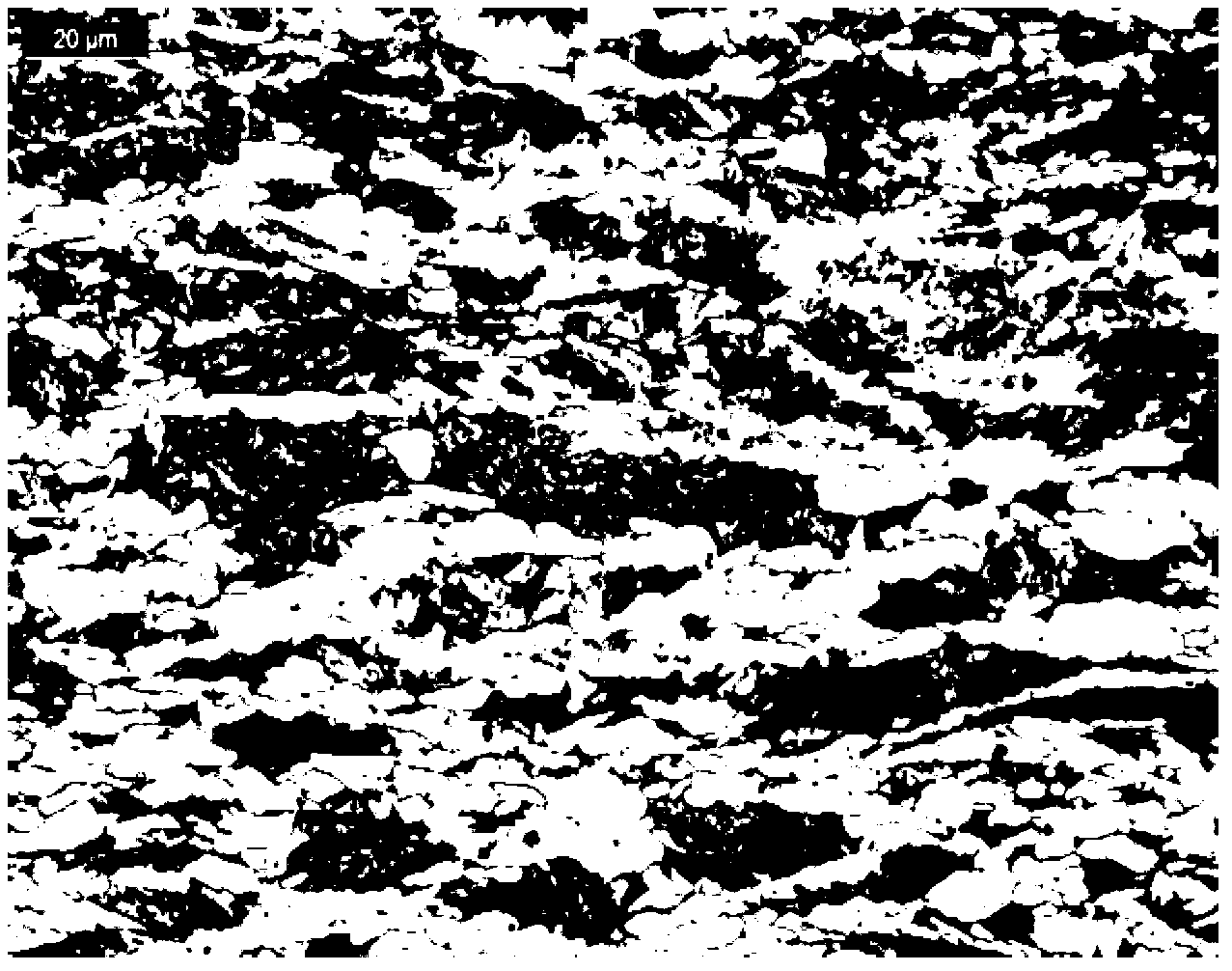

ActiveCN101962741AStrong plastic matchingSimple welding processRoll force/gap control deviceMolten metal pouring equipmentsSheet steelChemical composition

The invention provides a 80kg extra-thick quenched and tempered steel sheet. The steel sheet comprises the following chemical compositions: 0.10 to 0.16 percent of C, less than or equal to 0.20 percent of Si, 0.85 to 1.25 percent of Mn, less than or equal to 0.013 percent of P, less than or equal to 0.0030 percent of S, 0.20 to 0.45 percent of Cu, 0.90 to 1.50 percent of Ni, 0.45 to 0.75 percent of Cr, 0.40 to 0.65 percent of Mo, 0.030 to 0.060 percent of V, 0.045 to 0.070 percent of Als, 0.006 to 0.012 percent of Ti, less than or equal to 0.0060 percent of N, 0.0006 to 0.0014 percent of B, 0.001 to 0.005 percent of Ca, and the balance of iron and inevitable impurities, wherein the chemical compositions meet the following conditions that: the Mn equivalent / C is more than or equal to 10 and less than or equal to 20; the Als is more than or equal to (Mn equivalent / c)*(N-0.292Ti); the Ni equivalent is more than or equal to 1.15 percent; the Mo equivalent is more than or equal to 0.25 percent; Ca / S is more than or equal to 0.80 and less than or equal to 3.00, and (Ca)(S)0.18 is more than or equal to 5*10<-4> and less than or equal to 2.5*10<-3>; and F*DI equals to the effective hardenability index Deff and is more than or equal to 1.00*t. The invention also relates to a method for manufacturing the quenched and tempered steel sheet. The technology of optimal recrystallization controlled rolling+offline quenching and tempering is adopted to ensure that the microstructure of the finished product steel sheet is a fine tempered bainite and tempered martensite, the average colony size is less than 25mu m, and excellent obdurability / plasticity matching and uniform mechanical performance along the direction of the sheet thickness can be acquired.

Owner:BAOSHAN IRON & STEEL CO LTD

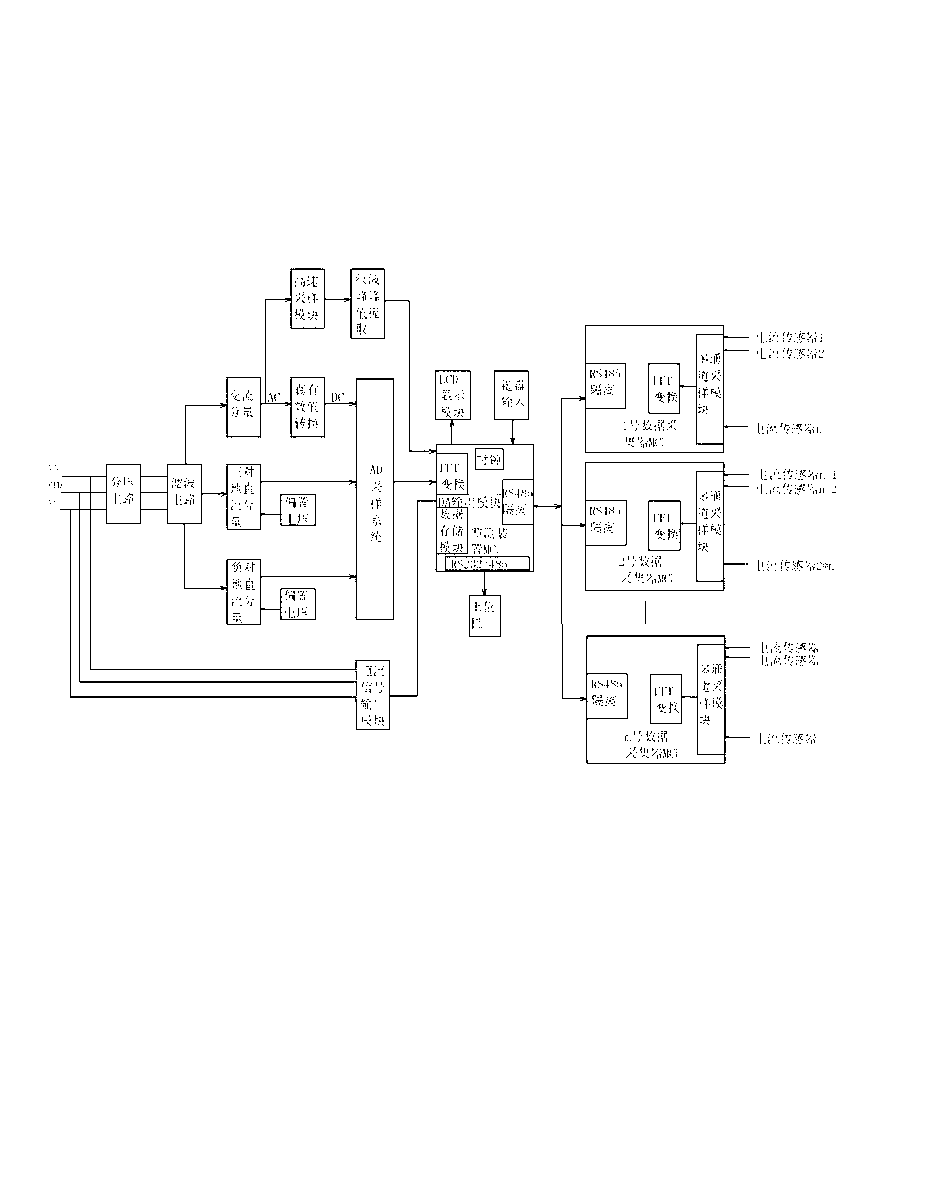

Chain state monitoring and protecting system for scraper conveyor

InactiveCN103434816AImprove stability and securityMonitor running statusControl devices for conveyorsModularitySystem structure

The invention discloses a chain state monitoring and protecting system for a scraper conveyor. The system is characterized by comprising a micro controller unit, a wireless measuring unit, an AC (Alternating Current) sampling unit, an analog quantity conditioning unit, a display unit, a communication unit, a keying unit, a switching value unit and a driving unit. According to the invention, a modularized system structure is adopted; all the units are combined into one organic integral body; a wireless measuring technology is adopted to more directly and accurately monitor an operating state of a chain; the state of the chain is dynamically regulated according to the load condition; after chain clamping and breaking accidents occur, fault protection is carried out by sending an alarm signal to an integral switch, and fault alarm is carried out; safety and stability of operation of the scraper conveyor are improved; and production safety of an underground coal mine is ensured.

Owner:TAIYUAN UNIV OF TECH +2

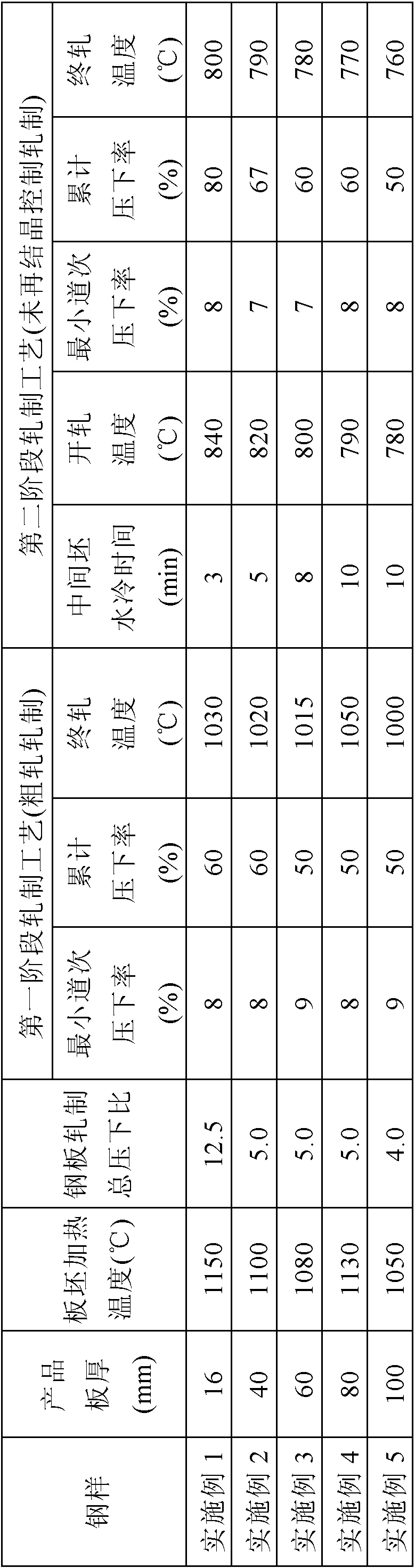

Super-thick quenched-tempered steel plate with 60kg-grade tensile strength and production method of the super-thick quenched-tempered steel plate

The invention discloses a super-thick quenched-tempered steel plate with 60kg-grade tensile strength and a production method of the super-thick quenched-tempered steel plate. The production method includes the means as follows: adopting a component system of low C-Mn-(Ti plus Nb plus V plus B) micro-alloy steel as base, appropriately improving the content of acid solution Als which is greater than or equal to (Mn equivalent / C) * (Ntotal minus 0.0292Ti); controlling (Mn equivalent) / C to be greater than or equal to 15, alloying (Cu plus Ni plus Mo plus Cr); controlling Ni equivalent to be greater than or equal to 0.90%, Mo equivalent to be greater than or equal to 0.25%, and Nb / Ti to be between 1.0 and 2.5; conducting Ca treatment, and controlling the ratio of Ca / S to be between 0.80 and 3.00, (Ca)*(S)0.18 to be less than or equal to 2.5*10 minus 3, and F*DI index to be greater than or equal to 0.65* thickness of a finished steel plate. Optimization control rolling plus an off-line special quenching-tempering technology enable the microstructural of the finished steel plate to be tiny tempering bainite plus tempered martensite, the average colony size is below 25 Mum, excellent matching of strong toughness / strong plasticity is obtained and the mechanical property along the direction of the thickness of the plate is uniform; the super-thick quenched-tempered steel plate with 60kg-grade tensile strength is specially applicable to large-sized steel structures and equipment such as water-electricity penstocks, volutes, ocean platforms, large-sized engineering machinery and can realize low-cost industrial production in stable batches.

Owner:BAOSHAN IRON & STEEL CO LTD

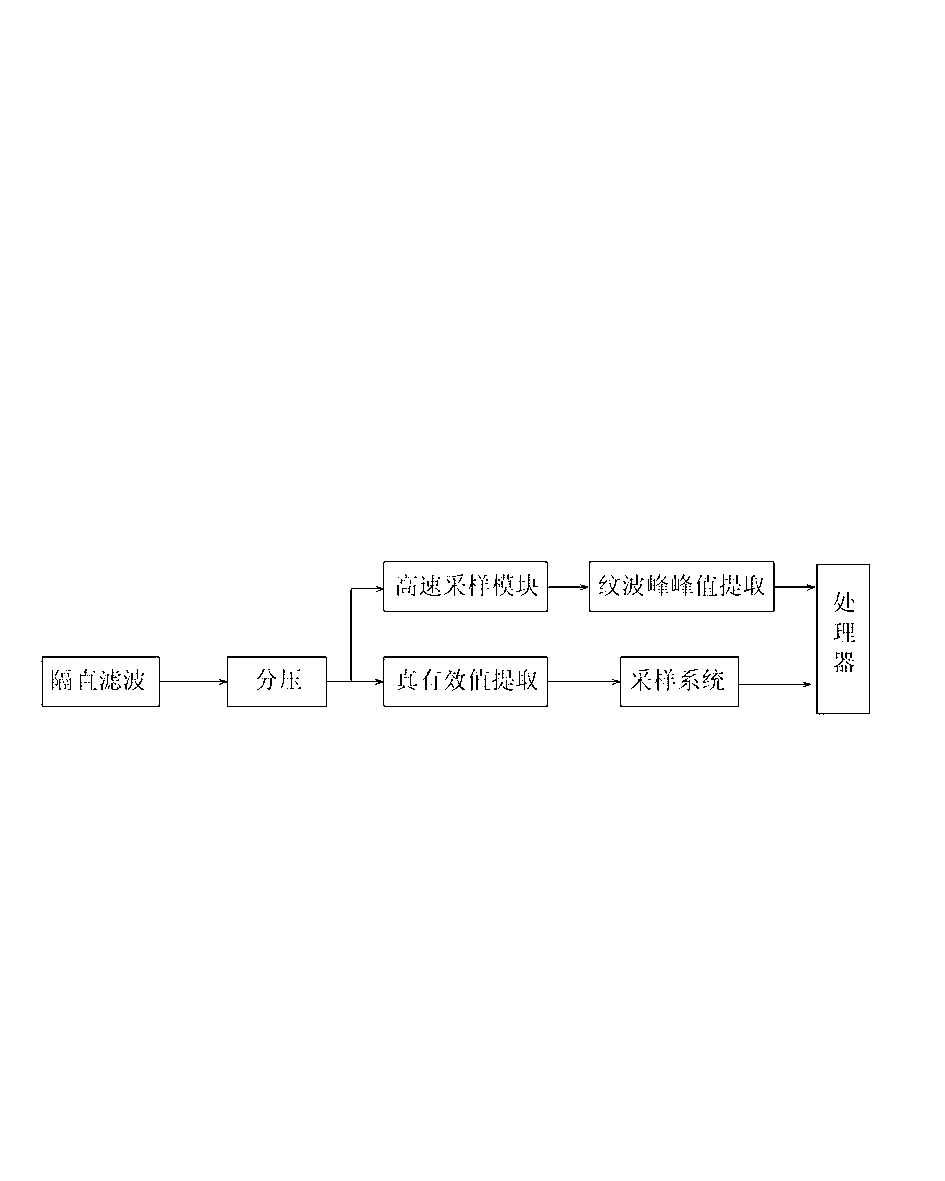

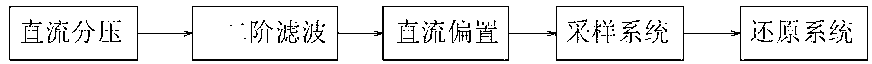

Alternative current electric crosstalk and insulation fault monitoring line selection method of direct current system

ActiveCN103135038ARealize line selection functionObvious ground faultCurrent/voltage measurementEarth resistance measurementsCurrent sensorData acquisition

The invention relates to an alternative current electric crosstalk and insulation fault monitoring line selection method of a direct current system. The direct current system is formed by an upper computer, a monitoring device, a sampling system and a current sensor. The alternative current electric crosstalk and insulation fault monitoring line selection method includes the steps of extracting a ripple crest value in the direct current system through extracting of an alternating component effective value, adopting the alternative current and direct current component separation digital filtering technology, the direct current leakage current detection technology, the recommend standard 485 (RS485) isolation communication technology and the fast fourier transform algorithm (FFT) conversion technology to monitor system bus over-the-ground alternative and direct current voltage and a ripple voltage peak value in real time to give an alarm, receiving loop leakage current information uploaded by a data collector, carrying out intelligent analysis through mode matching technology, calculating grounding resistance, carrying out artificial intelligence mode matching on feature status information of each loop and configured feature rules in the system, enabling the alternative current electric crosstalk faults, ripple voltage peak value monitoring data, grounding fault and insulation fault loop status information, loop information and the like which to be displayed on a liquid crystal display, assisting operation and maintenance workers to accurately know the current status to rapidly remove the faults.

Owner:GUANGZHOU PREFECT SERVICE ELECTRONICS TECH

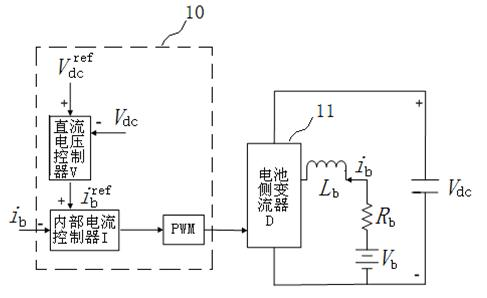

Double-fed wind generating set control system and stable control method

InactiveCN101950973AProtect DC side capacitorImprove stability and securitySingle network parallel feeding arrangementsEnergy storageElectricityLow voltage

The invention relates to a double-fed wind generating set control system and a stable control method. An energy storage cell is added at the DC side of a back-to-back converter of a double-fed motor, the DC side energy storage cell is connected to a DC bus capacitor by the double-way DC / DC cell side converter, and a third control circuit controls the cell converter to charge and discharge the energy storage cell. The cell can send active power and adsorbs the active power under the necessary condition, and residual energy is stored in the energy storage cell during breakdown. The invention provides the guarantee for the low voltage of wind power generation and improves the safety and stability of the voltage of the DC side of the converter of the double-fed wind generating set, thus further accelerating the better development of wind power generation.

Owner:SHANGHAI UNIVERSITY OF ELECTRIC POWER +1

80Kg grade steel plate with ultrahigh toughness and extreme thickness and manufacturing method of the steel plate

ActiveCN102605282AOptimizing Special Controlled Rolling + Offline Gradient Quenching and Tempering ProcessExcellent toughness/strong plasticitySteel platesPlasticity

The invention discloses a 80Kg grade steel plate with ultrahigh toughness and extreme thickness and a manufacturing method of the steel plate. The steel plate comprises the following components in percentage by weight: 0.08-0.13% of C, Si smaller than or equal to 0.10%, 0.80-1.20% of Mn, P smaller than or equal to 0.013%, S smaller than or equal to 0.0030%, 0.20-0.45% of Cu, 1.00-1.60% of Ni, 0.35-0.65% of Cr, 0.30-0.60% of Mo, 0.040-0.070% of Als, 0.010-0.030% of Nb, 0.030-0.060% of V, 0.004-0.010% of Ti, N smaller than or equal to 0.0050%, 0.001-0.004% of Ca, 0.0008-0.0016% of B, and balance of Fe. According to the manufacturing method, a component system of low C-ultralow Si-medium Mn-(Ti+V+Nb+B) microalloyed steel is used as a basis, special rolling control and offline gradient tempering technology (QQ+T) are optimized, so that microstructures of the produced steel plate are small tempered bainite+ tempered martensite, the average crystal colony size is less than 20 microns, excellent obdurability and plasticity match is obtained, and mechanical performance in the direction of the thickness of the steel plate is uniform.

Owner:BAOSHAN IRON & STEEL CO LTD

Nickel-free high-toughness 80kg-grade high-strength steel and manufacturing method thereof

ActiveCN102719757ASimple welding processHigh strengthHeat treatment process controlNickel freeToughness

The invention relates to nickel-free high-toughness 80kg-grade high-strength steel and a manufacturing method thereof. A component system of ultralow C, ultralow Si, medium Mn and Ti, V and B microalloy steel is used as a basis; the acid-soluble Als content in steel is properly improved, the Als is not less than 10*[(%Ntotal)-0.292(%Ti)], Mn / C is not less than 12, (%C)*(%Si) is not more than 0.01, and [(%Cr)+1.3(%Mo)]*[(%V)+(%C)] is not less than 0.087; Ca treatment is carried out, the Ca / S ratio is 1.00-3.00, and (%Ca)*(%S)<0.18> is not more than 2.5*10<-3>; F*DI index number * zeta is not less than 2.0* finished steel plate thickness, wherein zeta is on-line DQ (direct quenching) hardenability contribution factor, and F is B element hardenability contribution factor; DQ (thermo mechanical control process: TMCP) and off-line tempering process (T) are optimized; the microscopic structure of the steel plate is fine low-carbon tempered martensite and tempered lower bainite; the steel has the average colony size below 20 mu m, has excellent strength and plasticity and strong toughness, and is particularly suitable for hydroelectric pressure water pipes, steel branch pipes, scrolls, ocean platforms, large-sized engineering machines and other large-sized steel structures and equipment.

Owner:BAOSHAN IRON & STEEL CO LTD

Steel plate HT690 capable of being subjected to high heat input welding and manufacturing method thereof

ActiveCN102041459AImprove performanceShorten the manufacturing cycleRoll force/gap control deviceTemperature control deviceWater pipeThermo mechanical

The invention relates to an HT690 steel plate capable of being subjected to high heat inputwelding and a manufacturing method thereof. A component system treated by low C-high Mn-(Nb+V+B) microalloying-ultramicro Ti is adopted, the acid-soluble Als content in steel is properly improved, the Als is not less than (Mn equivalent / C)*(Ntotal-0.292Ti), (Mn equivalent) / C is between 20 and 40, Pcm is not more than 0.205 percent, the Ti / N is between 2.0 and 4.0, (Cu+Ni+Mo+Cr) is alloyed and Ni / Cu is not less than 1.0, the Ca is treated and the Ca / S ratio is between 0.80 and 3.00 and the F*DI index is controlled to be not less than 0.80*finished steel plate thickness, a TMCP (Thermo-Mechanical Control Process) and a tempering process are optimized to ensure that the microscopic structure of a finished steel plate is fine tempering bainite, and the average crystal cluster size is below 25mum. The steel plate can bear high heat input welding at the same time of obtaining the properties of uniform and excellent obdurability and strong plasticity matching, is especially suitable for large steel structures of a hydroelectric pressure water pipe, a vortex, a sea platform and the like, and can realize low-cost and stable batch industrialized production.

Owner:BAOSHAN IRON & STEEL CO LTD

HT 960 steel plate with excellent plasticity and toughness and manufacture method thereof

ActiveCN102691010AIncrease added valueGood plasticityRoll mill control devicesFurnace typesThermal treatmentToughness

An HT 960 steel plate with excellent plasticity and toughness and a manufacture method thereof. The HT 960 steel plate comprises, by weight, 0.07%-0.12% of C, Si no mare than 0.15%, 0.80% -1.20% of Mn, P no mare than 0.012%, S no more than 0.0030%, 0.30%-0.60% of Cr, 0.30%-0.60% of Mo, 1.00%-1.60% of Ni, 0.15%-0.45% of Cu, 0.0008%-0.0016% of B, 0.006%-0.014% of Ti, 0.010%-0.030% of Nb, 0.025%-0.060% of Als, 0.030%-0.060% of V, N no more than 0.0060%, O no more than 0.0040%, 0.001%-0.004% of Ca, residual Fe and unavoidable inclusions. A TMCP + tempering thermal treatment process is employed to obtain super high strong steel plate with tensile strength no less than 960 MPa, yield strength no less than 900 MPa, Charpy transverse impact work (separate value) no less than 47J at -60 DEG C, fracture elongation percentage delta 5 no less than 15%, uniform elongation percentage Ag no less than 6% and excellent weldability.

Owner:BAOSHAN IRON & STEEL CO LTD

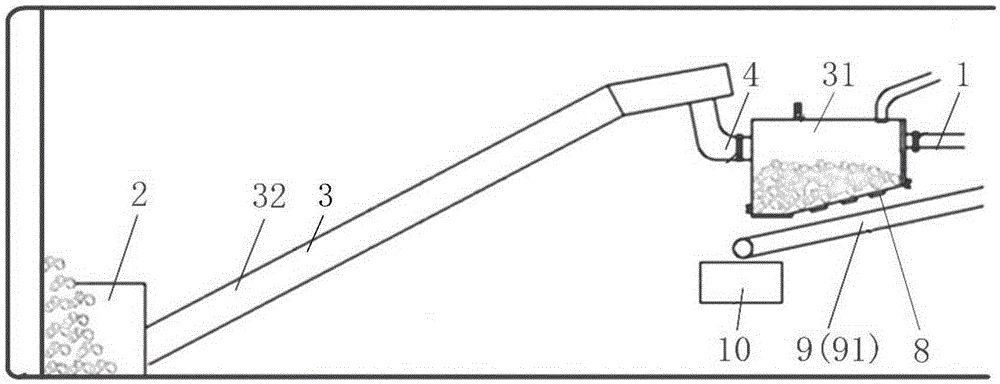

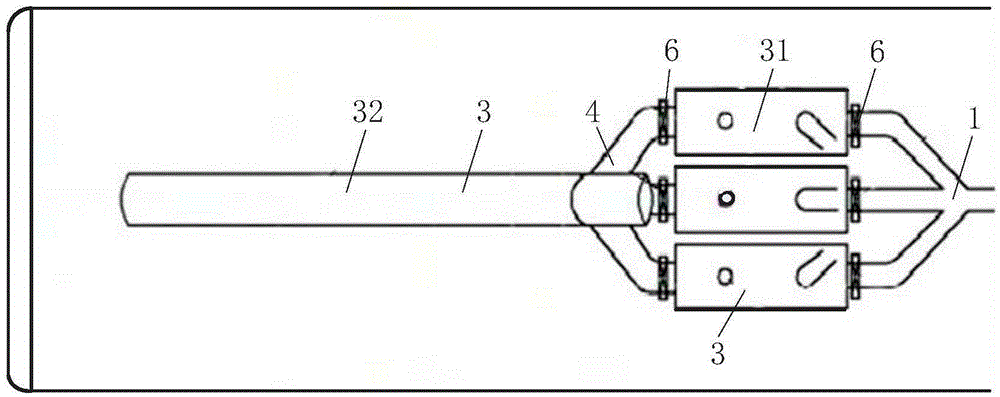

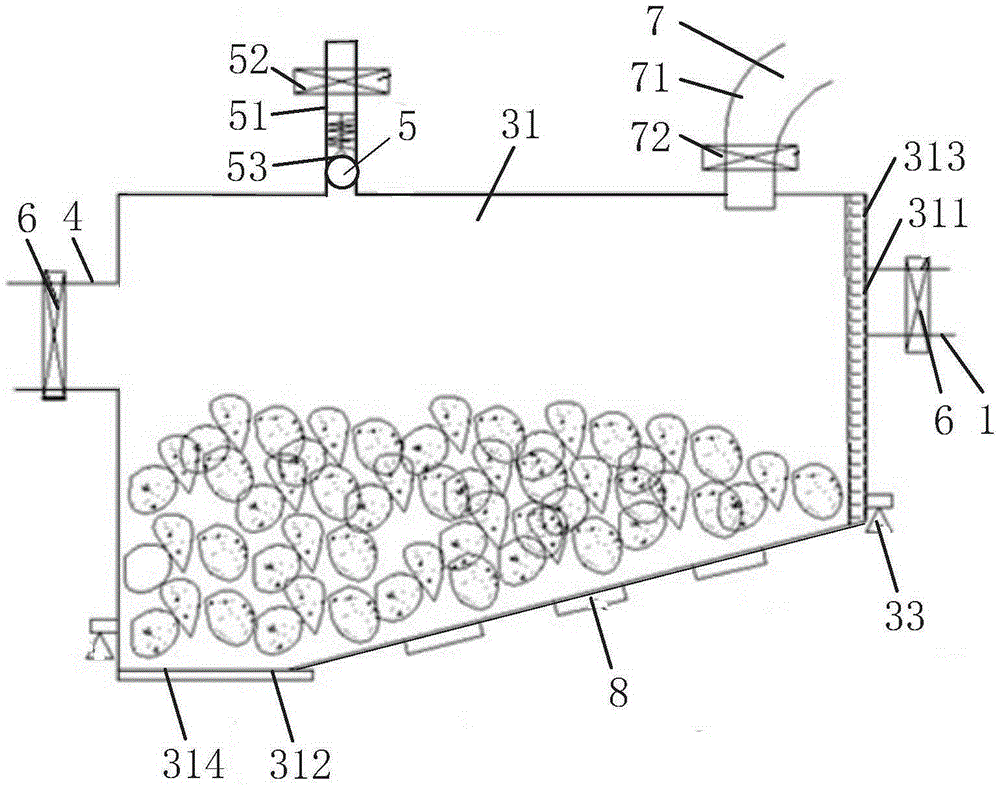

Slag discharging mechanism of shield tunneling machine and muddy water balance shield tunneling machine

The invention discloses a muddy water balance shield tunneling machine and a slag discharging mechanism thereof. The slag discharging mechanism comprises a mud discharging pipeline and a soil bin for storing residue soil; a separating device for separating mud in the residue soil from gravels is arranged between the soil bin and the mud discharging pipeline; the soil bin communicates with a feeding end of the separating device; a mud discharging end of the separating device communicates with the mud discharging pipeline; and a gravel discharging end of the separating device is provided with a gravel discharging device. The muddy water balance shield tunneling machine comprises a shield and the slag discharging mechanism which is arranged in the shield. The slag discharging mechanism has the advantages that safety and stability of a slag outlet system of the muddy water balance shield tunneling machine are improved, and construction efficiency is also improved.

Owner:RAILWAY CONSTR HEAVY IND XINJIANG CO LTD +1

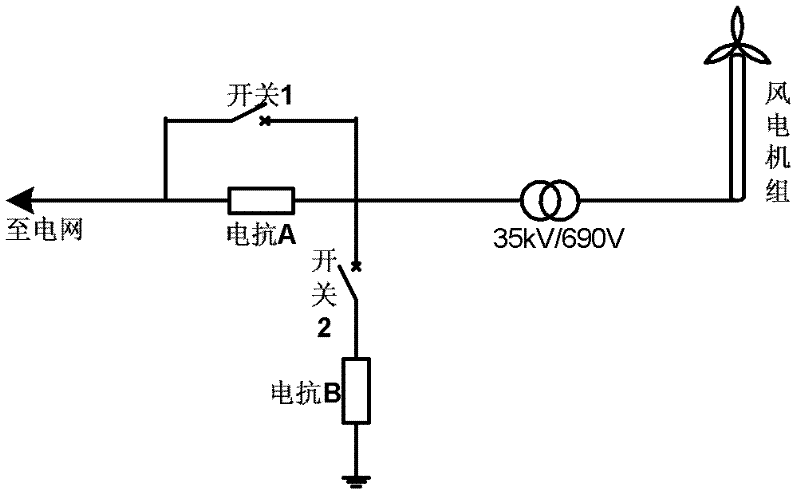

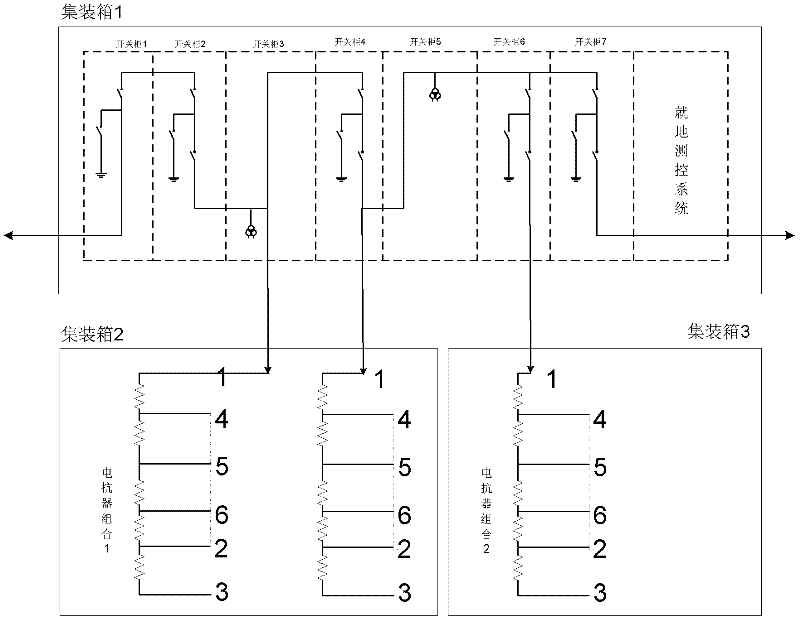

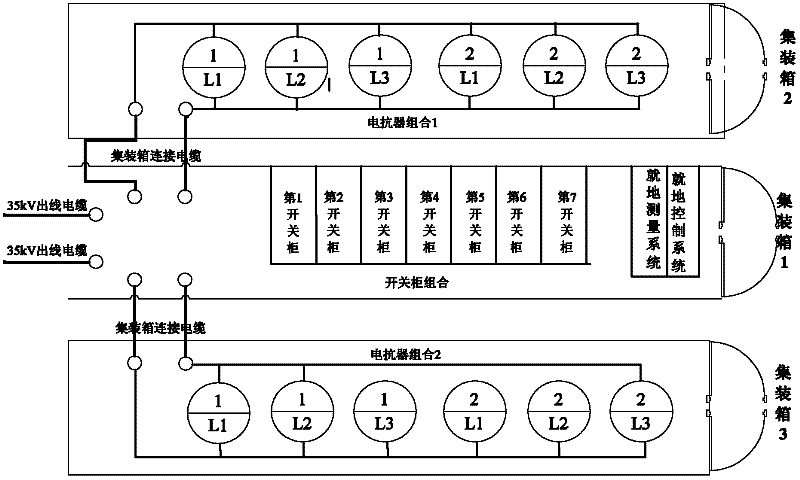

Low-voltage ride-through testing system of wind generating set

ActiveCN102508157AReduce mistakesImprove stability and securityDynamo-electric machine testingElectricityControl system

The invention provides a low-voltage ride-through testing system of a wind generating set. The testing system comprises a voltage dropping system, an on-site measuring system, a remote monitoring system and an on-site controlling system, wherein the on-site measuring system is in bidirectional connection with the remote monitoring system; the remote monitoring system is in bidirectional connection with the on-site controlling system; the on-site controlling system is in bidirectional connection with the voltage dropping system; the voltage dropping system is in one-way connection with the on-site measuring system; and the on-site measuring system is in bidirectional connection with the on-site controlling system. The low-voltage ride-through testing system of the wind generating set, disclosed by the invention, is in accordance with criterion IEC61400-21, can realize voltage drop of different degrees and various types and can satisfy requirements of wind generating sets in all countries on low-voltage ride-through testing. The low-voltage ride-through testing system is a movable detecting system which is adaptable to performing the low-voltage ride-through characteristic testing on all wind generating sets which have been operated in the wind power field, and has high safety as well as high stability.

Owner:CHINA ELECTRIC POWER RES INST +1

Wireless network connecting method of a terminal device

InactiveCN104394531AImprove stability and securityAvoid spoofing or threatening network securityTransmissionSecurity arrangementFingerprintIp address

The invention discloses a wireless network connecting method of a terminal device, the method comprising steps of: searching, by the terminal device, nearby wireless networks and selecting an available wireless network; obtaining, by the terminal device, a user's fingerprint image and extracting a fingerprint feature; by the terminal device, binding an MAC address with the fingerprint feature and transmitting the bound MAC address and fingerprint feature to a server of the wireless network; by the server of the wireless network, verifying the MAC address and the fingerprint feature; and after the verification of the MAC address and the fingerprint feature is passed, by the server of the wireless network, allocating an IP address to the terminal device for wireless connection. The invention avoids effectively behavior that a terminal device without authorization and a user without authorization connect to a wireless network, by performing dual identity verifications and limitations on an MAC address of a networking terminal device and a user fingerprint, improving security and stability of the verification of the wireless network connection.

Owner:WUXI BIOKEE BIOMETRICS TECH

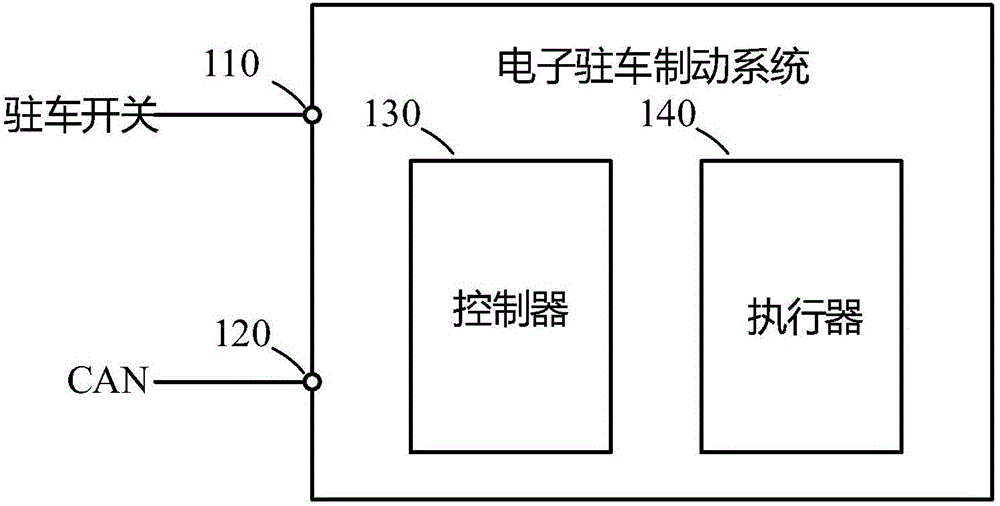

Electrical park brake system, vehicle and electrical park brake method

ActiveCN106218626AReduce manufacturing costImprove stability and securityBraking action transmissionArea networkBus interface

The invention discloses an electrical park brake system, a vehicle and an electrical park brake method. The electrical park brake system comprises a first hard wire interface, a bus interface, a controller and an executor, wherein the first hard wire interface is connected with a parking switch of the vehicle through a first hard wire, and used for acquiring a parking hard wire signal for indicating whether the parking switch is triggered or not; the bus interface is connected with a controller area network of the vehicle, and used for acquiring a bus signal of the controller area network; the controller is used for controlling the executor to execute the operation of electrical park brake operation according to the park hard wire signal and the bus signal; and the executor is used for executing the operation of electrical park brake operation under the control of the controller. According to the electrical park brake system, the vehicle and the electrical park brake method disclosed by the invention, the operation complexity of the vehicle can be reduced.

Owner:BEIJING CHEHEJIA AUTOMOBILE TECH CO LTD

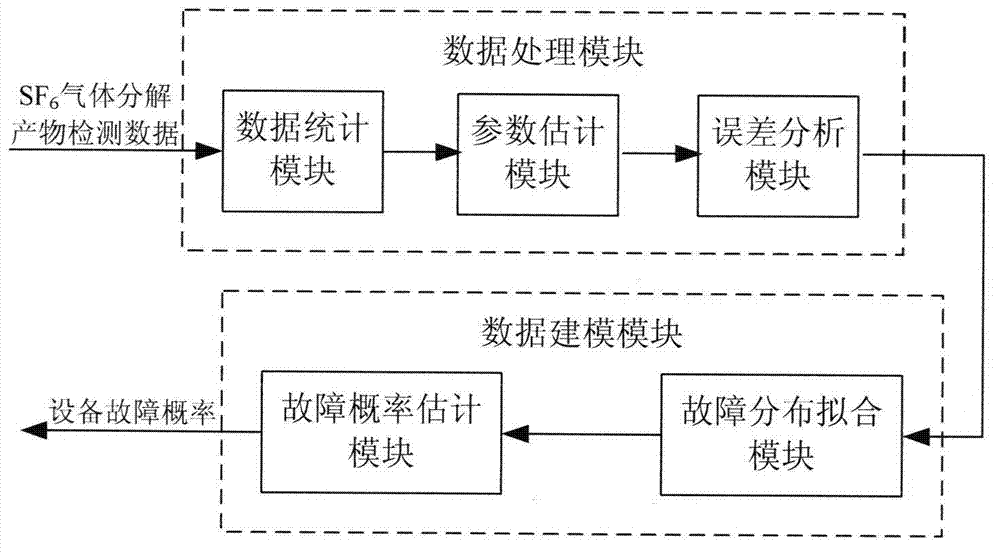

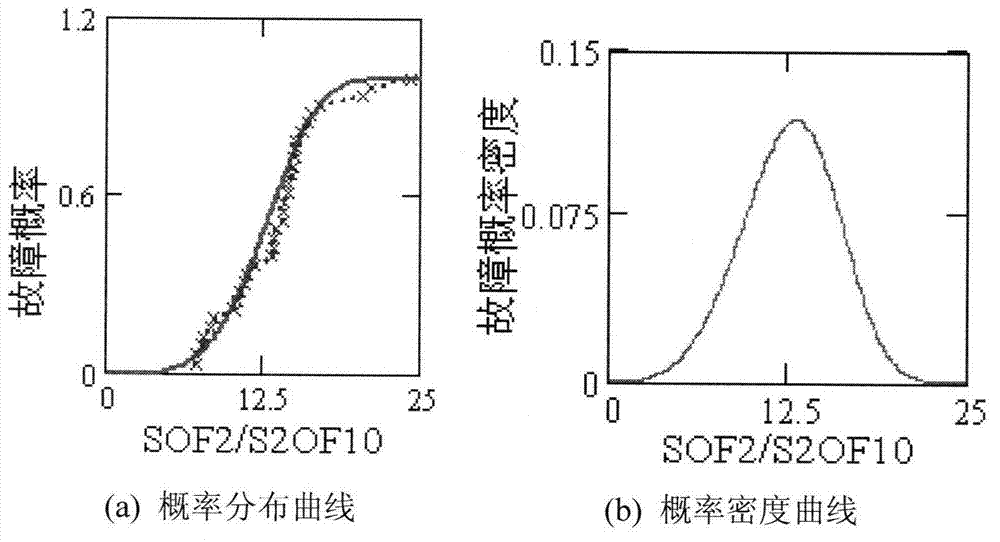

Probability forecasting method and system of switch equipment faults

ActiveCN102854461AKnow the running statusImprove stability and securityCircuit interrupters testingSpecial data processing applicationsDecompositionData modeling

The invention provides a probability forecasting method and \system of switch equipment faults. The method comprises the following steps of: A) carrying out data processing on SF6 gas decomposition product detection data that the switch equipment has faults, and selecting a probability distribution which meets the requirements on relevance as a fault distribution; B) establishing an SF6 gas decomposition product probability model according to the selected fault distribution, and thereby predicting the probability that the switch equipment has faults. The system comprises a data processing module and a data modeling module, wherein the data processing module comprises a data counting module, a parameter estimating module and an error analyzing module; and the data modeling module comprises a fault distribution fitting module and a fault probability estimating module. By adoption of the method and the system, the SF6 gas decomposition product detection data in the equipment are processed, the fault probability of the equipment is predicted by using the established SF6 gas decomposition product probability model, and an effective basis is provided for the state judgment and evaluation, the fault diagnosis and the like for SF6 switch equipment.

Owner:CHINA ELECTRIC POWER RES INST +5

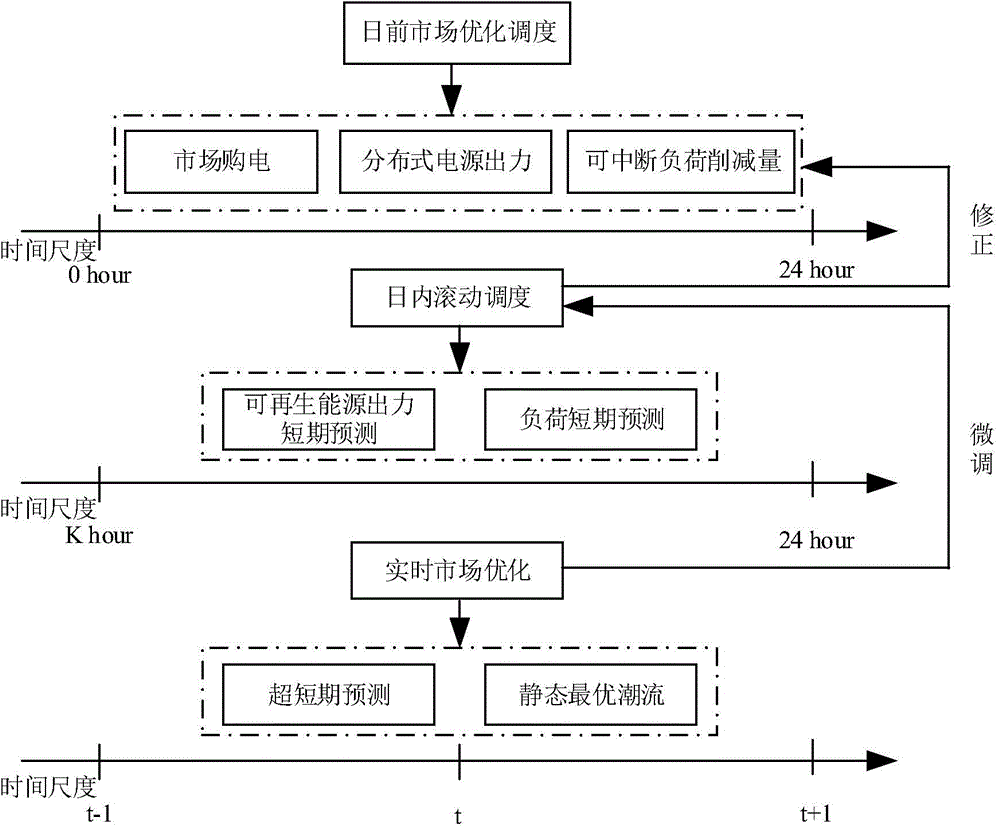

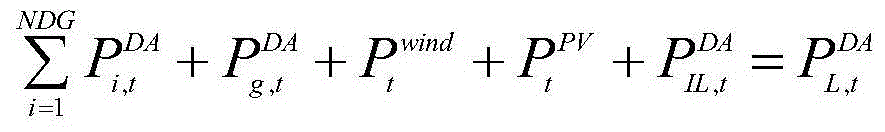

Multi-time-scale optimal scheduling method for power distribution company containing large-scale renewable energy sources

InactiveCN104951899AEliminate errorsReduce adverse effectsResourcesSystems intergating technologiesElectricity marketShort terms

The invention discloses a multi-time-scale optimal scheduling method for a power distribution company containing large-scale renewable energy sources. The method comprises steps as follows: optimal scheduling on the day-ahead market: the minimum day-ahead operating cost is taken as an optimal target, and the optimal scheduling is performed according to operating cost constraint conditions, load demand per hour in the next day, renewable energy source output and real-time electrovalence prediction; the intraday rolling optimal scheduling: according to predication for intraday short-term renewable energy source output, the optimal scheduling is performed again on the period after the moment with larger deviation, and deviation of the optimal scheduling on the day-ahead market is corrected; real-time market optimization: the optimal power flow optimization on a power distribution network is performed for a certain intraday moment according to super-short-term load and predication for renewable energy source output. With the adoption of the method, adverse effects of volatility and randomness of the large-scale renewable energy sources on the power distribution company can be reduced, the optimal scheduling for distributed power sources and interruptible loads accessed to the power distribution company in the electricity market environment is realized, and the safety and the stability of operation of the power distribution network are improved.

Owner:SOUTHEAST UNIV

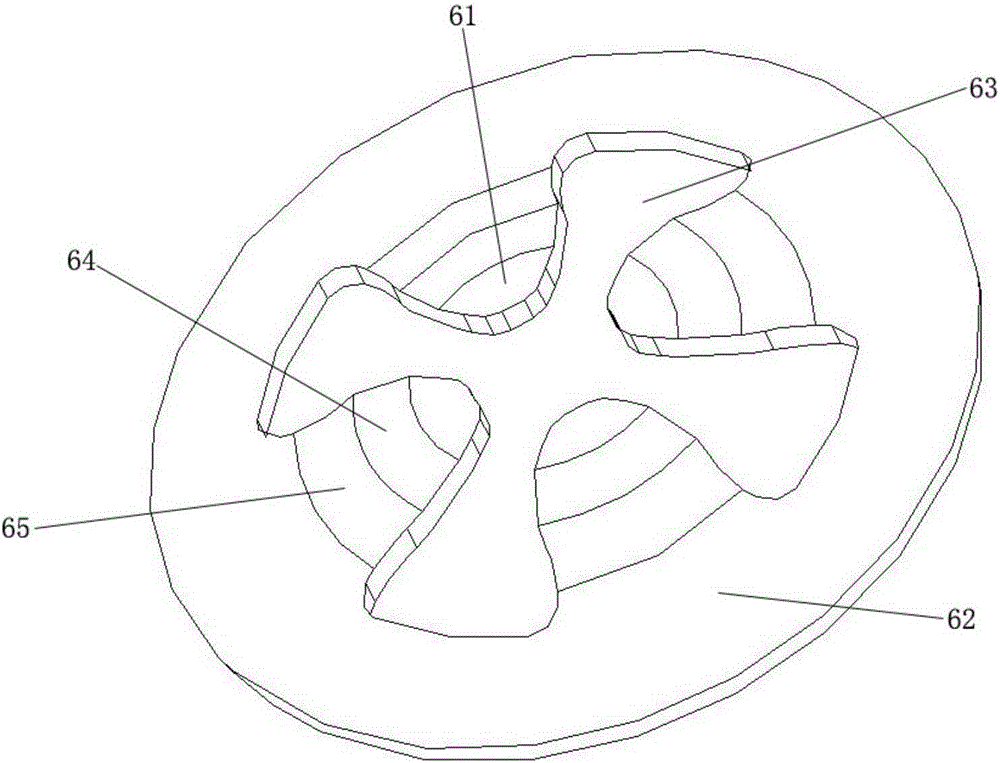

Multi-rotor flight vehicle undercarriage based on Stewart six-degree-of-freedom parallel mechanism

ActiveCN105644774AImprove shock absorptionImprove stability and securityUndercarriagesJet aeroplaneCarrying capacity

The invention relates to a multi-rotor flight vehicle undercarriage based on a Stewart six-degree-of-freedom parallel mechanism. The multi-rotor flight vehicle undercarriage comprises the parallel mechanism, supporting claws, a fixing base, supporting columns and damping springs. The supporting claws are symmetrically arranged on the outer sides of the lower end of the parallel mechanism. The fixing base is located at the center of the lower portion of the parallel mechanism. One end of each supporting column is fixed to an installation column of the fixing base, and the other end of each supporting column is fixed to a reinforcing rib on the lower portion of the inclined part of the corresponding supporting claw. Each damping spring is wound on the corresponding supporting column in a sleeving mode. According to the multi-rotor flight vehicle undercarriage based on the Stewart six-degree-of-freedom parallel mechanism, the dual damping effects of pneumatic damping and spring damping are achieved, the parallel mechanism in a six-degree-of-freedom mode is adopted, the carrying capacity is high, and the final motion precision is high; the damage caused by vibration during landing to an airplane body is reduced, the safety of carrying objects or personnel is ensured; moreover, the radial length of the multi-rotor flight vehicle undercarriage is adjustable, so that the multi-rotor flight vehicle undercarriage is applicable to landing of different types of multi-rotor flight vehicles on different landforms and landing site spaces, and the application range is wider.

Owner:平邑仁安中医药产业发展有限公司

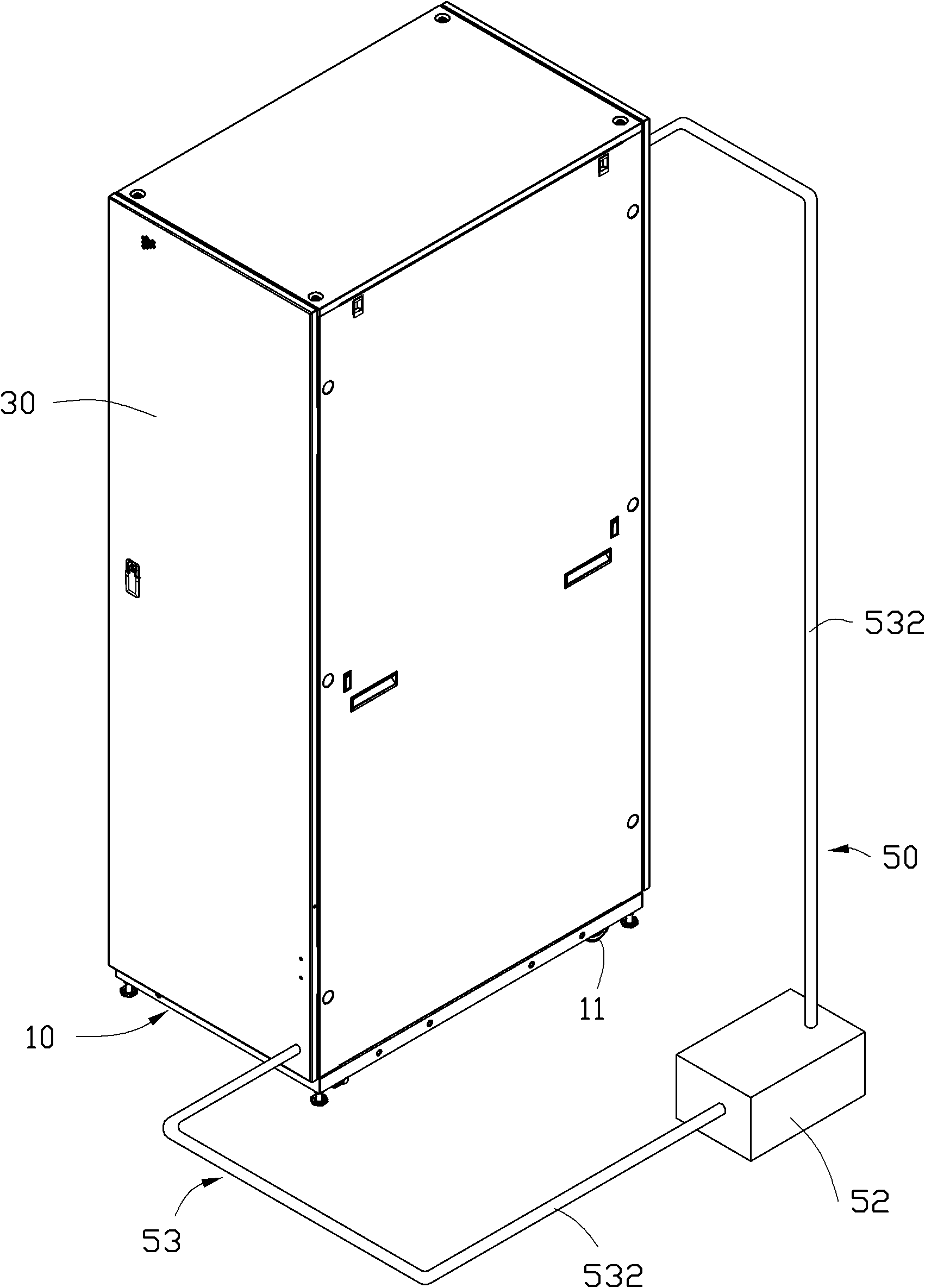

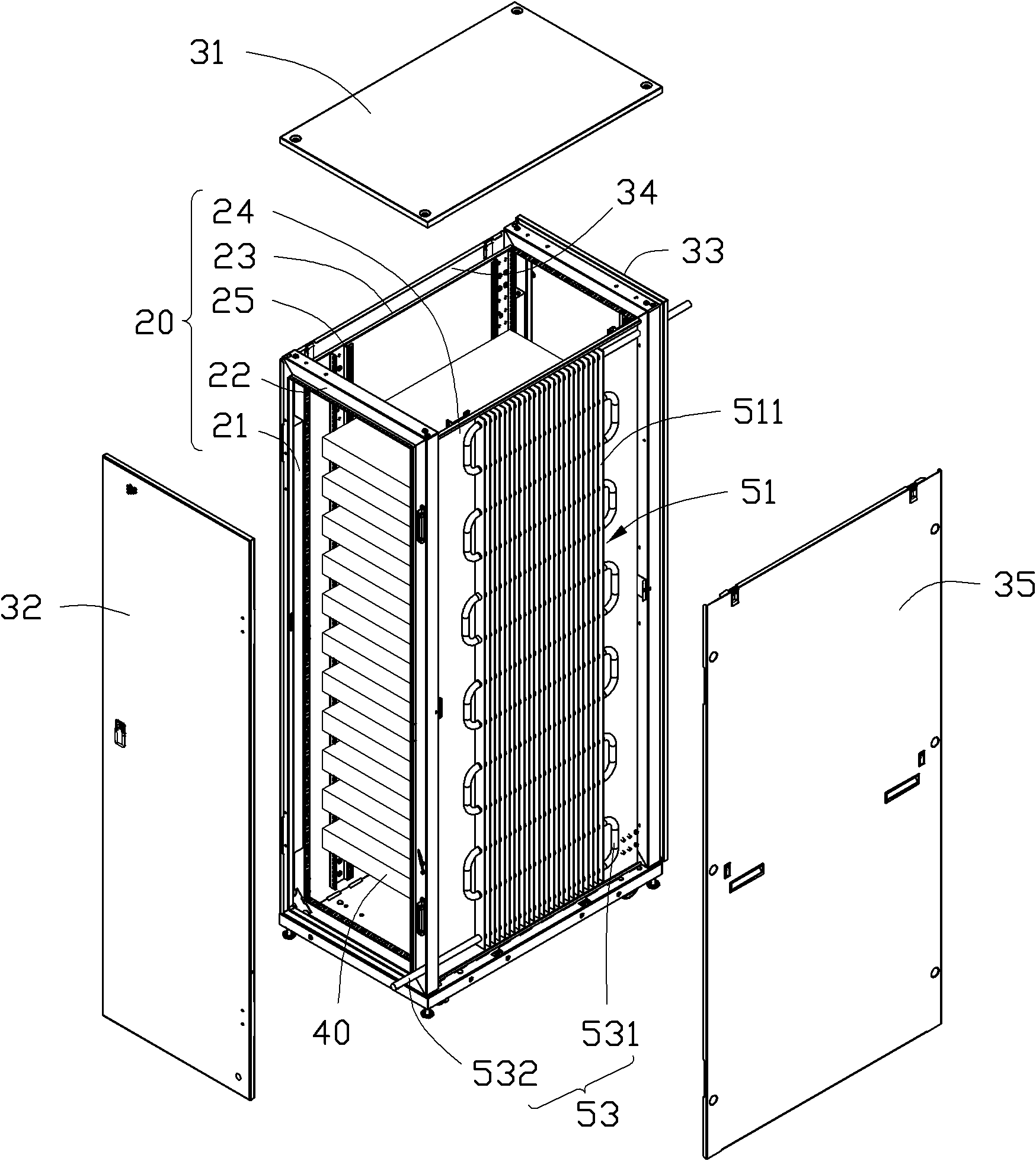

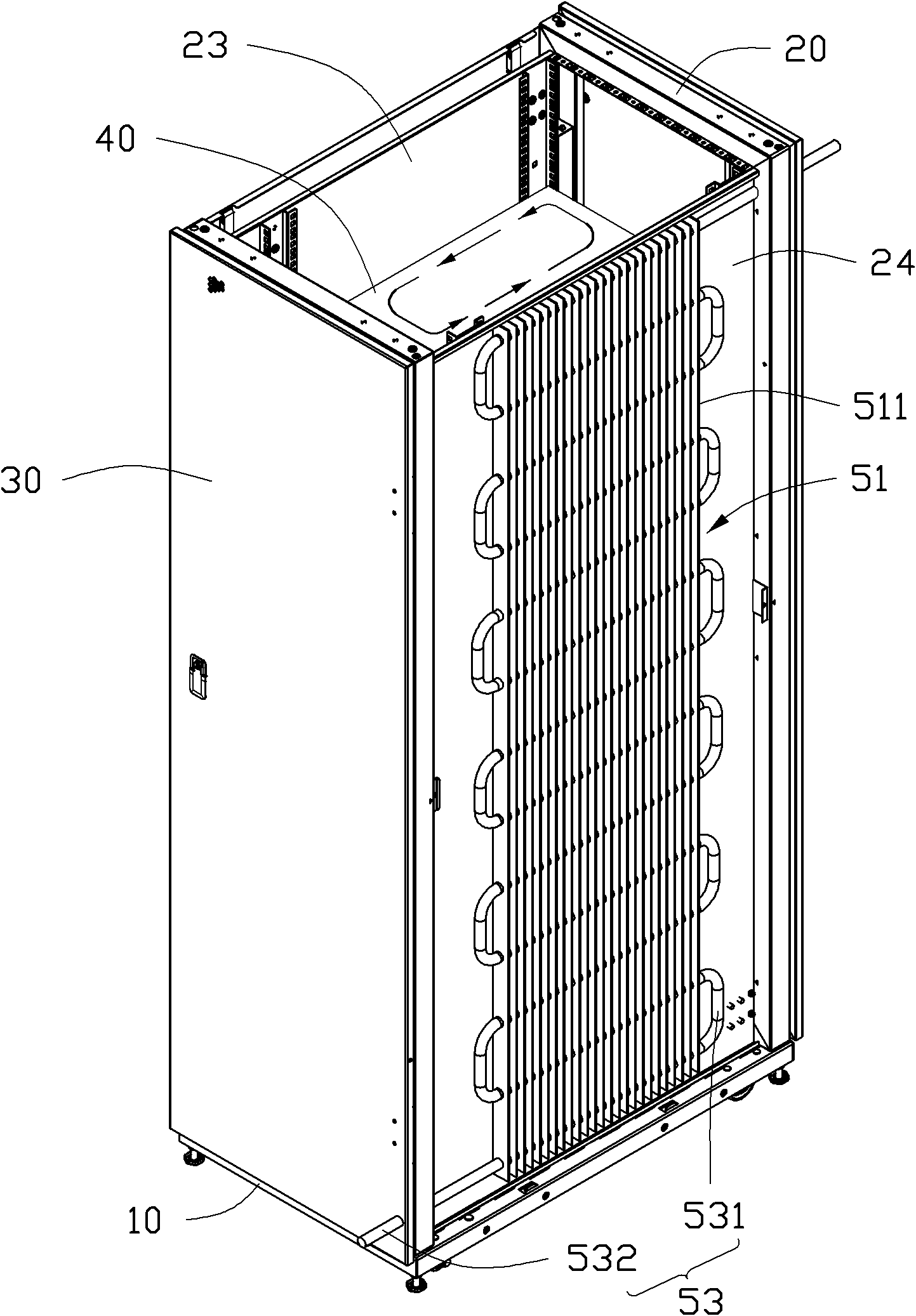

Server machine cabinet and liquid-cooled radiating system thereof

InactiveCN102378551AGood cooling effectImprove stability and securityDigital data processing detailsCooling/ventilation/heating modificationsHeat flowEngineering

The invention discloses a server machine cabinet. The server machine cabinet comprises a shell, a server and a liquid-cooled radiating system, wherein the server and the liquid-cooled radiating system are arranged in the shell; a heat conducting plate close to the server is arranged in the shell; the liquid-cooled radiating system comprises a refrigerator and a pipeline, wherein the refrigerator is arranged out of the shell; the pipeline connects the heat conducting plate with the refrigerator; the heat generated by the server in working forms a heat flow in the shell; the heat flow is cooled at the heat conducting plate; and the pipeline is extended out of the shell and is connected with the two opposite ends of the refrigerator respectively so as to transfer the heat, absorbed from the server, of the heat conducting plate to the refrigerator to perform heat exchange. In the server machine cabinet, cold-and-hot internal circulation is formed in the shell, so that the server machine cabinet contributes to reducing heat exchange space in the shell and increasing a radiating effect; therefore, the stability and the safety of server operation are improved.

Owner:HONG FU JIN PRECISION IND (SHENZHEN) CO LTD +1

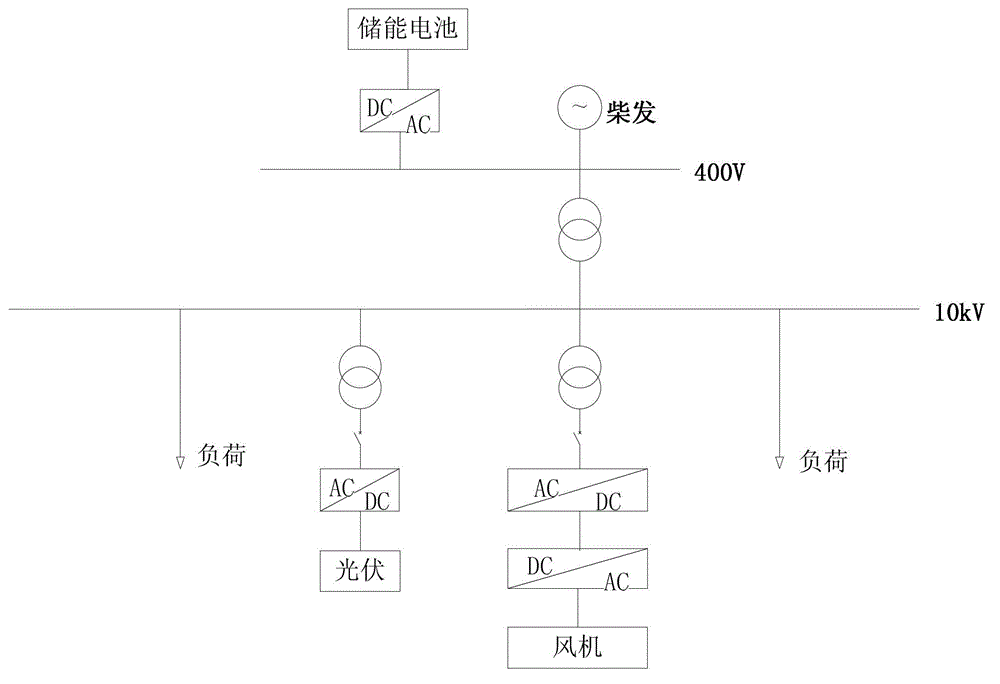

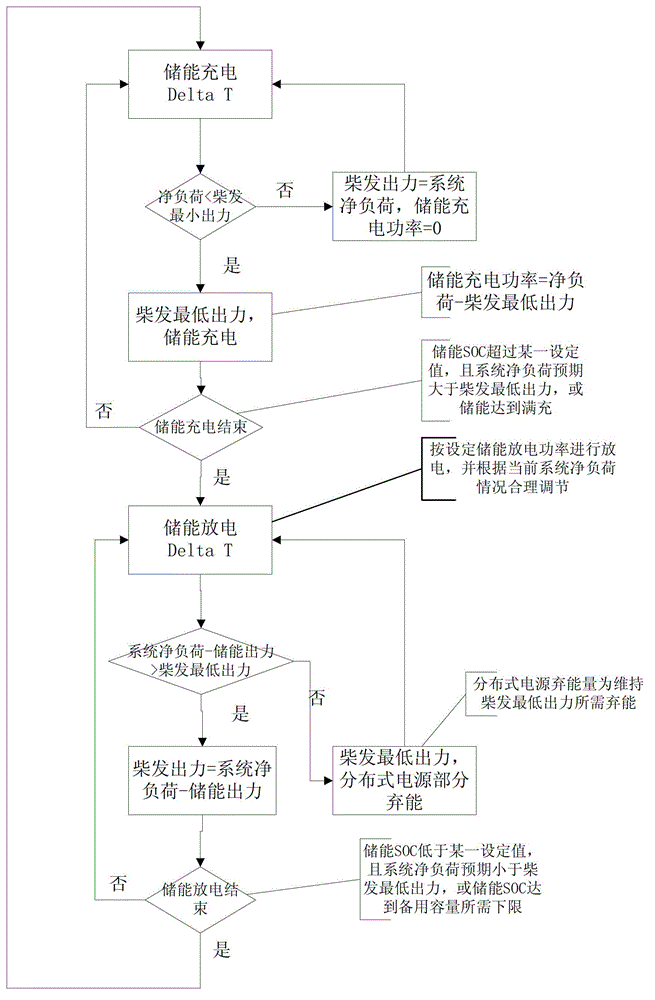

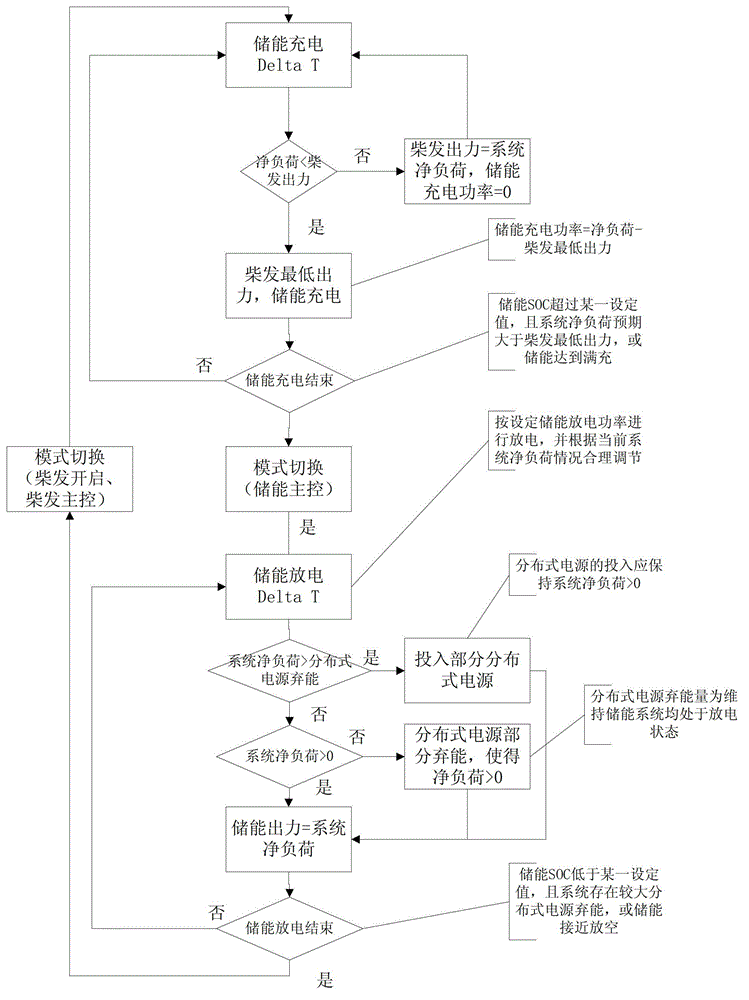

Control method for diesel and stored energy coordination of intelligent micro-grid

ActiveCN102916486ASolving Stability Control IssuesImprove stability and securityEmergency power supply arrangementsAutomotive engineeringPower grid

The invention belongs to the technical field of an intelligent micro-grid for an electric power system, and relates to a control method for diesel and stored energy coordination of the intelligent micro-grid. Diesel and stored energy coordination is controlled in two modes. In the first mode, diesel and stored energy do not switch with each other, a diesel power generator serves as a main power supply of the system, and the stored energy functions in a PQ manner. In the second mode, the diesel and the stored energy switch, the stored energy functions in the PQ manner when the diesel power generator serves as the main power supply; when the stored energy charges to be the upper limit of SOC(super capacitor state of charge), the main power supply is switched from the diesel power generator into a stored energy system, then the stored energy functions in a VF manner; and when the stored energy discharges to be the lower limit of the SOC, the main power supply is switched into the diesel power generator from the stored energy system. By the control method, problems about steady-state control of the micro-grid are solved, new-energy utilization rate and running economic effect can be improved effectively, and safety and stability of the micro-grid in running are improved.

Owner:ELECTRIC POWER RESEARCH INSTITUTE, CHINA SOUTHERN POWER GRID CO LTD

Automatic welding device for battery top cover

PendingCN107570869ACompact layoutAdd action functionLaser beam welding apparatusAction functionEngineering

The invention relates to an automatic welding device for a battery top cover. The automatic welding device for the battery top cover comprises a conveying device, a feeding device, a laser welding device, a clearing device, a detecting device and a rubberizing device; the conveying device comprises an annularly closed conveying belt which is provided with a clamping device; and the feeding device,the laser welding device, the clearing device, the detecting device and the rubberizing device are arranged on corresponding stations on the outer side of the conveying belt correspondingly. Automatic feeding and discharging are adopted for the automatic welding device for the battery top cover, in combination with an automatic assembling production mode of a cyclic flow channel, the whole machine arrangement is compact, space is saved, and maintaining operation is facilitated; and the action functions of a whole machine device are increased, all station actions are linked compactly, the manual participation degree is low, and the machine table automation degree and the safety and stability of the whole machine device are improved.

Owner:海目星(江门)激光智能装备有限公司

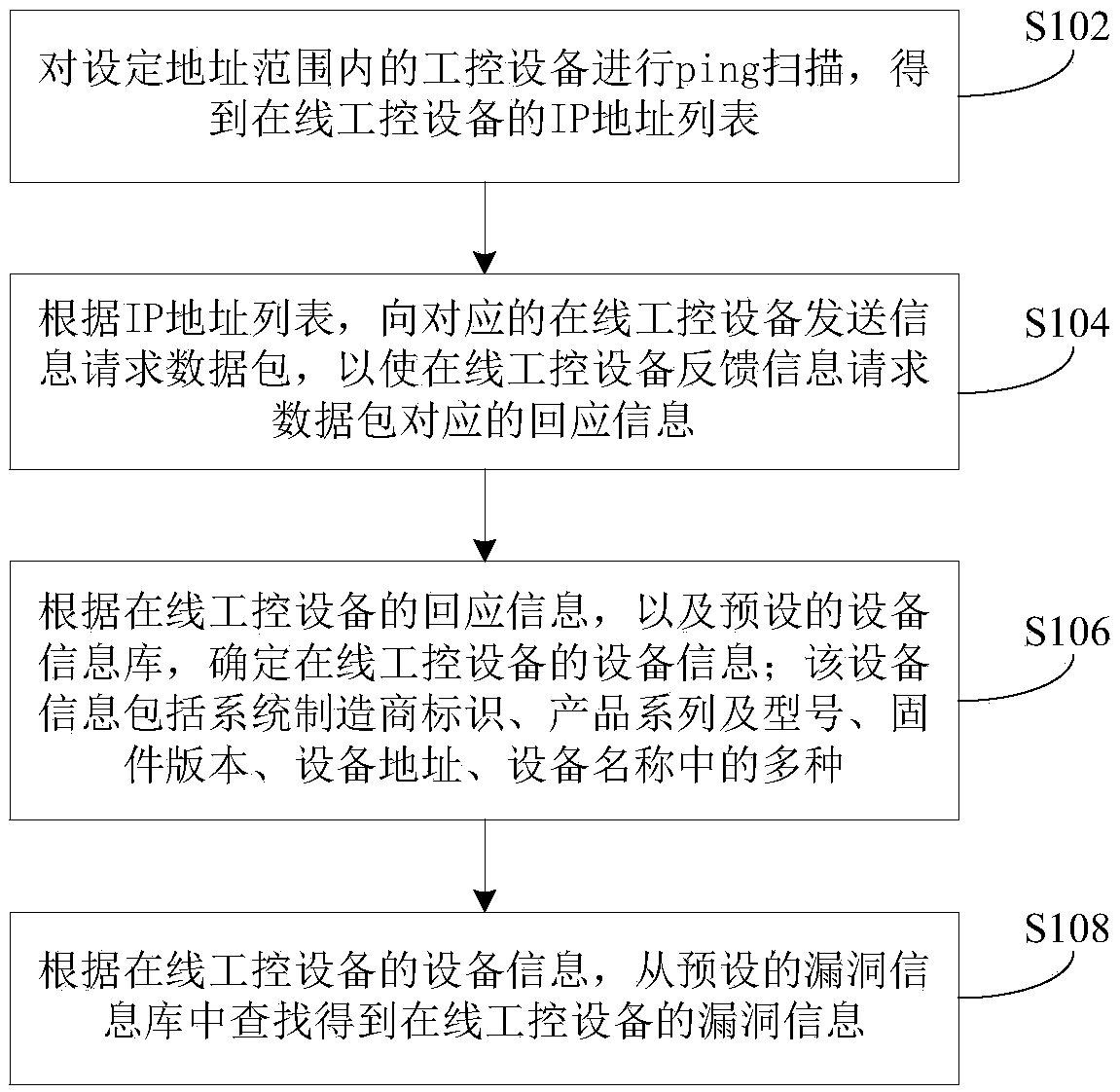

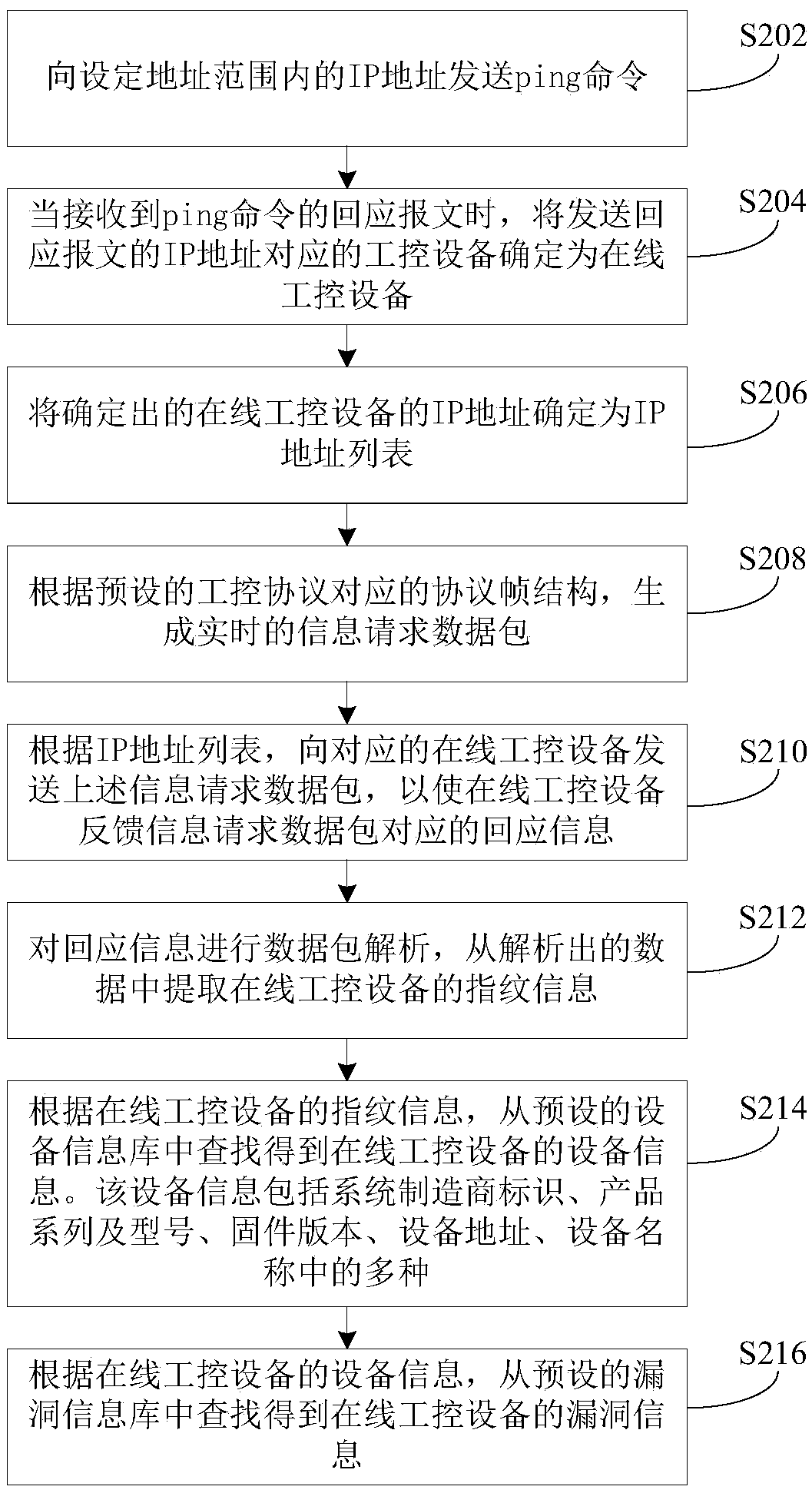

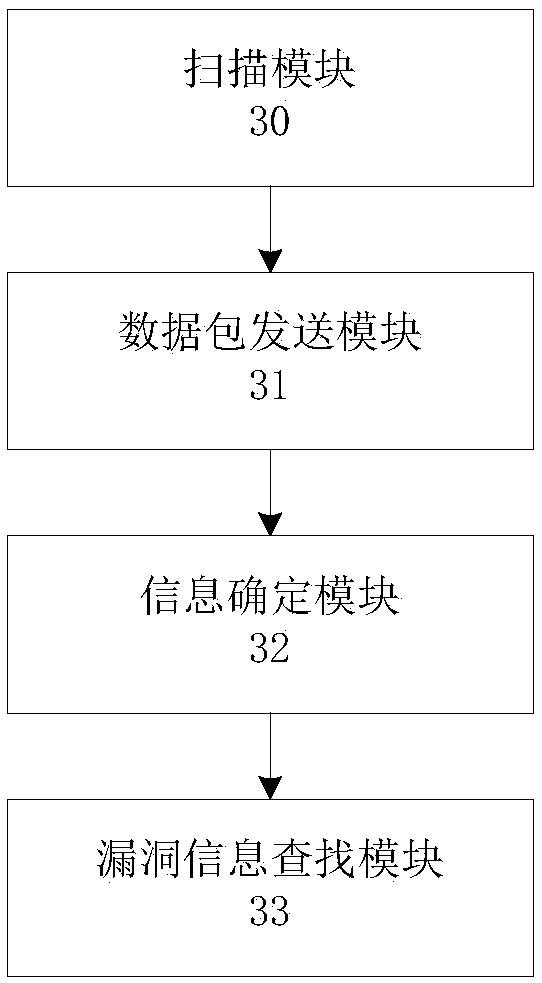

Security vulnerability detection method and apparatus based on industrial control system

InactiveCN108696544AGood practicalityImprove stability and securityTransmissionVulnerability detectionIp address

The invention provides a security vulnerability detection method and apparatus based on an industrial control system. The method comprises the following steps: performing ping scanning on industrial control devices within a set address range to obtain an IP address list of online industrial control devices; sending information request data packets to the corresponding online industrial control devices according to the IP address list; determining the device information of the online industrial control devices according to the response information of the online industrial control devices and apreset device information base, wherein the device information comprises multiple of a system manufacturer identifier, product series and model numbers, a firmware version, a device address and a device name; and searching for the vulnerability information of the online industrial control devices from a preset vulnerability information base. By adoption of the security vulnerability detection method and apparatus provided by the invention, the industrial control devices can be comprehensively and effectively detected in an active scanning manner, the practicability is relatively good, and thevulnerability information of different types of devices are searched, so that the safety and stability of the industrial control devices are improved.

Owner:HANGZHOU ANHENG INFORMATION TECH CO LTD

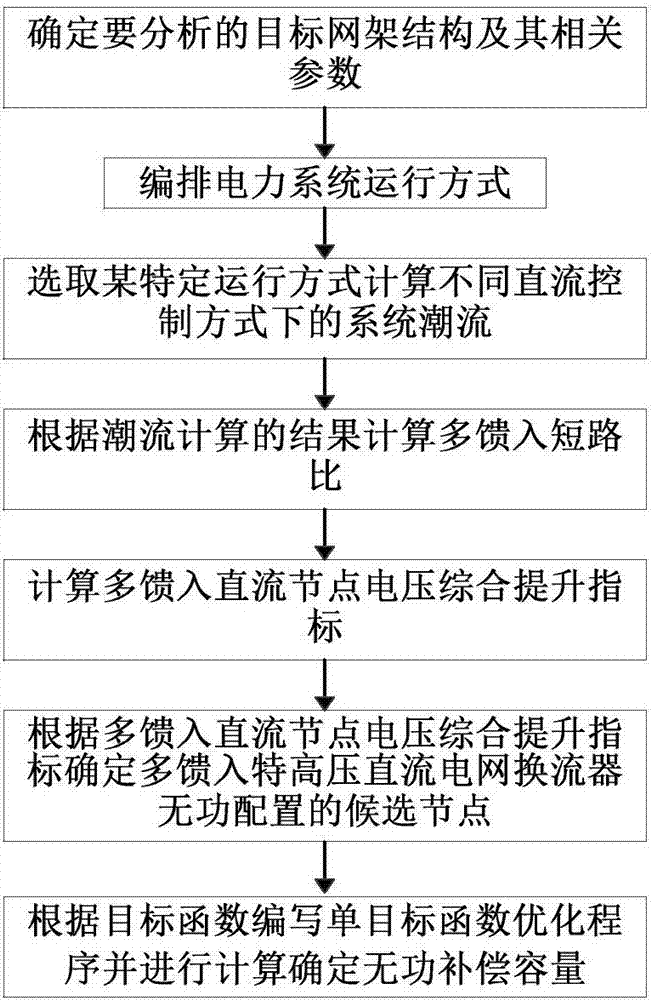

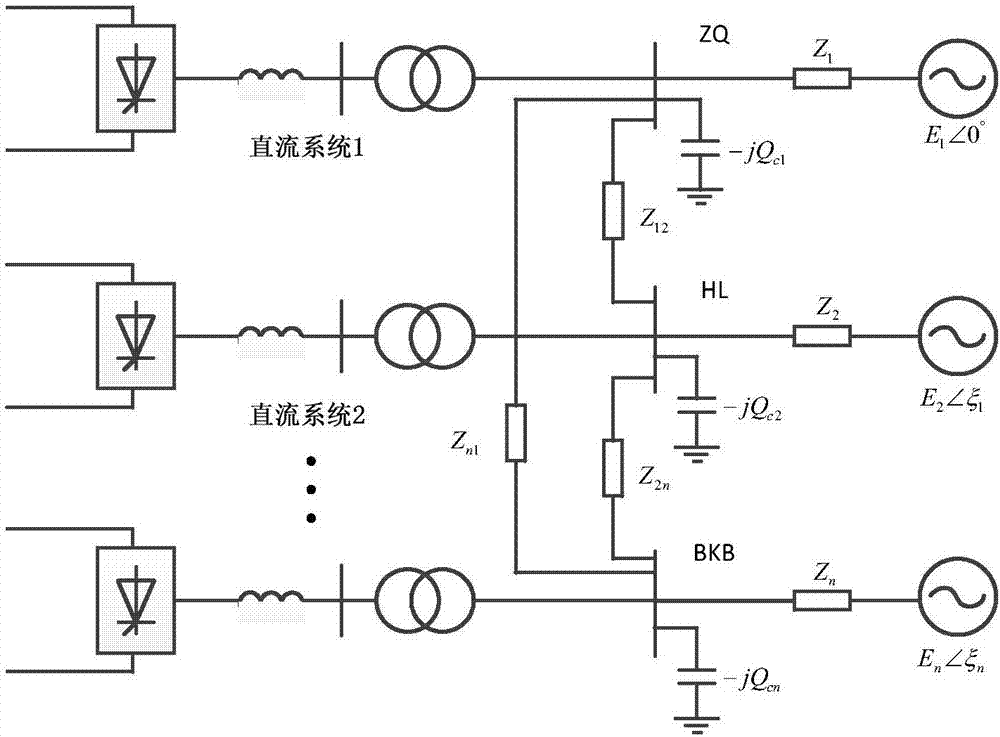

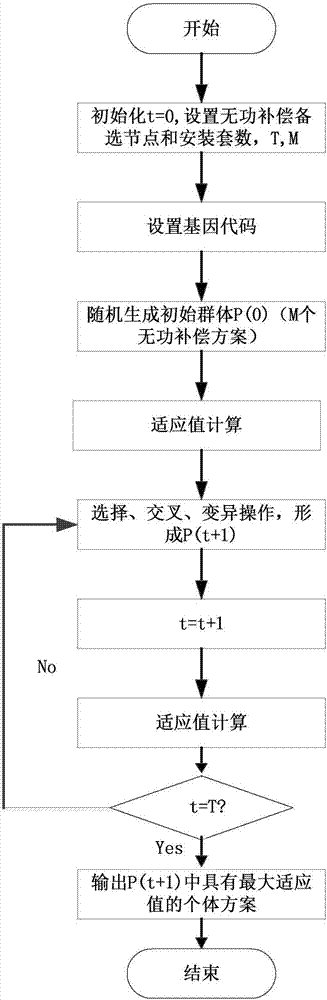

Extra-high voltage power grid transverter wattless configuration method based on short-circuit ratio

InactiveCN107134799AGuaranteed uptimeImprove stability and securityElectric power transfer ac networkReactive power adjustment/elimination/compensationFunction optimizationElectric power system

The invention discloses a multi-infeed extra-high voltage power grid transverter wattless configuration method based on a short-circuit ratio. The extra-high voltage power grid transverter wattless configuration method comprises steps of 1) determining an object grid structure to be analyzed and related parameters, 2) arranging operation modes of an electric power system, 3) selecting a specific operation mode to calculate system load flows under different DC control modes, 4) calculating a multi-infeed short circuit ratio according to a load flow calculation result, 5) calculating a multi-infeed DC node voltage comprehensive improvement index, 6) determining a candidate node of the multi-infeed extra-high voltage DC power grid transverter wattless configuration n according to the multi-infeed DC node comprehensive improvement index, and 7) programming a single objective function optimization program according to an objective function to determine a wattless compensation capacity. The extra-high voltage power grid transverter wattless configuration method guarantees to reduce the operation cost of the power grid, guarantee the power grid to safely, reliably, economically, and efficiently operate, has significance and provides technical basis to planning design and operation control of the mmulti-infeed high voltage DC power grid.

Owner:STATE GRID CORP OF CHINA +3

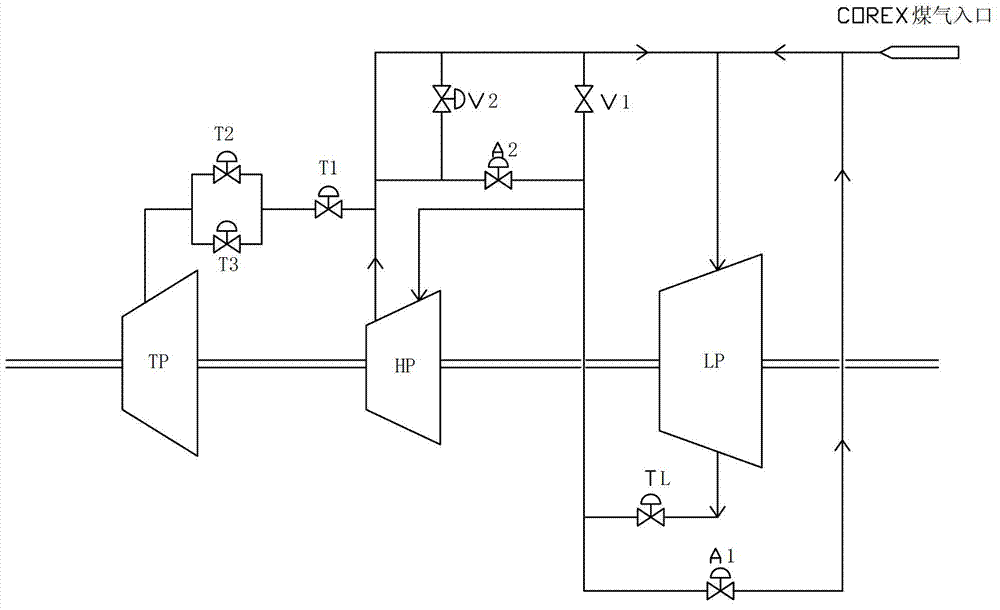

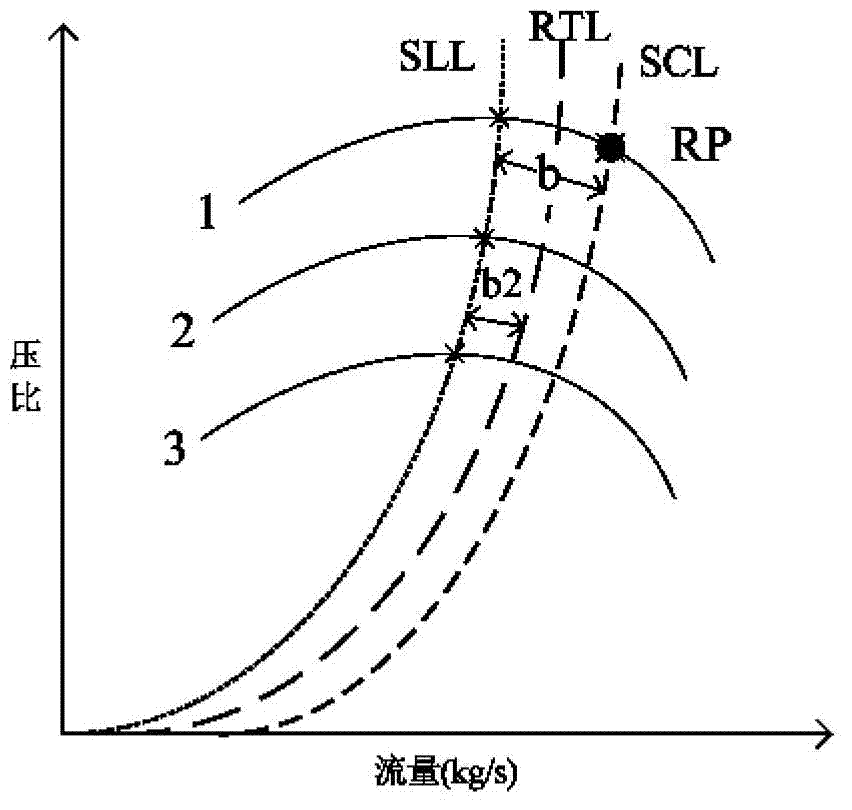

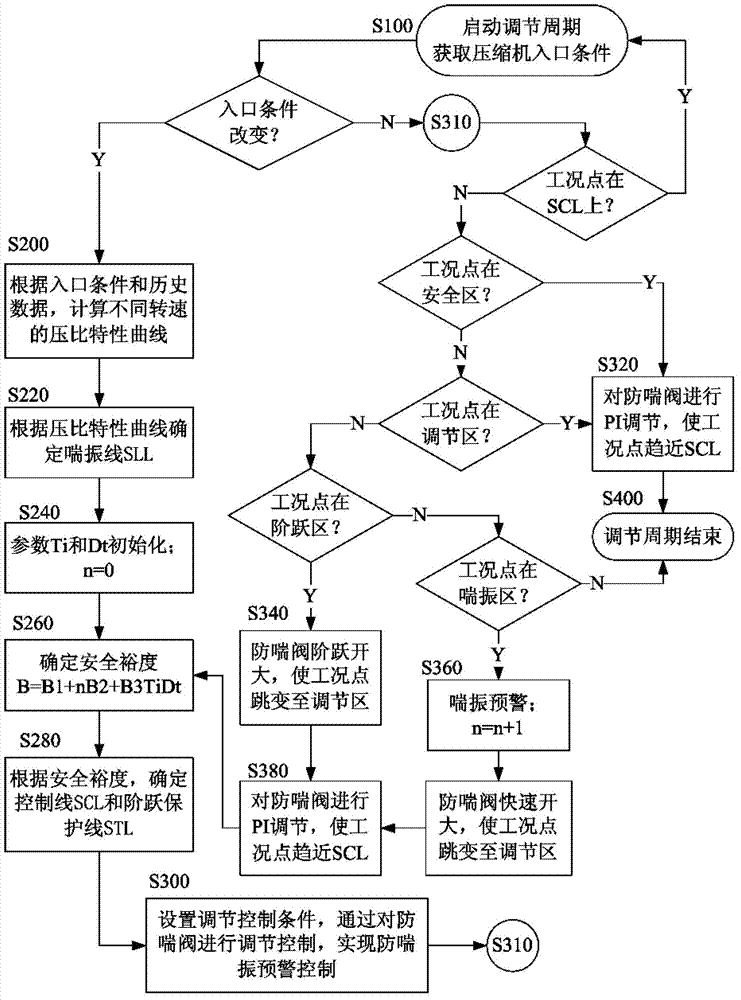

Anti-surge early warning control method of COREX gas compressor

ActiveCN102788004AEffective operating conditionsSolve the problem of high incidence of failurePump controlPositive-displacement liquid enginesFailure rateOperating point

The invention discloses an anti-surge early warning control method of a COREX gas compressor, and relates to control over gaseous fuel supply of a gas turbine and a device, in particular to an anti-surge detection, early warning and adjustment control method of the gas compressor of a CCPP (Combined Cycle Power Plant). The method comprises the following steps of: acquiring compressor inlet conditions through a CCPP monitoring system; determining safety margin, a surge line, a control line and a step protection line; if an operating point (RP) is positioned in a control region adjacent to the control line, linearly adjusting the opening of an anti-surge valve by using a PI adjustment algorithm; and if the operating point is positioned in a control region adjacent to the surge line SLL, performing step control over the opening of the anti-surge valve. According to the method, effective early warning and control adjustment functions can be effectively generated for the operating conditions of a low-voltage coal crusher and a high-voltage coal crusher of the CCPP and an operation state of the entire gas system, the problem of high failure rate of the COREX combined gas-steam combined cycle generating unit can be effectively solved, and the safety and the stability of the unit are improved.

Owner:BAOSHAN IRON & STEEL CO LTD

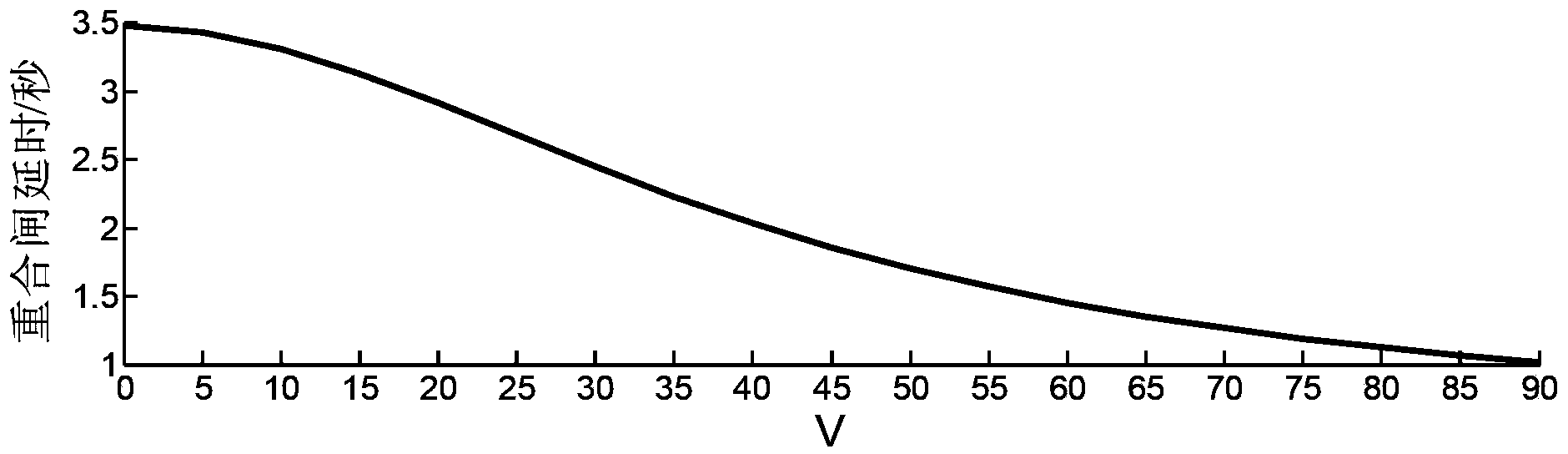

Method for protecting whole-line rapid-cutting and optimizing reclosure of current collection line

ActiveCN103414171ASolve the problem of low voltage ride through capacity demandFast power restorationEmergency protective arrangements for automatic disconnectionTime delaysLow voltage ride through

A method for protecting whole-line rapid-cutting and optimizing reclosure of a current collection line comprises the following steps that firstly, a three-phase current and a zero-sequence current of the protected current collection line of a wind power plant grid-connection transformer substation are measured; secondly, as for an interphase fault, protection configuration of current quick-break protection in the I-section direction is performed; thirdly, a busbar phase voltage of the wind power plant grid-connection transformer substation is measured and used for judging the fault direction; fourthly, as for a grounding fault, protection configuration of I-section zero-sequence current quick-break protection is performed; fifthly, the line is configured with automatic three-phase one-shot reclosure, as for a wind generation set grid-connection current collection line not having the low voltage ride through capability, reclosure is conducted once at 0.5s after the fault, and as for a wind generation set grid-connection current collection line having the low voltage ride through capability, reclosure is conducted once at a time delay t after the fault. The method for protecting whole-line rapid-cutting and optimizing reclosure of a current collection line can achieve rapid power service restoration of the line having a transient fault, lay a foundation for rapid and initiative grid connection of a wind generation set, and enhance safety and stability of a grid-connection electric power system.

Owner:TSINGHUA UNIV +1

Super-thick quenched and tempered steel plate with good obdurability matching, and manufacturing method thereof

ActiveCN101660100ASolve the problem of uneven strength and toughness in the thickness directionImprove stability and securityFurnace typesHeat treatment furnacesElectricitySheet steel

The invention relates to a super-thick quenched and tempered steel plate with good obdurability matching, which is manufactured by the following steps: adopting a component system of low C-Mn-(Ti+V+B)micro-alloyed steel as a basis to appropriately increase the content of acid soluble Als in the steel, wherein the Als is more than or equal to (Mn equivalent weight / C)*(Ntotal-0.292Ti); controllingthe ratio of (Mn equivalent weight) to C to between 10 and 30; alloying (Cu+Ni+Mo+Cr), wherein Ni / Cu is more than or equal to 1.5; performing Ca processing, wherein the ratio of Ca to S is between 0.80 and 3.00; controlling the F*DI index to be more than or equal to 0.50*the thickness of a finished steel plate and other metallurgy technological means; and performing optimization, crystallization and controlled rolling, and performing a quenching and tempering process (Q+T) so as to ensure that the microscopic structure of the finished steel plate is a tiny tempered bainite (probably containinga minute quantity of ferrite), and the average crystal group size is below 25 mum. Through the method, a large-scale steel structure, which has even and excellent obdurability / strong plastic matchingand is particularly suitable for water and electricity pressure water pipes, volutes, ocean platforms and the like, is obtained, and the stable mass industrial production with low cost can be achieved.

Owner:BAOSHAN IRON & STEEL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com