Grinding pad, grinding device and method for manufacturing grinding pad

A technology of grinding pads and grinding discs is applied in the fields of grinding pads, grinding devices and manufacturing grinding pads. The effect of fluid retention

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

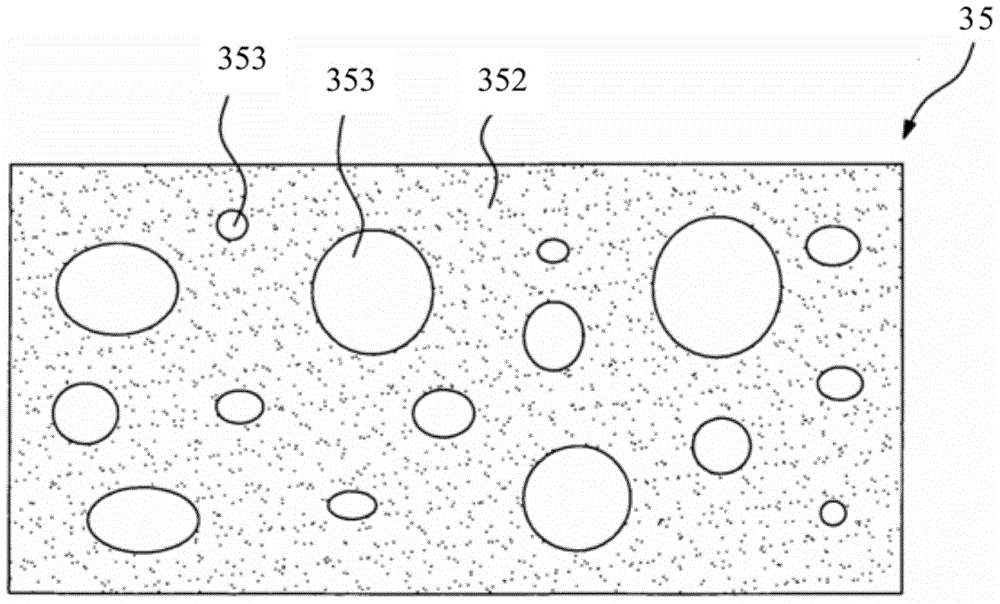

[0111] Stir evenly the resin composition comprising polyisocyanate with an equivalent of 1, polyol foaming agent with an equivalent of 50 to 150 and a diamine crosslinking agent with an equivalent of 50 to 250, wherein 25% by weight of Nylon fiber filaments, the diameter of which is about 0.3 denier, and air is injected into the resin composition, stirred and rotated at 1000rpm to 4000rpm for 40 to 60 minutes, coated on a flat release paper with a scraper, and then placed in an oven Dry at 110°C for 1 minute, then cure at 80°C for 30 seconds, and then cut off the surface.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com