Automatic sampling device of leather colour fastness

An automatic sampling device, color fastness technology, applied in sampling device, measuring device, strength characteristics and other directions, can solve problems such as high noise and affecting the service life of the device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

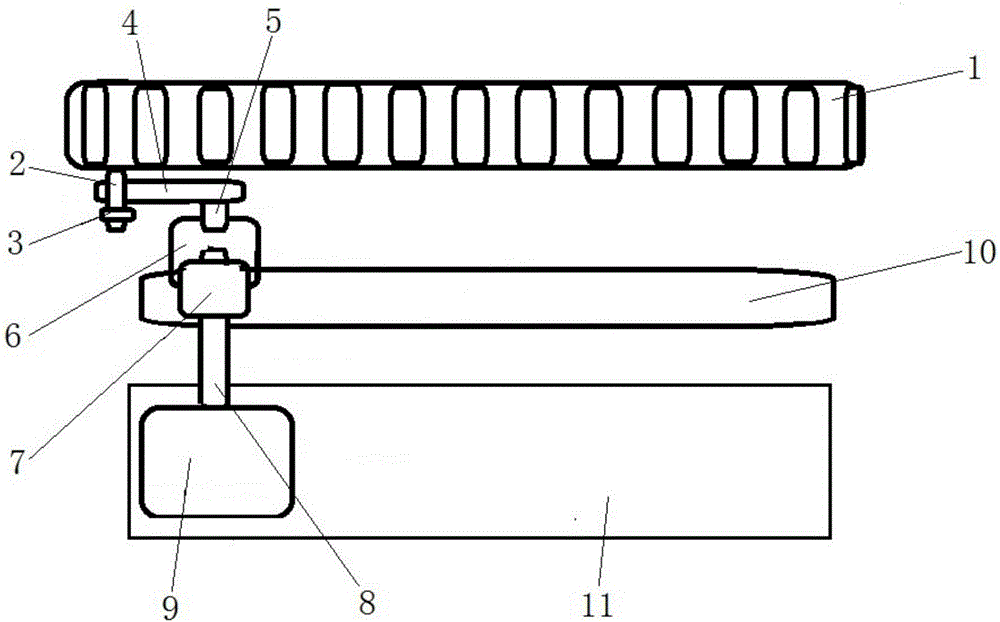

[0024] The present invention is described in further detail below in conjunction with accompanying drawing:

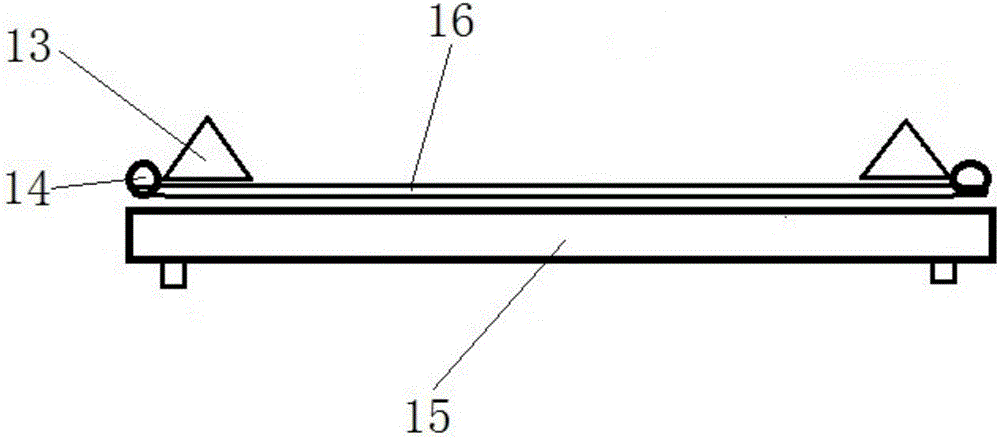

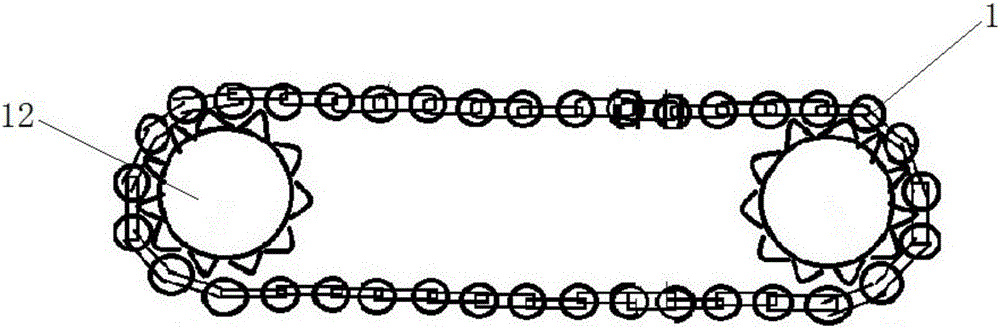

[0025] The invention provides an automatic sampling device for leather color fastness, such as figure 1 As shown, including chain 1, such as image 3 As shown, the chain 1 is driven to rotate by the driving gear 12 and the driven gear arranged horizontally, wherein the driving gear 12 is connected with the motor, and the driving gear 12 is driven to rotate by the motor, so that the chain 1 is rotated; the connecting shaft 2 is fixed on the chain 1, The connecting shaft 2 is fixed by the bolt 3, the connecting shaft 2 is fixedly connected with the fixed bar 4, the fixed bar 4 is connected with the rotating shaft 5, and the rotating shaft 5 is connected with the linear slide rail structure capable of linear motion; the linear slide rail structure includes a slider 6. The slider 6 is connected to the rotation shaft 5, the rotation shaft 5 can rotate in the rotation hole ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com