Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

58results about How to "Expand the luminous area" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

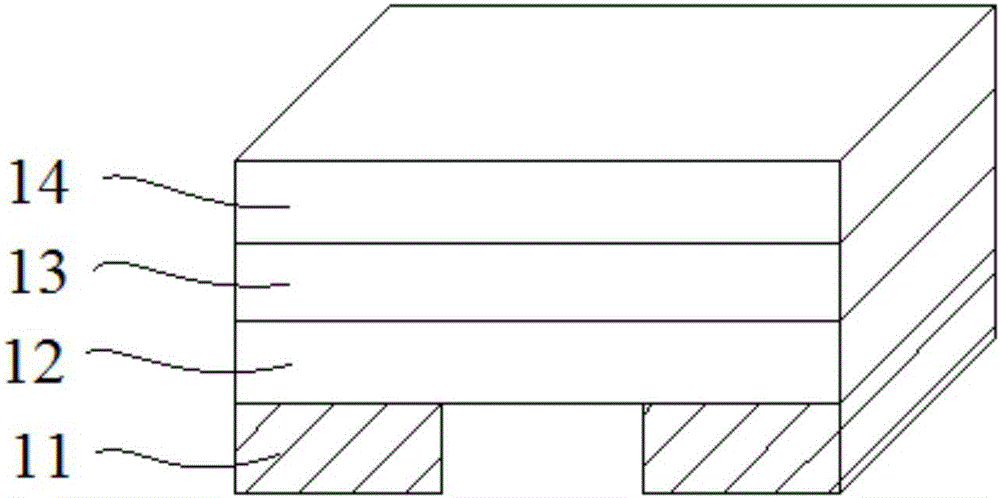

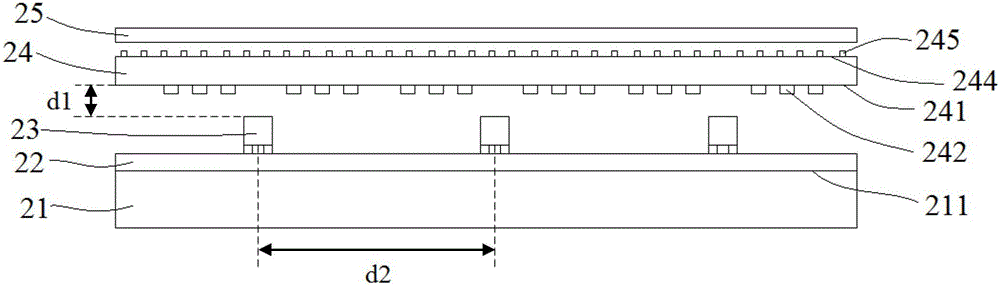

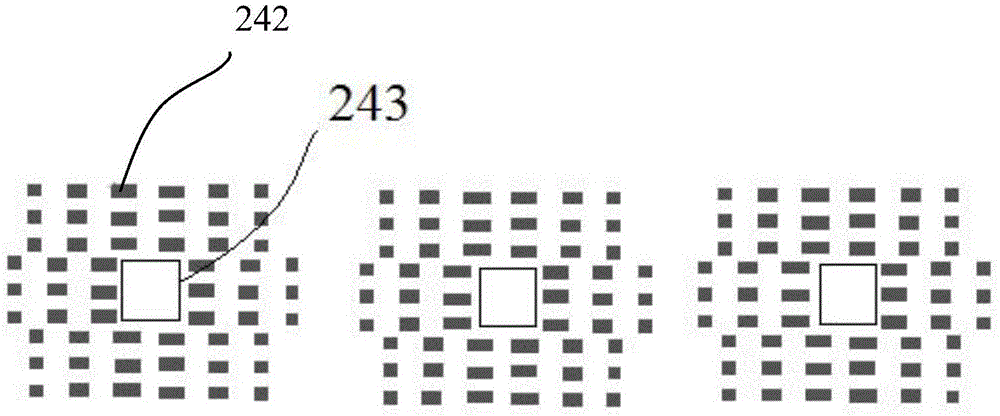

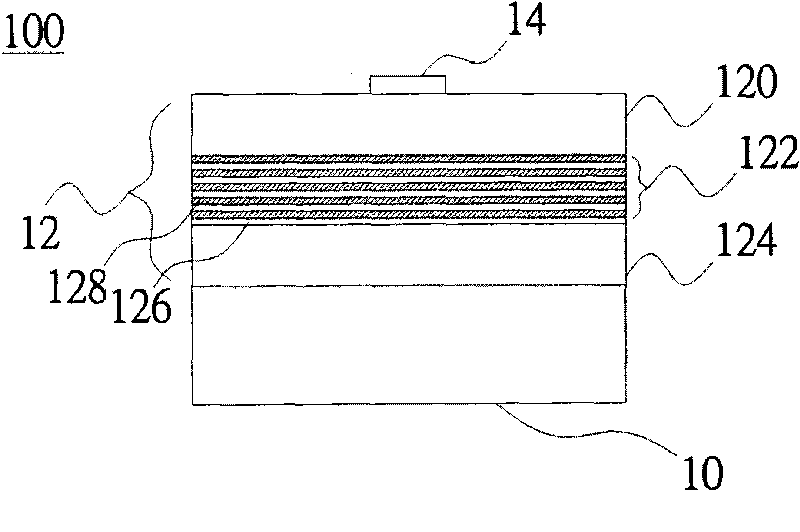

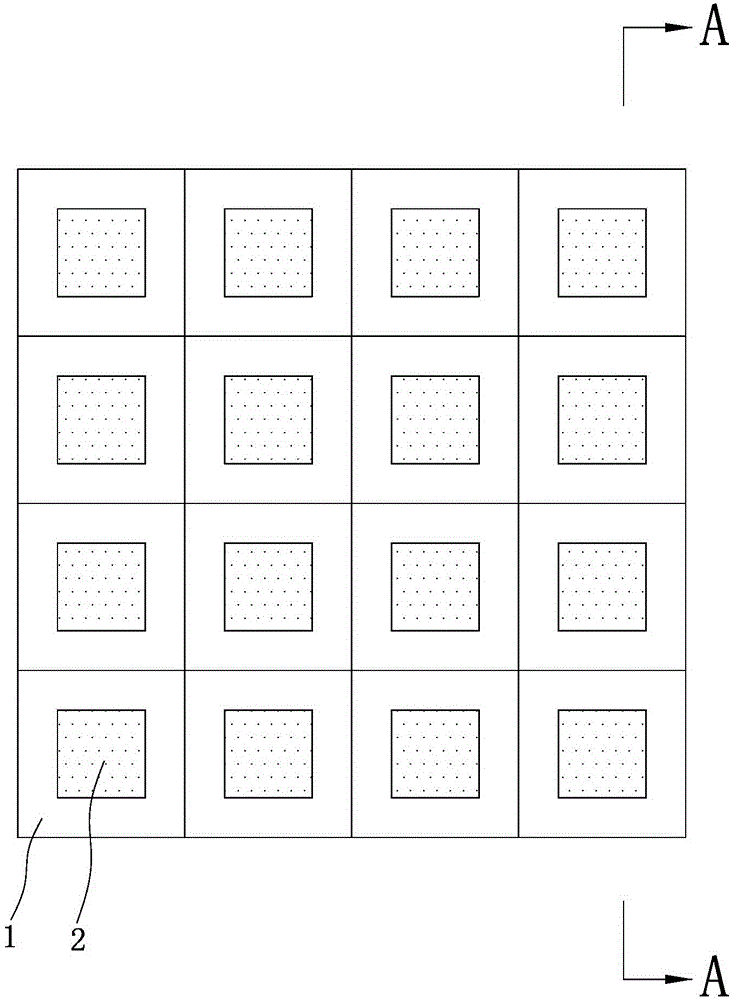

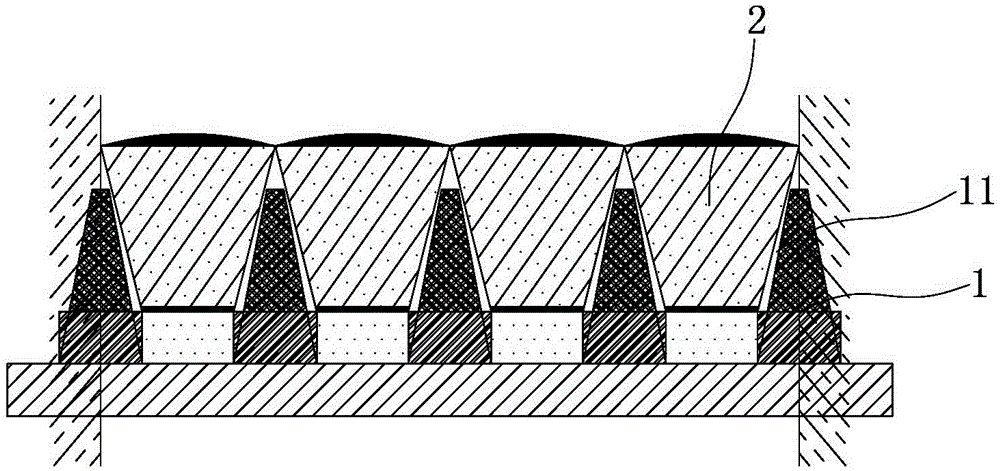

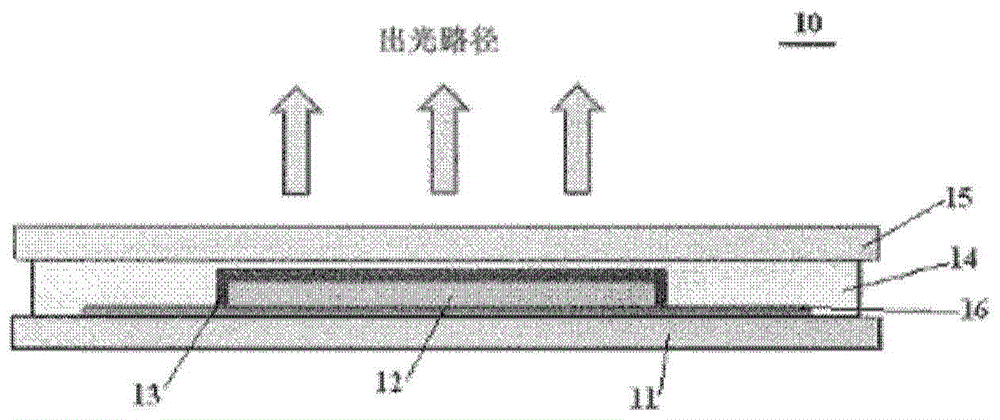

Backlight module and liquid crystal displayer

ActiveCN106842701AUniform light distributionImprove display qualityNon-linear opticsLiquid-crystal displayPrinted circuit board

The invention relates to the technical field of liquid crystal display, in particular to a backlight module and a liquid crystal displayer. The backlight module sequentially comprises a printed circuit board, a reflector plate, an LED light source and a diffusion plate from bottom to top. First protruding points are arranged on the light-in face, facing the LED light source, of the diffusion plate and around the projection, within the light-in face, of the LED light source. The first protruding points can conduct reflection diffusion on an illumination area, on the diffusion plate, of the LED light source, eliminate projection dark spaces and prevent light source gathering, so that the distribution of a light-emitting area on the diffusion plate is more uniform. Meanwhile, the LED light source can be independently controlled, local light control can be better achieved, and accordingly the display quality of a high-dynamic-comparison image is improved. The reflector plate can reflect leaking light again so that the light can irradiate the diffusion plate again, accordingly the utilization rate of the light source is increased, the light mixing distance is increased, and thinning design of the liquid crystal displayer is achieved easily.

Owner:TCL CHINA STAR OPTOELECTRONICS TECH CO LTD

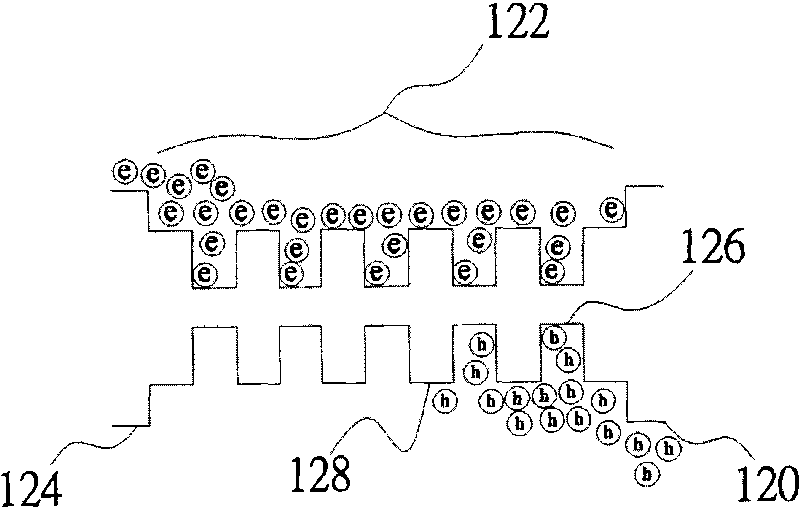

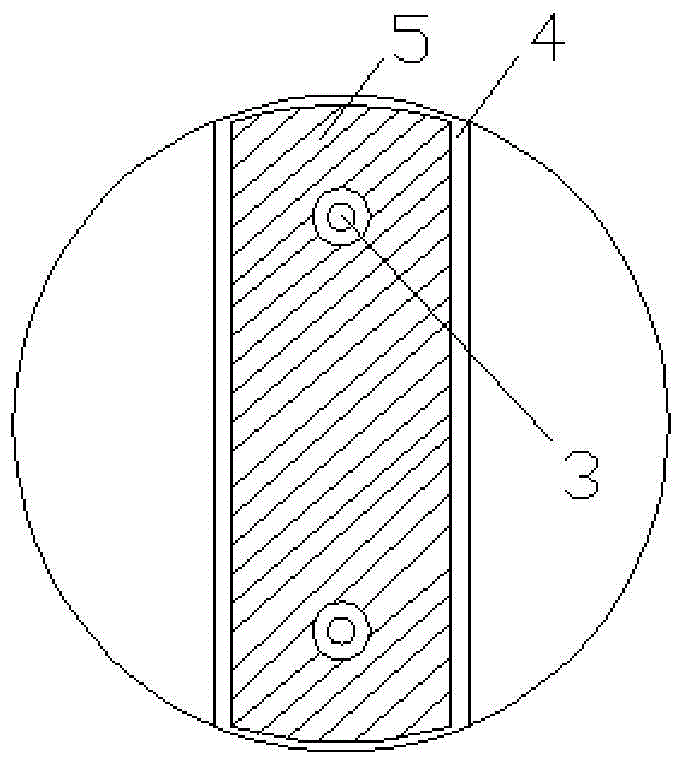

Gallium nitride (GaN) base light-emitting diode (LED) structure and method for improving photoelectric conversion efficiency thereof

InactiveCN103094441ALower forward voltageReduced resistance differenceSemiconductor devicesReverse currentGallium nitride

The invention relates to the field of photoelectric devices, in particular to a Gallium nitride (GaN) base light-emitting diode (LED) structure. The GaN base LED structure sequentially comprises a p electrode, a transparency electrode, a p type GaN layer, a multiple quantum well active area and an n type GaN layer from top to bottom. An n electrode, a first u type GaN layer and a substrate are etched on the n type GaN layer. A second u type GaN layer or a superlattice layer which is formed by a u type AlxGal-xN layer and low doping n type GaN in an alternate growing mode is inserted into between the multiple quantum well active area and the n type GaN layer. An x indicates the aluminous ingredient of the AlxGal-xN, and the value range of the x is that 0<=x<=1. Correspondingly, the invention further provides a method for improving the photoelectric conversion efficiency of the GaN base LED structure. Therefore, the transverse resistance difference of the GaN base LED structure is removed or reduced, so that currents can be expanded, forward voltages can be lowered, reverse currents are reduced, a luminous area is enlarged, and thus the photoelectric conversion efficiency of an LED is improved.

Owner:AQUALITE CO LTD

Luminous fabric device

InactiveCN1783169AExtended service lifeExpand the luminous areaArticle advertisingWoven fabricsYarnEngineering

The luminous fabric device includes one pattern layer and one optical fiber fabric layer. The pattern layer consists of one transparent area and one opaque area and forms the displayed pattern. The optical fiber fabric layer is woven with optical fibers and yarns and is used to provide light source for the luminous fabric device. The optical fiber fabric layer is fixed to the pattern layer through sewing or through one fixing assembly.

Owner:BAYCOM OPTO ELECTRONICS TECH

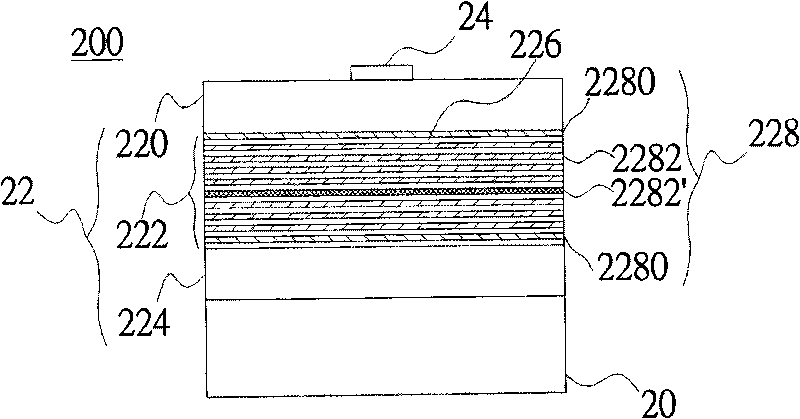

Light-emitting element

ActiveCN101740668AExpand the luminous areaHigh carrier mobilitySemiconductor devicesQuantum efficiencyCharge carrier mobility

The invention mainly aims at disclosing a light-emitting element which comprises a semiconductor stack, wherein the semiconductor stack comprises an active layer, the active layer is in a multiple quantum well (MQW) structure formed by stacking a plurality of quantum well layers and a plurality of barrier layers in a staggered manner, and the plurality of the barrier layers comprise at least one doped barrier layer and one undoped barrier layer. Therefore, the doped barrier layer can improve the carrier mobility of a hole, uniformize a light-emitting region in the active layer and improve the internal quantum efficiency (IQE) of the light-emitting element.

Owner:EPISTAR CORP

Light-emitting-diode chip

InactiveCN103840054AExpand the luminous areaReduce light blocking areaSemiconductor devicesElectrical conductorSemiconductor structure

Disclosed is a light-emitting-diode chip which includes a substrate, a semiconductor structure formed on the substrate and two electrodes which are formed on the semiconductor structure and mutually spaced. The semiconductor structure is provided with two exposed semiconductor layers, wherein one electrode is formed on the upper surface of one semiconductor layer and the other electrode is formed on the upper surface of the other semiconductor structure. At least one of the two electrodes extend in a bent manner from the upper surface of a corresponding semiconductor layer to the side face of the semiconductor structure and is electrically connected with an external electrode through a conductive glue. The electrodes of the light-emitting-diode chip do not need to be connected by gold wires so that compared with traditional metal electrode pads, the electrodes of the light-emitting-diode chip do not need to be provided with areas for gold wire welding and thus the areas of the electrodes can be significantly small so that the light-blocking areas of the electrodes are reduced, the light-emitting area of the light-emitting-diode chip is increased and the light exiting quantity is improved.

Owner:ZHANJING TECH SHENZHEN +1

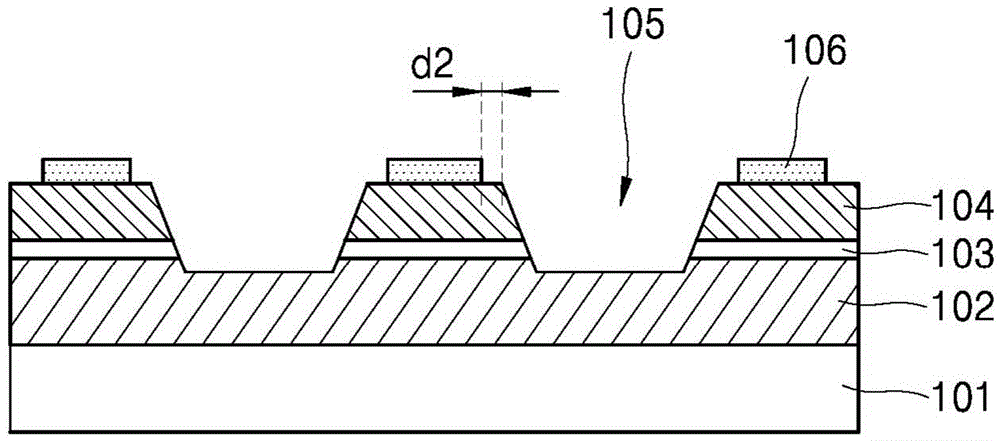

LED (light-emitting diode) chip with novel structure and production method thereof

ActiveCN103972350AImprove effective utilizationImprove luminous efficiencySemiconductor devicesIndiumEngineering

The invention discloses an LED (light-emitting diode) chip with a novel structure and a production method of the LED chip, and belongs to the field of a semiconductor device. The LED chip structure comprises an N-side electrode, a substrate, an active layer, a gallium phosphide layer, an indium-gallium-phosphorus layer, a P-side soldering wire electrode, an expanded electrode and a current barrier groove. The production method comprises the steps: growing the indium-gallium-phosphorus layer with the thickness of 1000 angstroms on a P side of a chip, etching and coarsing the gallium phosphide layer, evaporating the P-side soldering wire electrode and the expanded electrode by utilizing a vacuum film coating technology, etching the current barrier groove by virtue of plasma, and facilitating the ohm contact between the expanded electrode and the gallium phosphide layer in virtue of alloy. By adopting the produced LED chip, the current can be expanded to the entire chip surface through the expanded electrode, so that the effective application of the current is improved; meanwhile, by adopting the surface coarsing, the light emitting rate of the chip can be effectively improved. The LED chip has the advantages of simplicity in structure, simple and feasible production method and easiness in manufacturing.

Owner:马鞍山太时芯光科技有限公司

LED display screen

InactiveCN101916534AExpand the luminous areaImprove uniformityPoint-like light sourceIdentification meansLED displayEngineering

The invention relates to an LED display screen which comprises a circuit substrate and a plurality of LED elements distributed and arranged on the circuit substrate. In addition, the LED display screen further comprises a light-mixing device arranged on the circuit substrate; the light-mixing device comprises a plurality of diffusion cavities; and each diffusion cavity is provided with at least one of the LED elements. By the invention, LED lights are scattered by adopting the diffusion cavities of the light-mixing device, the light-emitting region and the light-mixing region of an LED are enlarged, and the area of the dark region is reduced. Therefore, the granular sensation and the glaring sensation of the pixels are decreased or eliminated, and the uniformity of the picture brightness is improved. Moreover, with the mode, the arrangement density of the LED elements cannot be increased, special LED elements are not needed to be designed and manufactured, ordinary LED elements are directly used, and the cost is relatively low.

Owner:GUANGDONG VTRON TECH CO LTD

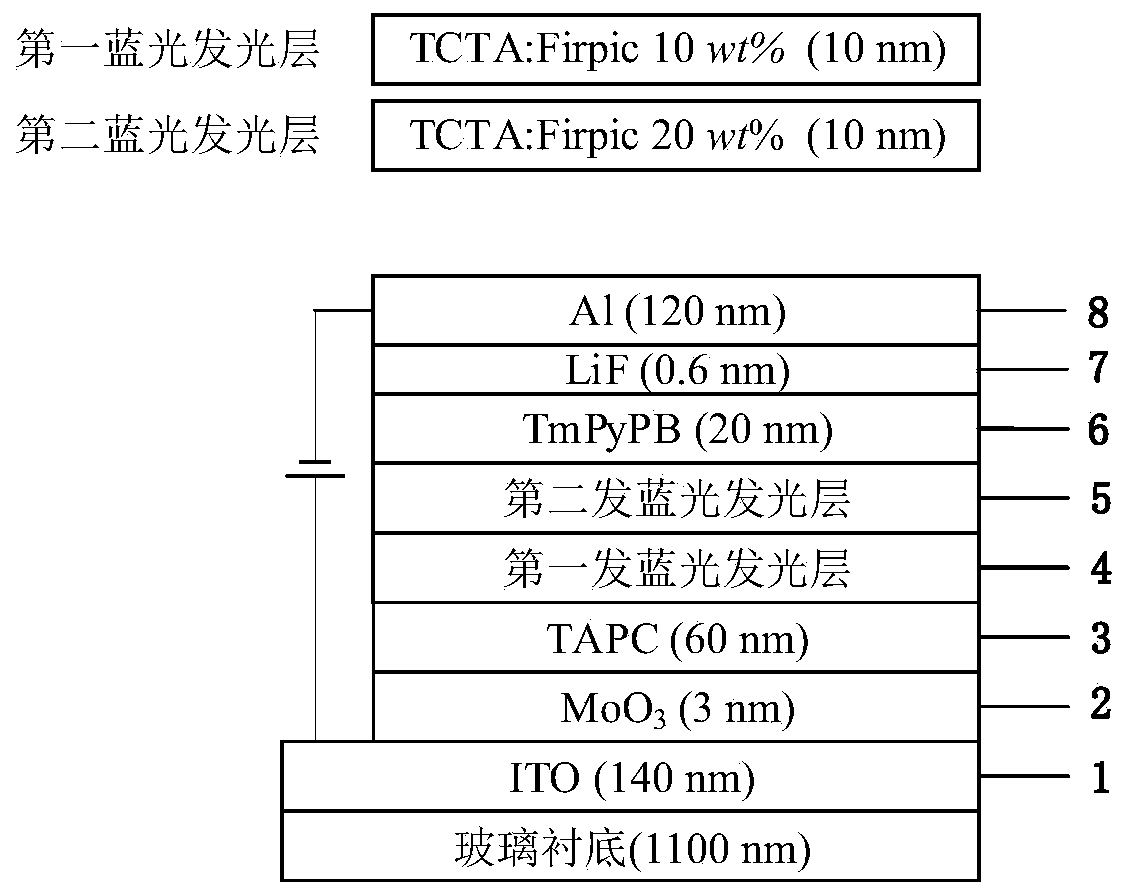

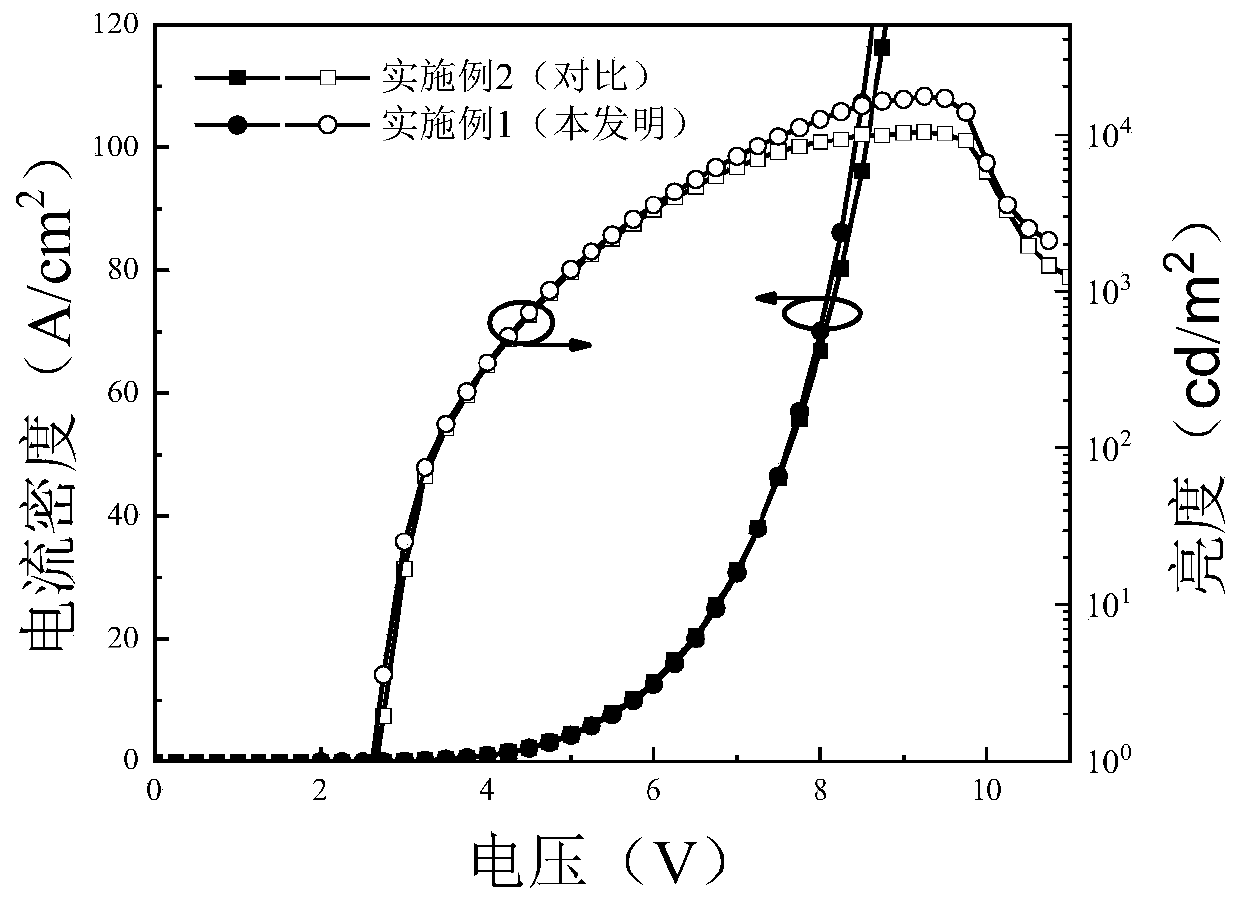

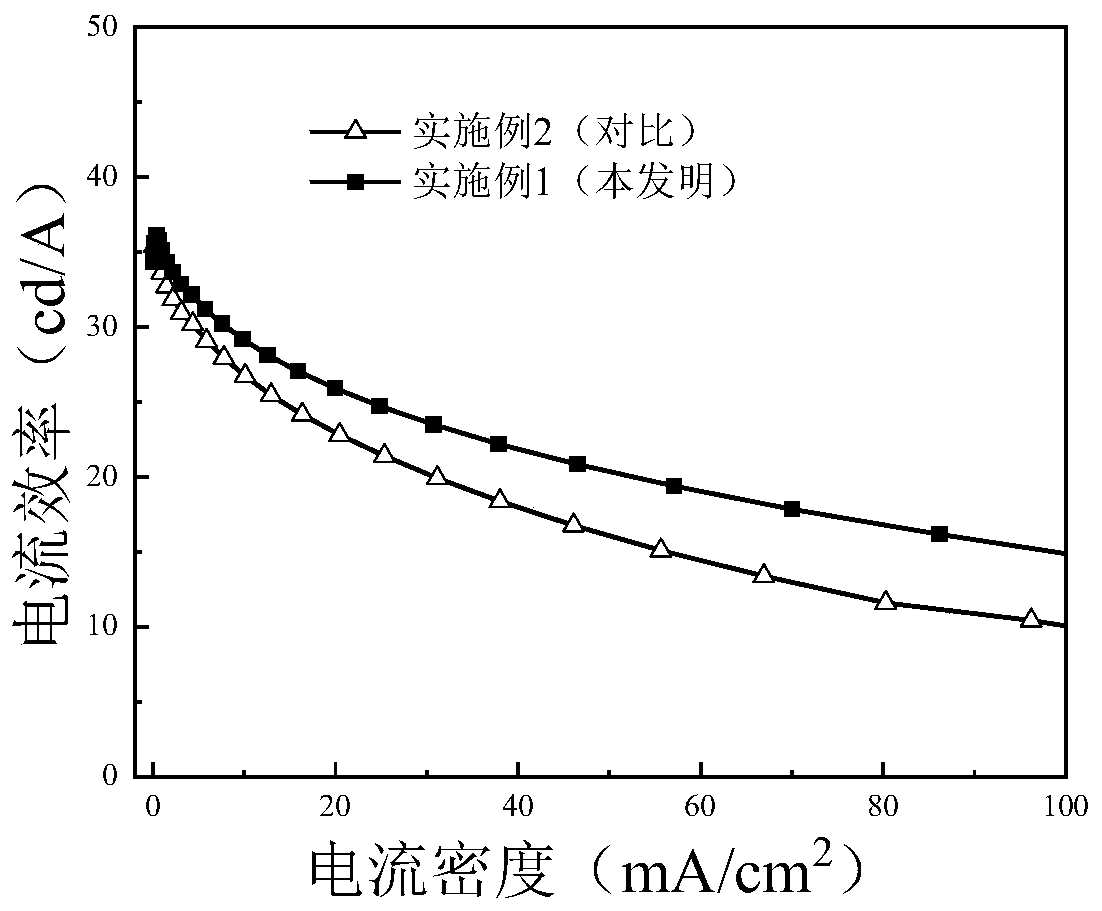

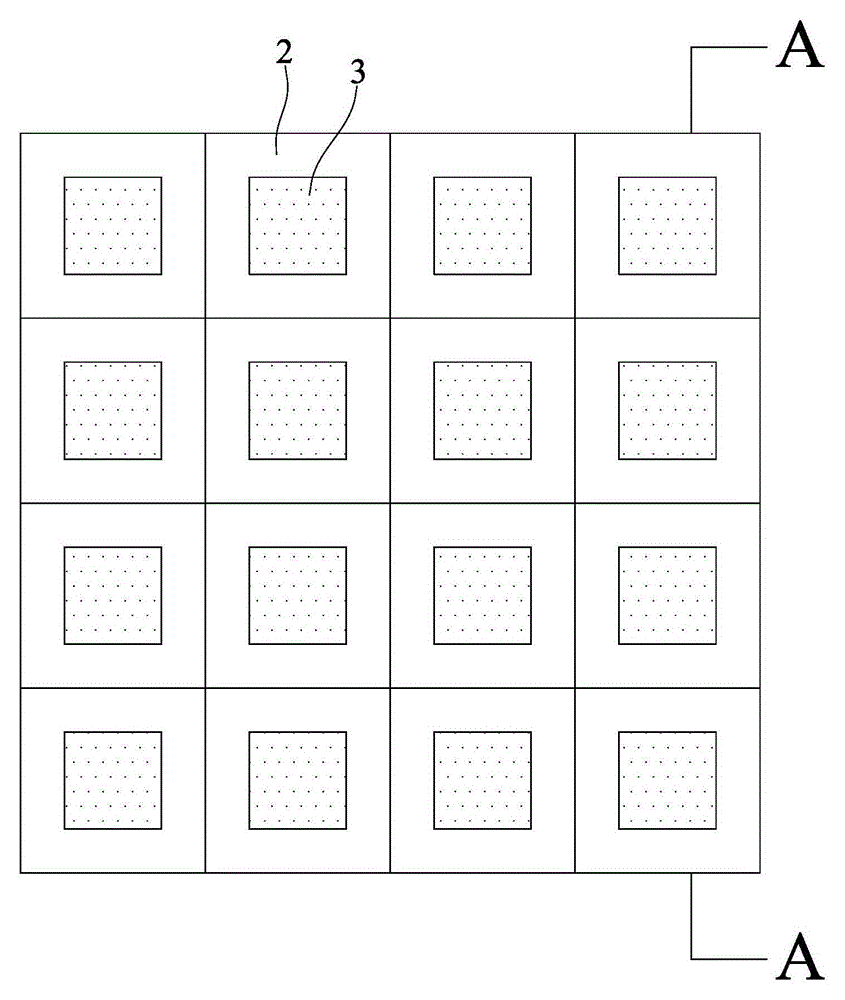

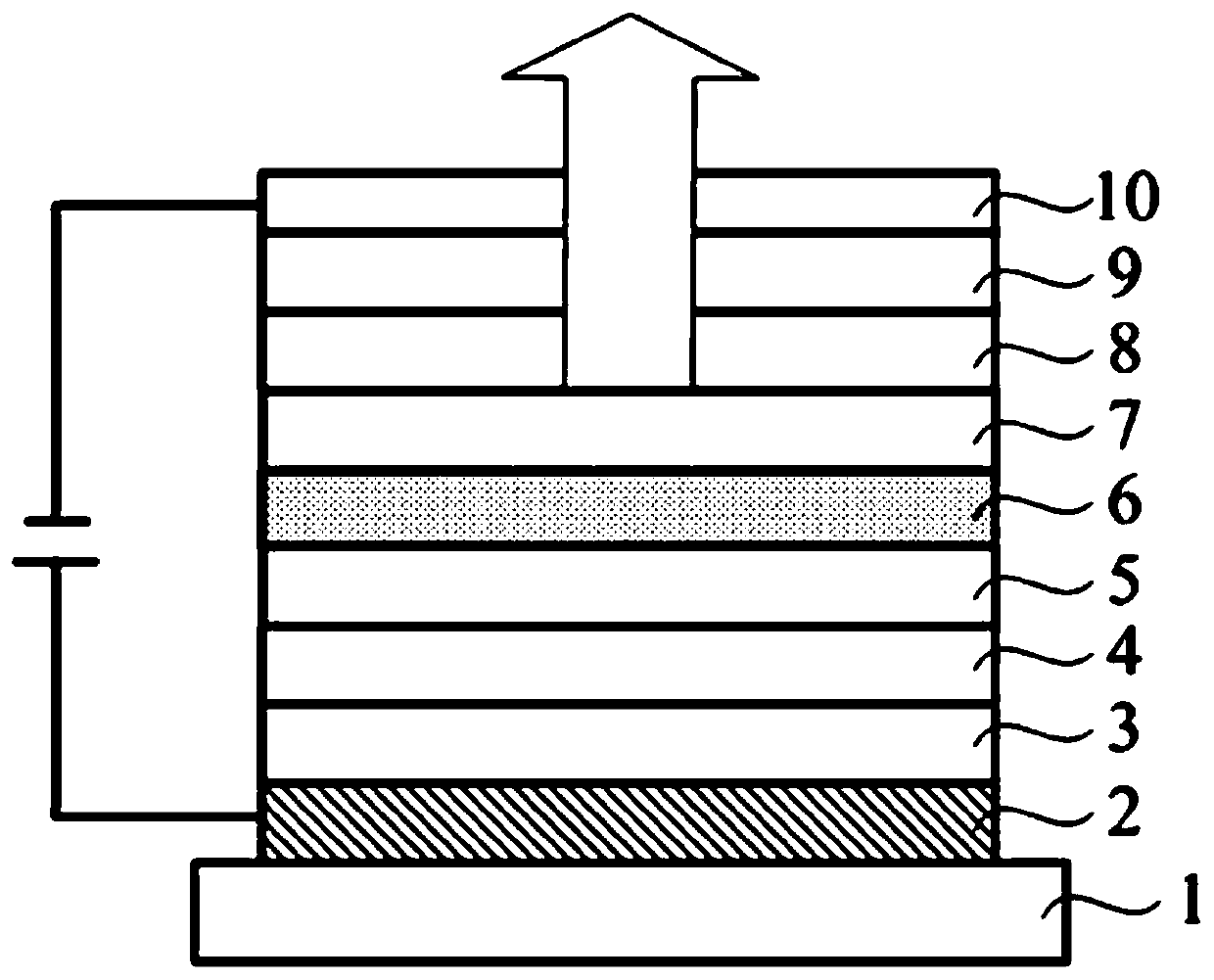

Dual-light emitting layer structure blue-light OLED and manufacturing process thereof

InactiveCN110265560ASimple preparation processLow costSolid-state devicesSemiconductor/solid-state device manufacturingElectronic transmissionHole injection layer

The invention requests and protects a dual-light emitting layer structure blue-light OLED device and a manufacturing process thereof. The device comprises a positive electrode substrate, a hole injection layer, a hole transmission layer, a first light-emitting layer, a second light-emitting layer, an electronic transmission layer, an electronic injection layer and a negative electrode, wherein the first light-emitting layer and the second light-emitting layer employ the same main body materials, same object material and same thickness, and the object doping concentration of the first light-emitting layer is not higher than 50% of the object doping concentration of the second light-emitting layer. The dual-light emitting layer structure provided by the technical scheme is simple, the exciton utilization rate and the composite region can be expanded, and the efficiency roll-off of the device is effectively improved.

Owner:CHONGQING UNIV OF POSTS & TELECOMM

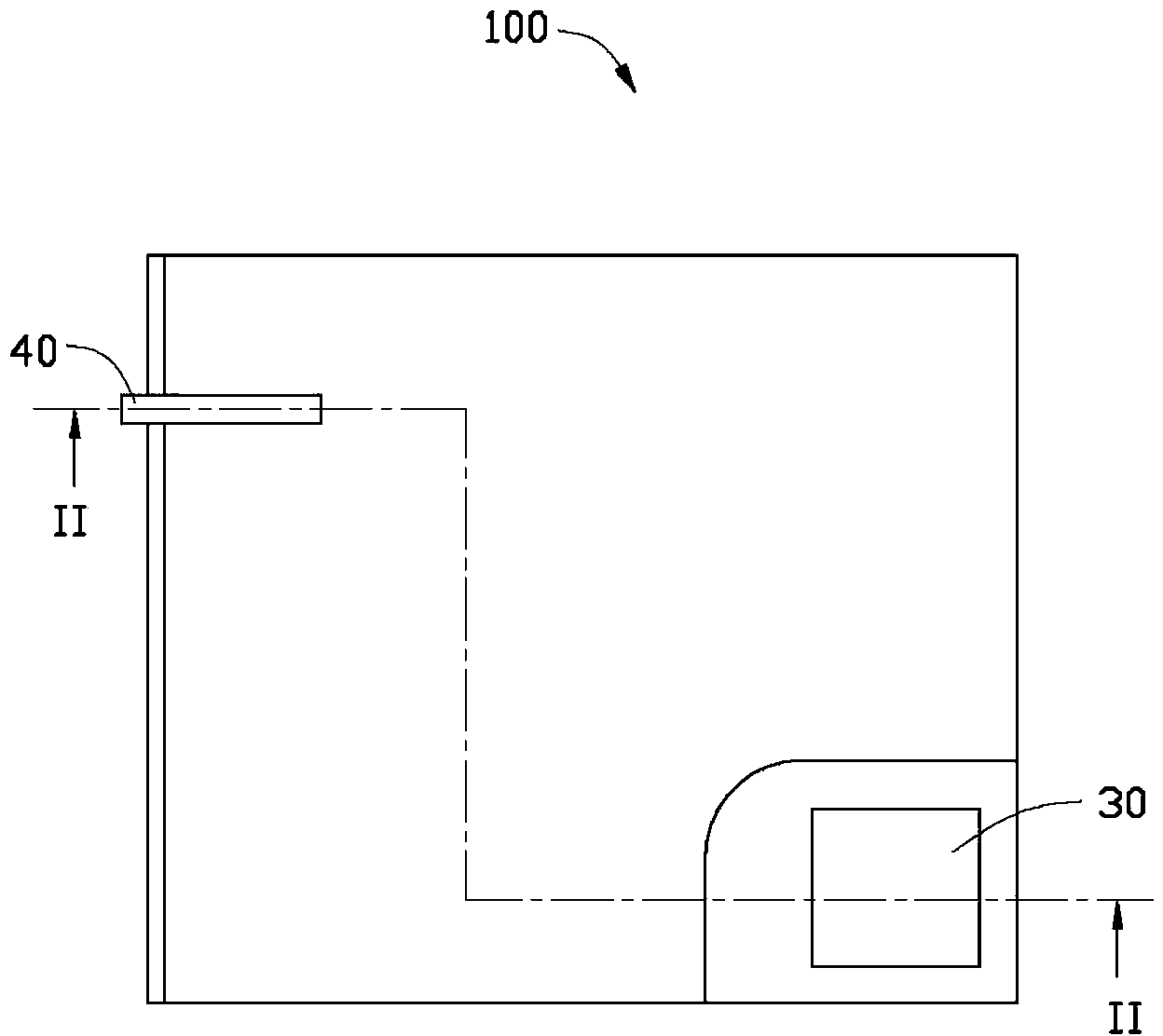

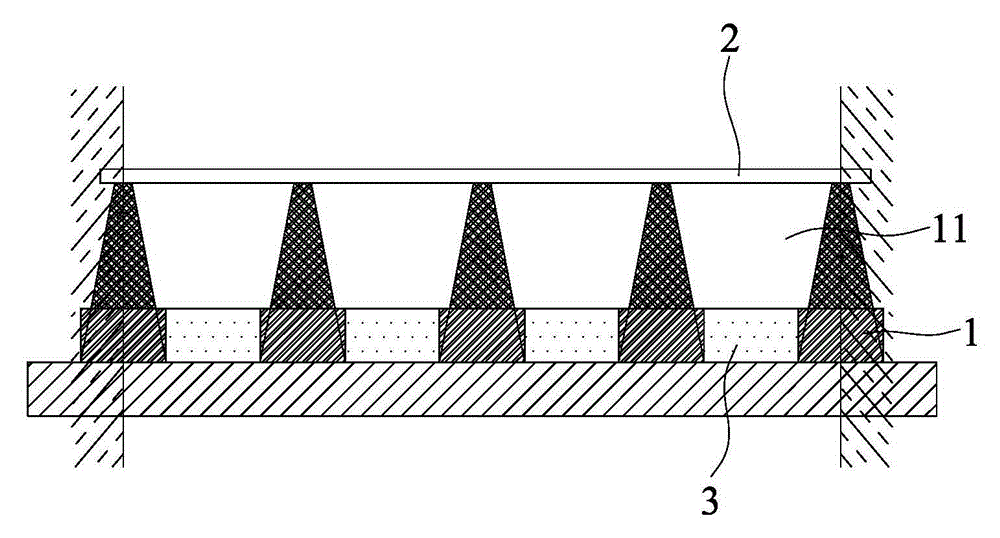

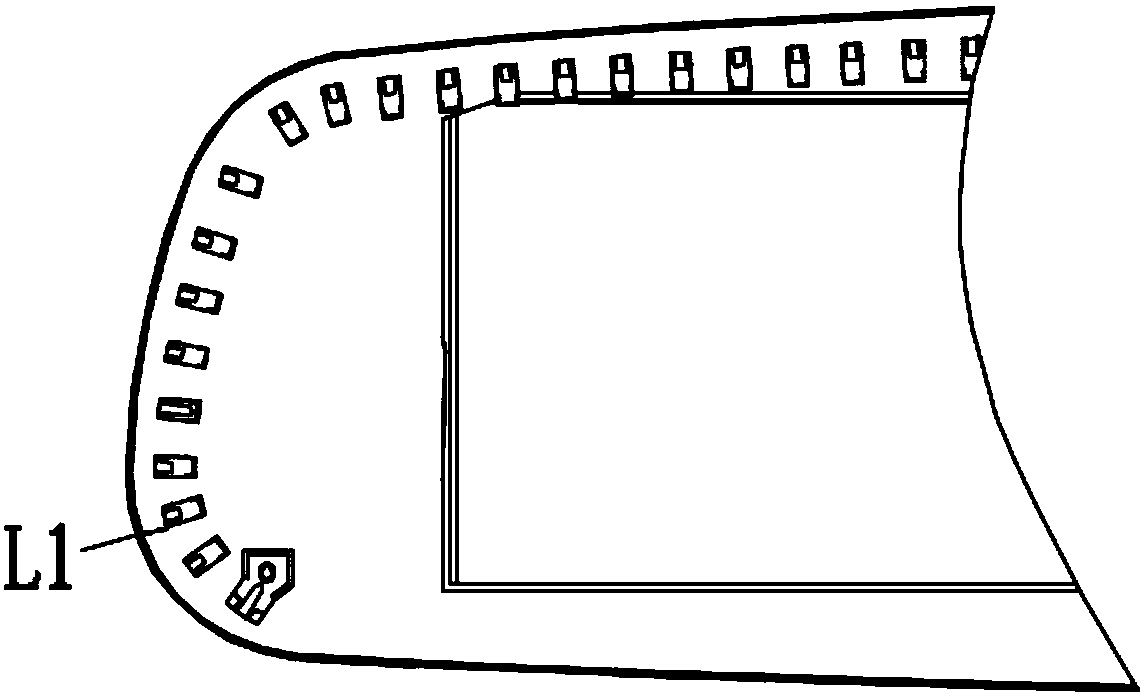

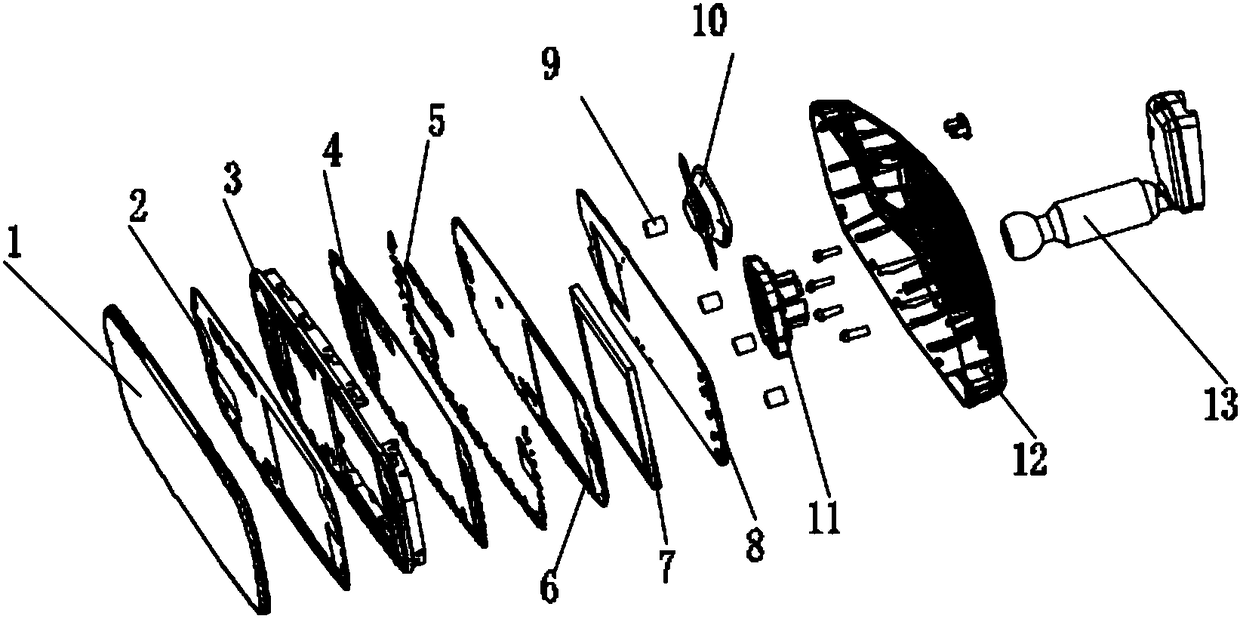

Light-expanding imaging device for eliminating moire of LED display screen

InactiveCN105206188AExpand the luminous areaEliminate structureDiffusing elementsIdentification meansDigital videoContinuous light

The invention discloses a light-expanding imaging device for eliminating moire of an LED (Light Emitting Diode) display screen. The light-expanding imaging device comprises a mask base plate and a light-expanding imaging dielectric slab, wherein the mask base plate is provided with a plurality of light-conducting cavities; the light-conducting cavities are arranged as back tapered holes with square cross sections; point light sources are arranged at the bottom of the light-conducting cavities; the light-expanding imaging dielectric slab is covered on the top surfaces of the light-conducting cavities of the mask base plate; the LED display screen is totally covered by the light-expanding imaging device provided by the invention, so that the point light sources can be turned into area light sources after the light emitted from the luminous points is subjected to the treatment, such as, the light conduction of the light-conducting cavities, the light emission of the walls of the light-conducting cavities, the light absorption, light filtering, color mixing and scattering of the light-expanding imaging dielectric slab, and the like, after the LED display screen is lightened; the luminous points are imaged on the surface of the light-expanding imaging dielectric slab after the light conduction of the light-conducting cavities, the light radiation of the walls of the light-conducting cavities and the color mixing treatment and scattering of the light-expanding imaging dielectric slab, the continuous light is formed, the grid structure and the granular sensation of the luminous points are eliminated, the moire generating conditions of a digital video (or camera) and the LED display screen are eliminated and the effect of eliminating the moire is good.

Owner:厦门科安技术开发有限公司

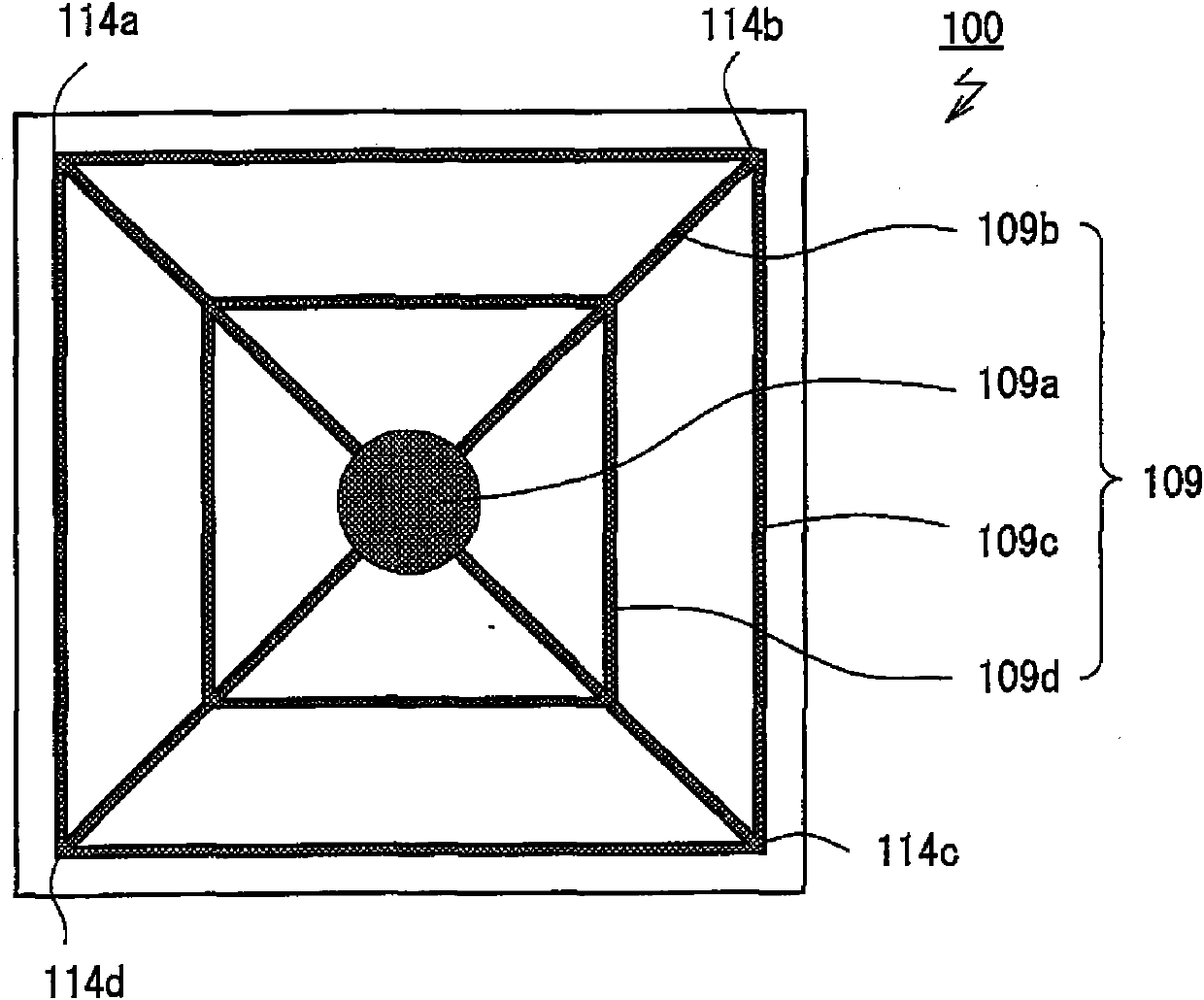

Group iii nitride semiconductor light-emitting device

ActiveCN102024892AReduce areaEasy extractionSolid-state devicesSemiconductor devicesAuxiliary electrodeActive layer

A Group III nitride semiconductor light-emitting device includes an electrically conductive support; a p-electrode provided on the support; a p-type layer, an active layer, and an n-type layer, which are formed of a Group III nitride semiconductor and are sequentially provided on the p-electrode; an n-electrode which is connected to the n-type layer; a first trench extending from the surface of the p-type layer on the p-electrode's side to reach the n-type layer; an auxiliary electrode which is in contact with the surface of the n-type layer serving as the bottom of the first trench, but is not in contact with the side walls of the first trench; and an insulating film which exhibits light permeability and covers the auxiliary electrode and the bottom and side walls of the first trench. According another embodiment, the light-emitting device comprises a second trench which is provided in a region facing a portion of the auxiliary electrode in a direction perpendicular to the main surface of the device, and which has a depth extending from the surface of the n-type layer on the side opposite the side of the p-electrode to the auxiliary electrode; and the n-electrode is formed of only a pad portion and is provided on a portion of the auxiliary electrode exposed through the second trench.

Owner:TOYODA GOSEI CO LTD

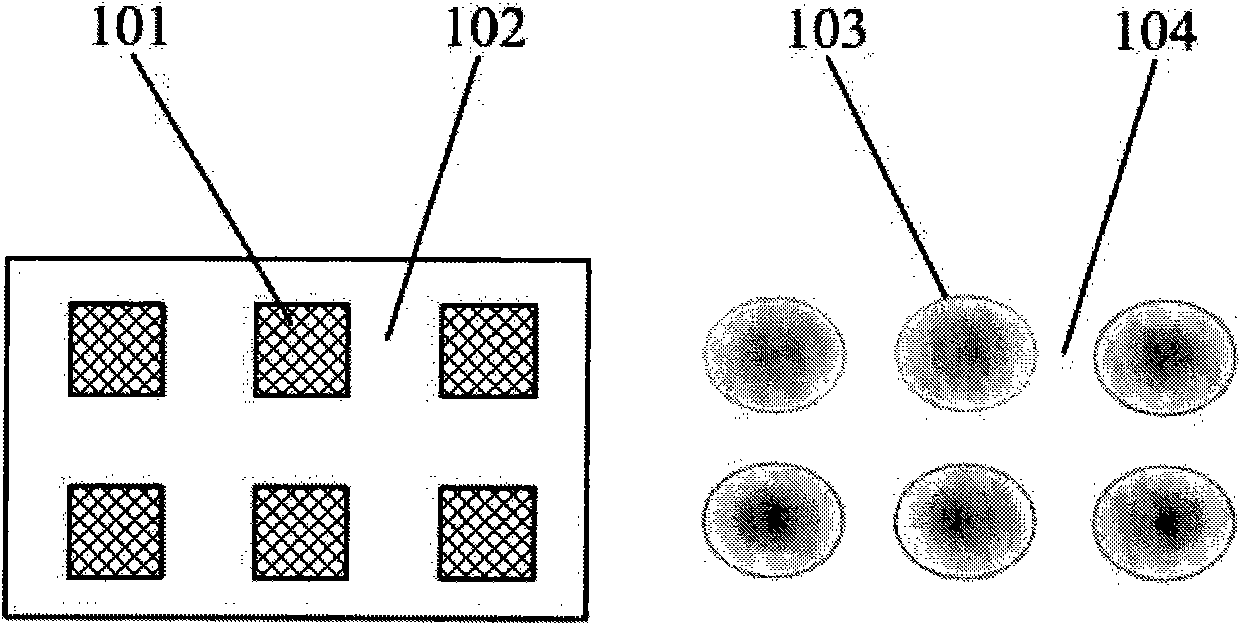

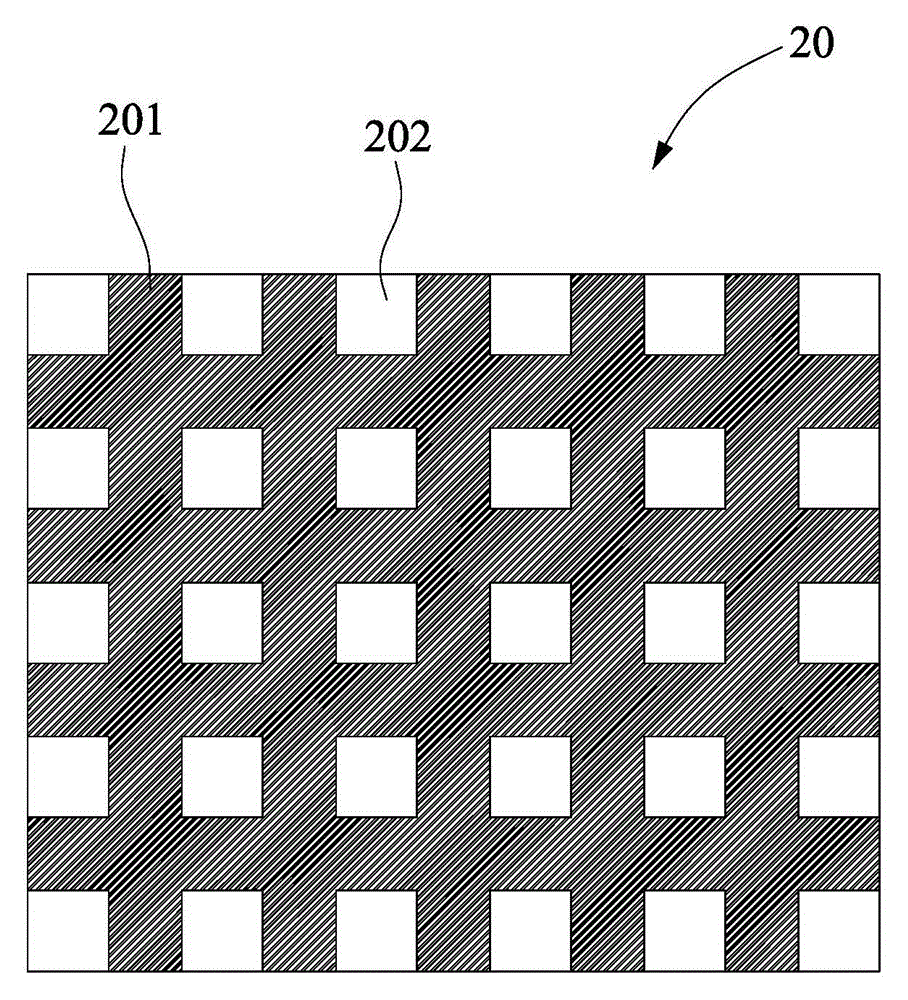

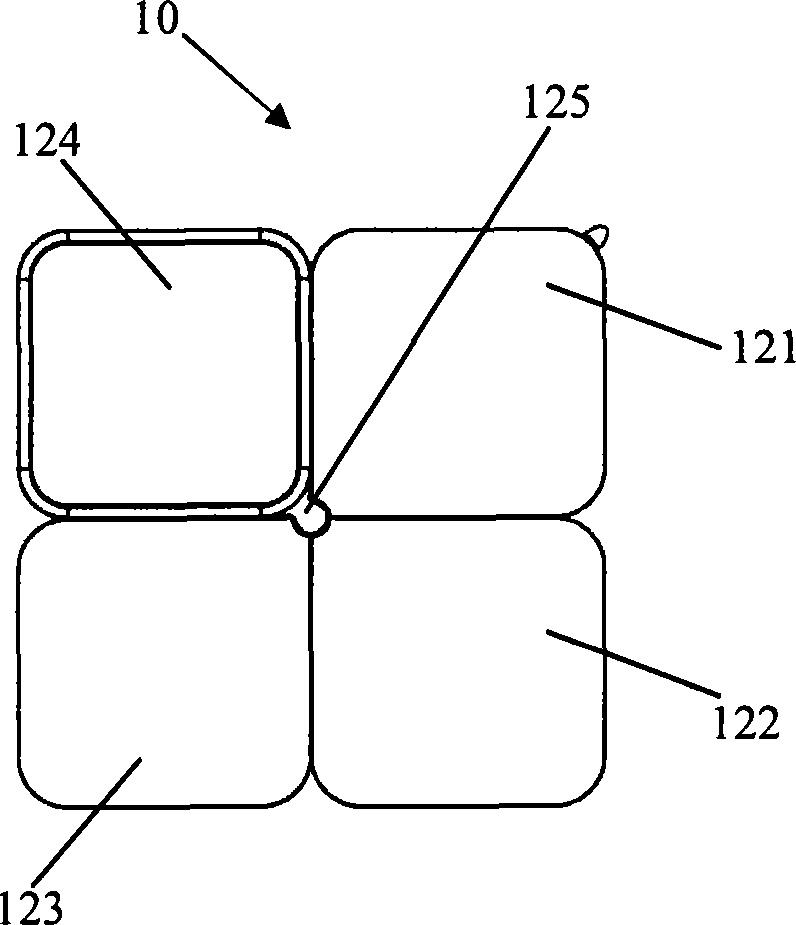

LED display screen moire-eliminating and color-mixing face cover

InactiveCN105161012AEliminate grid structure and graininessConditions to exclude moiréIdentification meansColor mixingDigital camera

The invention discloses an LED display screen moire-eliminating and color-mixing face cover which is composed of a face cover bottom plate and a plurality of color mixing devices. A plurality of embedment grooves are formed in the face cover bottom plate. The color mixing devices are embedded in the embedment grooves in the face cover bottom plate. Due to the fact that the non-luminance areas between LED display screen luminance points are all covered with the face cover, after an LED display screen is turned on, light absorbing, light filtering, color mixing, scattering and other processing are conducted on light emitted by the luminance points through the color mixing devices, color-mixed light is scattered on the surfaces of all the color mixing devices, and therefore the non-luminance areas of the LED display screen all become luminance areas, and the luminance areas and light mixing areas of LED tube cores are enlarged. The luminance points form continuous light on the surfaces of the color mixing devices after color mixing and scattering are conducted on light through the color mixing devices, and therefore the grid structure and granular sensation of the luminance points are eliminated, the moire interference to LED display images shot by a digital camera or a camera is eliminated, and the moire eliminating effect is good.

Owner:厦门科安技术开发有限公司

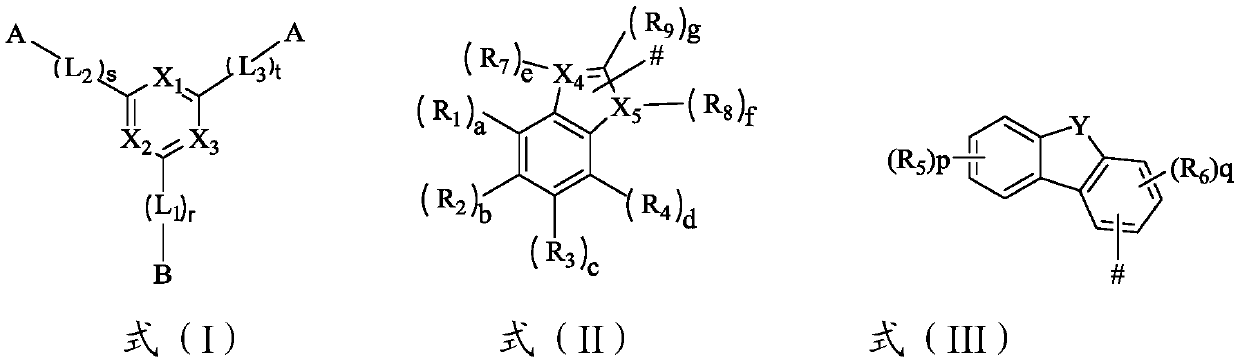

Compound, organic light-emitting device and display device

InactiveCN110642841ALower HOMO levelIncrease spawn rateOrganic chemistrySolid-state devicesDisplay deviceOrganic electroluminescence

The invention relates to the technical field of organic electroluminescence, and especially relates to a compound, an organic light-emitting device and a display device. The compound has a structure represented by formula (I).

Owner:SHANGHAI TIANMA AM OLED

Lamp

InactiveCN103775895ACompact structureAchieve expansionPoint-like light sourceLight fasteningsEngineeringLight emitting device

Owner:OSRAM GMBH

Electronic device

InactiveCN103037649AGood indicationExpand the luminous areaCasings/cabinets/drawers detailsLighting device detailsLight guideEngineering

Owner:HONG FU JIN PRECISION IND WUHAN CO LTD +1

Circular-emitting lamp

InactiveCN102338299AImprove luminous brightnessExpand the luminous areaElectric lightingLight fasteningsEngineeringClosed cavity

The invention provides a circular-emitting lamp which comprises a base, a light source, a side wall and a top cover, wherein the side wall is fixed on the base; the top cover is fixed on the side wall; the base, the side wall and the top cover form an enclosed cavity together; the light source is arranged on the base in the cavity; one surface of the top cover positioned in the cavity is a reflection surface capable of reflecting light rays; the reflection surface is an indent or convex arc surface; and the side wall is transparent, and scattering dots are distributed on the inner surface and / or the outer surface of the side wall. The emitting region is wide for the circular-emitting lamp, and the light ray uniformity and continuity are high.

Owner:BYD CO LTD

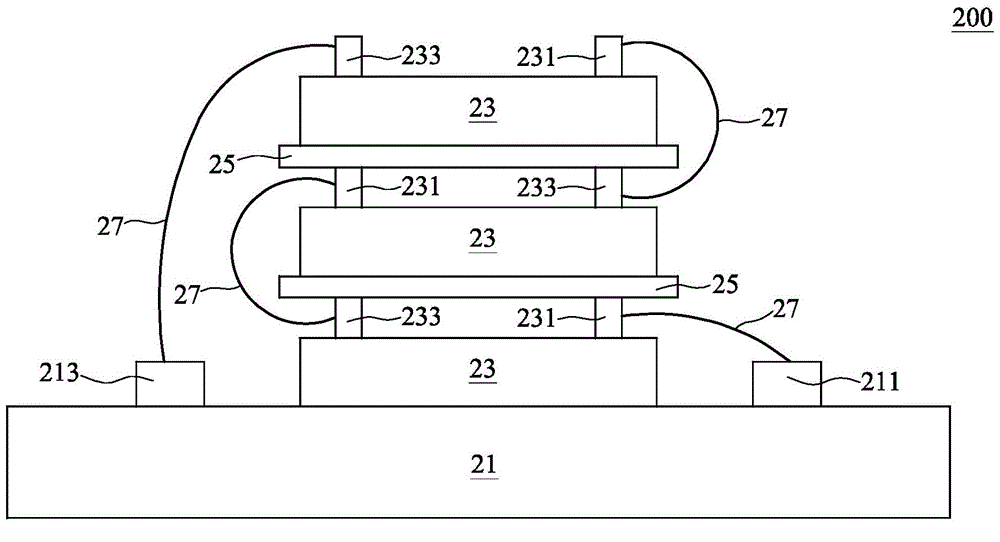

Stacked light emitting diode array structure

InactiveCN103956372AEasy to manufactureReduce setup volumeSolid-state devicesSemiconductor devicesElectrical conductorLight-emitting diode

The invention provides a stacked light emitting diode array structure. The structure comprises a substrate and multiple light emitting diode dies which are sequentially stacked on the substrate. Each of the light emitting diode dies comprises a first semiconductor layer and a second semiconductor layer, wherein a first electrode is arranged on the first semiconductor layer, and the second semiconductor layer is stacked on the first semiconductor layer; and a second electrode is arranged on the second semiconductor layer, and the first semiconductor layer of another light emitting diode die is stacked on the second semiconductor layer. The second electrode of each light emitting diode die is connected with the first electrode of another light emitting diode die through a metal layer, thereby forming a light emitting diode array in a series connection manner. In other words, the multiple light emitting diode dies are stacked to form the light emitting diode array through a stacking mode. Not only is the manufacture easy, but also the arrangement size of the overall light emitting diode array can be reduced effectively.

Owner:MEILU SCI & TECH

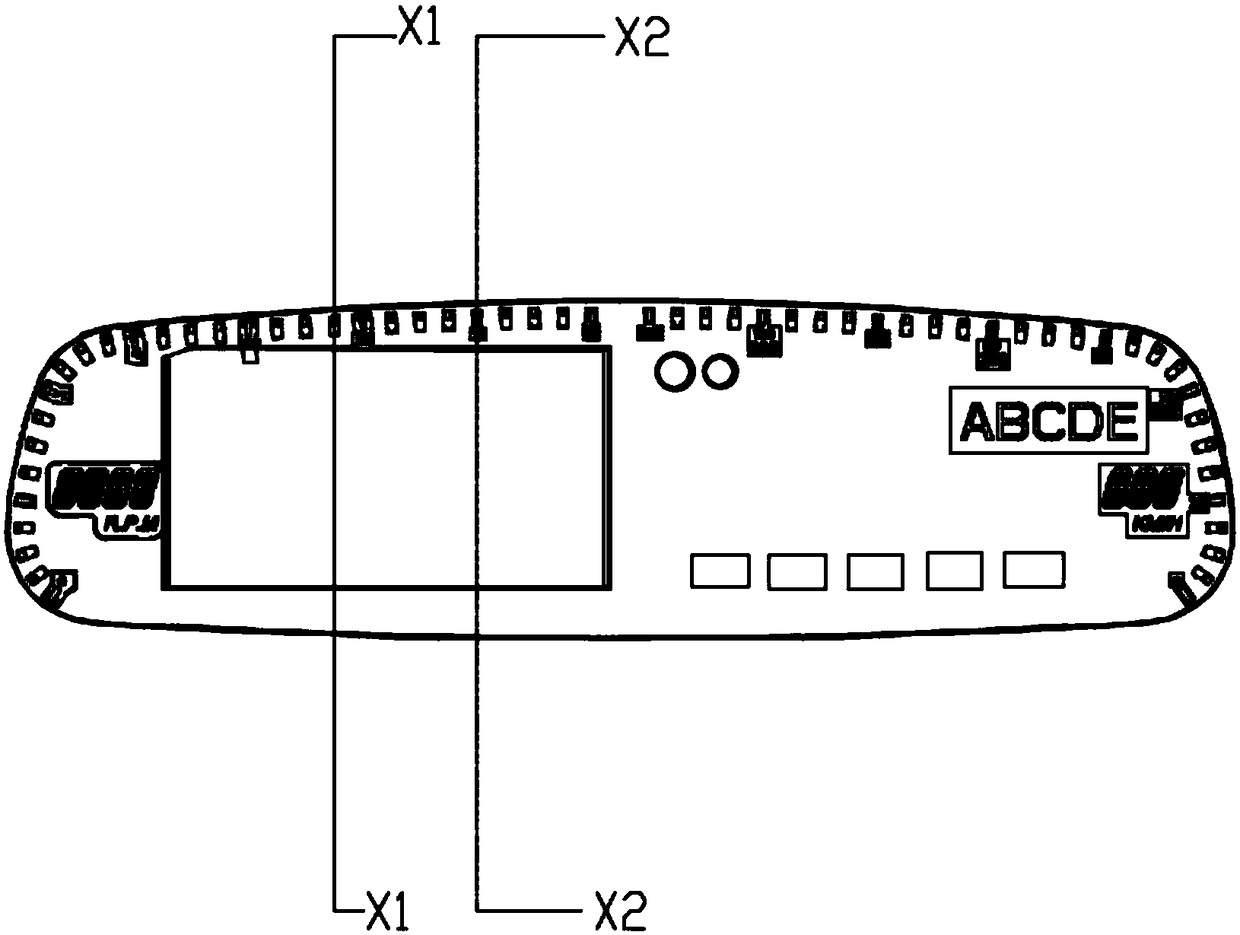

Rearview mirror with display instrument function and control system of rearview mirror

PendingCN108216043AExpand the luminous areaMulti-mirror areaAcoustic signal devicesOptical signallingInstrument functionControl system

The invention relates to the technical field of automobile parts, in particular to a rearview mirror with a display instrument function and a control system of the rearview mirror so as to solve the technical problem the display area of the rearview mirror with the display instrument function is small in the prior art. The rearview mirror comprises an LED lamp, a glue-filled fluorophor and glass;the glue-filled fluorophor is located between the LED lamp and the glass, and light emitted by the LED lamp is directed to the glass via the glue-filled fluorophor; the glue-filled fluorophor comprises a fluorophor body and an extension part, the fluorophor body is flushed with the LED lamp, the extension part is located above the fluorophor body and higher than the LED lamp, and luminous zones are formed on the outer surface of each of the fluorophor body and the extension. The display area of the rearview mirror is large.

Owner:GLOBAL MEDIA IND GRP CO LTD +1

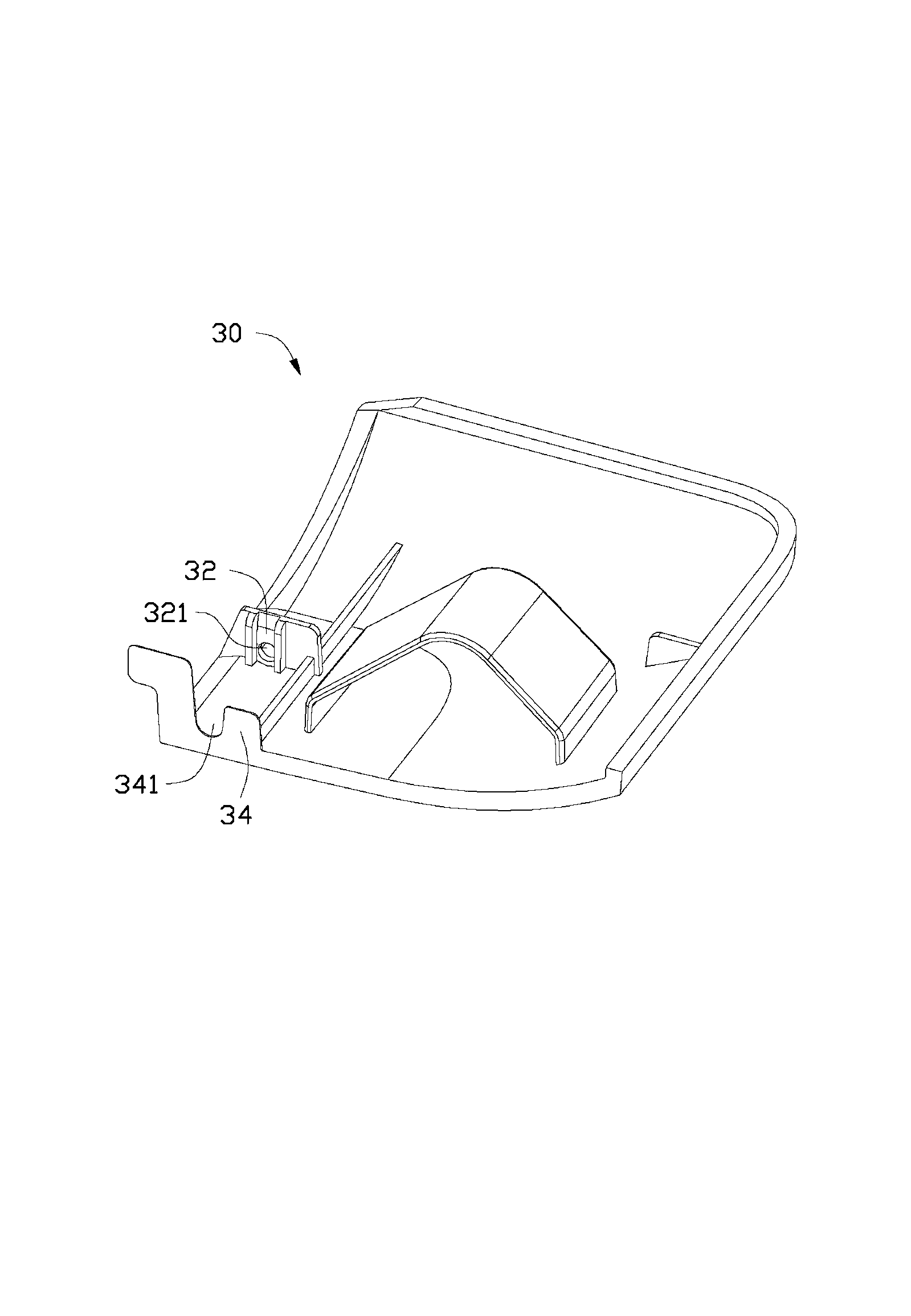

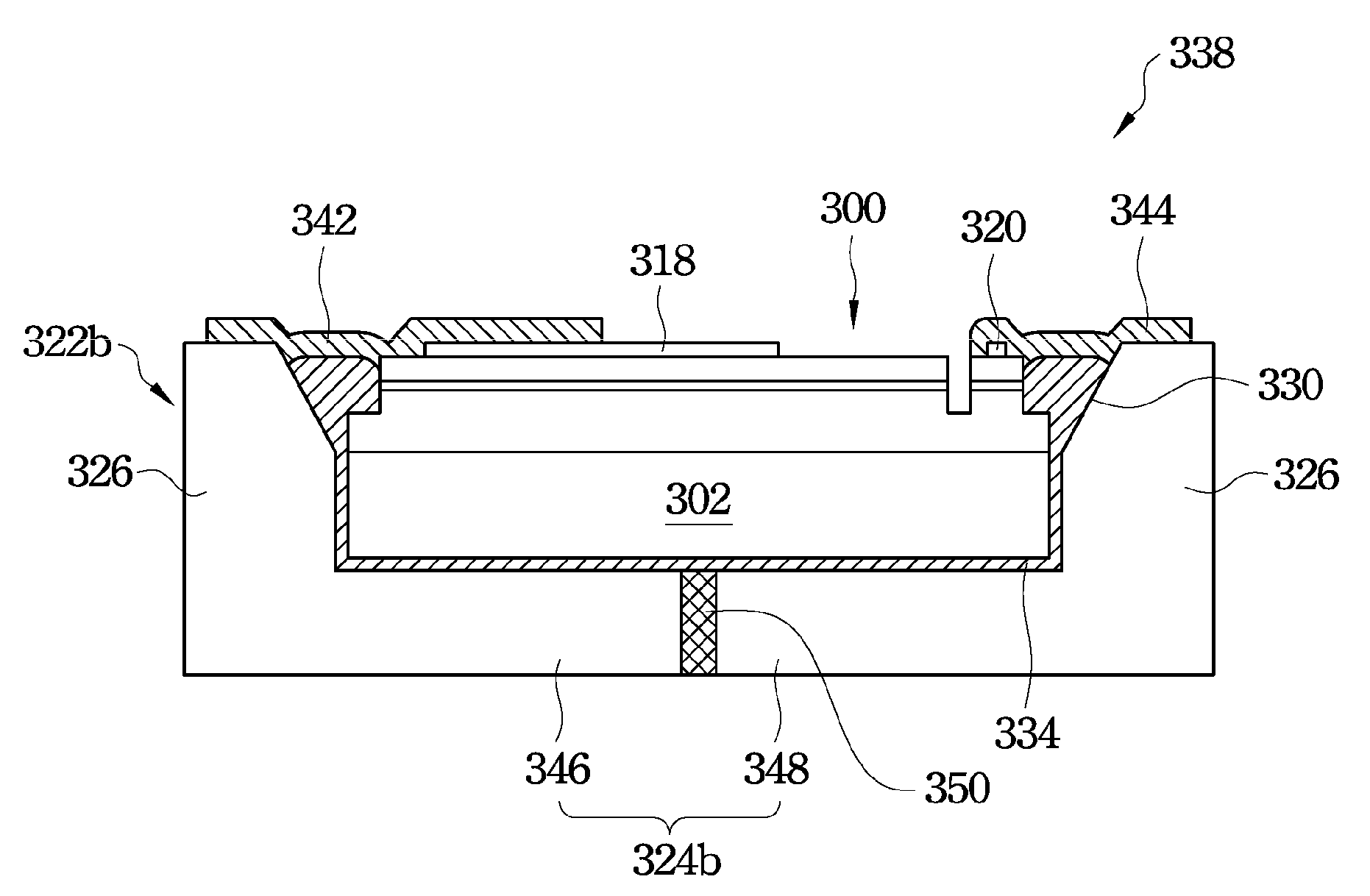

Light-emitting diode structure and method for manufacturing the same

InactiveUS20120168794A1Reduce proportionManufacturing cost be reduceSolid-state devicesSemiconductor/solid-state device manufacturingLead structureEngineering

A light-emitting diode (LED) structure and a method for manufacturing the same. In one embodiment, the LED structure includes a carrying component, an LED chip, a first conductivity type electrode and a second conductivity type electrode. The carrying component includes a carrier, a sidewall disposed on the carrier and forms a carrying tank. The LED chip is fixed within the carrying tank and includes a first conductivity type semiconductor layer having a first region and a second region, an active layer and a second conductivity type semiconductor layer stacked in sequence. The LED chip further includes a second conductive finger disposed on the second semiconductor layer in the first region, and a first conductive finger disposed on the first semiconductor layer in the second region. The first electrode extends on the sidewall and the first conductive finger. The second electrode extends on the sidewall and the second conductive finger.

Owner:CHI MEI LIGHTING TECH

Organic light emitting diode package method and package structure and device containing structure

InactiveCN105098099AExtended service lifeImprove barrier propertiesSolid-state devicesSemiconductor/solid-state device manufacturingMetal foilLight-emitting diode

The invention discloses a package method of an organic light emitting diode. The package method comprises the following steps of: arranging a first substrate, wherein the first substrate is made of metal foil; arranging the organic light emitting diode on the first substrate; arranging a passivation layer for covering the organic light emitting diode; coating package glue on the whole first substrate, wherein the package glue covers the passivation layer; arranging a second transparent substrate on at least part of the passivation layer covered with the package glue; and curving the package glue to form the package of the organic light emitting diode. The invention also discloses a package structure of the organic light emitting diode and an organic light emitting diode device containing the package structure.

Owner:BOE TECH GRP CO LTD

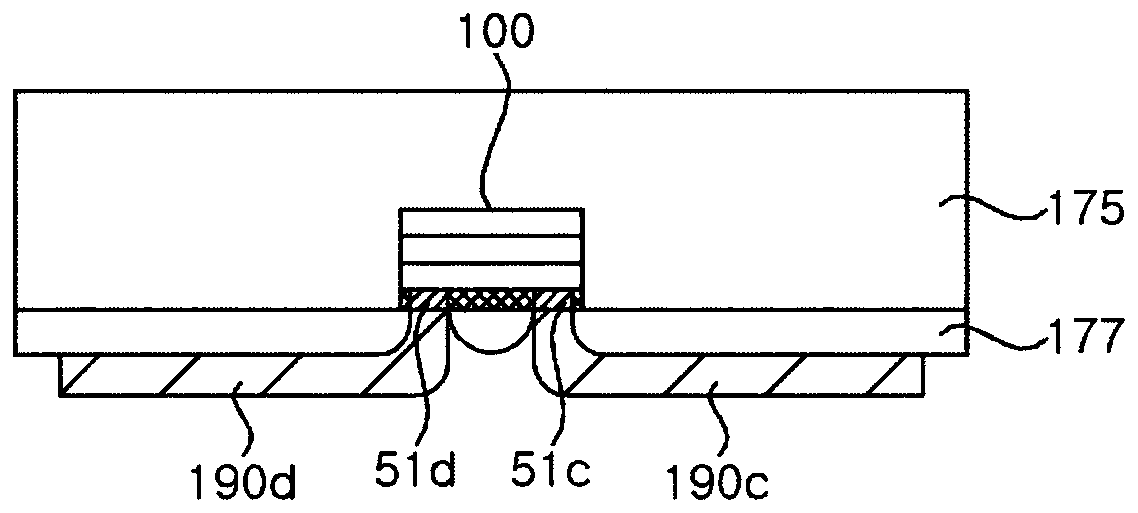

Light emitting device with LED stack for display and display apparatus having the same

PendingCN110692136AExpand the luminous areaSmall sizeSolid-state devicesSemiconductor devicesDisplay deviceLight emitting device

Owner:SEOUL VIOSYS CO LTD

Semiconductor light emitting device

ActiveCN105720161AReduce manufacturing costDrive stabilitySemiconductor devicesActive layerLight emitting device

A semiconductor light emitting device may include: a first conductive type nitride semiconductor layer; an active layer formed under the first conductive type nitride semiconductor layer; a second conductive type nitride semiconductor layer formed under the active layer; mesa regions formed upward from the second conductive type nitride semiconductor layer so as to expose the first conductive type nitride semiconductor layer; a second electrode formed under the second conductive type nitride semiconductor layer; a cover metal layer formed at a corner under the second conductive type nitride semiconductor layer so as to overlap a part of the second electrode, and partially exposed in the upward direction; an insulating layer formed under the cover metal layer, the second electrode, and the mesa regions; openings of the insulating layer, formed at portions corresponding to the mesa regions so as to expose the first conductive type nitride semiconductor layer; a first electrode formed under the insulating layer and in the openings; a conductive substrate formed under the first electrode; and a second electrode pad formed over the exposed cover metal layer.

Owner:SEOUL VIOSYS CO LTD

LED lamp

ActiveCN105674114ASimple structureReasonable structureNon-macromolecular adhesive additivesElectrical apparatusAdhesiveEngineering

The invention relates to an LED lamp. The LED lamp comprises a tube and a metal lamp holder capable of being used for high-frequency heating, wherein the tube comprises a straight part and necked parts arranged at two ends of the straight part, and smooth transition sections are arranged between the necked parts and the straight part; a lamp belt adheres to the straight part by the aid of an adhesive, and a patch power supply and LED light-emitting units are arranged on the lamp belt; the metal lamp holder is arranged outside the necked parts and is closely connected with the necked parts by the aid of welding mud; the metal lamp holder is 10-12 mm long, the necked parts are 6-8 mm long, and the gap between the metal lamp holder and the necked parts is 1-2 mm; the patch power supply is arranged in the position close to one end of the straight part, and the distance between the patch power supply and the end of the straight part is 3-5 mm. The LED lamp is simple in structure, high in lighting efficiency and low in rejection rate, comprises few components, is beneficial to industrial production line production and has unique technical advantages in aspects of breaking through the production bottleneck and substantially increasing the profit margin of products, and the welding mud is efficient and quick to solidify.

Owner:CHENHUI GUANGBAO TECH CO LTD

Compound, organic light-emitting device, display panel and display device

InactiveCN110627821AWays to reduce non-radiative attenuationReduce the driving voltageSilicon organic compoundsGroup 5/15 element organic compoundsOrganic filmOrganic light emitting device

The invention relates to a compound, an organic light-emitting device, a display panel and a display device. The compound has a structure shown as formula (I), the compound is applied to an organic light-emitting display device, the organic light-emitting display device comprises the organic light-emitting device, the organic light-emitting device comprises: an anode, a cathode and at least one layer of organic film located between the anode and the cathode, wherein the organic film contains the compound shown as the formula (I). The compound provided by the invention is a macrocyclic compoundcontaining a D-A (electron donating group-electron withdrawing group) structure, is a bipolar material, and can endow the device with high luminous efficiency, low driving voltage and long service life when used, especially as a luminescent layer material in the organic light-emitting device.

Owner:WUHAN TIANMA MICRO ELECTRONICS CO LTD

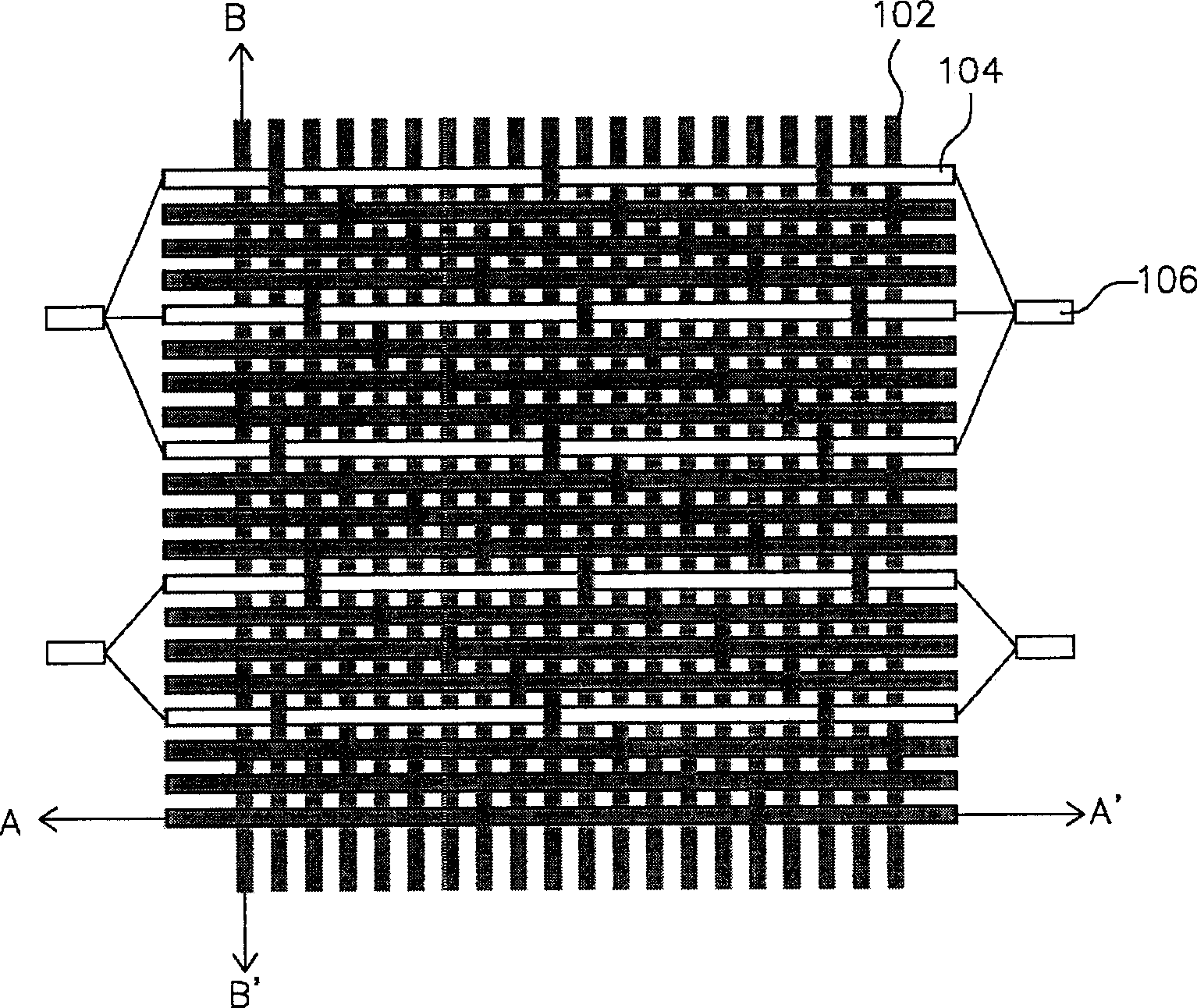

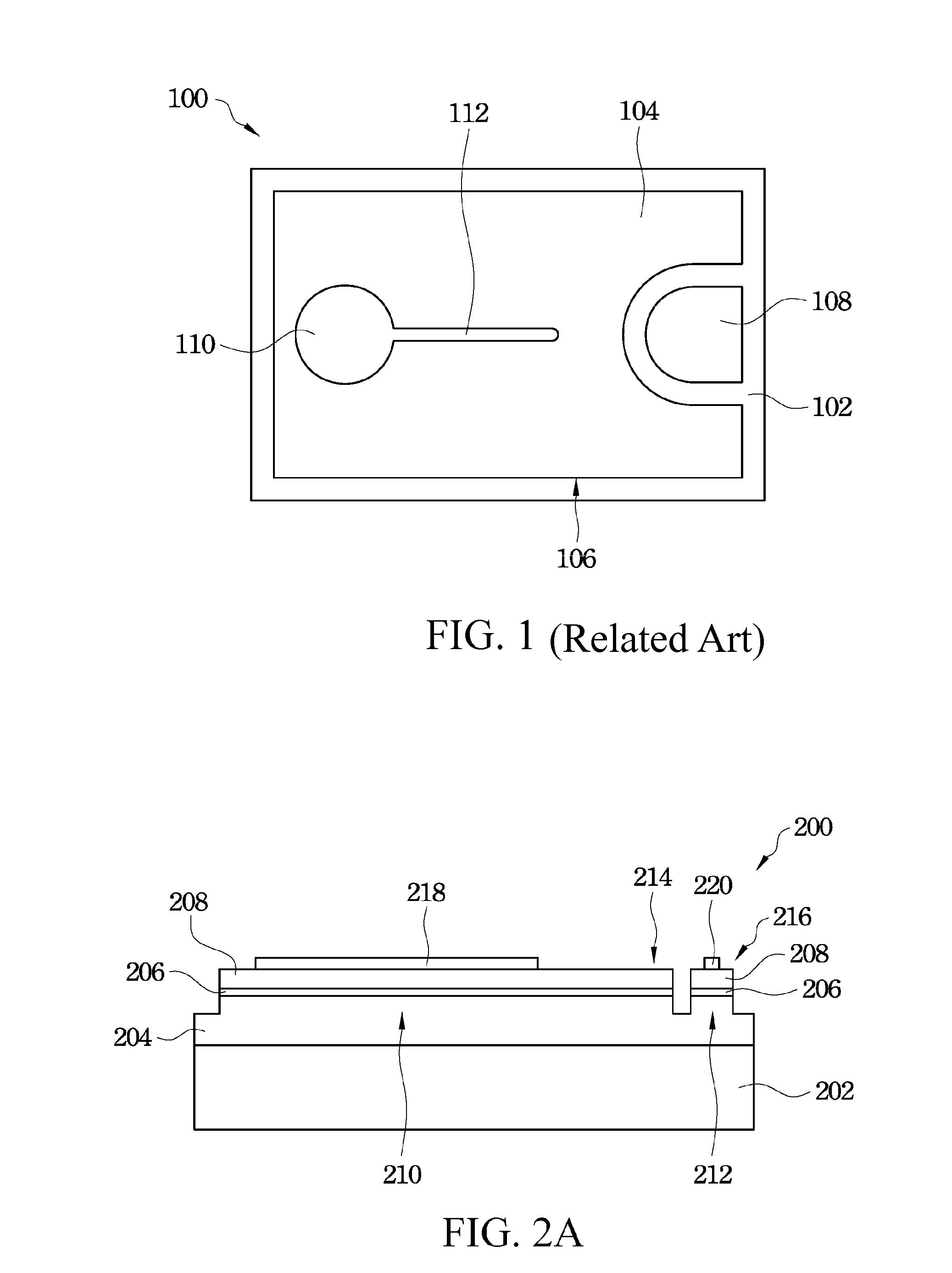

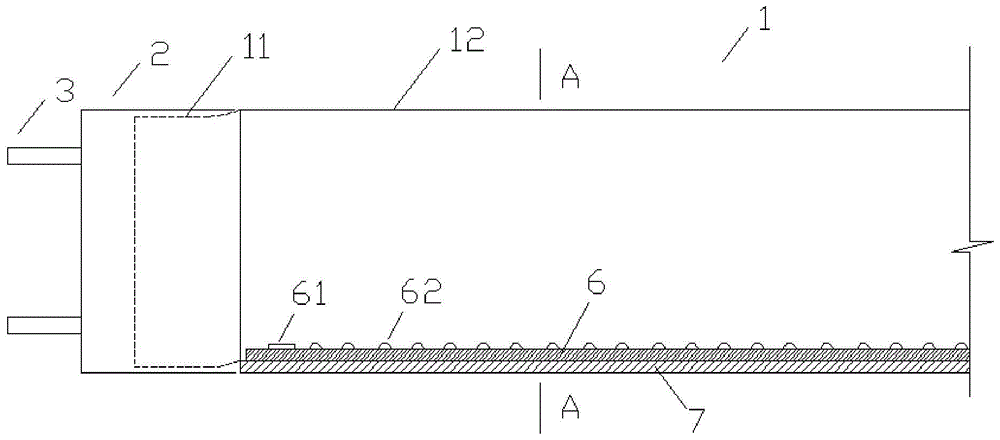

Flat type fluorescent lamp

InactiveCN1643643ACreativeEliminate non-luminous areasSolid cathode detailsGas discharge lamp detailsTube SpacerPhosphor

The present invention discloses a flat type fluorescent lamp that is improved in its light emission efficiency and brightness by installing a tube spacer between 2 panels. A flat type fluorescent lamp includes an outer lamp body comprising front and rear panels, and circumference seal members, and tube spacers installed in the outer lamp body to divide the discharge spaces in plural sections communicating with each other to define a discharge path, a phosphor layer deposited on the outer lamp body and the tube spacers, and a discharge electrode supported on the outer lamp body.

Owner:李桂承

Organic electroluminescence display panel, manufacturing method thereof and display device

InactiveCN106784350APrevent short circuit between cathode and anodeExpand the luminous areaSolid-state devicesSemiconductor/solid-state device manufacturingOrganic electroluminescencePhysics

The invention discloses an organic electroluminescence display panel, a manufacturing method thereof and a display device. The organic electroluminescence display panel comprises a substrate, an anode, a cathode, an organic light-emitting layer and a semiconductor layer, wherein the anode and the cathode are located on the substrate, the organic light-emitting layer is located between the anode and the cathode, and the semiconductor layer covers the whole substrate; the semiconductor layer is located between the anode and the organic light-emitting layer or between the cathode and the organic light-emitting layer. The organic electroluminescence display panel has the advantages that a pixel definition layer in the prior art can be omitted, and pixel light-emitting areas can be increased.

Owner:BOE TECH GRP CO LTD

Thick-wall part structure, light-emitting device and light-emitting mode

PendingCN114046480AEnsure normal lightingMeet the demand for uniform light emissionVehicle headlampsOptical signallingLight guideEngineering

The invention discloses a thick-wall part structure, a light-emitting device and a light-emitting mode. The thick-wall part structure comprises a light guide structure body, and the light guide structure body is provided with a light source incident plane, a first reflecting plane set, a second reflecting plane set and a light-emitting plane perpendicular to the light source incident plane; the first reflecting plane set is suitable for reflecting incident light in a plane perpendicular to the light-emitting plane and the light source incident plane and forming a central light-emitting area on the light-emitting plane; and the second reflecting plane set diverges the incident light towards two opposite sides parallel to the light-emitting plane, and forms a diffusion light-emitting area on the light-emitting plane, so that the light-emitting width on the light-emitting plane is greater than the width of the light source incident surface. Light emitting of the central area is guaranteed, meanwhile, the diffusion light emitting area is added, the light emitting width is larger than the initial irradiation width of the light sources, when the distance between the light sources is large, the area between the two light sources can be completely irradiated, dark areas are avoided, and the uniform light emitting requirement of customers is met.

Owner:CHANGZHOU XINGYU AUTOMOTIVE LIGHTING SYST CO LTD

Chiplet display with electrode connectors

ActiveCN103443922AImproved pixel drive performanceExpand the luminous areaSolid-state devicesSemiconductor devicesDisplay deviceEngineering

Owner:GLOBAL OLED TECH

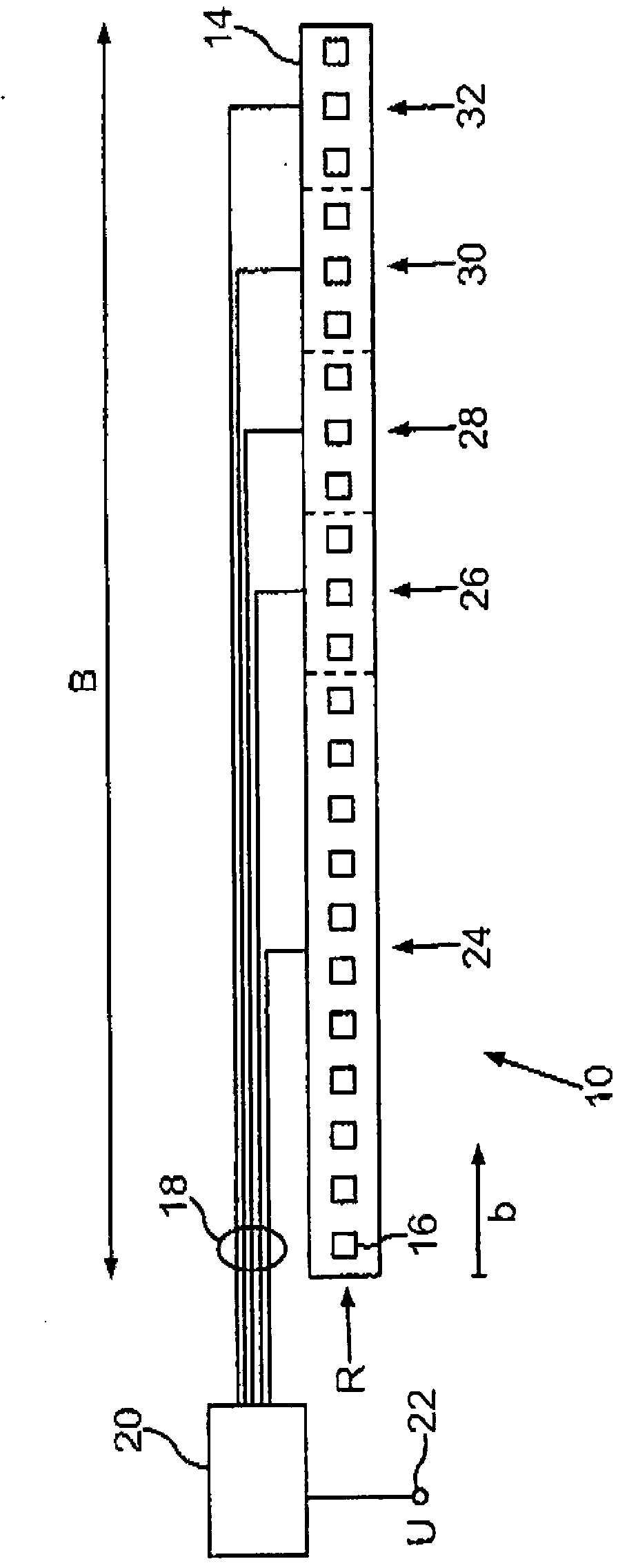

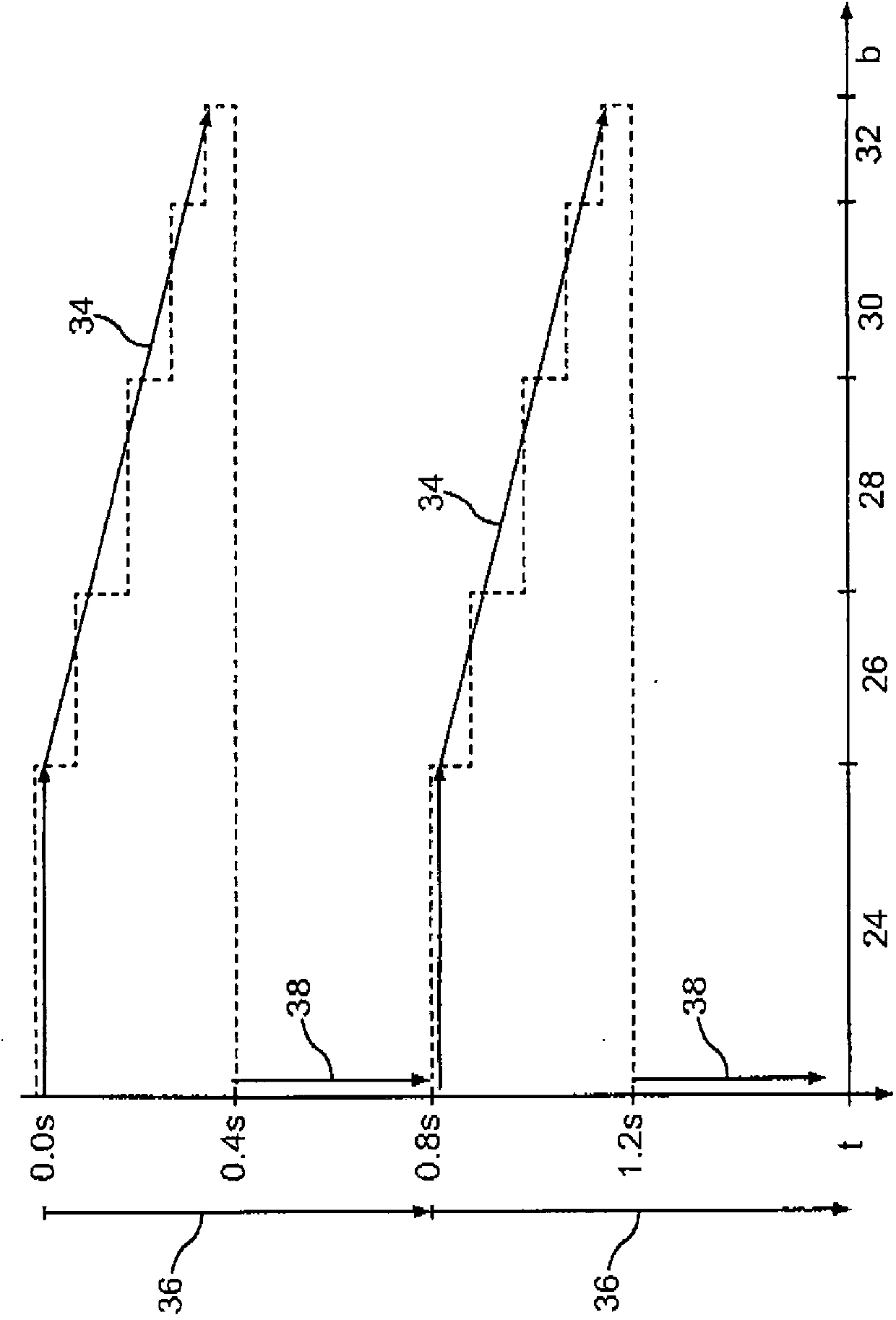

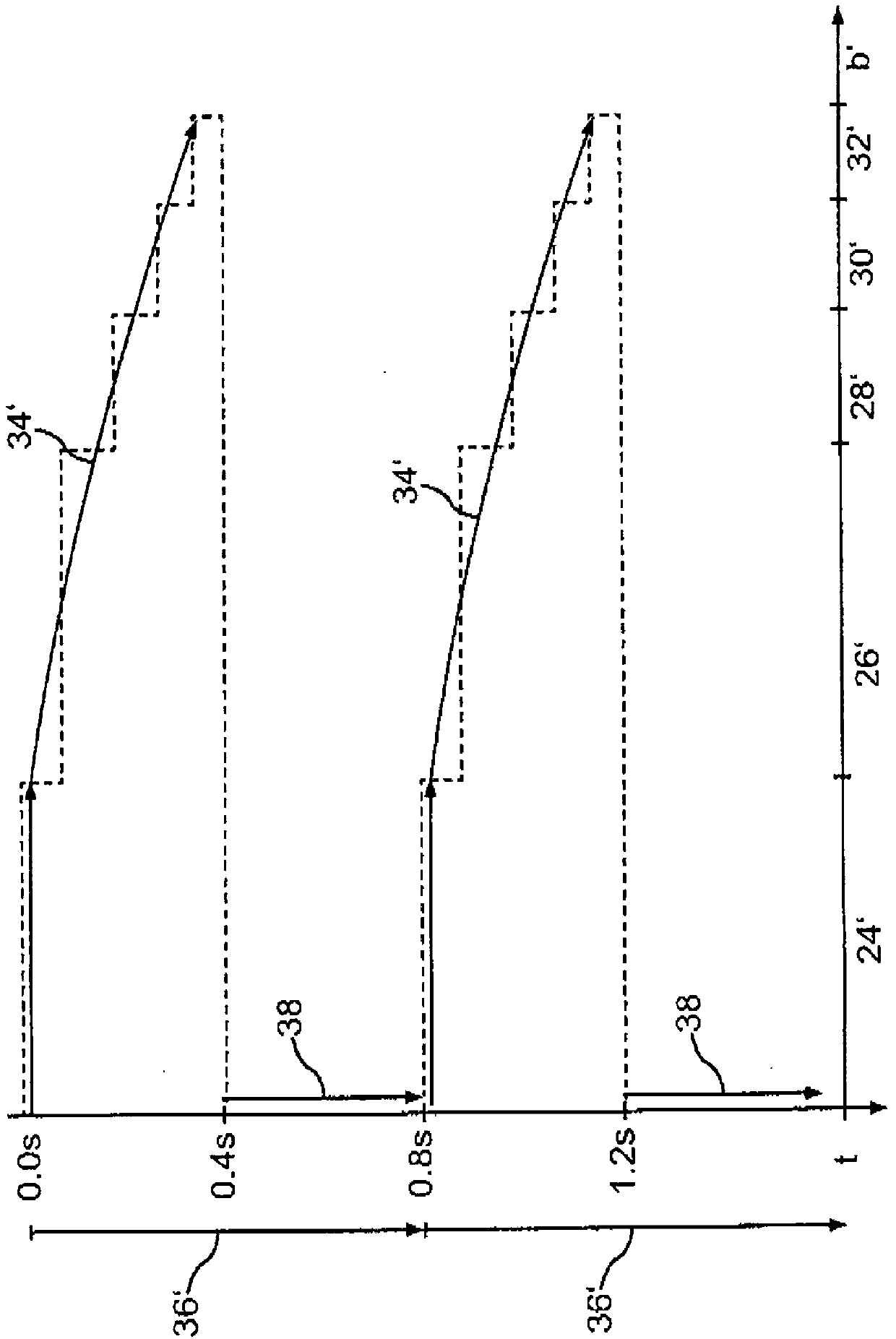

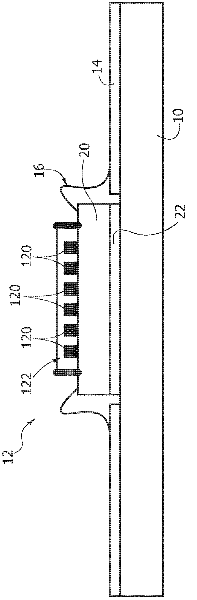

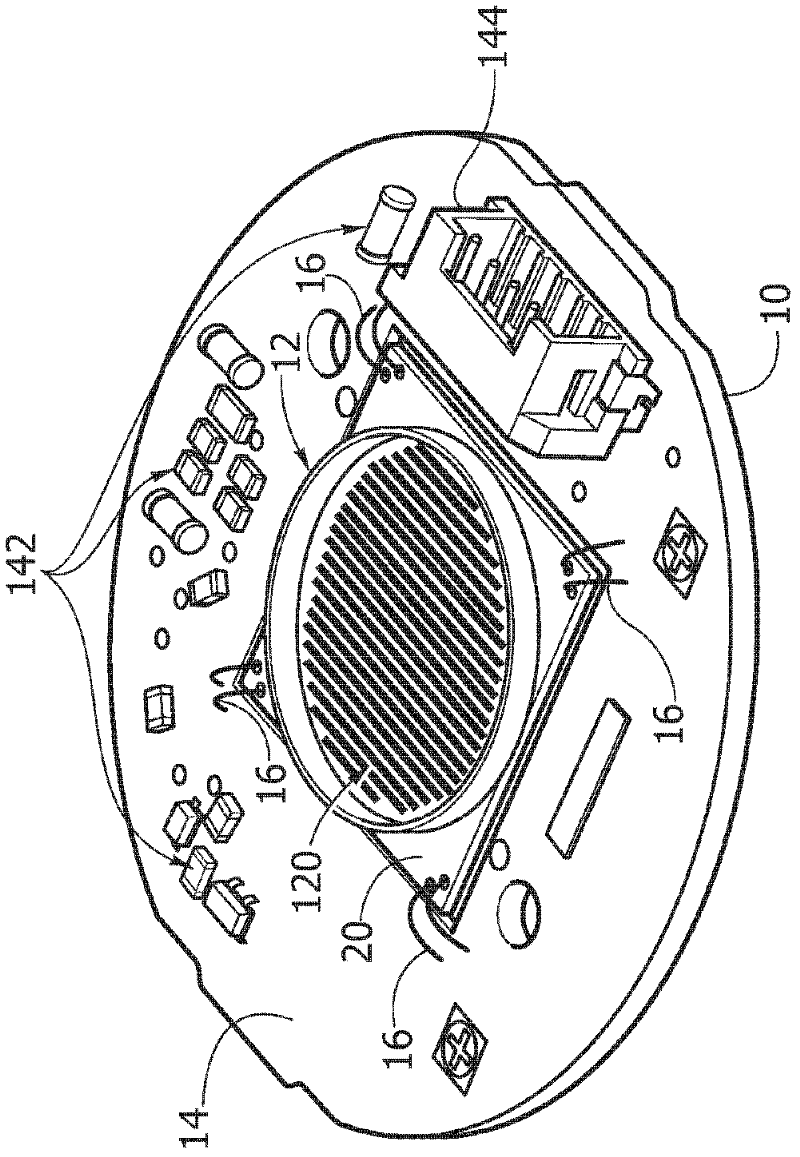

Mounting structure for solid-state light sources

ActiveCN102691980AHeat flow path minimizationExpand the luminous areaPoint-like light sourceElectric circuit arrangementsHemt circuitsMechanical engineering

A mounting structure for solid-state light sources, for example of the LED type (120), comprises: - a support board (10), - a submount (20) mounted on said support board (10) and having at least one solid-state light radiation source (120) mounted thereon, - a drive board (14) carrying drive circuitry (142) for the light radiation source (120), the aforementioned drive board being mounted on the support board (10) and extending peripherally with respect to the aforementioned submount (20), - electrical interface connections (16, 162) between the submount (20) and the drive board (14) for connecting the light radiation source (120) to the drive circuitry (142), and - mechanical and thermal interface connections (22; 162, 220) between the submount (20) and the support board (10).

Owner:OPTOTRONIC GMBH

A kind of LED chip of novel structure and its manufacturing method

ActiveCN103972350BImprove effective utilizationImprove luminous efficiencySemiconductor devicesIndiumEngineering

The invention discloses an LED (light-emitting diode) chip with a novel structure and a production method of the LED chip, and belongs to the field of a semiconductor device. The LED chip structure comprises an N-side electrode, a substrate, an active layer, a gallium phosphide layer, an indium-gallium-phosphorus layer, a P-side soldering wire electrode, an expanded electrode and a current barrier groove. The production method comprises the steps: growing the indium-gallium-phosphorus layer with the thickness of 1000 angstroms on a P side of a chip, etching and coarsing the gallium phosphide layer, evaporating the P-side soldering wire electrode and the expanded electrode by utilizing a vacuum film coating technology, etching the current barrier groove by virtue of plasma, and facilitating the ohm contact between the expanded electrode and the gallium phosphide layer in virtue of alloy. By adopting the produced LED chip, the current can be expanded to the entire chip surface through the expanded electrode, so that the effective application of the current is improved; meanwhile, by adopting the surface coarsing, the light emitting rate of the chip can be effectively improved. The LED chip has the advantages of simplicity in structure, simple and feasible production method and easiness in manufacturing.

Owner:马鞍山太时芯光科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com