Macro-micro composite constant-pressure polishing device and method

A polishing device and polishing head technology, applied in the field of optical polishing, can solve the problems of large pressure control range, error, long polishing iteration time, etc., and achieve the effect of high polishing accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings.

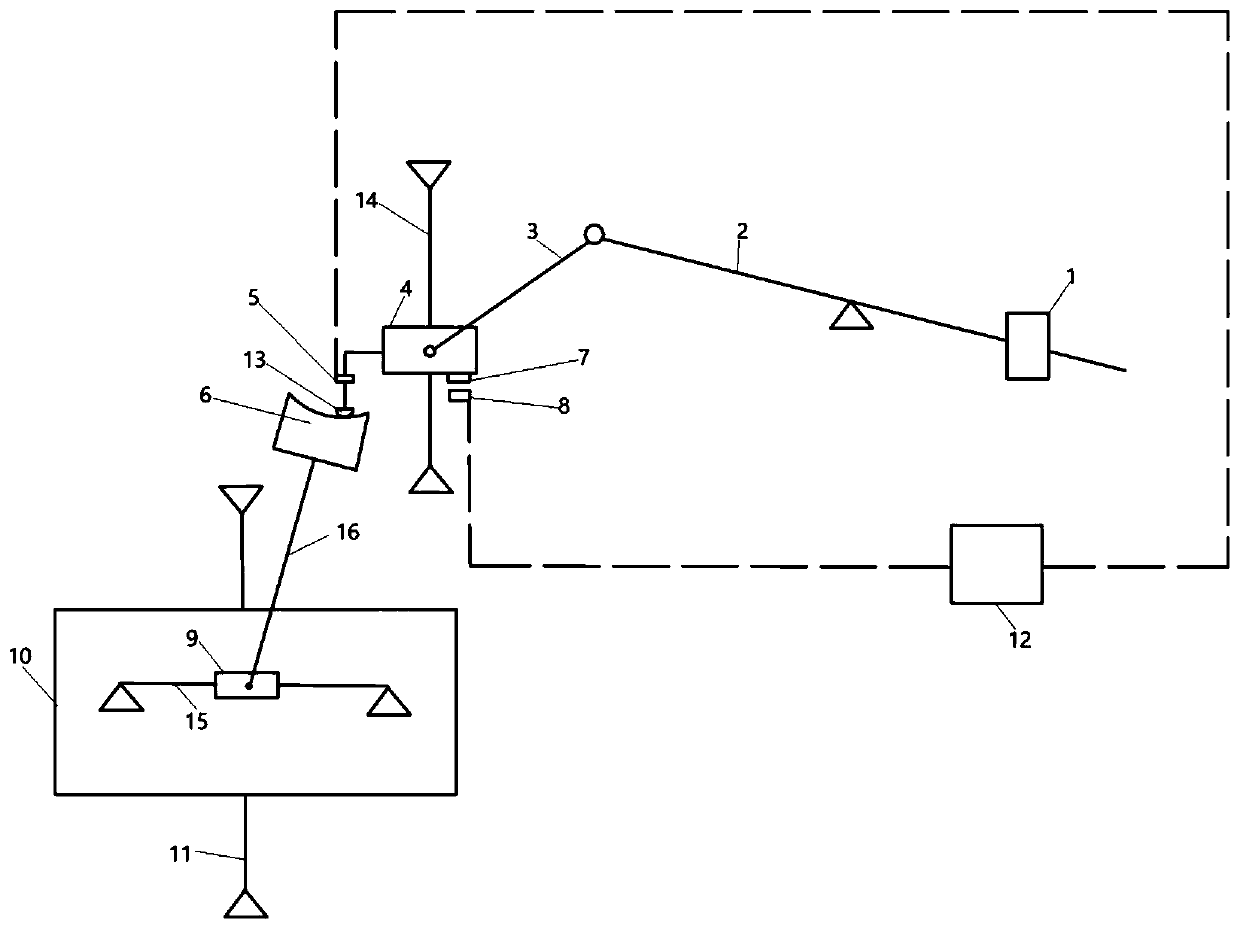

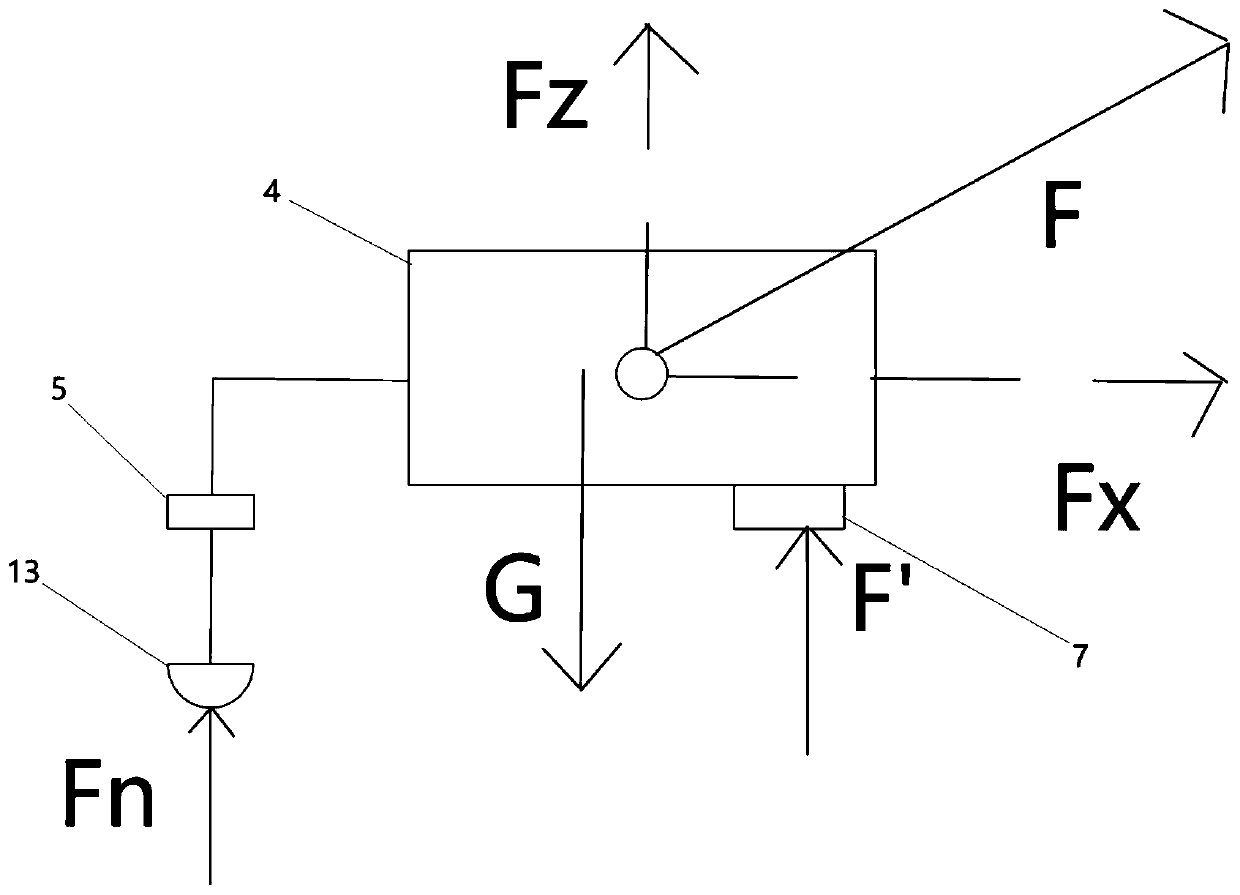

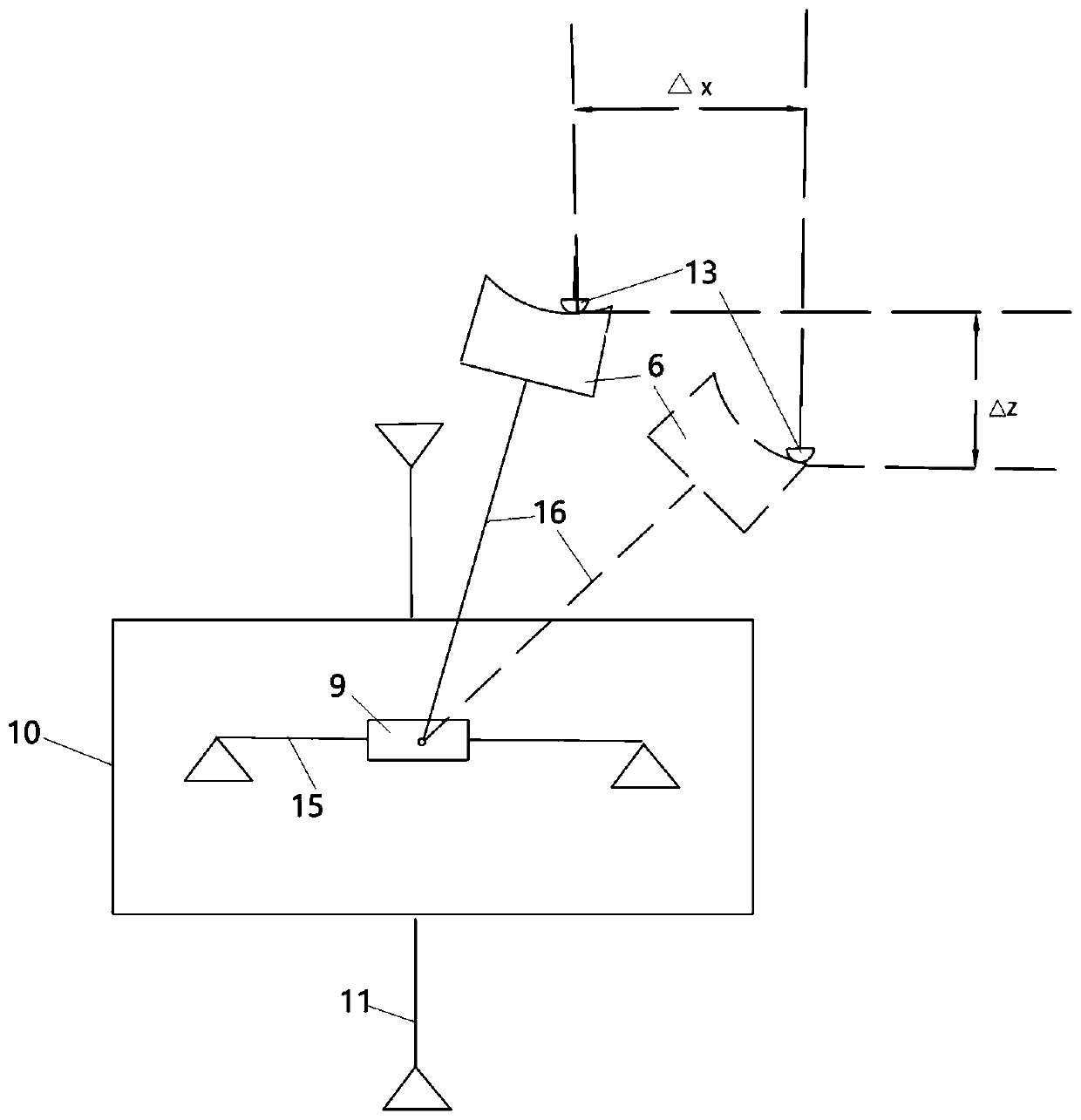

[0024] Such as figure 1 As shown, the present invention provides an implementation case of a macro-micro compound constant pressure polishing device and method, which includes an adjustment weight 1, a force applying lever 2, a force transmission lever 3, an air flotation guide block 4, a pressure sensor 5, a mold Kernel 6, permanent magnetic drop 7, magnetic device 8, left and right moving table 9, up and down lift table 10, up and down lead screw 11, pressure controller 12, polishing head 13, air bearing guide rail 14, left and right lead screw 15, rotating shaft 16.

[0025] figure 1 The schematic diagram is a schematic diagram of the movement of a mechanical structure of the present invention. It is a commonly used motion scheme expression method in engineer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com