Inner storage constant-pressure preparative column device

A technology for column preparation and energy storage, applied in chemical instruments and methods, separation methods, solid adsorbent liquid separation, etc., to achieve the effect of automatically compensating the pressure in the column, ensuring the separation effect, and being easy to popularize and apply.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

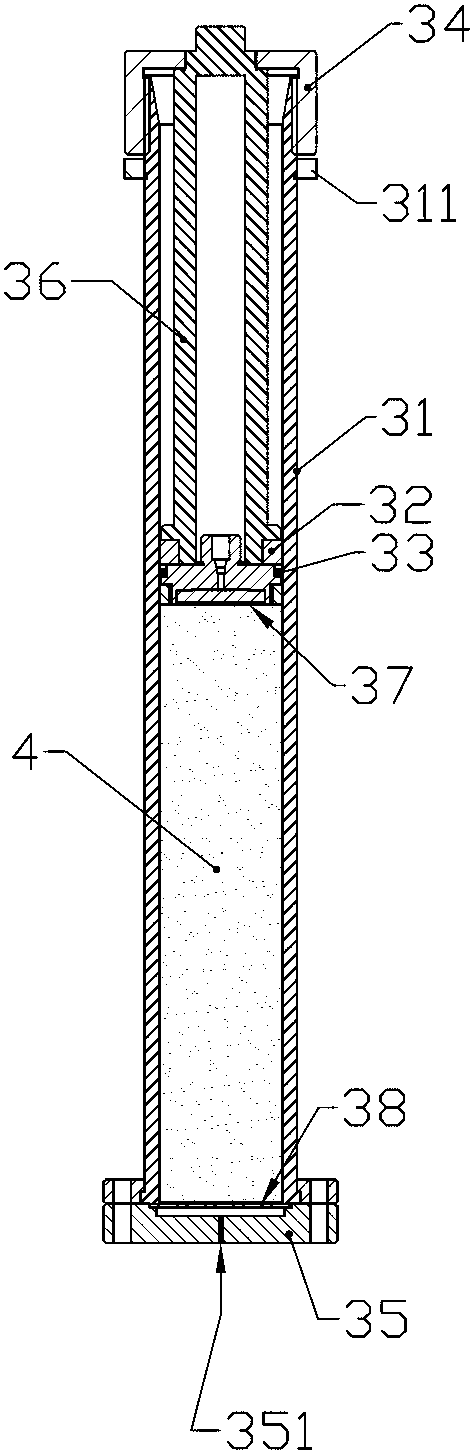

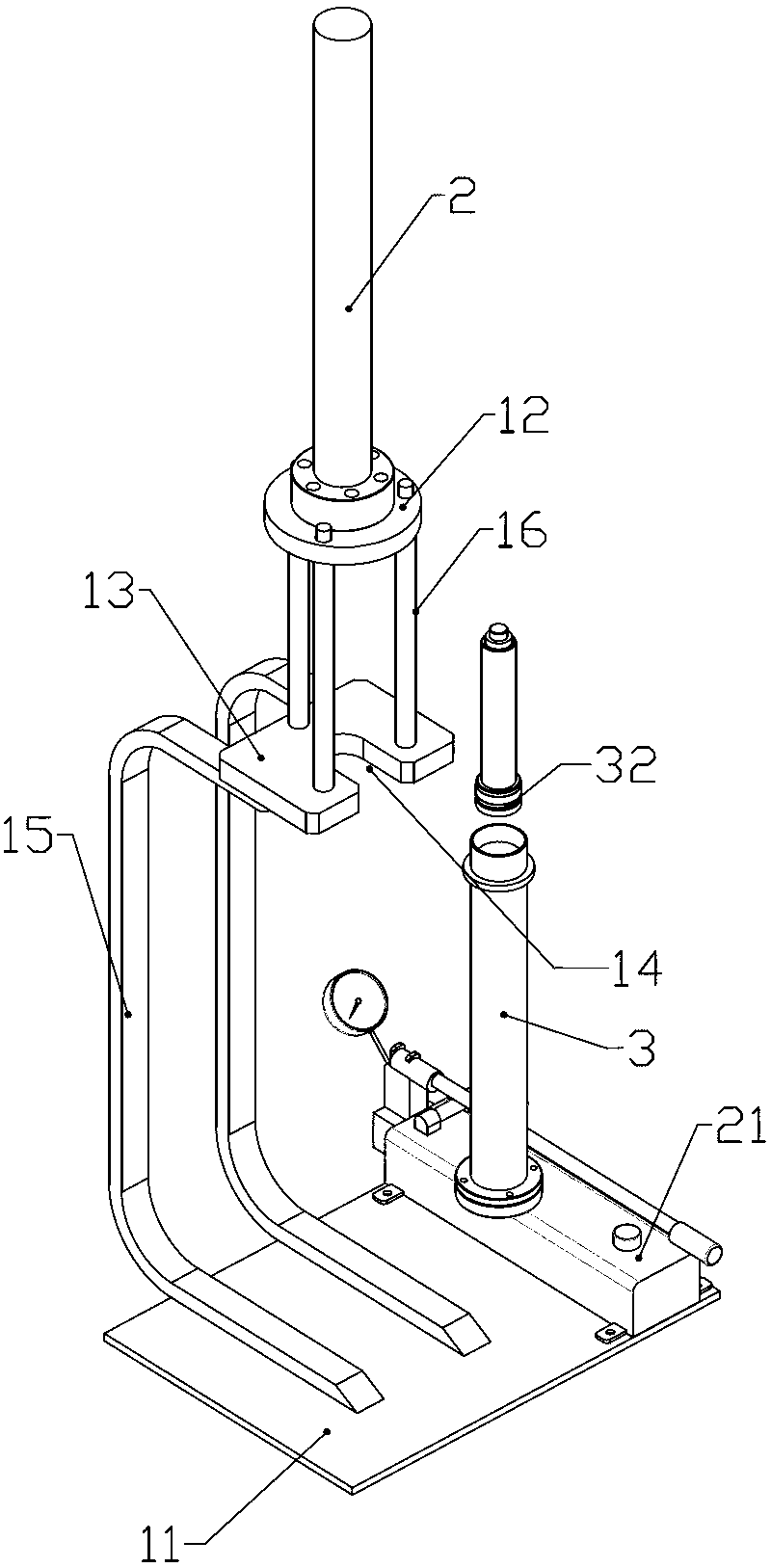

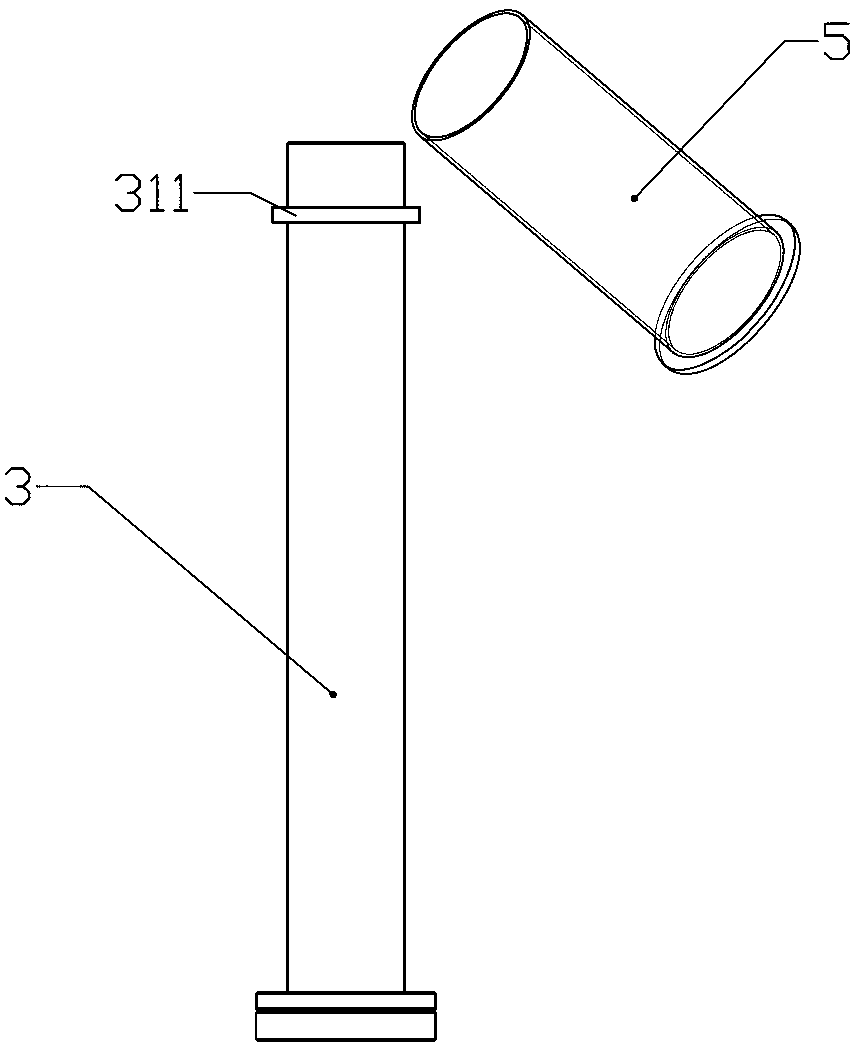

[0024] Such as Figure 1 to Figure 5 as shown,

[0025] The internal energy storage constant pressure preparation column device includes a support, a preparation column and a hydraulic oil cylinder.

[0026] The support includes a horizontal base 11, an upper support plate 12 and a lower support plate 13, the upper and lower support plates are connected by three columns 16, the upper support plate is circular, and the hydraulic cylinder 2 is installed at the center of the upper support plate 12, in a vertical position. A U-shaped notch 14 is provided at the center of the lower support plate 13, and the U-shaped notch is located at a certain distance below the hydraulic cylinder, which is less than the working range of the hydraulic cylinder, and is used for fixing the preparation column 3. The lower support plate 13 and the base 11 are connected by several C-shaped rods 15, and the C-shaped rods protrude backward, so that a relatively large operating space can be obtained. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com