Direct-acting overflow valve

A technology of direct-acting relief valve and valve sleeve, which is applied in the direction of fluid pressure actuation device, fluid pressure actuation system safety, servo motor components, etc. Large pressure deviation and other problems, to achieve the effect of high pressure control precision, small pressure regulation deviation, and reduce shock and vibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be described in further detail below in conjunction with the accompanying drawings.

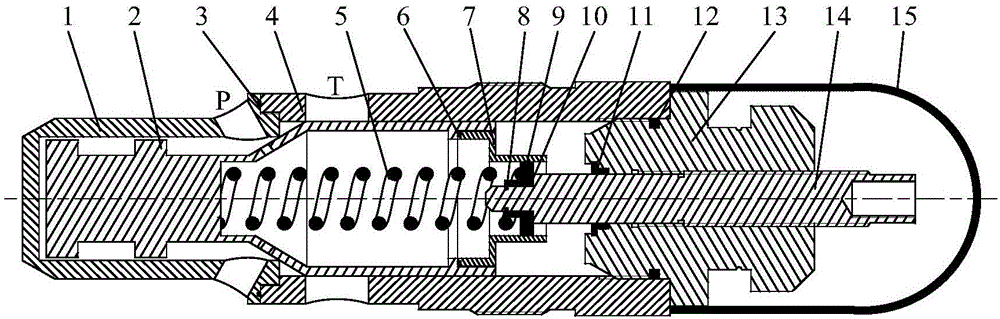

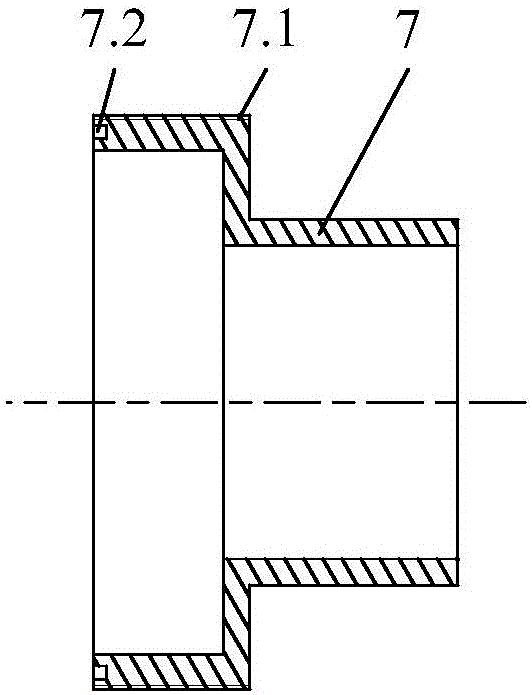

[0014] exist figure 1 In the schematic diagram of the main view of the direct-acting overflow valve, the valve sleeve is composed of a circular groove-shaped housing 1 opening and a cylindrical housing 4 threaded at one end, and a sealing ring I3 is arranged between the two, and the valve sleeve The opening part of the circular groove-shaped housing 1 is truncated cone-shaped, and its peripheral surface is provided with at least one through hole, that is, the liquid inlet P. The hole is the outlet hole T. There are corresponding main and auxiliary spools in the valve sleeve, the main spool 2, such as figure 2 As shown, the part corresponding to the valve sleeve circular groove housing 1 is a solid cylinder, and its outer peripheral surface is provided with two protruding rings connected with it, that is, the piston 2.1, the main valve core 2 and the valve ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com