Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

68results about How to "Improve grinding uniformity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

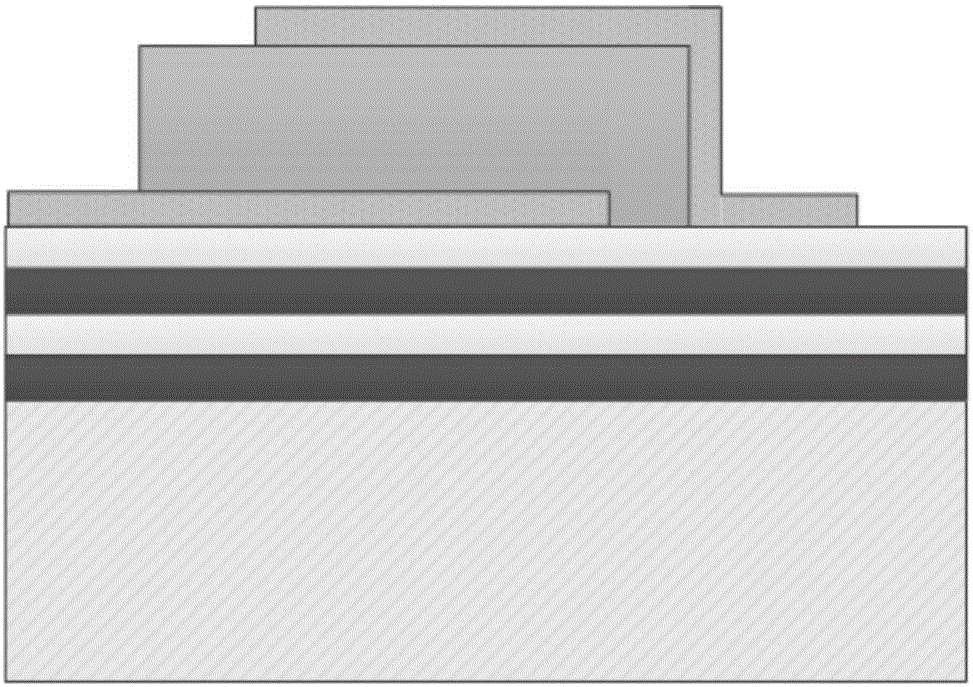

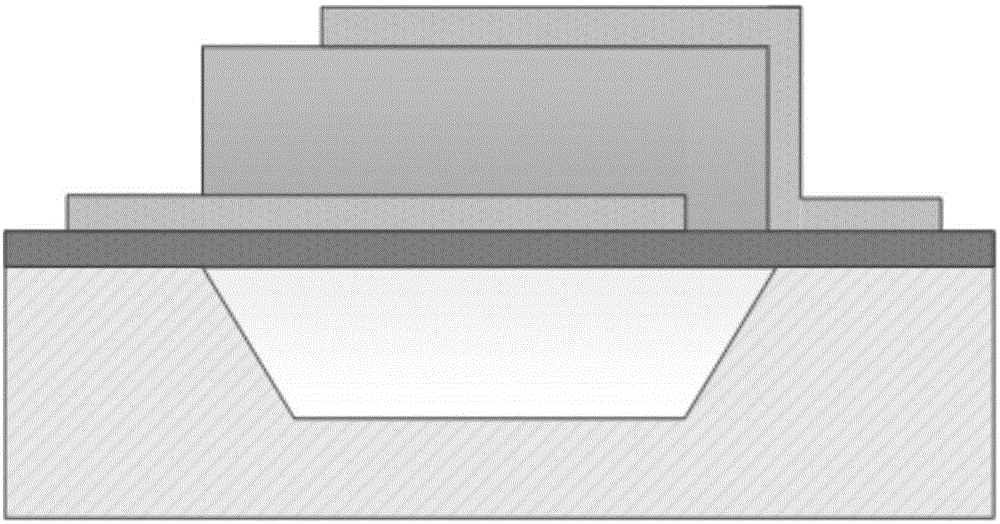

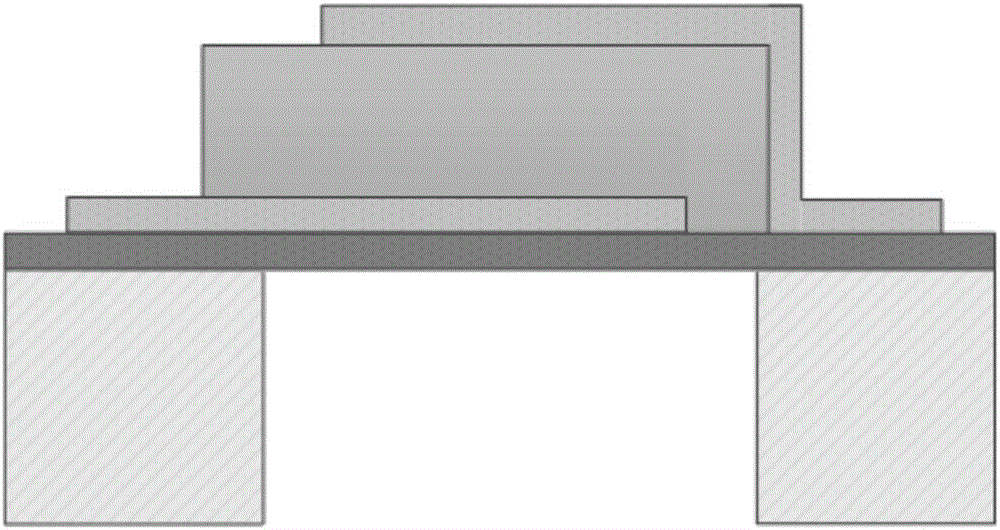

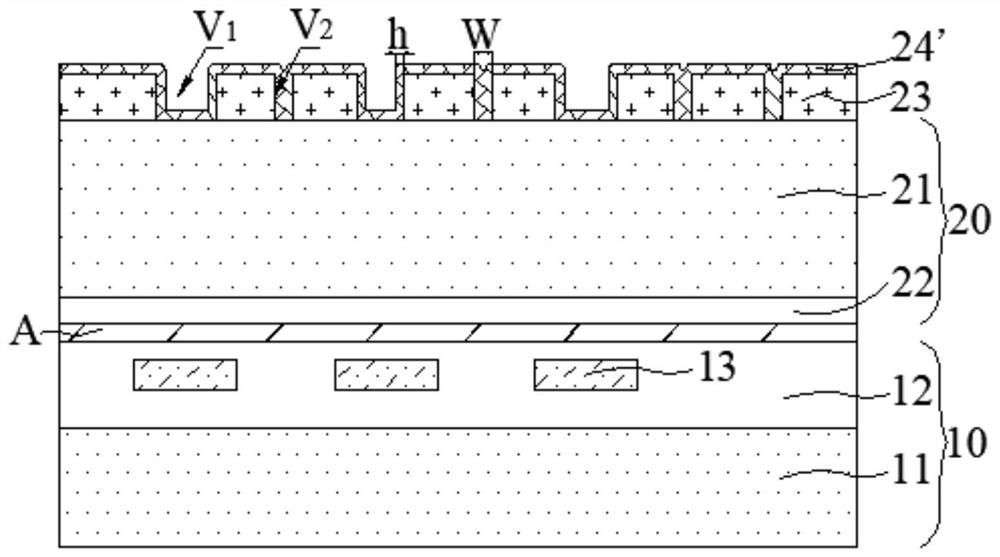

Cavity type film bulk acoustic resonator and preparation method thereof

InactiveCN107528561AReduce the thermal steady state temperatureHigh hardnessImpedence networksSteady state temperatureAmorphous silicon

The invention relates to a cavity type film bulk acoustic resonator, comprising a substrate, an isolation layer, a support layer, a bottom electrode layer, a piezoelectric layer and a top electrode layer that are sequentially arranged from bottom to top, wherein the middle part of the upper surface of the isolation layer is recessed downwards to form a groove, the groove is sealed by the support layer and the substrate to form a sealed cavity, the height of the lower surface of the sealed cavity is less than the height of the upper surface of the substrate, the lower surface of the sealed cavity is a flat surface, and the material of the support layer is SiC. And meanwhile, the invention also discloses a preparation method of the acoustic resonator. According to the cavity type film bulk acoustic resonator and the preparation method thereof disclosed by the invention, the structure of the device is stabilized by the SiC support layer, and the power capacity can be improved; the heat can be effectively dissipated, the thermal steady-state temperature of the device can be reduced, and good thermal stability can be achieved; and according to the method, amorphous silicon layers are removed by using an acetone solution lift-off process, a CMP process can be simplified, the grinding time can be reduced, the grinding uniformity can be improved, and the frequency stability and the rate of finished products of the device can be improved.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

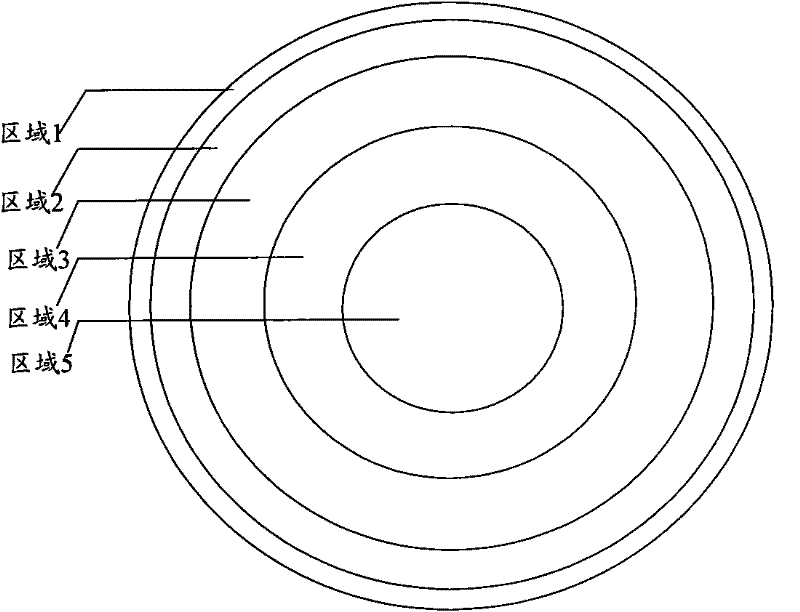

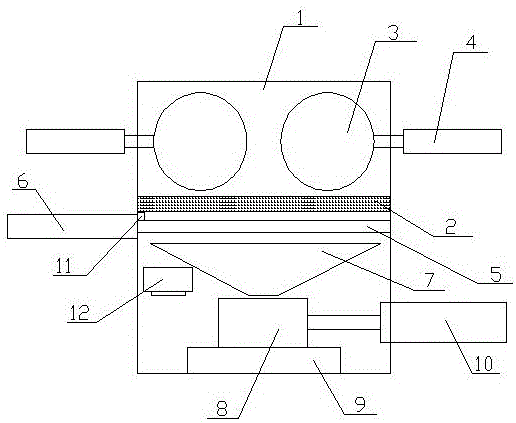

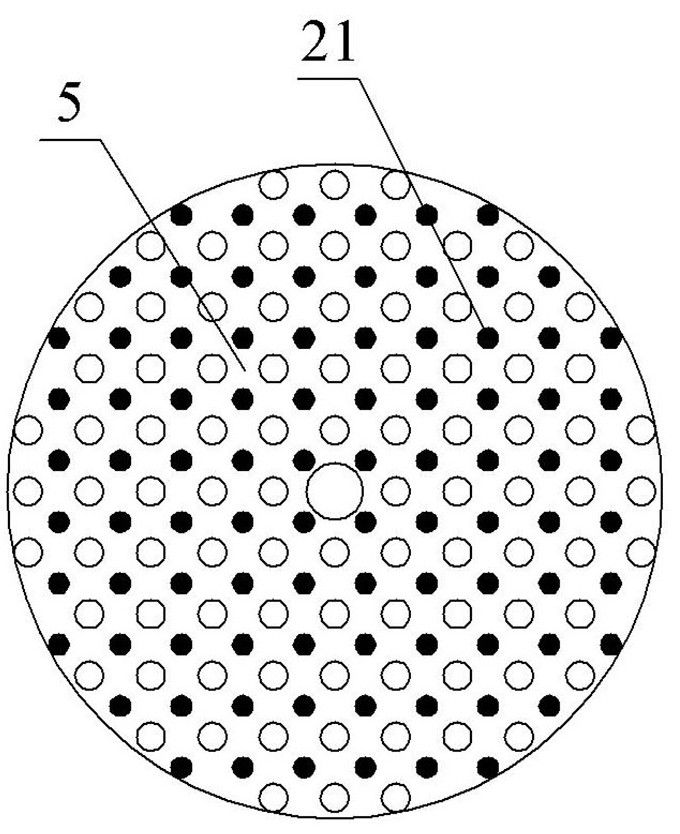

Grinding head and chemical mechanical grinding machine table

InactiveCN102294646AImprove uniformityImprove grinding uniformityLapping machinesCircular surfaceBiomedical engineering

The invention provides a grinding head, the surface in contact with the wafer is circular, and the circular surface has more than 5 relatively independent areas, each area is connected with a corresponding pneumatic device, and the pneumatic device is used for each grinding head. Zones provide pressure. The present invention also provides a chemical mechanical polishing machine platform comprising the above-mentioned polishing head. The adoption of the device of the invention effectively improves the uniformity of grinding wafers.

Owner:SEMICON MFG INT (SHANGHAI) CORP +1

Method for utilizing solid waste for preparing light-weight heat-insulating wall material

ActiveCN106542843ARealize resource utilizationImprove protectionCeramic materials productionCeramicwareFiberCopper

The invention discloses a method for utilizing solid waste for preparing a light-weight heat-insulating wall material. The method comprises the steps of drying copper tailings, gold tailings and chromite residues in a blast air oven at the temperature ranged from 105 to 110 DEG C until the moisture content is lower than 1.0 percent, and then using steel balls for grinding powder and the chromite residues until all material can be sieved through a 150mum standard sieve; mixing the copper tailings, the gold tailings, the chromite residues, a compound expanding agent and a compound dispersant agent, powder grinding for 2 to 10h, and obtaining billets through sieving all ground billets through a 250-mesh standard sieve; filling billet powder into a mould assembled by refractory slabs through a natural stacking way, and isolating the billets and the refractory slabs through ceramic fiber paper; putting the mould into a kiln, raising the temperature to be ranged from 1080 DEG C to 1200 DEG C, and sintering, wherein the temperature raising rate is ranged from 3 to 8 DEG C / min, and the heat preservation time is ranged from 0.5 to 2h; and cooling in the kiln to obtain the light-weight heat-insulating wall material, wherein the cooling rate is ranged from 0.5 to 4 DEG C / min, and the cooling time is ranged from 6h to 15h.

Owner:WUHAN UNIV OF TECH

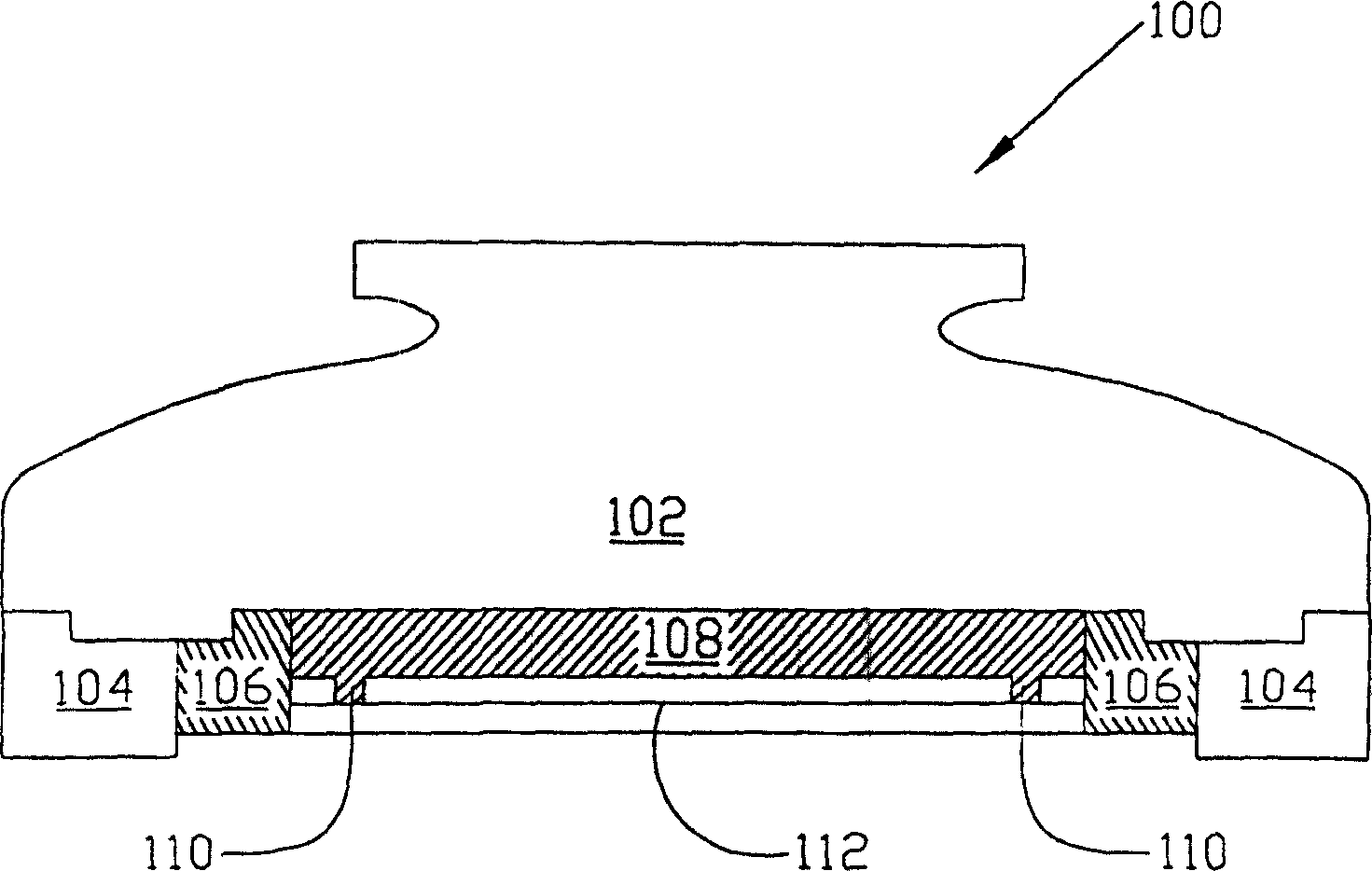

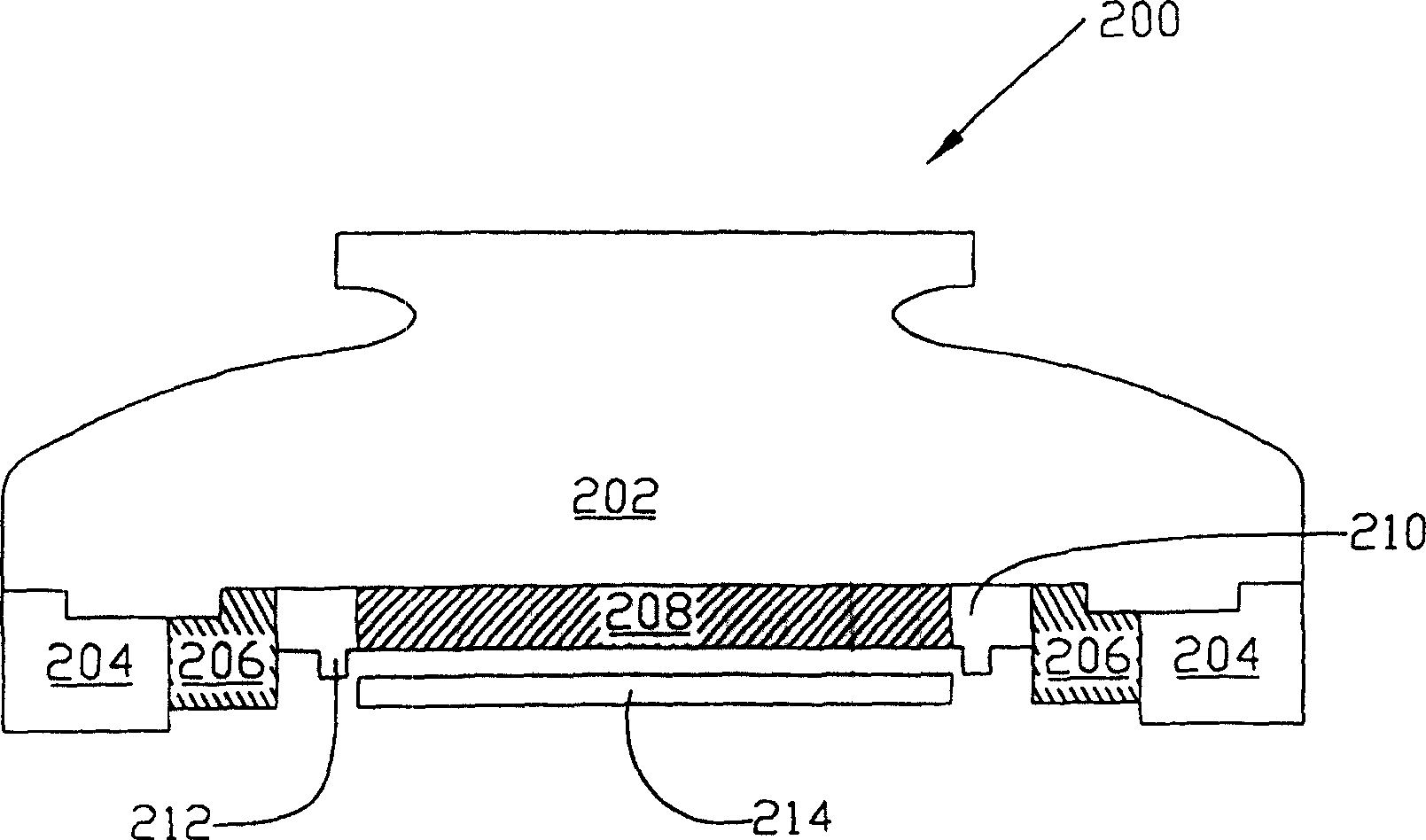

Abrading head for chemical mechanical abrading

InactiveCN1419269AImprove grinding uniformityOvercome the Fast Belt EffectSemiconductor/solid-state device manufacturingWork carriersEngineeringBiomedical engineering

The present invention discloses a abrading head for chemical-mechanical abrading. The abrading head is provided with a non-rigid cutter ring that thas a downwardly projecting non-rigid cutting edge. And the non-rigid cutter ring surrounds the support plate of the grinding head in place of the cutting edge of the conventional support plate. The abrading head also is provided with the elastic membrane that extends to the external margin of the support plate, while the external margin of the elastic membrane is located for a predetermined distance away from the cutting edge.

Owner:UNITED MICROELECTRONICS CORP

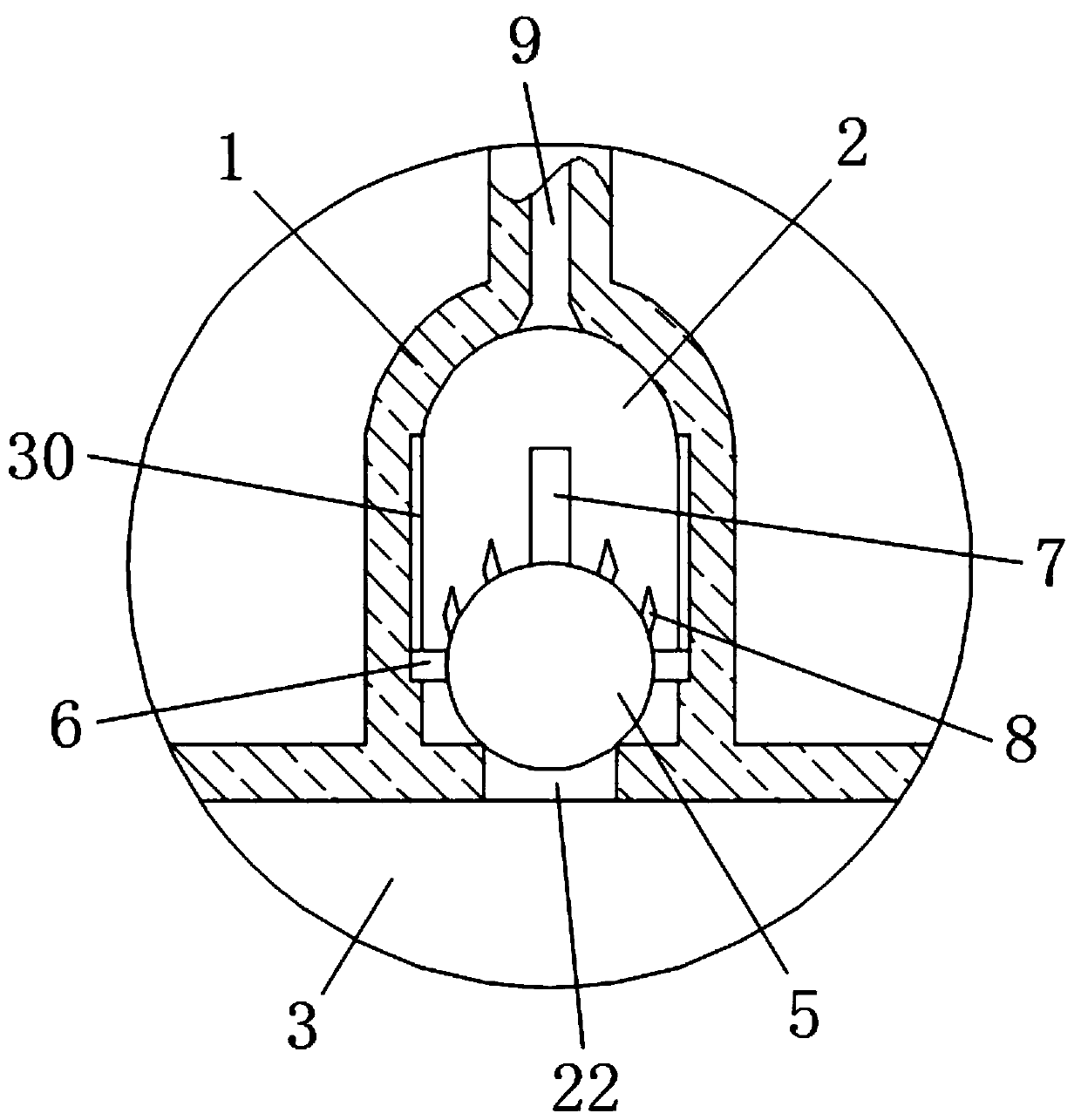

Tablet grinding device for medical care

InactiveCN110813477ANot easy to squeeze outImprove grinding efficiencyOral administration deviceGrain treatmentsNursing careEngineering

The invention discloses a tablet grinding device for medical care, and relates to the field of medical care. The problems that when tablets are ground at present, under the condition that the tablet amount is large, the ground tablets are easily extruded to the position above a grinding disc due to extrusion of the grinding disc, and grinding of the tablets is not uniform can be solved. Accordingto the technical scheme, the device comprises a fixed base, a grinding inner container and a grinding disc. A fixed groove is formed in the fixed base, the grinding disc is arranged in the grinding inner container, an elastic fixed part is connected between the grinding inner container and the inner bottom wall of the fixed groove, a scraping assembly is fixed to the outer wall of the top of the grinding inner container, and a vertical shaft of a grinding motor is connected with the grinding disc. The device is novel in structure, the grinding inner container is driven to vibrate, tablets which are ground to be qualified are discharged, the grinding tablet amount is reduced, the tablets are prevented from being extruded from the grinding contact face, through a scraping plate, the extrudedtablets are pushed back again, and the grinding uniformity is improved.

Owner:丽水市第二人民医院

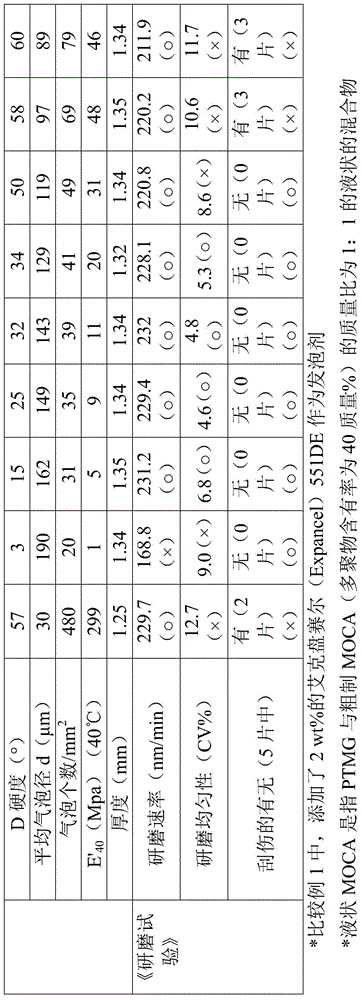

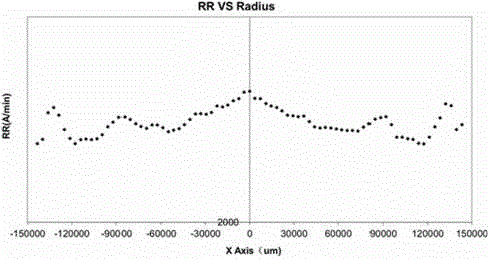

Polishing pad and manufacturing method therefor

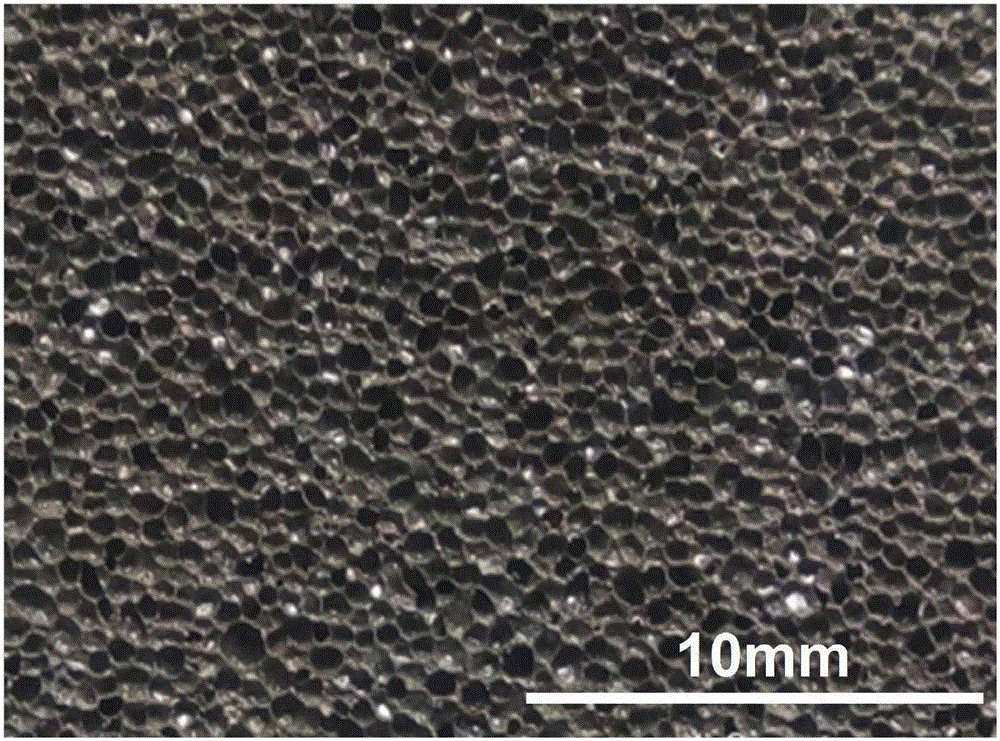

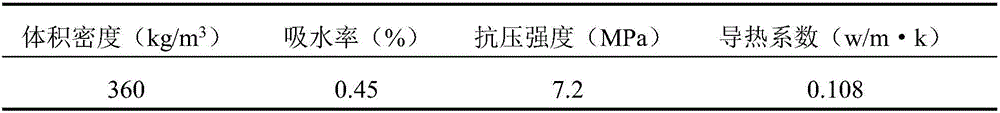

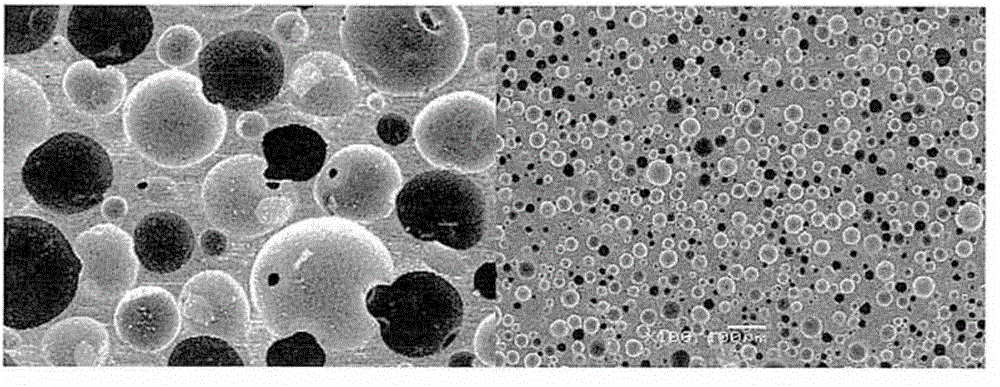

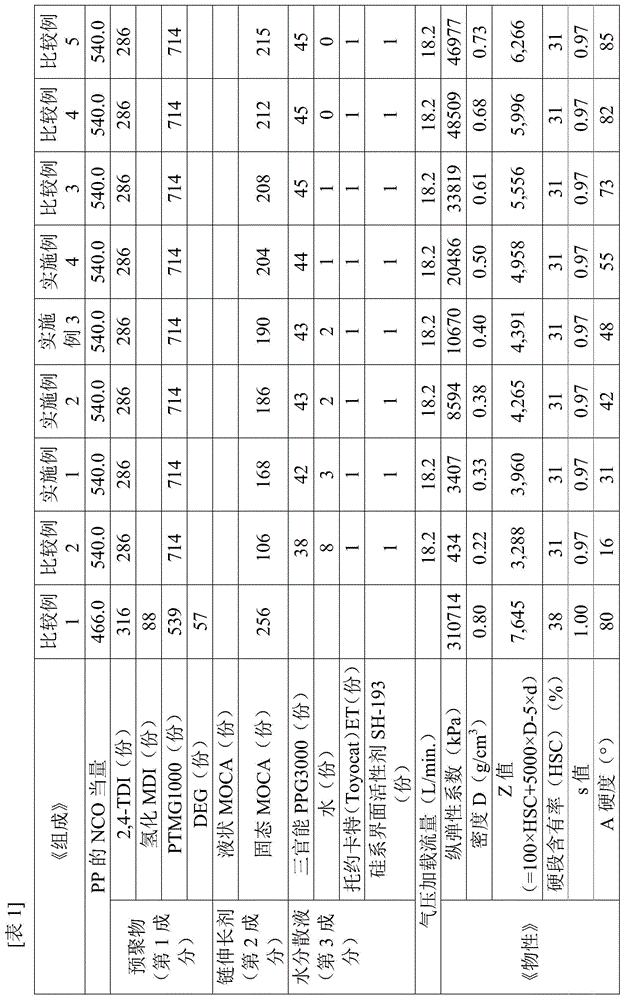

InactiveCN103608903ASuppress strong pressureReduce wearAbrasion apparatusSemiconductor/solid-state device manufacturingYoung's modulusPolyurea

Provided are a polishing pad which remedies the problem of scratches occurring when a conventional hard (dry) polishing pad is used, which is excellent in polishing rate and polishing uniformity, and which can be used for not only primary polishing but also finish polishing, and a manufacturing method therefor. The polishing pad is a polishing pad for polishing a semiconductor device, comprising a polishing layer having a polyurethane-polyurea resin foam containing substantially spherical cells, wherein the polyurethane-polyurea resin foam has a Young's modulus E in a range from 450 to 30000 kPa, and a density D in a range from 0.30 to 0.60 g / cm 3 .

Owner:FUJIBO HLDG

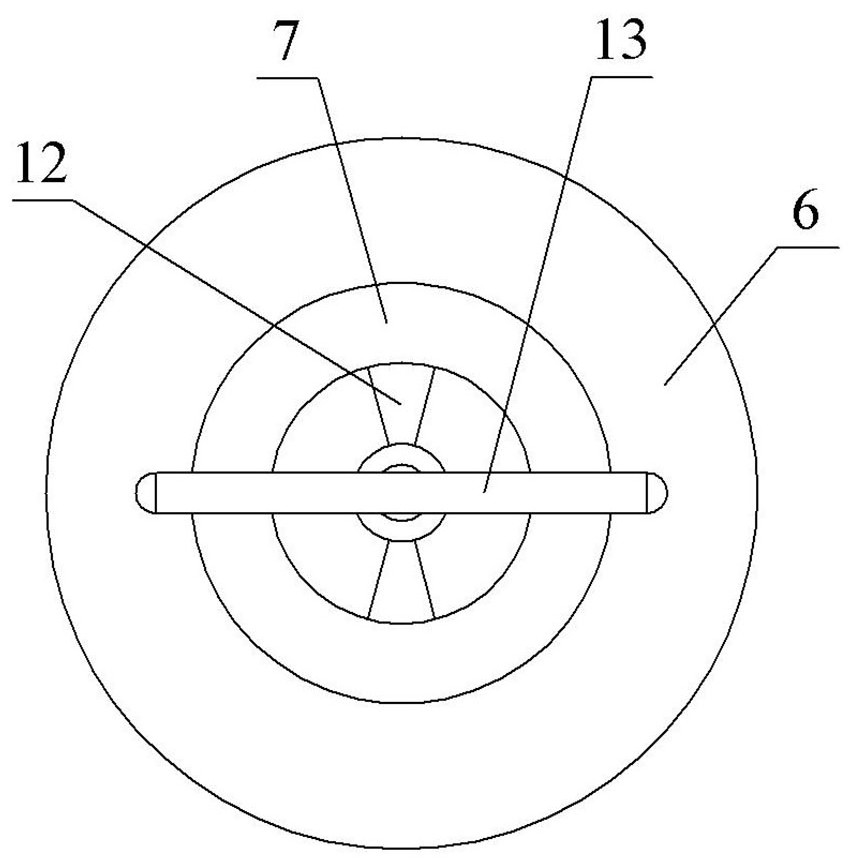

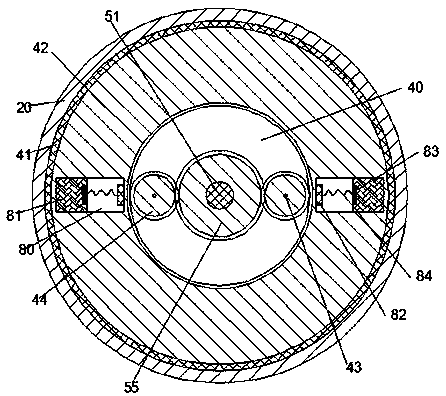

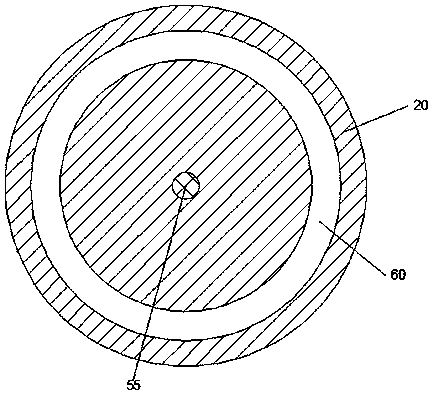

Polishing head for chemical polishing device and chemical polishing device with polishing head

InactiveCN102909651AEasy to operateEasy to useLapping machinesLapping toolsAsymmetric distributionEngineering

A polishing head for a chemical polishing device comprises concentric annular polishing areas with independent polishing subareas, and a force application device, wherein the concentric annular polishing areas are symmetrically distributed by taking the center of the polishing head as the center; the independent polishing subareas are arranged in the concentric annular polishing areas respectively; and the force application device acts on the polishing head and independently controls stresses of the polishing subareas respectively. The invention further relates to the chemical polishing device with the polishing head. The chemical polishing device further comprises a rotating shaft, a polishing table and a polishing pad. Asymmetric polishing in a wafer can be achieved by adopting the polishing head, applying larger pressure in an area with a thicker film and applying smaller pressure in an area with a thinner film, so as to improve the polishing uniformity of asymmetric distribution of film thickness in the wafer. The polishing head is simple to operate, convenient to use and popularize and high in practicability, and can satisfy polishing requirements of different products.

Owner:SHANGHAI HUALI MICROELECTRONICS CORP

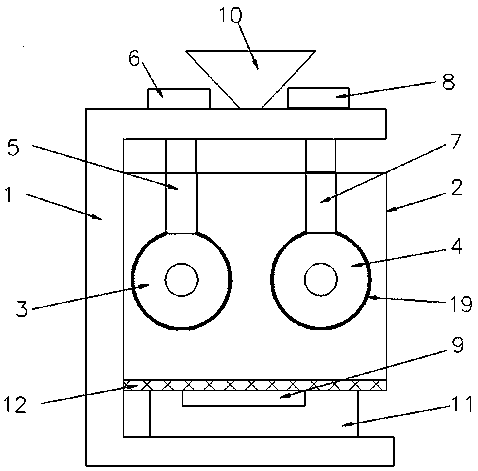

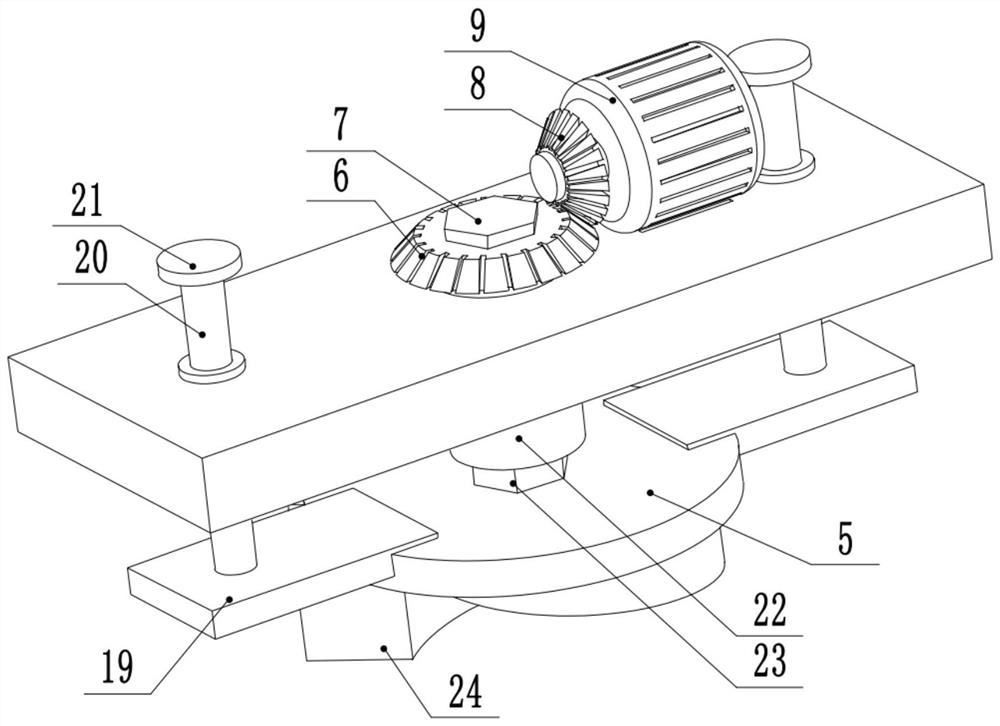

Double-layered bean grinding device

InactiveCN106000535AImprove grinding uniformityPrevent damage screenSievingScreeningTelescopic cylinderDischarge efficiency

The invention provides a double-layer bean grinding equipment, which includes a box body. A screen is arranged in the middle of the box body. The grinding ball is driven to move left and right by the push cylinder arranged at one end, the lower end of the screen is provided with a grinding bottom plate, the left end of the grinding bottom plate and the outside of the box are provided with a telescopic cylinder, and the telescopic cylinder drives the grinding bottom plate to close the screen, the lower layer A receiving hopper is arranged inside the box body, and a placing box is arranged under the receiving hopper. Grind the bean raw materials through the grinding balls, and screen the ground raw materials through the sieve to improve the uniformity of the grinding, set the grinding bottom plate, protect the sieve, prevent the grinding ball from damaging the sieve, set the placement box and weigh The device weighs the ground product, and sets up a scraper and a cleaning device to improve the feeding efficiency of the equipment and improve the grinding accuracy of the bean raw material.

Owner:ANHUI JIAGUDOU FOOD CO LTD

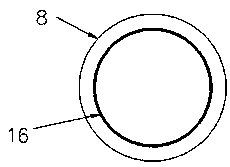

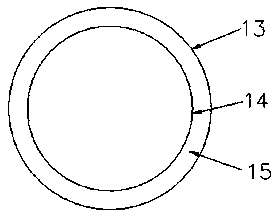

Pipeline grinding tool

InactiveCN109290863APolished evenlyQuality improvementRevolution surface grinding machinesGrinding drivesDrive shaftArchitectural engineering

The invention discloses a pipeline grinding tool. The pipeline grinding tool comprises a base, a fixing column is fixedly installed on one side of the upper end surface of the base, one side of the fixing column is connected with a first telescopic mechanism, one end of the first telescopic mechanism is provided with a first fixing block, and a first clamping groove is formed in the first fixing block; a second fixing block is further arranged on the upper end surface of the base, the second fixing block is symmetrically arranged with the first fixing block, a second clamping groove is formedin the second fixing block, a plurality of sets of grinding rings are installed between the first fixing block and the second fixing block, and a fixing base is installed at the bottoms of the grinding rings; and the fixing base is fixedly connected with the upper surface of the base through a right-angled connecting piece, one end of the second fixing block is connected with a second telescopic mechanism, the second telescopic mechanism is connected with a driving shaft, the driving shaft is connected with a motor, and the motor is fixed on an installing base. According to the tool, the structure design is novel, uniform grinding of the outer wall of a pipeline can be realized, the grinding efficiency is high, the grinding uniformity is good, so that the pipeline quality is improved; andin addition, the adopted grinding rings are not easy to damage, and the service life is long.

Owner:马鞍山金顺来工业设计有限公司

Sand making device for building engineering

InactiveCN111604153ASmall granularityImprove grinding uniformityGrain treatmentsArchitectural engineeringElectric machinery

The invention relates to a sand making device for building engineering. The device includes a barrel, an end cap is arranged at an opening in the top end of the barrel, the center of the end cap is provided with a feed inlet, the feed inlet is internally provided with a mounting frame, a vertical shaft is rotationally connected to the mounting frame, the portion, in the barrel, of the vertical shaft is connected with smashing hammers, a filter plate is arranged on the inner side face of the barrel and located below the smashing hammers, a grinding block is connected to the vertical shaft and located below the filter plate, the position, corresponding to the grinding block, on the inner side face of the barrel is provided with a grinding base, the surfaces of the grinding block and the grinding base are provided with grinding protrusions, a screening net is arranged on the bottom end face of the barrel and located below the grinding block, a discharge hopper is arranged on the outer side face of the barrel and located below the screening net, the top end of the vertical shaft is connected with a motor, and the top end of the motor is connected to a fixing frame on the upper surfaceof the end cap through an adjusting mechanism. In general, the device has the advantages of reasonable structural design, uniform sand grain grinding size and long service life.

Owner:河南航天建筑工程有限公司

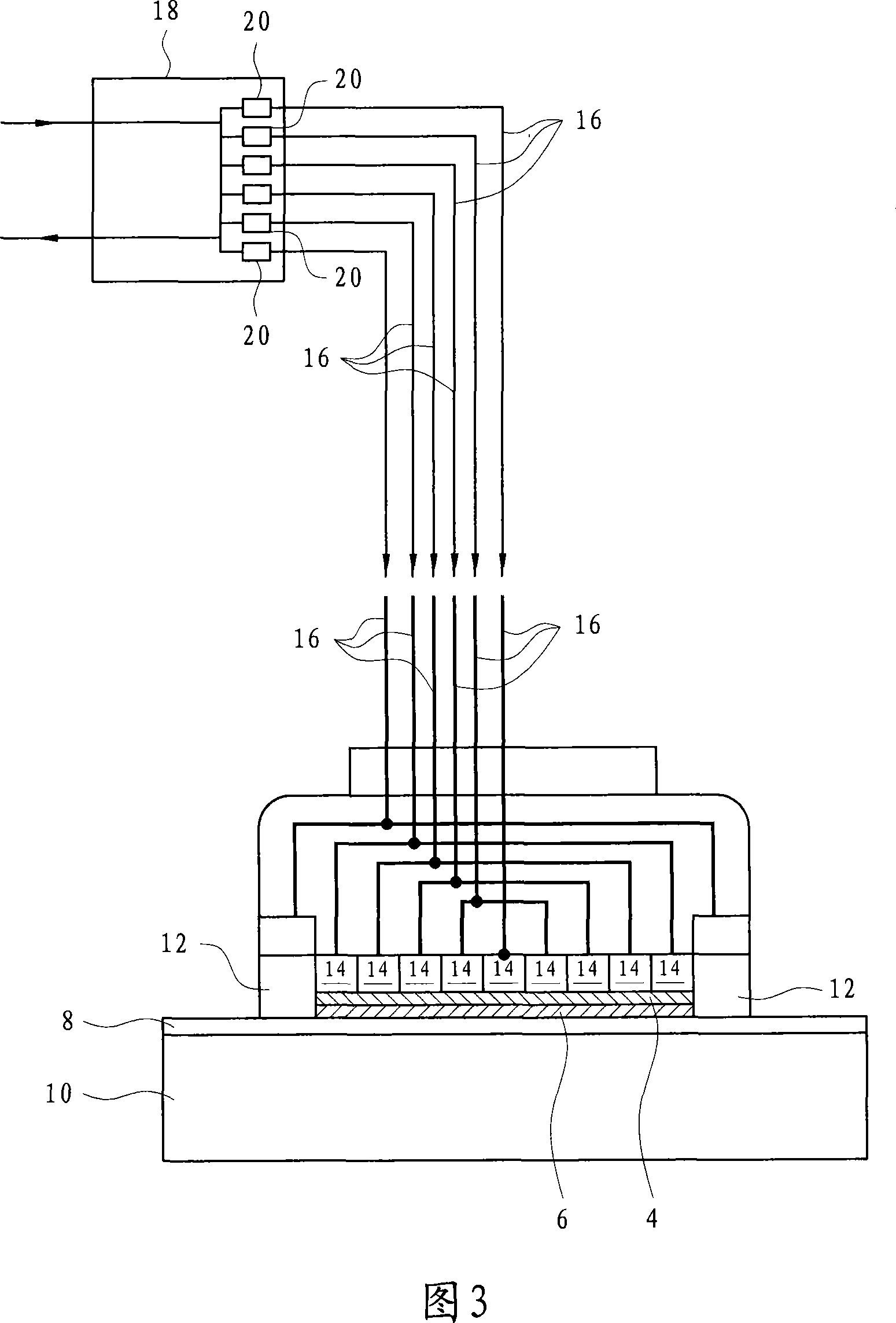

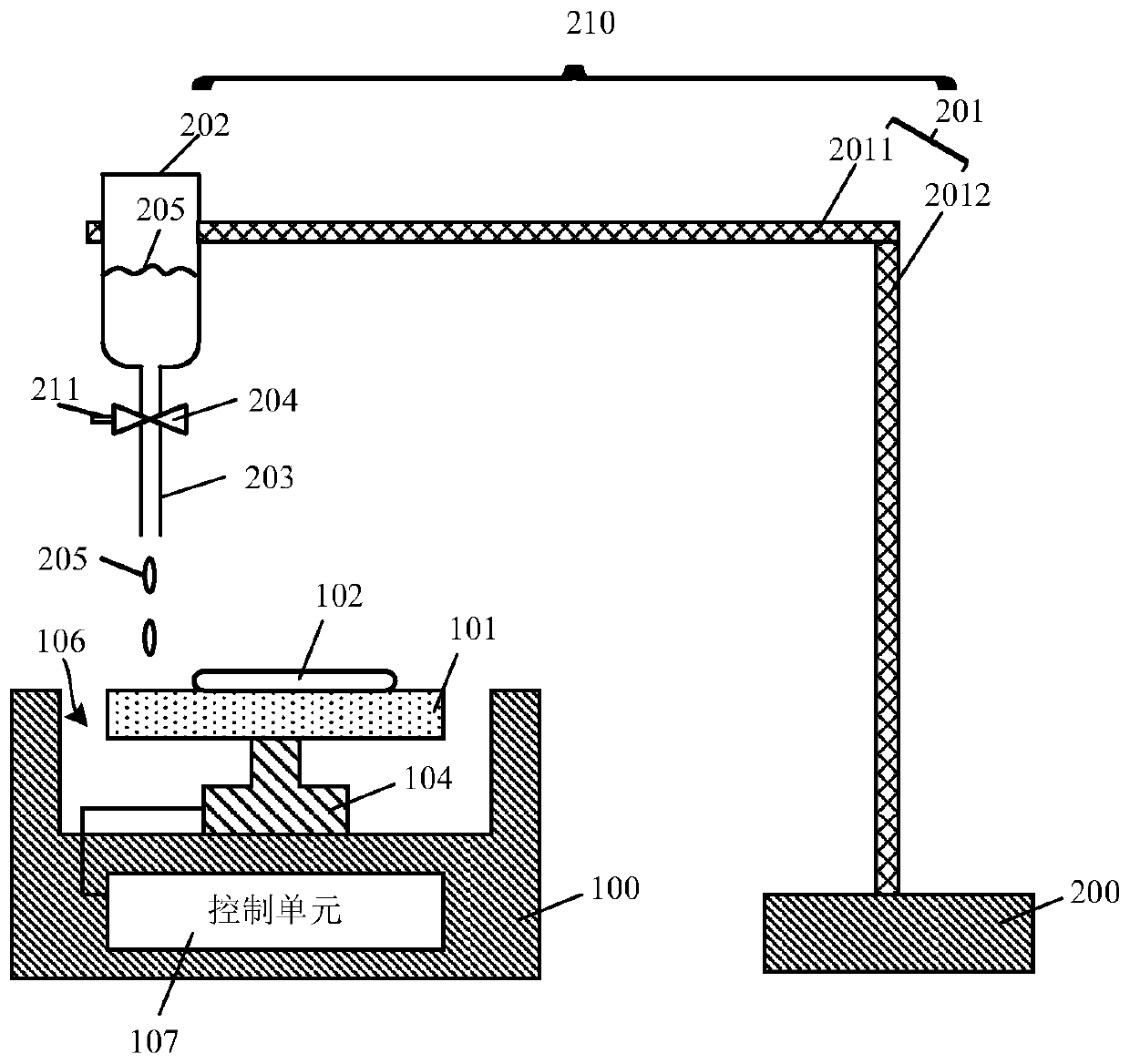

Cmp system with temperature-controlled polishing head

InactiveCN101224561AIncrease grinding rateImprove grinding uniformityPolishing machinesSemiconductor/solid-state device manufacturingTemperature controlEngineering

The invention relates to a chemical mechanical polishing system with a temperature-controlled grinding head for grinding wafers, which includes a grinding head; an inner tube connected to the grinding head, wherein the inner tube is filled with a heat medium; a connected inner tube medium heater; and a pressure controller connected to the inner tube. The chemical mechanical polishing system of the present invention does not create unnecessary complexity on the wafer, and can increase the chemical mechanical polishing rate and improve the chemical mechanical polishing uniformity.

Owner:TAIWAN SEMICON MFG CO LTD

Adjustment method for outer shape of ground component

ActiveCN105856060AImprove grinding uniformityConsistent grinding removal rateLapping machinesAutomotive engineering

The invention provides an adjustment method for the outer shape of a ground component. According to the adjustment method, all areas of the ground component are adjusted under different conditions so that the surface of the ground component can be kept flat all the time, and accordingly the overall grinding uniformity of the ground component is improved; residues of ground by-products in trenches of the ground component are reduced, and the ground chip is prevented from being scratched; the grinding and removal speed of the different areas of the ground component is made to be the same, and the grinding uniformity of the different areas of the ground component is improved; and the service life of the ground component is prolonged, and the grinding cost is reduced.

Owner:SEMICON MFG INT (SHANGHAI) CORP

Steel plate double-face grinding device

InactiveCN112123058ASimple structureAvoid manual operationGrinding carriagesGrinding drivesGear wheelSmart grid

The invention belongs to the technical field of intelligent power grids, and provides a steel plate double-face grinding device which comprises a workbench and a driving part. The upper surface of theworkbench is fixedly connected with a mounting frame, screw rods are rotatably arranged at the at least end of the mounting frame, two transmission parts are arranged oppositely on each screw rod ina matched mode, and the transmission parts are connected with grinding rolls; the driving part is connected with the screw rods through connecting pieces and used for driving the screw rods to rotate;and the transmission parts comprises shells and first steering gears, the first steering gears are rotatably arranged in the shells and matched with the screw rods, second steering gears are rotatably arranged in the shells and coaxially and fixedly connected to the ends of the grinding rolls, and the first steering gears mesh with the second steering gears. The steel plate double-face grinding device has the advantages of being simple in structure, convenient to operate, good in grinding uniformity, high in working efficiency and convenient to popularize and implement.

Owner:武秀侠

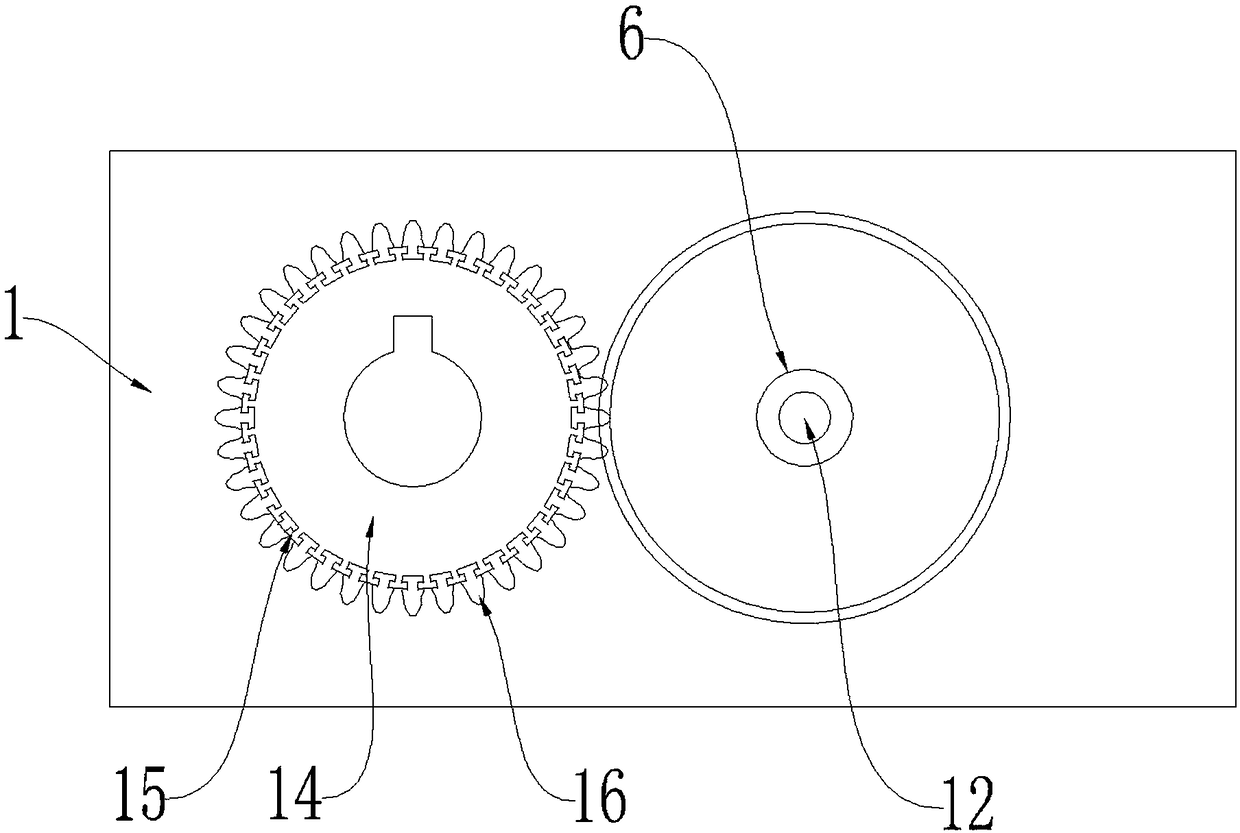

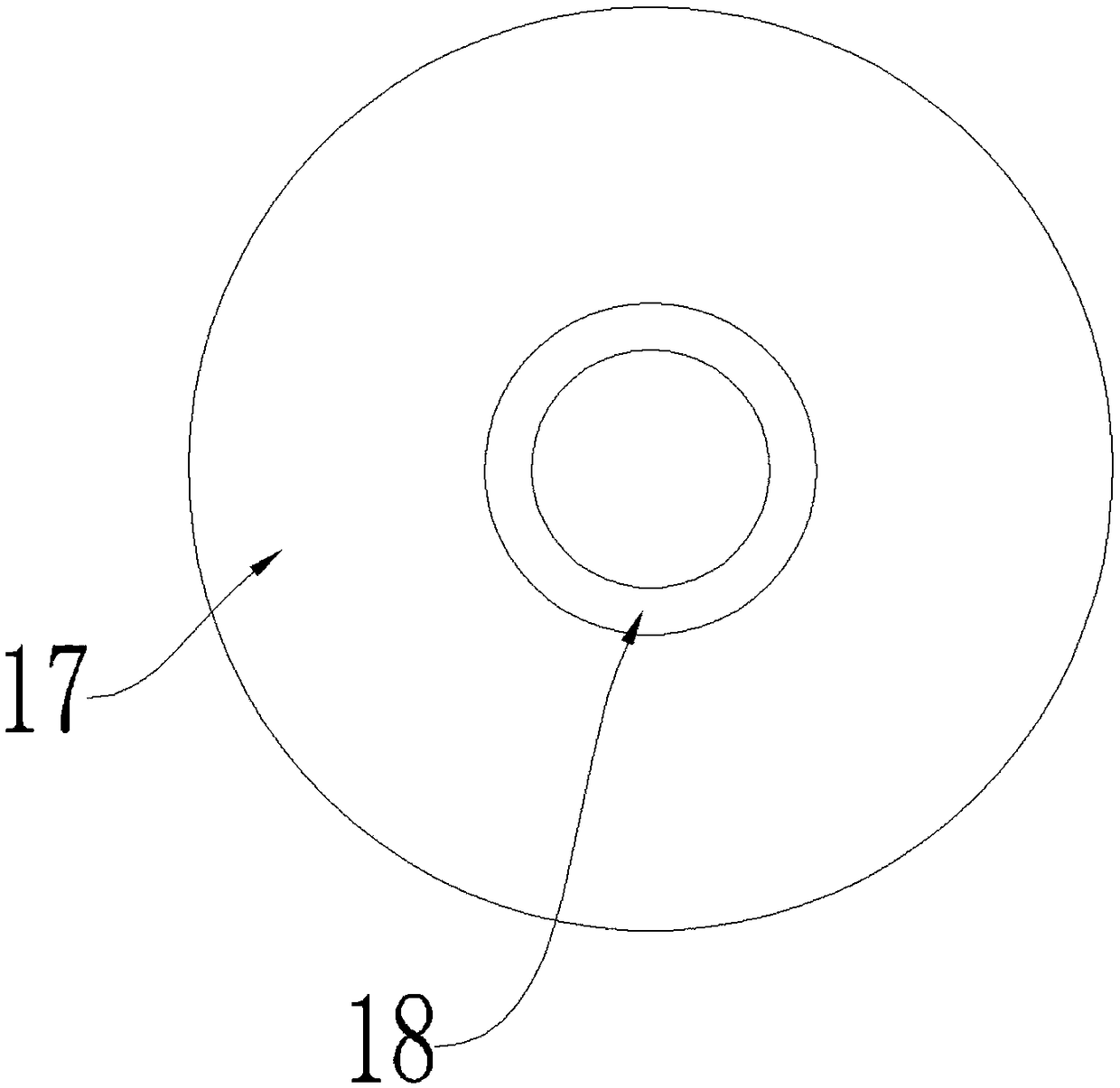

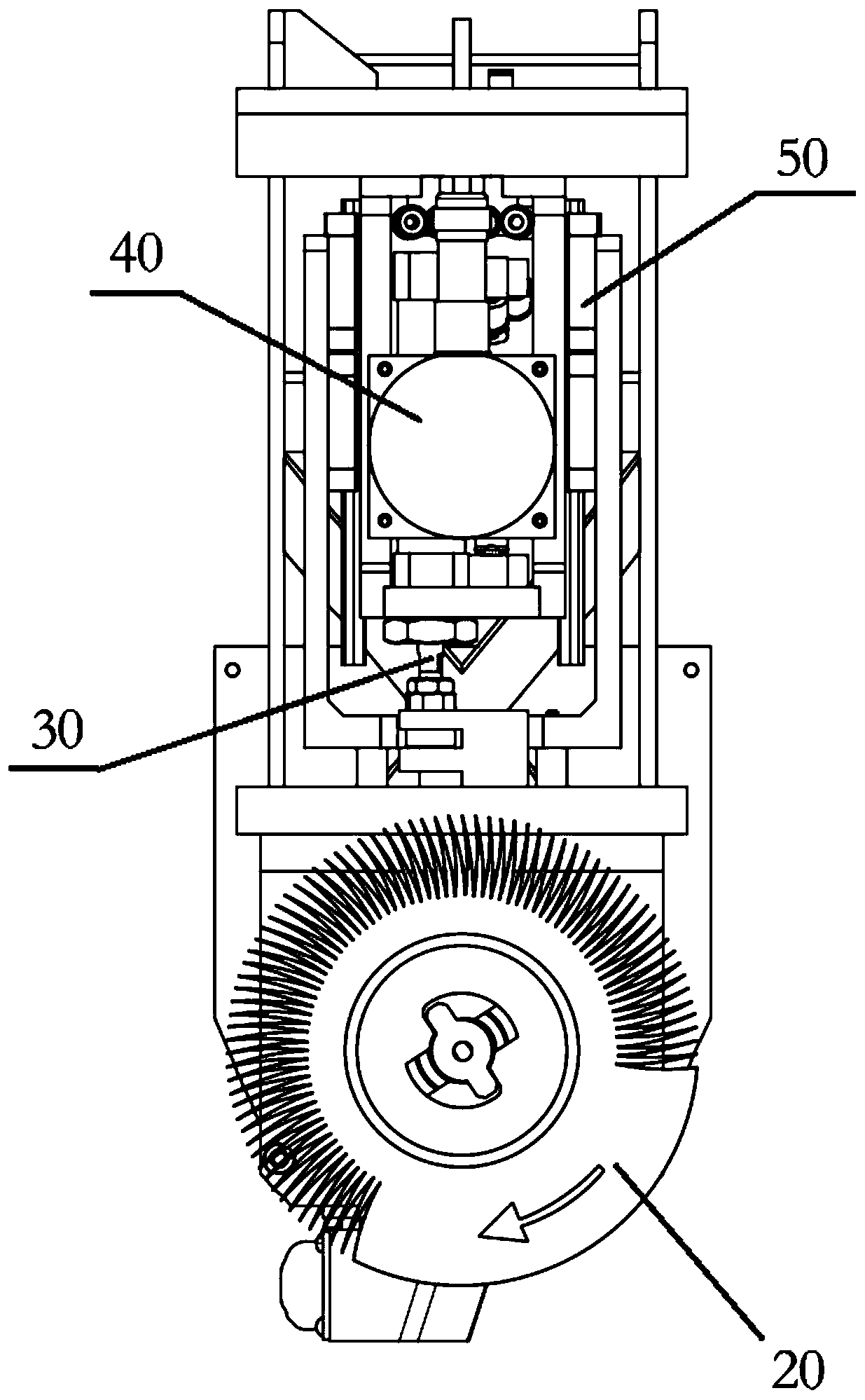

Burr polisher for gear machining

InactiveCN108942485AEasy to installAchieve grindingEdge grinding machinesGrinding drivesGear wheelDrive motor

The invention relates to a burr polisher for gear machining. The burr polisher comprises a base, the base is internally provided with a driving chamber, the driving chamber is internally provided witha driving motor, the base is rotatably provided with a brush shaft, and the driving motor drives the brush shaft to rotate; the brush shaft is fixedly provided with a wheel brush, the wheel brush comprises a brush wheel hub, the outer side wall of the brush wheel hub is evenly provided with a plurality of clamping grooves extending in the axial direction of the brush wheel hub, the clamping grooves are internally provided with brush strips, and the brush strips are in tooth shapes; and the burr polisher further comprises a gear supporting shaft fixed on the base, the gear supporting shaft isfurther slidably provided with a lower friction disc and an upper friction disc, the lower side of the lower friction disc is provided with a bearing supporting part, the upper side of the upper friction disc is provided with a compressing part, and the bearing supporting part and the compressing part are both fixed on the gear supporting shaft. By means of the burr polisher for the gear machining, comprehensive polishing on gear end surfaces and gear teeth can be realized, meanwhile, because the gear supporting shaft is vertically arranged, installation of gears to be performed burring is facilitated, the gears and a brush wheel contact highly consistent, and the polishing uniformity of each gear tooth is good.

Owner:合肥银泉铸造有限责任公司

Semiconductor device, manufacturing method thereof and chip bonding structure

PendingCN112509915AUniform pattern densityImprove grinding uniformitySemiconductor/solid-state device detailsSolid-state devicesDevice materialElectrical connection

The invention provides a semiconductor device and a manufacturing method thereof, and a chip bonding structure. The manufacturing method comprises the steps of providing a first wafer and a second wafer which are bonded; forming a patterned insulating layer on the second substrate, wherein the patterned insulating layer is provided with a first opening and an auxiliary opening which are exposed out of the second substrate; forming a protective layer, wherein the protective layer fills partial depth of the auxiliary hole and covers the side wall of the first hole; forming a silicon through hole; forming a second metal layer, wherein the second metal layer comprises an interconnection metal layer and an auxiliary metal layer, the interconnection metal layer fills the silicon through hole andis electrically connected with the first metal layer, and the auxiliary metal layer fills the auxiliary opening. According to the method, the forming process of the auxiliary metal layer is compatible with the TSV process, no extra process needs to be added, the auxiliary metal layer is formed under the condition that the cost is not increased, the pattern density (metal distribution density) ofthe surface of the second wafer tends to be uniform, the chemical mechanical polishing uniformity is improved, and therefore the flatness of the surface of the wafer obtained after CMP is improved.

Owner:WUHAN XINXIN SEMICON MFG CO LTD

Gear polishing device

PendingCN110125491AAchieve grindingNovel structural designEdge grinding machinesGear-cutting machinesGear wheelEngineering

The invention discloses a gear polishing device. The gear polishing device comprises a base, a U-shaped bracket and a polishing mechanism, the base is fixedly mounted on the inner side of the U-shapedbracket, two sets of rotating bearings are perpendicularly mounted on the upper end surface of the base, an annular blocking block is fixedly welded to the outer wall of the upper end of each rotating bearing, a to-be-machined gear is fixedly mounted on each rotating bearing, one end of each rotating bearing is connected with a first motor arranged on the base, and a transverse sliding rail is further mounted on the upper end surface of the base; and a sliding block is slidably connected with the transverse sliding rail, a polishing piece fixing seat is mounted on the sliding block, a double-surface longitudinal polishing piece is mounted on the polishing piece fixing seat and arranged between the two sets of rotating bearings, the polishing mechanism comprises a transverse beam, a secondmotor, a rotating shaft and a polishing assembly, and a plurality of sets of telescopic cylinders are mounted between the upper end surface of the transverse beam and the inner side of the upper endof the U-shaped bracket. The gear polishing device is novel in structure design, surface and side face polishing of the gear can be achieved, the polishing effect is high, and the work efficiency is improved.

Owner:江苏兴利达齿轮有限公司

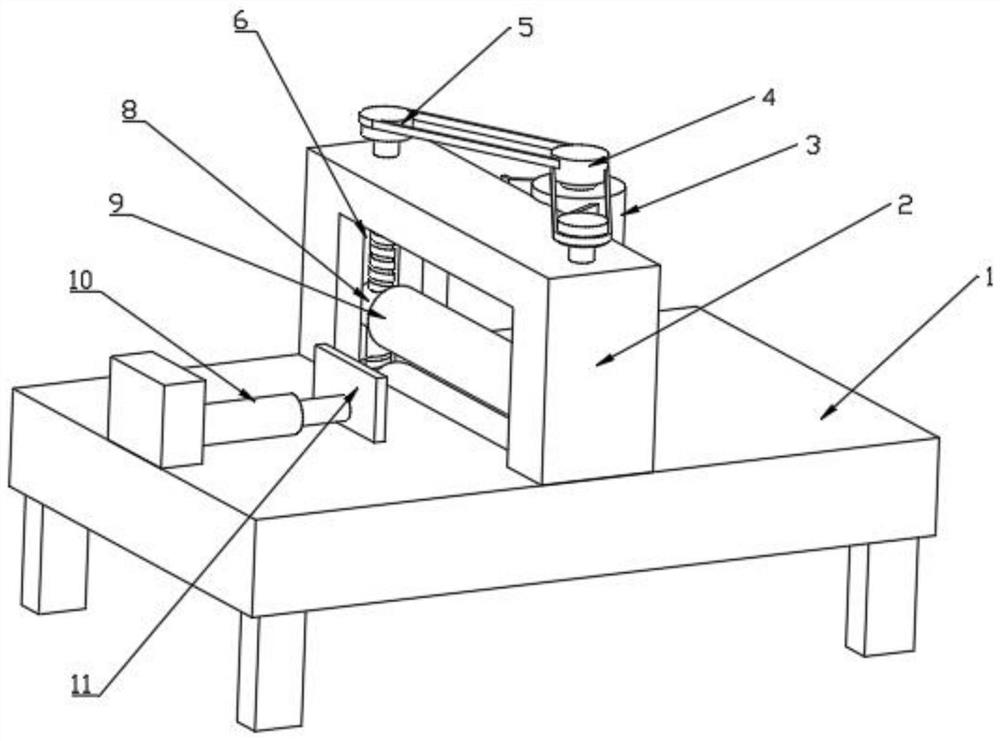

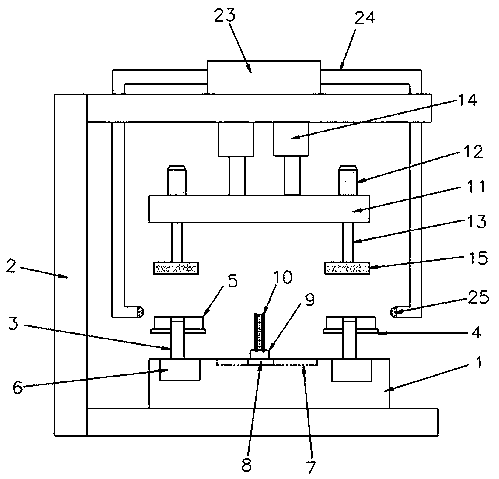

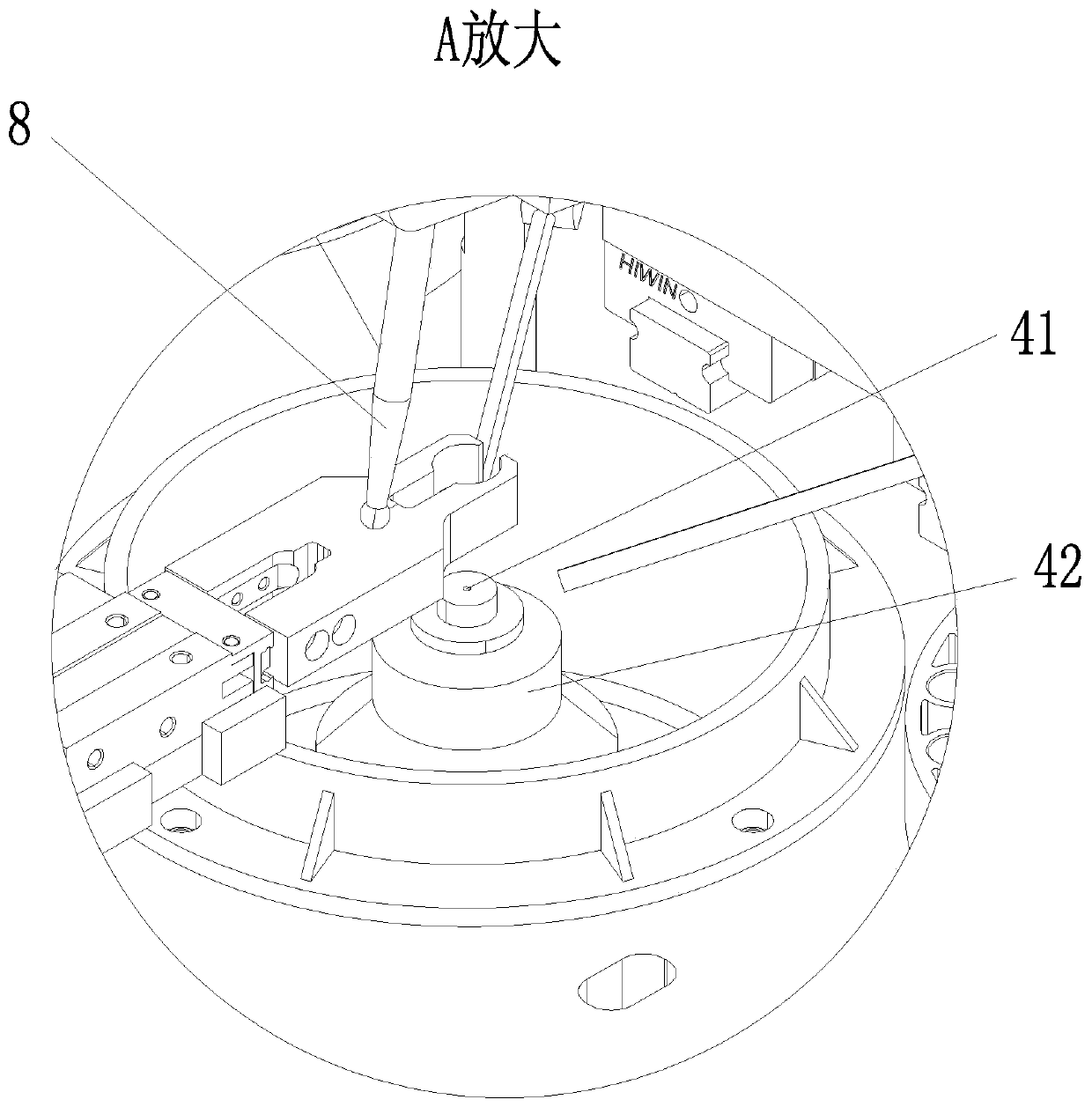

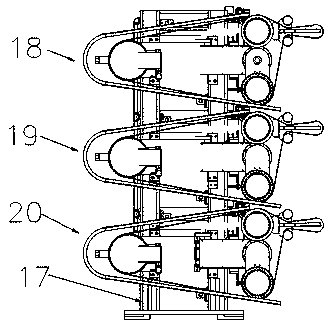

Upper swinging type lens grinding machine

PendingCN110153838AImprove grinding efficiencyImprove grinding uniformityOptical surface grinding machinesGrinding drivesMaterial transferEngineering

The invention relates to an upper swinging type lens grinding machine. One or more grinding complete machines are included. Each grinding complete machine comprises a rack, wherein the rack is provided with a grinding mechanism for grinding to-be-machined materials, a material storage mechanism arranged on one transverse side of the grinding mechanism, and a finished product storage mechanism arranged on the other transverse side of the grinding mechanism, and the rack is further provided with a material transferring mechanism. The materials include a material clamp and a material body arranged on the material clamp, wherein the material to-be-machined face at the bottom of the material body is exposed out of the bottom of the material clamp. Each grinding mechanism comprises a grinding groove, a grinding rotation driving mechanism, a material pressing bar arranged above the grinding groove, and a swing arm mechanism which is used for clamping the material pressing bar and driving thematerial pressing bar to swing around the contact point where the material pressing bar and the materials are in contact in the longitudinal direction of the grinding groove in a reciprocating manner.The upper swinging type lens grinding machine can replace manual grinding, the grinding efficiency of the grinding machine is high, operation is simple, and the quality of ground finished products isgood.

Owner:福州研达自动化有限公司

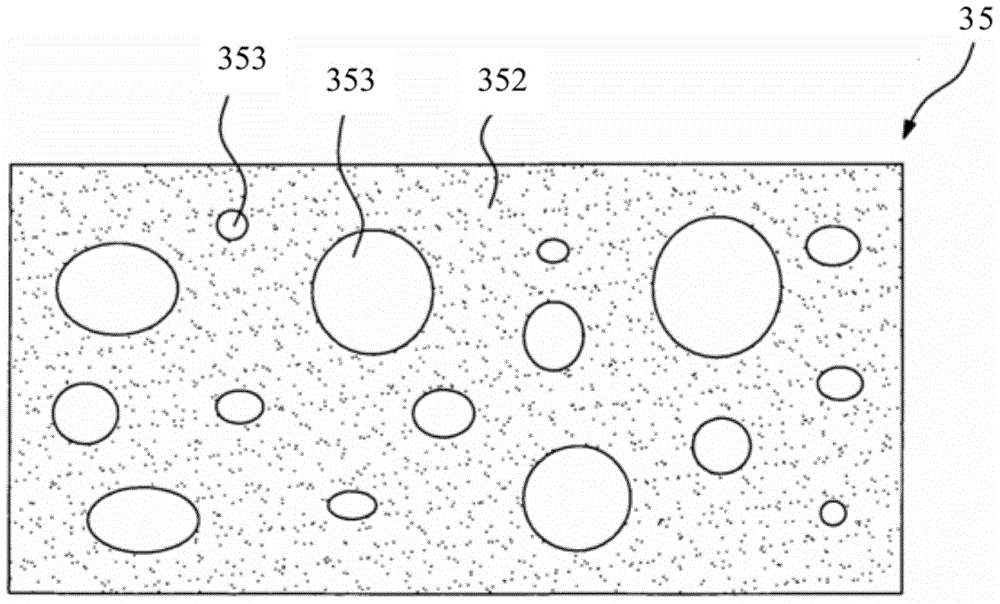

Grinding pad, grinding device and method for manufacturing grinding pad

ActiveCN104552034AHigh hardnessImprove grinding uniformityAbrasion apparatusGrinding devicesFiberPolymer chemistry

The invention relates to a grinding pad which comprises a foam resin structural framework and a plurality of auxiliary fibers. The auxiliary fibers are independent to one another and optionally dispersed in the foam resin structural framework. The invention further provides a grinding device and a method for manufacturing the grinding pad.

Owner:SAN FANG CHEM IND

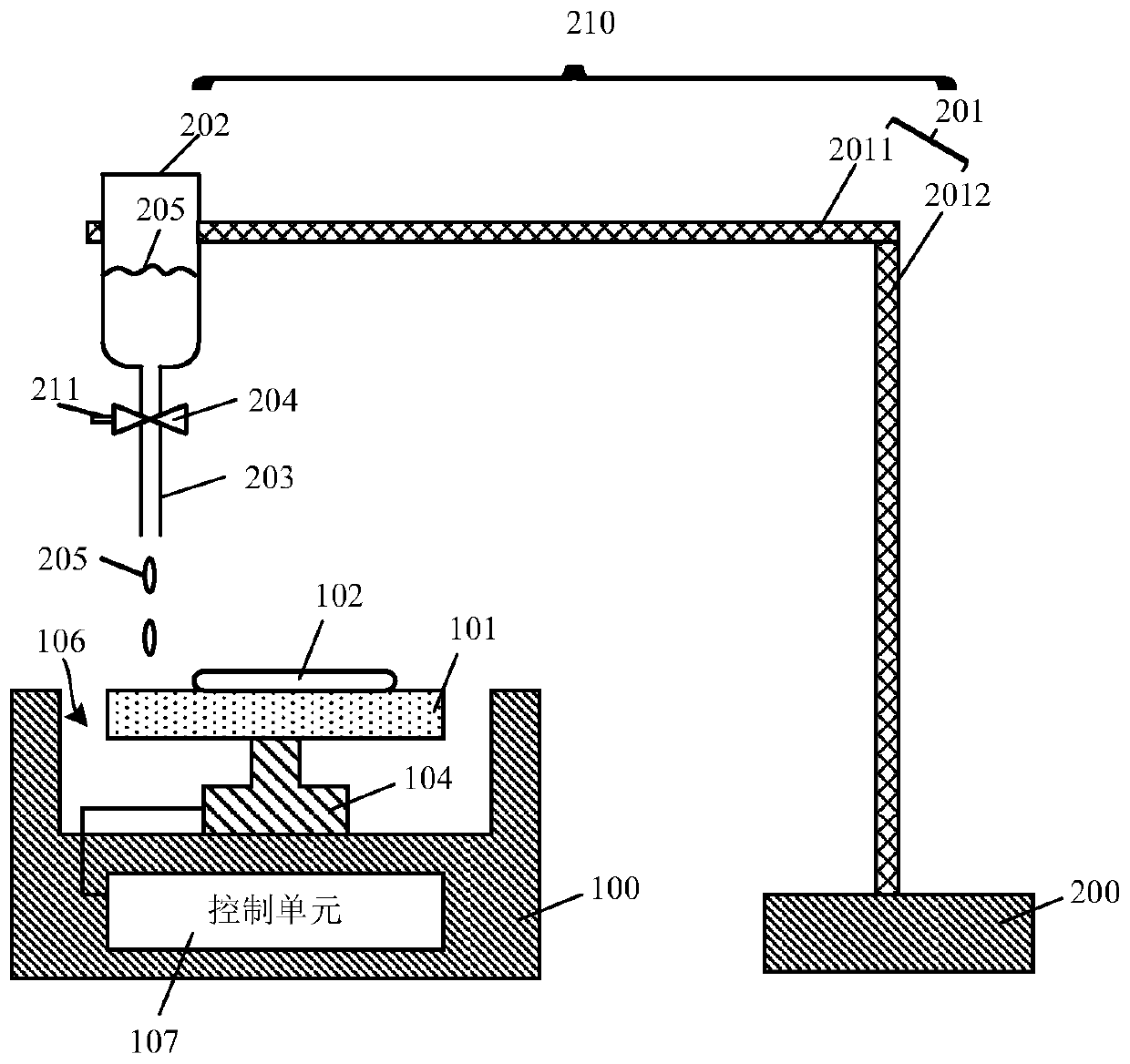

Invalid wafer grinding device

PendingCN111152128AImprove grinding uniformityImprove uniformityLapping machinesGrinding/polishing apparatusWaferEngineering

The invention provides an invalid wafer grinding device. The invalid wafer grinding device comprises a grinding table provided with a grinding surface and used for grinding the to-be-ground surface ofan invalid wafer, and a grinding fluid automatic dripping unit used for evenly dripping grinding fluid onto the grinding surface of the grinding table when the grinding table carries out grinding onthe to-be-ground surface of the invalid wafer. The grinding fluid automatic dripping unit can evenly drip the grinding fluid onto the grinding surface of the grinding table when the grinding table carries out grinding on the to-be-ground surface of the invalid wafer. Thus, the invalid wafer grinding device can accurately control the dripping rate and dripping quantity of the grinding fluid to prevent waste of the grinding fluid through manual dripping and can improve the grinding evenness of the invalid wafer. When the reverse side of the invalid wafer needs to be pressed during grinding, an operator or an inspector can press the reverse side of the invalid wafer with the two hands so as to improve the grinding evenness of the invalid wafer.

Owner:YANGTZE MEMORY TECH CO LTD

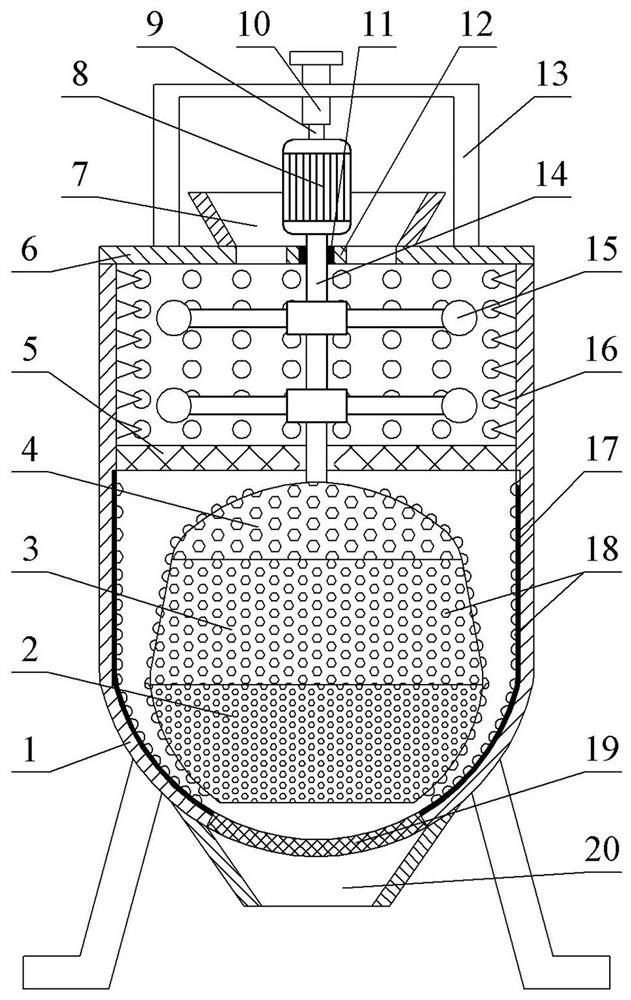

Material ball grinding device

InactiveCN108816450ABall milled evenlyImprove the quality of ball millingGrain treatmentsEngineeringMechanical engineering

The invention discloses a material ball grinding device. The material ball grinding device comprises a bracket and a ball grinding cylinder, wherein the ball grinding cylinder is fixedly arranged at the inner side of the bracket; two groups of grinding heads are arranged in the ball grinding cylinder, namely a first grinding head and a second grinding head; the first grinding head is connected with a first rotary motor through a first rotary shaft, and the first rotary motor is arranged at the top part of the bracket; the second grinding head is connected with a second rotary motor through a second rotary shaft, and the second rotary motor is arranged at the top part of the bracket; the bottom part of the ball grinding cylinder is provided with a material outlet, and the top part of the ball grinding cylinder is provided with a material inlet; a material collection box is arranged under the material outlet. The material ball grinding device has the advantages that the structure principle is simple, the operation is convenient, the material can be fully performed with ball grinding, the ball grinding efficiency is high, and the ball grinding quality of the material is improved.

Owner:MAANSHAN NIUZE TECH SERVICE

High-efficiency workpiece polishing and polishing device

PendingCN110039416ANovel structural designHigh degree of automationPolishing machinesBelt grinding machinesManipulatorSurface finishing

The invention discloses a high-efficiency workpiece polishing and polishing device. The high-efficiency workpiece polishing and polishing device comprises a base station main body; a grabbing manipulator, an abrasive belt mechanism and a polishing mechanism are arranged on the base station main body; and a cutting fluid circulation filtering system is arranged on one side of the base station mainbody, and the cutting fluid circulation filtering system communicates with the abrasive belt mechanism and the polishing mechanism through pipelines. The high-efficiency workpiece polishing and polishing device is novel in structural design, high in automation degree, and capable of rapidly grinding and polishing workpieces, good workpiece surface treatment uniformity is achieved, and the workpiece quality is improved.

Owner:JIANGSU ZUNSION AUTOMOBILE TECH CO LTD

Dedicated grinding aid capable of prolonging service life and improving uniformity of ceramic grinding ball and manufacturing method of grinding aid

InactiveCN109503025AImprove the lubrication effectImprove cutting performanceActivated carbonNitrogen

The invention discloses a dedicated grinding aid capable of prolonging life and improving uniformity of a ceramic grinding ball and a manufacturing method thereof. The dedicated grinding aid for the ceramic grinding ball is composed of three components, namely a component A, a component B and a component C, wherein the component A is 15-18 parts by weight of silica gel, the component B is sufficiently fermented produced acquired by taking 15-18 parts of corn starch as a raw material and 0.2-0.3 part of yeast powder as a microorganism; and the component C is a ceramic body solidified after performing high-temperature nitrogen atomization by taking 2-3 parts of active carbon powder and 8-10 parts of silicon dioxide as raw materials; the ceramic body comprises three ingredients, namely silicon dioxide, silicon nitride and active carbon; and the composition relation of the three components is that the component C is a core, the component A takes the component C as the center, and the component B is solidified surrounding the component A as a tackifier and an intermediate mass. The grinding aid disclosed by the invention has the technical effects of helping cutting, providing a buffer function, achieving a lubricating function and improving the cutting uniformity.

Owner:山东天汇科技有限公司

Novel biological medicine grinding equipment

The invention discloses novel biological medicine grinding equipment. The novel biological medicine grinding equipment comprises a base and a grinding table fixedly mounted above the base through supporting plates; a rotating cavity is formed in the grinding table; annular grinding grooves communicating with the rotating cavity are formed in the positions, above the rotating cavity, of the end face of the top of the grinding table; a mounting groove is formed in the position, below the rotating cavity, of the grinding table; a driving motor is fixedly mounted in the mounting groove and is in power connection with a first rotating shaft arranged in an upwards extending mode; and the upwards-extending end of the first rotating shaft penetrates through the rotating cavity and extends out of the top of the grinding table.

Owner:广州必果贸易有限公司

Grinding device with grinding dust removing function for derusting surface of steel pipe

ActiveCN110125780AGuaranteed constant pressureImprove grinding uniformityGrinding drivesGrinding machinesEngineeringConstant-force spring

The invention discloses a grinding device with a grinding dust removing function for derusting the surface of a steel pipe. The device comprises two supporting seats, a driving mechanism, a hollow shaft, a plurality of grinding mechanisms, an adjusting mechanism and a grinding dust removing mechanism, the hollow shaft is rotatably arranged on the two supporting seats, the driving mechanism drivesthe hollow shaft to rotate, an adjusting mechanism is arranged on the peripheral surface of the rear end of the hollow shaft, a grinding mechanism is arranged on the adjusting mechanism, the grindingmechanism comprises a constant-force spring, a spring box, a shaft body, a gear, a rack, a sliding rail, a sliding seat, a mounting seat and a grinding head, a spring box and a sliding rail are arranged on the mounting base, a rotatable shaft body is arranged on the spring box, and the spring box is internally provided with a constant-force spring which is fixedly connected with the spring box andthe shaft body respectively. Compared with the prior art, the device has the advantages that the grinding uniformity is good, the derusting effect is good, the application range is wide, and the working efficiency is improved.

Owner:JIAXING JCC PIPING ENG & CONSTR

Abrading head for chemical mechanical abrading

InactiveCN1200449CImprove grinding uniformityOvercome the Fast Belt EffectSemiconductor/solid-state device manufacturingWork carriersEngineeringMechanical engineering

The invention discloses a grinding head for chemical mechanical grinding. The grinding head has a non-rigid knife-edge ring with non-rigid knife-edges protruding downward. The non-rigid knife-edge ring surrounds a support plate of the grinding head to replace the knife-edges on the traditional support plate. The grinding head also has an elastic film extending to the outer edge of the support plate, and the outer edge of the elastic film is a predetermined distance away from the knife edge.

Owner:UNITED MICROELECTRONICS CORP

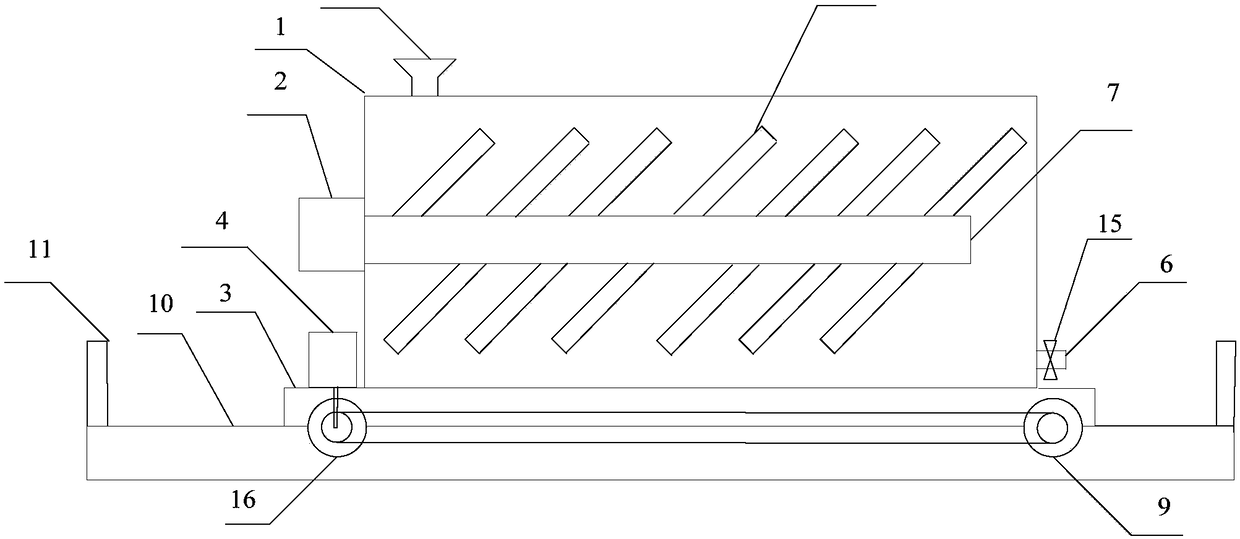

Vortex type small-sized pulverizer

ActiveCN112892792AImprove work efficiencyImprove grinding uniformityGrain treatmentsEngineeringPiston rod

The invention relates to the technical field of grinding, and discloses a vortex type small-sized pulverizer. The vortex type small-sized pulverizer comprises a bottom plate; supporting columns are arranged at the left end and the right end of the upper surface of the bottom plate; the upper portions of the supporting columns are slidably connected with a lifting plate; an air cylinder is arranged on the upper portion of the bottom plate; a piston rod of the air cylinder is fixedly connected with the left end and the right end of the lifting plate; the middle of the lifting plate is rotationally connected with a first rotating rod; a grinding plate is arranged on the lower portion of the first rotating rod; an upper grinding head is arranged on the lower portion of the grinding plate; supporting plates are arranged on the left side and the right side of the upper surface of the bottom plate; first sliding grooves are formed in the lower portions of the supporting plates; the middles of the first sliding grooves are slidably connected with the middles of sliding rods; and the ends, close to the center of the device, of the two sliding rods are fixedly connected with the left side and the right side of a supporting plate, and a grinding pipe is arranged on the outer side of the upper surface of the supporting plate. According to the vortex type small-sized pulverizer, materials are ground through the upper grinding head and a lower grinding head which are provided with vortex structures.

Owner:新乡汇淼科技有限公司 +2

Manufacturing process of grinding and rolling wheel

ActiveCN112894636AStable structureSmall compression deformationAbrasion apparatusGrinding devicesUltimate tensile strengthBinding force

The invention discloses a manufacturing process of a grinding and rolling wheel. The manufacturing process comprises a grinding material belt preparation step and a grinding material belt rolling step, specifically, a nylon three-dimensional base belt and a grinding and bonding composition are selected and blended, and the grinding and bonding composition is sprayed on the nylon three-dimensional base belt and curing is carried out to form a grinding material belt; winding coating glue is selected, traction and stretching are carried out on the grinding material belt, the traction and stretching opening degree is maintained, roller coating of the winding coating glue is carried out, and after roller coating, tightening and rolling are carried out to form a grinding and rolling wheel blank; and baking and curing are carried out the ground and rolled wheel blank. The prepared grinding and rolling wheel has a very stable structure, no layering phenomenon exists in the using process, the compression deformation quantity is very small, and the grinding uniformity is very remarkable; through softening and stretching before winding and coating, the permeability and binding degree of the winding coating glue are greatly improved, and the a relatively firm binding force is achieved after thermocuring; and a specific formula combination is adopted, so that the requirements of grinding particle uniformity and bonding strength are met, and meanwhile, the service life of the grinding and rolling wheel is prolonged.

Owner:佳研新材料科技(重庆)有限公司

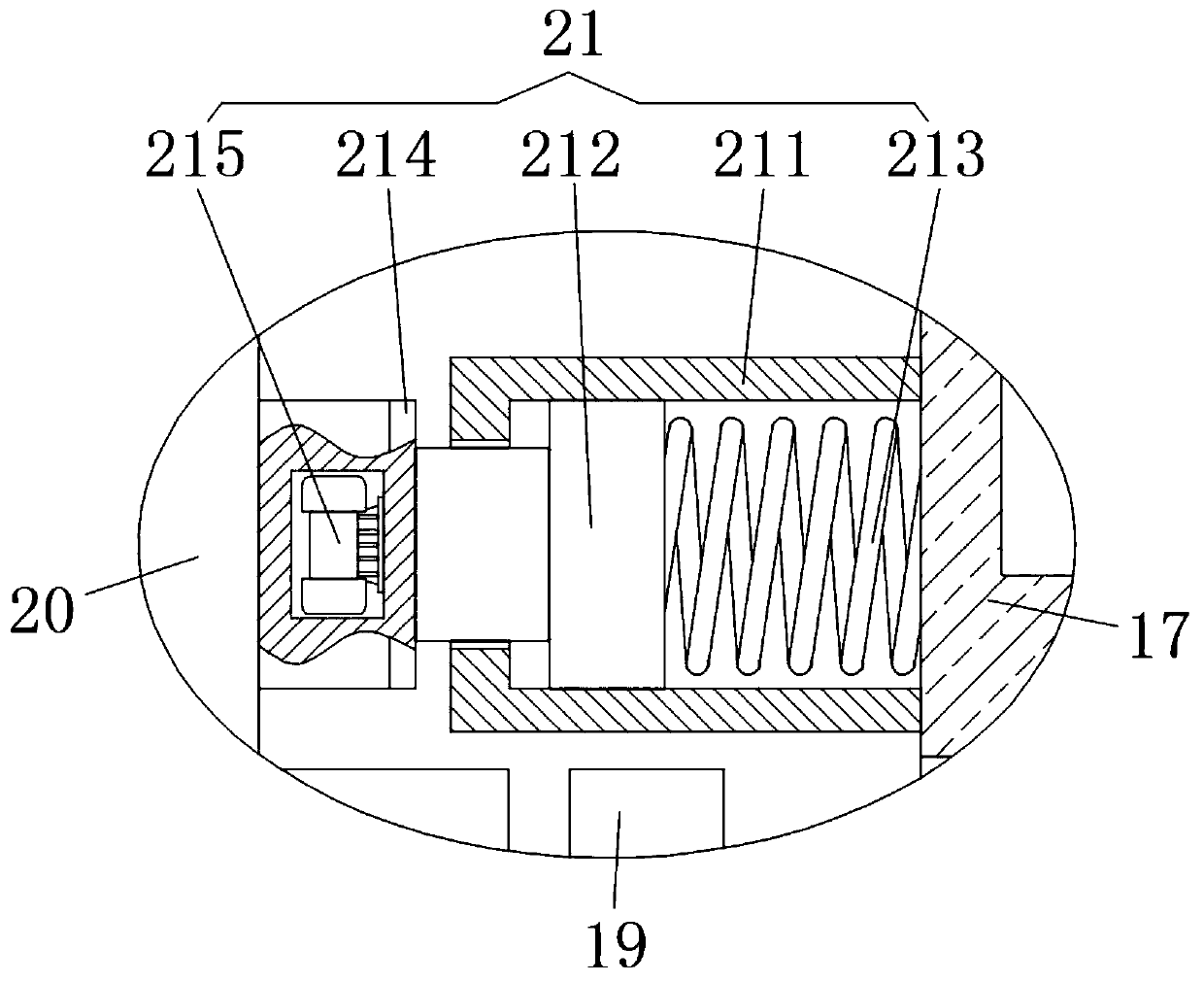

Floating sensing grinding head device and constant force grinding method

ActiveCN110842782AConstant pressureStable structureGrinding carriagesGrinding feed controlControl engineeringLoad cell

The invention provides a floating sensing grinding head device and a constant force grinding method. The floating sensing grinding head device comprises a grinding head frame body, a grinding machine,a bidirectional floating assembly, a floating sensing assembly and a controller. The bidirectional floating assembly comprises an upper fixed connection plate, a forward driver, a reverse driver anda lower floating connection plate, wherein the upper fixed connection plate is arranged on the grinding head frame body, the lower floating connection plate is arranged at the driving tail ends of theforward driver and the reverse driver, and a grinding machine is fixed on the lower floating connection plate. The floating sensing assembly comprises a weighing sensor and a position sensor, whereinthe weighing sensor is used for detecting a weight signal of the grinding machine, and the position sensor is used for detecting a position signal of the grinding machine; and the controller can simultaneously judge the weight signal and the position signal to adjust the driving force output by the reverse driver in real time. According to the floating sensing grinding head device, constant grinding pressure can be generated, complete automation of the grinding process is achieved, and the polishing uniformity is improved.

Owner:DONGFENG MOTOR CO LTD

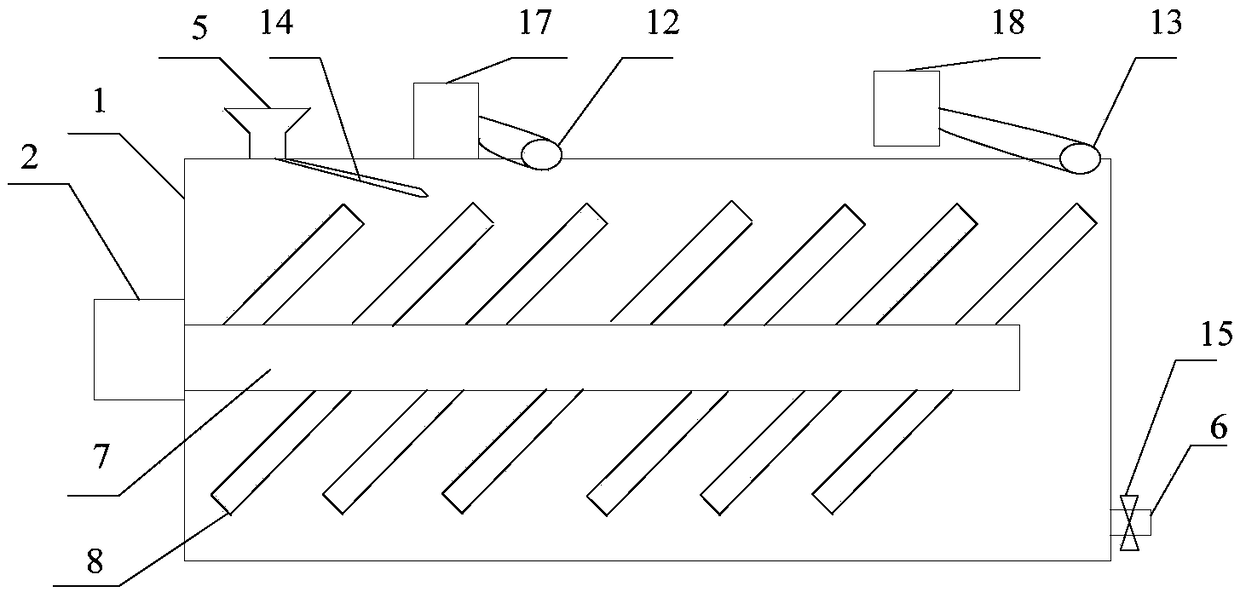

Swing type grinding machine for paint production

InactiveCN108057492AImprove grinding sufficiencyImprove grinding uniformityGrain treatmentsElectric machineryEngineering

The embodiment of the invention provides a swing type grinding machine for paint production. The grinding machine includes a horizontal type grinding tank, a first motor, a grinding tank bottom seat,a second motor and a pulley block. The top of the horizontal type grinding tank is provided with a feeding opening. The bottom of the horizontal type grinding tank is provided with a discharging opening. The side part of the horizontal type grinding tank is provided with the first motor. The interior of the horizontal type grinding tank is provided with a screw rod transversely. The screw rod is provided with multiple inclined grinding blades. The arraying distance between each two adjacent grinding blades is less than the projected length of the grinding blades on the screw rod. The first motor is connected with the screw rod. The bottom seat of the grinding tank is fixedly arranged below the horizontal type grinding tank. The second motor is arranged on the bottom seat of the grinding tank. The bottom of a grinding tank supporting frame is provided with the pulley block. According to the swing type grinding machine for paint production, the horizontal type grinding tank can sway horizontally under the action of the second motor and the pulley block, flowing and mixing of materials in the horizontal type grinding tank are promoted, and the grinding sufficiency and uniformity are improved.

Owner:湖南太子化工涂料有限公司

Periodic material crushing and grinding device

The invention discloses a periodic material crushing and grinding device, and relates to the technical field of material grinding. The periodic material crushing and grinding device comprises an innershell; a pre-pressing cavity, a discharging cavity and a grinding cavity are sequentially formed in the inner shell, a movable ball is arranged on the inner wall of the pre-pressing cavity, cutting boards are arranged on the outer side of the movable ball at equal intervals, a plug rod is fixedly connected to the center of the top of the movable ball, protruding thorns are arranged on the surfaceof the movable ball and located between the cutter boards and the plug rod at equal intervals, the top of the pre-pressing cavity communicates with a feeding pipe, a movable plug is movably connectedto the inner wall of the discharging cavity, an ejector rod is arranged in the center of the top of the movable plug, and a grinding block is rotationally connected to the outer end of a connecting rod. According to the periodic material crushing and grinding device, the problems that at present, grinding devices on the market are various in type, but generally, a large number of materials are stacked and then ground in a centralized mode, the grinding efficiency is low, the discharging uniformity is poor, and high-precision material grinding machining and using are difficult to achieve are solved.

Owner:山东亨瑞达硅铝新材料有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com