Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

141results about How to "High precision of pressure control" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

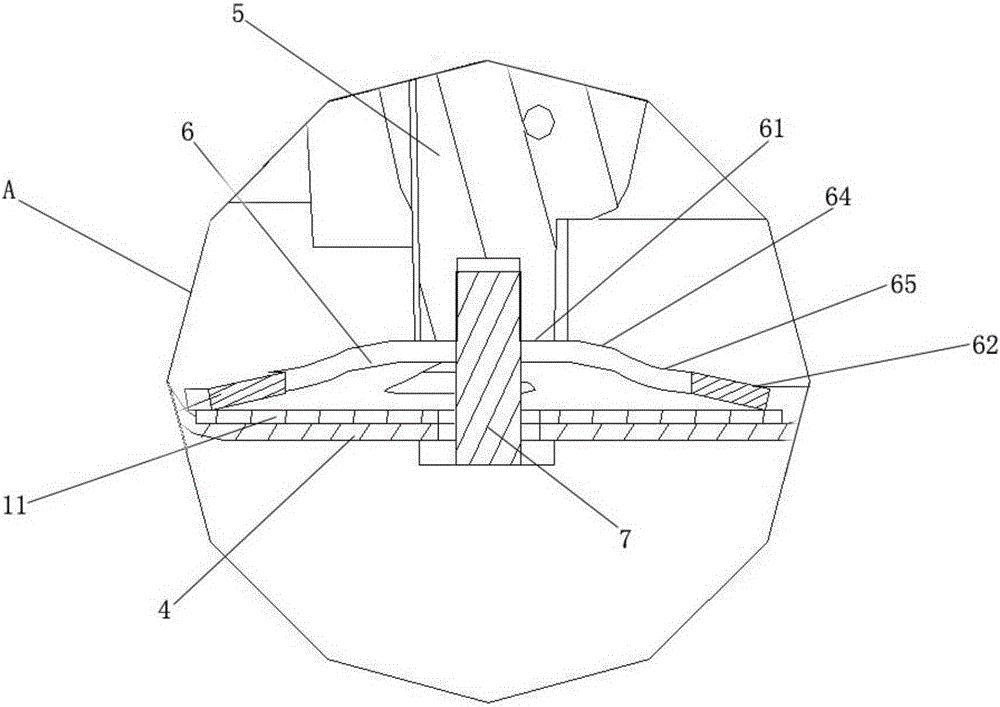

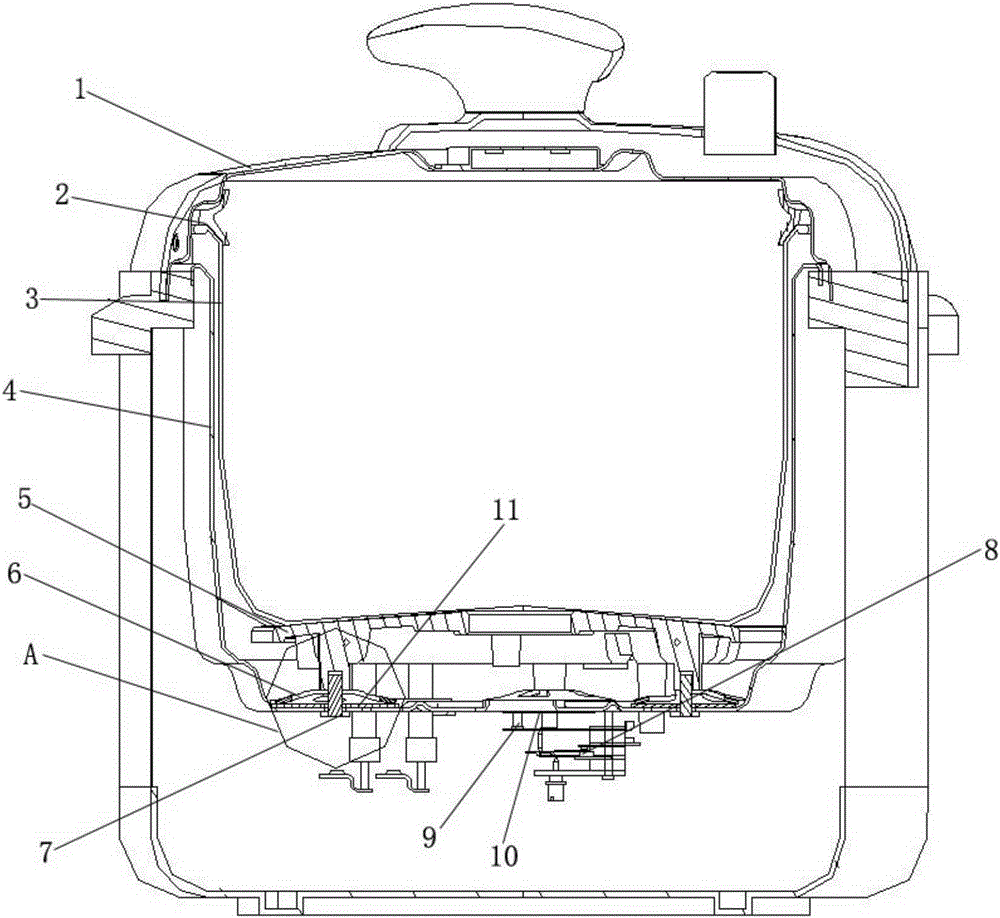

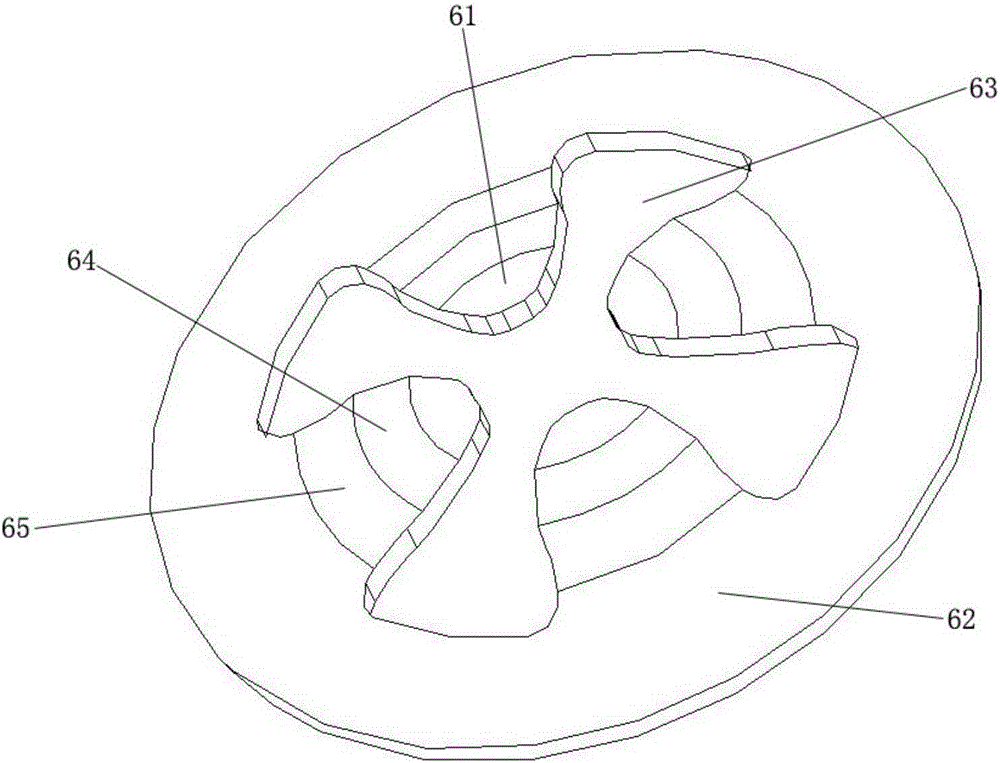

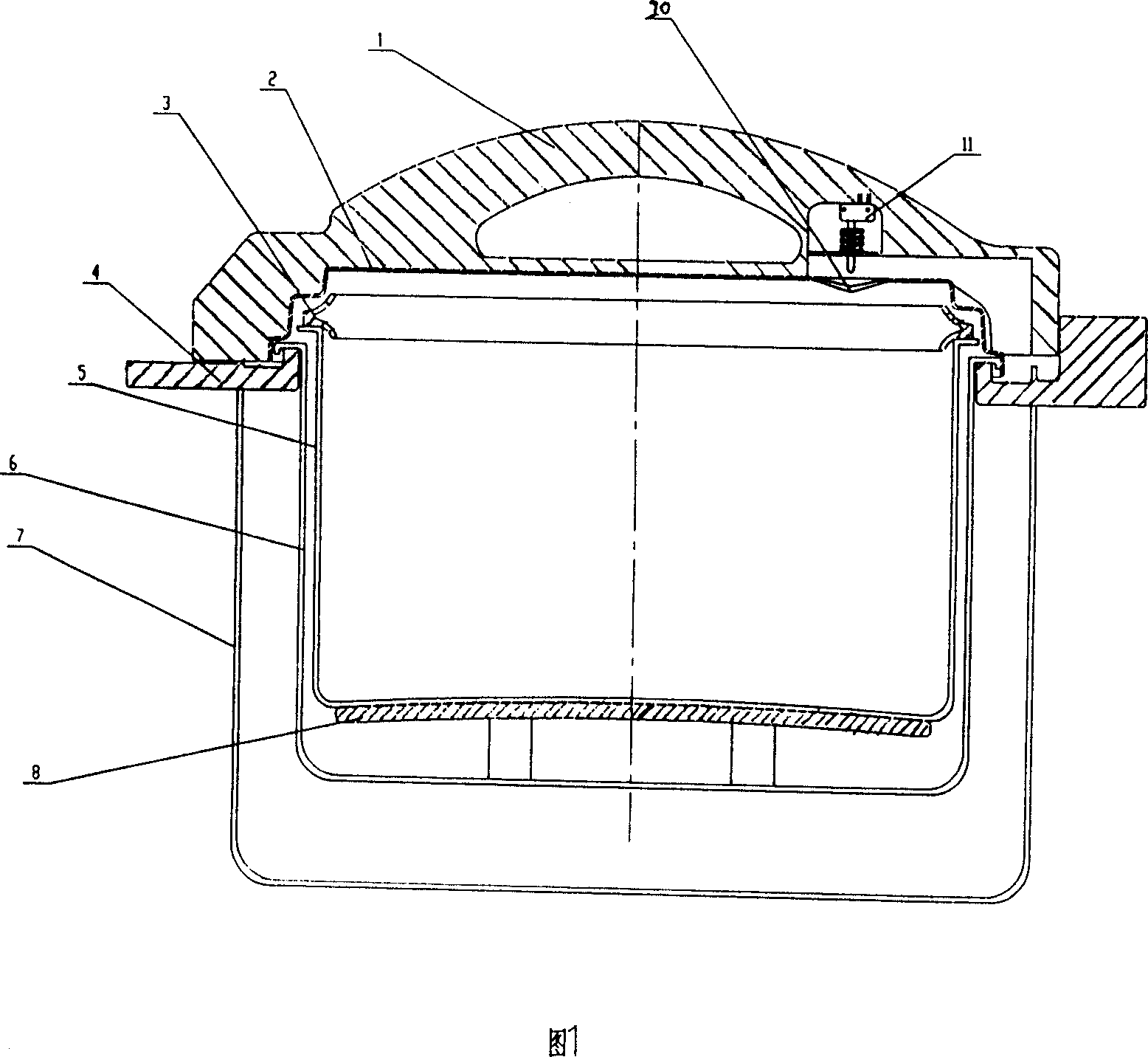

Pressure-control type electric pressure cooker

ActiveCN105286498AImprove stability and securitySimple structurePressure-cookersEngineeringPressure controlled ventilation

The invention discloses a pressure-control type electric pressure cooker. A sealed body is formed by sequentially connecting a pot cover, a seal ring, an inner pot and an outer pot; a plurality of belleville springs, which are provided with opening grooves, are arranged between a heating plate and the outer pot; upper supporting rings are formed by horizontally flanging the small-diameter ends of the belleville springs towards inner sides, and lower supporting rings are formed by the big-diameter ends of the belleville springs; an elastic deformation area is formed by a conical wall parts between each of the upper supporting rings and each of the lower supporting rings; the elastic deformation areas penetrate through the upper supporting rings in a radial direction and extend to conical body parts, and the opening grooves that contour lines projected on a horizontal plane are in a cross form are formed; the opening grooves are of gradually expanded structures with upsides smaller than downsides from openings to bottoms; the lower supporting rings are supported on the bottom of the outer pot; the upper supporting rings are propped against supporting legs of the heating plate; and the supporting legs and the belleville springs are integrally positioned with and connected to the outer pot by virtue of fixed screws. The amount of elastic deformation of the electric pressure cooker is effectively improved by virtue of the belleville springs, and the change in induction pressure of a pressure detection device is more conveniently to be detected, so that the precision and the safety stability of pressure control are improved.

Owner:HANGZHOU YONGYAO TECH

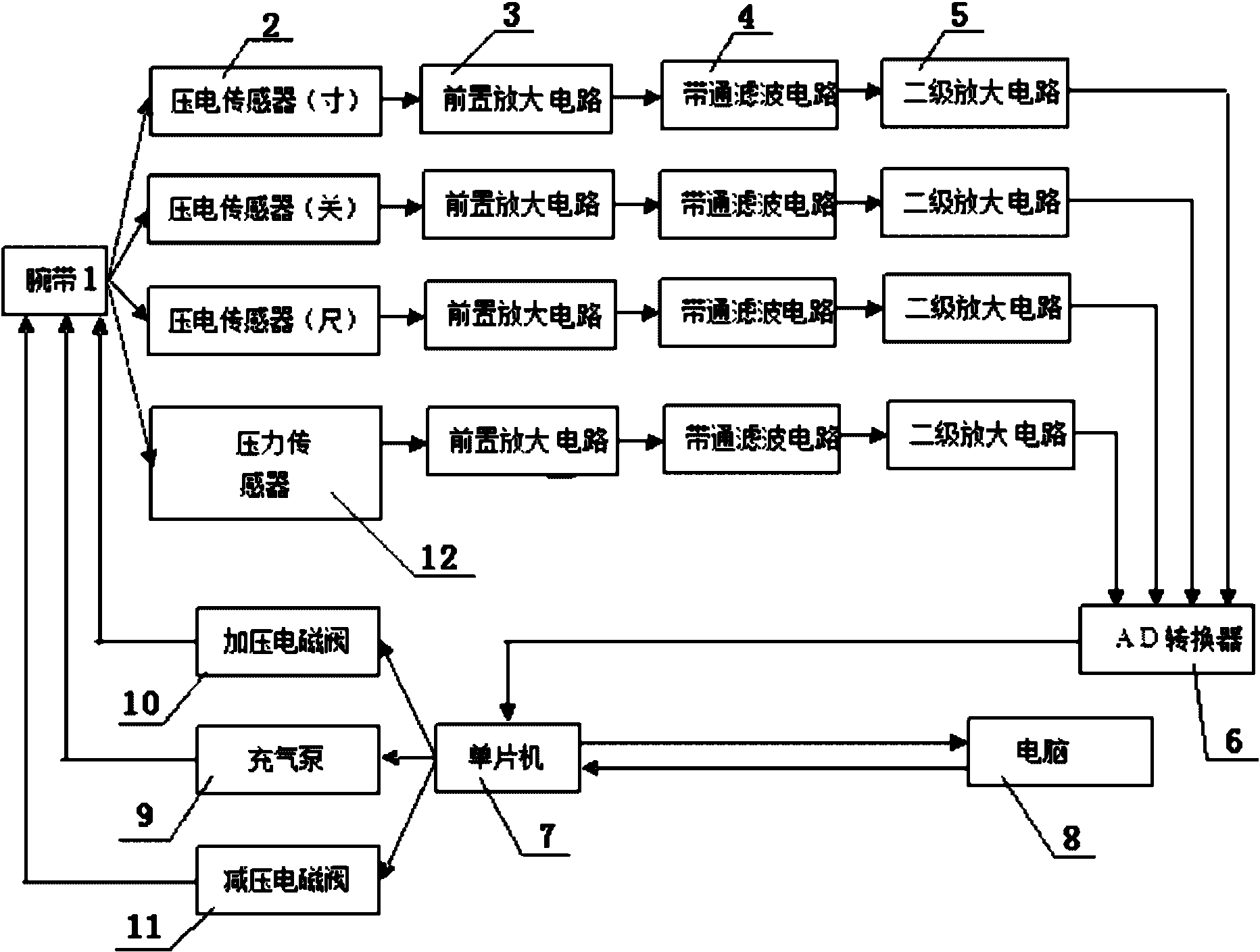

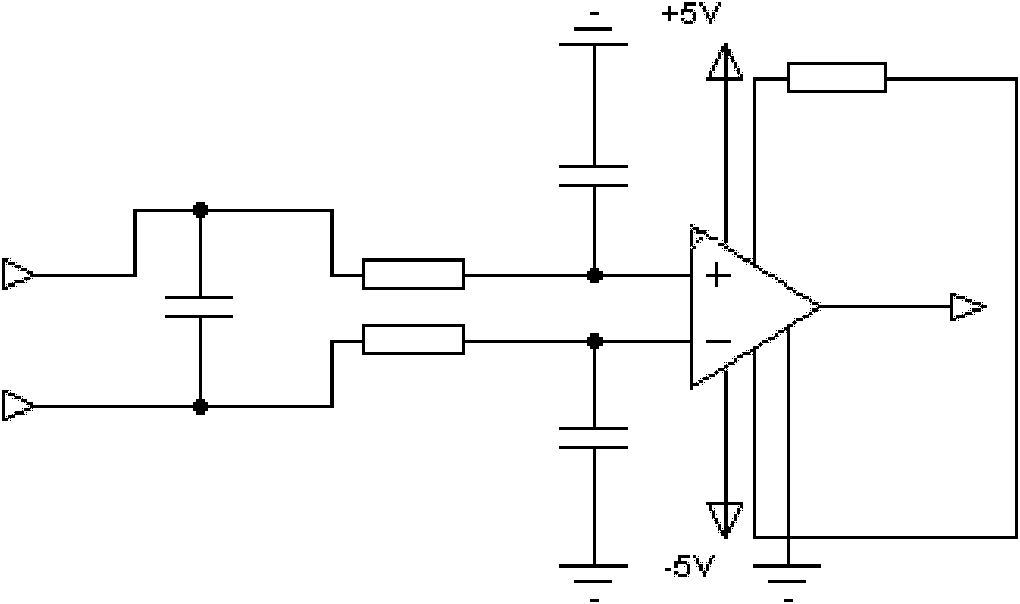

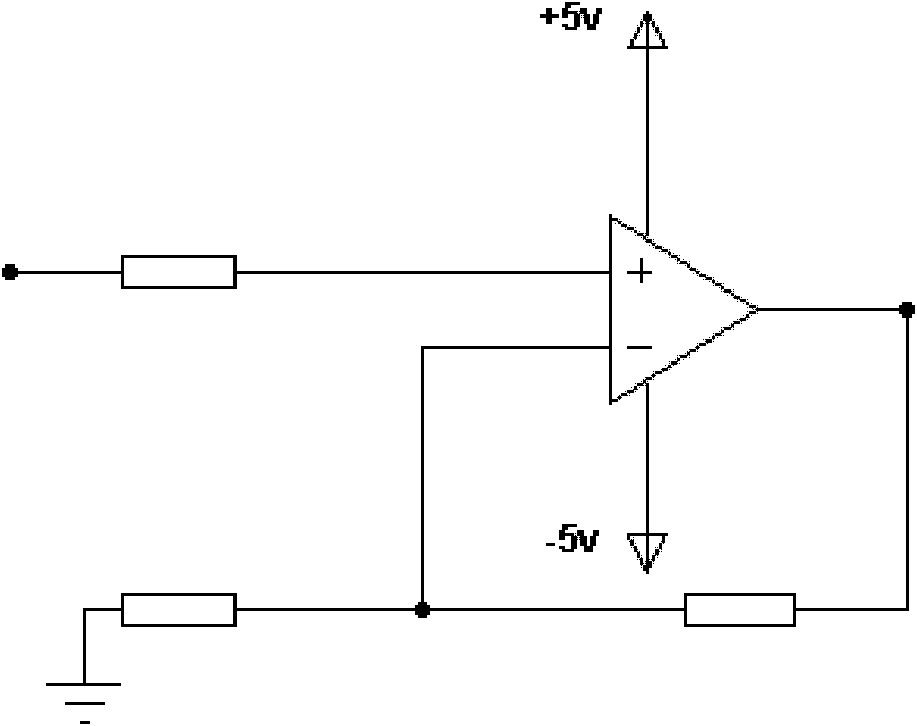

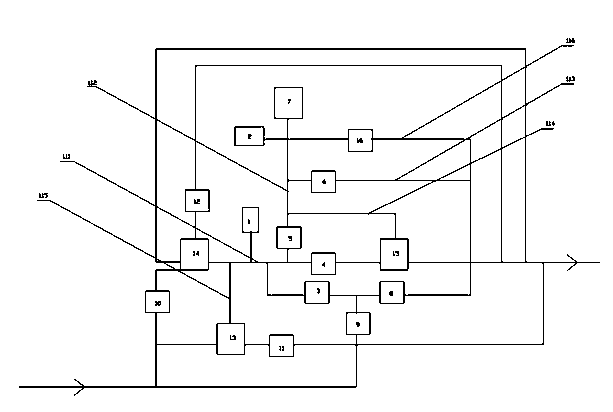

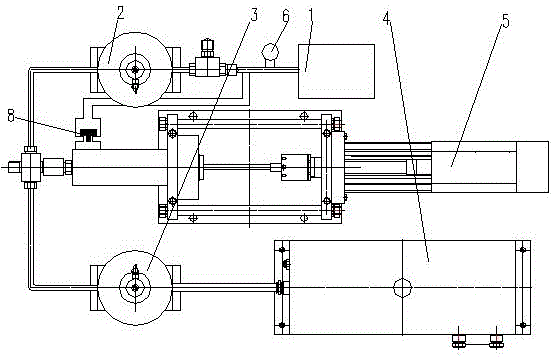

Multi-channel pulse signal detecting method and device capable of automatically regulating pressure

InactiveCN102144916ARealize multi-point acquisitionHigh precision of pressure controlCatheterMicrocontrollerPulse characteristics

The invention relates to a multi-channel pulse signal detecting method and device capable of automatically regulating pressure. The method comprises the following steps: 1) sticking wrist bands with a cun-pulse sensor, a guan-pulse sensor and a chi-pulse sensor on a wrist respectively; 2) collecting pulse signals under collecting pressures of light, medium and heavy, and transmitting the signals to a signal regulating circuit; 3) converting the pulse signals which are processed by the signal regulating circuit into digital signals, and storing the digital signals in a singlechip; and 4) transmitting the digital signals to a computer by the singlechip, displaying a real-time pulse signal curve by the computer, and performing pulse cycle identification and pulse characteristic extraction onthe pulse signal curve to complete the pulse signal detection. The device comprises the wrist bands, the cun-pulse sensor, the guan-pulse sensor, the chi-pulse sensor, a pressure sensor, the signal regulating circuit, an analog / digital (A / D) converter, the singlechip, the computer and a pressurizing module. Compared with the prior art, the device has the advantages of low power consumption, high pressure control accuracy, multi-pulse position integral representation and the like.

Owner:EAST CHINA UNIV OF SCI & TECH

Brake-by-wire system of automobile

ActiveCN103010199AEliminate bad effectsOptimize layoutBraking action transmissionHydraulic control unitElectric machinery

The invention relates to a brake-by-wire system of an automobile and belongs to the technical field of automobile brake systems. In the brake system, a vacuum booster of the traditional vacuum booster hydraulic brake system is replaced with a motor, and a piston in a brake main cylinder is pushed to move to generate brake hydraulic pressure, so that dependence on vacuum degree of an engine is canceled; through the adoption of a pedal simulator, influences on feelings of a brake pedal during coordinated control of feedback and brake are eliminated; a hydraulic control unit of the traditional brake system is kept to implement hydraulic adjustment; and as a standby hydraulic brake system is integrated, braking with certain strength can be implemented by a driver under a situation that the power supply of the system is ineffective. Compared with the traditional distributed brake-by-wire scheme, the brake-by-wire system provided by the invention has the advantages as follows: the structure is changed when compared with the structure of the traditional vacuum booster hydraulic brake system, the system can be mounted on the automobile more conveniently, and more existing technologies in the traditional brake system can be succeeded in the control aspect.

Owner:TSINGHUA UNIV

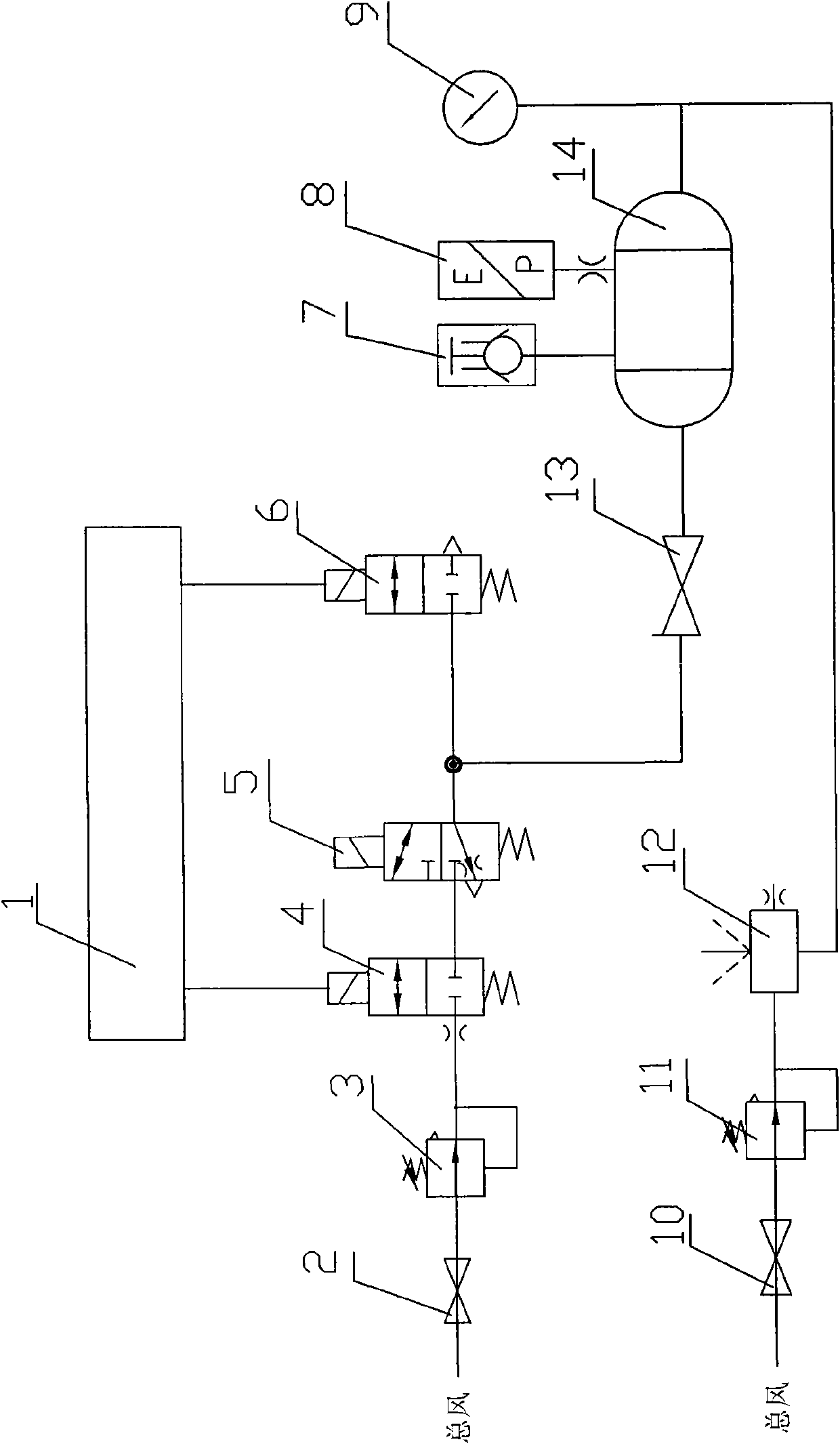

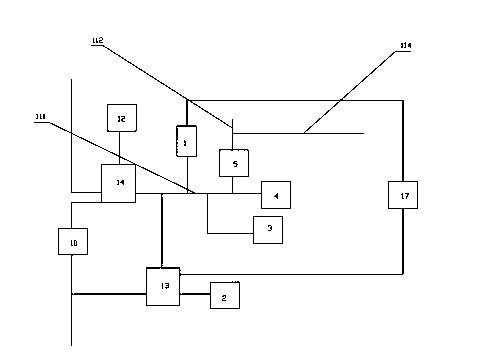

Pressure control device for equalizing reservoir of motor vehicle

InactiveCN101767583AHigh precision of pressure controlHigh control precisionBraking action transmissionElectricityProportional control

The invention discloses a pressure control device for an equalizing reservoir of a motor vehicle. The pressure control device comprises a closed-loop main control part and a backup control part, wherein the closed-loop main control part comprises a pressure sensor, an air inlet branch, an air exhaust branch and a proportion controller; the pressure sensor is connected into the equalizing reservoir; the air inlet branch is formed by the serial connection of a main air control cock, a pressure regulating valve, an air inlet high-speed electropneumatic valve and a conversion valve in sequence; the main air control cork is connected with a main air delivery outlet, and the conversion valve is connected into the equalizing reservoir. The air exhaust branch is composed of an air exhaust high-speed electropneumatic valve and a conversion valve connected into the equalizing reservoir. The air inlet high-speed electropneumatic valve and the air exhaust high-speed electropneumatic valve are respectively connected with the control end of the proportion controller, and the signal input end of the proportion controller is connected with the output end of the pressure sensor. The backup control part comprises a control cork, a pressure regulating valve and a backup brake valve which are sequentially connected in series; the control cork is connected with the main air delivery outlet, and the backup brake valve is connected into the equalizing reservoir. The pressure control device carries out closed loop control on the pressure of the equalizing reservoir and has high controlling precision, and meanwhile adopts redundancy control on the pressure of the equalizing reservoir so as to improve the controlling reliability; the equalizing reservoir can automatically reduce pressure and discharge air to carry out automatic protection when system failure or power failure occurs, so that the safety of the motor vehicle can be improved.

Owner:ZHUZHOU ELECTRIC LOCOMOTIVE CO

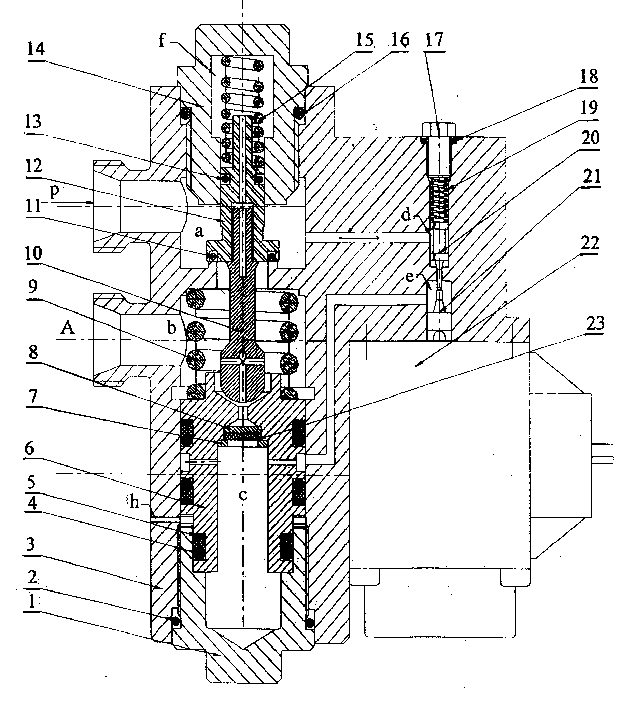

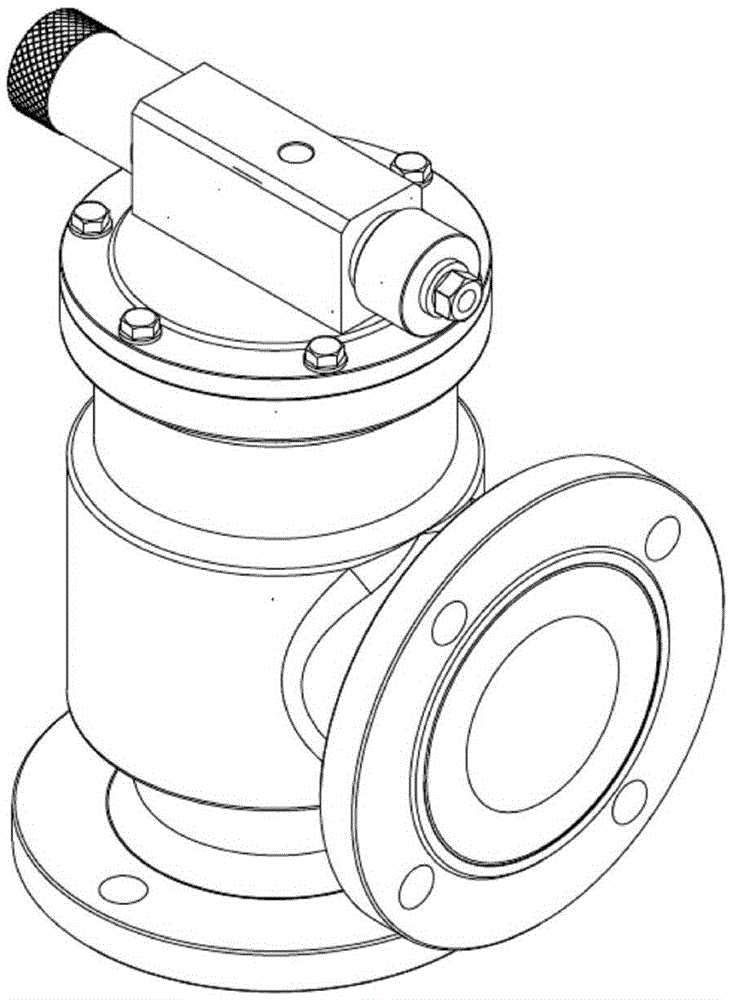

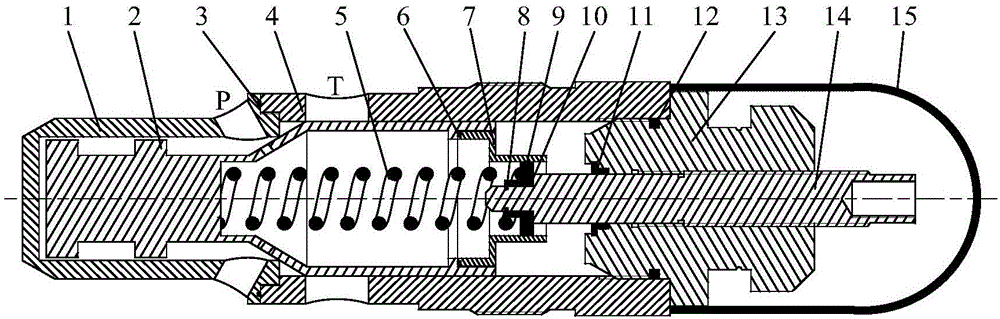

Super high pressure air-actuated proportional pressure-reducing valve

The present invention discloses an extra high pressure pneumatic proportional reducing valve, and it is characterized by that it adopts proportional pilot valve and electric feedback technique to implement full automatic pressure control, save human resources and raise reaction speed. Its main valve adopts gas pressure control, regulated pressure is high, the designed maximum input pressure can be up to 40 MPa, and output pressure is 0-25 MPa, and said pressure can be continuously regulated. Its pilot-level gas circuit adopts C-type semibridge structure, the pilot valve controlled by proportional electromagnetic iron is formed into the dynamic damping of input end, the damping plate can be used as fixed damping of output end. The input end of pilot valve is led from air inlet end of reducing value, and its output end is connected with air outlet end of the reducing valve. After the system is powered off, the pilot valve and main valve can be automatically closed by action of reset spring and gas pressure.

Owner:ZHEJIANG UNIV

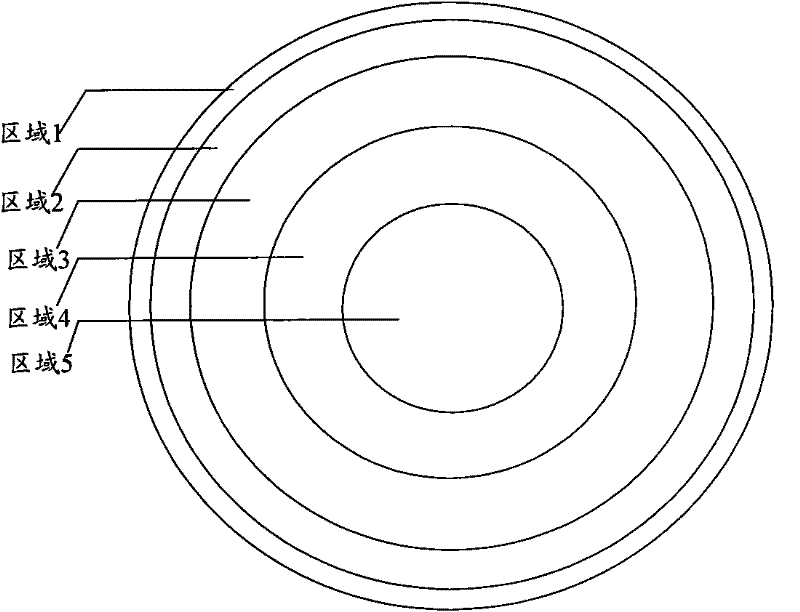

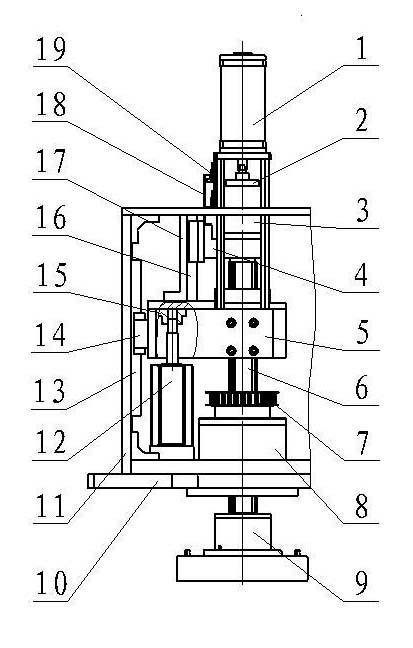

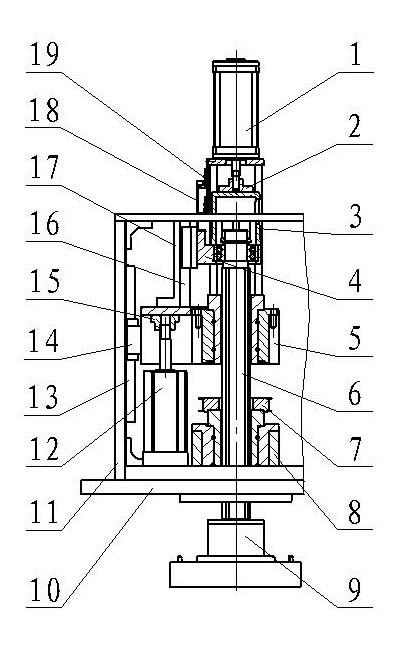

Grinding head and chemical mechanical grinding machine table

InactiveCN102294646AImprove uniformityImprove grinding uniformityLapping machinesCircular surfaceBiomedical engineering

The invention provides a grinding head, the surface in contact with the wafer is circular, and the circular surface has more than 5 relatively independent areas, each area is connected with a corresponding pneumatic device, and the pneumatic device is used for each grinding head. Zones provide pressure. The present invention also provides a chemical mechanical polishing machine platform comprising the above-mentioned polishing head. The adoption of the device of the invention effectively improves the uniformity of grinding wafers.

Owner:SEMICON MFG INT (SHANGHAI) CORP +1

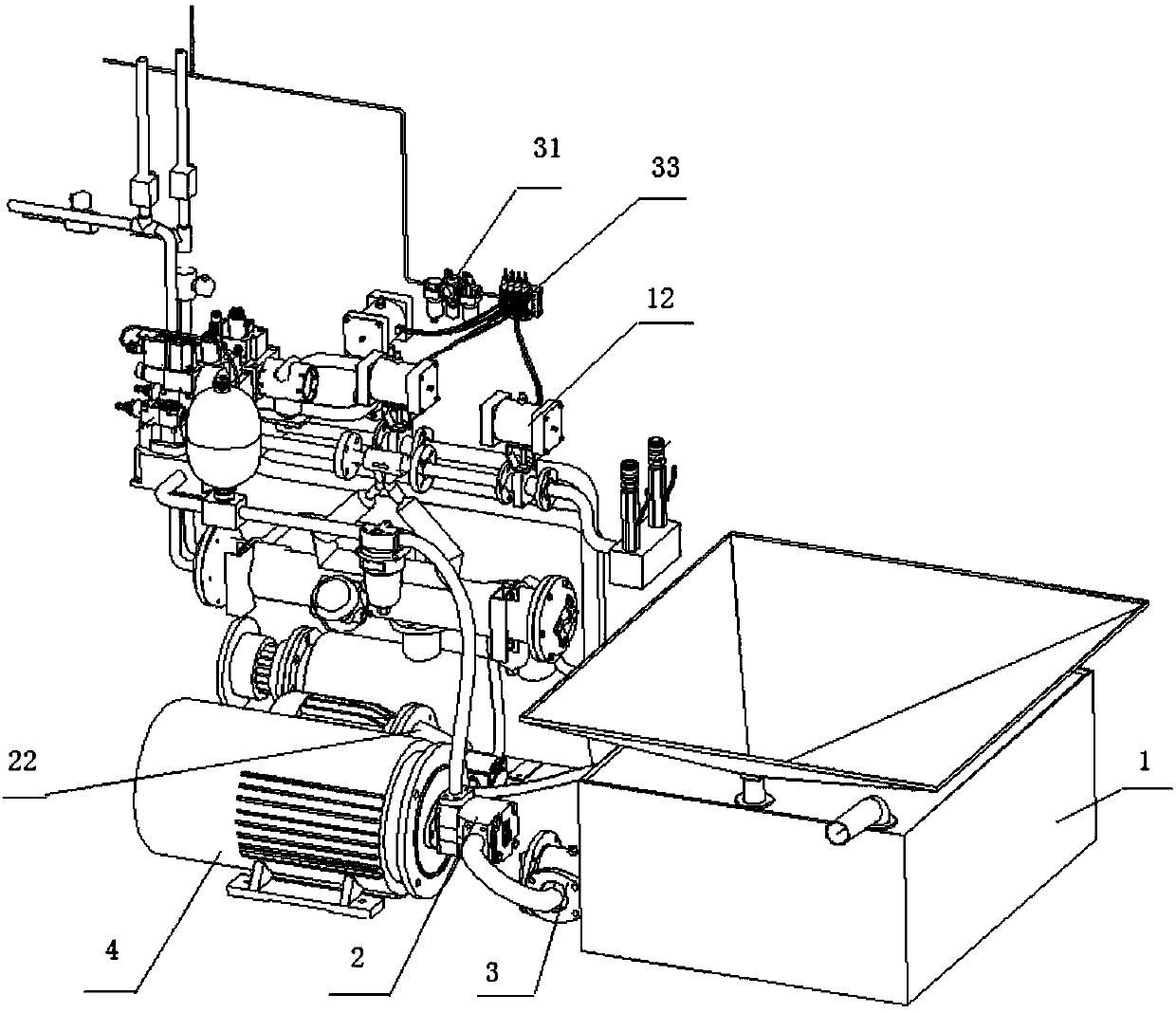

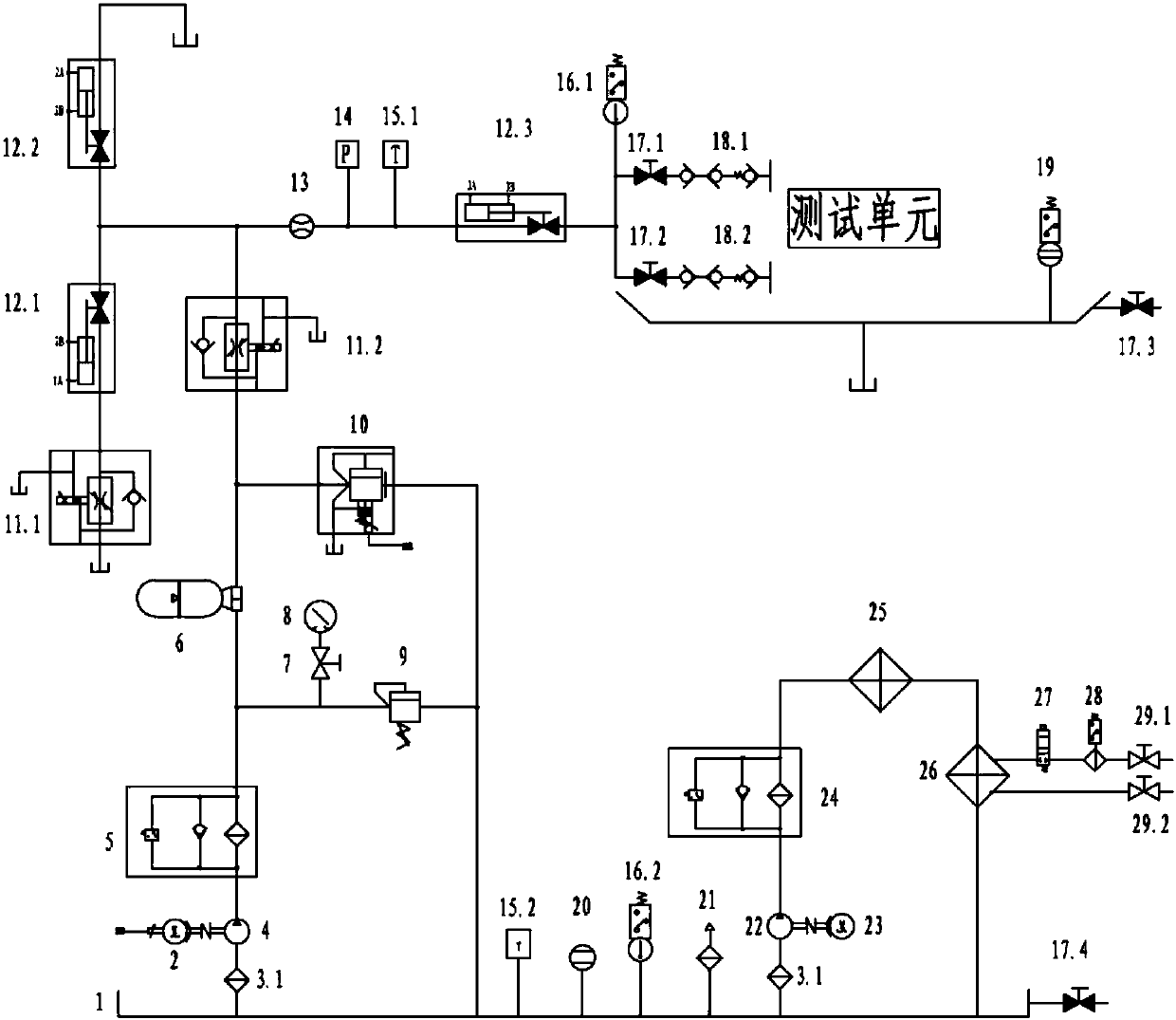

Valve body detection system of automatic gearbox

ActiveCN108051192APrecise control of pressure stabilityWide temperature range of test mediumMachine part testingSystem integrationLiquid temperature

The invention discloses a valve body detection system of an automatic gearbox. The detection system comprises a pneumatic and hydraulic system, a measuring and control system and a platform, and boththe pneumatic and hydraulic system and the measuring and control system are arranged in the platform; the pneumatic and hydraulic system is composed of a hydraulic subsystem and a pneumatic subsystem,and is used to provide a pressure, flow and temperature controllable test medium; and the measuring and control system is used for parameter adjustment, data collection and processing and distribution protection of the pneumatic and hydraulic system; and an operation control panel is arranged on the platform, and used to adjust the oil liquid temperature, working pressure and flow. Via the detection system, the temperature range of the test medium is wider, and the measuring precision and system integration degree are high.

Owner:NANJING CHENGUANG GRP

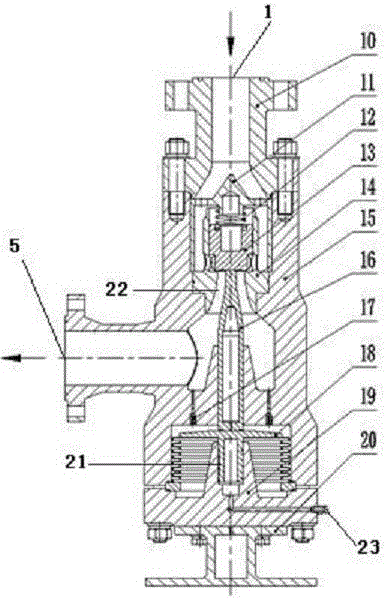

Pilot control branch pipeline flow stabilization regulation apparatus

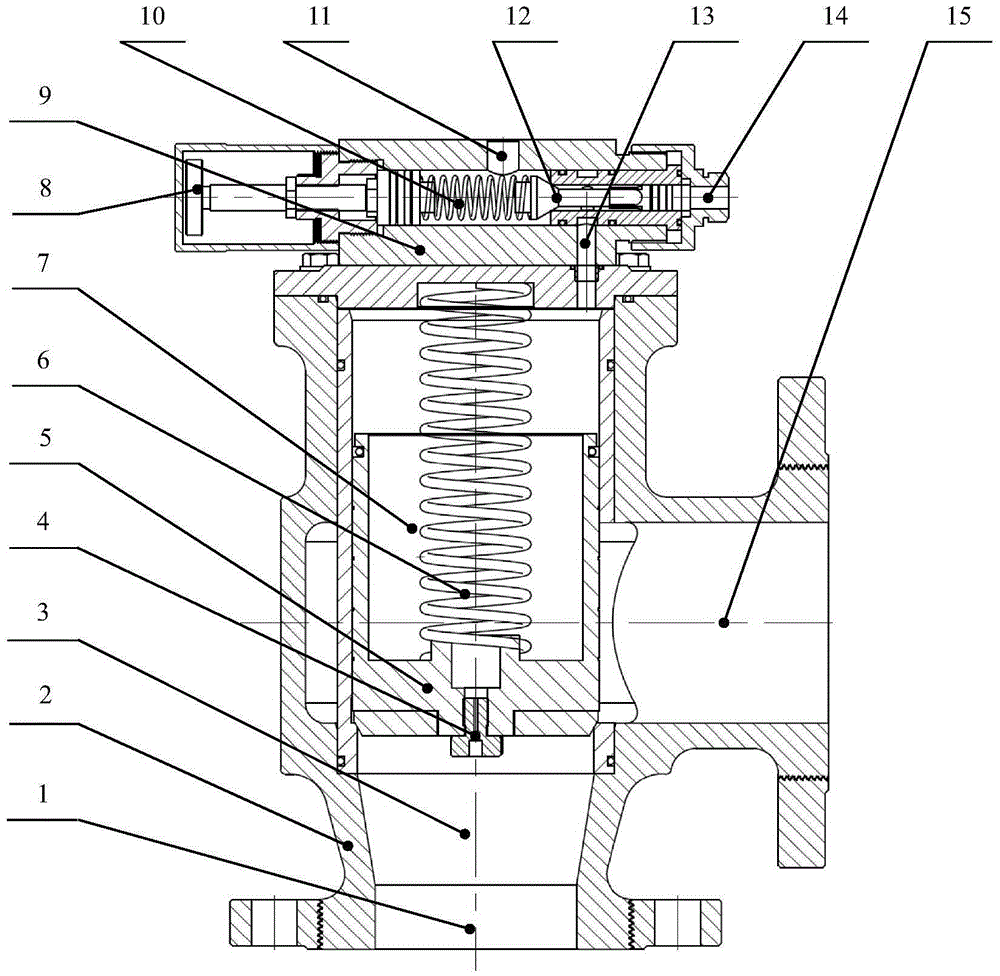

InactiveCN105605263AGood opening and closing characteristicsSmall pressure changeEqualizing valvesSafety valvesEngineeringPiston

The invention claims to protect a pilot control branch pipeline flow stabilization regulation apparatus which comprises a main valve and a pilot valve. The main valve comprises a main valve body, a main valve inlet positioned in the lower part of the main valve body and a main valve element lower cavity; a main valve element is mounted inside the main valve body; the main valve element is communicated with the main valve element lower cavity by a main valve element damping hole; the main valve element is connected with a main valve element upper cavity; a main valve spring is arranged at the middle position of the main valve element upper cavity; one end of the main valve spring is fixed on the main valve element, and the other end of the main valve spring is positioned at the upper part of the main valve element upper cavity; the pilot valve comprises a pilot valve body and a regulation handle arranged in the pilot valve body; the regulation handle is provided with a pilot valve spring along the axial end; a pilot valve element is arranged in the pilot valve body; an inner cavity of the pilot valve body is communicated with the main valve element lower cavity by a buffer hole; by a piston, the pilot valve element interacts with a pressure medium at a pressure acquisition point, which is introduced by a pressure introduction hole. The apparatus balances and regulates pressure in a refueling pipeline.

Owner:LOGISTICAL ENGINEERING UNIVERSITY OF PLA

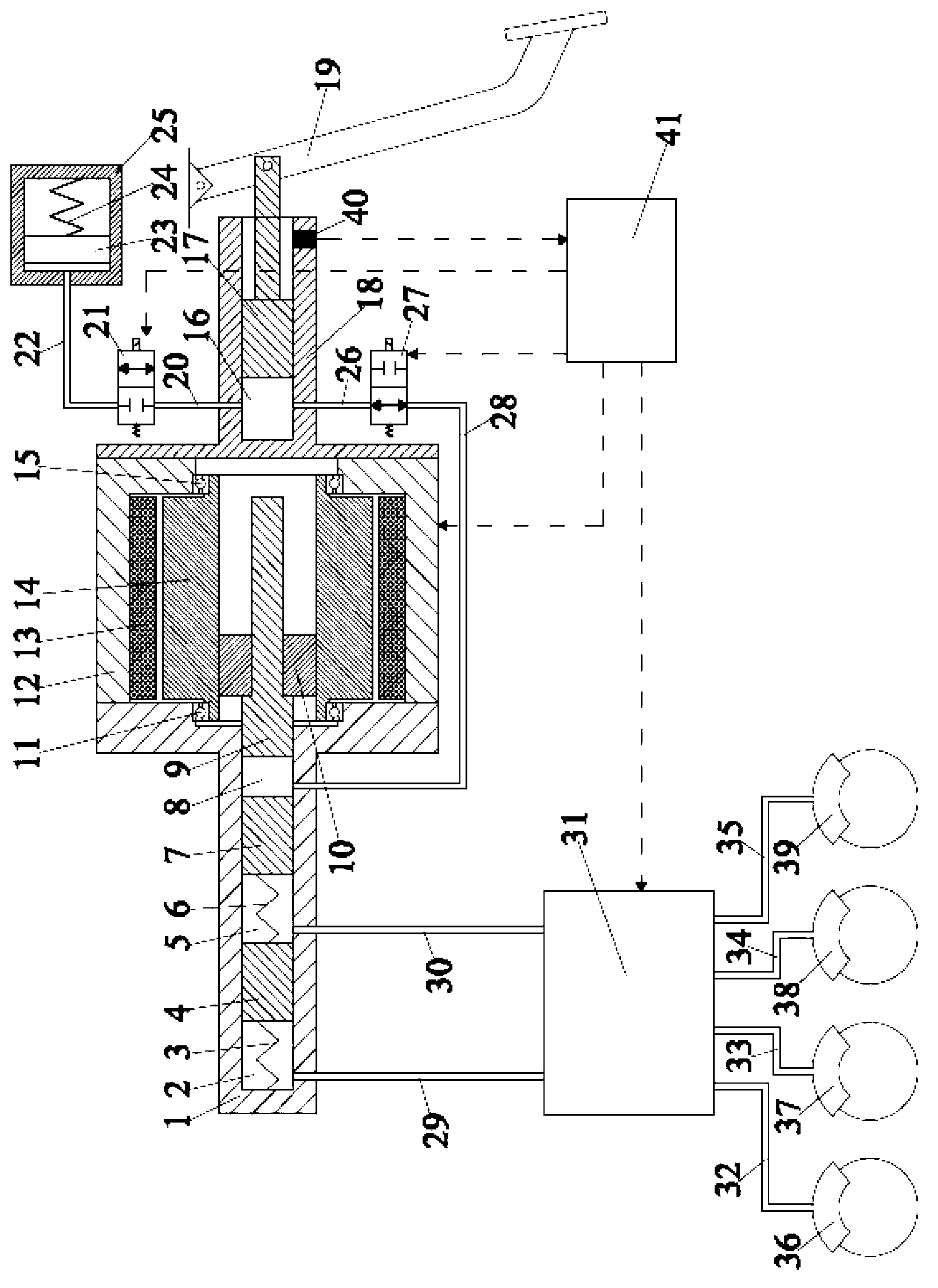

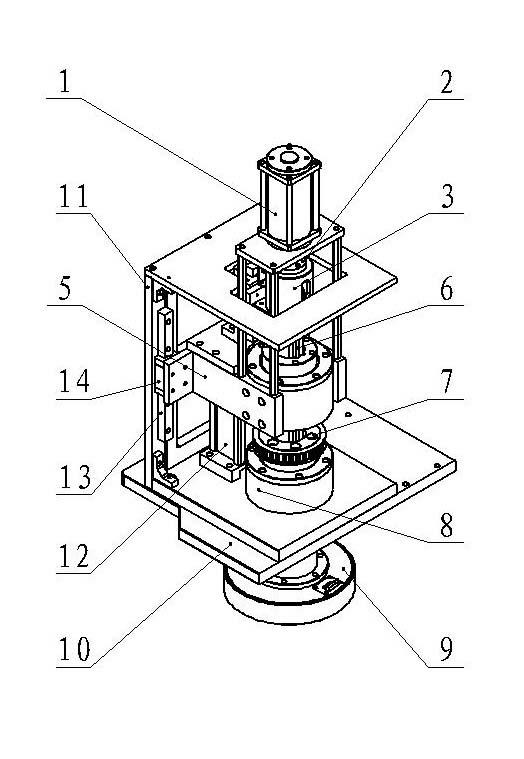

Lifting and pressing mechanism applied to wafer polishing equipment

The invention relates to a lifting and pressing mechanism applied to wafer polishing equipment, which can separate lifting motion and pressure loading motion from each other in a polishing process of a polishing head. The lifting and pressing mechanism applied to the wafer polishing equipment comprises a bearer, a frame, and a lifting mechanism and a pressing mechanism, wherein the lifting mechanism and the pressing mechanism are arranged on the frame and are connected with the bearer for controlling a pressing action and a lifting action of the bearer respectively. Through the lifting and pressing mechanism, a lifting function and a pressing function on a polishing machine can be separately performed; and the requirements for reducing the impact of the mechanism to a pressing process, improving control accuracy of wafer polishing pressure and control sensitivity and the like are also met while the requirement of a lifting travel is met.

Owner:THE 45TH RES INST OF CETC

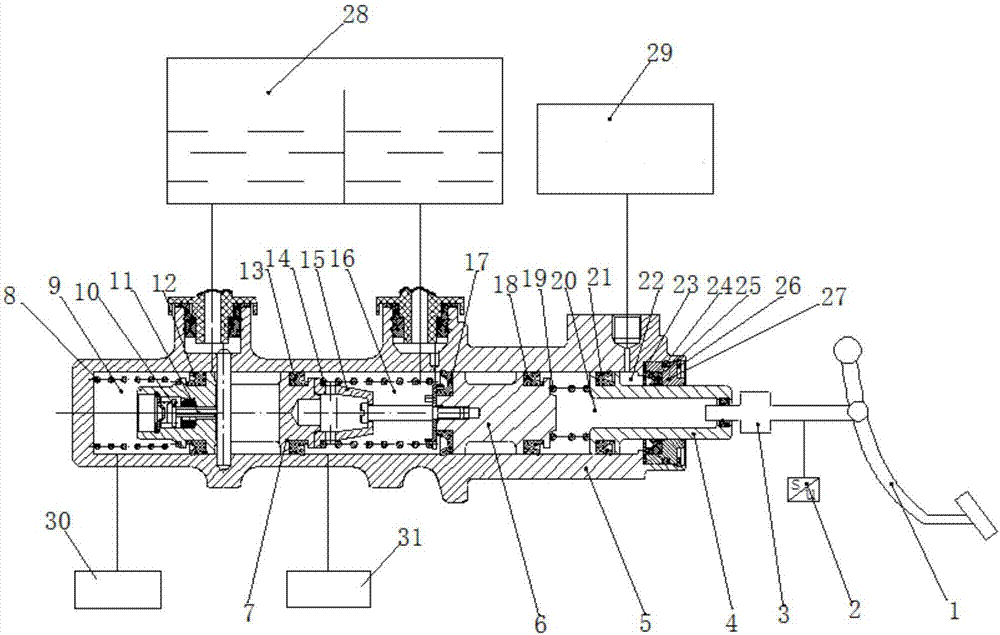

Multi-cavity braking main cylinder system with pedal feeling simulator

PendingCN106985805AReduce axial force fluctuationsAxial force fluctuations are reducedBraking action transmissionMaster cylinderEngineering

The invention relates to a vehicle braking system, in particular to a multi-cavity braking main cylinder system with a pedal feeling simulator. The multi-cavity braking main cylinder system comprises a braking pedal, a first pushing rod, a main cylinder body, an oil pot and a pressurizing system. The main cylinder body comprises a T-shaped piston, a first piston and a second piston. The braking pedal is connected with the T-shaped piston through the first pushing rod. The T-shaped piston and the first piston form a first cavity. The first piston and the second piston form a second cavity. The second piston and the main cylinder body form a third cavity. A baffle is arranged between the T-shaped piston and the main cylinder body. The baffle and the T-shaped piston form a pressurizing cavity connected with the pressurizing system. The oil pot is connected with the first cavity and the second cavity. The effective cross sectional area of the T-shaped piston is smaller than that of the first piston. According to the multi-cavity braking main cylinder system, the controlling precision of main cylinder pressure is improved, pressure fluctuation of a braking main cylinder at the time of active pressurizing is reduced, braking force is made to be smoother, and the driving experience of a user is improved.

Owner:潘泓冰

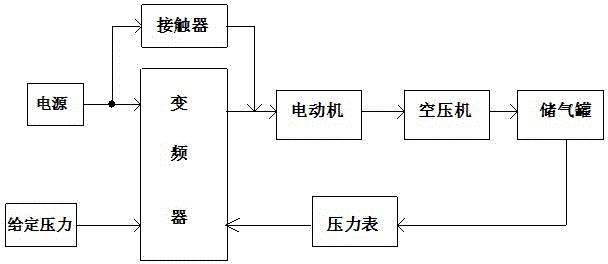

Control system of air compressor

InactiveCN103334913AReduce noiseExtended service lifePump controlPositive-displacement liquid enginesMotor speedFrequency changer

The invention relates to a control system of an air compressor, which belongs to the technical field of air compressor control. According to the control system of the air compressor, disclosed by the invention, the output pressure of compressed air of the air compressor is used as a control object, the regulation of motor speed by air demand is realized by using a variable frequency speed regulating mode, the pressure at an air outlet can rise when the air consumption is reduced, the pressure can be fed back to a frequency converter through a pressure sensor, the motor speed can be slowed down, and the shaft output power can be reduced; the pressure of the air outlet drops when the air consumption is increased, the motor speed is quickened, and the shaft output power is increased; and therefore the air compressor control system disclosed by the invention has the advantages that the pressure control accuracy can be controlled, the energy source is saved, the running cost is reduced, the noise of the air compressor is reduced at the same time, and the service life of the air compressor is prolonged.

Owner:HENAN COMM CABLE

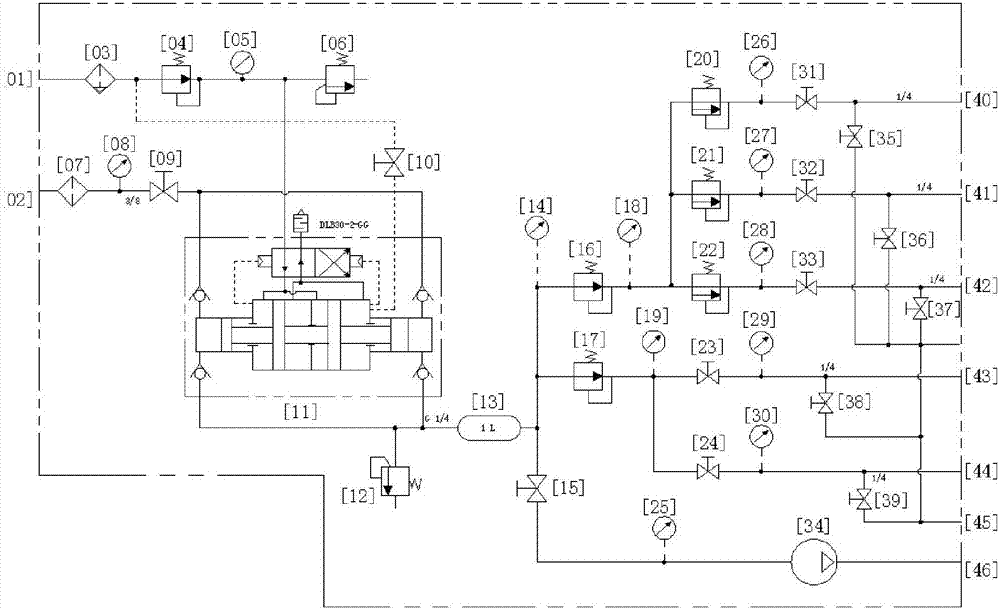

Gas distribution method and device for spacecraft leak rate detection

InactiveCN108007651AHigh degree of automationTroubleshoot specific pressure inflation problemsDetection of fluid at leakage pointMeasurement of fluid loss/gain rateTurbochargerEngineering

The invention discloses a gas distribution device for spacecraft leak rate detection, including a gas turbocharger, a pressure transmitter, a filter, a pressure stabilizing chamber, a high pressure reducing valve, a medium pressure reducing valve, a driving air pressure reducing valve, a driving air stop valve, an air intake stop valve, a vacuum stop valve, a safety valve, an unloading valve, a vacuum pump, a pressure gauge and a stainless steel pipe. A gas source inlet is connected with a leak indication gas for leak rate detection. A driver inlet is connected with compressed air to drive thegas turbocharger. The leak indication gas is pressurized through the gas turbocharger, and then enters the pressure stabilizing chamber and a corresponding gas transmission loop. Two channels of highpressure and three channels of low-pressure gas are output through devices such as the pressure reducing valves, a high pressure stop value and the pressure transmitter. The vacuum pump is used for pumping out the gas in a gas transmission pipe to improve the purity of the leak indication gas. The gas distribution device of the invention meets the requirement of spacecraft service life and reliability detection, and can improve the reliability of the charging and discharging process of the leak indication gas, shorten the gas charging and discharging time and reduce the cost of leak rate detection.

Owner:SHANGHAI INST OF SATELLITE EQUIP

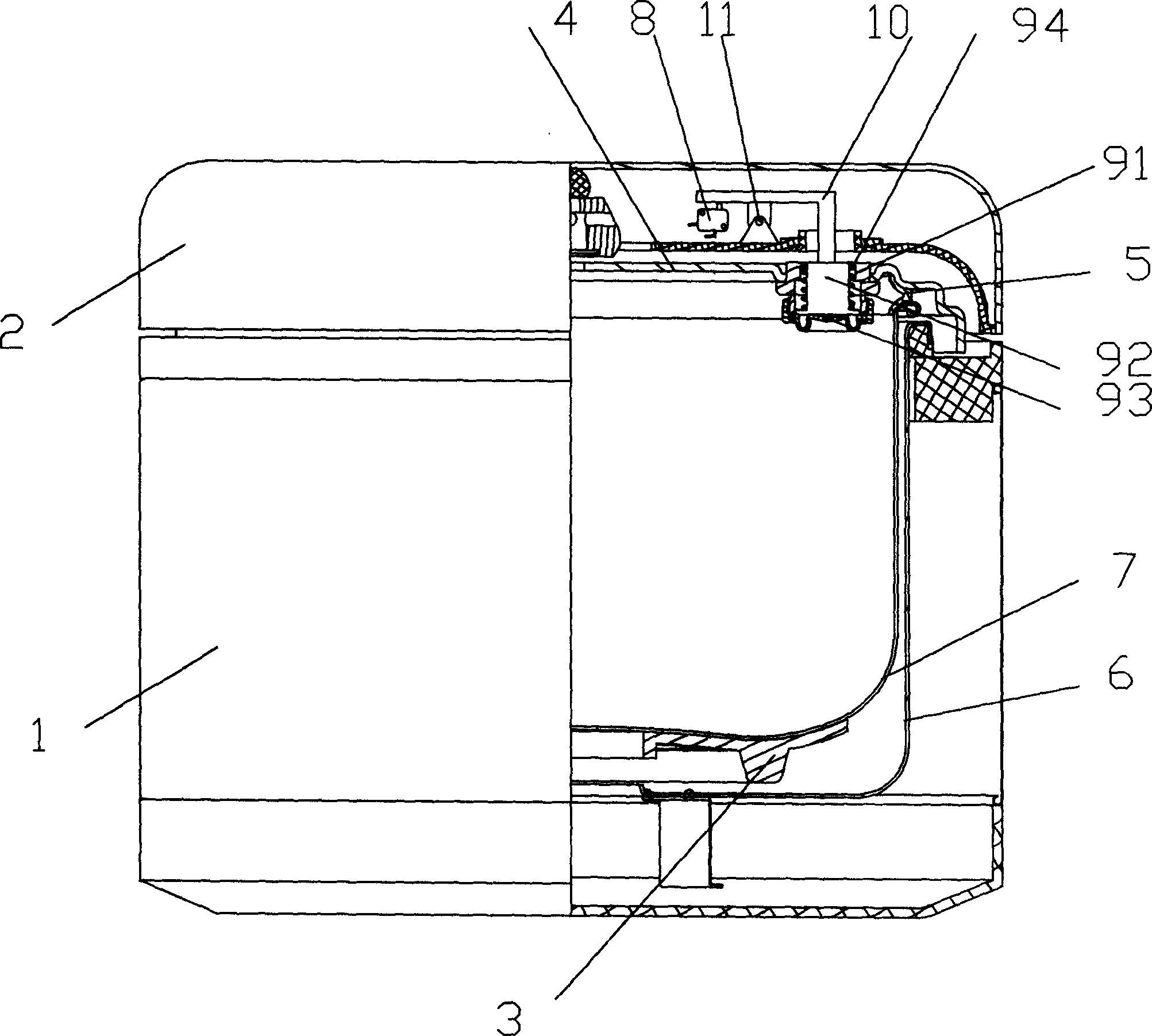

Electric pressure cooking vessel

InactiveCN1718139AHigh precision of pressure controlGood cooking effectPressure-cookersEngineeringHigh pressure

An electric pressure cooker is composed of a main body, a cover unit with internal cover, an internal pot, a sealing ring between internal cover and internal pot, and a pressure control unit arranged on cover unit and consisting of pressure sensing valve and shift detector. Its advantages are high pressure controlling accuracy and high reliability.

Owner:MIDEA GRP CO LTD

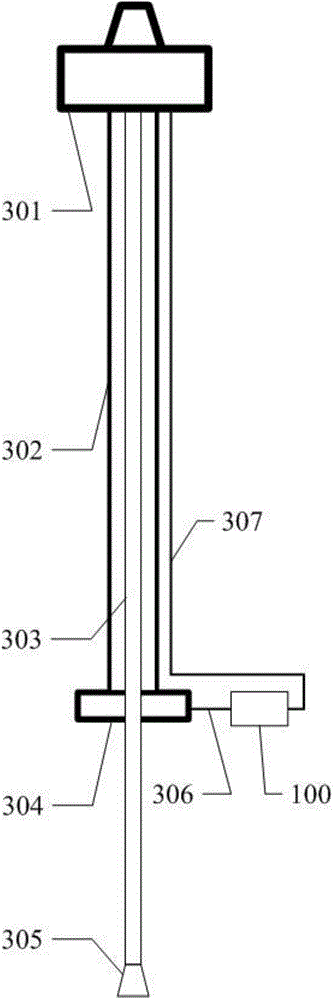

Method and device for sampling produced fluid of oil reservoir for microbial flooding

InactiveCN102071933AGuaranteed test accuracyGuaranteed test reliabilityFluid removalCommunity structureEnvironmental engineering

The invention relates to a method and a device for sampling a produced fluid of an oil reservoir for microbial flooding. The technical scheme comprises the following steps of: (1) test and control of the temperature and pressure of the oil reservoir; (2) anaerobic treatment for the sampling device; (3) high-temperature and high-pressure separation of oil, gas and water; (4) anaerobic and high-pressure sampling of the oil, the gas and the water; (5) on-line test of oil, gas and water samples; and (6) processing and remote transmission of oil, gas and water test results. The invention has the advantages of solving the problem of the sampling of oil, gas and water mixtures under high-temperature, high-voltage and anaerobic conditions, ensuring that materials cannot diffuse on the spot during the sampling so as to protect on-site environment, ensuring that recovered crude oil and gas can be effectively utilized, ensuring the accuracy and reliability of parameter testing of the produced fluid of the oil reservoir of the microbial flooding, improving the accuracy of microbial community structures by over 30 percent and the accuracy of oxidation-reduction potential by over 40 percent, and providing a reliable theoretical basis for the ecological regulation and control of the oil reservoir of the microbial blooding.

Owner:CHINA PETROLEUM & CHEM CORP +1

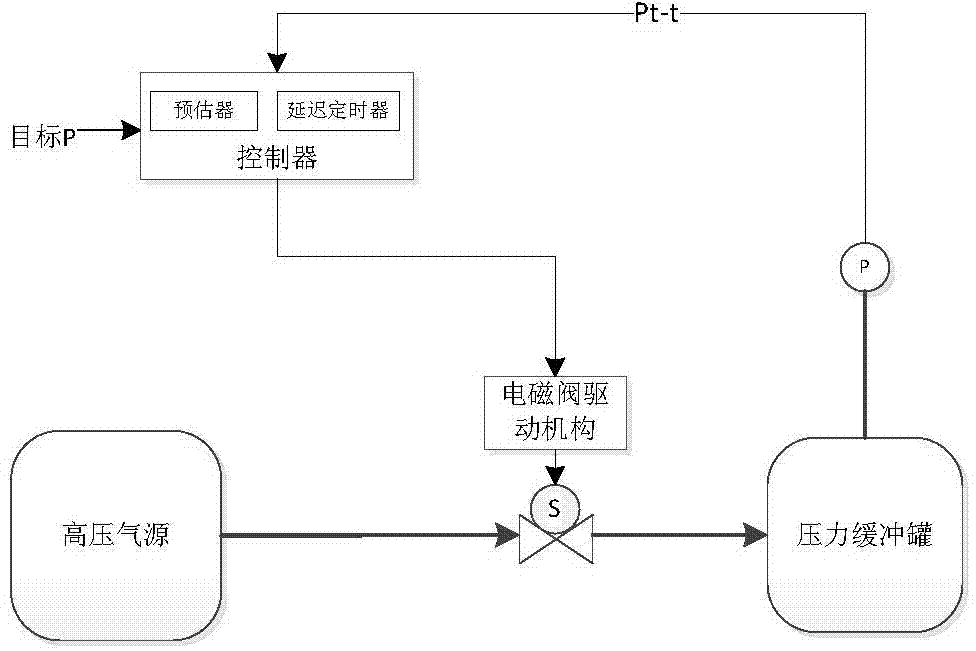

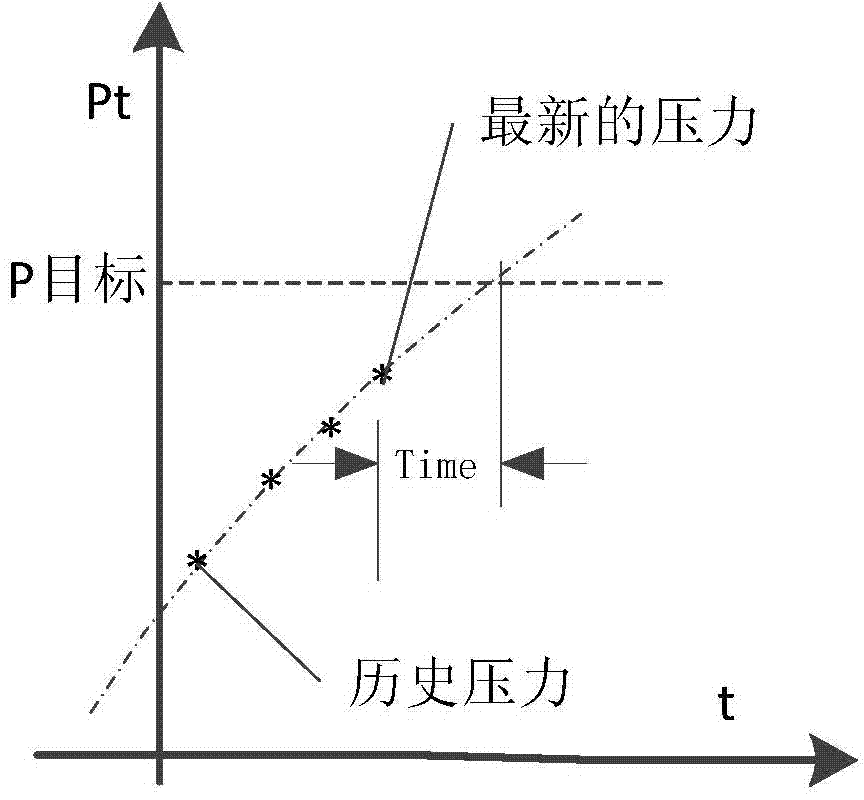

Method for controlling pressure switch through pressure predictor

ActiveCN103699147AHigh precisionAvoid time delayFluid pressure control using electric meansAutomatic controlClosed loop

The invention discloses a method for controlling a pressure switch through a pressure predictor. A pressure predictor and a delay timer are additionally arranged in a pressure closed loop controller, pressure control on a controlled object is converted into remaining valve switching time control, the precision of the time control is greater than that of the circular pressure detection and regulation, therefore, the problem that the conventional on-off valve cannot precisely control given pressure can be solved by using the method under the condition that the existing pressure automatic control hardware is not changed.

Owner:LANZHOU INST OF PHYSICS CHINESE ACADEMY OF SPACE TECH

Direct-acting overflow valve

ActiveCN106438549AOvercome internal oil pressureImprove the state of stressFluid-pressure actuator safetyServomotor componentsStressed statePressure control

The invention discloses a direct-acting overflow valve. Main and secondary valve elements are arranged in a valve sleeve; a spring is arranged in an inner cavity of the main valve element; and the other end is positioned on a spring base. The main valve element is in threaded connection with the secondary valve element; a large-diameter cylinder of the secondary valve element is positioned in the main valve element; one end of an adjusting screw rod is positioned in a small-diameter cylinder; a spring base for connecting the secondary valve element with the adjusting screw rod and coating a shaft shoulder of the adjusting screw rod is arranged at the shaft shoulder of the end part of the adjusting screw rod; the adjusting screw rod is provided with an external thread, is in threaded connection with a center screw hole of the locking nut, and extends out of the locking nut; an inner screw hole is formed in the end top; and the locking nut is in threaded connection with the valve sleeve. The direct-acting overflow valve optimizes the stress state in movement of the main valve elements I and II to reduce the spring rigidity; a peripheral damping hole in the main valve element I enables the main valve elements I and II to reach high opening and closing moment motion stability; the impact and the vibration of the direct-acting overflow valve are effectively reduced; the pressure adjusting deviation is low; and the pressure control precision is high.

Owner:YANSHAN UNIV

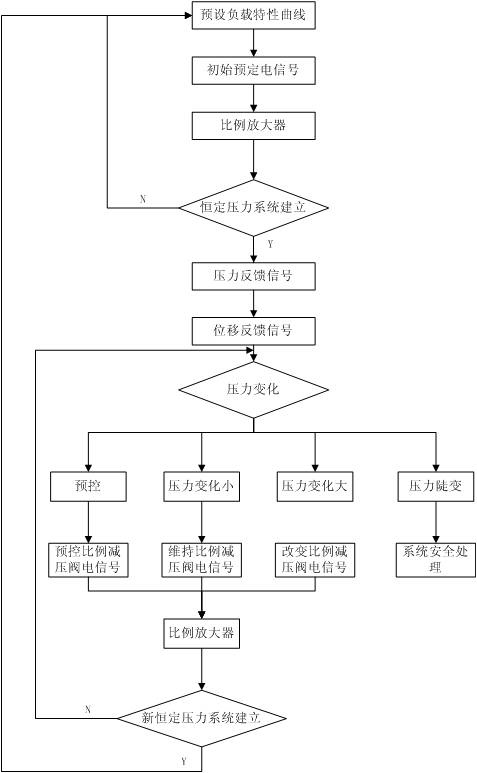

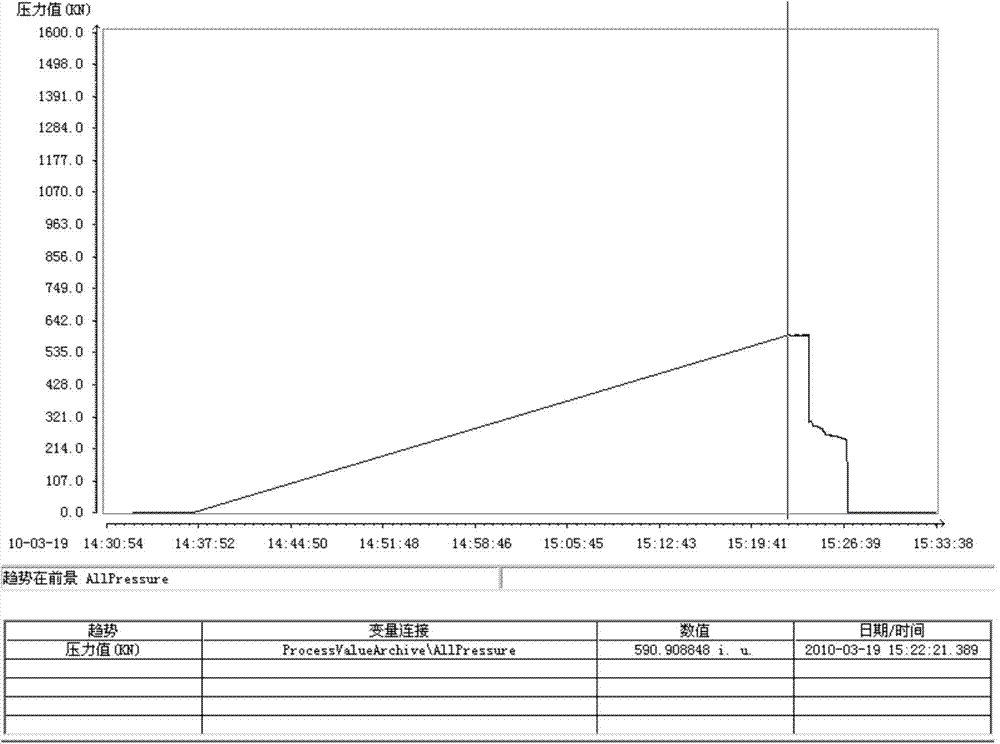

Constant pressure oil line system and control method in process of graphitizing carbon product

ActiveCN102674338AConstant outputStable pressureCarbon compoundsServomotorsHydraulic cylinderContact pressure

The invention discloses a constant pressure oil line system and a constant pressure control method in the process of graphitizing a carbon product. The method comprises the following steps of 1, inputting a load characteristic curve of a hydraulic cylinder into a control system; 2, starting an oil pump, and injecting hydraulic oil into the hydraulic cylinder and an energy accumulator through a three-position reversing valve and a two-position reversing valve respectively; and 3, comparing the load characteristic curve input into the control system and the preset load characteristic curve according to data fed back by a pressure sensor and a displacement sensor, wherein (a) when pressure of a rear cavity of the hydraulic cylinder and displacement of a piston of the hydraulic cylinder are on the load characteristic curve, the control system adjust output pressure of a proportional pressure-reducing valve in advance; (b) when deltaP is smaller than or equal to the adaptive pressure adjusting range of the constant pressure oil line system, the proportional pressure-reducing valve adjusts the output pressure; (c) when deltaP is greater than the adaptive pressure adjusting range of the constant pressure oil line system, the control system controls the output pressure of the proportional pressure-reducing valve; and (d) when the deltaP exceeds the pressure adjustment range of the control system, the control system controls the hydraulic system for emergency stop. By adoption of the constant pressure oil line system and the constant pressure control method, contact pressure output by the hydraulic cylinder can be accurately controlled.

Owner:CMCU ENG

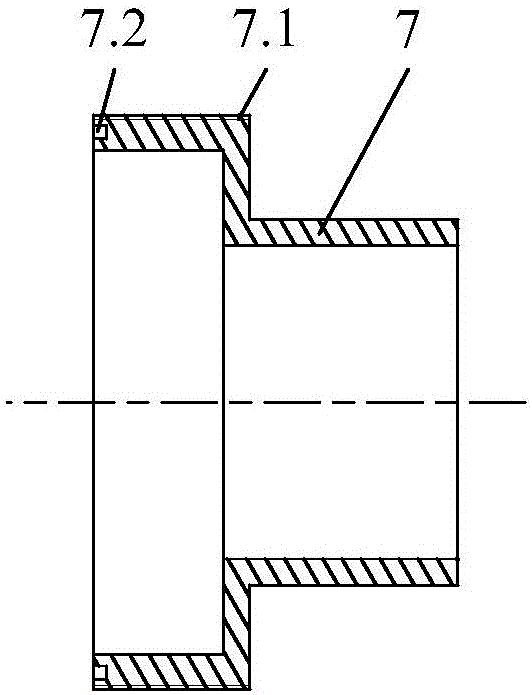

Proportional type proportional pressure reducing valve

ActiveCN105909844AGood hydrodynamic eliminationHigh precision of pressure controlEqualizing valvesSafety valvesPiezoelectric actuatorsEngineering

The invention discloses a proportional type proportional pressure reducing valve and belongs to the technical field of pressure reducing valves. A piezoelectric actuator is connected with a pilot valve element. The pilot valve element is matched with a pilot valve seat to form a pilot valve port. A main valve upper cavity is formed between a pilot valve oil supply device and the pilot valve seat. A main valve element damper is arranged in a main valve element. A shoulder of an upper section of the main valve element and the edge of a sinking and cutting groove in the upper portion of a valve body are matched to form an oil draining valve port, a shoulder of a lower section of the main valve element is matched with the edge of a sinking and cutting groove in the lower portion of the valve body to form an oil inlet valve port, and a shoulder of a middle section of the main valve element corresponds to a sinking and cutting groove in the middle portion of the valve body to form an output and flow guide part. The valve body is arranged in a valve block. An oil inlet and an oil draining port of the valve block communicate with the oil inlet valve port and the oil draining valve port correspondingly. A load opening of the valve block communicates with the sinking and cutting groove formed in the middle portion of the valve body, and a zero adjustment spring is arranged in a main valve lower cavity. Partial pressure of the pilot valve port and a throttling hole of the pilot valve oil supply device is used as a main valve element instruction, and the zero adjustment spring is used for expanding the pressure adjusting range. By means of the proportional type proportional pressure reducing valve, the output pressure of the valve and the input pressure of the valve can change proportionally.

Owner:HARBIN INST OF TECH

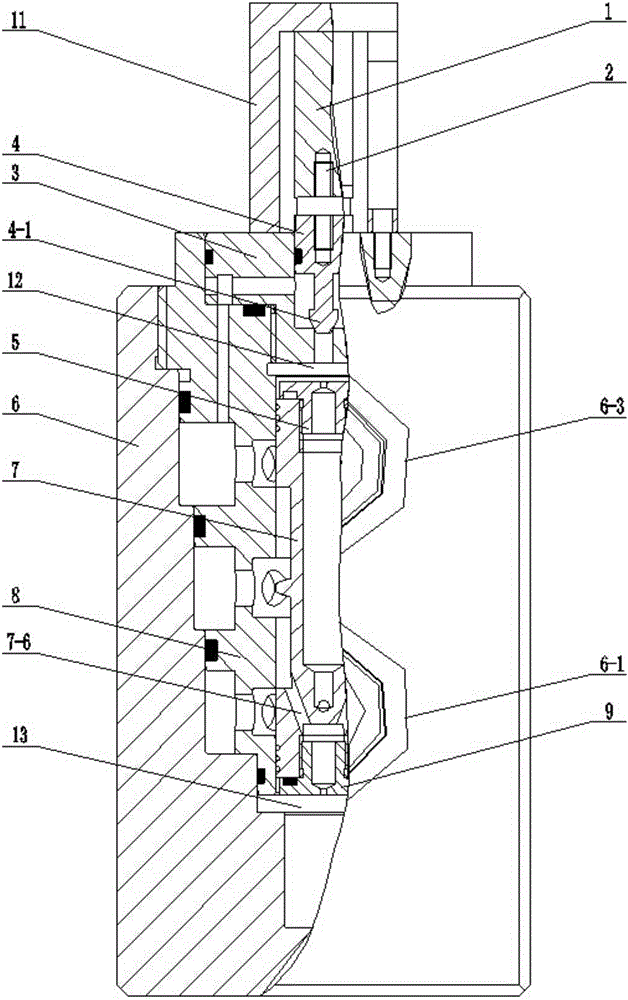

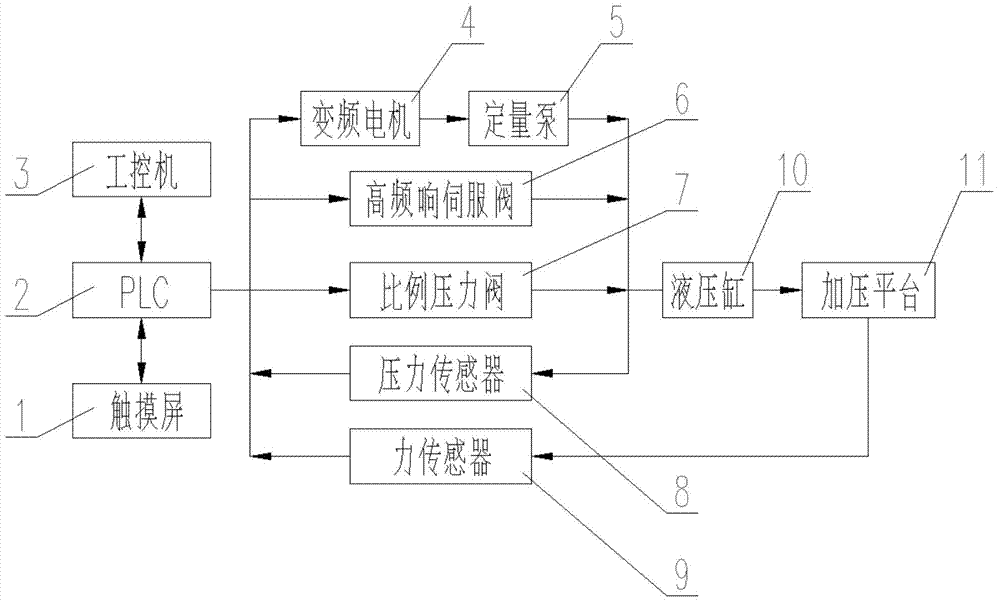

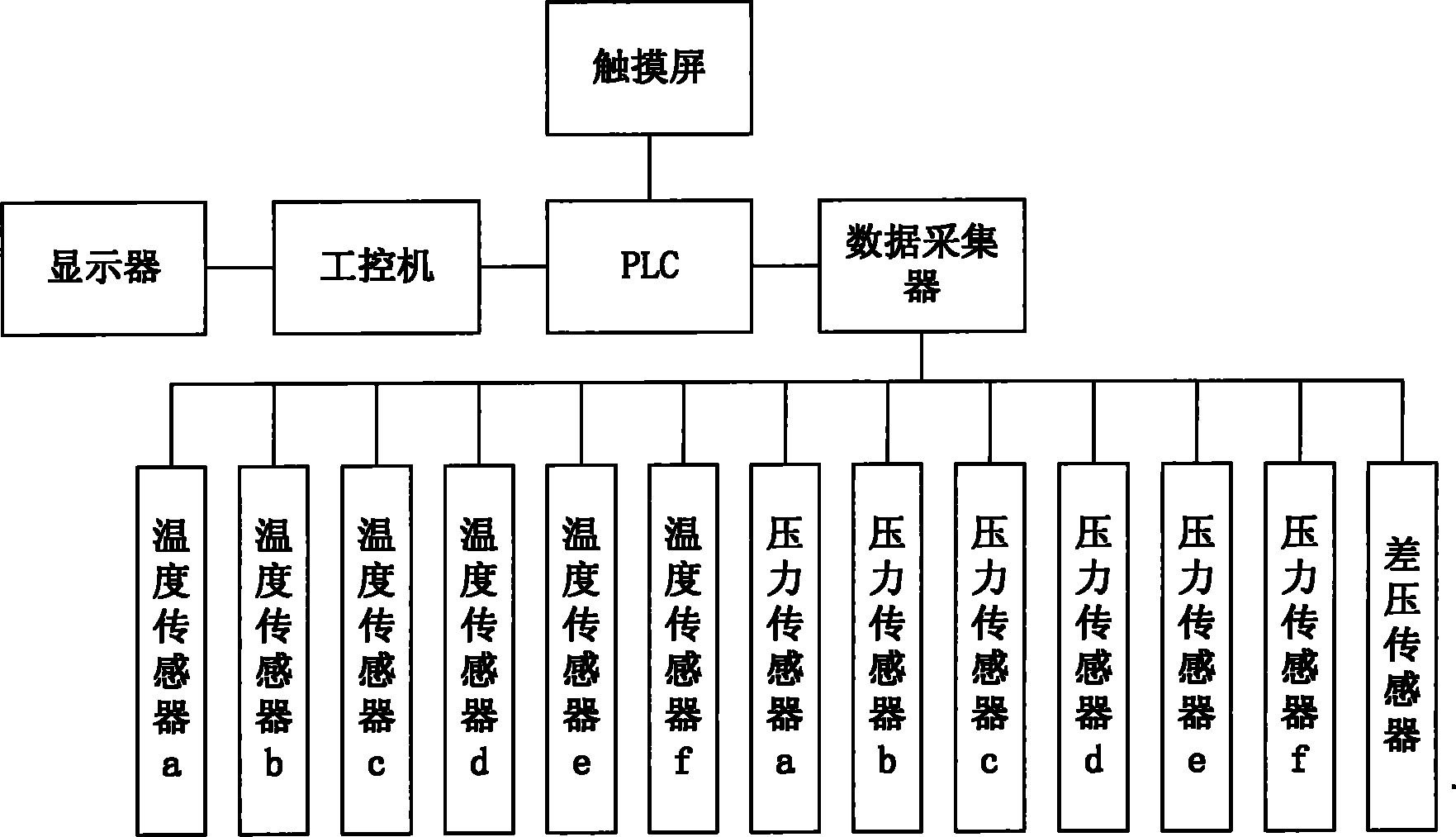

Double-closed-loop redundancy pressure control system of coil hydraulic press

ActiveCN104260409ACause damageHigh precision of pressure controlPressesClosed loopHydraulic cylinder

A double-closed-loop redundancy pressure control system of a coil hydraulic press comprises a PLC (programmable logic controller) used for controlling the coil hydraulic press, a touch screen exchanging parameters with the PLC through a bus and an industrial personal computer exchanging complex operation functions with the PLC through the industrial Ethernet. The PLC is connected with one end of each of a variable frequency motor, a high-frequency response servo valve and a proportional pressure valve, the variable frequency motor, the high-frequency servo valve and the proportional pressure valve are controlled through the PLC, the other end of the variable frequency motor is connected with a metering pump driven by the variable frequency motor, the other end of each of the metering pump, the high-frequency servo valve and the proportional pressure valve is connected with a hydraulic cylinder of the coil hydraulic press driven through each of the metering pump, the high-frequency servo valve and the proportional pressure valve, the other end of the hydraulic cylinder is connected with a pressurized platform driven through the hydraulic cylinder, a pressure sensor connected with the PLC and feeding back pressure feedback signals of the hydraulic cylinder to the PLC is arranged on the hydraulic cylinder, and a force sensor connected with the PLC and feeding back stress signals of a coil to the PLC is arranged on the pressurized platform. The double-closed-loop redundancy pressure control system has the advantages that double-closed-loop redundancy control is realized, the system is highly integrated, stable and reliable pressurization is achieved, and pressure control is high in precision and timeliness.

Owner:HEFEI METALFORMING MACHINE TOOL

Hot electric pressing cooking device used in kitchen

InactiveCN101032371AAdjustable pressureSimple structurePressure-cookersControl circuitPressure controlled ventilation

The electrically heated pressure cooker includes an outer cover, an inner cover, a sealing ring, an inside pan, an outer casing, a heating disc, a pressed elastic plate, a switch, a control circuit, etc. It can form one pressurized cooking cavity; one electrically insulating, heat insulating and protecting shell; and one cooking control mechanism with the control circuit, the pressed elastic plate and the switch. The present invention has the advantages of simple structure, low cost, reliable operation, high control precision, etc.

Owner:广东鸿智智能科技股份有限公司

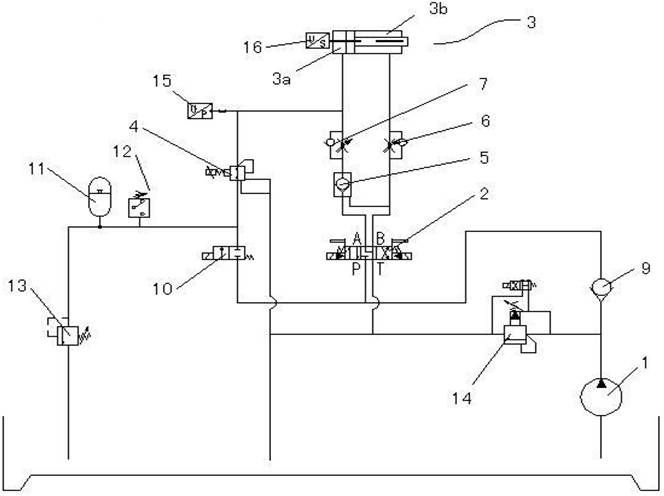

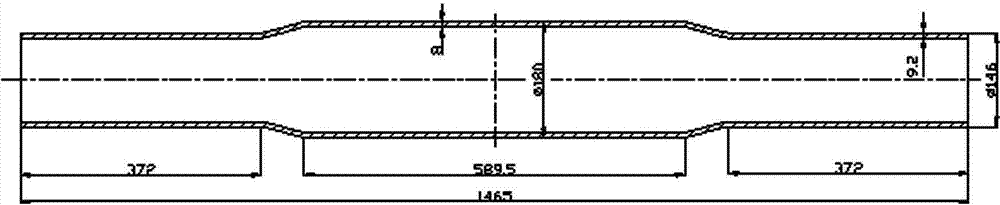

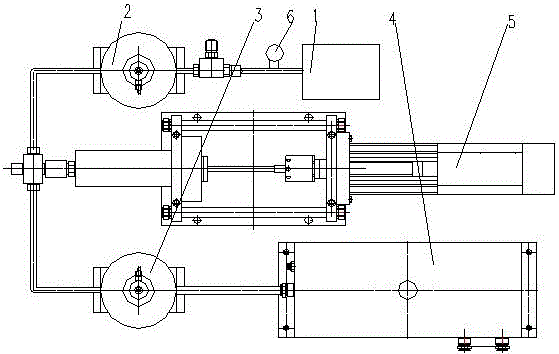

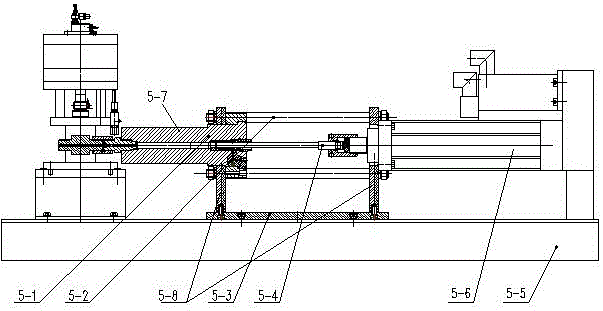

Automobile axle case piece hydraulic-bugling two-stage pressurization system

ActiveCN104707890AImprove forming qualityHigh precision of pressure controlUltra high pressureHigh pressure

The invention discloses an automobile axle case piece hydraulic-bugling two-stage pressurization system which is composed of a low-pressure liquid injection system, a bugling two-stage pressurization system, an ultra-high-pressure relief system and an electric control system. The low-pressure liquid injection system injects liquid rapidly into a pipe blank through water pumps before bulging. The bugling two-stage pressurization system comprises a single-cavity type work feeding pressurizer and a two-cavity type shape correction pressurizer, the work feeding pressurizer is used for supplementing high-pressure liquid at large flow in an axial material supplementing and bulging stage of the pipe blank, the shape correction pressurizer is used for supplementing liquid and correcting the shape of a pipe after dies are closed, oil is supplied to low-pressure cavities of the two pressurizers through an oil pump, and the flow and the pressure of oil output by the oil pump are accurately controlled through a proportional overflow valve and a proportional throttle valve. According to the ultra-high-pressure relief system, one-way valves connected with the pipe blank are controlled by a pressure relief pressurizer to conduct sealing operation in the bulging process and to release pressure rapidly after the bulging process. By the adoption of the automobile axle case piece hydraulic-bugling two-stage pressurization system, the high-pressure liquid supplementing flow is large, pressure control accuracy is high, pipe forming quality is good, system energy consumption is low, efficiency is high, and the system is safe and reliable.

Owner:QINHUANGDAO TONGQIAO TECH CO LTD

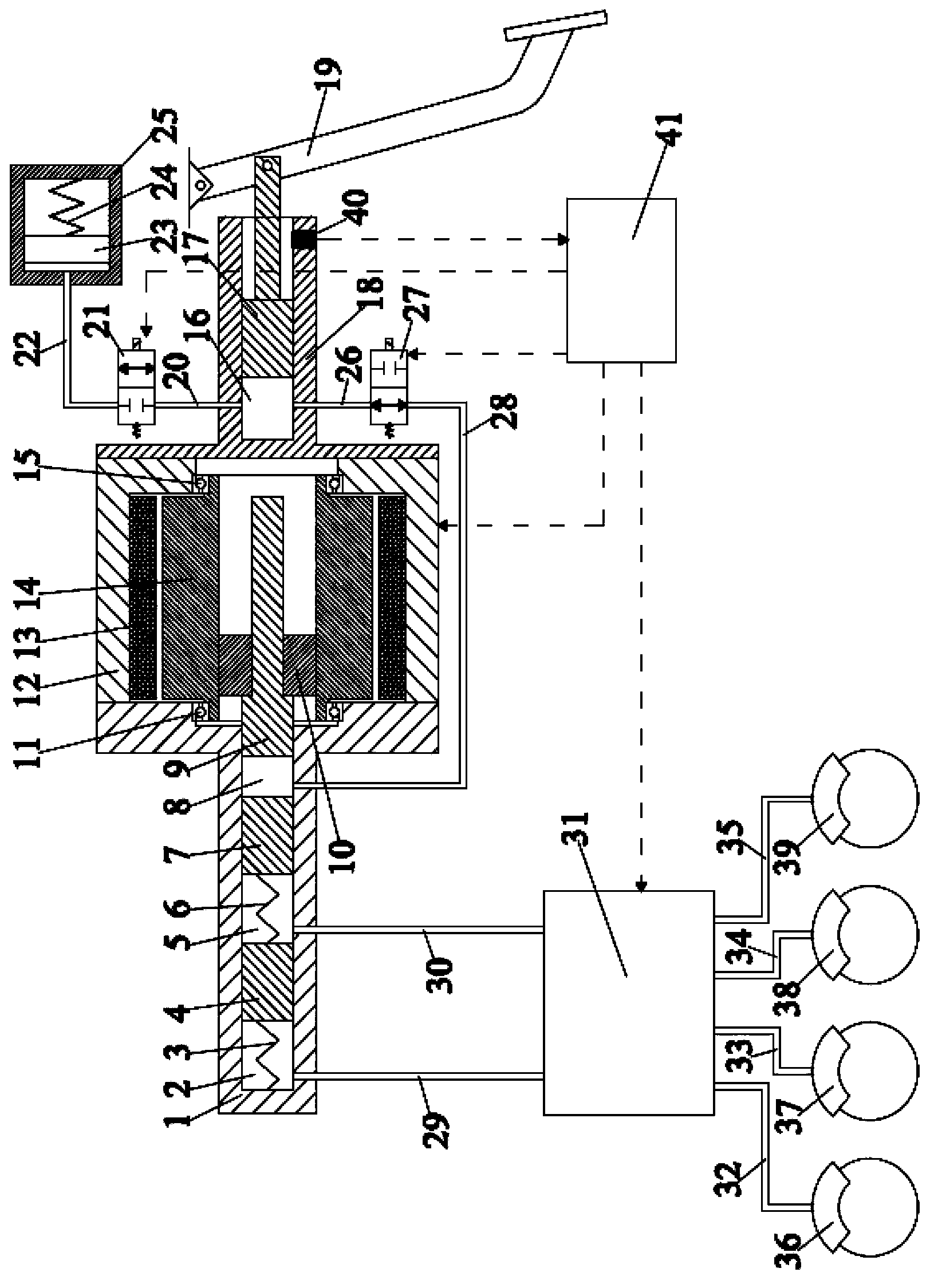

Oil well cement maintenance kettle

ActiveCN103317595AControl pressure fluctuationsAutomatic Pressure Stability ControlCeramic shaping apparatusControl systemEngineering

The invention discloses an oil well cement maintenance kettle which comprises a box, a kettle body and a control panel, wherein the control panel is arranged on the box, the box is provided with a kettle body installing cavity and also comprises a constant-pressure control system, the constant-pressure control system comprises a back pressure controller, a back pressure accumulator and a connecting pipeline I, the back pressure controller is communicated with the kettle body through the connecting pipeline I, the connecting pipeline I is communicated with a connecting pipeline II, one end of the connecting pipeline II is communicated with the connecting pipeline I, and the other end of the connecting pipeline II is communicated with the back pressure accumulator; the connecting pipeline I is provided with a pressure control valve, the connecting pipeline II is provided with a back pressure booster valve, the connecting pipeline II is also communicated with a connecting pipeline III, the connecting pipeline III is provided with a back pressure dropping valve, and the pressure control valve, the back pressure booster valve and the back pressure dropping valve are all arranged on the control panel. According to the invention, due to the utilization of the constant-pressure control system, the actual control precision of the oil well cement maintenance kettle can be up to + / - 0.25 MPa.

Owner:JIAHUA SPECIAL CEMENT

Computer test control system for pressure alternating test of air-air intercooler

InactiveCN102645373AFriendly human-computer interfaceBeautiful appearanceMeasurement of fluid loss/gain rateMaterial strength using tensile/compressive forcesControl systemComputer module

The invention relates to a computer test control system for pressure alternating test of an air-air intercooler. The computer test control system comprises an industrial personal computer, a data collecting module, a temperature sensor, a pressure sensor, a touch screen and a programmable controller, wherein the industrial personal computer is connected with the display screen and the programmable controller, the programmable controller is respectively connected with the data collecting module and the touch screen, the data collecting module is respectively connected with the temperature sensor and the pressure sensor, the computer test control system collects one to three circulation data of an air circulating system at the set time interval, the temperature, the pressure, the set value, the real-time operation curve, the wave form and the warning signal during the real-time operation of the air circulating system are displayed on the display screen, and values are regulated on the touch screen for measuring the fatigue resistance intensity of test pieces. Compared with the prior art, the computer test control system has the advantages that the structure design is novel and practical, the operation and the maintenance are convenient, the safety performance is higher, and the like.

Owner:SHANGHAI DELANG AUTO PARTS MFG

Seabed wellhead pressure indicating and automatic adjusting device for deepwater dual-gradient well drilling

ActiveCN104895548ASimple structureEasy to implementFluid removalAutomatic control for drillingWell drillingHydrostatic pressure

The invention belongs to the field of deepwater well drilling of petroleum engineering, and particularly relates to a seabed wellhead pressure indicating and automatic adjusting device for deepwater dual-gradient well drilling. The seabed wellhead pressure indicating and automatic adjusting device for the deepwater dual-gradient well drilling comprises a seabed drilling fluid manifold system and a seabed wellhead pressure indicating and automatic adjusting device, wherein the seabed drilling fluid manifold system provides a flowing channel to shaft returning and drilling fluid so that the drilling fluid can successfully return to a drilling platform and provide a foundation to the seabed wellhead pressure indicating and automatic adjusting device; the seabed wellhead pressure indicating and automatic adjusting device can display and adjust seabed wellhead pressure in real time, and keep seabed wellhead pressure to be constantly equal to seawater hydrostatic pressure at the seabed. According to the seabed wellhead pressure indicating and automatic adjusting device for the deepwater dual-gradient well drilling provided by the invention, the seabed wellhead pressure can be automatically kept to be constantly equal to the hydrostatic pressure of seawater deepwater dual-gradient well drilling process at the seabed so that the dual-gradient well drilling can be ensured to be successfully implemented.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

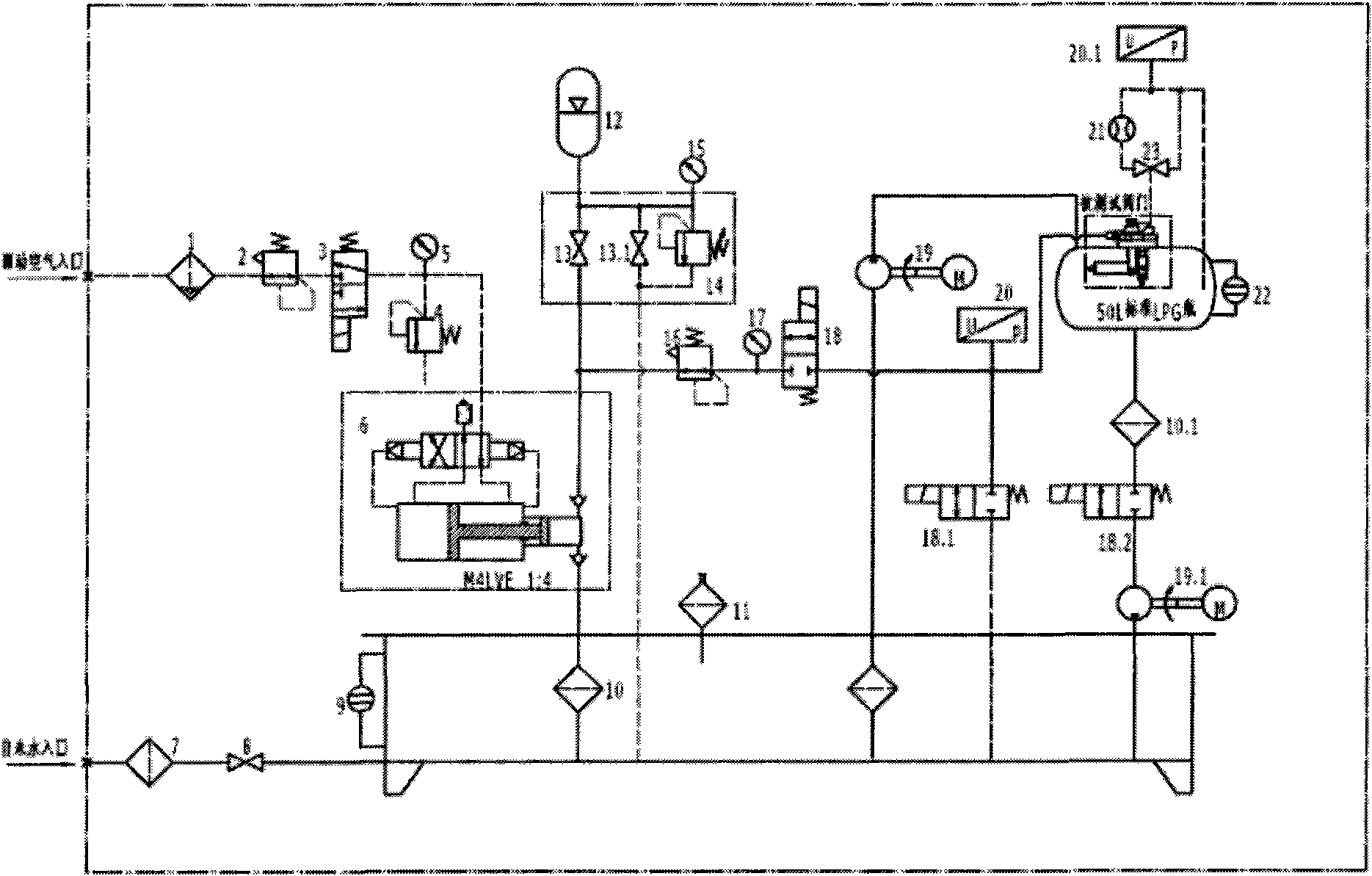

80 percent limit filling serviceability test bed

InactiveCN101819088AHigh precision of pressure controlVisualize progressMachine part testingElectrical controlAutomotive engineering

The invention relates to an 80 percent limit filling serviceability test bed which is used for an 80 percent limit filling and loading serviceability test of an LPG (liquefied petroleum gas) gas cylinder integrating valve for a vehicle, and according to a dedicated test bed which is designed according to requirements and regulations in GB18299 Liquefied Petroleum Gas Steel Cylinder Integrating Valve for a Motor Vehicle, the test bed consists of an electrical control part and a water pressure part, the electrical part comprises a control system and a computer display system, and the water pressure part mainly consists of a gas drive liquid pump, an energy accumulator, a pressure reducing valve, a centrifugal water-pump and the like. The combination of the energy accumulator and the pressure reducing valve can precisely control the pressure difference of two ends of a valve to be tested, and the test bed has the characteristic of stable pressure, thus guaranteeing the test pressure to meet the demands of GB18299 standards completely.

Owner:SHANGHAI INST OF SPECIAL EQUIP INSPECTION & TECHN RES

Ultrahigh pressure testing system and control method thereof

ActiveCN106094913AUnder high pressurePrecise position controlMaterial strength using tensile/compressive forcesFluid pressure control using electric meansPressure riseAutomatic control

The invention discloses an ultrahigh pressure testing system and a control method thereof. The ultrahigh pressure testing system comprises a liquid box, a first control valve and a servo supercharger. The liquid box is connected with the first control valve and the servo supercharger in sequence. The servo supercharger is connected with a pressure testing device. A second control valve is connected between the servo supercharger and the pressure testing device. A first pressure detection module is arranged between the first control valve and the second control valve. A second pressure detection module is arranged between the pressure testing device and the second control valve or in the pressure testing device. The technical purpose of the invention is to provide the ultrahigh pressure testing system which uses the servo supercharger as a power source to ensure high precision and high pressure of medium pressurization and intelligently control the pressure rising / reducing rate, and provide the control method of the ultrahigh pressure testing system to realize automatic control in the pressure testing process.

Owner:四川杰特机器有限公司

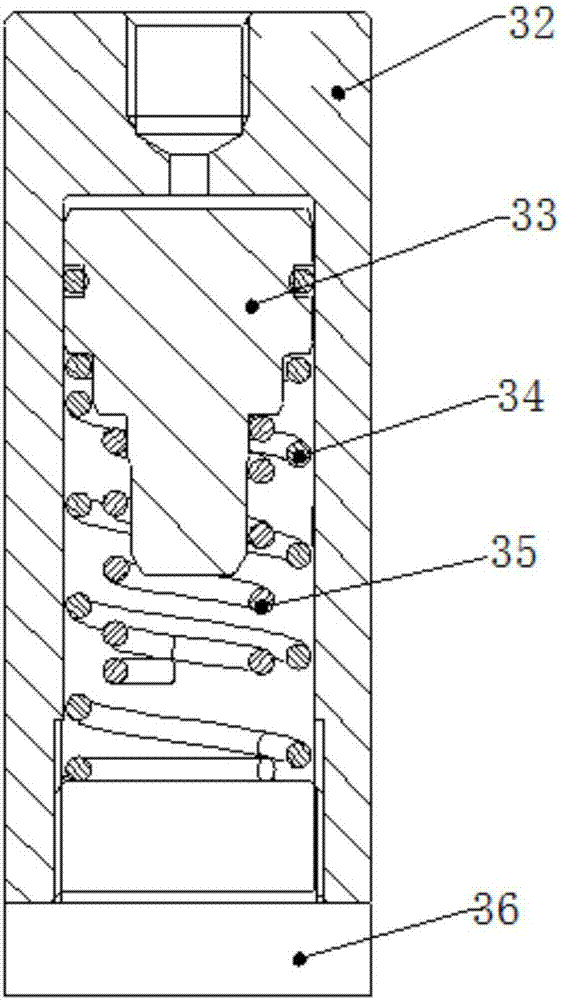

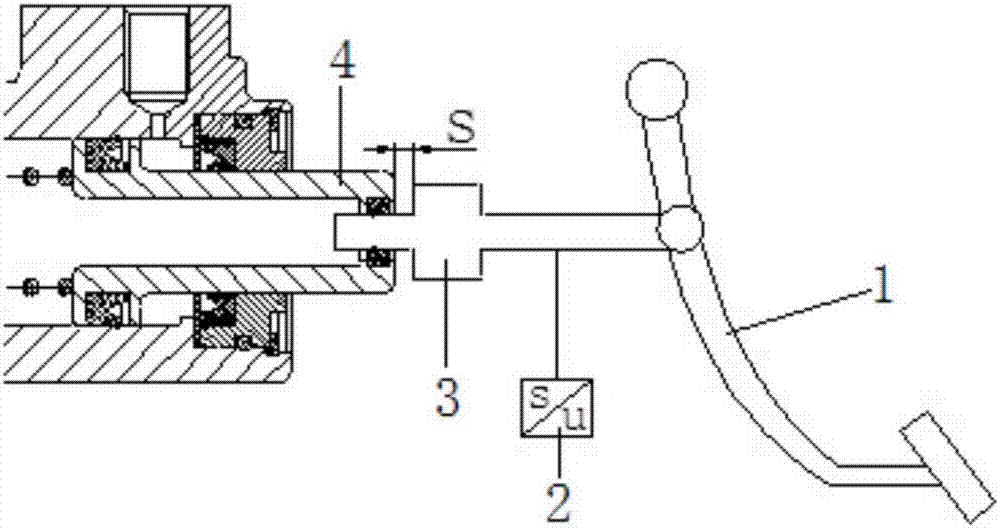

Novel wire control brake system

PendingCN107031595AHigh precision of pressure controlSmall effective cross-sectional areaBraking action transmissionSolenoid valveConnection control

The invention relates to automobile brake systems, in particular to a novel wire control brake system. By adoption of the novel wire control brake system, the master cylinder pressure control precision is improved, brake master cylinder pressure fluctuation during active pressurization is reduced, brake force fluctuation is reduced, brake force is made smoother, and user riding experience is improved. The novel wire control brake system adopts a hydraulic direct feedback type pedal feeling simulator, a spring in an original simulator is removed, pedal brake force is directly fed back through hydraulic pressure, and meanwhile, different pedal feelings can be fed back by selecting different push rod diameters. The novel wire control brake system comprises a brake pedal, a brake master cylinder, a pressurization device, an oil pot, a control system and a brake terminal. The brake pedal is connected with the brake master cylinder which is connected with the pressurization device and the oil pot. An outlet of the brake master cylinder is connected with the control system and the brake terminal. The pressurization device is connected with the oil pot through a pressure sensor and a normally-open electromagnetic valve. The pressurization device comprises a pressurization cylinder, a piston and a motor. The piston is arranged in the pressurization cylinder. The motor pushes the piston for pressurization.

Owner:潘泓冰

Brake-by-wire system of automobile

ActiveCN103010199BEliminate bad effectsOptimize layoutBraking action transmissionHydraulic control unitElectric machinery

The invention relates to a brake-by-wire system of an automobile and belongs to the technical field of automobile brake systems. In the brake system, a vacuum booster of the traditional vacuum booster hydraulic brake system is replaced with a motor, and a piston in a brake main cylinder is pushed to move to generate brake hydraulic pressure, so that dependence on vacuum degree of an engine is canceled; through the adoption of a pedal simulator, influences on feelings of a brake pedal during coordinated control of feedback and brake are eliminated; a hydraulic control unit of the traditional brake system is kept to implement hydraulic adjustment; and as a standby hydraulic brake system is integrated, braking with certain strength can be implemented by a driver under a situation that the power supply of the system is ineffective. Compared with the traditional distributed brake-by-wire scheme, the brake-by-wire system provided by the invention has the advantages as follows: the structure is changed when compared with the structure of the traditional vacuum booster hydraulic brake system, the system can be mounted on the automobile more conveniently, and more existing technologies in the traditional brake system can be succeeded in the control aspect.

Owner:TSINGHUA UNIV

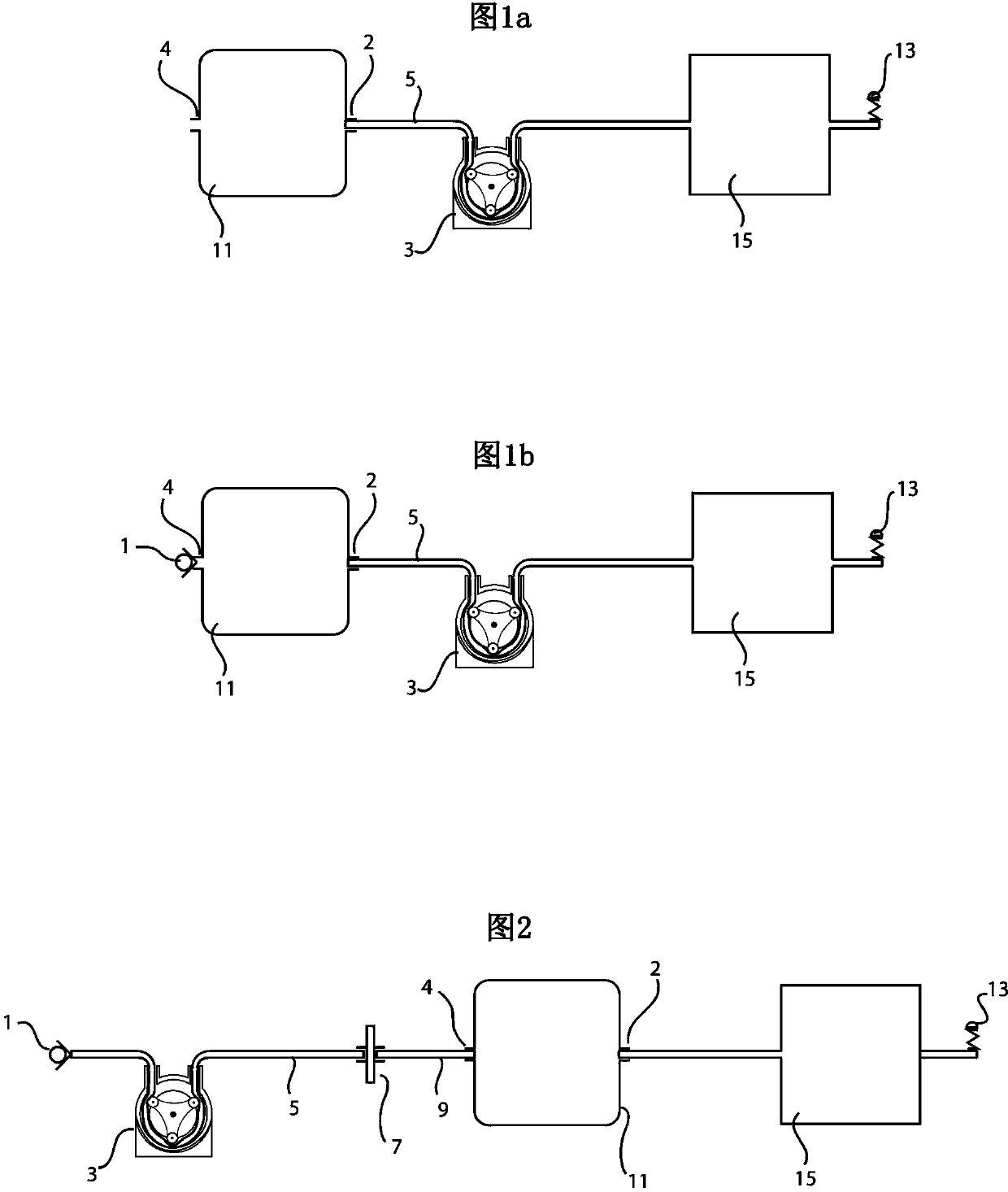

Portable medical device system

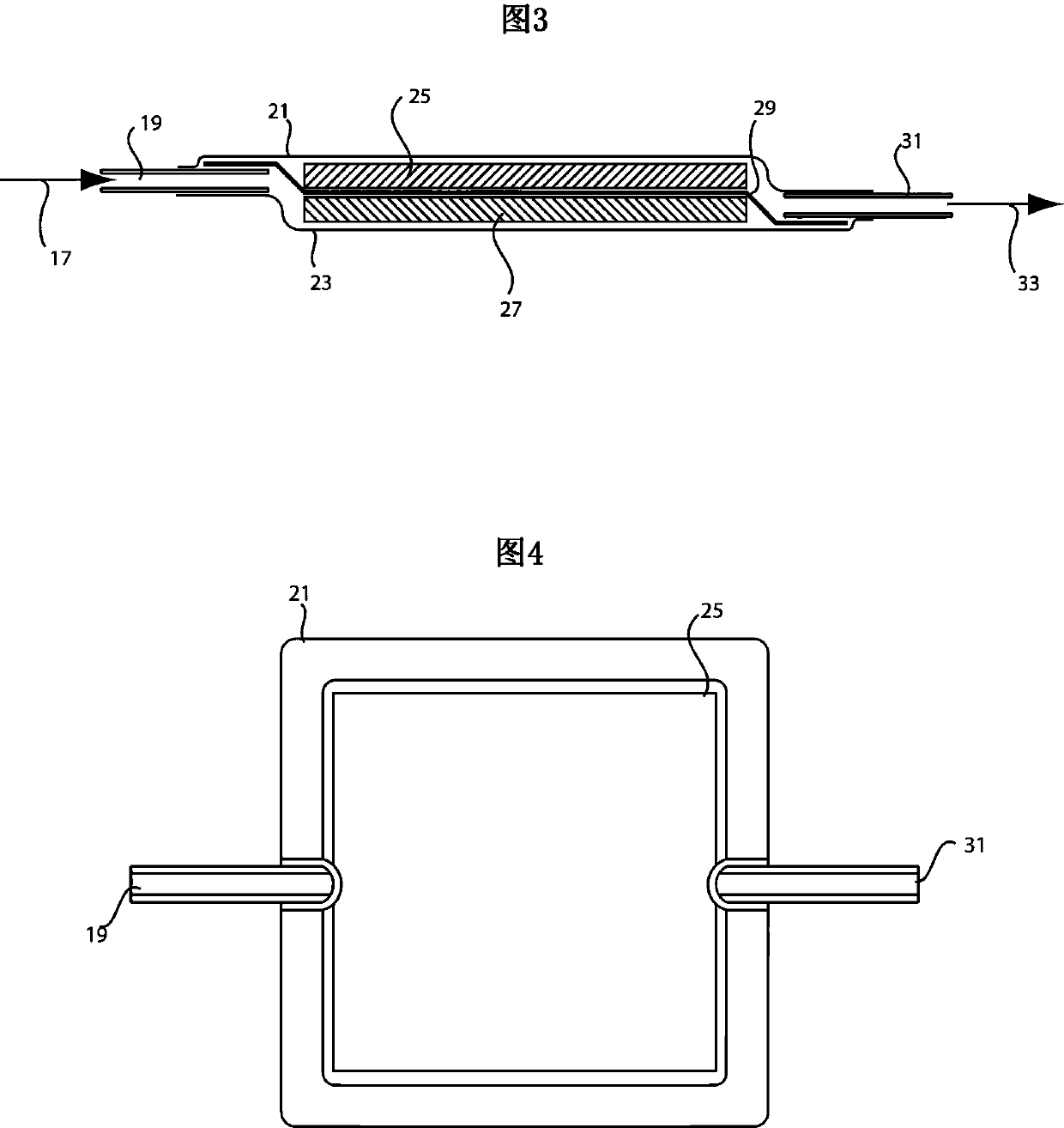

ActiveCN104797277ARealize NPWTHigh precision of pressure controlPharmaceutical containersMedical devicesExtensibilityWound dressing

The present invention provides an apparatus comprising a wound dressing 15 connected to a pump 3 and a fluid container 11, which has an inlet 2 and an outlet 4, and wherein the wound dressing is in communication with a mechanical pressure control valve 13. Also provided is a flexible fluid container comprising at least two layers of film (21, 23, see figure 3) with an integrated vent, which may be a microporous, hydrophobic membrane 29; a wound dressing comprising a porous pad, a flexible covering and a connection to a control valve; a multi-compartment wound fluid container (35, 63, see figures 6 or 7) comprising at least two internal compartments divided by a microporous fluid separator 41, 55 and provided with an inlet 49, 59 and an outlet 37, 51, wherein the microporous fluid separator permits gas flow between the compartments and prevents fluid flow to the outlet of the container; and a means for detecting the level of fluid in a multi-compartment container comprising a strap with limited extensibility.

Owner:I2R MEDICAL

Large-flow air-control corrugated pipe type pressure reducing valve

InactiveCN106090403ASolve the problem of low flowSimple structureOperating means/releasing devices for valvesEqualizing valvesEngineeringProduct gas

The invention discloses a large-flow air-control corrugated pipe type pressure reducing valve. An inlet cavity (2), an outlet cavity (4), a damping cavity (6), a control cavity (7) and an unloading cavity (9) are sequentially arranged in a valve body from top to bottom. The large-flow air-control corrugated pipe type pressure reducing valve is characterized in that the front end of the valve inlet cavity (3) is externally provided with a bypass pipeline (23) communicating with the unloading cavity (9), and the acting force applied by a medium to a throttling valve element (13) is balanced. Compared with the prior art, the large-flow air-control corrugated pipe type pressure reducing valve has the remarkable beneficial effects that a metal corrugated pipe serves as a sensitive element of the pressure reducing valve, rigidity is small, sensitivity is good, the effective area is large and the mass is small, and therefore the kind of valve has the beneficial effects of being high in outlet pressure control precision, stable in pressure, large in flow, small in dynamic-static pressure difference, good in dynamic characteristic and the like; and the unloading cavity can be used for counteracting the acting force applied by the high-pressure gas medium to the throttling valve element, the opening conditions of the throttling valve element are improved, the loads of the sensitive element are reduced, and the service life of the metal corrugated pipe is prolonged.

Owner:CHANGDE XIANGYU EQUIP MFG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com