Steel plate HT690 capable of being subjected to high heat input welding and manufacturing method thereof

A large input energy welding and manufacturing method technology, applied in the direction of temperature control, rolling force/roll gap control, etc., can solve the problems of reduced welding efficiency, high steel plate manufacturing cost, and high welding cold crack sensitivity index

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

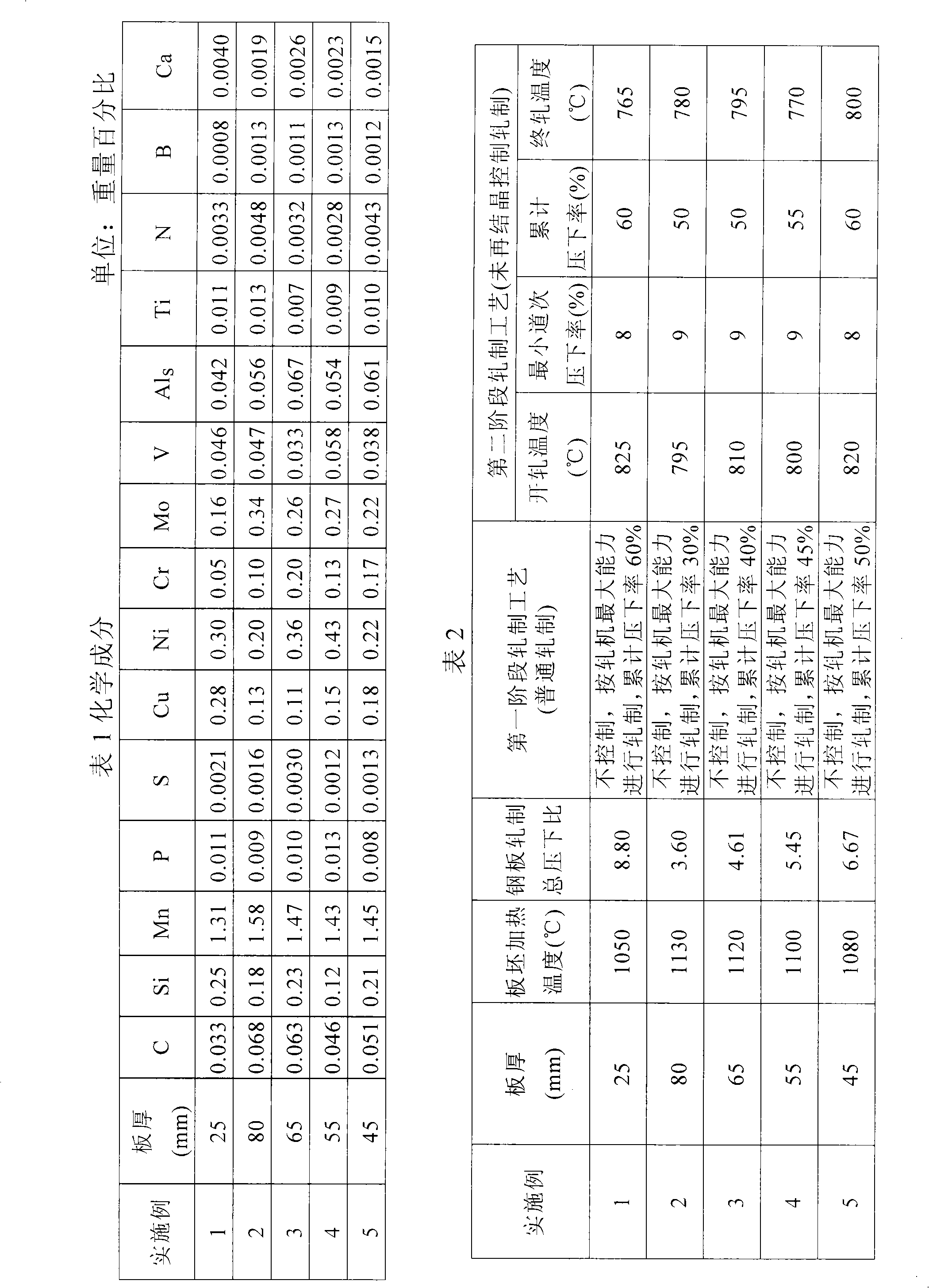

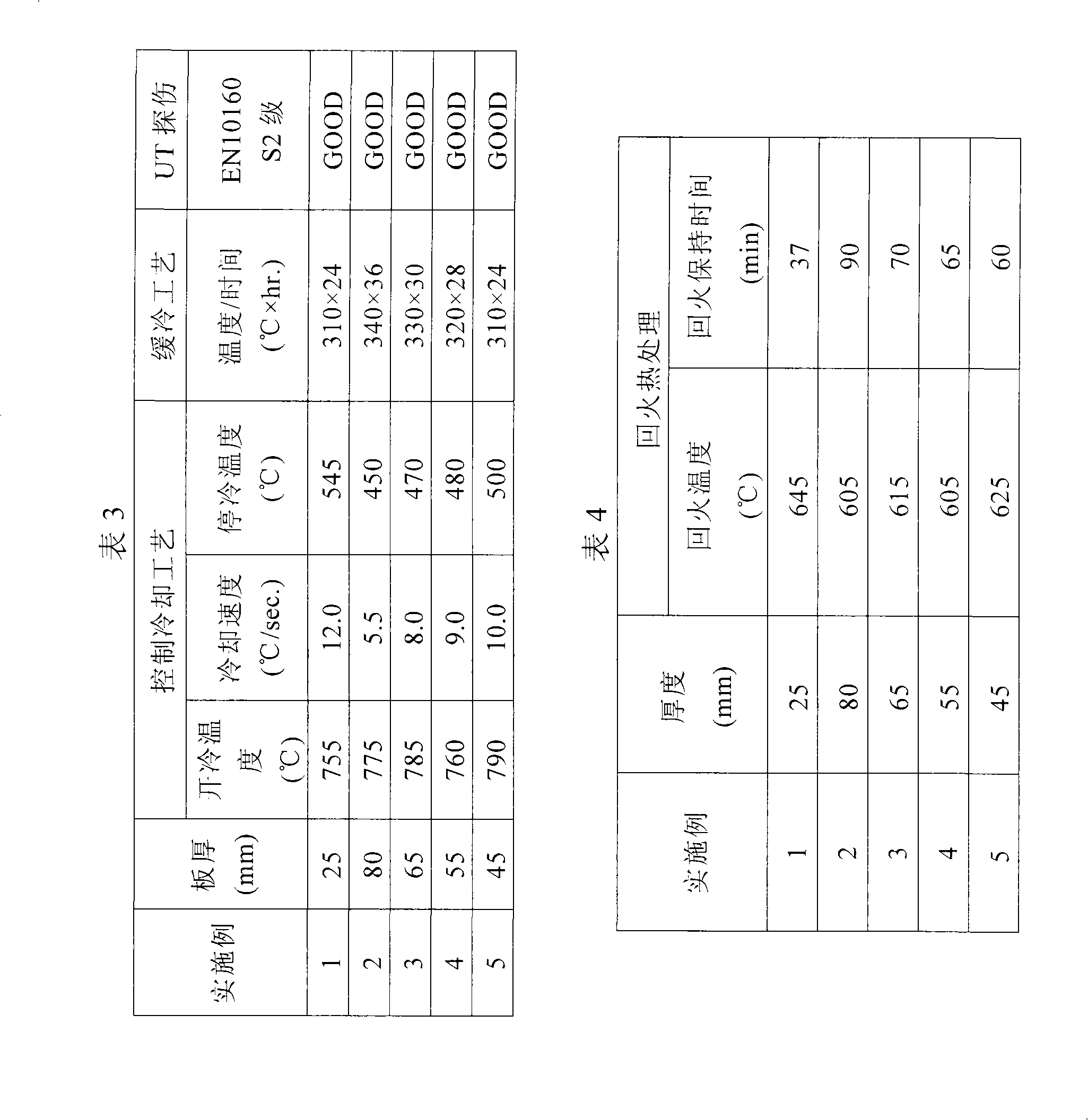

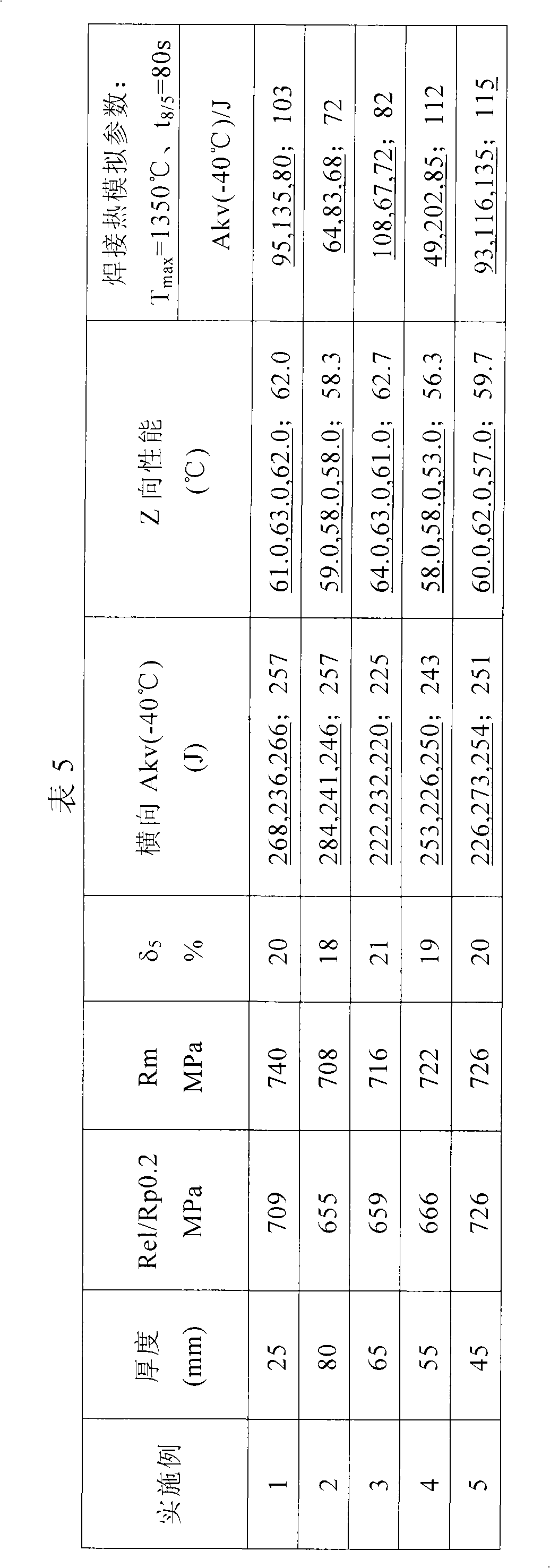

[0072] The present invention will be further described below in conjunction with embodiment.

[0073] Among them, Table 1 shows the chemical composition of the examples of the present invention, Table 2 to Table 4 show the manufacturing process of the examples of the present invention, and Table 5 shows the properties of the steel plates of the examples of the present invention.

[0074] It can be seen that the properties of the steel plate of the present invention can reach: yield strength ≥ 620MPa, tensile strength ≥ 690MPa, Charpy impact energy (single value) ≥ 47J at -40°C.

[0075] The steel plate of the present invention is designed through a simple composition combination, and in the composition system of low C-high Mn-high Als-(Cu+Ni+Mo+Cr) alloying-(Nb+V+B) microalloying-ultramicro Ti treatment, And through the TMCP + high-temperature tempering process, not only the TMCP steel plate with excellent comprehensive performance is produced at low cost, but also the manufac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com