Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

44results about How to "Guaranteed constant pressure" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Technique for continuously preparing super fine nano powder by using precipitation method and its specialized equipment

ActiveCN1446654ASame sizeUniform particle sizeCalcium/strontium/barium oxides/hydroxidesCrystalliteNanometre

A process for continuously preparing nano powder by deposition method includes quantiatively and proportionally feeding raw materials in reactor at a certain speed, stirring while nucleating reaction, quickly coming in crystal nuclear growing tube, moving forward under the action of mixer, collecting suspension at tube end, and drying. Its advantages are controllable granularity, high dispersity and uniformity, and high productivity.

Owner:NANJING UNIV OF TECH

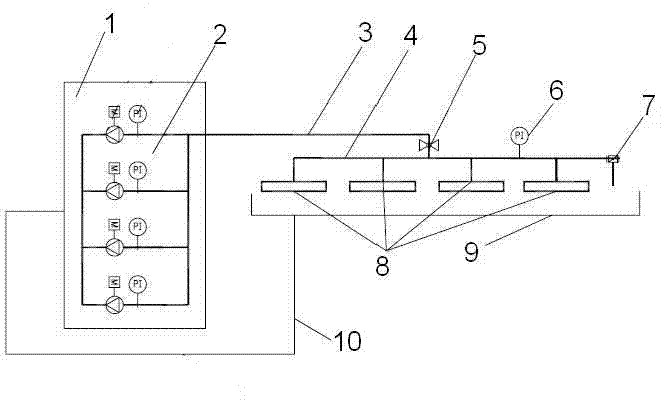

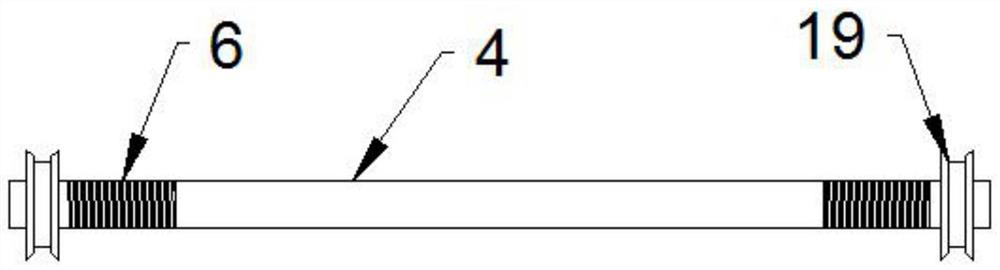

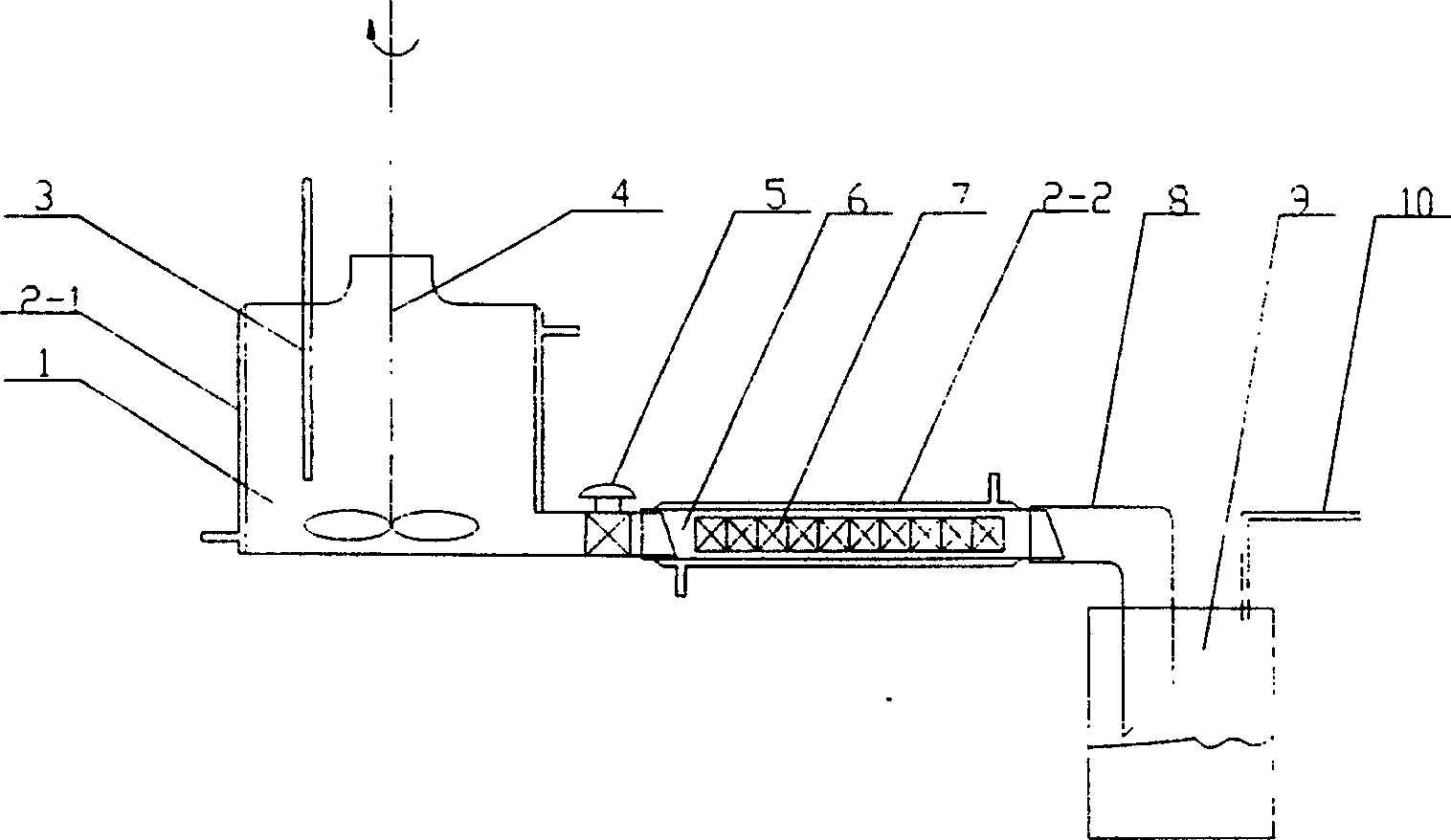

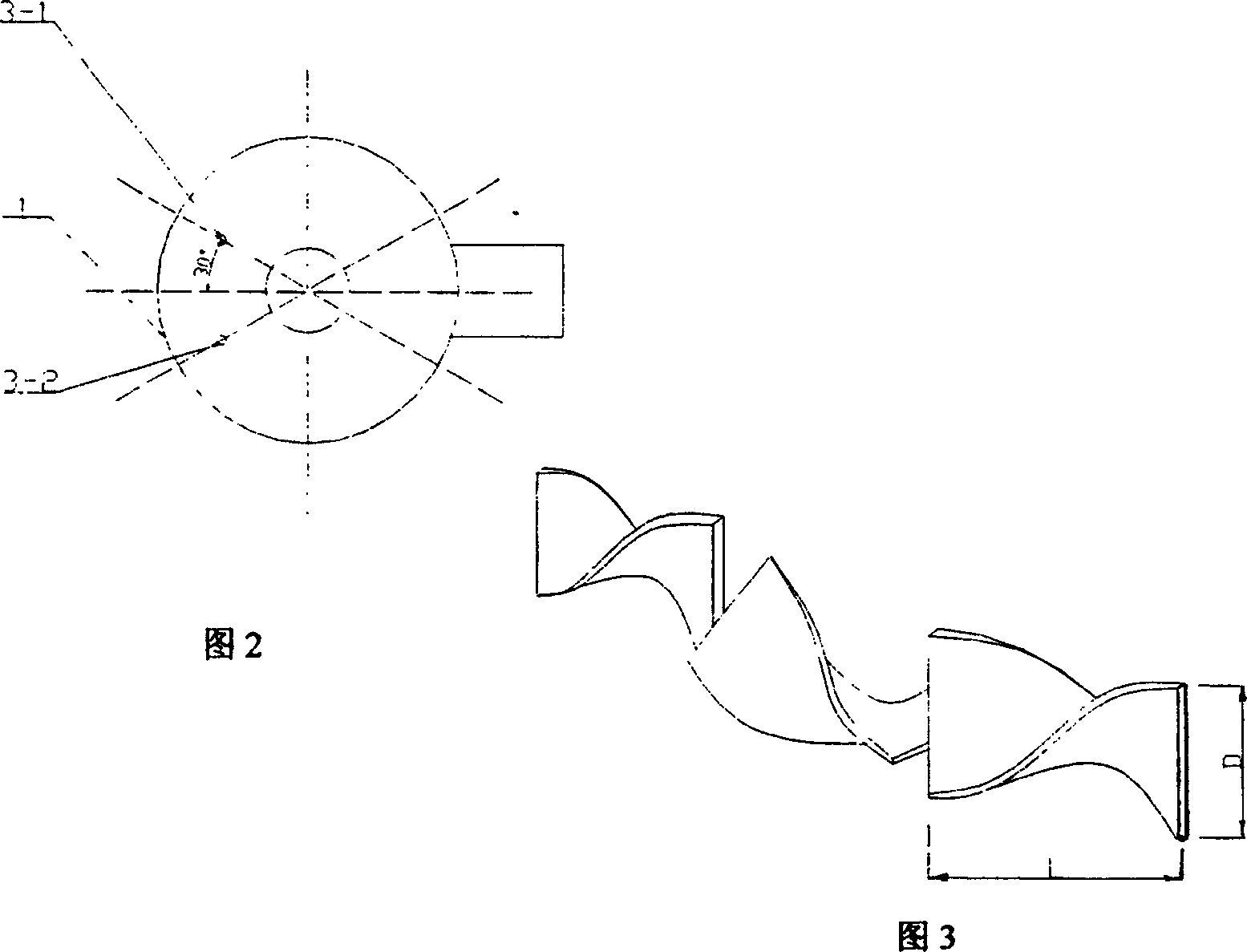

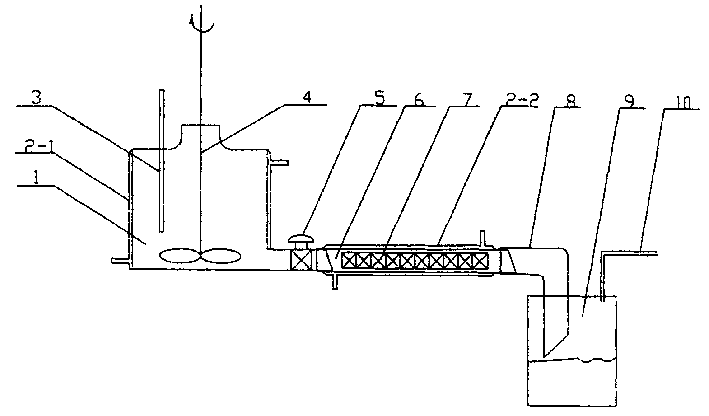

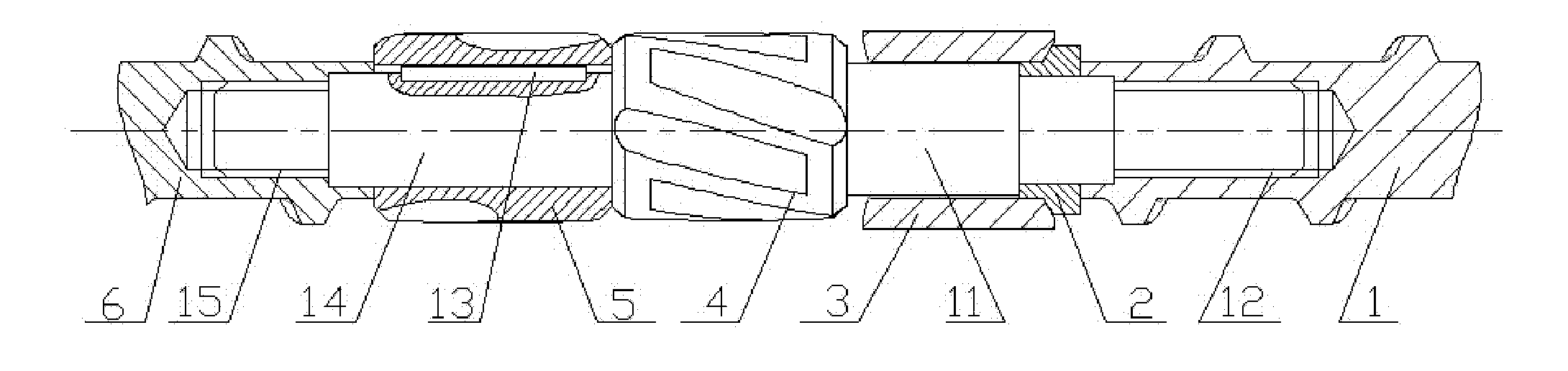

Small bar material through-water cooling stable device

InactiveCN103495609AGuaranteed economyGuaranteed constant pressureWork treatment devicesMetal rolling arrangementsEngineeringWater supply

The invention discloses a small bar material through-water cooling stable device which comprises a water supply pump and a through-water cooling device. The water supply pump and the through-water cooling device are connected with each other through a water supply pipe. A pressure holding and releasing valve is arranged on the water supply pipe. According to the small bar material through-water cooling stable device, the pressure holding and releasing valve is further arranged on the main water supply pipe, thus, when the water supply amount of the water supply pump is not matched with water demanding amount, redundant water can be drained through the pressure holding and releasing valve, so that the stability of a through-water cooling system and the economy of the water supply pump are ensured, the constant pressure of the water supply pipe is ensured, and the water pump and equipment are prevented from being damaged.

Owner:WISDRI ENG & RES INC LTD

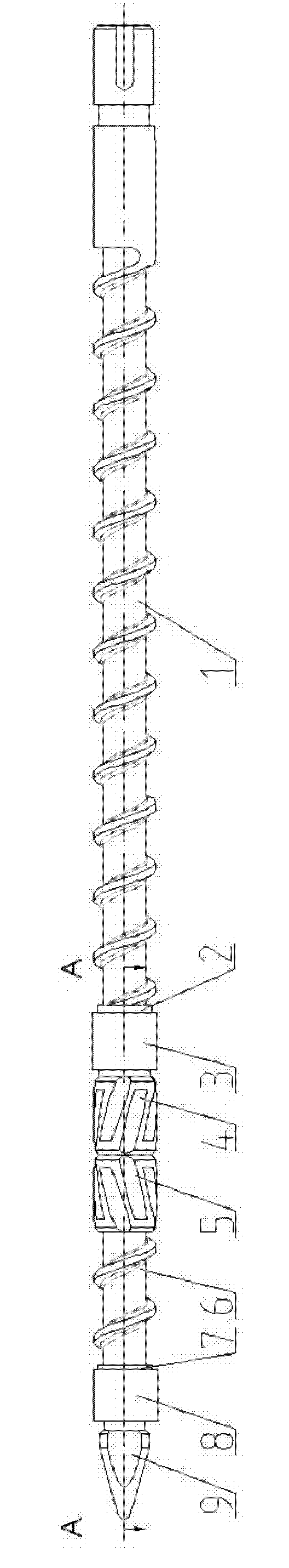

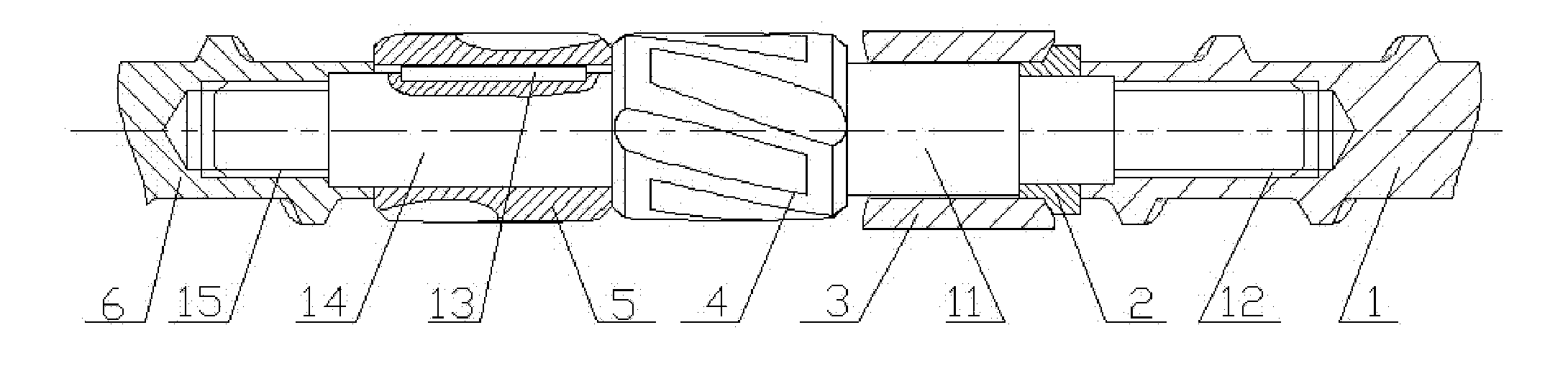

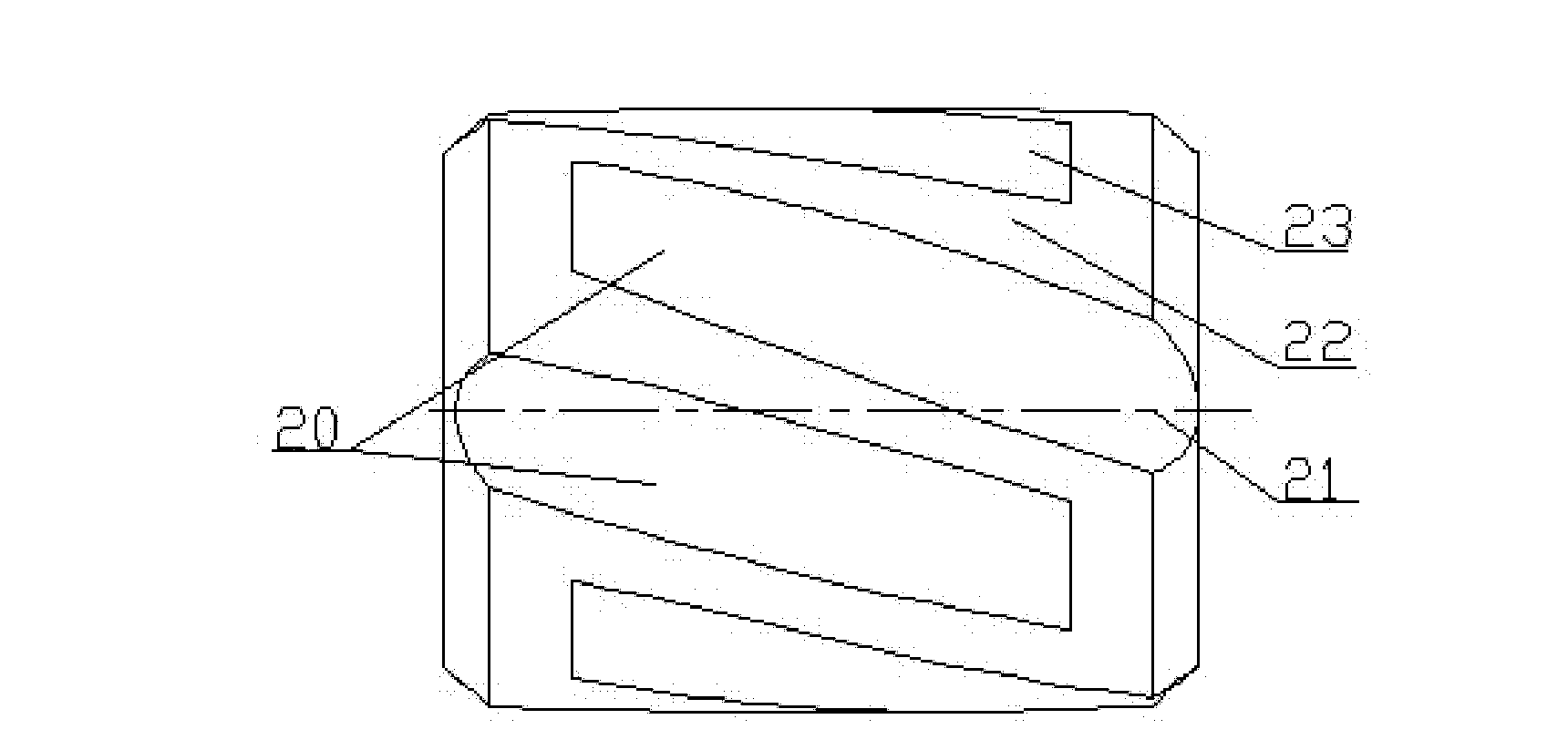

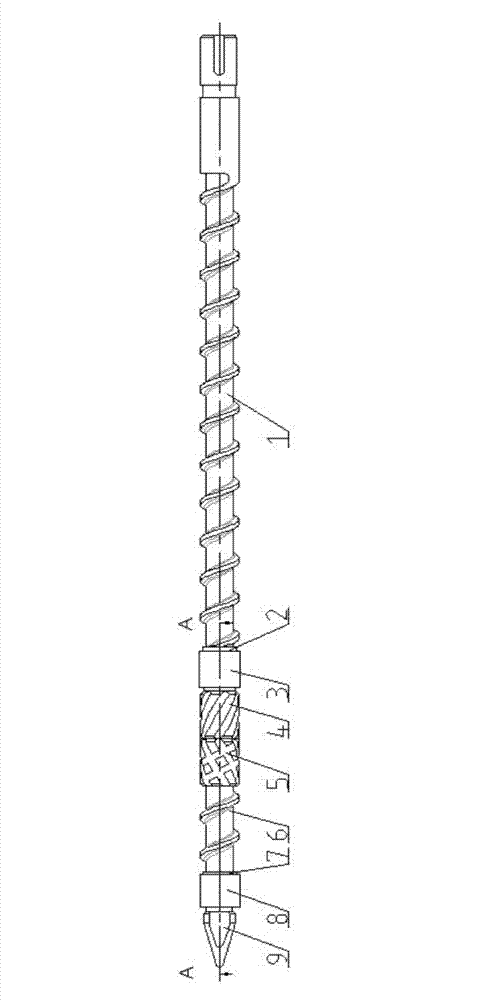

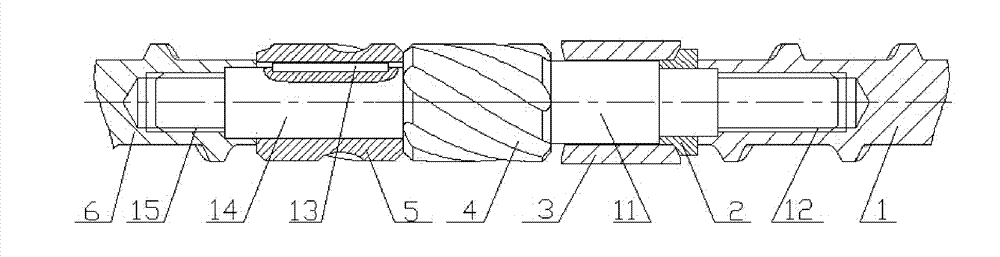

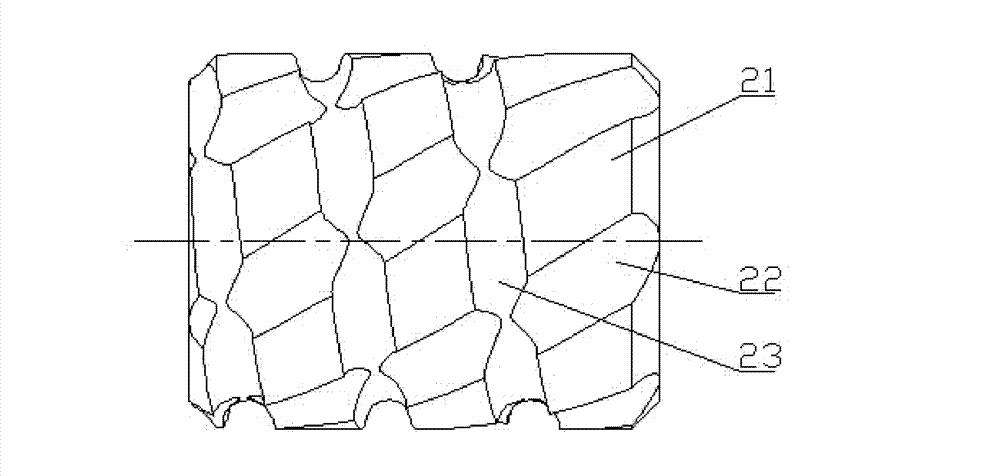

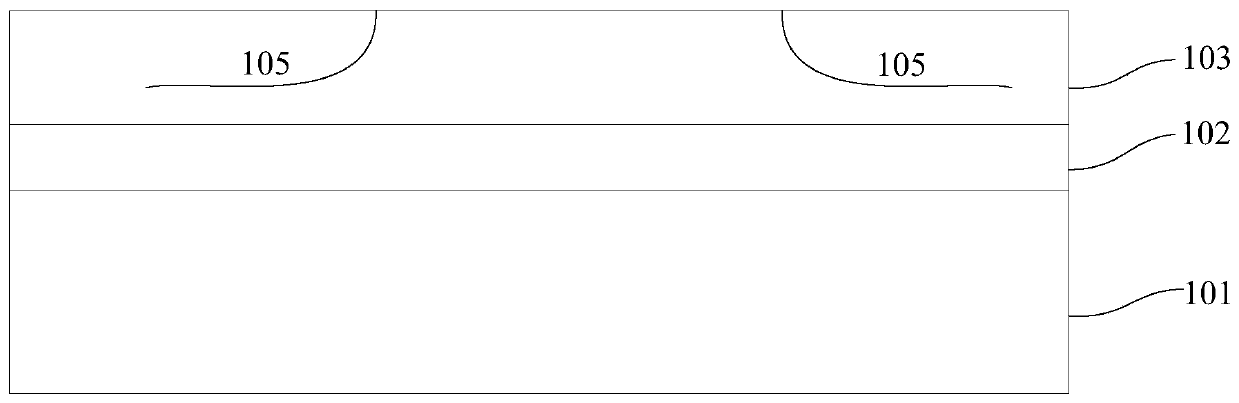

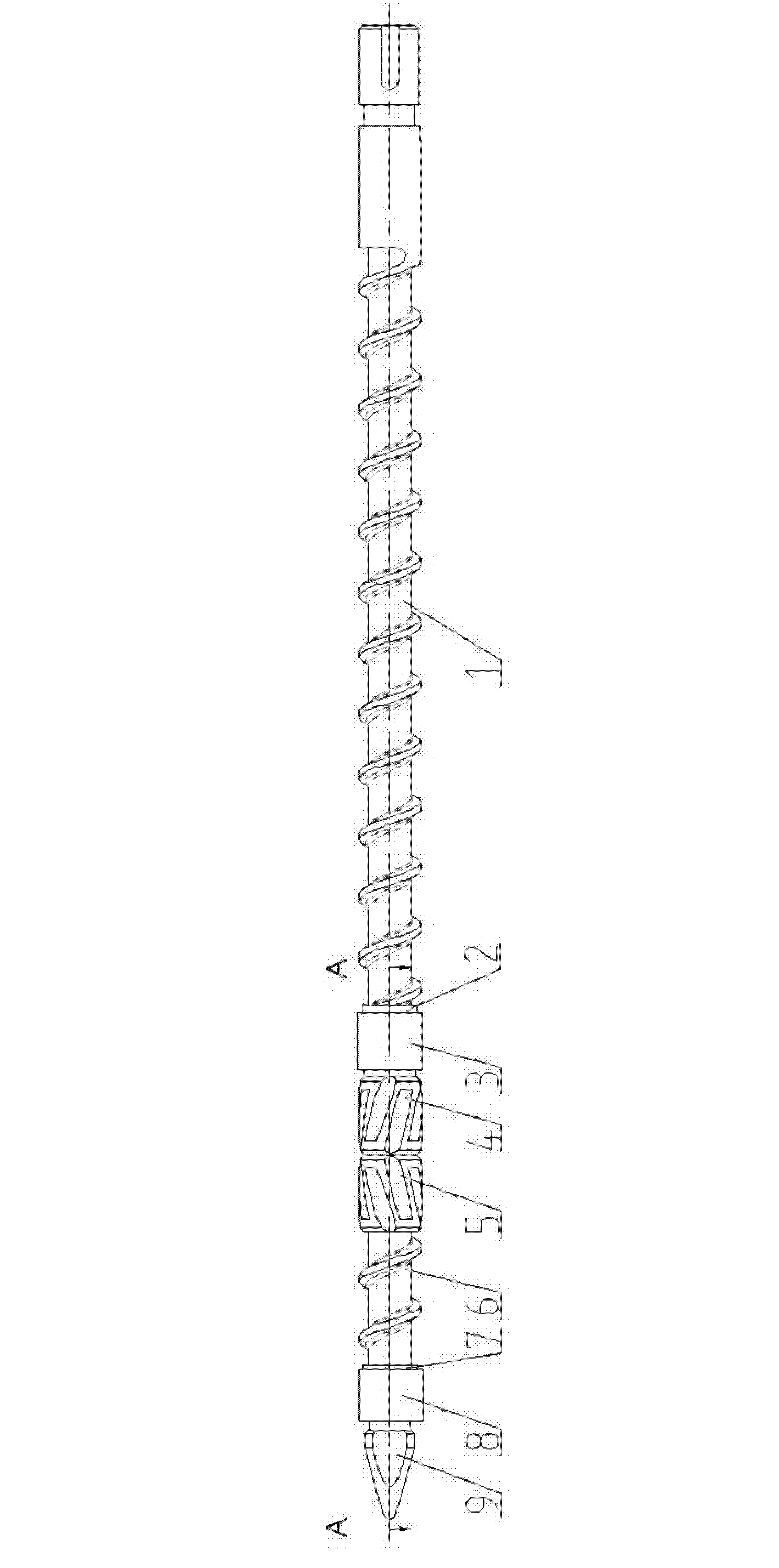

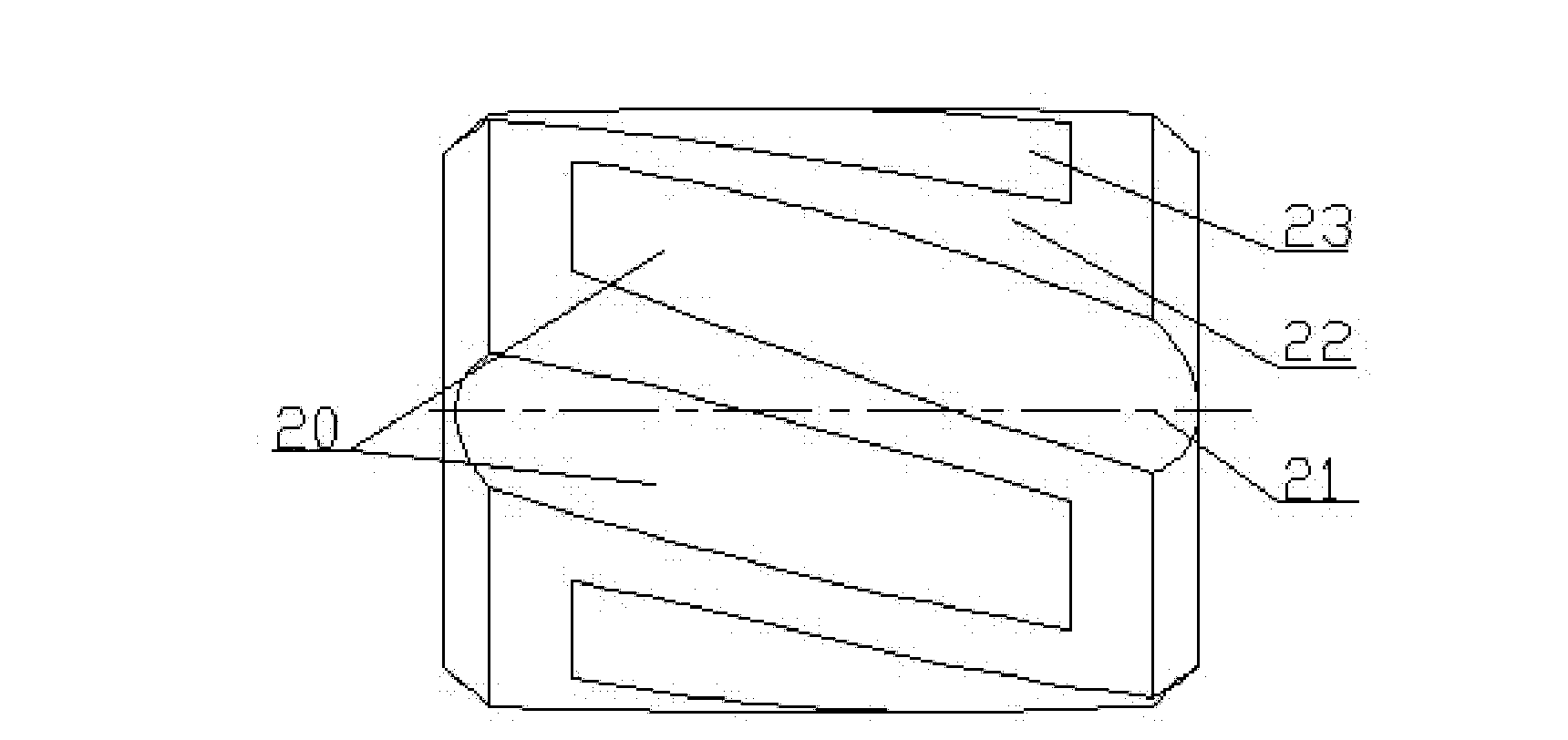

Micro-foaming injection-molded screw

The invention discloses a micro-foaming injection-molded screw, which mainly comprises a rear screw, a rear positioning ring, a rear non-return ring, a rear mixing section, a front mixing section, a front screw, a front positioning ring, a front non-return ring, and a screw head; the rear mixing section and the front mixing section has skewed slot barriers; a left and a right ends of the mixing sections are provided alternately with four charging troughs and discharging troughs; ribs between the charging and discharging skewed slots have a length less than the diameter of the mixing sections;the rear mixing section adopts a positive skewed slot with the same rotation direction as the screw, and the front mixing section adopts a reverse skewed slot. The screw has greatly improved mixing homogenization effect, and allows supercritical gas to distribute rapidly and uniformly in polymer melt so as to form a stable polymer melt / supercritical gas homogeneous system; meanwhile, a non-return ring is used at the air-inlet position, which can effectively prevent the obstruction of the air-inlet channel due to melt reflux; the novel micro-foamed injection-molded screw is widely applicableto various micro-foaming injection machines.

Owner:BEIJING UNIV OF CHEM TECH

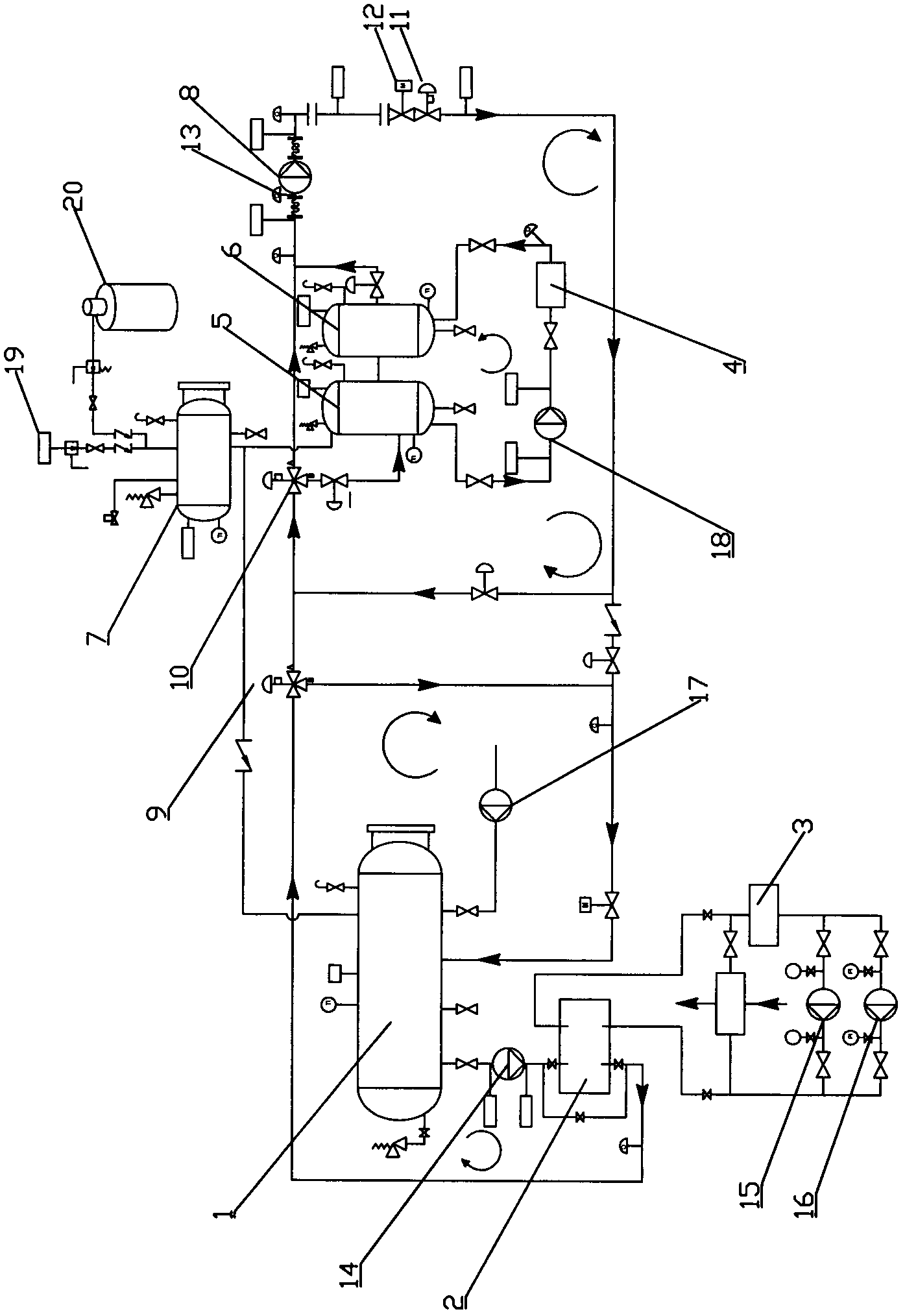

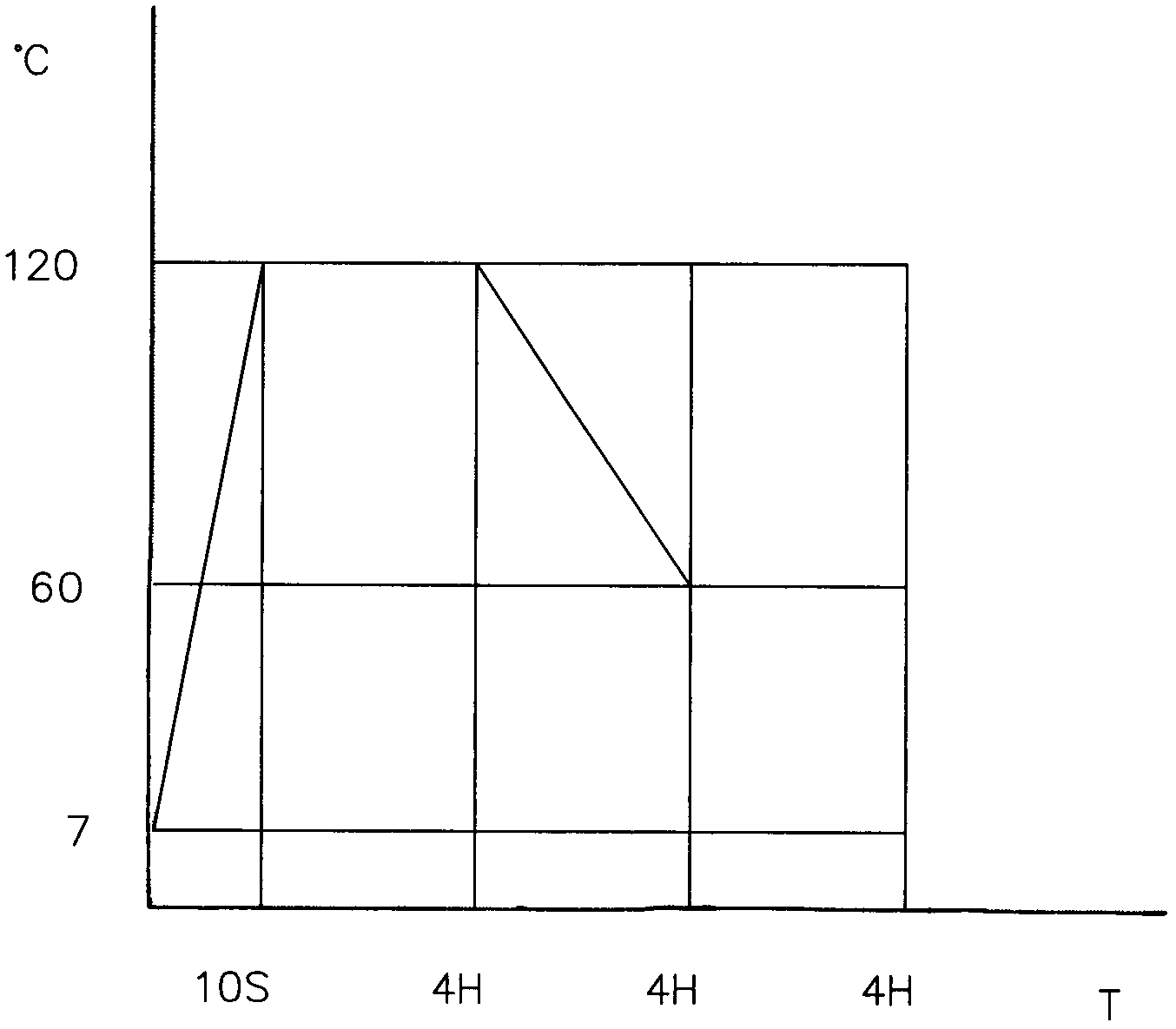

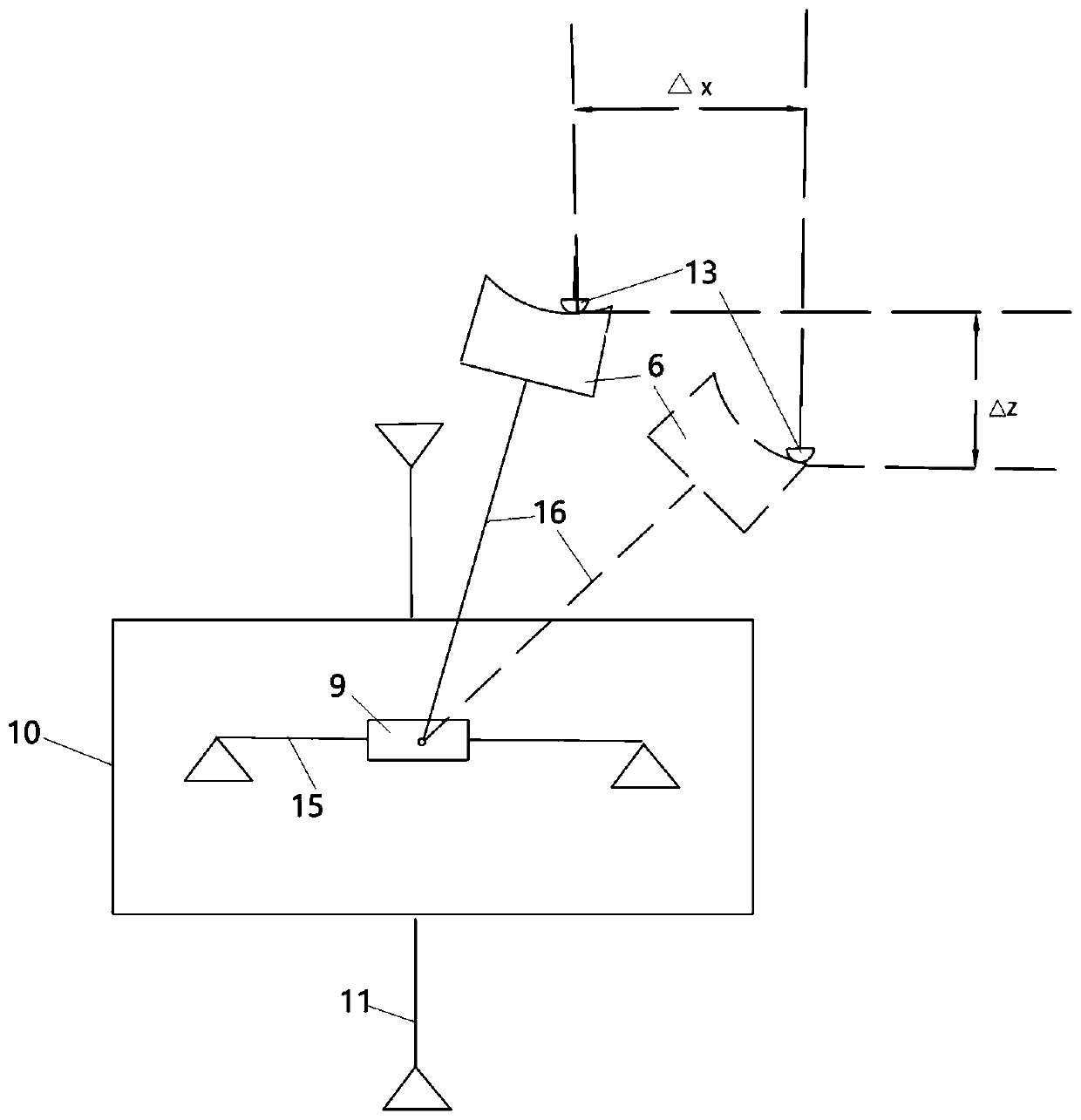

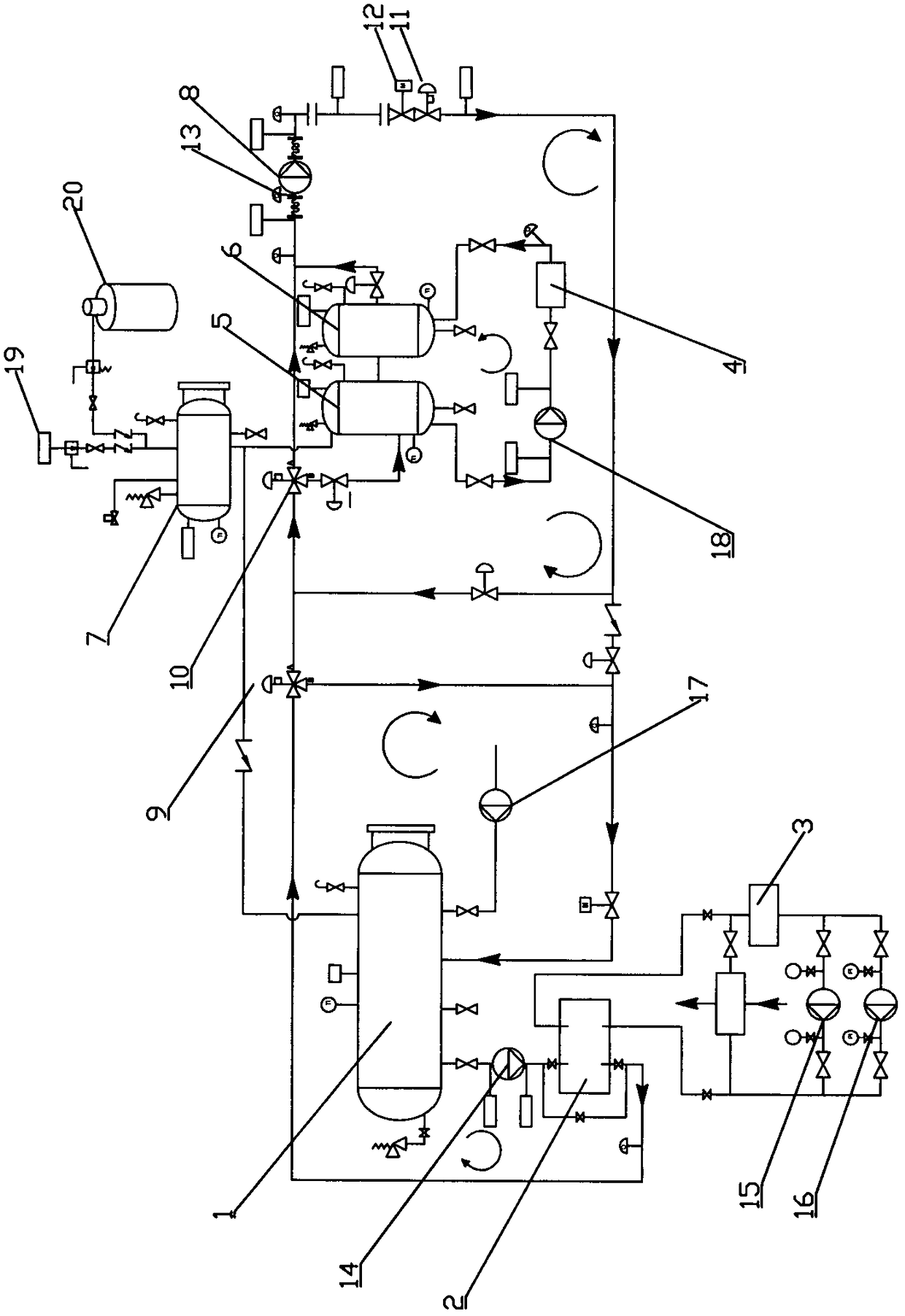

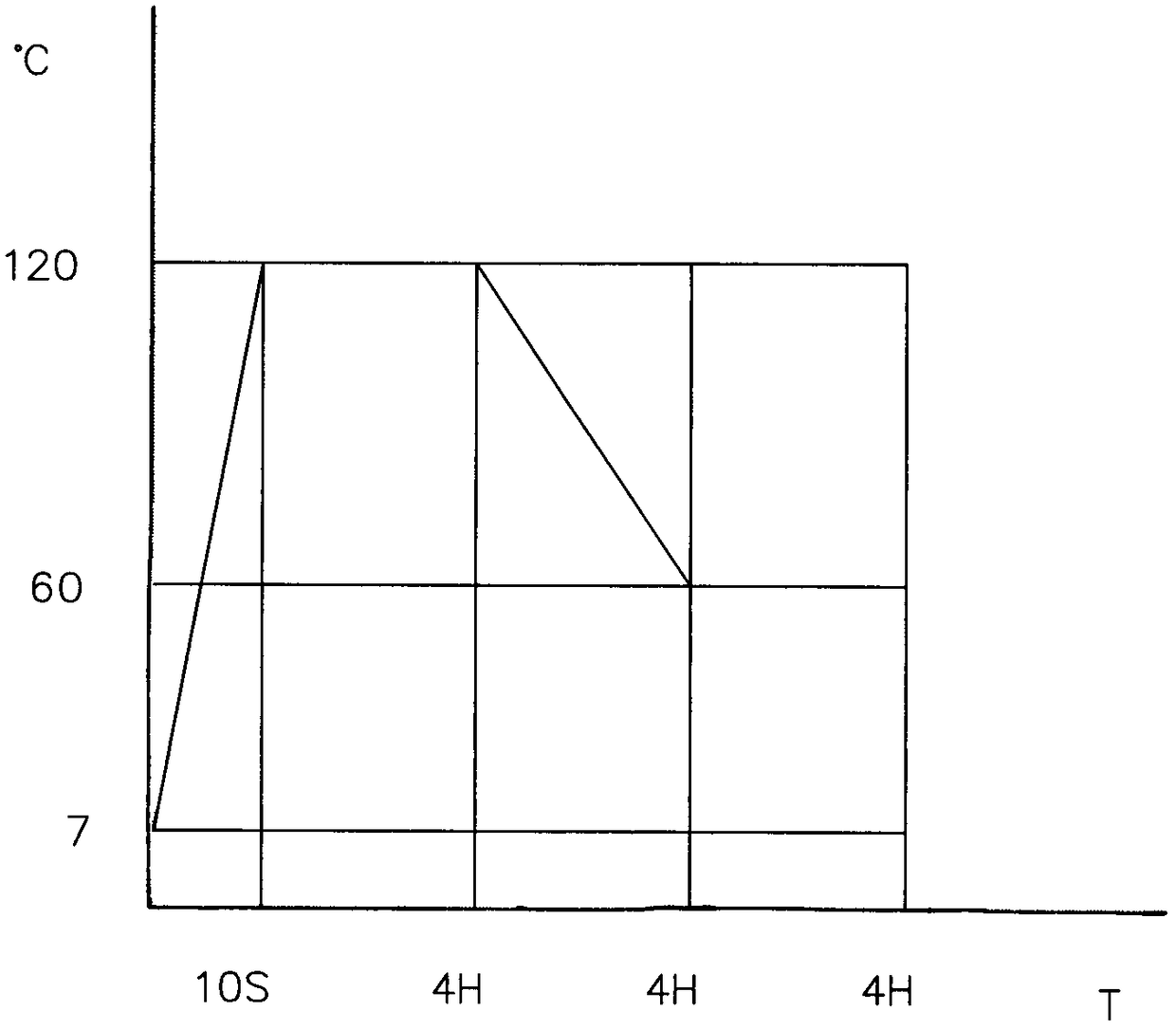

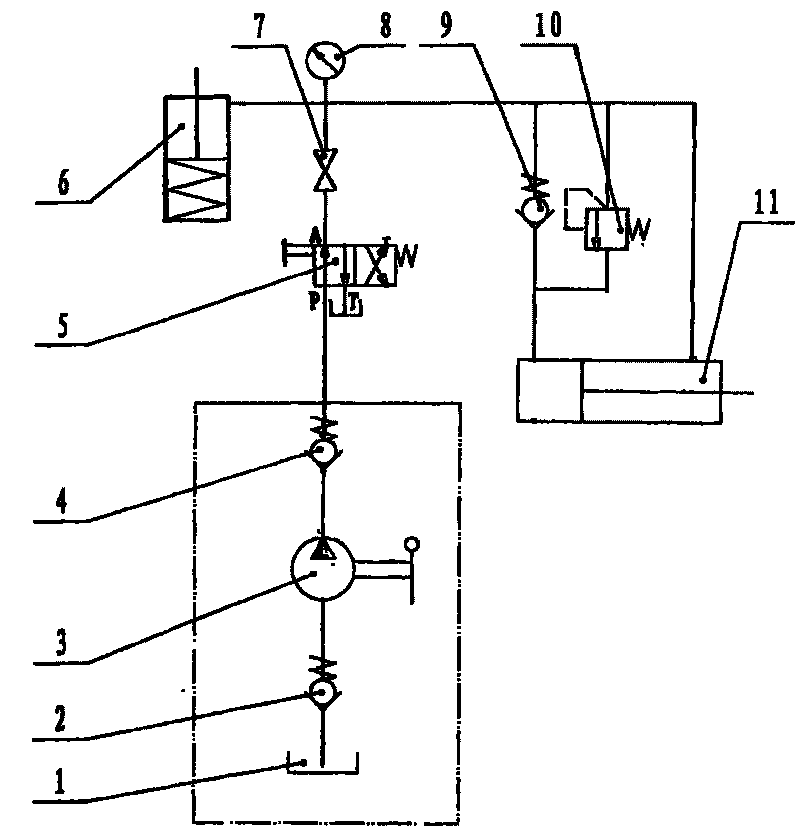

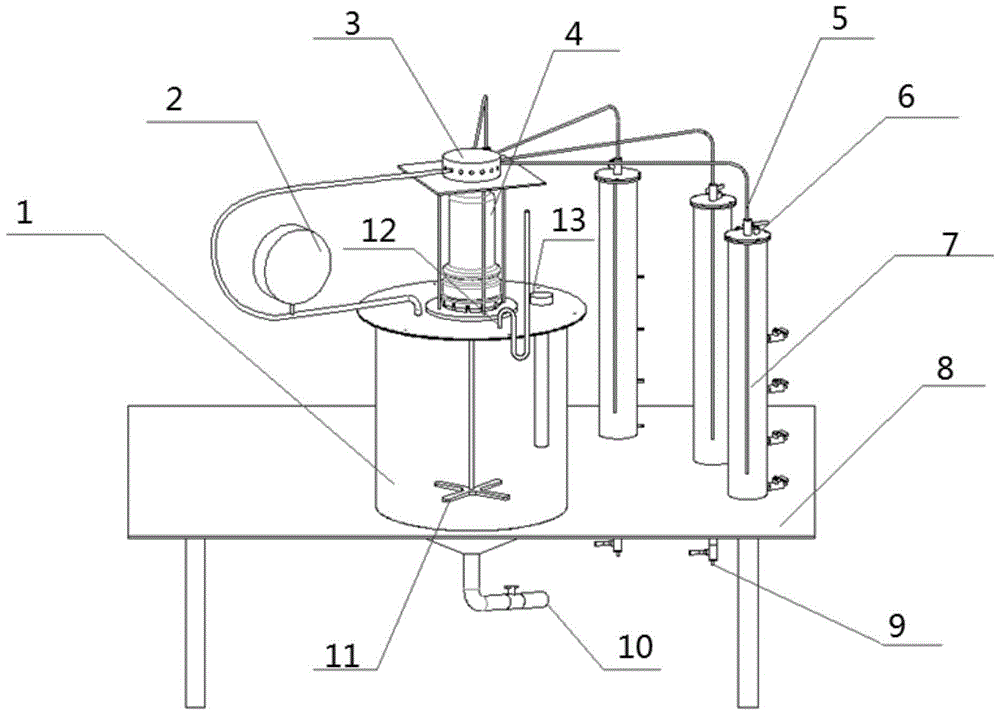

Thermal shock testing method and system for pump

ActiveCN103437990AGuaranteed constant pressureGuarantee the effect of pump thermal shock testPump testingPositive-displacement liquid enginesExpansion tankCooling tower

The invention discloses a thermal shock testing method and a thermal shock testing system for a pump. The method comprises the following steps of system injection, system exhaust, trial running of the tested pump, system pressurization, preheating, pre-cooling and thermal shocking, and is used for performing a thermal shock test on the pump in a cold state by using the thermal shock testing system for the pump. The thermal shock testing system for the pump comprises a chilled water tank, a chiller, a cooling tower, an electric heater, a high-temperature hot water tank I, a high-temperature hot water tank II, an expansion tank, the tested pump, a three-way valve I and a three-way valve II, wherein a regulating valve and an electric valve are arranged on a loop of the tested pump, and are used for controlling the flow of the tested pump; a temperature sensing rod is arranged at an inlet of the tested pump; the expansion tank is connected with the chilled water tank and the high-temperature hot water tank I respectively, and is connected with an air compression device and a nitrogen bottle through a one-way valve. Due to the adoption of the testing scheme, potential safety hazards caused by the fact that the pump is not subjected to the thermal shock test before being produced are avoided.

Owner:SHANGHAI SHUOYI M & E

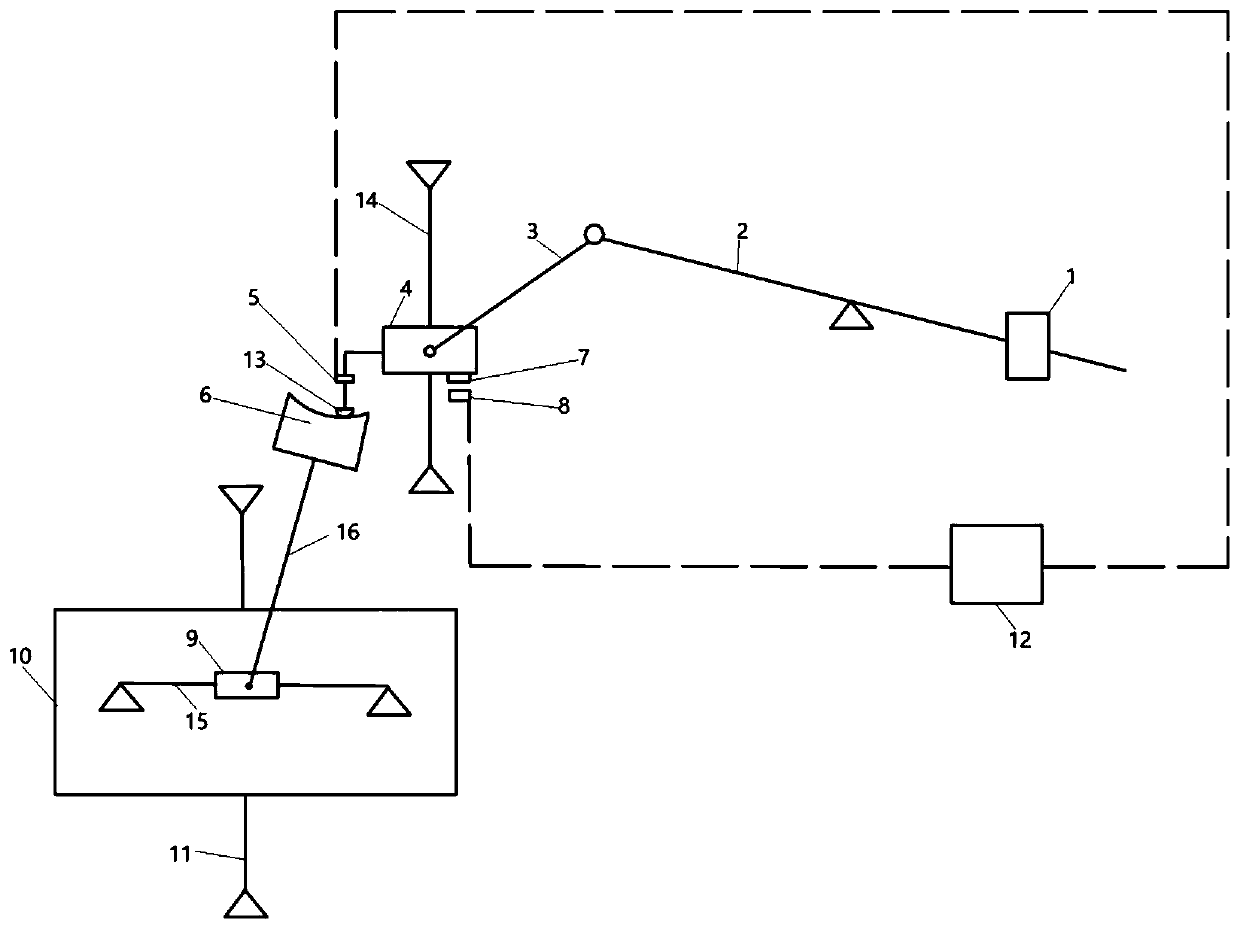

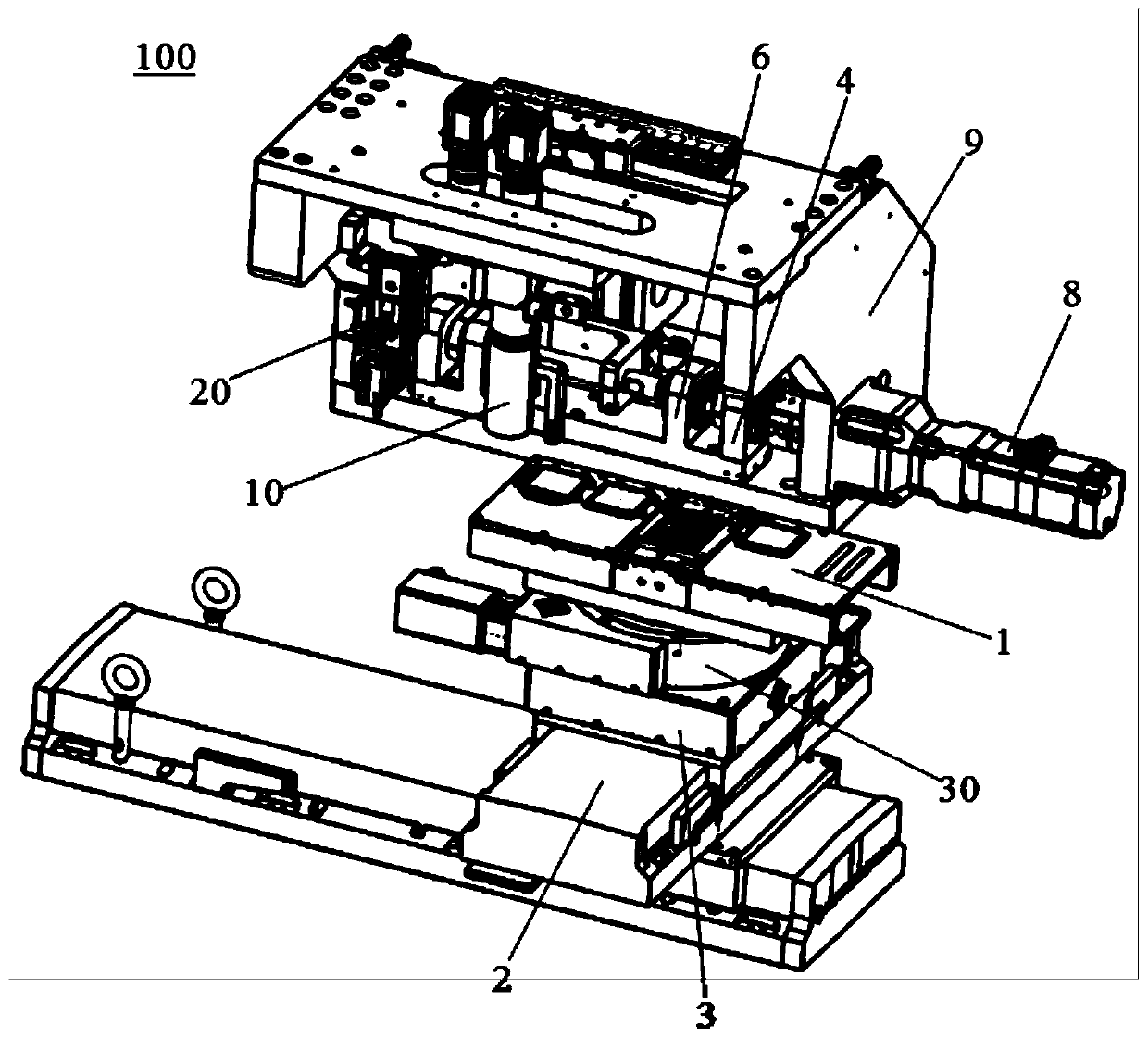

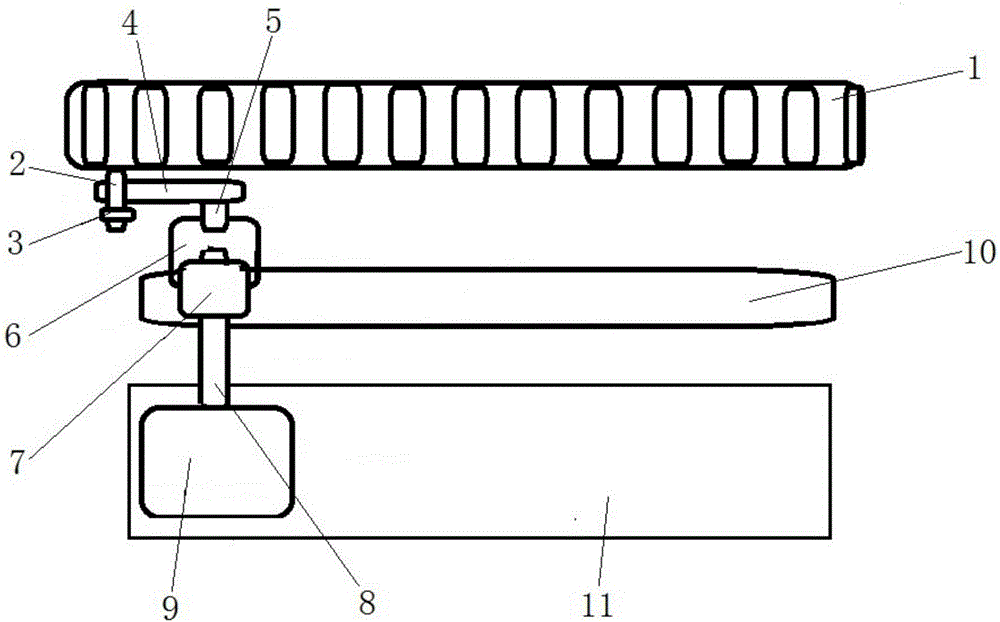

Macro-micro composite constant-pressure polishing device and method

ActiveCN111230654AStable polishing pressureGuaranteed constant pressureOptical surface grinding machinesGrinding feed controlLoop controlPolishing

The invention discloses a macro-micro composite constant-pressure polishing device and method. The method comprises the following steps of adjusting the polishing pressure by using a lever structure,counterweights at the two ends of a lever, and the force arm changes of the lever; when polishing equipment is used for polishing processing on the surface of a rotating symmetric non-spherical die core, the polishing position is controlled by using a left and right moving shaft and a rotating swinging shaft, the position of a die core polishing point is kept unchanged in space by utilizing a lifting servo shaft in space, and the polishing pressure is kept stable in the macro perspective by combining a lever principle. A polishing head is provided with a pressure sensor and an electromagneticforce device. The electromagnetic force device is controlled by polishing pressure changes to adjust and compensate for polishing pressure changes in the micro perspective. Constant pressure is ensured in the polishing process through closed-loop control. By means of the macro-micro composite constant-pressure polishing device and the method, the stability of polishing pressure is kept through a macro-micro composite method, and the control precision is higher.

Owner:广州精点科技有限公司

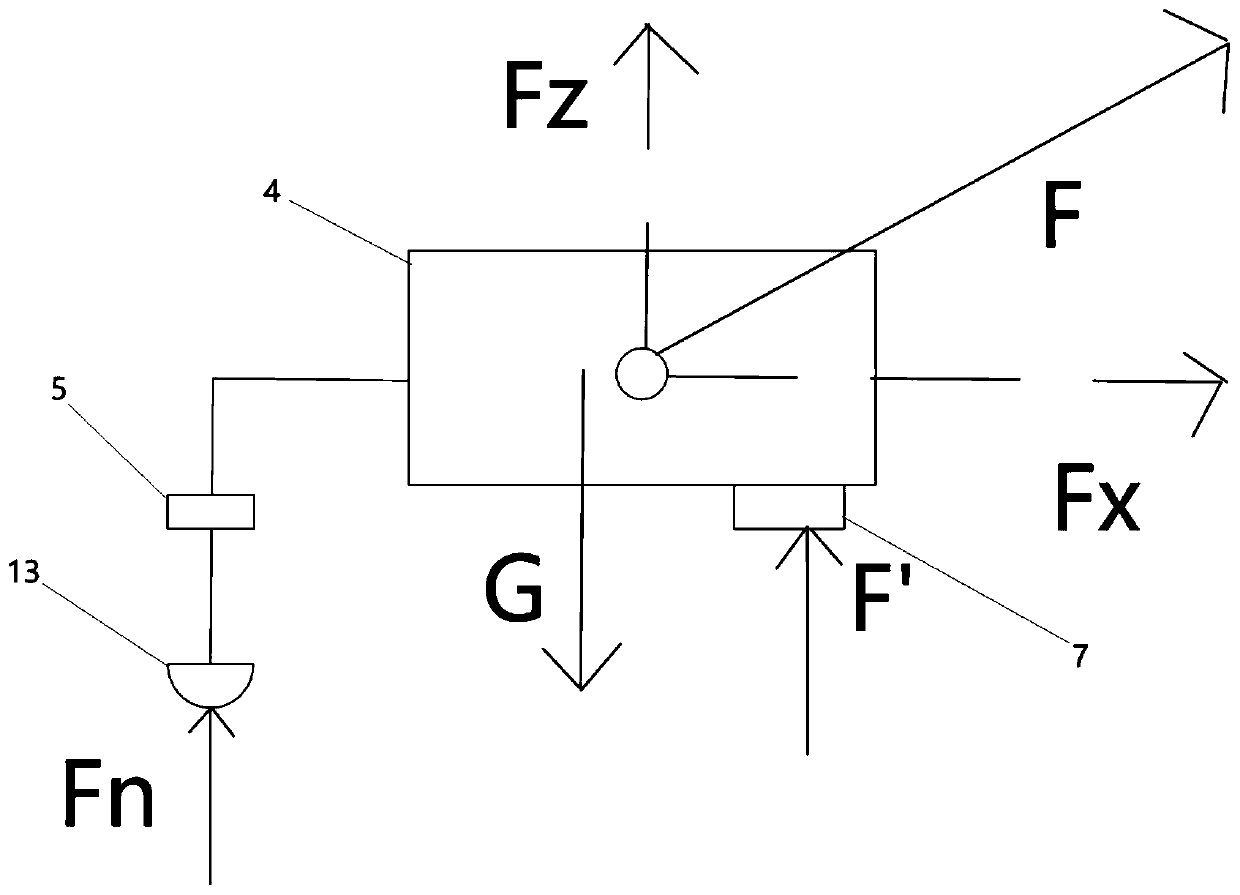

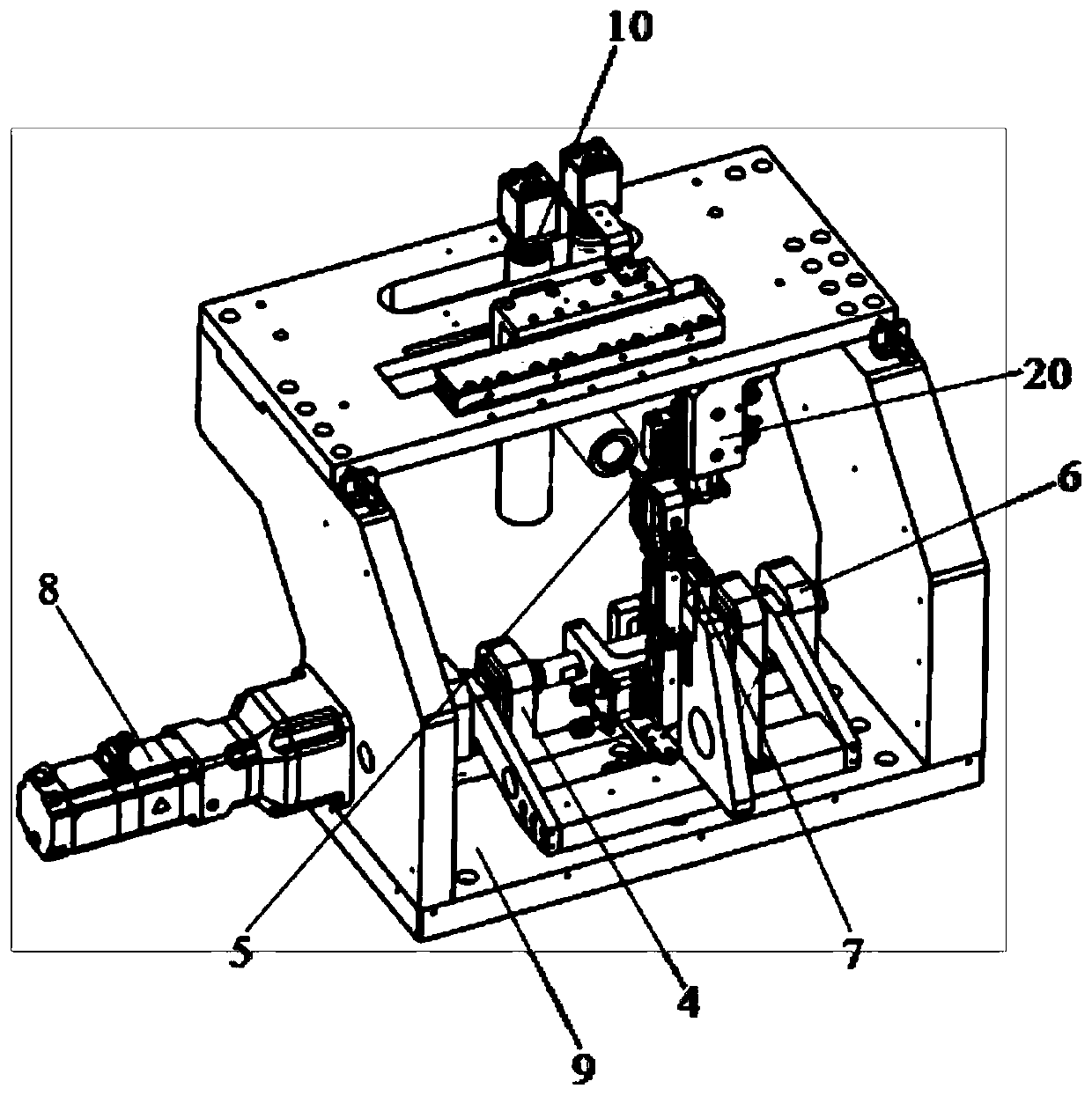

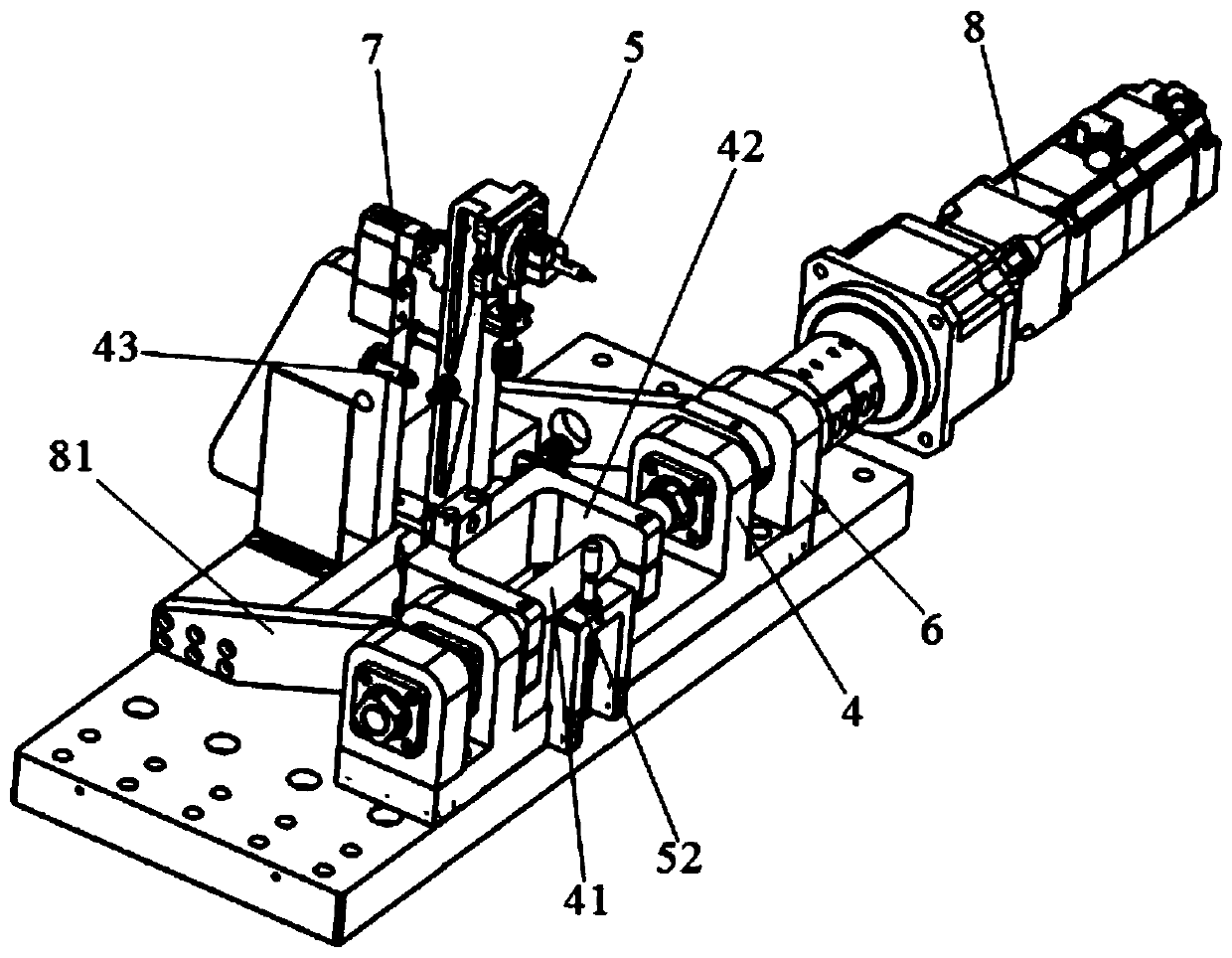

High-precision eutectic welding equipment capable of maintaining constant pressing force

PendingCN110434417AGuaranteed constant pressureHigh precisionMetal working apparatusSoldering auxillary devicesClosed loopEngineering

The invention discloses high-precision eutectic welding equipment capable of maintaining constant pressing force. The equipment comprises a eutectic welding table which supports and fixes a workpieceA, an XY-axis driving unit driving the eutectic welding table to move in a horizontal plane, a Z-axis driving unit is driving the eutectic welding table to carry out fine adjustment on the Z axis, a pressing head assembly rotatably arranged on a first support and pressing a workpiece B, a pressure sensor assembly which is rotatably arranged on a second support and applies pressure to the pressinghead assembly, and a servo driving part which drives the pressure sensor assembly to rotate, the pressure sensor assembly is in closed-loop control with the Z-axis driving unit, and when pressure dataof the pressure sensor assembly is smaller than a set value, the Z-axis driving unit drives the eutectic welding table to move upwards until the data acquired by the pressure sensor assembly is in aset range. According to the equipment, the pressing force between eutectic welding core wire pieces can be effectively guaranteed to be constant, and the welding quality is improved.

Owner:SUZHOU MAKING INTELLIGENT EQUIP CO LTD

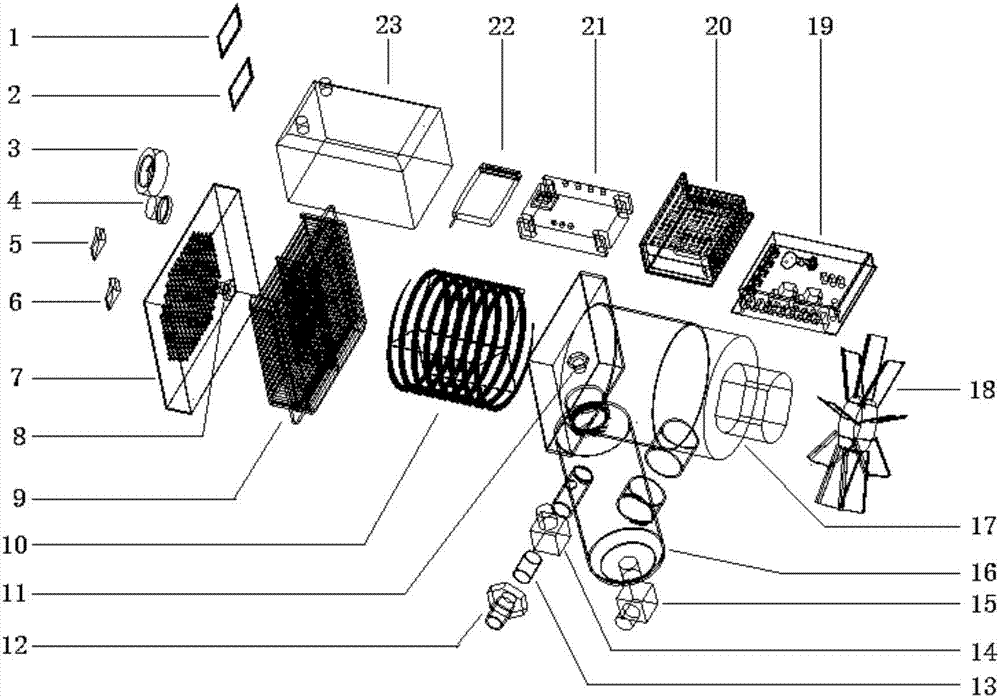

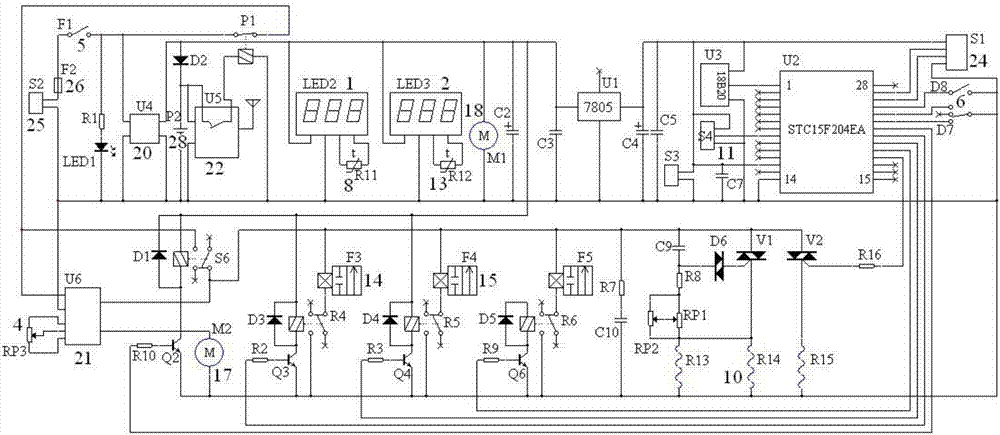

Intelligent double-control rapid paint sprayer

InactiveCN107008585AReasonable designCompact structurePretreated surfacesLiquid spraying apparatusAir filterSprayer

The invention discloses an intelligent double-control rapid paint sprayer which comprises an air inlet thermometer, an air outlet thermometer, a barometer, an electric turbine speed governing rotary knob, a main switch, an electric turbine switch, an air filter, an air inlet heater, an air pressure sensor, an air outlet, an air outlet electromagnetic valve, an air leakage water draining electromagnetic valve, an air cylinder, an electric turbine, a controller, an AC-DC and a storage battery. The intelligent double-control rapid paint sprayer is reasonable in design, compact in structure, simple in operation and high in adaptability and intelligent level, can be controlled in a remote manner, can effectively improve the paint spraying operation efficiency, is high in paint utilization ratio and low in environmental pollution and does not generate an oil molecule; and the air inlet temperature can be heated for the first time through the heater, so that paint flash-off is accelerated, moisture in the air is removed, and constant temperature is ensured.

Owner:陕西恩玛智能科技股份有限公司

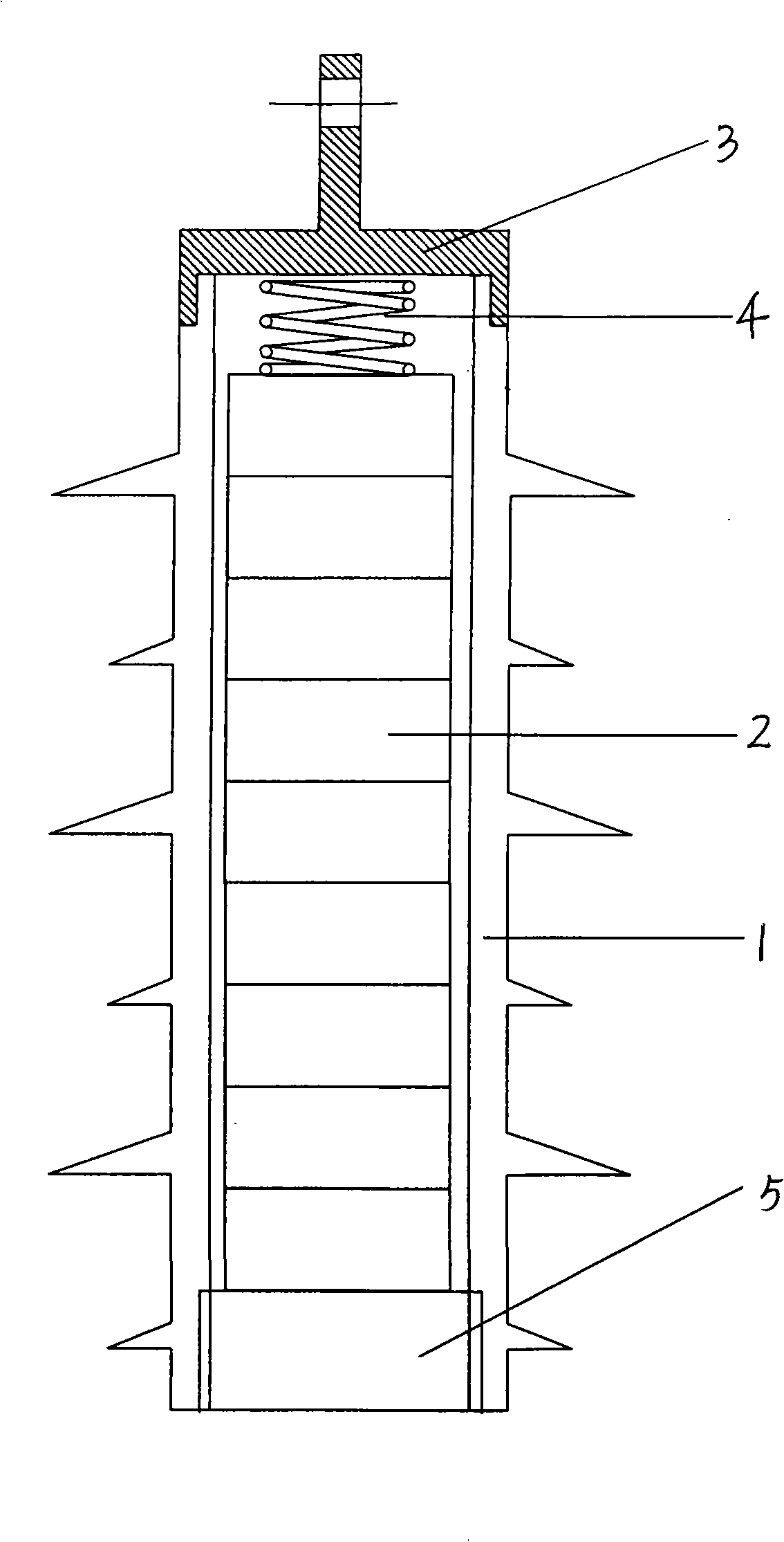

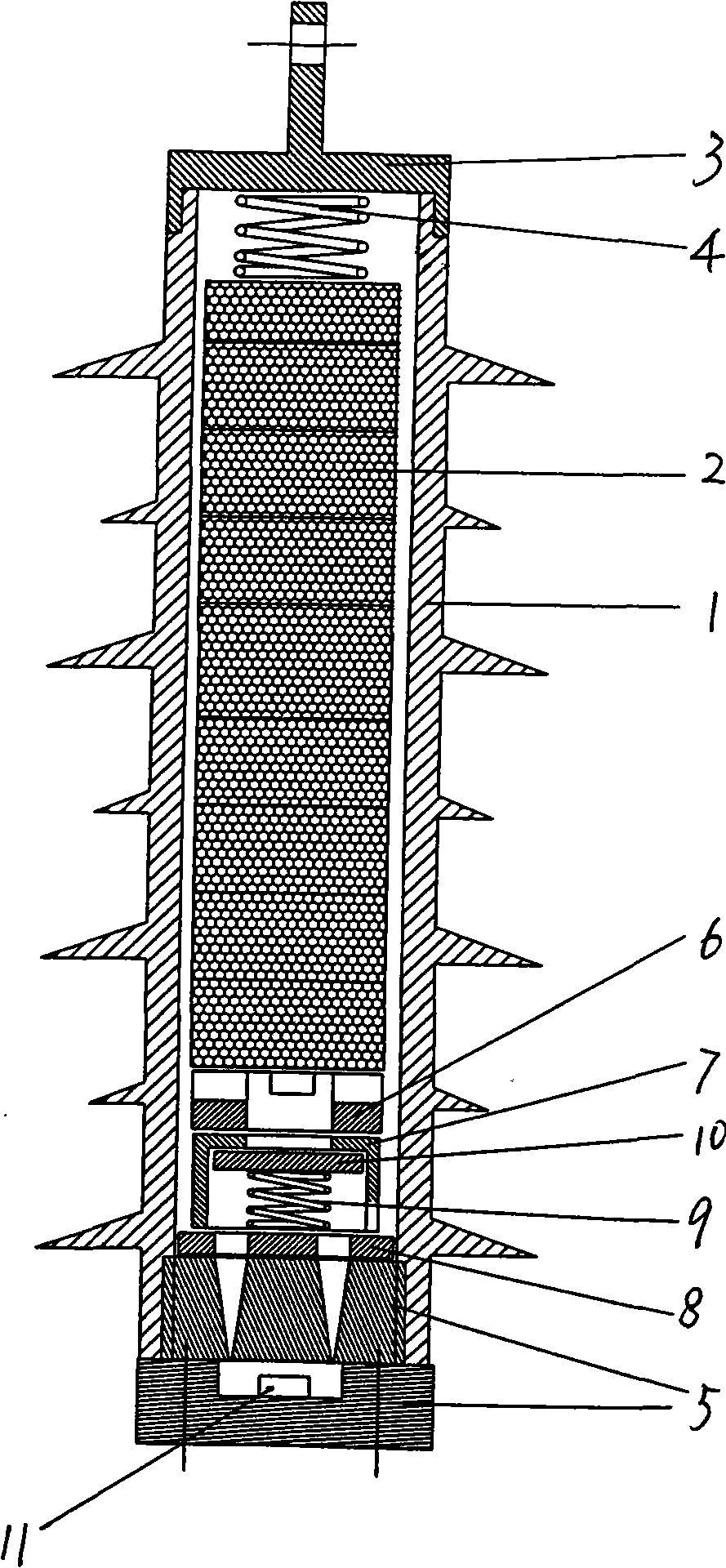

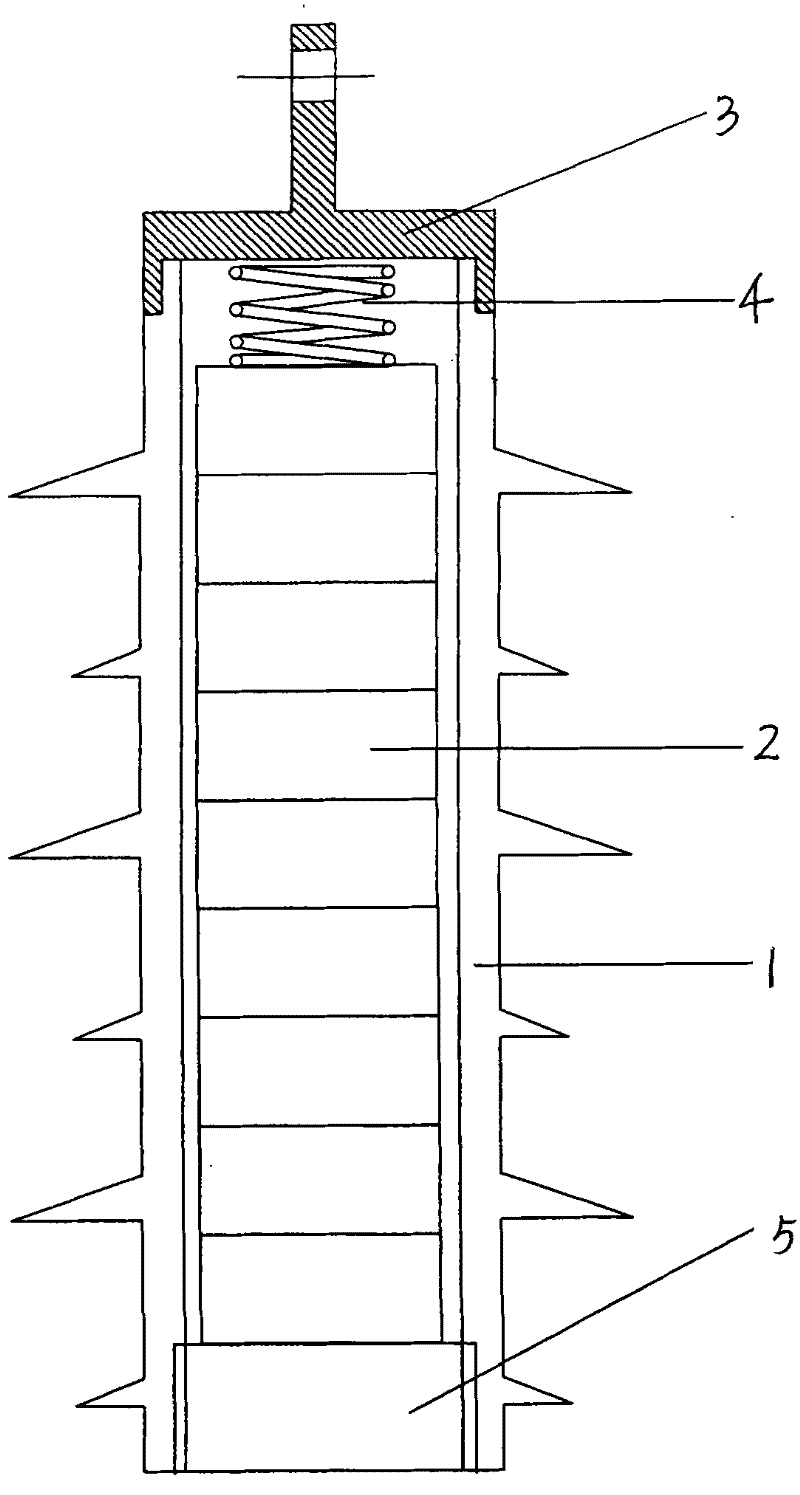

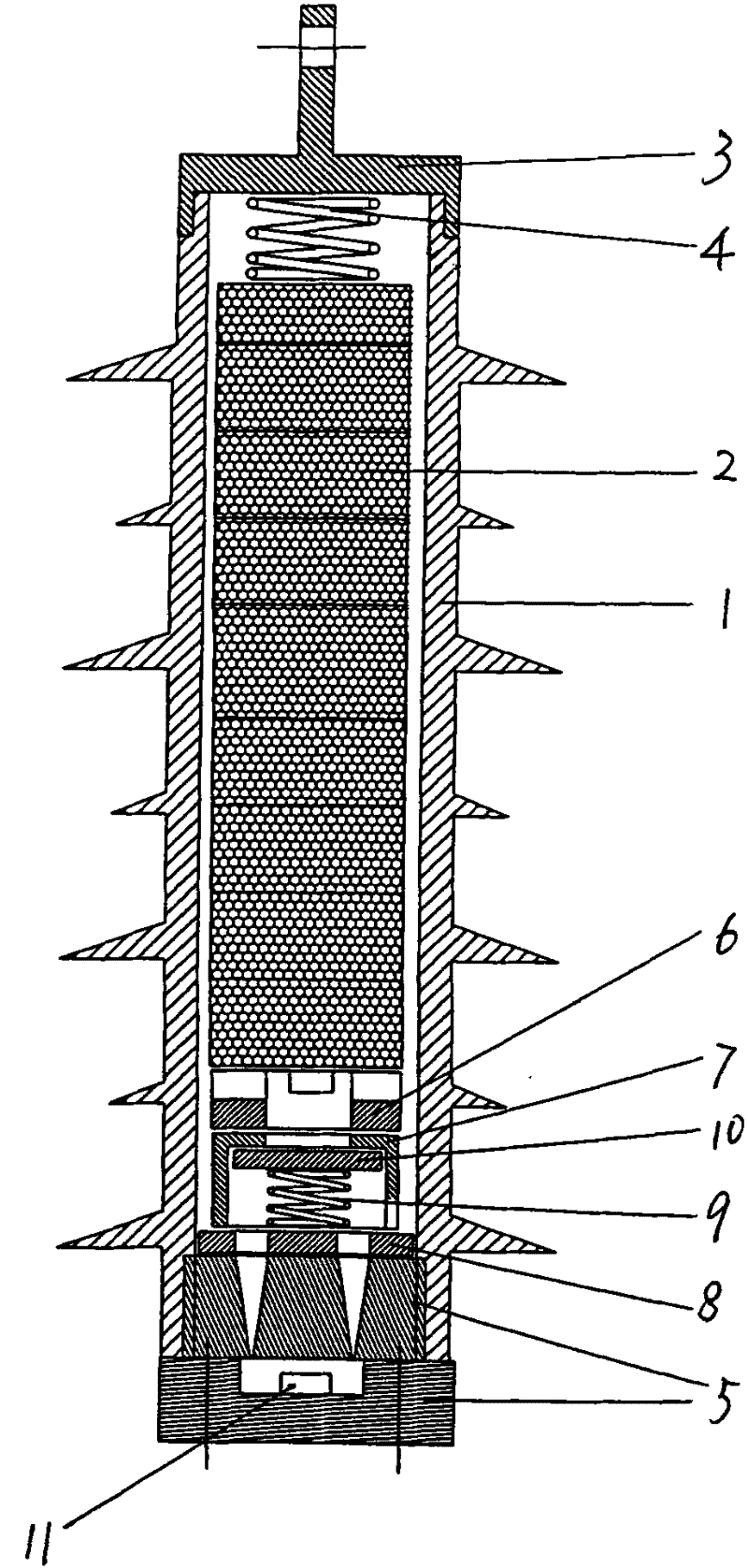

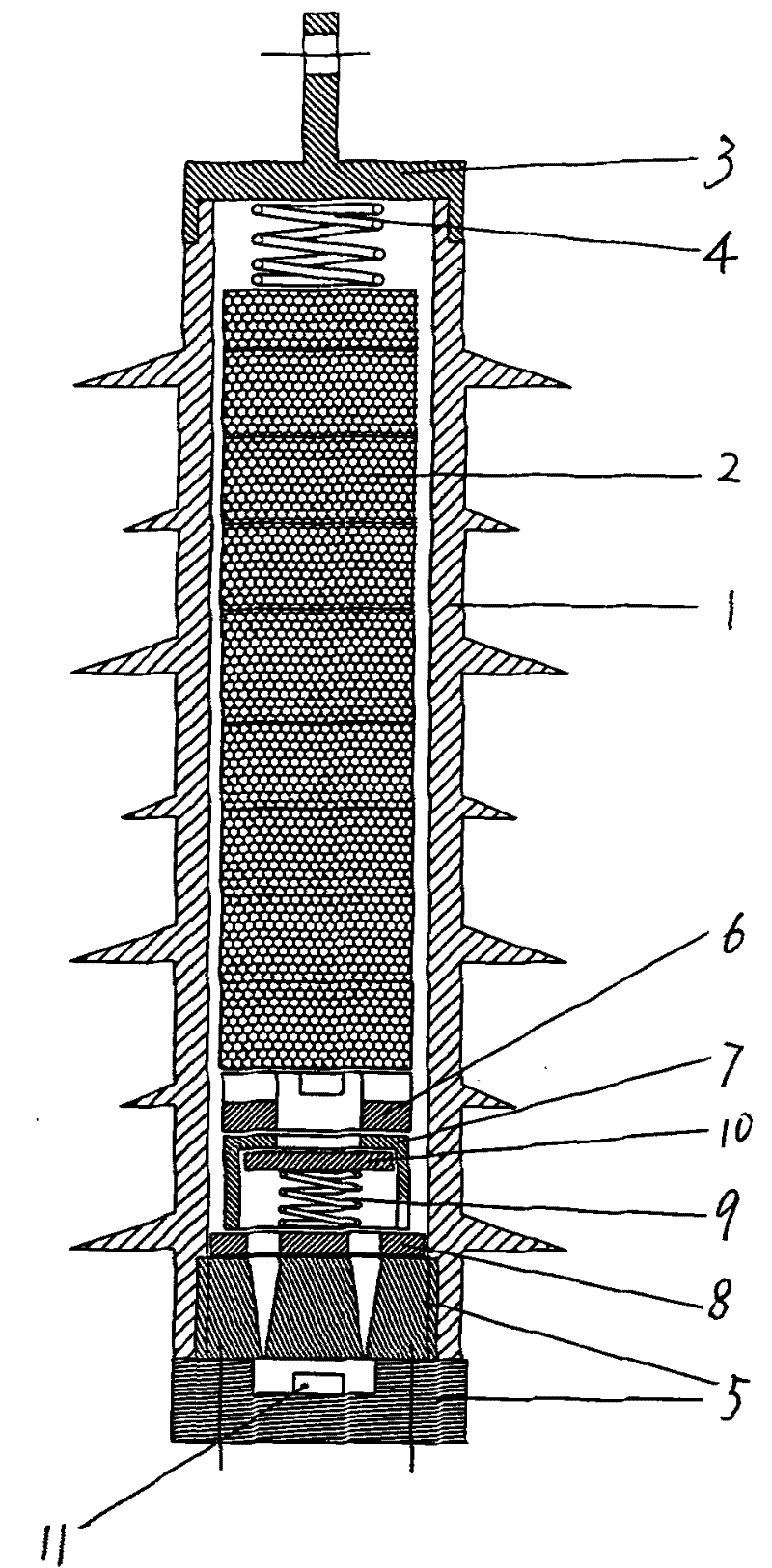

Constant voltage overvoltage protector

InactiveCN101325106AKeep dry airStable dry humidityOvervoltage protection resistorsOvervoltageEngineering

The invention discloses a constant-voltage over-voltage protector, which comprises an insulating sleeve. A zinc oxide valve plate is installed in the insulating sleeve, a metal cap is installed at the upper end of the insulating sleeve, an upper spring is installed between the zinc oxide valve plate and the metal cap, a metal blocking seat is installed at the bottom part of the insulating sleeve, a gap ring block, a shrouding barrel, a lower spring, a negative voltage sealing pad and a positive voltage sealing pad are superposed between the zinc oxide valve plate and the metal blocking seat in sequence, a breathing hole is formed on the metal blocking seat, and communicates with the inner cavity of the insulating sleeve. The constant-voltage over-voltage protector eliminates the explosion phenomenon under the over-positive voltage condition by adopting the metal blocking seat with the breathing hole and the circulation pattern of breathe-out and breathe-in, further avoids the valley zone of the Paschen curve under the over-negative voltage, and ensures the realization of the constant voltage state of the voltage protector under the action of the double springs. The problem with the explosion of the prior lightning protector caused by gaseous discharge during the process of operation is thoroughly solved, and the safety performance of the product is enhanced.

Owner:HEFEI NANNAN POWER EQUIP CO LTD

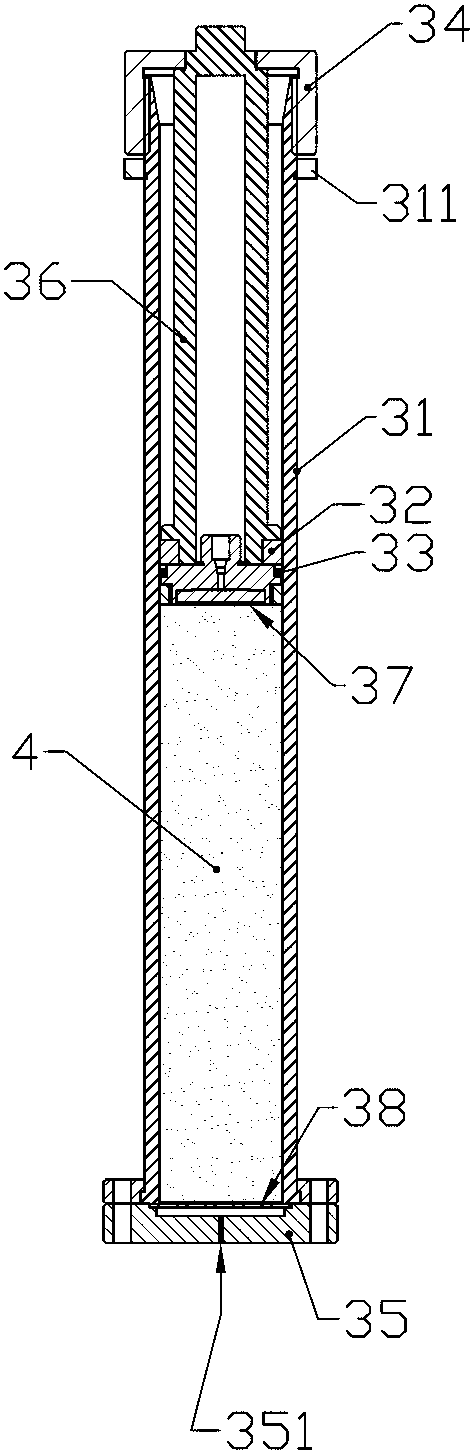

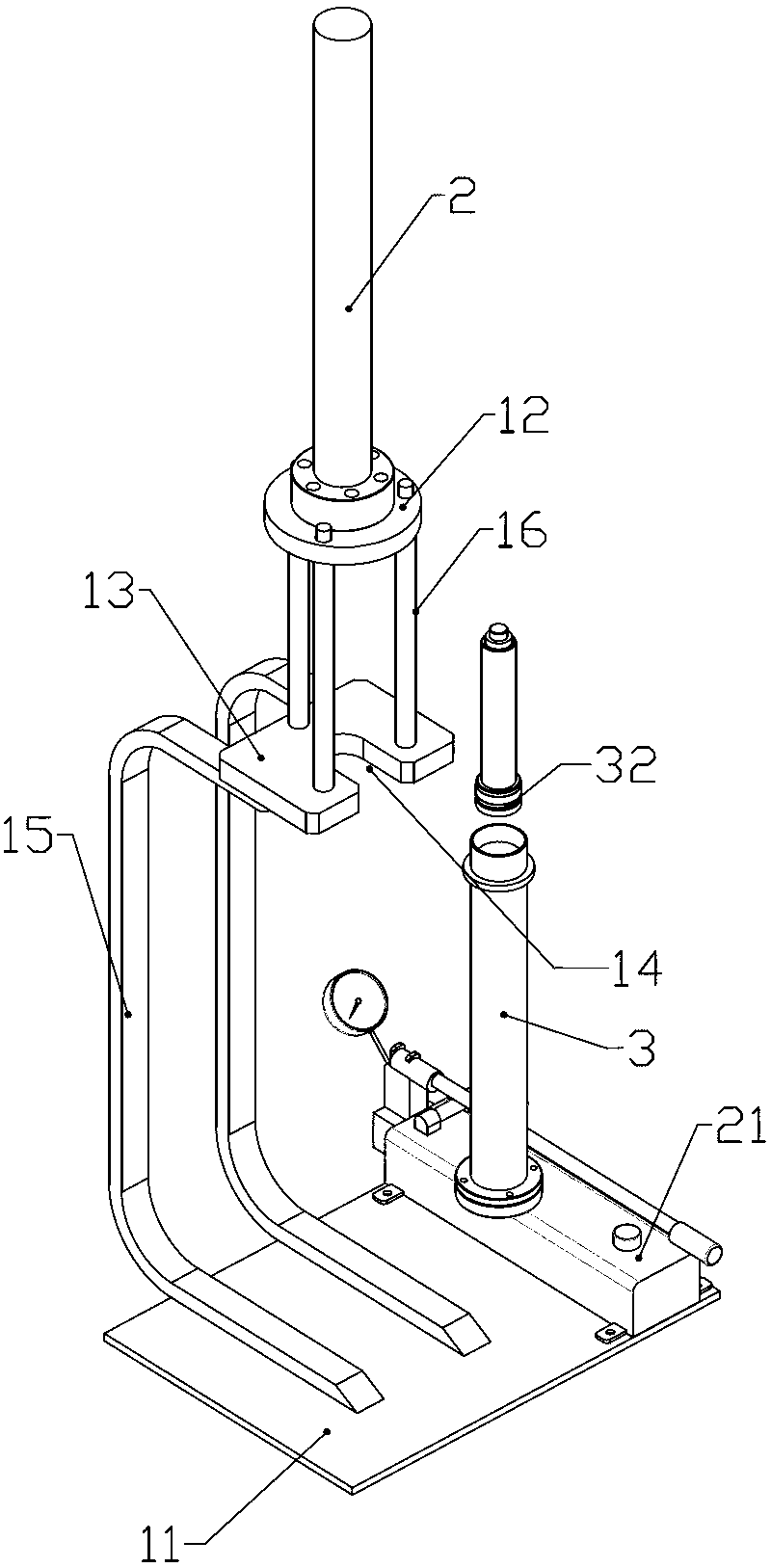

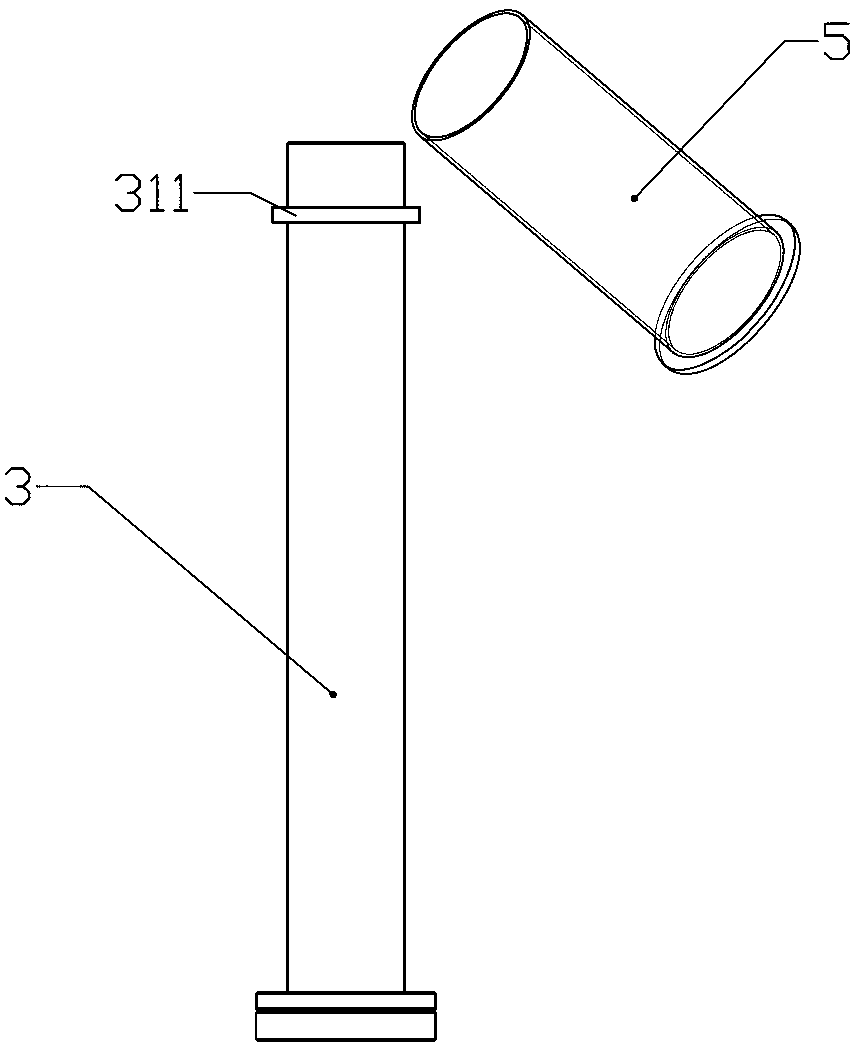

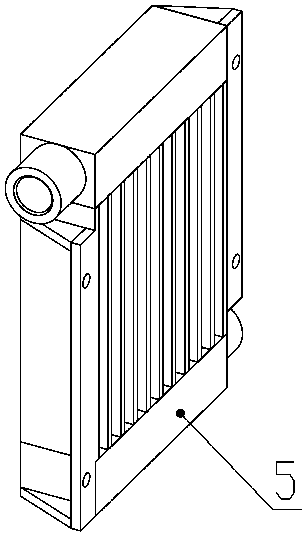

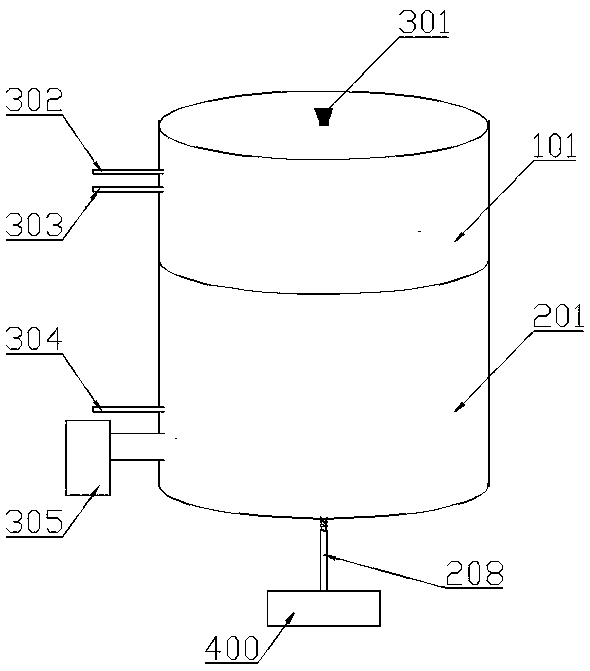

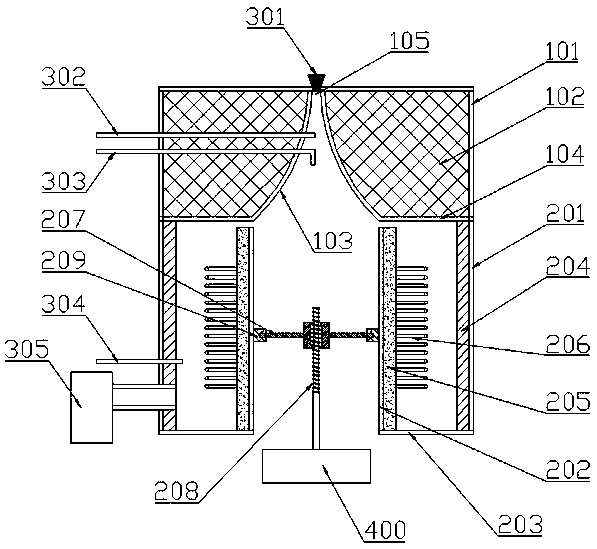

Inner storage constant-pressure preparative column device

ActiveCN102989199AConstant pressureGuaranteed separation effectSolid sorbent liquid separationHydraulic cylinderDefect repair

The invention relates to an inner storage constant-pressure preparative column device, and provides a miniaturization device. The device comprises a bracket, a preparative column and a hydraulic cylinder. The hydraulic cylinder is vertically mounted on the bracket, and a U notch for fixing the preparative column is arranged at a distance under the hydraulic cylinder; and the hydraulic cylinder acts on the preparative column and drives the preparative column to compress. The preparative column has functions of automatic inner column pressure compensation and automatic column bed defect repair, and also can ensure constant pressure state of packing in the column. The device is especially suitable for development and research on different target products and different processes in a laboratory, so as to greatly reduce development costs, and improve development efficiency.

Owner:LIAOCHENG WANHE IND MFR

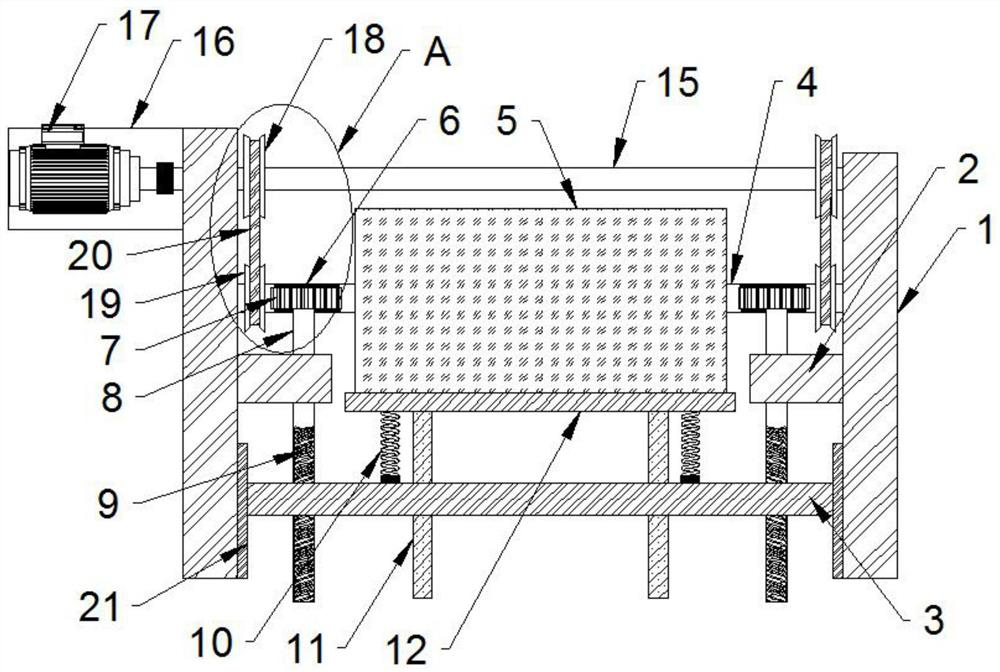

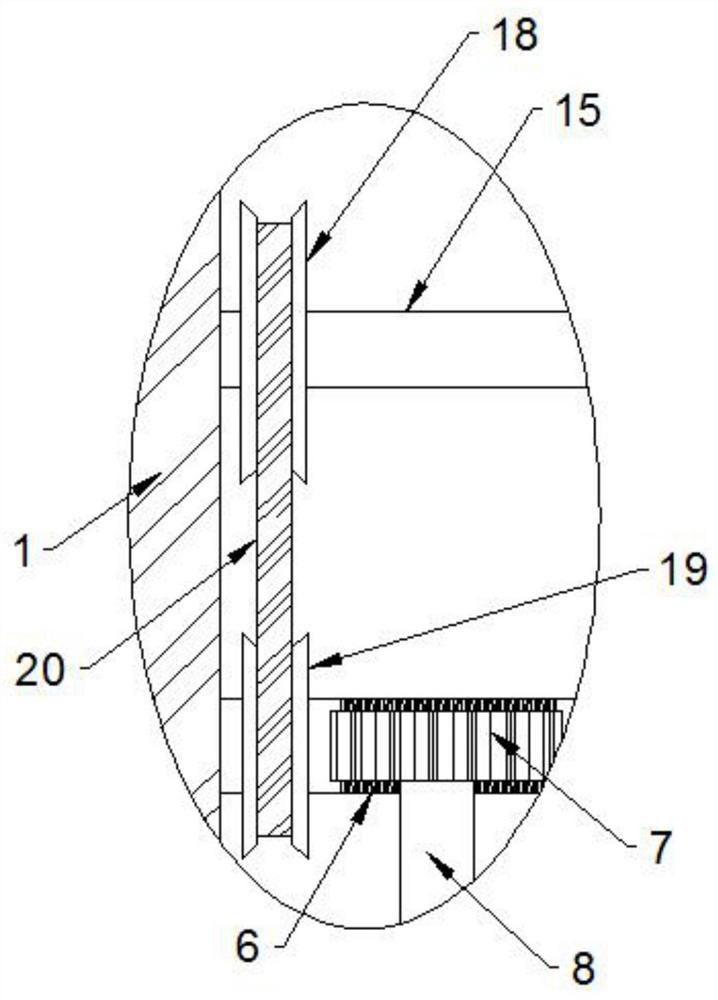

Grinding device with grinding dust removing function for derusting surface of steel pipe

ActiveCN110125780AGuaranteed constant pressureImprove grinding uniformityGrinding drivesGrinding machinesEngineeringConstant-force spring

The invention discloses a grinding device with a grinding dust removing function for derusting the surface of a steel pipe. The device comprises two supporting seats, a driving mechanism, a hollow shaft, a plurality of grinding mechanisms, an adjusting mechanism and a grinding dust removing mechanism, the hollow shaft is rotatably arranged on the two supporting seats, the driving mechanism drivesthe hollow shaft to rotate, an adjusting mechanism is arranged on the peripheral surface of the rear end of the hollow shaft, a grinding mechanism is arranged on the adjusting mechanism, the grindingmechanism comprises a constant-force spring, a spring box, a shaft body, a gear, a rack, a sliding rail, a sliding seat, a mounting seat and a grinding head, a spring box and a sliding rail are arranged on the mounting base, a rotatable shaft body is arranged on the spring box, and the spring box is internally provided with a constant-force spring which is fixedly connected with the spring box andthe shaft body respectively. Compared with the prior art, the device has the advantages that the grinding uniformity is good, the derusting effect is good, the application range is wide, and the working efficiency is improved.

Owner:JIAXING JCC PIPING ENG & CONSTR

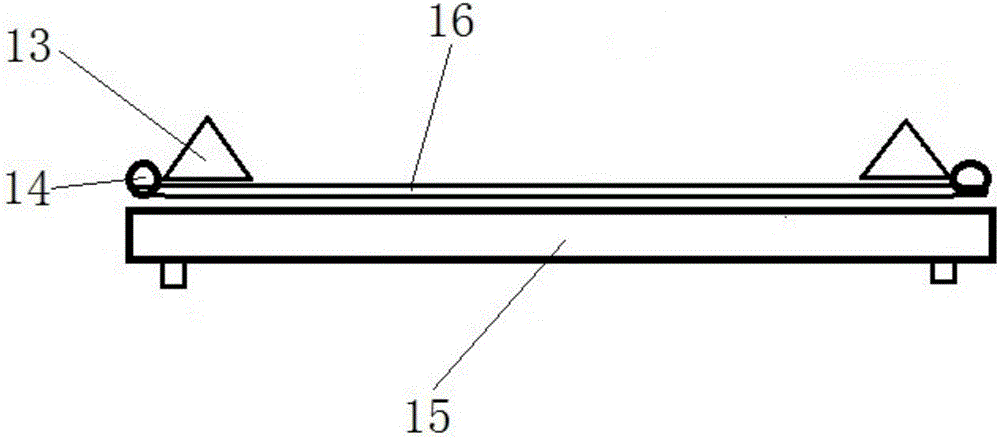

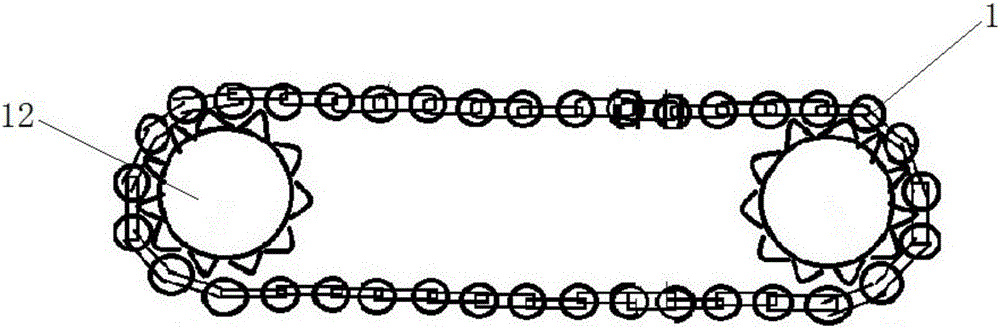

Automatic sampling device of leather colour fastness

InactiveCN106404449AGuaranteed constant pressureWithdrawing sample devicesInvestigating abrasion/wear resistanceColour fastnessReciprocating motion

The invention discloses an automatic sampling device of leather colour fastness. The automatic sampling device comprises a chain, wherein the chain is driven to rotate on a level through a driving gear and a driven gear; the chain is fixedly connected with a fixing strip through a connecting shaft, and the fixing strip is connected with a rotating shaft; the rotating shaft is connected with a linear slide rail structure capable of linear movement; the linear slide rail structure is connected with a connector, and the connector performs the straight reciprocating motion; the connector is connected with a solid sampler, and the lower part of the solid sampler is provided with a platform for testing the leather colour fastness, wherein the platform includes a bottom plate; both ends of the bottom plate are connected with pressing plates through a spring clip. The automatic sampling device solves the problems in the prior art that the noise during the reciprocating linear frictional sampling process is big and the service life of the device is influenced for the motor load output torque is always under the heterogeneous changing state.

Owner:SHAANXI UNIV OF SCI & TECH

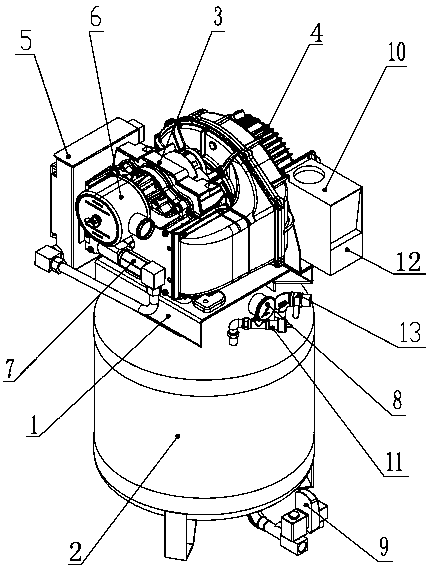

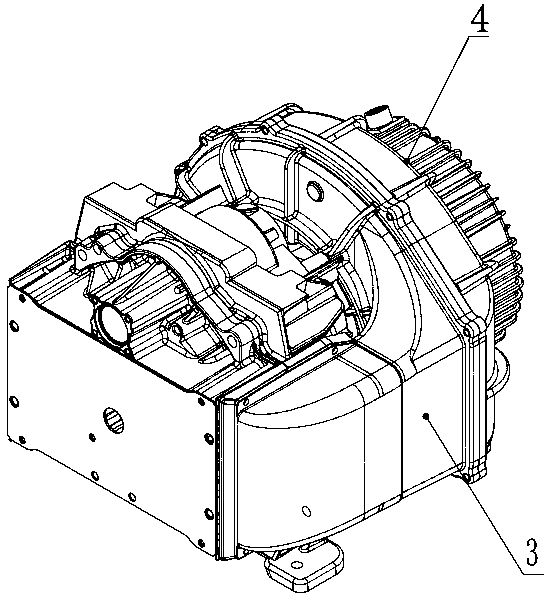

Medical oilless vortex variable frequency air compressor

PendingCN108953151AAir pressure is automatically kept constantKeep air pressure constantRotary/oscillating piston combinations for elastic fluidsMachines/enginesAir compressionSynchronous motor

The invention discloses a medical oilless vortex variable frequency air compressor. The medical oilless vortex variable frequency air compressor comprises a mounting frame, an air storage tank, a mainmachine of the oilless vortex air compressor mounted on the mounting frame, a motor, a radiator, and an air filter and a one-way valve mounted in an air inlet of the main machine; the air storage tank is mounted on the mounting frame, and communicates with an air outlet of the main machine; a pressure gauge is mounted on the air storage tank; an electronic drainage valve is mounted under the airstorage tank; a variable frequency controller for controlling the motor to operate is mounted on the mounting frame; and a pressure sensor, associated with the variable frequency controller, is mounted in the air storage tank. The all-oilless vortex air compression main machine is adopted to guarantee safer and more healthy medical gas; the permanent magnetic synchronous motor is adopted for variable frequency control and automatic control to guarantee constant pressure and constant flow of the gas for terminals; and the medical oilless vortex variable frequency air compressor is simple in structure, convenient to use, low in noise, low in vibration and free of influence in nearby use.

Owner:浙江高领新能源科技有限公司

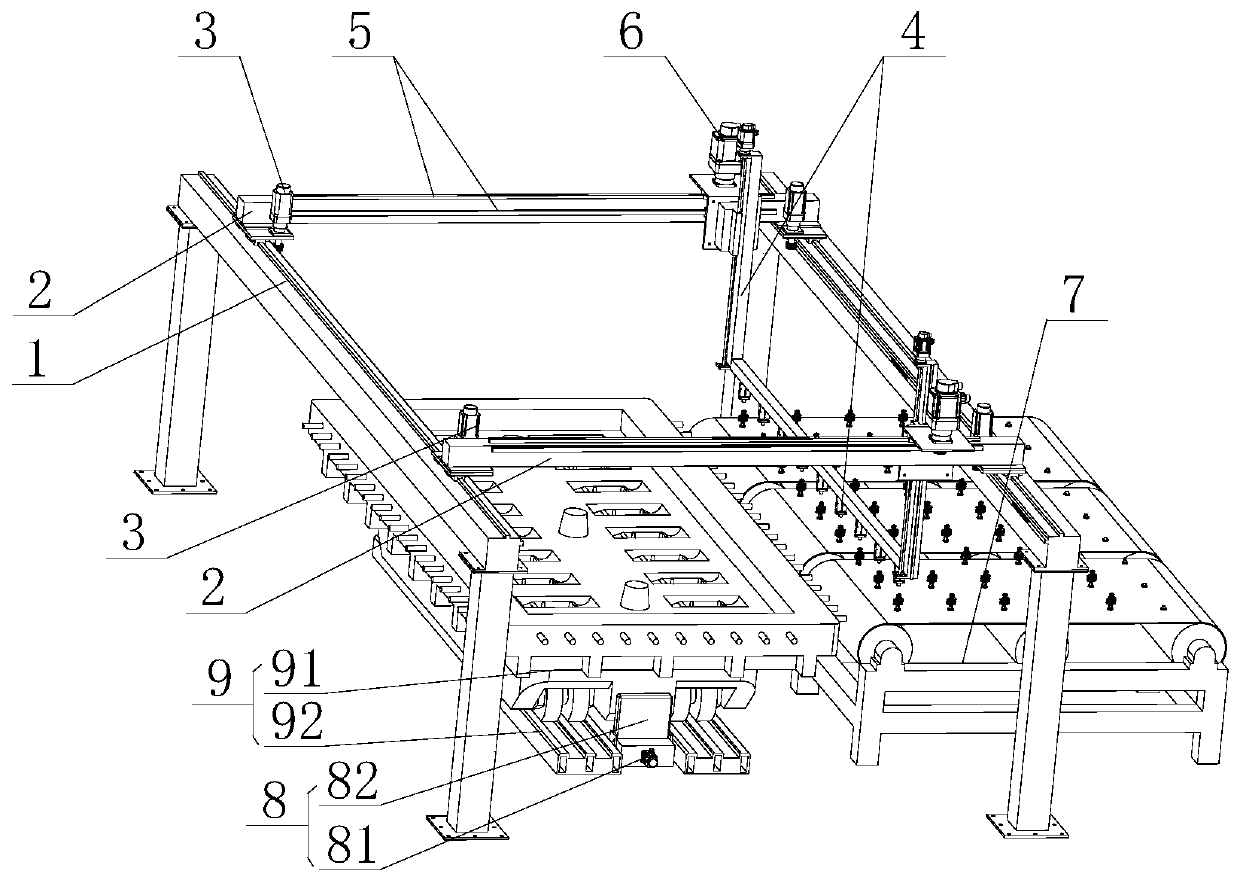

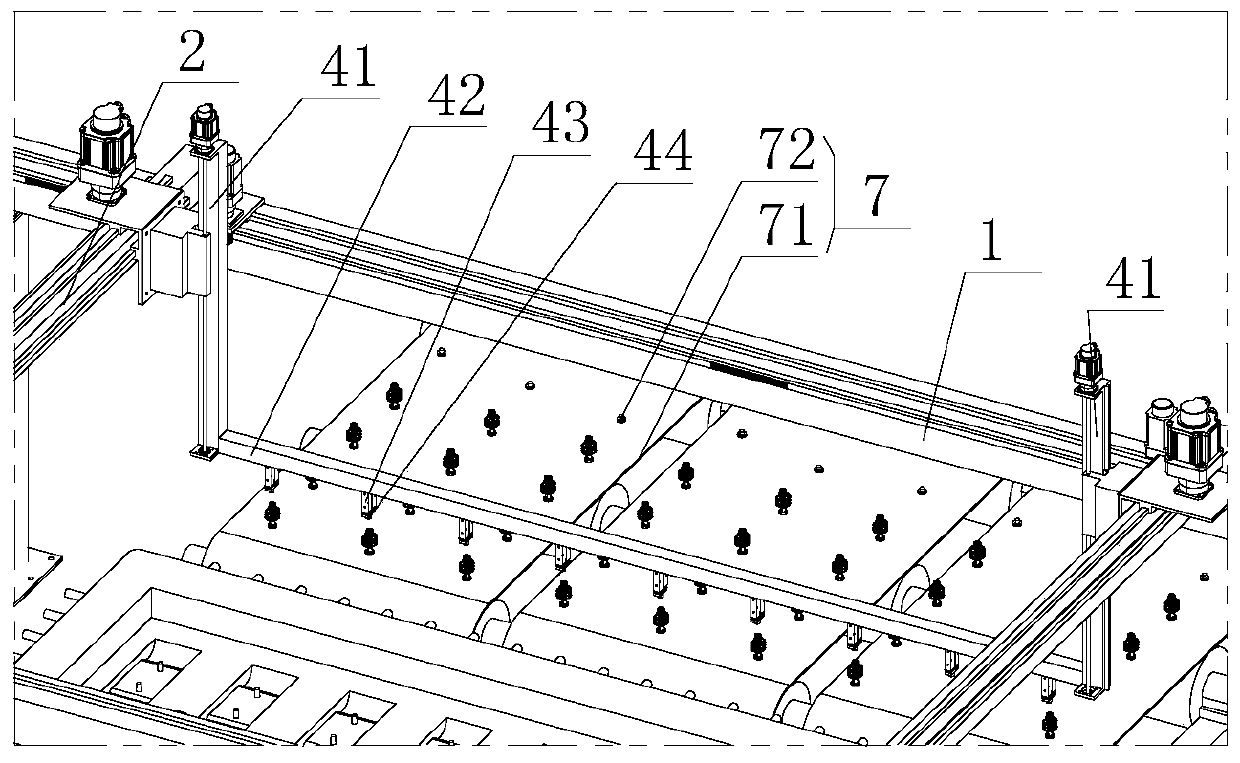

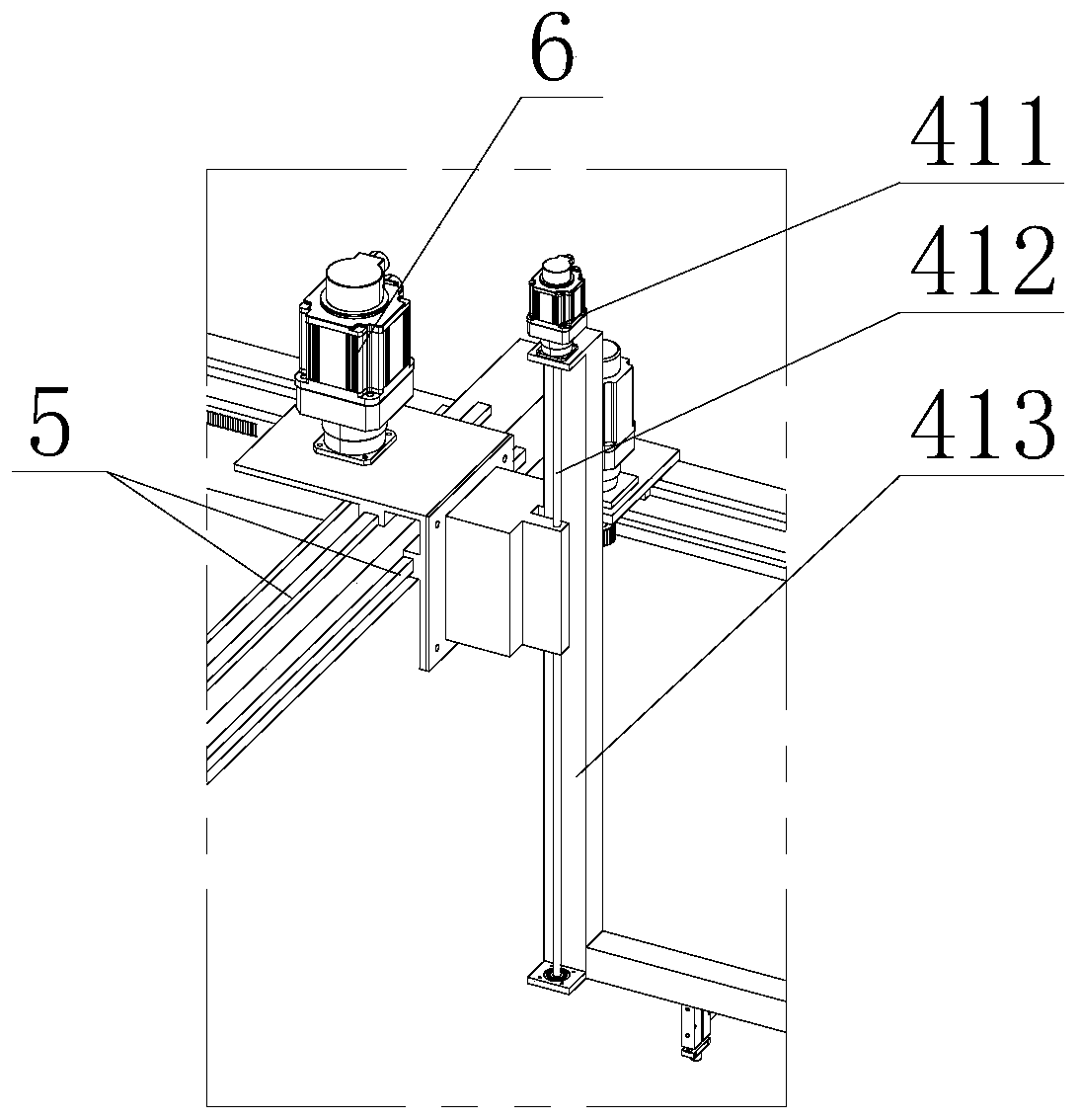

Track plate spiral rib sleeve installing machine

PendingCN110774439AQuick installationAccurate placementAuxillary shaping apparatusMould fastening meansElectric machineryStructural engineering

The invention provides a track plate spiral rib sleeve installing machine. The track plate spiral rib sleeve installing machine comprises guide rails, truss cross beams, a sleeve mounting assembly, transverse moving guide rails and transverse moving motors; the sleeve mounting assembly can move along the transverse moving guide rails on each truss cross beam; the sleeve mounting assembly compriseslifting mechanisms, a cross rod, pressing air cylinders and suckers, and the lifting mechanisms can drive the cross rod to ascend and descend; and a plurality of pressing air cylinders are arranged on the cross rod, and telescopic rods of pressing air cylinders are connected with the suckers capable of sucking spiral rib sleeves. According to the track plate spiral rib sleeve installing machine,the truss cross beams are driven by moving motors to move on the guide rails, the sleeve mounting assembly is driven by the transverse moving motors to move on the transverse moving guide rails, so that the sleeve mounting assembly can move to the position above positioning columns of different columns on a mold, the suckers capable of sucking the sleeves are driven by lifting motors to perform lifting motion, so that the sleeves are accurately placed on the positioning columns; and after the sleeves are placed on the positioning columns, the pressing air cylinders are started to press the sleeves against the positioning columns, so that the problem of high failure rate of manual installation of the spiral rib sleeves is solved.

Owner:北京好运达智创科技有限公司

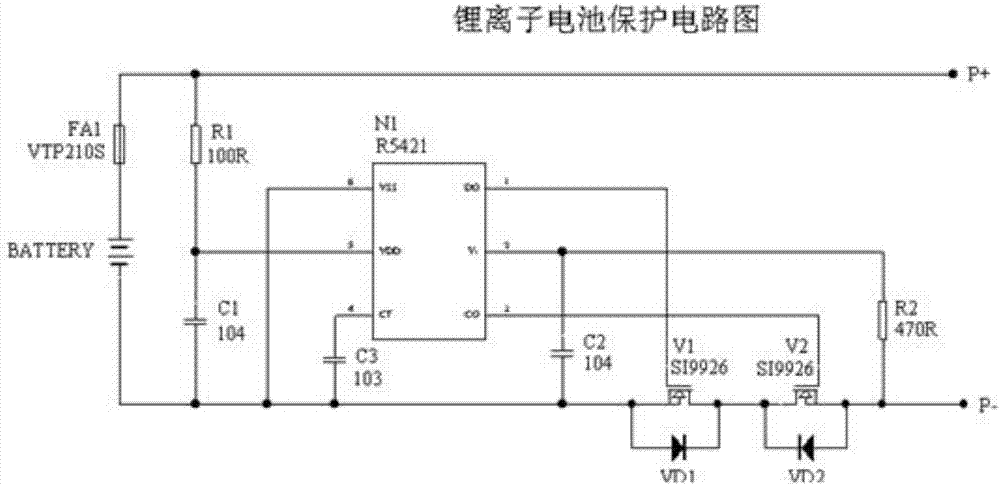

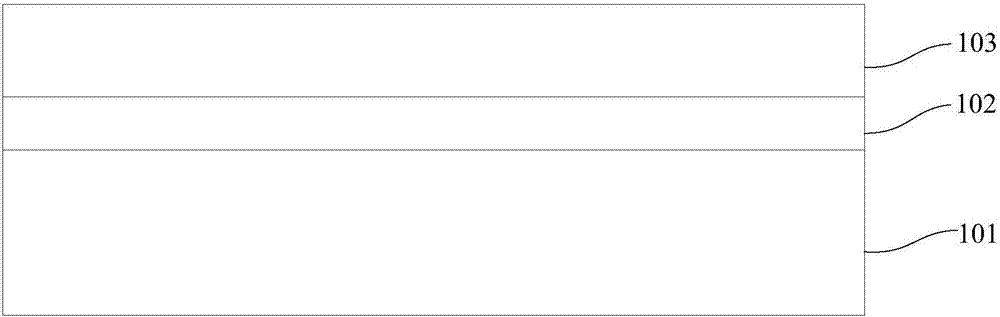

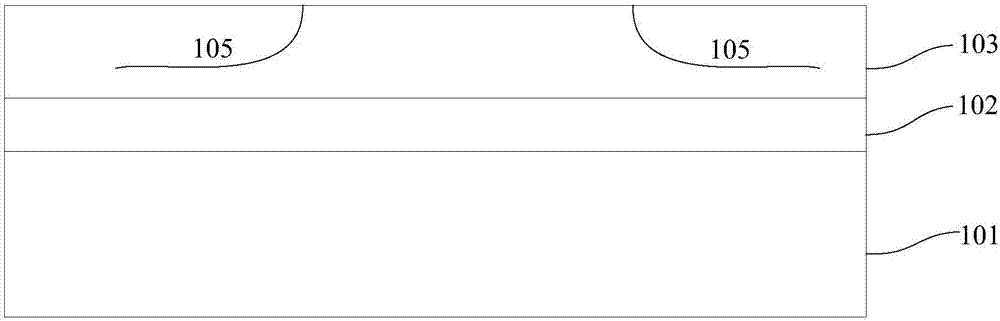

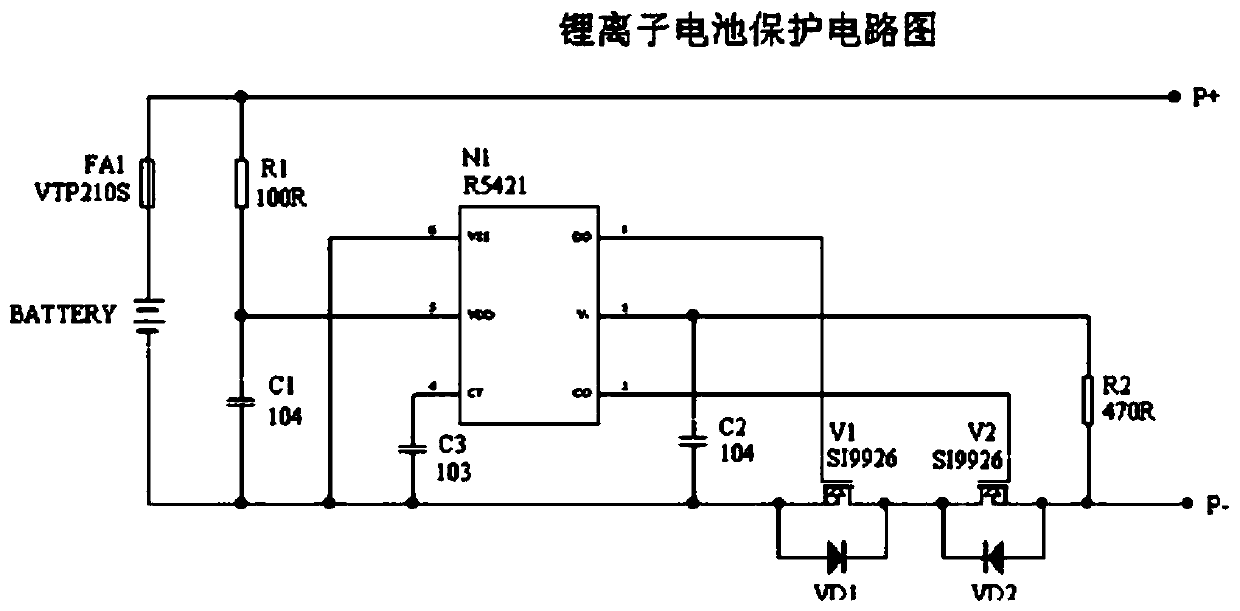

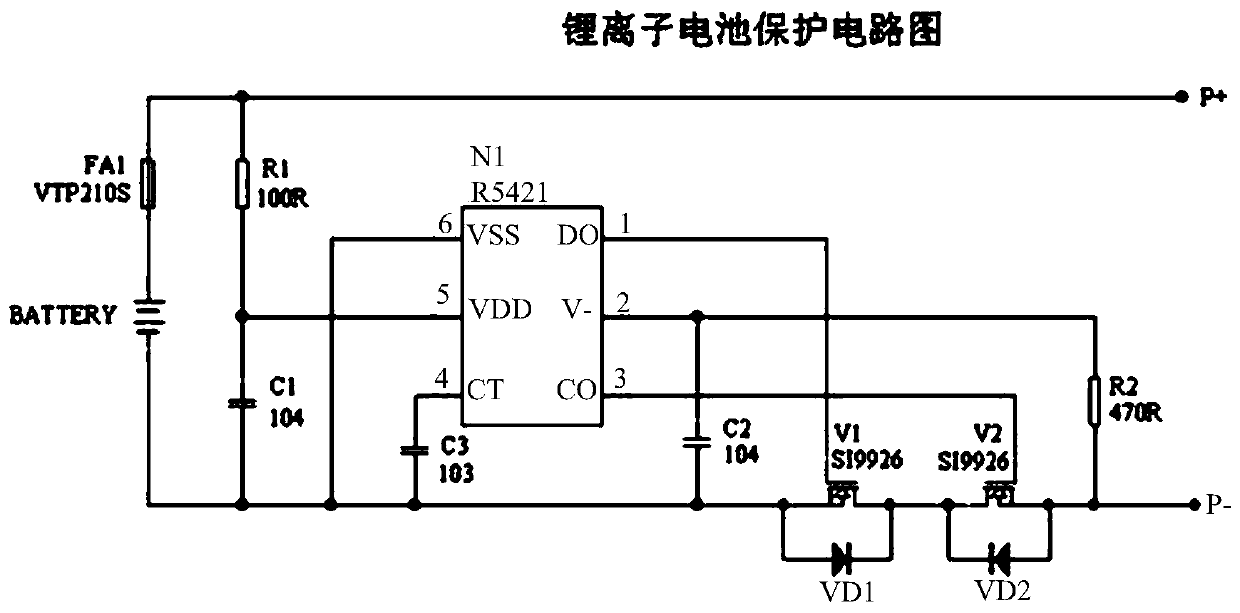

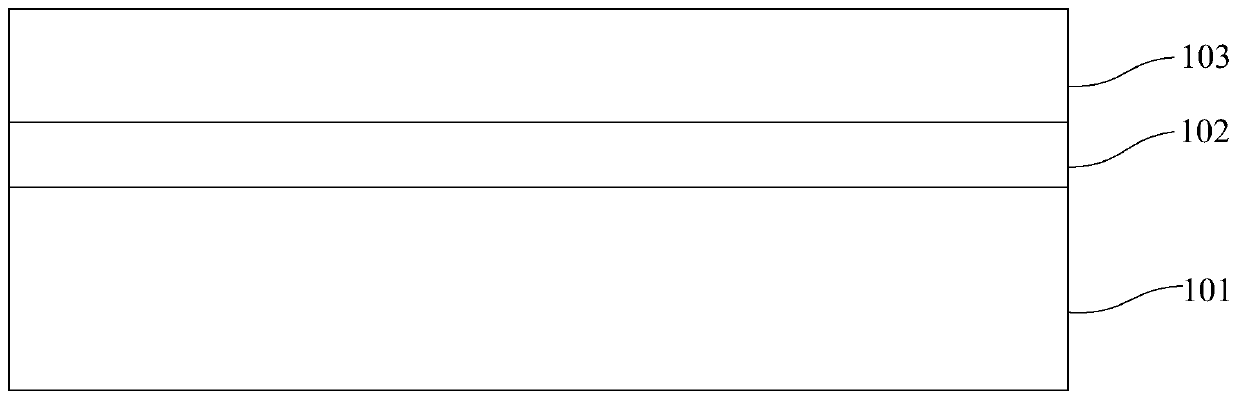

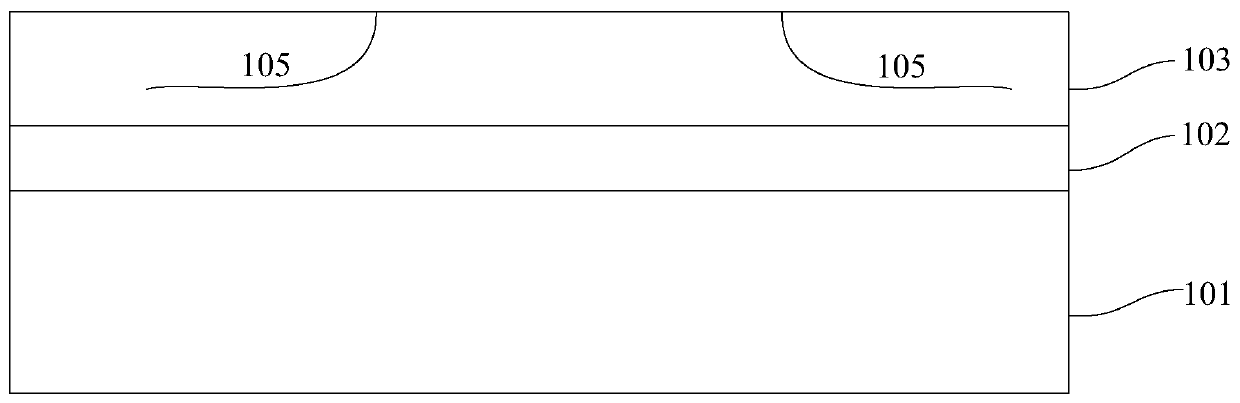

Switching device used for lithium battery protection and manufacturing method thereof

ActiveCN106920777AReduced area resistanceLower resistanceTransistorSemiconductor/solid-state device manufacturingMOSFETElectrical resistance and conductance

The invention provides a switching device used for lithium battery protection and a manufacturing method thereof. The switching device comprises a P+ type substrate and a P- type epitaxial layer, an N type well region, two P type well regions, two gate structures, a shared N- type drifting region, an N type source region and a P+ type contact region, a dielectric layer and an electrode material, wherein the shared N- type drifting region is formed between the two gate structures; two source region contact windows and a body region contact window are formed in the dielectric layer, and the P- type epitaxial layer in the body region contact window is removed to form a groove until the P+ type substrate; and the source region contact windows, the body region contact window and the groove are filled with the electrode material. An MOSFET device is constructed by adopting a drifting region sharing manner, so that the region resistance of the drifting region can be greatly reduced, and meanwhile voltage resistance is guaranteed to be unchanged. One of source region electrodes is introduced to the back of a chip in a body region electrode manner, and can be welded with a base during packaging, so that a wire bonding resistor is omitted, and the manufacturing method is extremely effective in an extremely low internal resistance requirement.

Owner:宁波宝芯源功率半导体有限公司

Constant voltage overvoltage protector

Owner:HEFEI NANNAN POWER EQUIP CO LTD

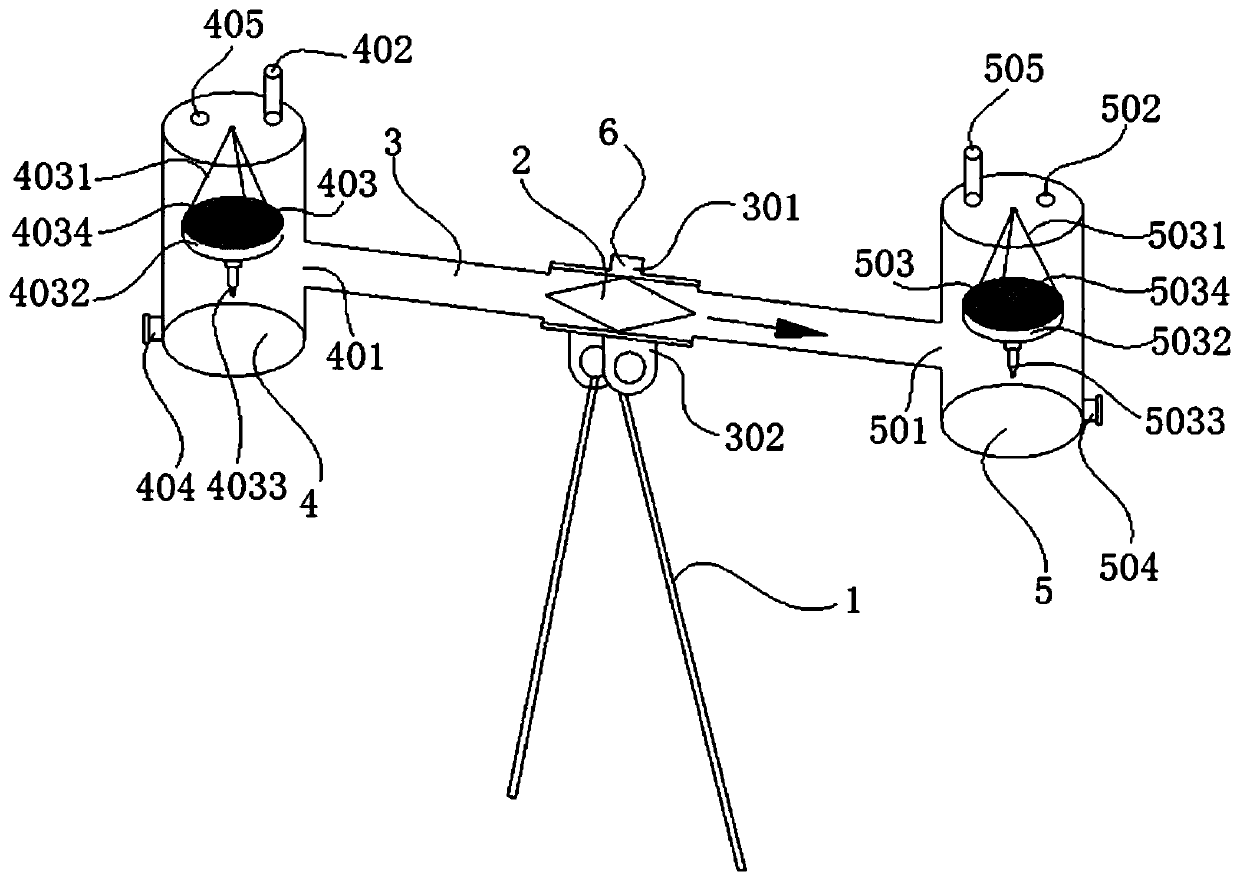

A kind of high-temperature soot gas jet experimental device and method

The invention provides a high-temperature soot gas jet experiment device and method, belonging to the technical field of jet devices. The high-temperature soot gas jet experiment device comprises a jet flow outlet control component, a gas heating and storage component, a driving component and an auxiliary component; wherein the jet flow outlet control component comprises an outer jet flow tube, ajet flow guiding structure and a first insulating layer; the gas heating and storage component comprises an outer sleeve hermetically connected with the outer jet flow tube, an inner sleeve arranged in the outer sleeve, a bottom plate connecting the lower edge of the outer sleeve with the lower edge of the inner sleeve, a second insulating layer arranged on the inner wall of the outer sleeve, a third insulating layer arranged on the outer wall of the inner sleeve, a heating part arranged on the third insulating layer, a baffle arranged in the inner sleeve, and a transmission member; the transmission member is connected with the driving component; and the auxiliary component comprises a sealed sieve, a soot particle injection pipe, a dynamic and static pressure testing sensor, a temperaturedetecting sensor and a smoke generator. The device of the invention can form high-emperature soot gas with stable speed and controllable temperature.

Owner:TAIYUAN UNIV OF TECH

Micro-foaming injection-molding screw rod

The invention discloses a micro-foaming injection-molding screw rod, mainly comprising a rear screw rod, a rear positioning ring, a rear check ring, a rear mixing section, a front mixing section, a front screw rod, a front positioning ring, a front check ring and a screw rod head, wherein hexagonal threads are adopted for the rear mixing section and the front mixing section, forward threads consistent with the turning direction of the screw rod are adopted for the rear mixing section, and reverse threads are adopted for the front mixing section and are provided with forward grooves. The micro-foaming injection-molding screw rod has a greatly improved mixing and homogenizing effect so that supercritical gas rapidly and uniformly distributes in a polymer melt so as to form a stable polymer melt / supercritical gas homogeneous system; meanwhile, checking is carried out in a gas inlet position so as to effectively prevent the melt from flowing back to block a gas inlet channel; and the special micro-foaming injection-molding screw rod can be widely applied to micro-foaming injection machines of various types.

Owner:BEIJING UNIV OF CHEM TECH

Pump thermal shock test method and system

ActiveCN103437990BGuaranteed constant pressureGuarantee the effect of pump thermal shock testPump testingPositive-displacement liquid enginesExpansion tankCooling tower

Owner:SHANGHAI SHUOYI M & E

A kind of auxiliary winding device of cotton spinning sliver parallel winding machine

ActiveCN110791840BUniform tightnessImprove the winding effectLap-winding devicesWinding machineGear wheel

The invention relates to an auxiliary winding device for a cotton sliver doubling machine, which comprises two side frames, a rotating shaft is embedded in the inside of the two side frames, a roller shaft is installed between the two side frames, and a roller wheel is embedded in the outside of the roller shaft , Both ends of the roller shaft are provided with worm threads, the upper side of the worm threads is provided with gears, the gears mesh with the worm threads, the inside of the gears is embedded with a transmission shaft, the other end of the transmission shaft is provided with external threads, two side frames Slide rails are installed on the inside of the two slide rails, and a support plate is slidably connected between the two slide rails. There are two guide holes and two threaded holes inside the support plate. The transmission shaft is embedded in the threaded holes, and the two guide holes Guide rods are embedded inside, a pressing plate is fixed at the ends of the two guiding rods close to the rollers, and two springs are connected between the pressing plate and the support plate. The auxiliary winding device of the cotton sliver doubling machine can automatically adjust the pressure, so that the winding effect of the cotton sliver is better.

Owner:谷城县顺祥纺织有限责任公司

A photobiological reaction device that can effectively absorb and utilize exhaust gas

ActiveCN108823075BFree rotationImprove photophysiological response rateBioreactor/fermenter combinationsGas treatmentChemical physicsLiquid state

The invention discloses a photo-biological reaction device capable of effectively absorbing and utilizing tail gas. The device is characterized in that tail gas is sufficiently absorbed and utilized through a photo-biological reactor, so that liquid substances such as bio-oil and the like are produced; energy of a light source is sufficiently utilized, and the light utilization rate and the photo-biological reaction rate are increased; by use of a flow plunger, tail gas introduced into a hollow rotating shaft is subjected to two-way non-equivalent conveying, and due to change of reaction quality in transparent photo-biological reaction containers, vertical movement in the vertical surface of the hollow rotating shaft is realized; the liquid substances such as bio-oil and the like obtainedthrough photo-biology can be recycled; through equal-length connecting lines connecting a horizontal reaction kettle and the transparent photo-biological reaction containers, the horizontal reaction kettle is slightly shaken and finally kept horizontal; through a constant-pressure valve nozzle, dynamic stability and controllable function of photo-biological and photo-physiological reactions in thetransparent photo-biological reaction containers are realized, constant pressure of the photo-biological and photo-physiological reactions in the transparent photo-biological reaction containers is guaranteed, and the photo-biological reaction substance utilization rate in the transparent photo-biological reaction containers is increased.

Owner:CHONGQING UNIV

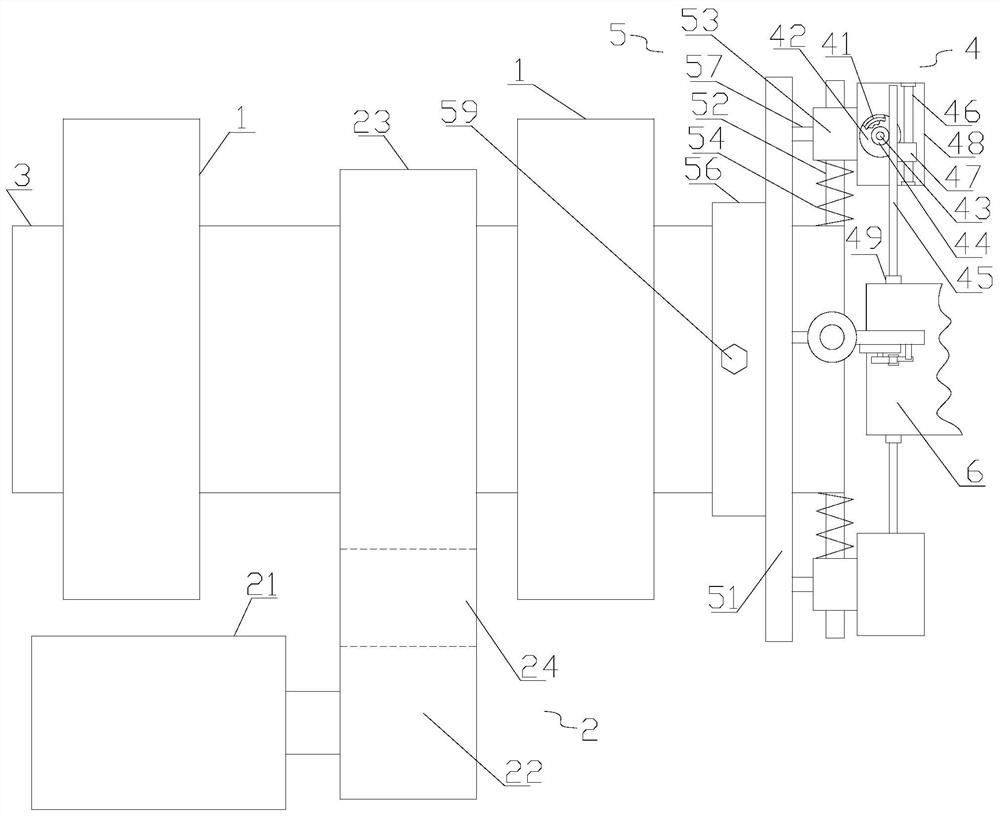

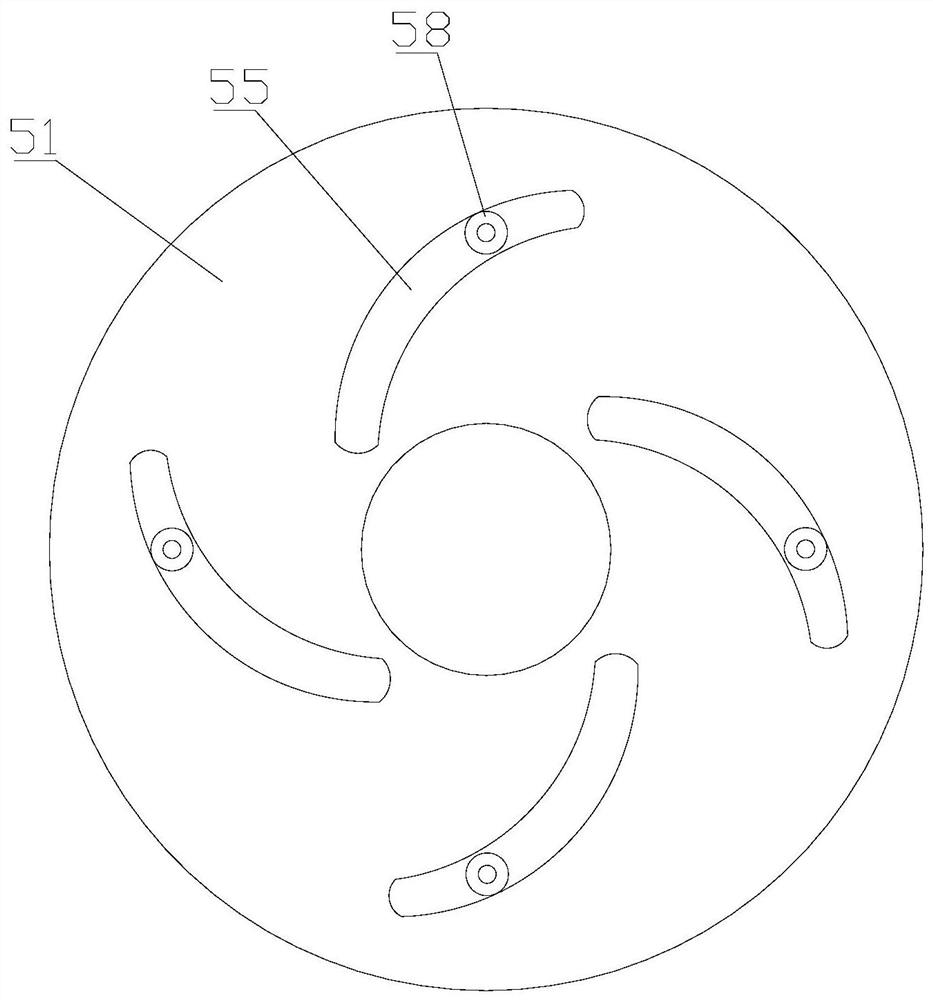

Grinding device for steel pipe surface derusting device with good grinding uniformity

ActiveCN110000680BGuaranteed constant pressureImprove grinding uniformityRevolution surface grinding machinesGear wheelGear tooth

The invention discloses a grinding device for a steel pipe surface rust removal device with good grinding uniformity. The grinding device comprises two supporting seats, a driving mechanism, a hollowshaft, a plurality of grinding mechanisms and an adjusting mechanism, wherein the hollow shaft is rotatably arranged on the two supporting seats, the driving mechanism drives the hollow shaft to rotate, an adjusting mechanism is arranged on the peripheral surface of the rear end of the hollow shaft, and the grinding mechanisms are arranged on the adjusting mechanism; and the grinding mechanism comprises a constant-force spring, a spring box, a shaft body, a gear, a rack, a sliding rail, a sliding seat, a mounting seat and a grinding head, a spring box and a sliding rail are arranged on the mounting base, a rotatable shaft body is arranged on the spring box, and the spring box is internally provided with a constant-force spring with two ends fixedly connected with the spring box and the shaft body respectively. Compared with the prior art, the grinding device is good in grinding uniformity, good in derusting effect and wide in application range.

Owner:JIAXING JCC PIPING ENG & CONSTR

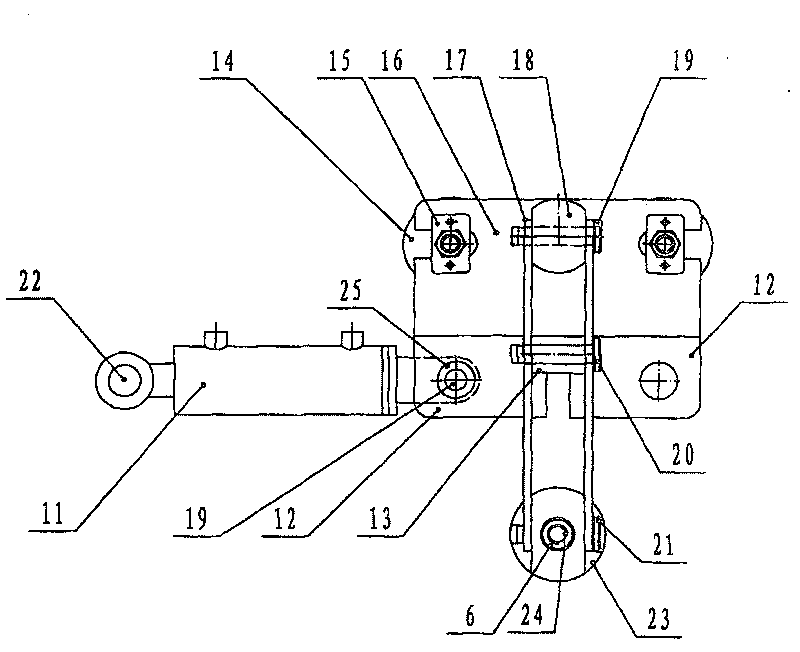

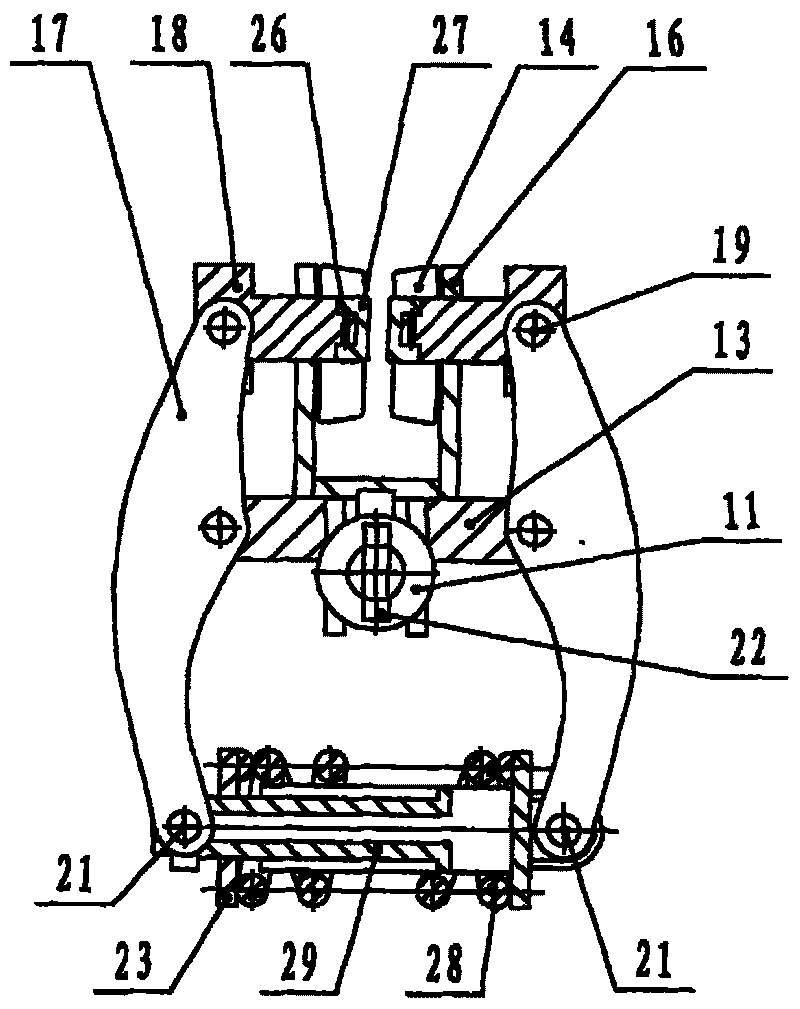

On-off synchronous control rail-hanging type brake

InactiveCN101255898BSynchronous start and stopAvoid runawayBrake actuating mechanismsCheck valveRelief valve

A start-stop synchronization control hanging rail type arrester used for braking system of rail type transport equipment is provided, which has simple structure, easy operation and start-stop synchronization control function. The present invention comprises a synchronization control mechanism and a hydraulic pressure locking mechanism; the synchronization control mechanism comprises a manual pump,a reversing valve, a stop valve, a check valve, a relief valve, a single directional hydraulic cylinder and a double-acting cylinder; the oil inlet and outlet ports of the single directional hydrauliccylinder are connected with the stop valve and cavity of pole of the double-acting cylinder, the oil inlet port of the stop valve is connected with manual pump; the hydraulic pressure locking mechani sm comprises a dangler connection board, a support rack, a square rigid body, a pin, a driver plate, a transmission shaft, a friction block, a spring, a spring baffle, a support axes, a nut, a location-limited plate, an idler wheel and a bearing; the dangler of cavity of pole of double-acting cylinder is connected with dangler connection board by pin; the square rigid body is connected driver plate by pin, the driver board is connected with the transmission shaft by pin, the friction block is arranged on transmission shaft by taper pin.

Owner:TAIYUAN UNIV OF TECH

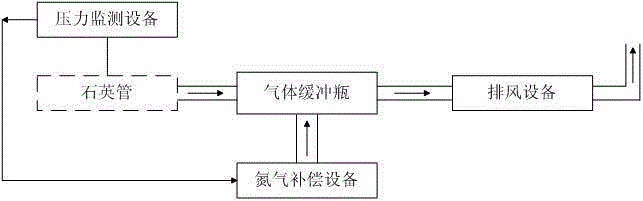

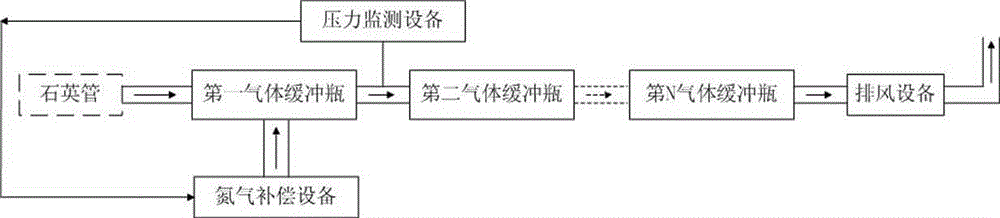

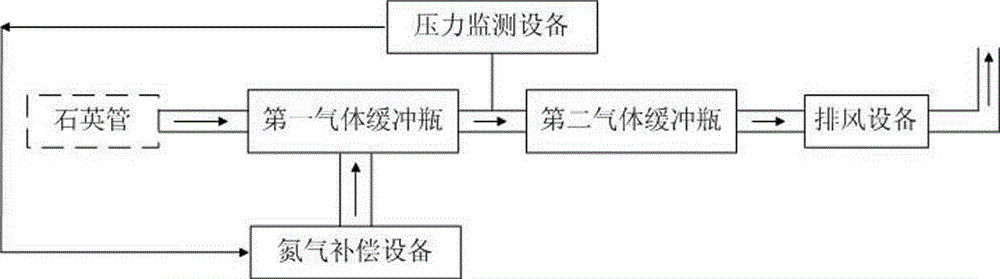

An Improved Diffusion Furnace Exhaust Gas Emission Device

ActiveCN103374757BIncrease the number ofAvoid contagionDiffusion/dopingDiffusionElectrical resistance and conductance

The invention discloses an improved exhaust gas emission device for a diffusion furnace. The device comprises a first gas surge flask, a ventilation device, a pressure monitoring device and a nitrogen compensation device. The pressure monitoring device and the nitrogen compensation device are in one-way connection; one end of the first gas surge flask is sequentially connected with a second surge flask,... an N surge flask, and then connected to the ventilation device; and the pressure monitoring device is arranged on any gas surge flask after the gas surge flask, which the nitrogen gas compensation device is in, or a connecting pipe between gas surge flasks. According to the invention, on the basis of the original device, the number of gas surge flasks is increased, the position of the pressure monitoring device is adjusted, so as to avoid lagging gas compensation, directly reduce influences of fluctuations of the ventilation device on the flow in a quartz tube, facilitate stability of flow in the quartz tube, ensure constant pressure of flow in the diffusion quartz tube, improve process stability, and ensure uniformity of square resistance and the quality of a PN junction.

Owner:YINGLI ENERGY CHINA

A switch device for lithium battery protection and manufacturing method thereof

ActiveCN106847750BReduced area resistanceLower resistanceTransistorSemiconductor/solid-state device manufacturingMOSFETInternal resistance

The invention provides a switch device used for lithium battery protection and a manufacturing method thereof. The switch device includes a P+ type substrate, a P- type epitaxial layer, an N type well region, two P type well regions, two gate structures, a common N- type drifting region, N type source regions, P+ type contact region, a groove, a metal silicide, a dielectric layer and an electrode material, wherein the common N- type drifting region is formed between the two gate structures, the groove is formed in the body contact region, the metal silicide is connected with the first N type source region and the P+ type substrate based on the groove, a contact window of the second N type source region is opened in the dielectric layer, and the contact window is filled with the electrode material. According to the switch device and the manufacturing method, an MOSFET device is constructed by adopting the common drifting region, the resistance of the drifting region can be largely reduced, and at the same time, voltage resistance is kept constant. The contact of one of source region is introduced to the reverse side of a chip by using the electric conduction mode of the metal silicide and can be welded to the substrate during packaging, one wire bonding resistor is omitted, the switch device is very effective when the internal resistance requirement is low, and the overall structure of the switch device is very simple.

Owner:中微半导体(深圳)股份有限公司

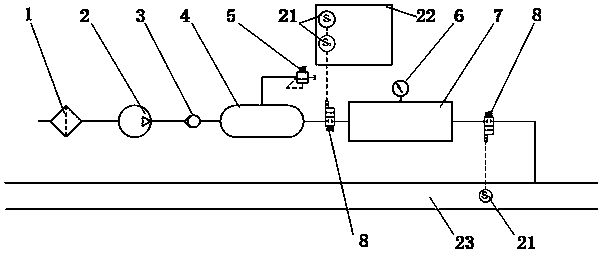

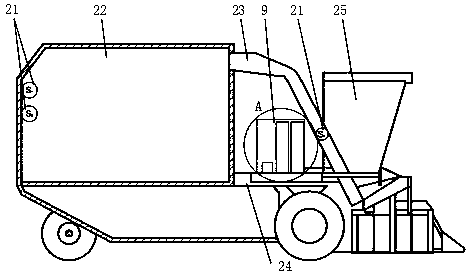

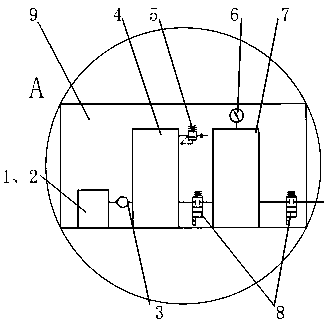

Cotton picker fire monitoring system

PendingCN110428575AGuaranteed constant pressureMeasurement devicesFire rescueEngineeringElectromagnetic valve

The invention discloses a cotton picker fire monitoring system. The system comprises a cotton picker main body, a cab, a cotton box, an air duct, a fire extinguishing device (containing a filter, an air pump, a one-way valve, an air vessel, an overflow valve, a pressure gauge, a fire extinguishing agent vessel and electromagnetic valves), a smoke sensor, temperature sensors and a near infrared sensor, wherein the fire extinguishing device is fixedly mounted between the cab and the cotton box on the cotton picker main body and positioned under the air duct; the smoke sensor and the temperaturesensors are mounted in the cotton box, and the near infrared sensor is mounted in the air duct. The fire extinguishing device is connected with the air duct through a pipeline; only certain treatmentneeds to be carried out on the air duct of the cotton picker, and then the preset function is easily realized. When a fire occurs, the sensors transmit signals to the corresponding electromagnetic valve, then the electromagnetic valve is started, and the fire extinguishing agent is pressed into the air duct by utilizing the pressure difference formed between the air duct and the fire extinguishingdevice and then reaches the cotton box along with wind, so that the purpose of isolating ignited cotton from unignited cotton in the cotton box is achieved, a great deal of time is gained for the cotton picker to shut down for unloading the cotton and extinguishing the fire, and the economic loss is reduced for farmers and machine owners.

Owner:SHIHEZI UNIVERSITY

Technique for continuously preparing super fine nano powder by using precipitation method and its specialized equipment

InactiveCN1206072CSame sizeUniform particle sizeCalcium/strontium/barium oxides/hydroxidesProduction rateProcess equipment

The invention relates to a process for continuously preparing superfine nano-powder by precipitation method. In this process, materials are fed to a reaction kettle at a certain ratio and speed through a metering and feeding device at the same time. , quickly enters the crystal nucleus growth tube, advances under the action of the material mixing device, and finally collects the suspension at the tube end outlet of the crystal nucleus growth tube and obtains ultrafine nano-powder after proper drying. The control of the grain size is realized by adjusting the temperature of the reaction kettle and the crystal nucleus growth tube, the proportion of the reaction materials, the feeding speed, the stirring speed and other control factors. The present invention can make the precipitation reaction proceed continuously, and the productivity is high; at the same time, the nucleation process and the growth process in the precipitation reaction are separated, and the nucleation and growth are formed in a relatively stable environment, and the particle size of the generated particles can be regulated, and the single particle size Good dispersibility, narrow distribution and small difference in morphology. The invention also provides special equipment for the new process.

Owner:NANJING TECH UNIV

Micro-foaming injection-molded screw

Owner:BEIJING UNIV OF CHEM TECH

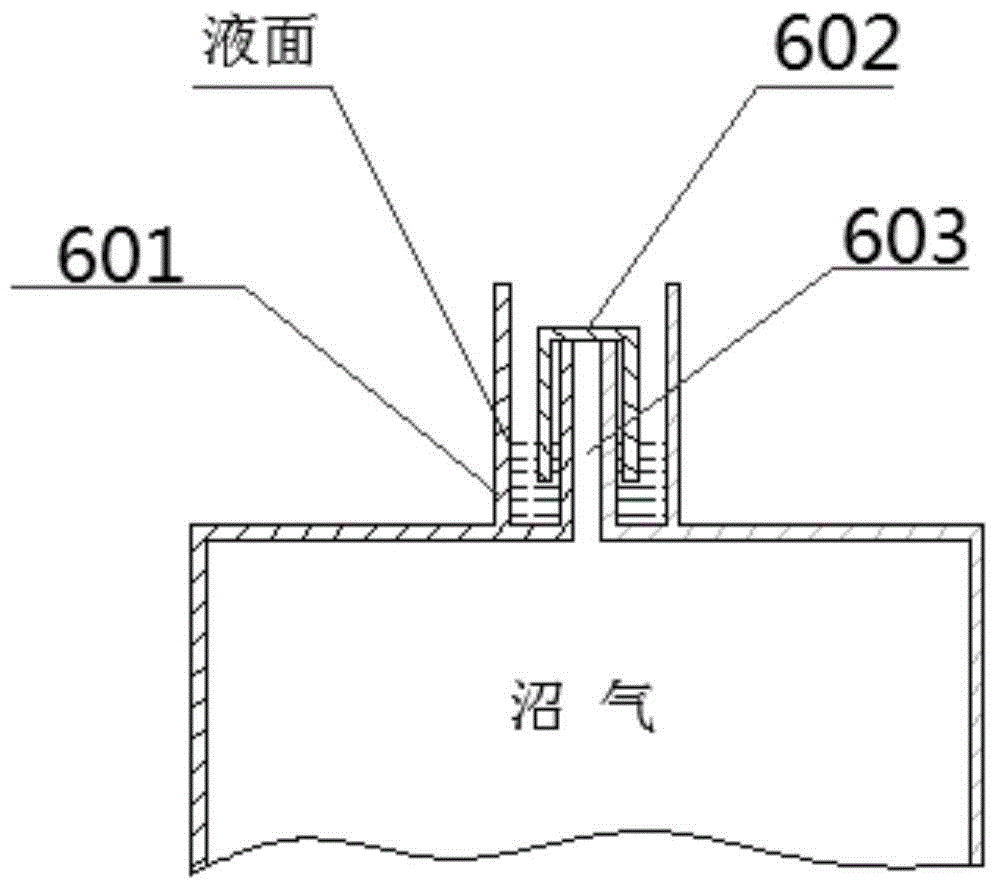

An anaerobic microorganism enrichment culture device

InactiveCN105255717BLow costReduce security risksBioreactor/fermenter combinationsBiological substance pretreatmentsPropellerEnvironmental engineering

Owner:FISHERY MACHINERY & INSTR RES INST CHINESE ACADEMY OF FISHERY SCI

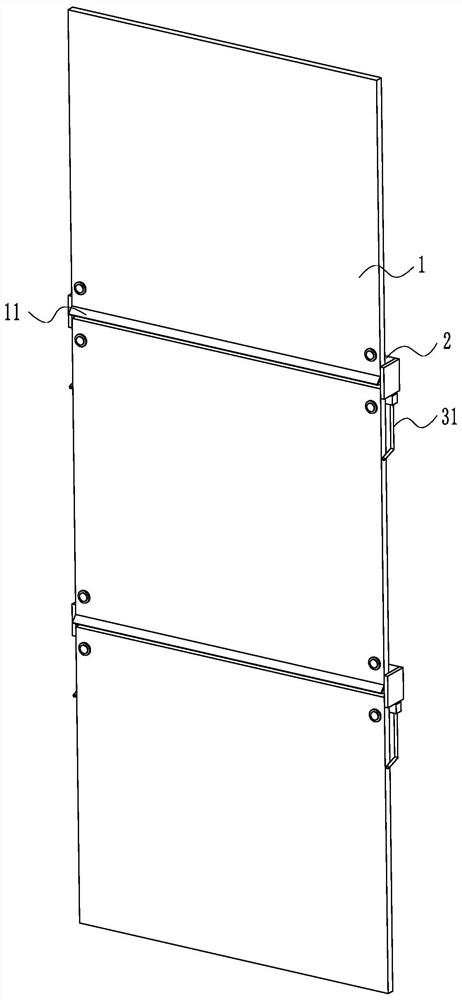

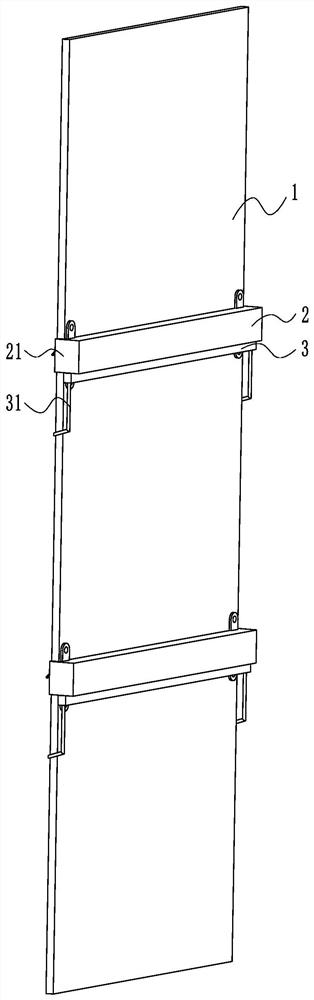

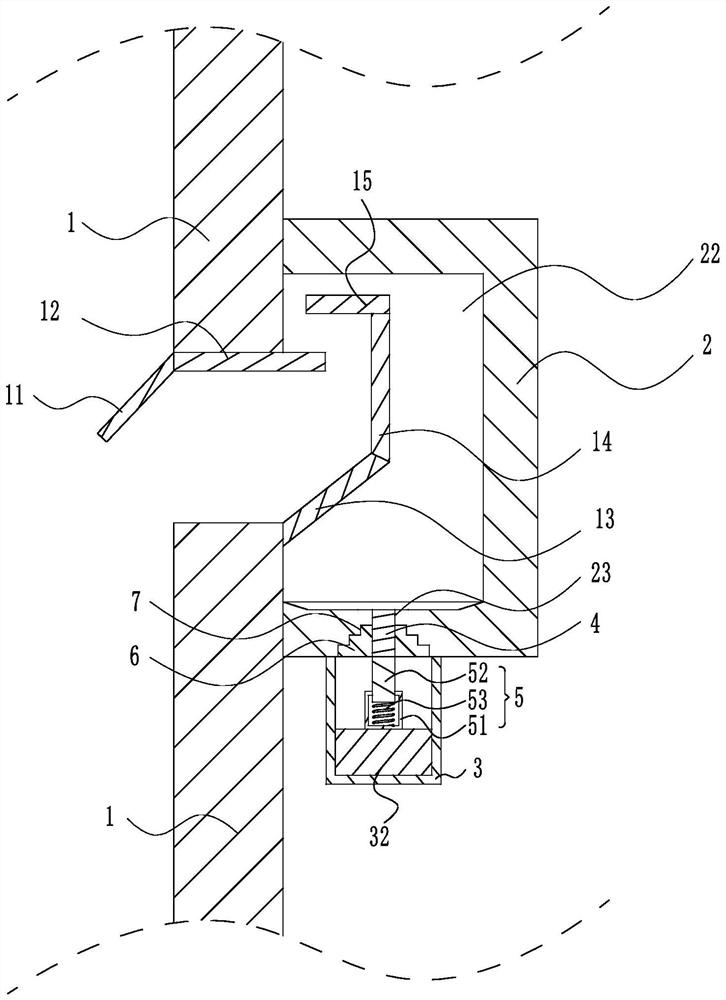

Unit type glass curtain wall system

PendingCN112832429AReduce the phenomenon of infiltrationGuaranteed constant pressureWallsBuilding insulationsEngineeringWater seepage

The invention relates to a unit type glass curtain wall system, and relates to the field of glass curtain walls. The unit type glass curtain wall system comprises glass curtain plates and a hidden frame keel, wherein the hidden frame keel is horizontally and fixedly arranged between the back parts of the two glass curtain plates in the longitudinal direction; one side, deviating from the glass curtain plates, of the hidden frame keel is fixedly connected with a wall body; baffle plates are arranged at the two sides of the hidden frame keel; the inner walls of the two baffle plates are in butt joint with the two sides of the glass curtain plates; the inside of the hidden frame keel is of a hollow structure to form an equal-pressure cavity; and the equal-pressure cavity communicates with a seam position between the upper and lower glass curtain plates. The unit type glass curtain wall system has the effect of reducing the water seepage problem in the seam position of the glass curtain plates.

Owner:广东世纪达建设集团有限公司

A switch device for lithium battery protection and manufacturing method thereof

ActiveCN106920777BReduced area resistanceLower resistanceTransistorSemiconductor/solid-state device manufacturingMOSFETElectrical resistance and conductance

The invention provides a switching device used for lithium battery protection and a manufacturing method thereof. The switching device comprises a P+ type substrate and a P- type epitaxial layer, an N type well region, two P type well regions, two gate structures, a shared N- type drifting region, an N type source region and a P+ type contact region, a dielectric layer and an electrode material, wherein the shared N- type drifting region is formed between the two gate structures; two source region contact windows and a body region contact window are formed in the dielectric layer, and the P- type epitaxial layer in the body region contact window is removed to form a groove until the P+ type substrate; and the source region contact windows, the body region contact window and the groove are filled with the electrode material. An MOSFET device is constructed by adopting a drifting region sharing manner, so that the region resistance of the drifting region can be greatly reduced, and meanwhile voltage resistance is guaranteed to be unchanged. One of source region electrodes is introduced to the back of a chip in a body region electrode manner, and can be welded with a base during packaging, so that a wire bonding resistor is omitted, and the manufacturing method is extremely effective in an extremely low internal resistance requirement.

Owner:宁波宝芯源功率半导体有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com