Organic light emitting diode package method and package structure and device containing structure

A technology of light-emitting diodes and encapsulation structures, which can be applied to organic semiconductor devices, electric solid-state devices, semiconductor devices, etc., and can solve problems such as OLED damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

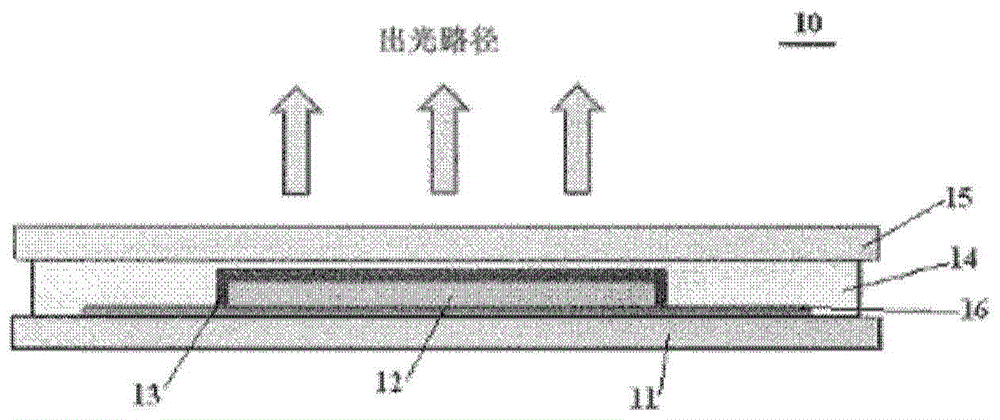

example 1

[0032] Set a 50 μm thick Invar alloy as the first substrate, form a 0.5 μm thick SiNx film on it as a flat layer by CVD, make an OLED on the flat layer, and use CVD to form a 1 μm thick SiNx film as a passivation layer , where the passivation layer covers the OLED. Coating encapsulation glue on the surface of the first substrate, covering the entire area of the first substrate, at least setting a plastic film on the part of the encapsulation glue covering the passivation layer as the second substrate, the area of the second substrate is smaller than the area of the first substrate . The edge of the first substrate is folded so as to cover the second substrate and expose the light-emitting area, leaving one edge of the first substrate unfolded, thereby allowing the circuit part to extend to the outside. Finally, the encapsulation glue is cured to complete the encapsulation structure of the OLED.

example 2

[0034] Set a 100 μm thick Kovar alloy as the first substrate, heat and evenly paste a 0.5 μm thick plastic film on it as a flat layer, make an OLED structure on the flat layer, and use atomic force deposition (ALD) to form a 0.5 μm thick Al 2 o 3 The thin film acts as a passivation layer, where the passivation layer covers the OLED. Coating encapsulation glue on the surface of the first substrate, covering the entire area of the first substrate, at least setting a plastic film on the part of the encapsulation glue covering the passivation layer as the second substrate, the area of the second substrate is smaller than the area of the first substrate . The edge of the first substrate is folded so as to cover the second substrate and expose the light-emitting area, and one edge of the first substrate is left unfolded, thereby allowing the circuit part to extend to the outside. Finally, the encapsulation glue is cured to complete the encapsulation structure of the OLED. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com