Thermal shock testing method and system for pump

A shock test and thermal shock technology, applied in the field of testing, can solve problems such as pump usage concerns, hidden dangers in production and life safety, etc., and achieve the effect of wide practicability and pressure protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] A preferred embodiment will be given below, and the present invention will be described more clearly and completely in conjunction with the accompanying drawings.

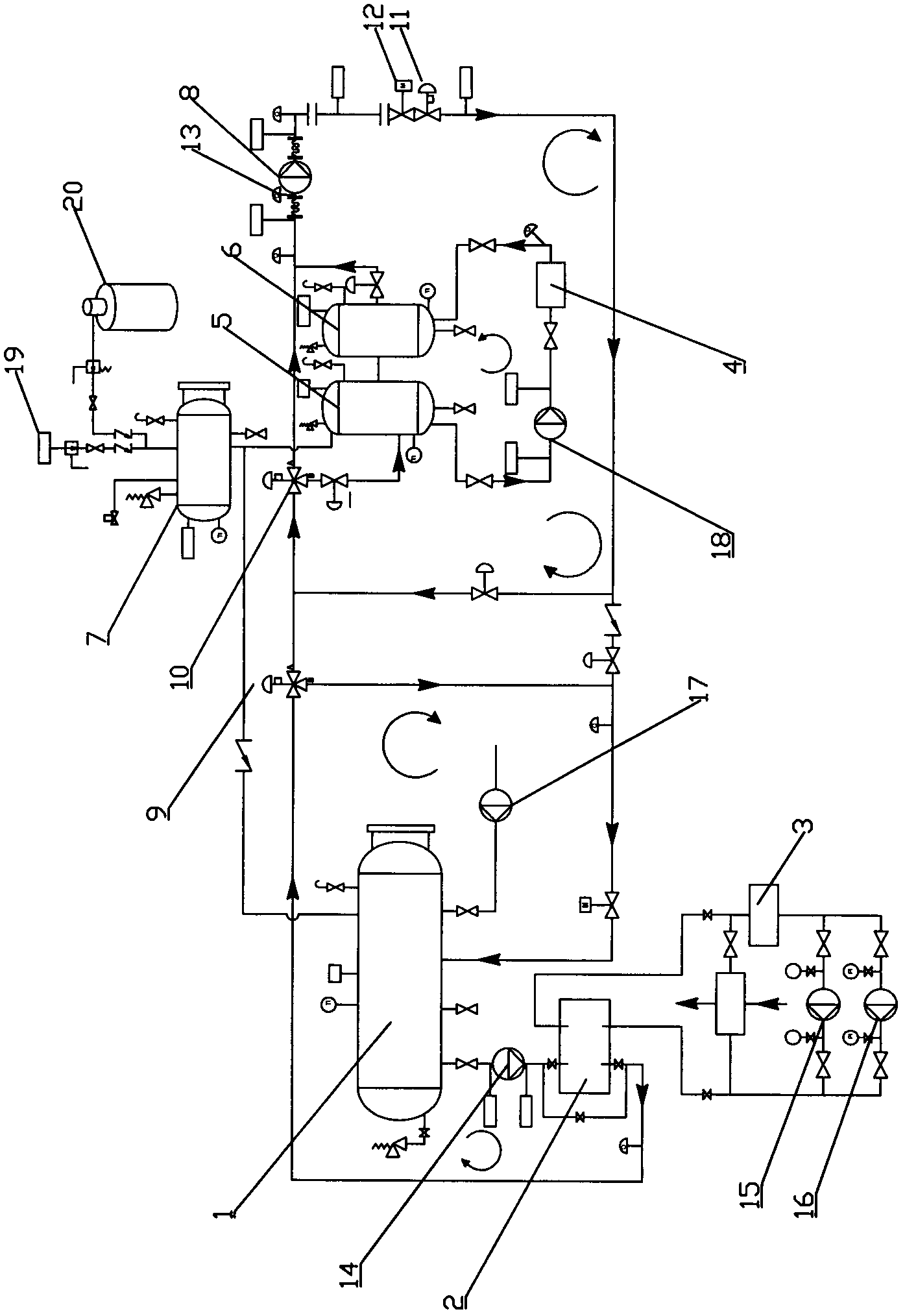

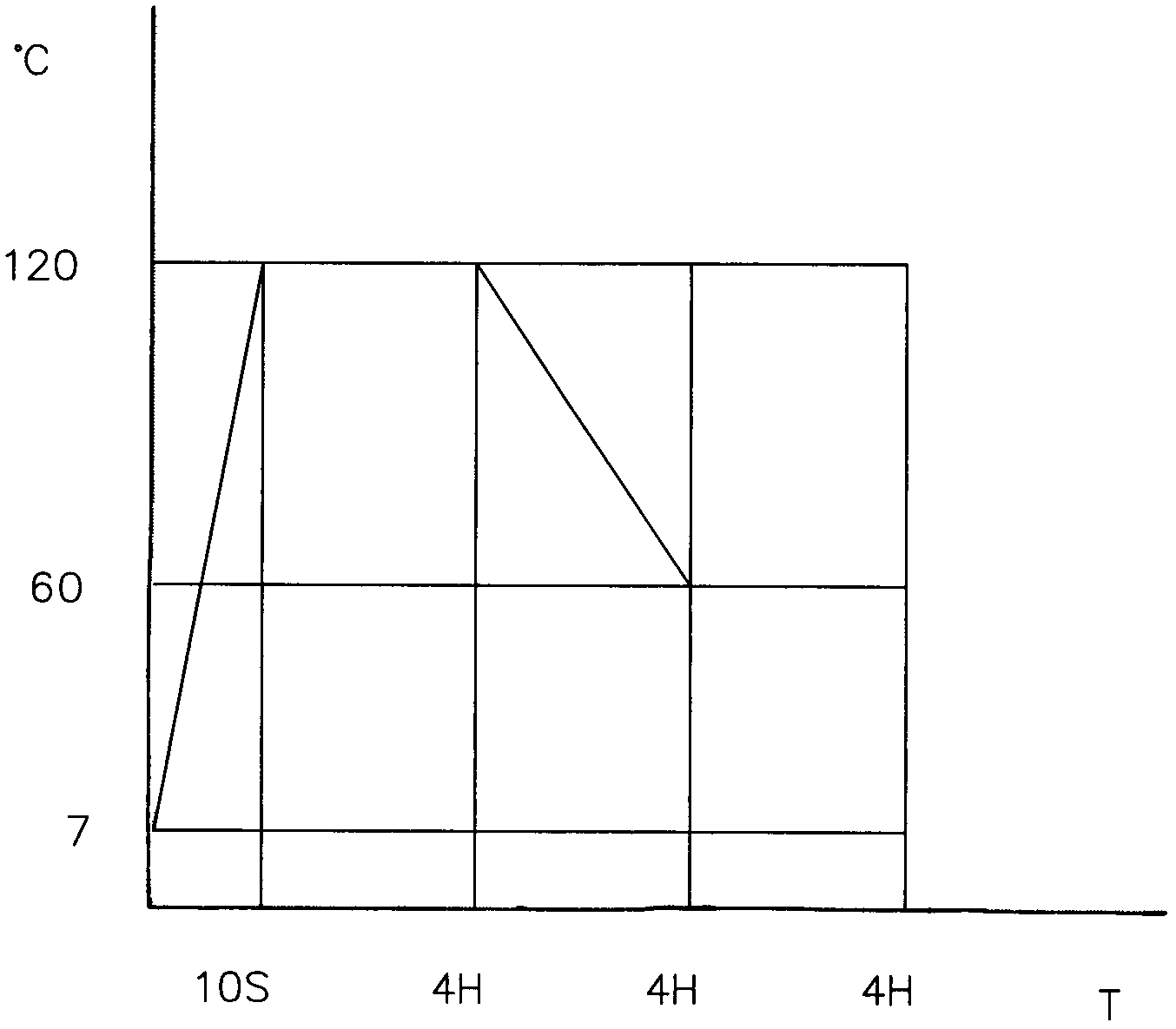

[0026] Such as Figure 1-Figure 2 As shown, the pump thermal shock test system includes the control system for starting the valve opening and closing, and also includes the chilled water tank 1, the refrigerator 2, the cooling tower 2, the electric heater 4, the high-temperature hot water tank I5, the high-temperature hot water tank II6, Expansion tank 7, tested pump 8, three-way valve I9, three-way valve II10, the circuit of the tested pump 8 is provided with a regulating valve 11 and an electric valve 12 for controlling the flow of the tested pump, and the inlet of the tested pump 8 is provided with There is a temperature sensing rod 13, a chilled water circulation pump 114 is connected between the chilled water tank 1 and the refrigerator 2, the chilled water tank 1 is connected to the replenishing water ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com