Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

31 results about "Invar" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Invar, also known generically as FeNi36 (64FeNi in the US), is a nickel–iron alloy notable for its uniquely low coefficient of thermal expansion (CTE or α). The name Invar comes from the word invariable, referring to its relative lack of expansion or contraction with temperature changes.

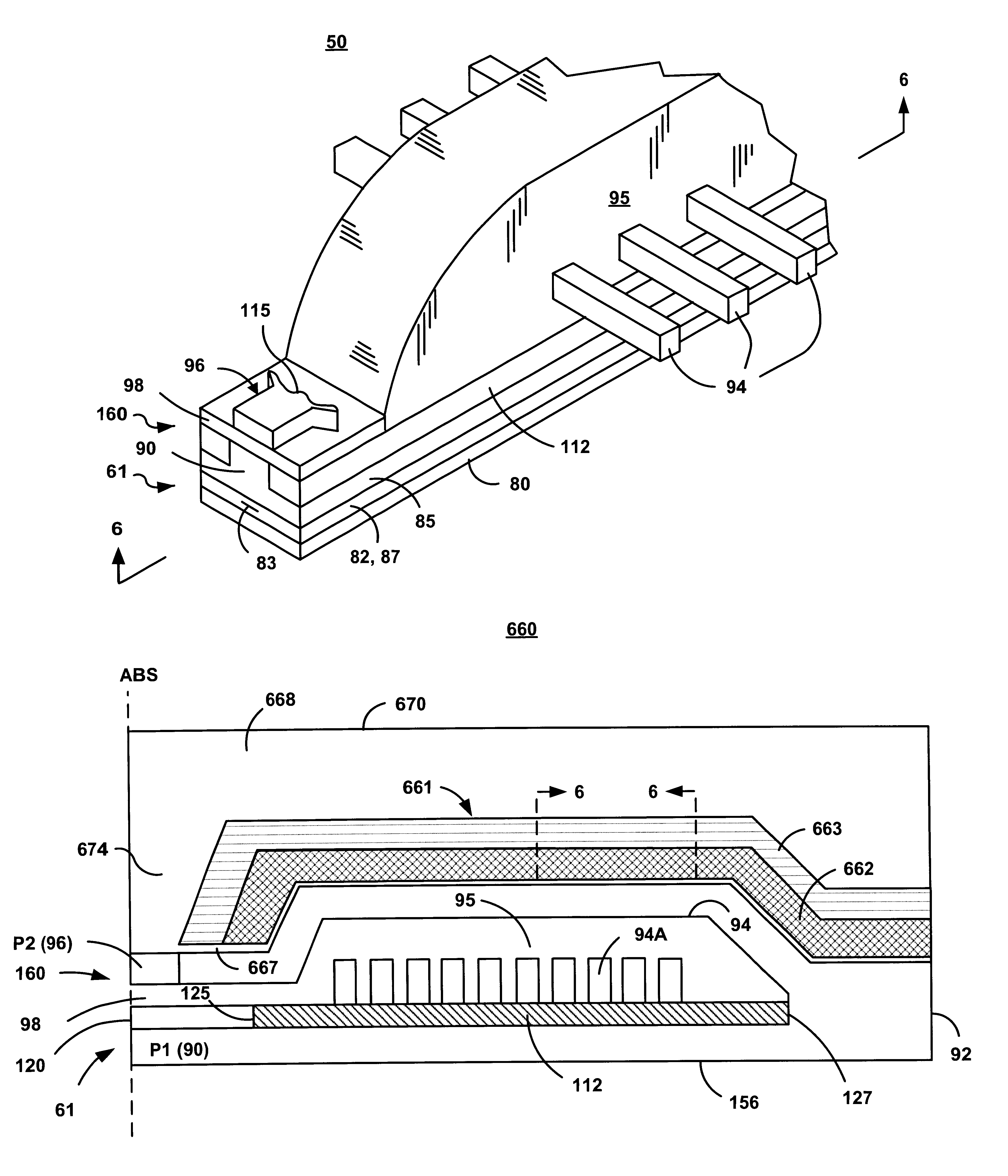

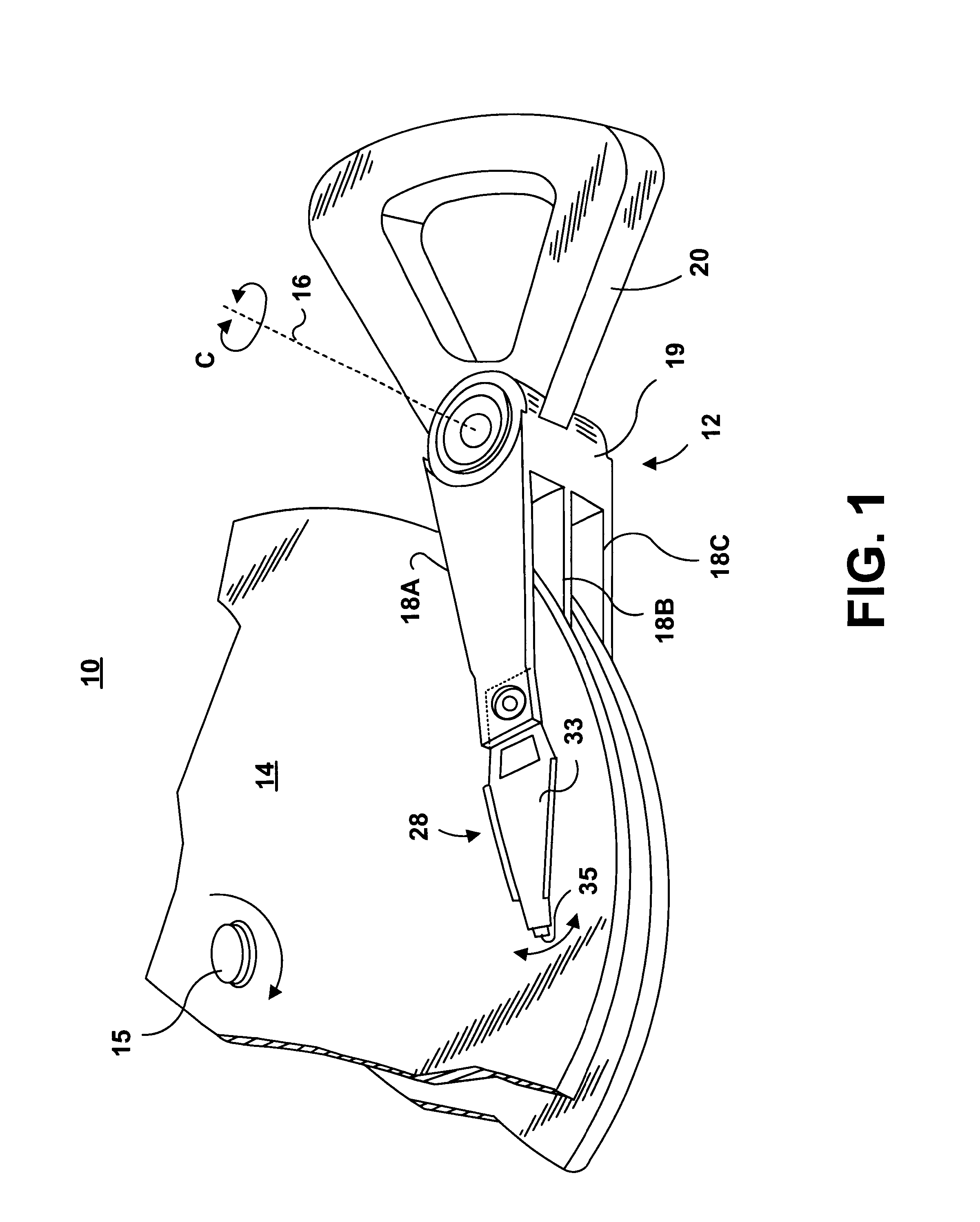

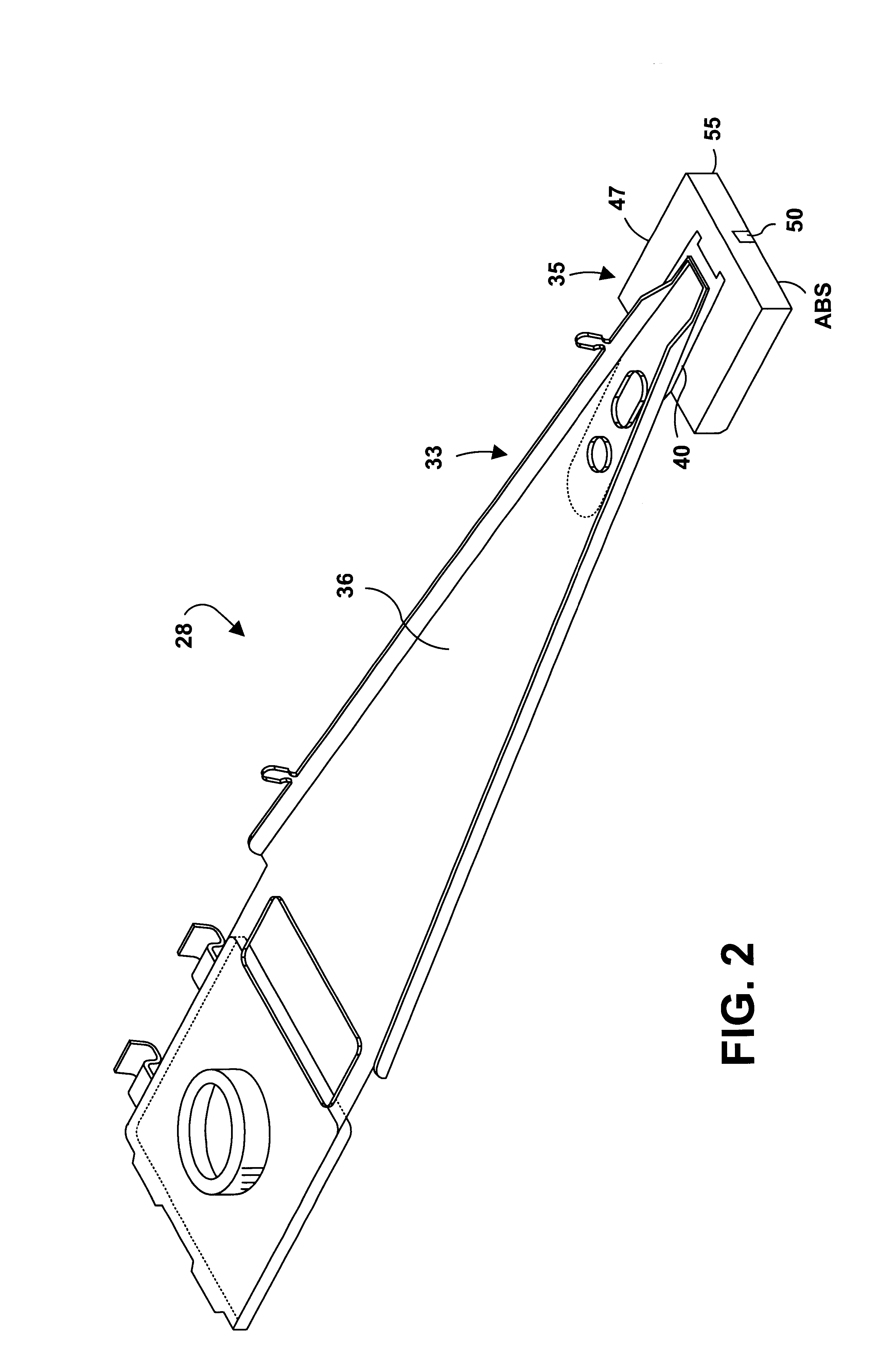

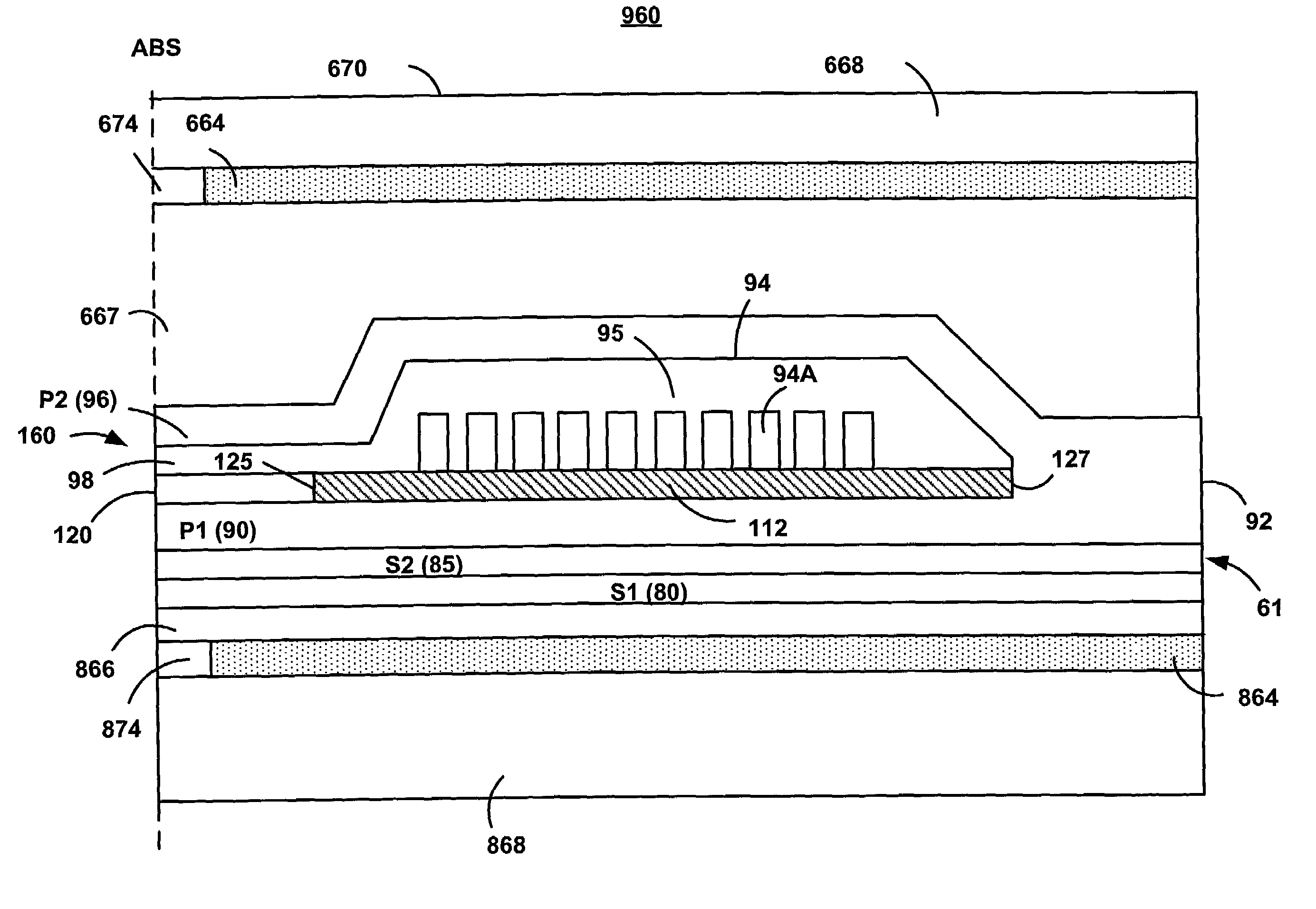

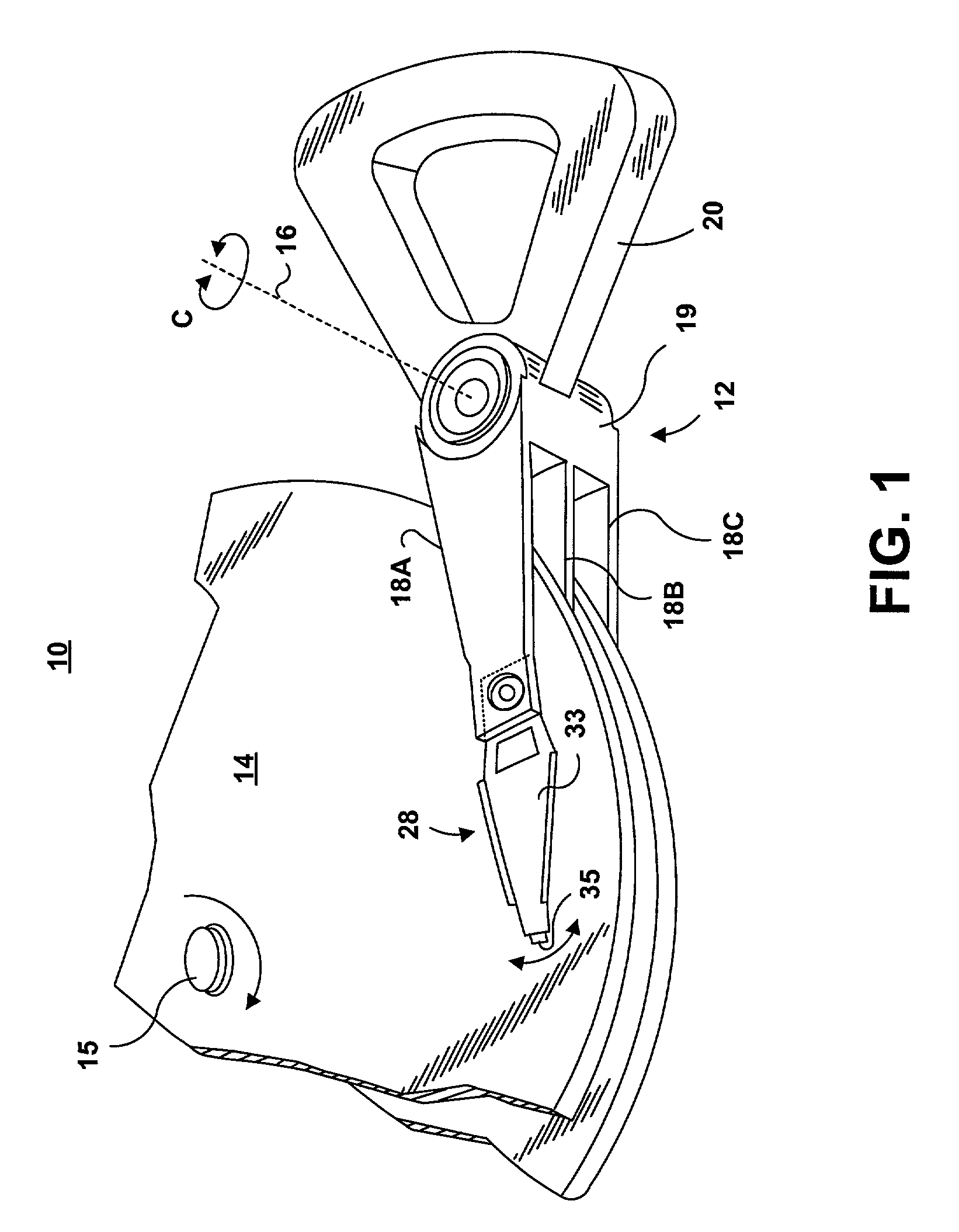

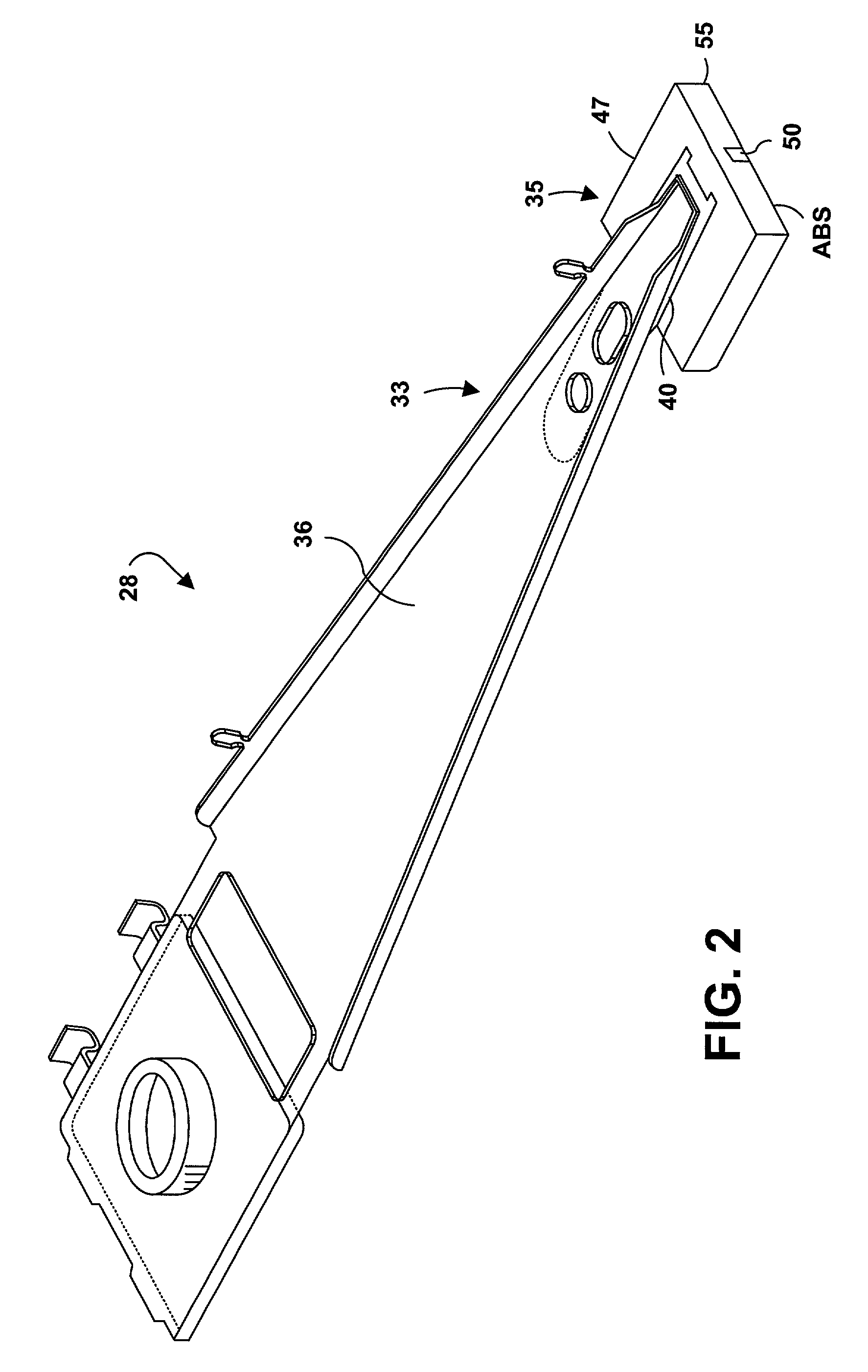

Hybrid diffuser for minimizing thermal pole tip protrusion and reader sensor temperature

InactiveUS6859343B1Reduces reader sensor temperatureImprove thermal conductivityManufacture head surfaceRecord information storageInvarInsulation layer

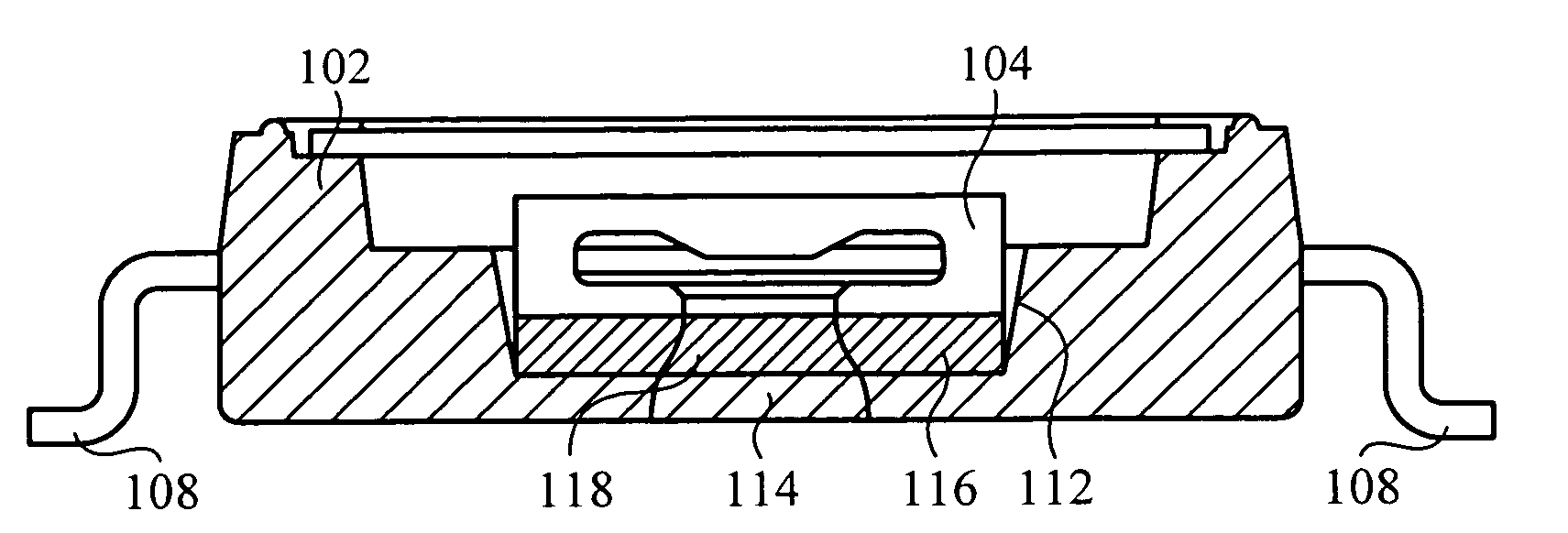

An enchance recording head design provides conduction and mechanical restraint control in order to minimize the pole tip protrusion and the head temperature resulting from the thermal heating of the magnetic recording head during operation. In one embodiment, the recording head includes a hybrid diffuser formed within an insulation layer, at a predetermined distance from the head write section. The hybrid diffuser is comprised of a thermal conduction layer with high thermal conductivity, such as gold or copper, and a mechanical restraint layer having near zero CTE, such as a 60-80% face-centered-cubic NiFe (Invar) material. The hybrid diffuser is recessed from the ABS to prevent the delamination of the hybrid diffuser due to the otherwise displacement incompatibility between the inner insulating layer and the hybrid diffuser at the ABS.

Owner:WESTERN DIGITAL TECH INC

System and method for minimizing thermal pole tip protrusion

InactiveUS7035046B1Minimize pole tip protrusionSimple designRecord information storageProtective measures for recording headsInvarDiffusion

An enhanced recording head design provides thermal diffusion and thermal expansion control in order to minimize the pole tip protrusion resulting from the thermal heating of the magnetic recording head during operation. In one embodiment, the recording head a thermal restraint section formed above a write section, and is made of a 60–80% face-centered-cubic NiFe (Invar) material. According to another embodiment, the thermal restraint section is formed under the read section. According to yet another embodiment, one thermal restraint section is formed above the write section, and another thermal restraint section formed under the read section.

Owner:WESTERN DIGITAL TECH INC

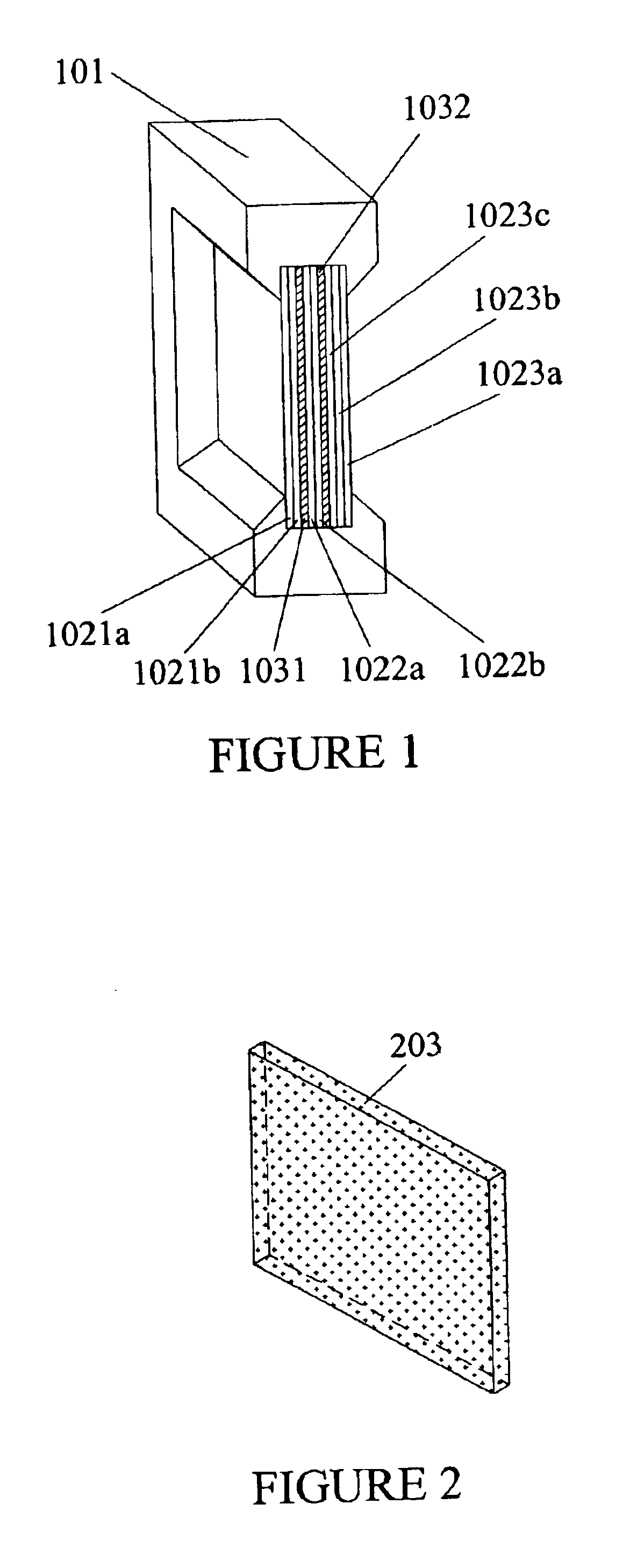

Electromagnetic radiation attenuating and scattering member with improved thermal stability

ActiveUS6912049B2Improve thermal stabilityLower requirementPhotometry using reference valueDiffusing elementsInvarSpectralon

The present invention provides a thermally stable reference member comprising, at least one radiation attenuating element and at least one radiation scattering element. The radiation attenuating element comprising at least one aperture for transmission of radiation therethrough. The attenuating and scattering elements placed in series so that radiation transmitted through the reference member passes through each of the attenuating and scattering elements. The attenuating and scattering elements of the reference member may further comprise a thermally stable mount to hold the elements in a selected position relative to each other, and in relation to an instrument, or the elements may be bonded together. The radiation attenuating element may be comprised of a material selected from the group consisting of INVAR, tungsten, brass, and a material substantially non-transparent for incident radiation, and the radiation scattering element may be comprised of a radiation scattering material selected from the group consisting of opalescent glass, SPECTRALON, PTFE, ZERODUR, fused silica, quartz, sapphire, diamond, and a transparent material with essentially low thermal expansion.

Owner:TYCO HEALTHCARE GRP LP

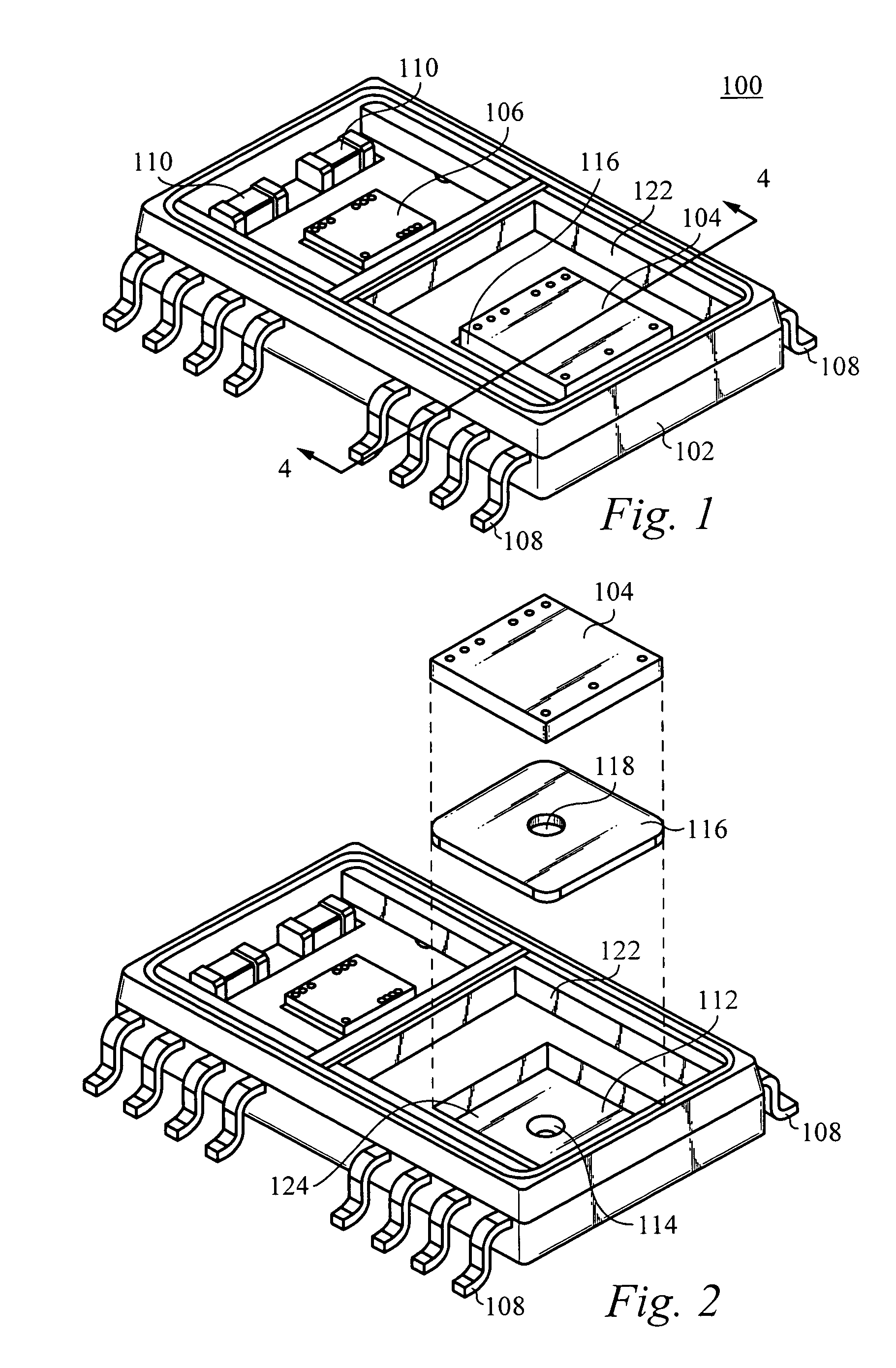

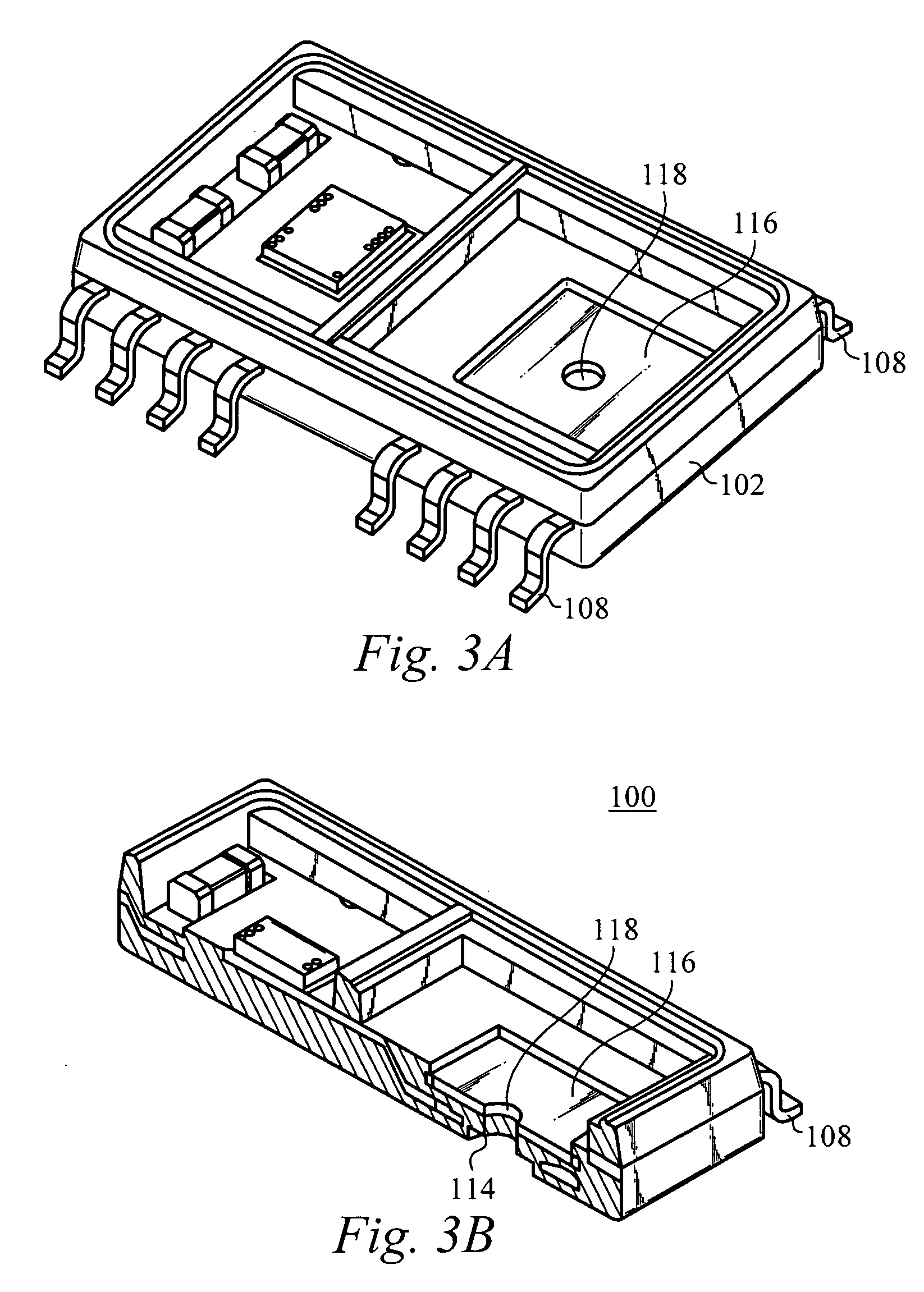

MEMS device package with thermally compliant insert

InactiveUS20070228499A1Easy to operateSolid-state devicesMicrostructural devicesInvarSignal conditioning

A low cost micro-electronic package for MEMS applications includes a package substrate, a MEMS device and a buffer insert which is placed between the MEMS device and the package substrate. The buffer insert has a coefficient of thermal expansion (CTE) which is compatible with the material of the MEMS device and is sufficiently rigid to isolate the MEMS device from thermal, mechanical and other physical stresses applied to the package substrate. In an embodiment, the package is formed as an integrated device which includes both the MEMS device and a signal conditioning integrated circuit, potentially found in the same die. The substrate insert may be made of a material having a CTE value compatible with silicon (Si), such as Kovar, Invar, or an appropriate ceramic material or the like.

Owner:S3C

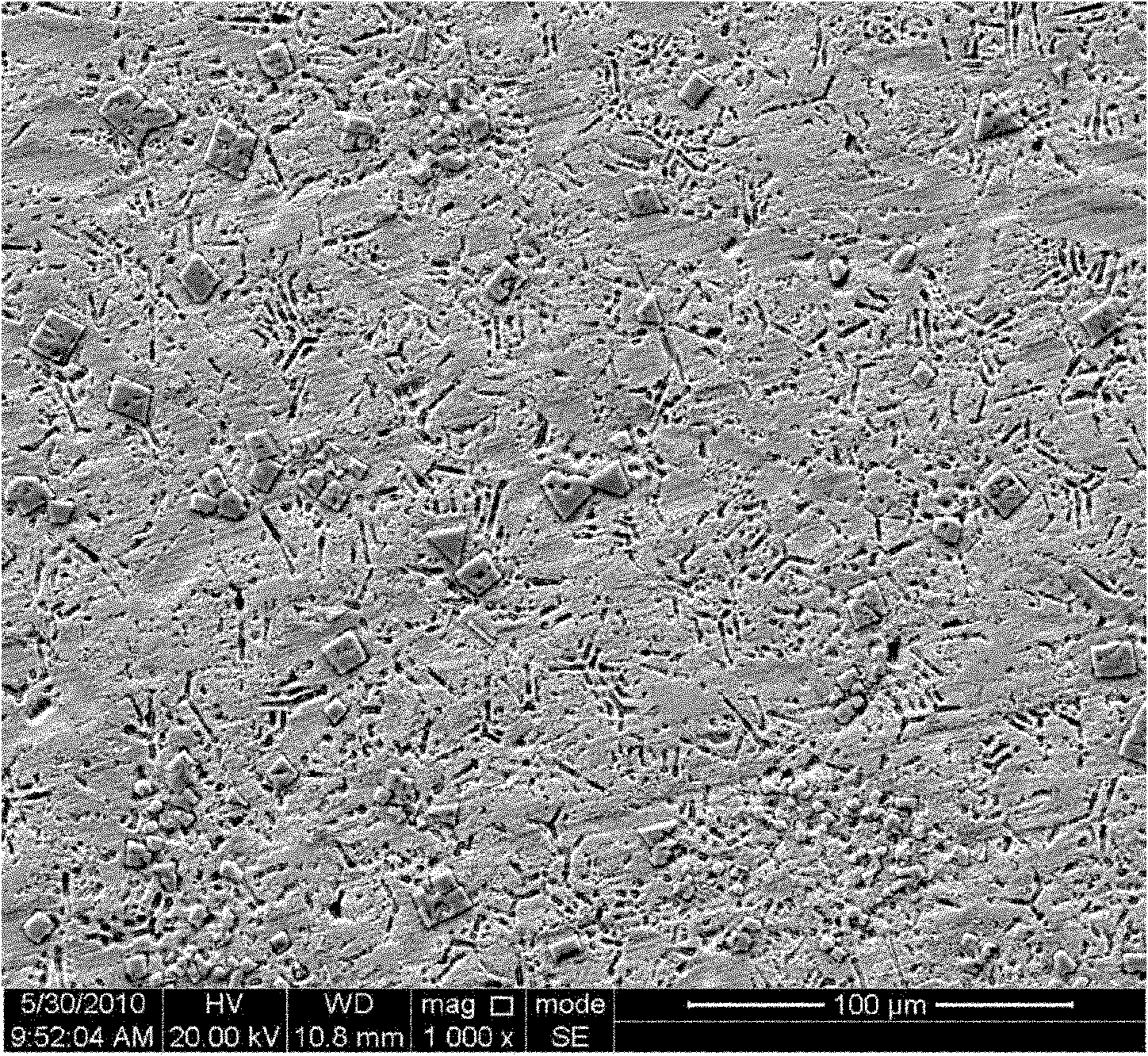

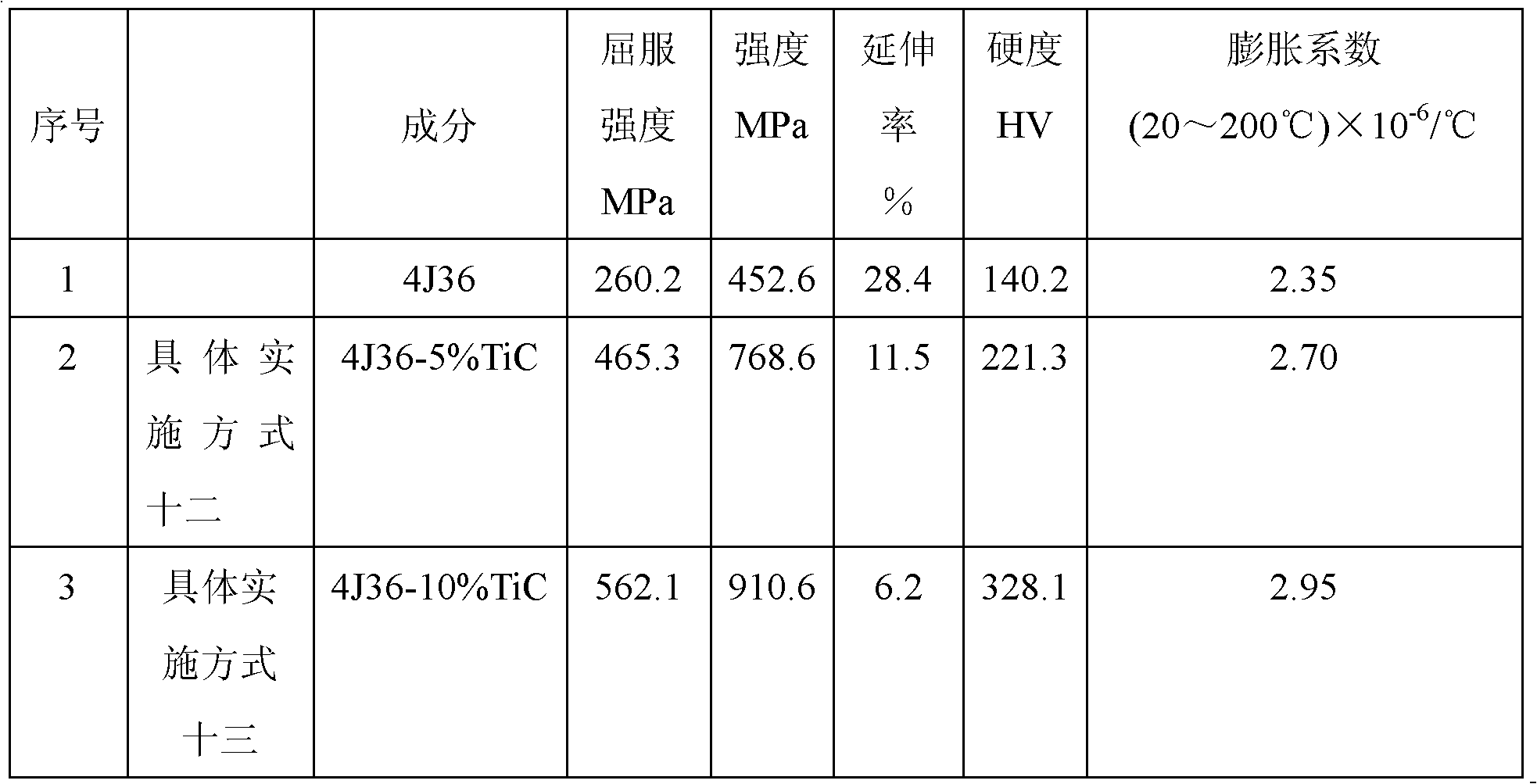

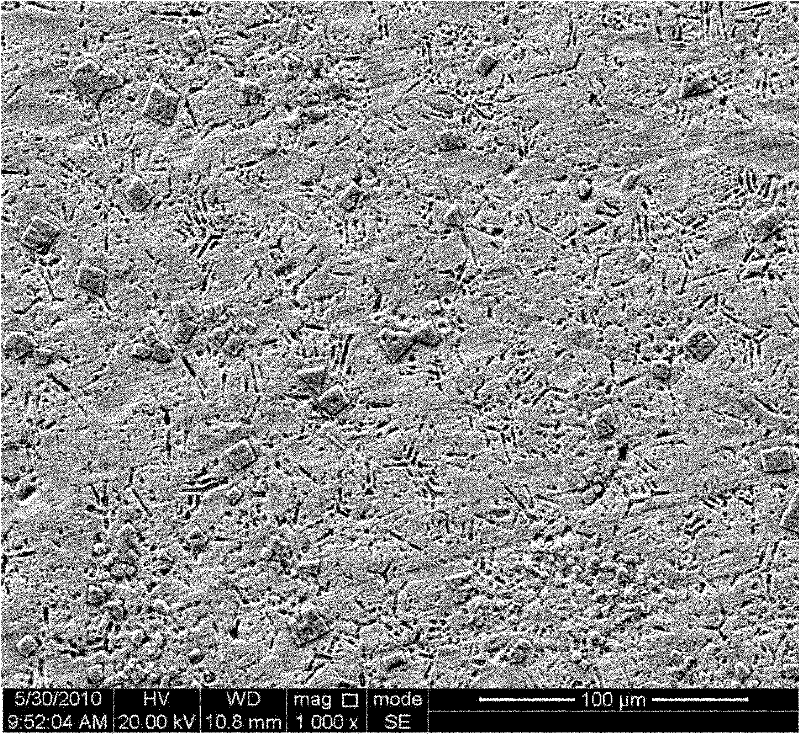

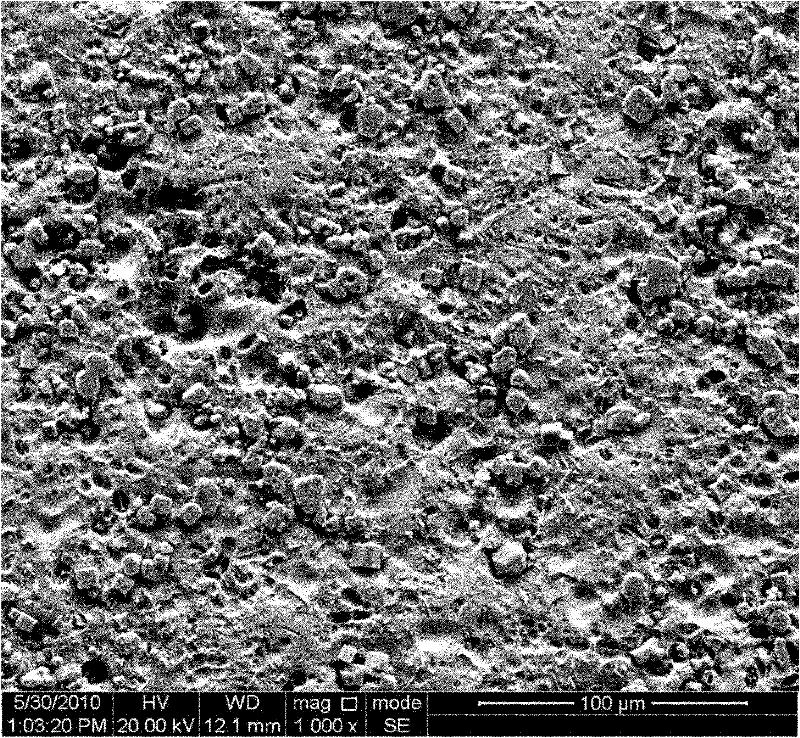

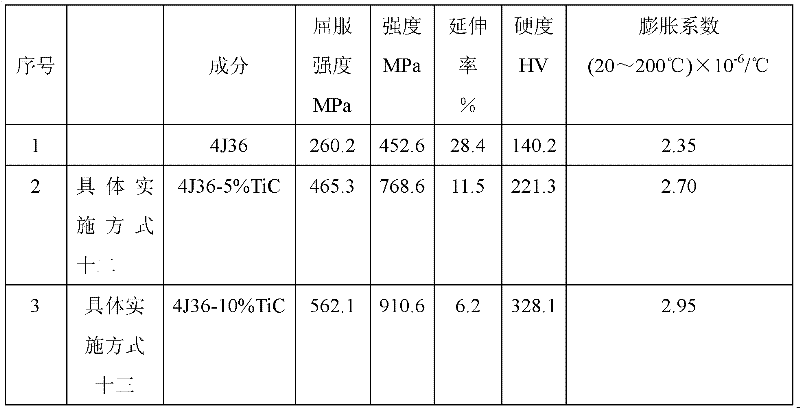

Preparation method of high-strength ultralow-expansion invar-based composite material

The invention relates to a preparation method of an invar-based composite material, in particular to a preparation method of a high-strength ultralow-expansion invar-based composite material. The invention aims to solve the technical problems that the deformation machining technique for the high-strength invar is complex and the high-strength invar is difficult to be machined into large-size components. The method comprises the following steps: 1. preparing high-purity titanium powder and carbon powder precast blocks; 2. smelting invar to obtain molten mass; 3. adding the precast blocks into the molten mass in step 2, and casting to obtain cast ingots or castings while keeping the temperature constant; and 4. carrying out heat treatment to obtain the high-strength ultralow-expansion invar-based composite material. Compared with the prior art, the high-strength ultralow-expansion invar-based composite material in the invention has the advantage of simple control on composition and technique and low cost, can be directly formed by casting without complex deformation hardening technique, does not contain precious metals, and particularly can control the coefficient of expansion of the invar at low level while greatly enhancing the strength of the low-expansion invar.

Owner:HARBIN INST OF TECH

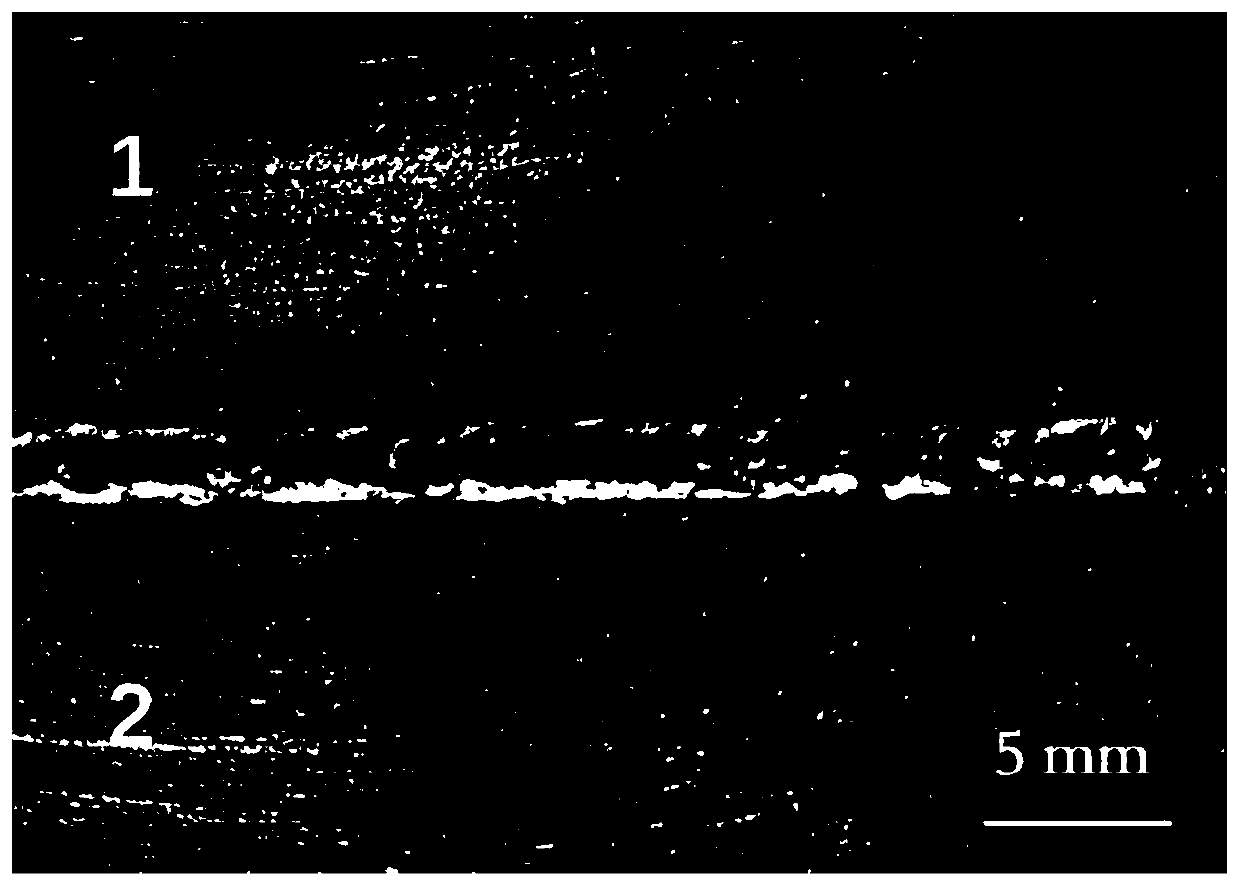

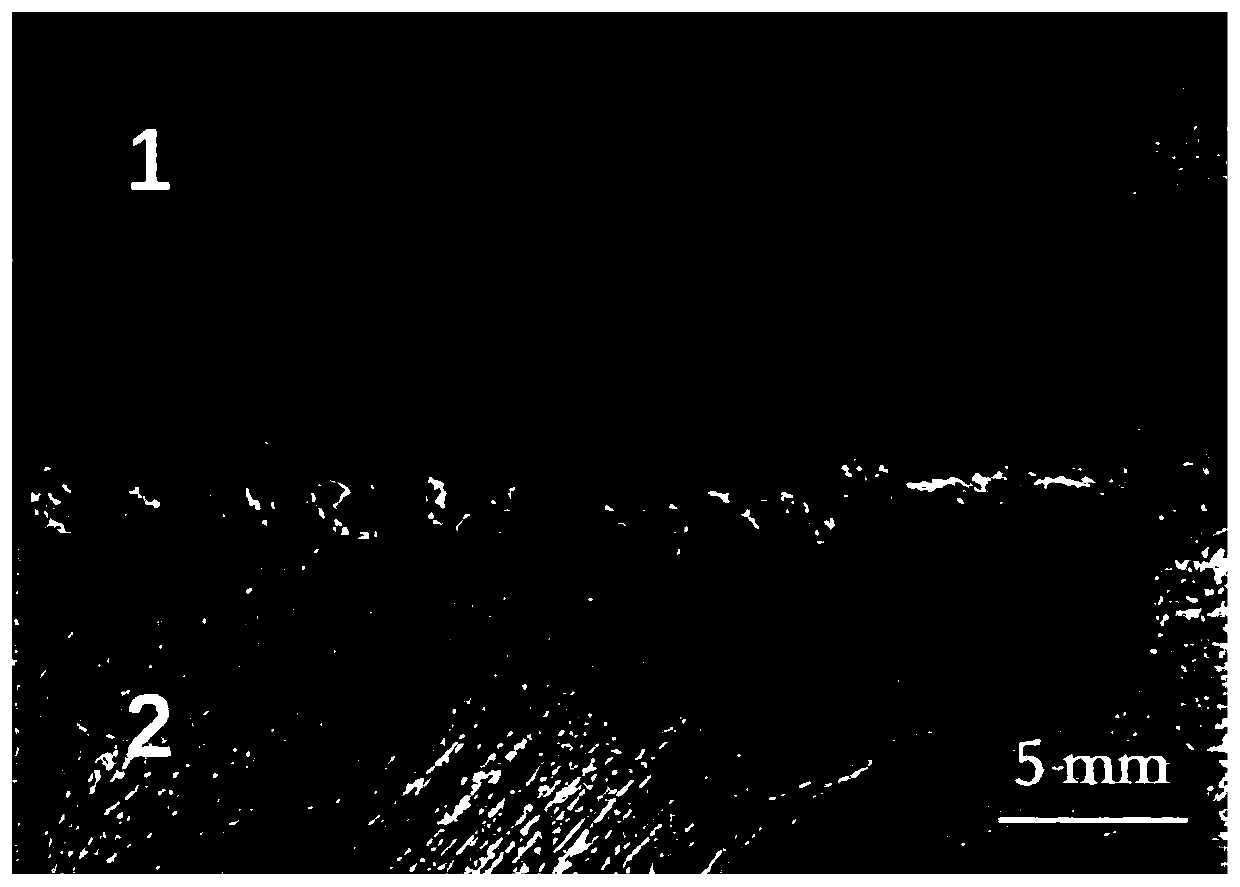

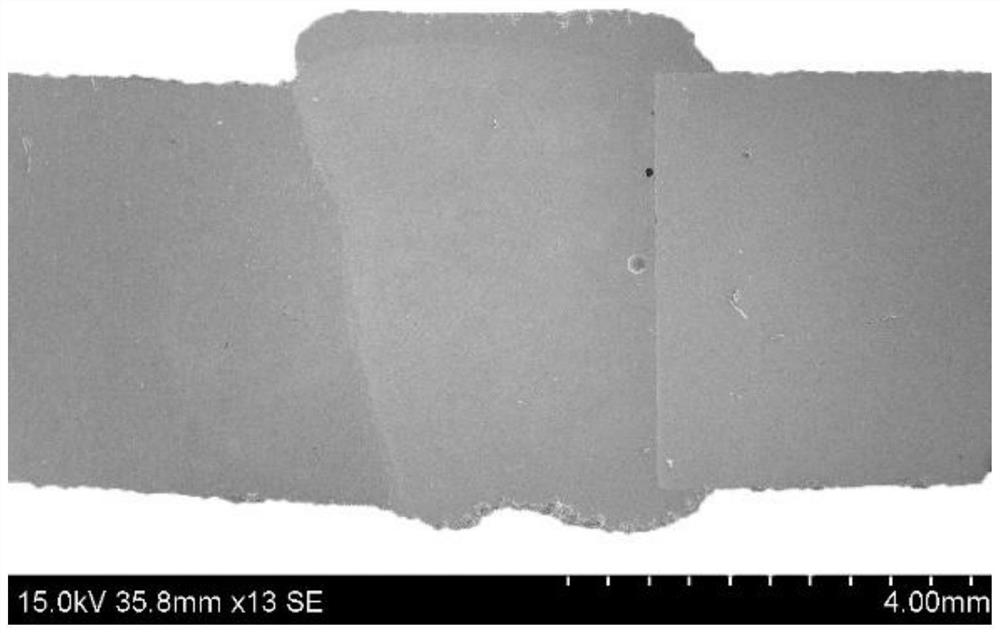

Metallographic corrosive agent for invar welded joint welded by using M93 welding wires and preparation method for metallographic corrosive agent

InactiveCN103014710AReasonable designFast corrosionPreparing sample for investigationInvarMaterials science

The invention relates to metallographic chemical corrosive agents and preparation methods thereof, in particular to a metallographic corrosive agent for an invar welded joint welded by using M93 welding wires and a preparation method for the metallographic corrosive agent. The metallographic corrosive agent and the preparation method thereof aim at solving the metallographic problem of the invar welded joint welded by using the M93 welding wires. The metallographic corrosive agent is prepared by mixing HCl solution with the mass concentration of 36-38%, FeCl3 and water. The preparation method includes: A, accurately weighing HCl solution, FeCl3 and water; B, adding the weighed FeCl3 into the water, and stirring until completely dissolving to form a uniform mixture; and C, slowly adding the HCl into the mixture to form the metallographic corrosive agent, namely, preparation of the metallographic corrosive agent for the invar welded joint welded by using the M93 welding wires is finished.

Owner:HARBIN INST OF TECH

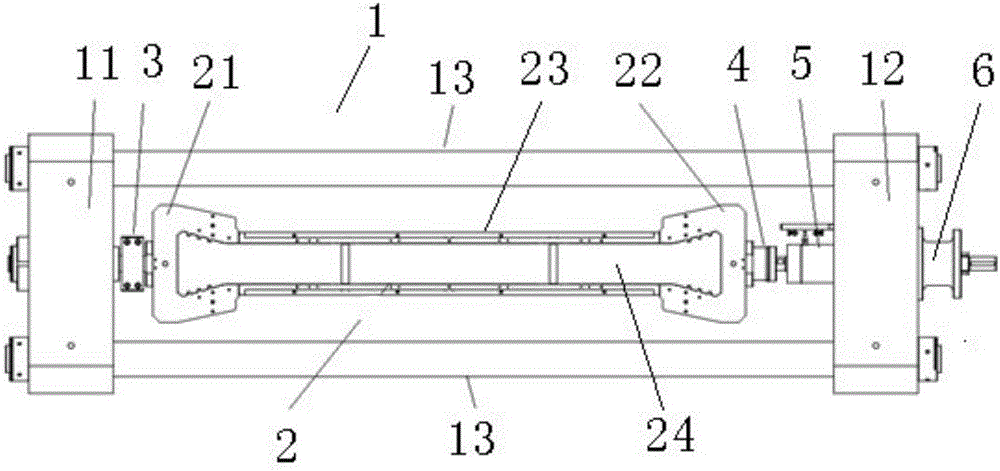

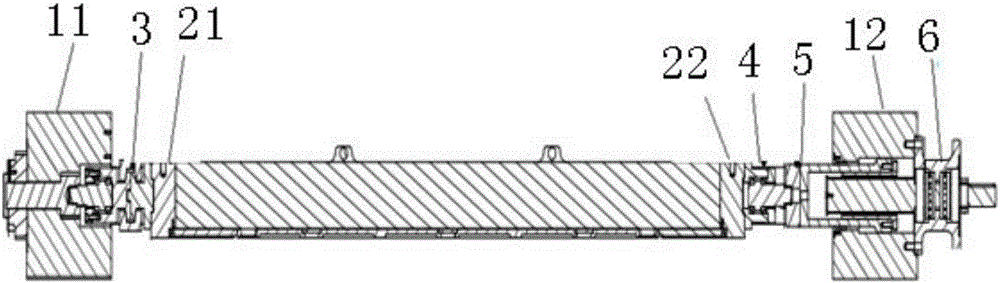

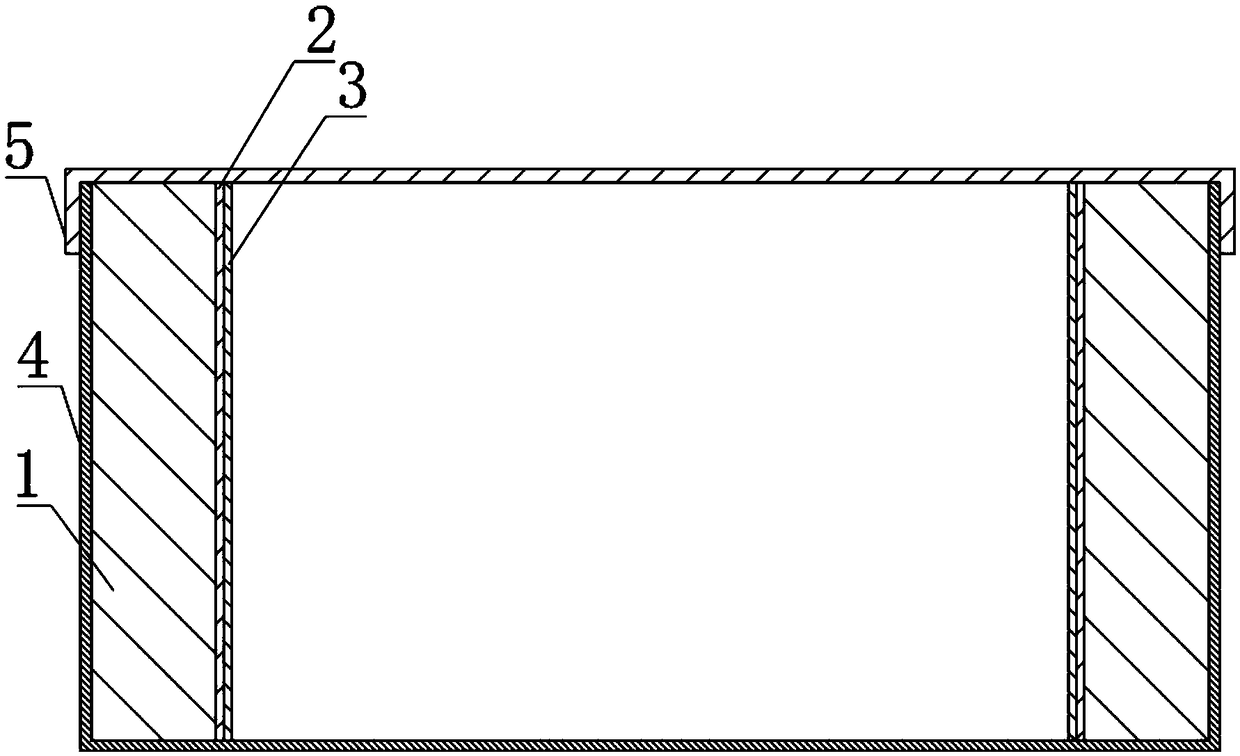

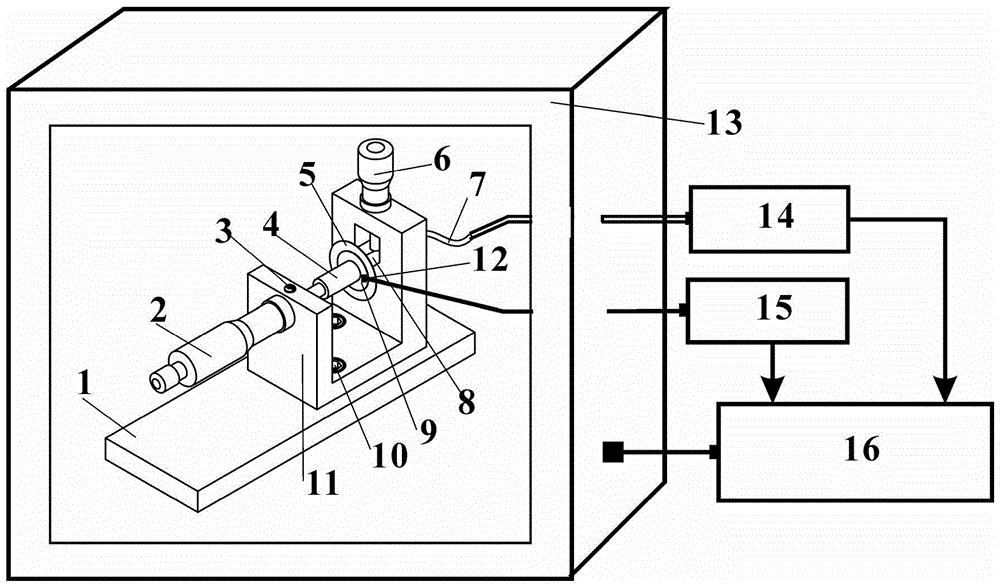

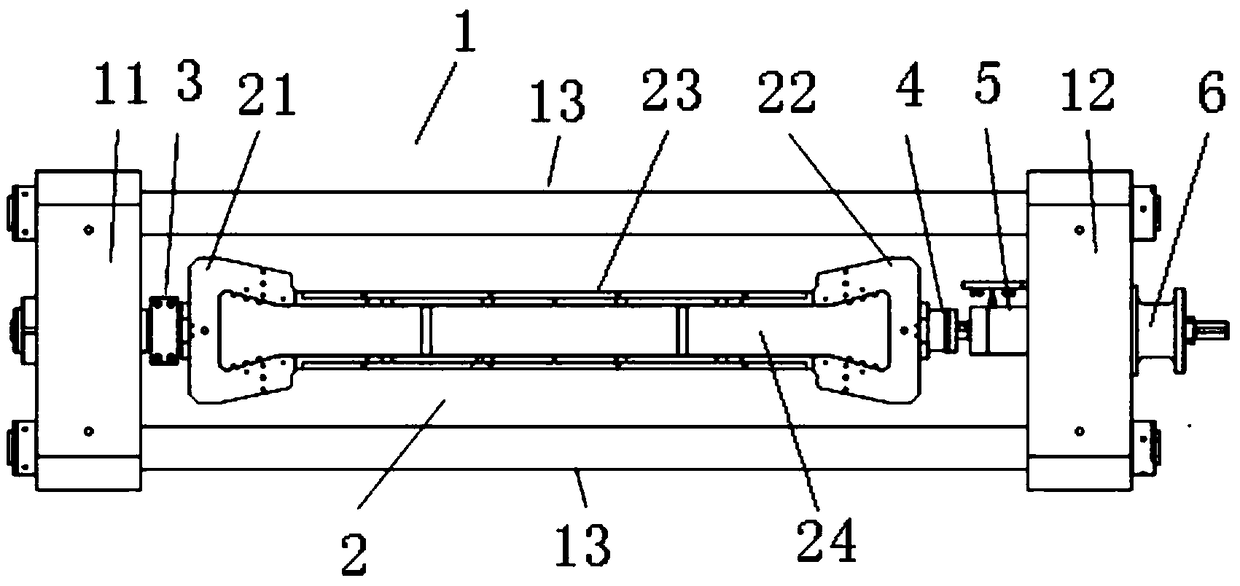

Concrete temperature stress testing machine with temperature deformation self-compensation function

ActiveCN106092724AAchieve impactImprove temperature regulation efficiencyMaterial testing goodsStrength propertiesTemperature stressInvar

The invention discloses a concrete temperature stress testing machine with a temperature deformation self-compensation function and belongs to the technical field of concrete temperature stress and deformation testing simulation. A polished rod is manufactured from No.4J36 invar, a left fixed end, a right fixed end, fixed end universal joints and movable end universal joints are manufactured from No.4J36 invar, and a fixed chuck, a movable chuck and a load sensor are manufactured from No.45 steel. Parts of the testing machine are made from different steel materials, the combination length of the parts is designed according to a certain proportion, when outside temperature changes, the total temperature deformation difference generated by all steel parts of the concrete temperature stress testing machine can be zero, accordingly temperature deformation, caused by outside temperature change, of steel of the testing machine is offset, and temperature deformation self-compensation of the testing machine is achieved.

Owner:TSINGHUA UNIV

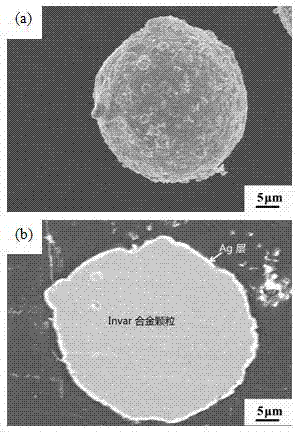

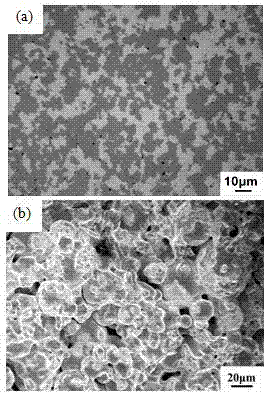

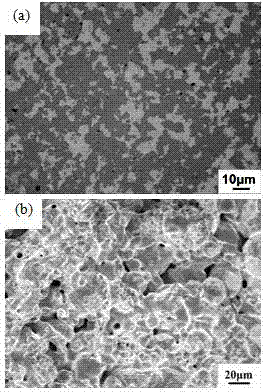

Preparation method of Cu/Ag (Invar) composite material for electronic packaging

InactiveCN107312945AAchieve densificationImprove mechanical propertiesTransportation and packagingMetal-working apparatusInvarChemical plating

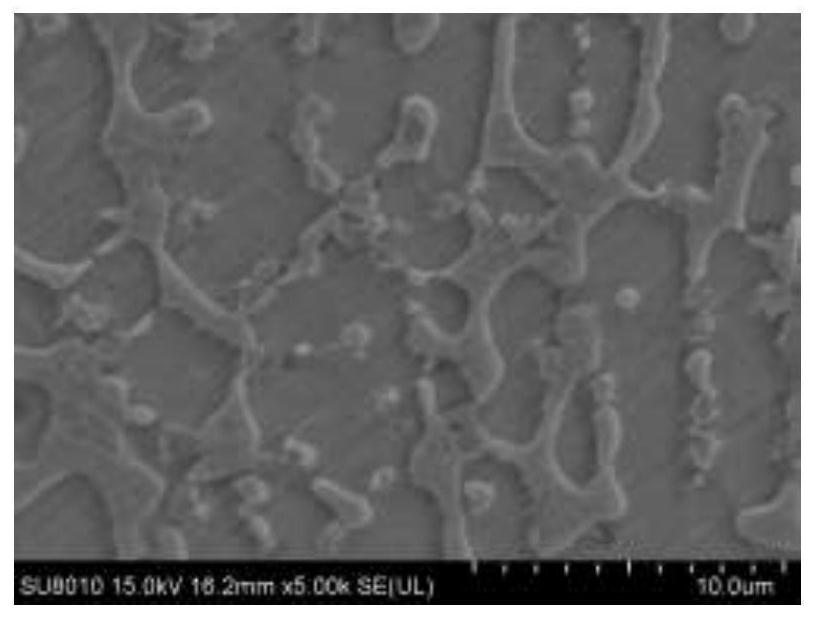

The invention relates to a preparation method of a Cu / Ag (Invar) composite material for electronic packaging. A chemical plating solution system of which a main salt is AgNO3 and a reducing agent is KNaC4H4O6 is used for chemically plating Ag on Invar powder of which the average particle size is 25 to 50 mum so as to prepare chemical plating Ag (Invar) composite powder, the Ag (Invar) composite powder and Cu powder of which the average particle size is 25 to 50 mum are used as raw materials and are mixed according to the component Cu of 30 to 50wt%, then zinc stearate of which the overall weight is 0.5wt% of the raw material powder is added as a lubricating agent, the raw materials are mixed by a double-shaft roller, are pressed in one direction under 300 to 600 MPa, are protected in a high-purity H2 atmosphere, are insulated for 1 to 3 h at 650 to 800 DEG C and are sintered under normal pressure so as to prepare the Cu / Ag (Invar) composite material, and a multi-pass cold rolling and annealing thermomechanical treatment process is adopted to realize the near-complete densification of the composite material. The prepared 40wt% Cu / Ag (Invar) composite material has excellent overall performance and can be used as a high-performance electronic packaging heat sink material, the density can reach 99%, the hardness is HV256, the coefficient of thermal expansion is 11.2*10<-6>K<-1>, and the heat conductivity is 53.7 W.(m.K)<-1>.

Owner:HEFEI UNIV OF TECH

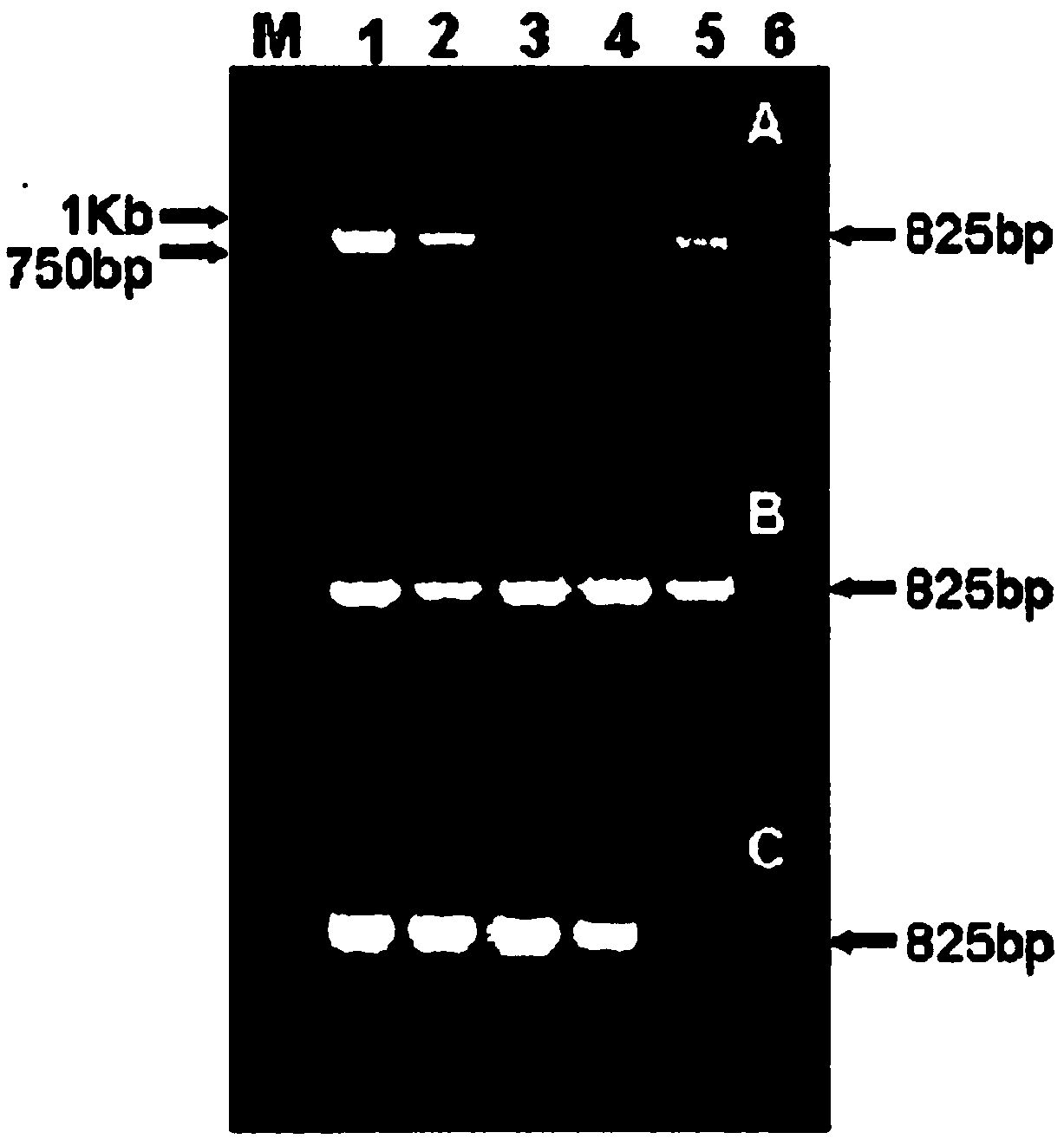

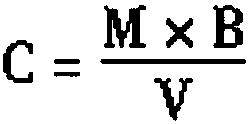

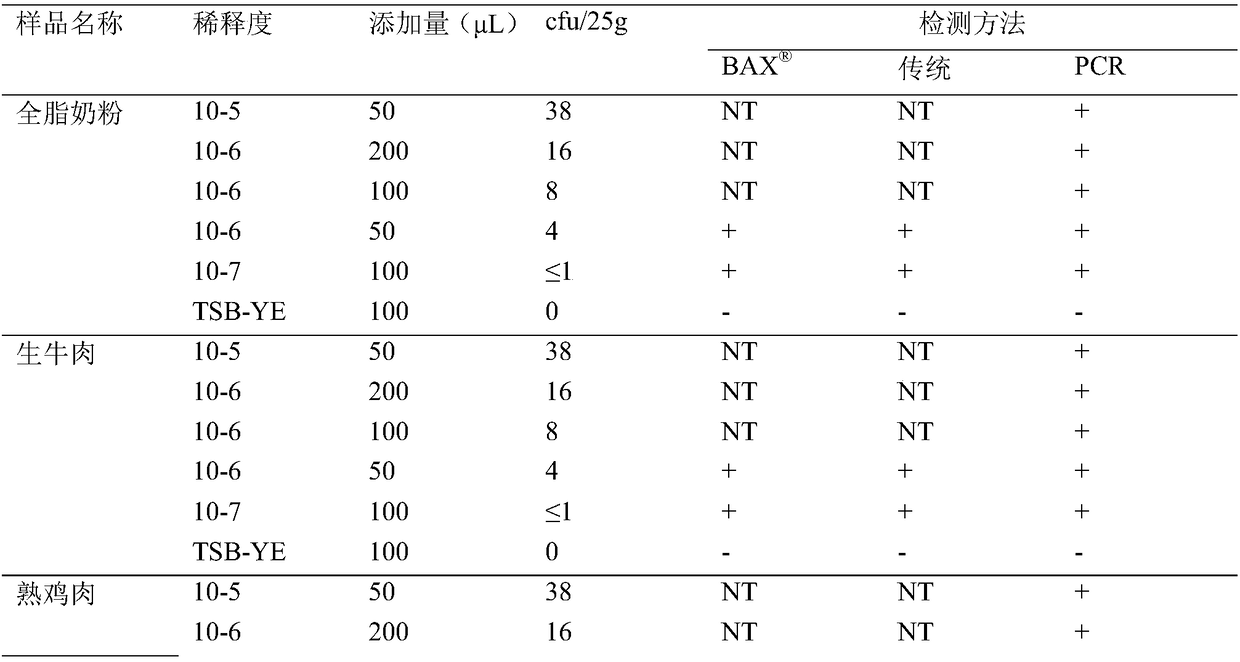

Method for rapidly detecting Salmonella in foods

InactiveCN108203736AThe test results are consistentMeet testing requirementsMicrobiological testing/measurementMicroorganism based processesInvarPcr method

The invention provides a method for rapidly detecting Salmonella in foods and relates to the technical field of food detection. A PCR method is used to detect inVA genes of Salmonella in a to-be-tested food sample. The method includes the steps of adding the to-be-tested food sample into buffered peptone water to enrich the bacteria, then washing the bacteria with physiological saline, boiling lysed cells, and centrifuging to obtain the supernatant; taking the obtained supernatant as a PCR reaction template, and using detection primers of Salmonella inVA gene for PCR detection; wherein the detection primers are as follows: an upstream primer inVAF:5'-tcctccgctctgtctactta-3', and a downstream primer inVAR: 5'-accgaaatattcattgacgtt-3'. The detection results of the method are consistent withthose of a conventional culture method and a BAX system, the detection limit is 100cfu / 25g, and the accuracy is 100%.

Owner:BEIJING UNIV OF TECH

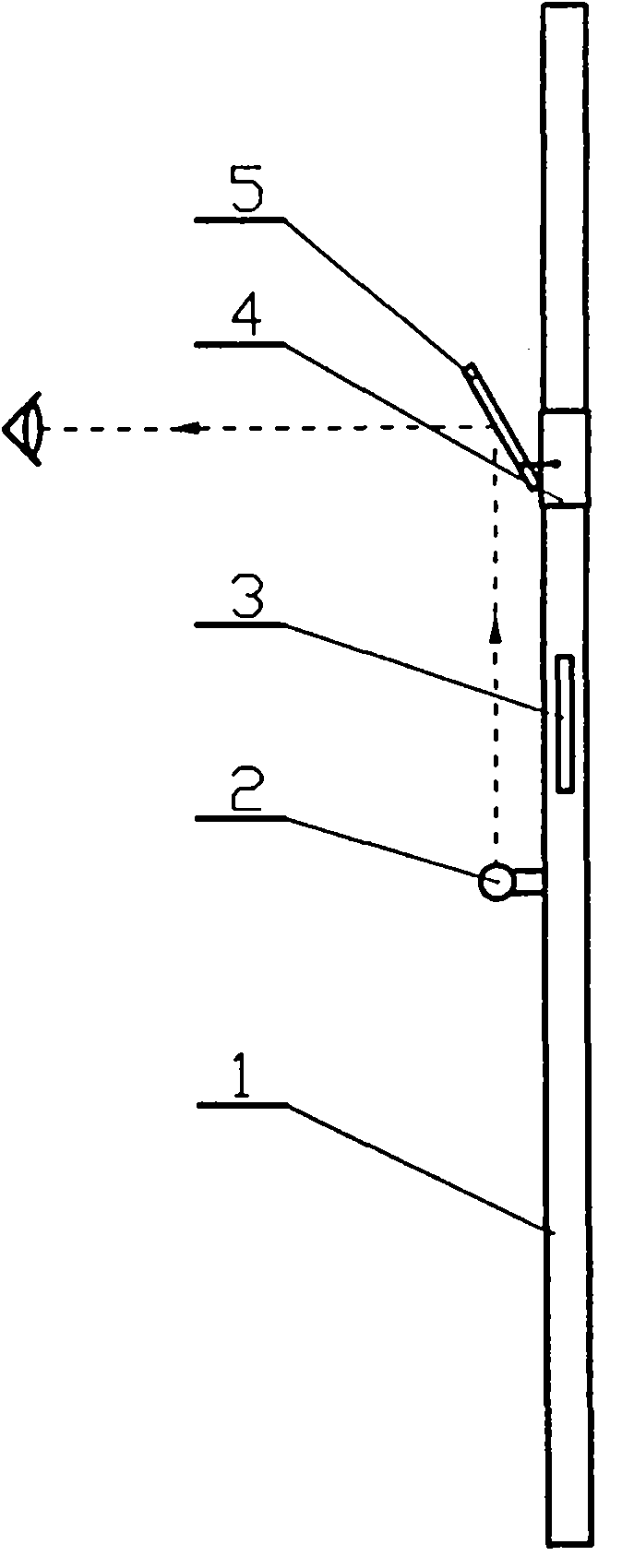

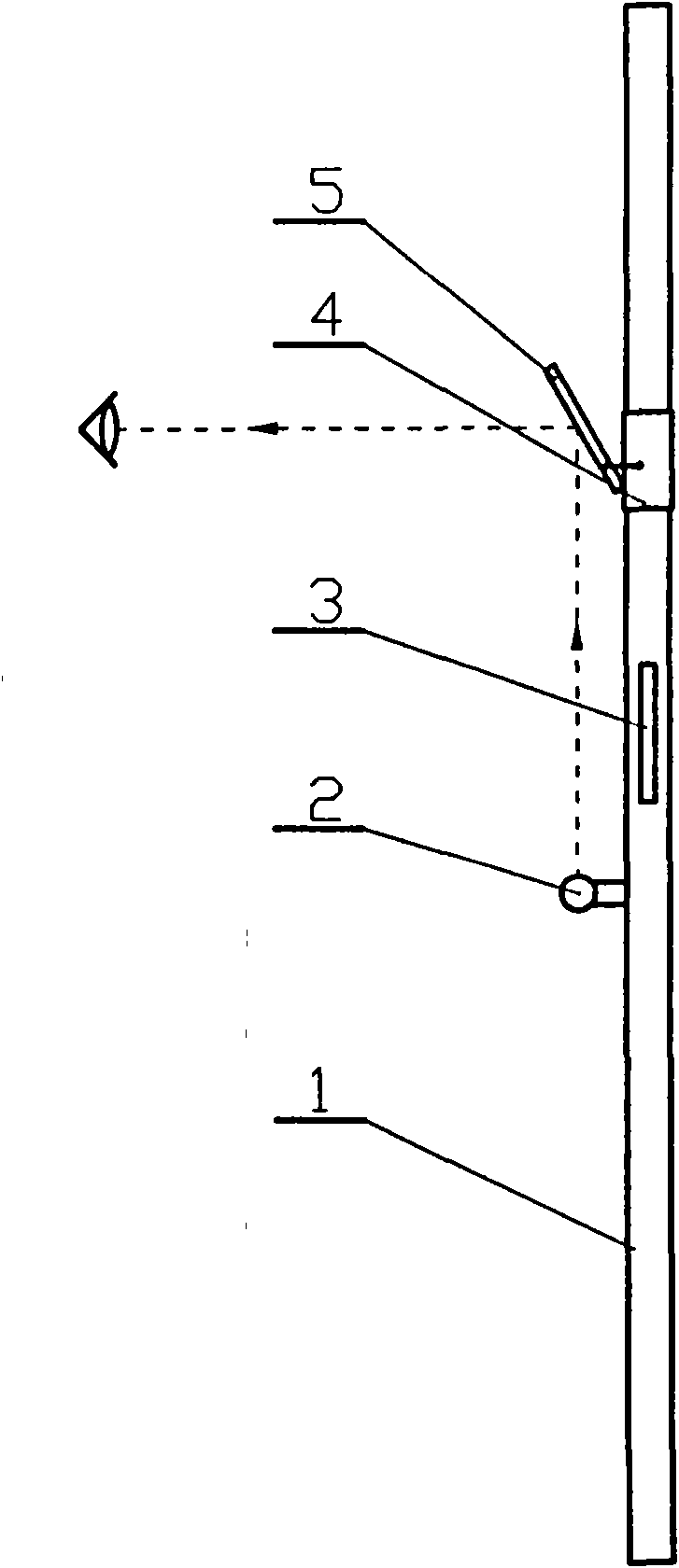

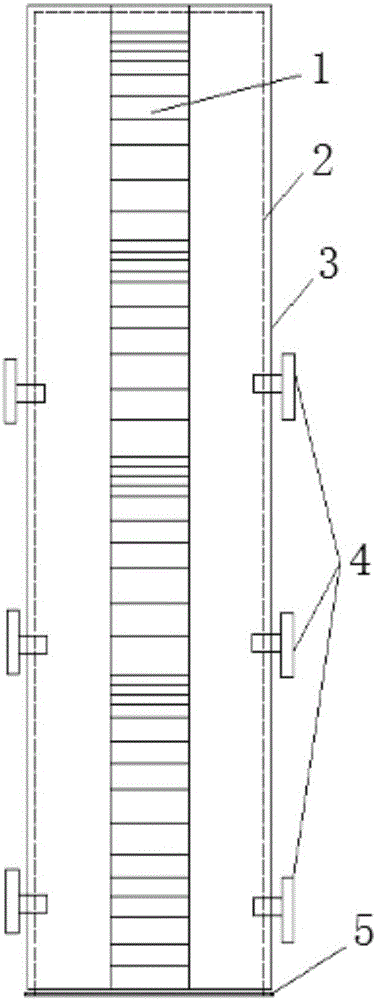

Novel precise invar leveling staff

The invention relates to a novel precise invar leveling staff. The novel precise invar leveling staff is provided with a prolate ruler with scales on the front surface; a handle is arranged on one side of the ruler; a leveling bubble is arranged at the back of the ruler; the upper part of the ruler is connected with a sliding sleeve capable of sliding up and down; and the sliding sleeve is positioned at the back of the ruler and is hinged with a reflecting mirror capable of adjusting an angle up and down. The novel precise invar leveling staff has a simple structure and convenient use; a user can conveniently align and calibrate the leveling bubble without lowering the head and can observe the conditions of a road surface and a surveyor on the opposite side at the same time to achieve timely communication; and measuring time is effectively saved and personal safety is ensured.

Owner:李鑫

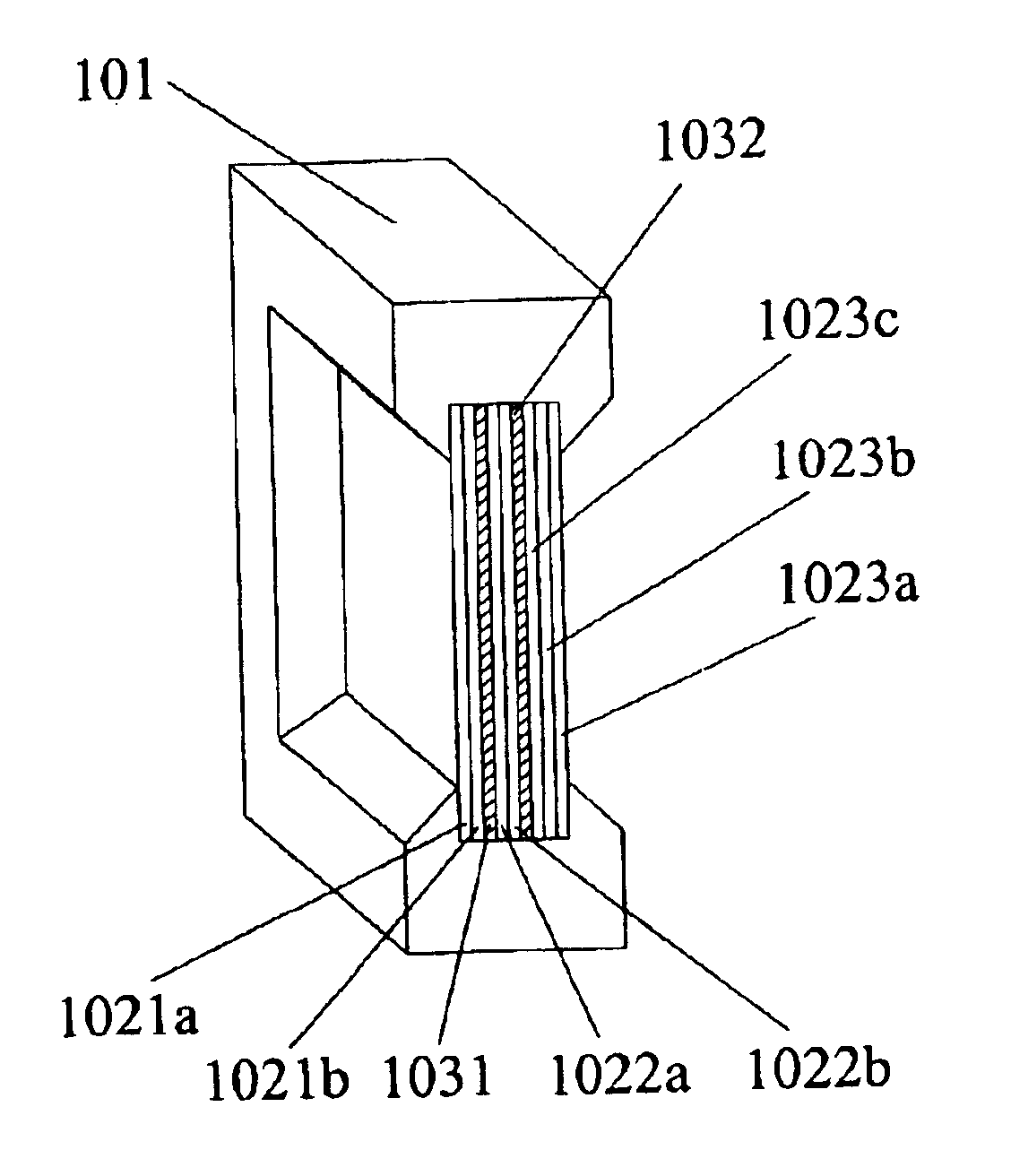

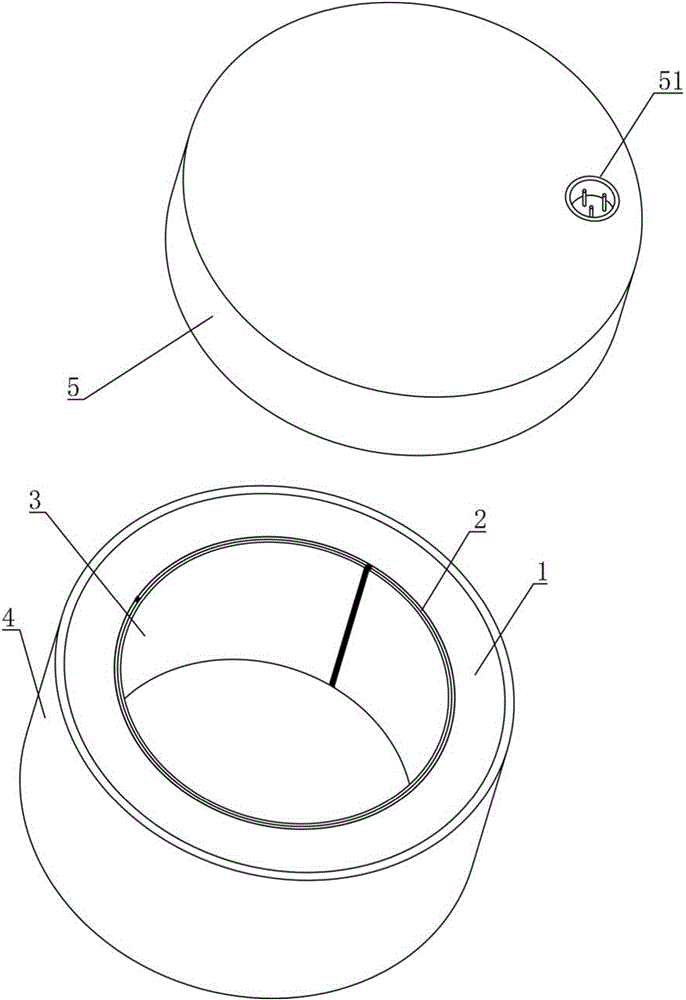

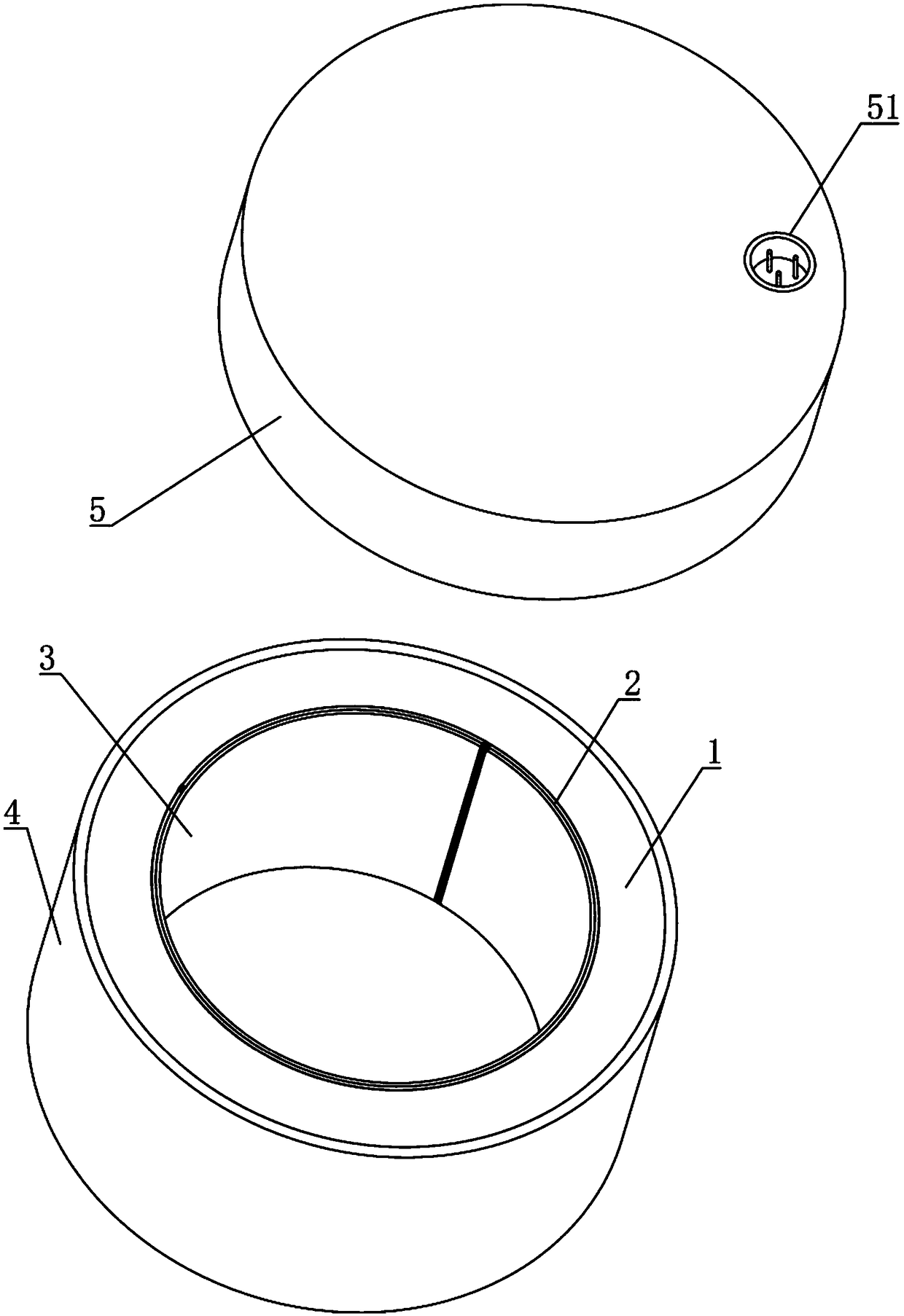

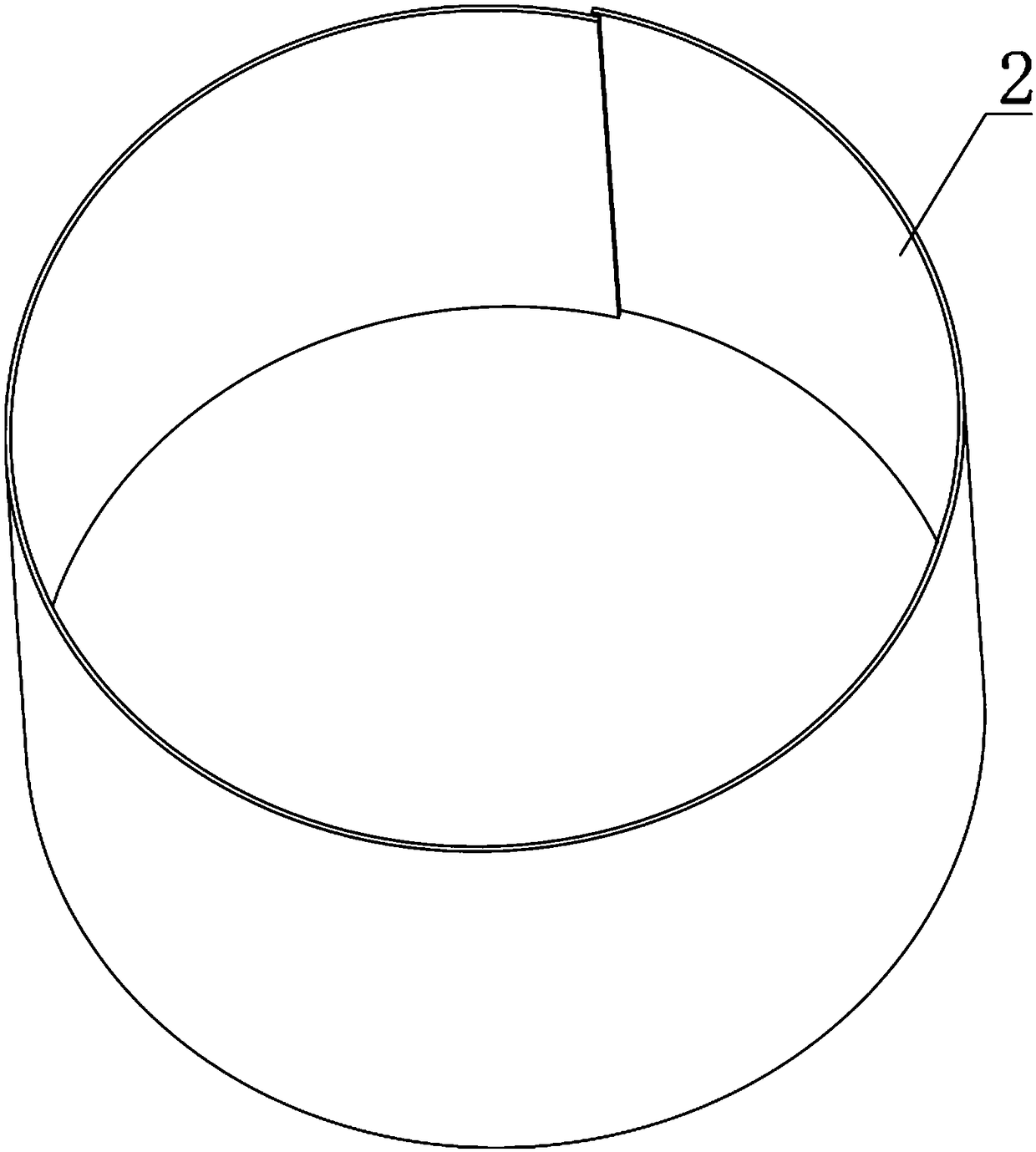

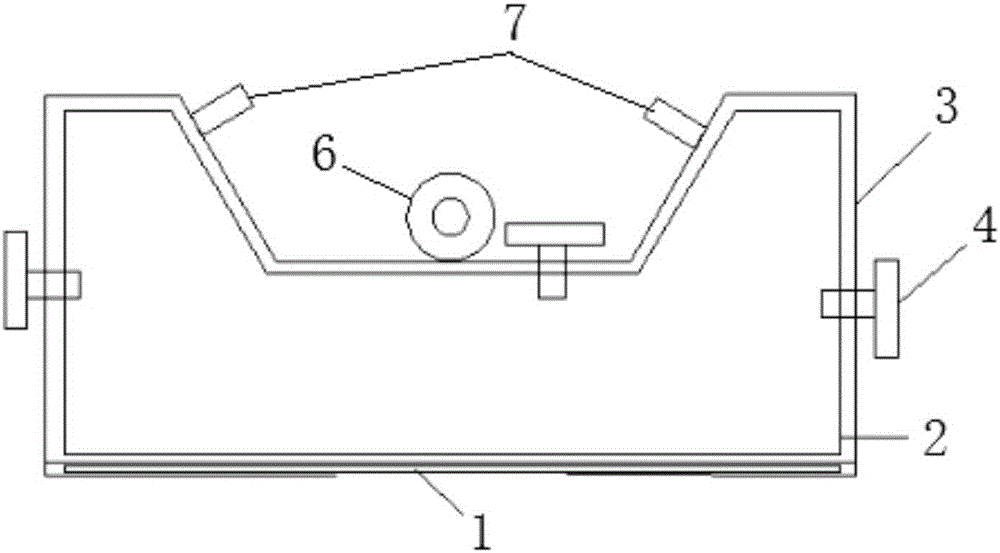

Transduction unit for ultrasonic transducer

ActiveCN106179931AAvoid transmission media from enteringImprove work performanceMechanical vibrations separationInvarElectricity

The invention relates to the technical field of ultrasonic transduction, in particular to a transduction unit for an ultrasonic transducer. The transduction unit comprises a sealed invar shell and a piezoelectric ceramic ring arranged in the invar shell. A silver layer on the outer side of the piezoelectric ceramic ring is tightly attached to the invar shell, an oil medium is removed from the position between the piezoelectric ceramic ring and the shell, and the transduction efficiency is improved. Meanwhile, the silver layer on the outer side of the piezoelectric ceramic ring is tightly attached to the invar shell, so that heat generated by the piezoelectric ceramic ring is dissipated out through the invar shell. Under the condition that heat dissipation is not affected, the problem that ultrasonic wave losses of a transduction unit of an existing ultrasonic transducer exist is solved, in addition, a sealed shell structure is adopted in the transduction unit, so that transmission media are prevented from entering the transducer in the use process, in addition, the heat expansion coefficient of invar is smaller than the heat exchange coefficient of piezoelectric ceramic, so that the fitness between the piezoelectric ceramic ring and the invar shell is better along with increasing of the temperature, and the working performance of the transduction unit is more stable.

Owner:哈尔滨龙声超声技术有限公司

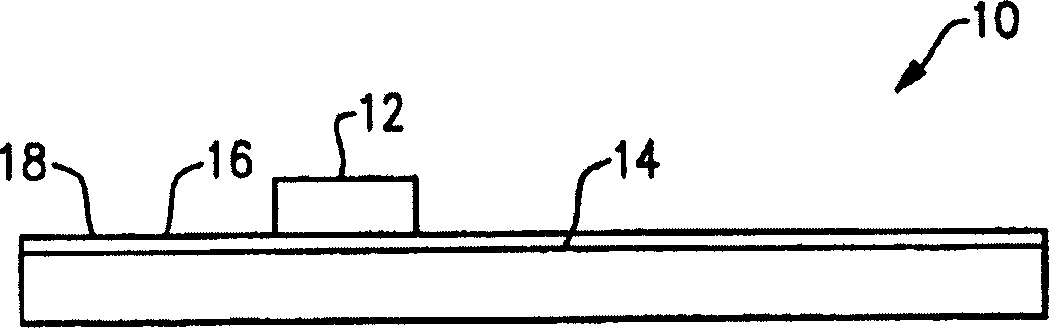

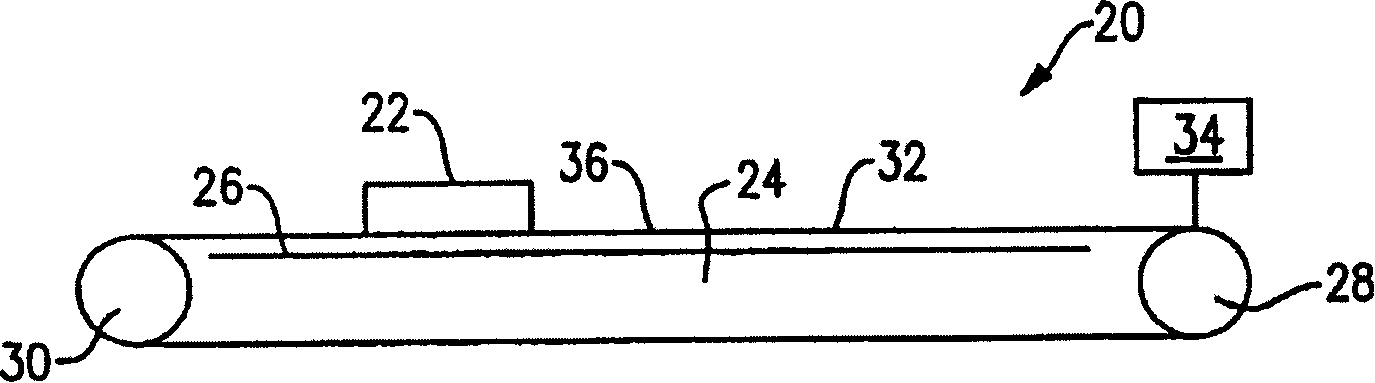

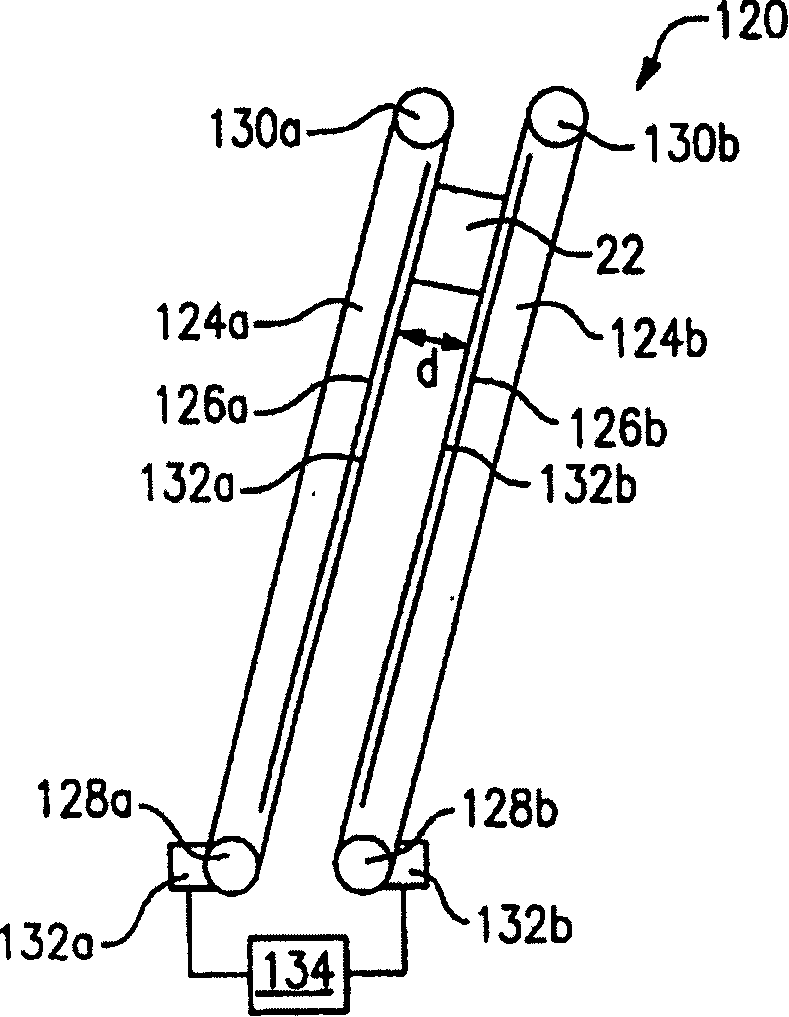

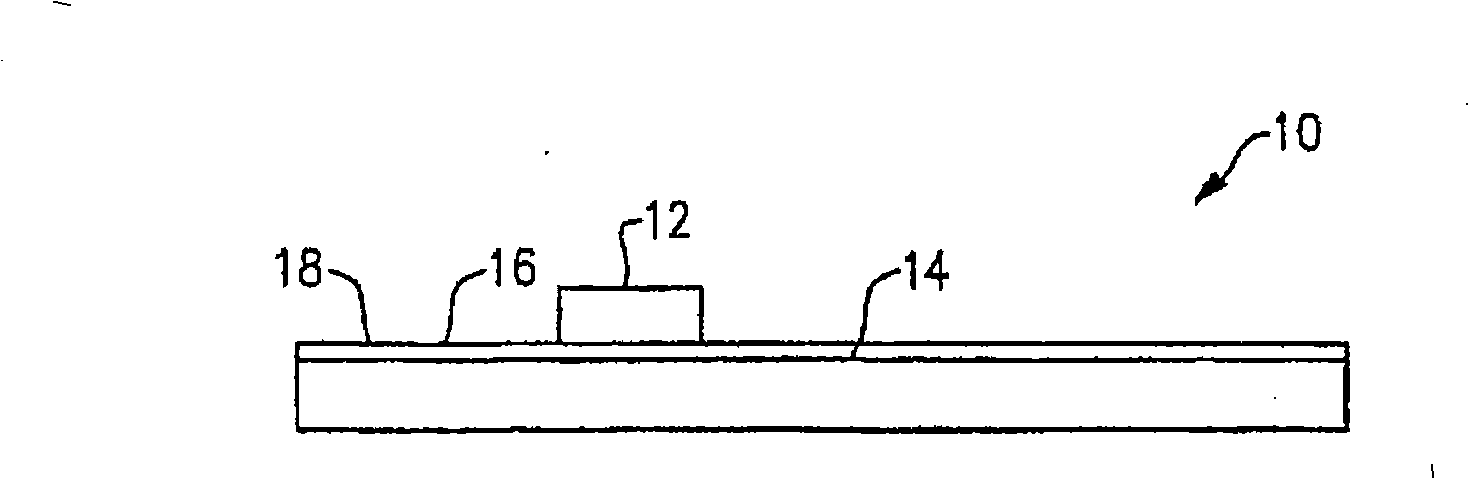

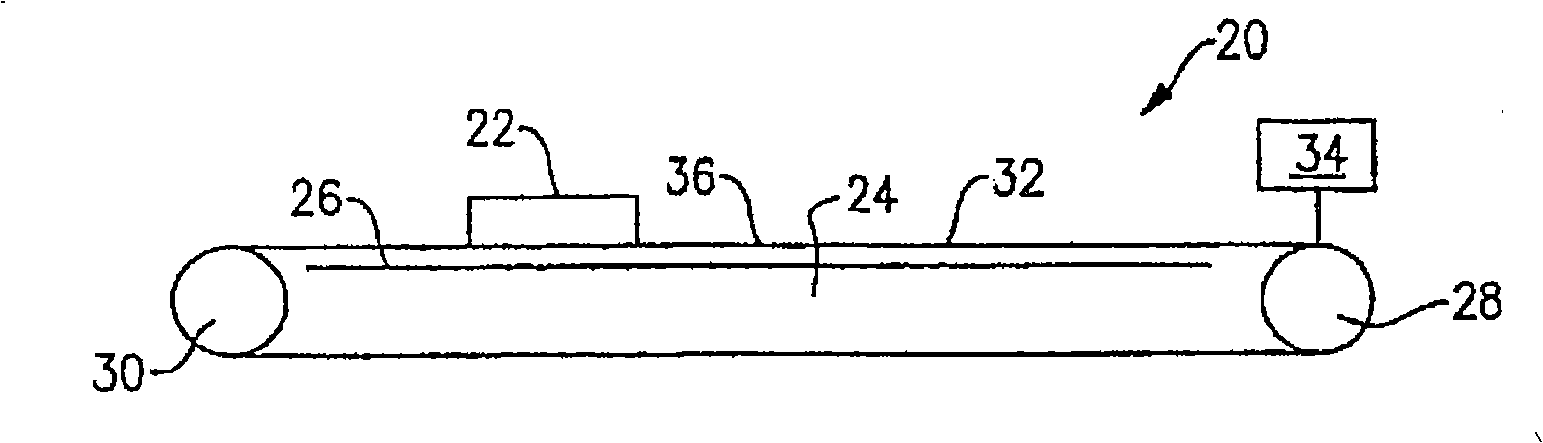

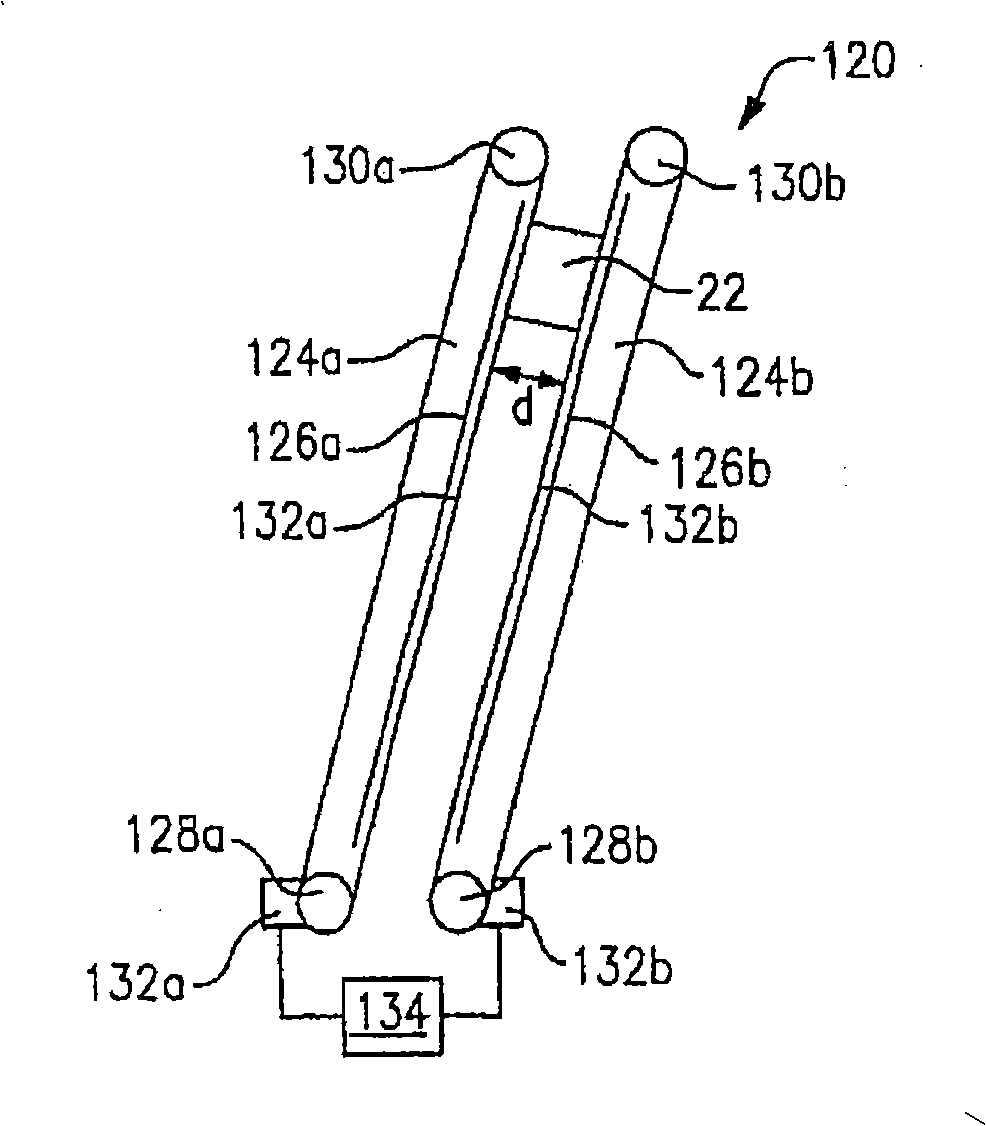

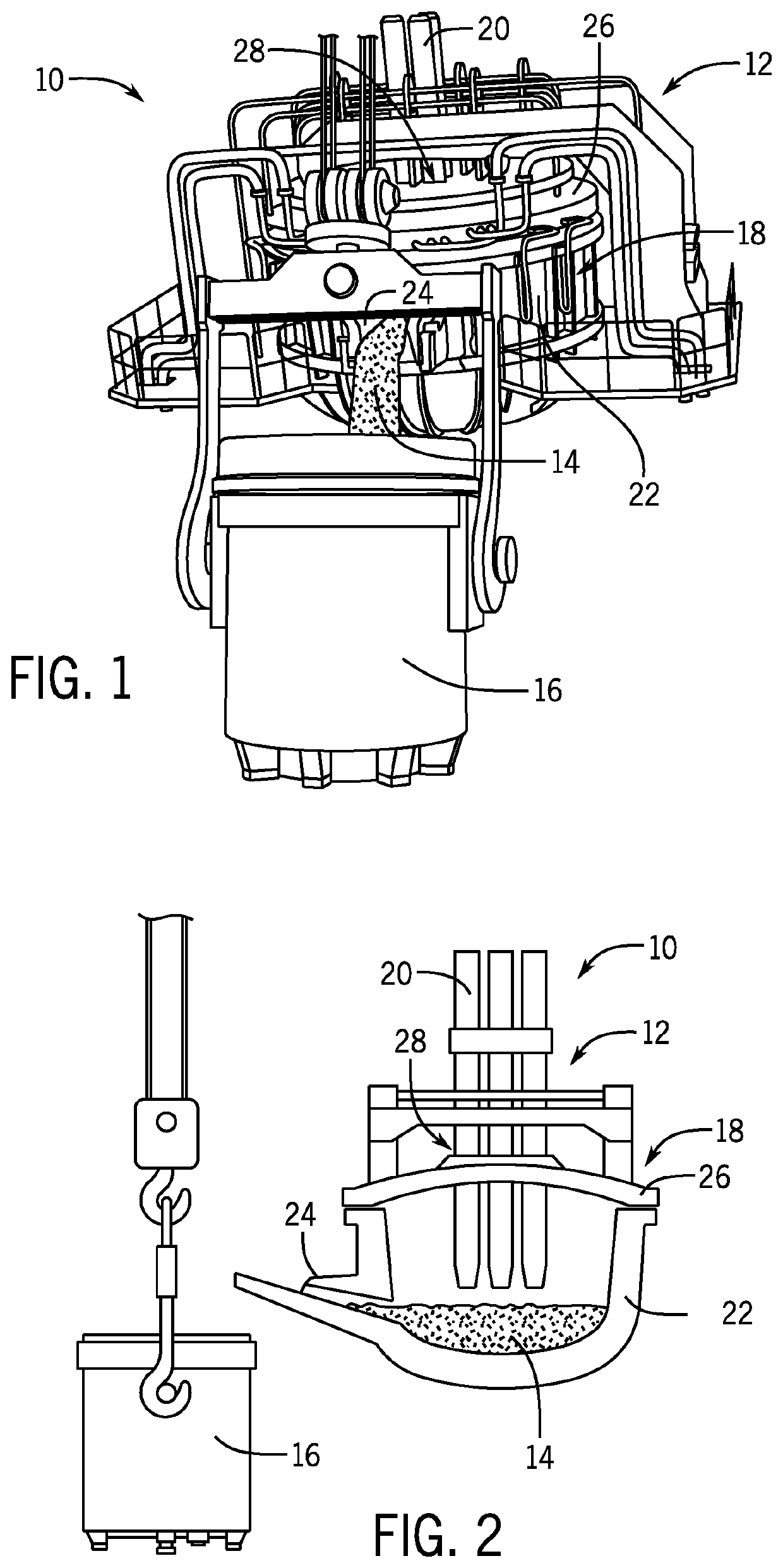

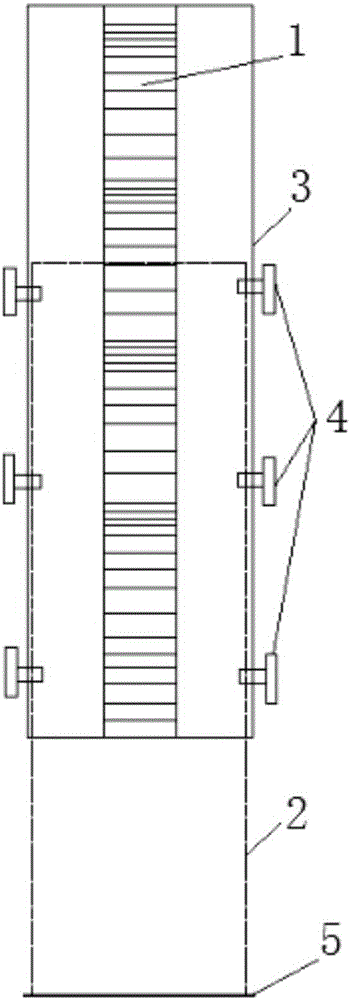

Grilling surface

A grilling component (10) employed to grill food items includes a grilling surface (16) made of a material having a low constant of thermal expansion. In one example, the grilling surface (16) is made of Invar. Invar is a metal allow comprised of Iron and 36% Nickel, and may include other trace elements. Invar has a low constant of thermal expansion and therefore moves and expands very little when heated. The grilling surface (16) further includes a non-stick coating (18), such as Teflon. The grilling surface can also be a conveyor belt (32) which travels over a heater (26).

Owner:开利商用制冷有限公司

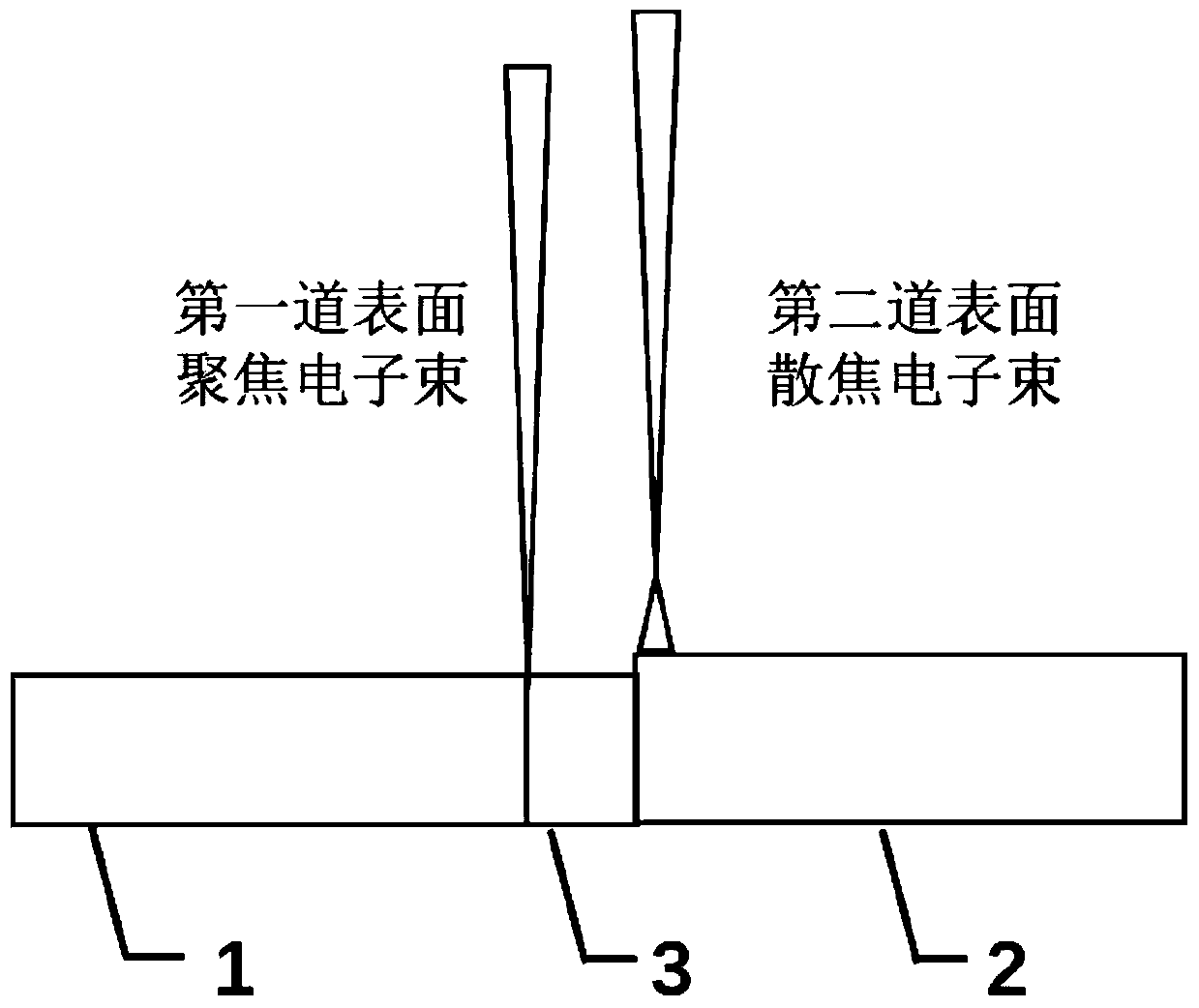

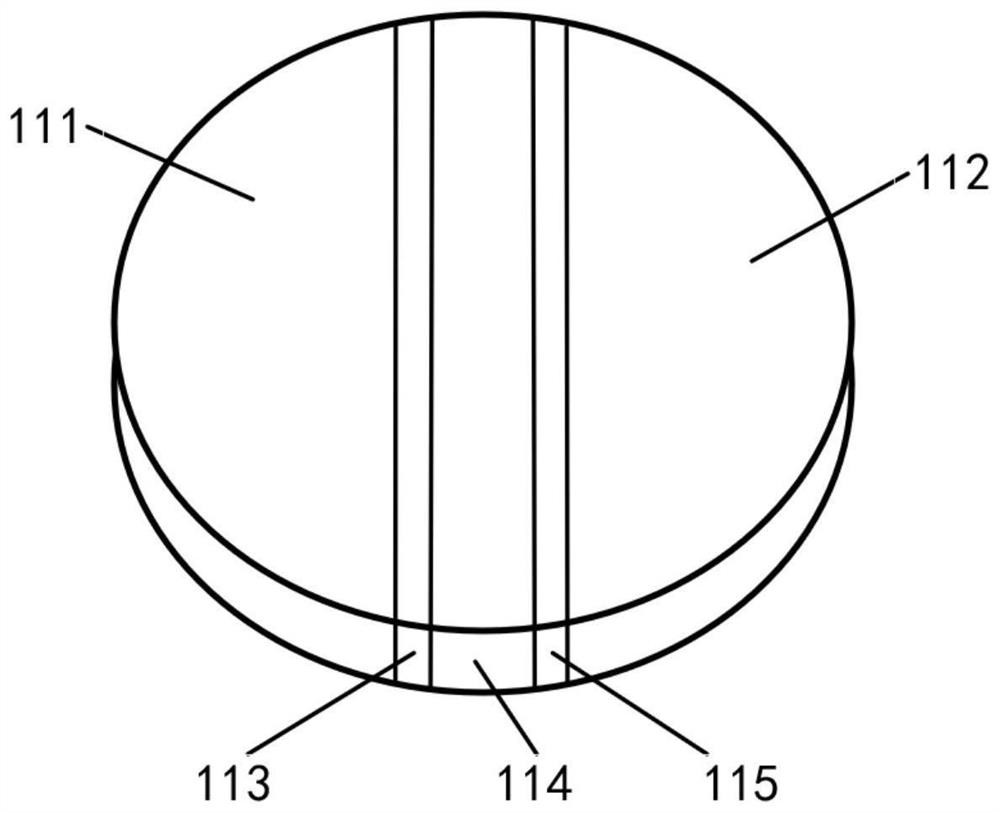

Invar and aluminum alloy dissimilar metal electron beam welding method

ActiveCN110293305AReduce complexityEvolution difficultyElectron beam welding apparatusWelding/soldering/cutting articlesInvarButt welding

The invention belongs to the field of material melting welding and particularly relates to an invar and aluminum alloy dissimilar metal electron beam welding method. Electron beams are adopted as theheat source, an intermediate layer is added between invar and aluminum alloy, electron beam welding between the intermediate layer and the invar is performed first in a two-step butt welding mode, andthen electron beam welding between the intermediate layer and the aluminum alloy is performed; and the material of the intermediate layer is a material which does not react with the invar to generateintermetallic compounds, and the linear expansion coefficient of the material falls in between those of the invar and the aluminum alloy. According to the invar and aluminum alloy dissimilar metal electron beam welding method, the intermediate layer made of steel or copper or a metal which does not react with the invar to generate brittle intermetallic compounds is added, the complexity of metallurgical reaction between the invar and an aluminum joint can be reduced, ternary metallurgical reaction or polybasic metallurgical reaction is converted into binary metallurgical reaction, and the metallurgical regulation difficulty is reduced.

Owner:NANJING UNIV OF SCI & TECH

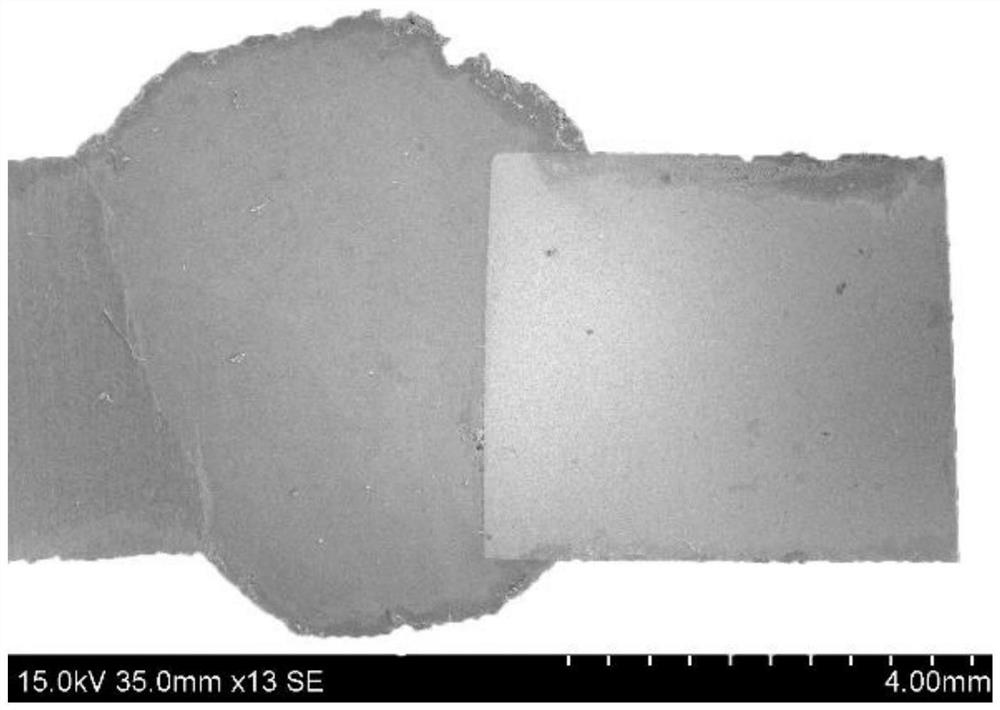

Cu/INVAR/Ni composite brazing filler metal for heterogeneous connection of hard alloy and steel and laser welding and brazing process thereof

PendingCN113634839AReduce stressSolve crackingWelding/cutting media/materialsSoldering mediaInvarAlloy

The invention discloses Cu / INVAR / Ni composite brazing filler metal for heterogeneous connection of hard alloy and steel and a laser welding and brazing process thereof, and belongs to the technical field of laser brazing. The Cu / INVAR / Ni composite brazing filler metal is of a sandwich sheet structure composed of a Cu foil, an INVAR sheet and an Ni foil, the Cu foil is arranged on one side of steel in advance, the Ni foil is arranged on one side of hard alloy in advance, the INVAR sheet is located between the Cu foil and the Ni foil, the thickness of the Cu foil is consistent with that of the Ni foil, the thickness of the INVAR sheet is larger than that of the Cu foil and that of the Ni foil, and laser welding and brazing is conducted through an automatic platform based on a laser, a robot and an outer shaft positioner. According to the Cu / INVAR / Ni composite brazing filler metal and the laser welding and brazing process thereof, the stress between the hard alloy and the steel with overlarge difference of physical properties such as thermal expansion coefficients is buffered, the welding heat input is reduced, and the problem of cracks caused by overlarge heat input in laser welding of the hard alloy and the steel is solved.

Owner:SHANGHAI UNIV OF ENG SCI

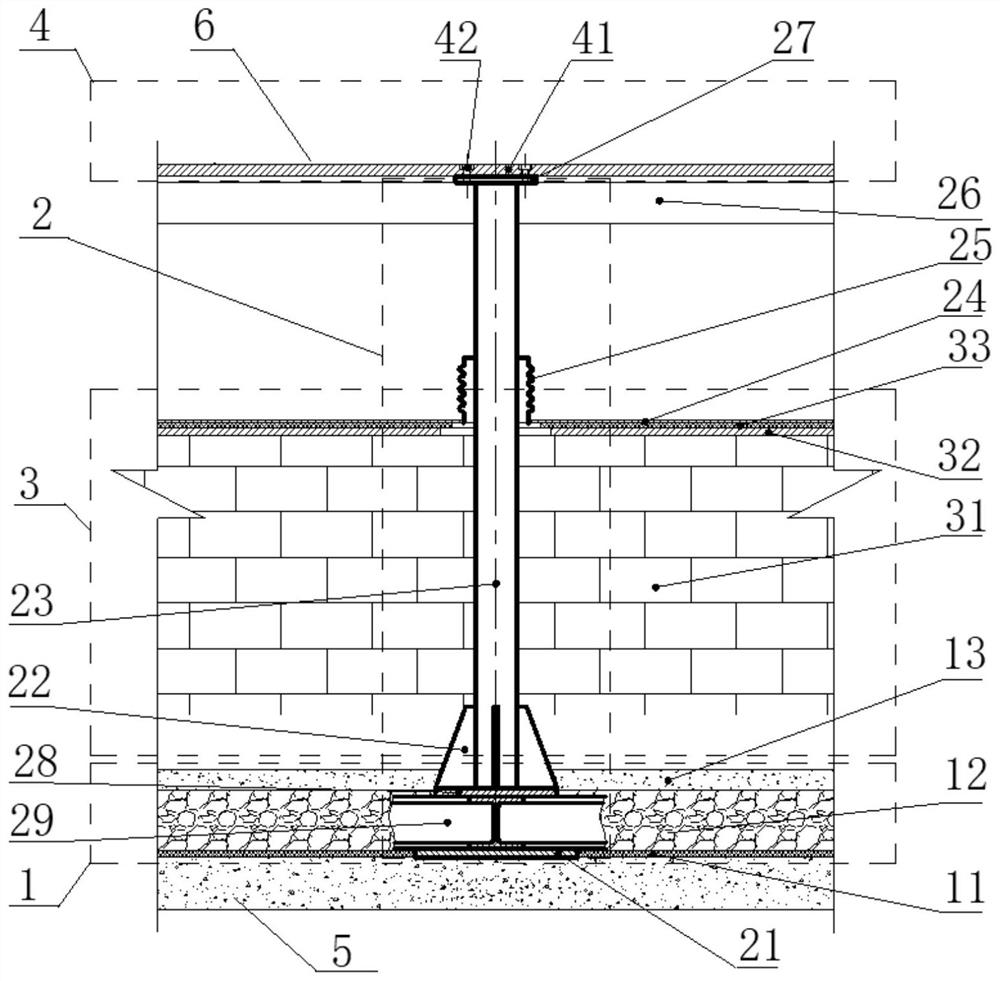

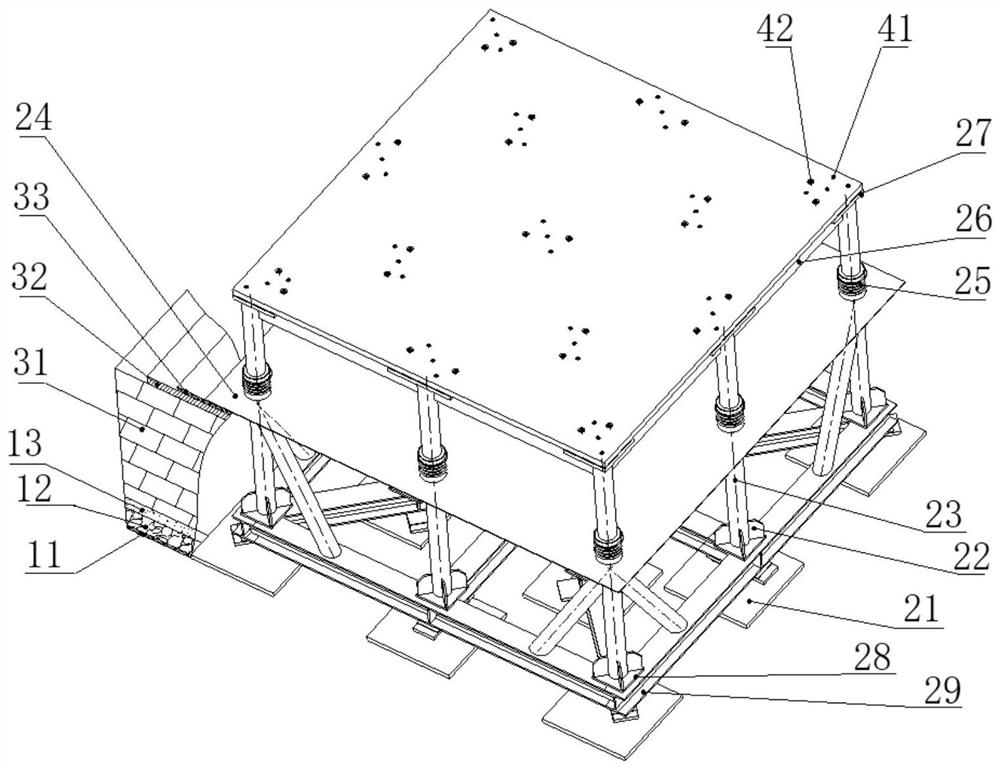

A ground support structure for high and low temperature environment simulation test system

ActiveCN113443177BGuaranteed waterproof performanceGuaranteed moisture-proof effectCosmonautic condition simulationsInvarBrick

The invention discloses a ground support structure for a high and low temperature environment simulation test system, comprising a bottom heat storage structure, an invar bottom support structure, a heat preservation structure and an invar non-deformation platform; the support structure is divided into four layers from bottom to top, The bottom heat storage structure, the Invar bottom support structure, the thermal insulation structure and the Invar non-deformation platform are in sequence; the bottom heat storage structure includes the foundation pit waterproof coating, the melon seed sheet heat storage layer and the cement mortar leveling layer; the Invar bottom support structure includes Bottom embedded steel plate, Invar rib, Invar steel tube, stainless steel sealing plate at the bottom of the box, stainless steel bellows, Invar mesh rib, Invar mounting flange, stainless steel bottom plate and carbon steel I-beam frame; thermal insulation structure includes Insulation glass brick, pressure steel plate and asbestos plate; Invar non-deformable platform including non-deformation platform and connecting bolts. The whole supporting structure of the present invention has strong load-bearing capacity and high and low temperature resistance, and has good stability, deformation resistance and safety.

Owner:SHANGHAI JIAO TONG UNIV +1

A transducer unit of an ultrasonic transducer

ActiveCN106179931BAvoid transmission media from enteringImprove work performanceMechanical vibrations separationInvarElectricity

The invention relates to the technical field of ultrasonic transduction, in particular to a transduction unit for an ultrasonic transducer. The transduction unit comprises a sealed invar shell and a piezoelectric ceramic ring arranged in the invar shell. A silver layer on the outer side of the piezoelectric ceramic ring is tightly attached to the invar shell, an oil medium is removed from the position between the piezoelectric ceramic ring and the shell, and the transduction efficiency is improved. Meanwhile, the silver layer on the outer side of the piezoelectric ceramic ring is tightly attached to the invar shell, so that heat generated by the piezoelectric ceramic ring is dissipated out through the invar shell. Under the condition that heat dissipation is not affected, the problem that ultrasonic wave losses of a transduction unit of an existing ultrasonic transducer exist is solved, in addition, a sealed shell structure is adopted in the transduction unit, so that transmission media are prevented from entering the transducer in the use process, in addition, the heat expansion coefficient of invar is smaller than the heat exchange coefficient of piezoelectric ceramic, so that the fitness between the piezoelectric ceramic ring and the invar shell is better along with increasing of the temperature, and the working performance of the transduction unit is more stable.

Owner:哈尔滨龙声超声技术有限公司

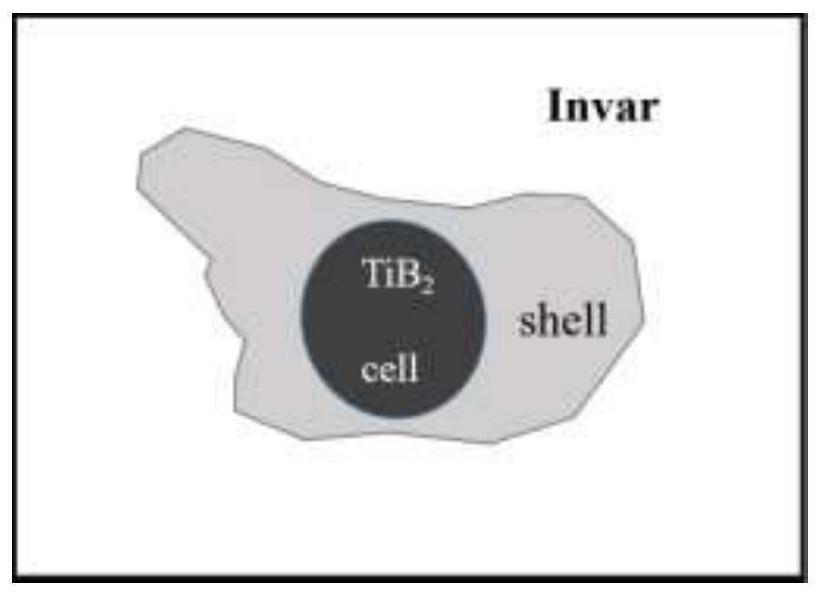

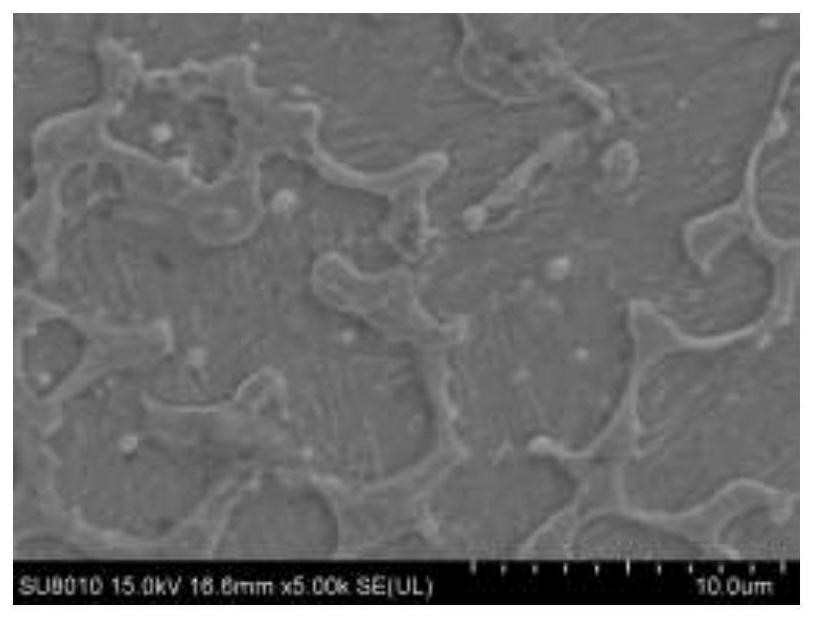

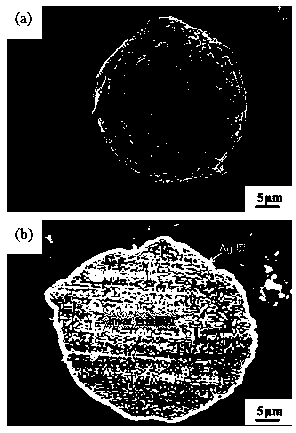

A core-shell tib 2 -fe 64 ni 36 Invarky Composite

ActiveCN112795850BHigh hardnessImprove wear resistanceAdditive manufacturingInvarChemical composition

The invention belongs to the field of composite materials and relates to a core-shell type TiB 2 ‑Fe 64 Ni 36 Invarky Composite. The core-shell TiB 2 ‑Fe 64 Ni 36 Invar-based composites are made of TiB 2 Reinforced structure of core-shell structure as the core and Fe as the matrix 64 Ni 36 Composed of Invar alloy; TiB 2 The reinforced structure of the core-shell structure is evenly distributed in the matrix, and the reinforced phase of different structures is formed by adjusting the added Ti / B atomic ratio; the core-shell TiB 2 ‑Fe 64 Ni 36 The composition of the tile-based composite material is laser deposited from the mixed powder of elemental Fe, Ni, Ti and Fe-B alloy; the particle size of the mixed powder is 140-300 mesh, the shape is spherical, and the chemical composition is: elemental Fe , Ni, and Ti are all 99.9% high-purity powders, and the B element content in the Fe-B alloy powder is 20wt.%. The invention provides a core-shell type TiB 2 ‑Fe 64 Ni 36 Invar-based composite material, the material composition is controllable, the performance is superior, and the Invar characteristics and wear resistance of the material can be taken into account at the same time. By changing the atomic ratio of Ti / B, the Fe 64 Ni 36 Composite coating prepared with TiB 2 Core-shell structure.

Owner:EAST CHINA JIAOTONG UNIVERSITY

A kind of preparation method of cu/ag (invar) composite material for electronic packaging

InactiveCN107312945BImprove performanceReduce spreadTransportation and packagingMetal-working apparatusInvarChemical plating

Owner:HEFEI UNIV OF TECH

A kind of preparation method of non-expanding sealing and capping film for plastic container containing soy sauce

The invention belongs to the field of composite flexible package, and particularly relates to a preparation method for a package expansion-free sealing cover film of a plastic container containing soybean sauce. The preparation method comprises the steps of preparation of a PETG printing film, preparation of a VMPET film, preparation of a cast polypropylene film, dry compounding and the like. Stereo block polypropylene and metallocene polyethylene are added into polypropylene resin for modification, and the special base film, namely the cast polypropylene film, produced through a CPP machine has the advantages of low-temperature heat sealing, easy uncovering, high air impermeability and the like. The package expansion-free sealing cover film prepared through the method is of the structure of a PETG film / a VMPET (vacuum polyester aluminum laminated film) / a CPP(cast polypropylene film) composite film. The composite film can fully generate a high-airtight environment for soybean sauce, so that the soybean sauce is in a good state and is not influenced by the outside.

Owner:GUANGDONG BAOJIALI COLOR PRINTING IND CO LTD

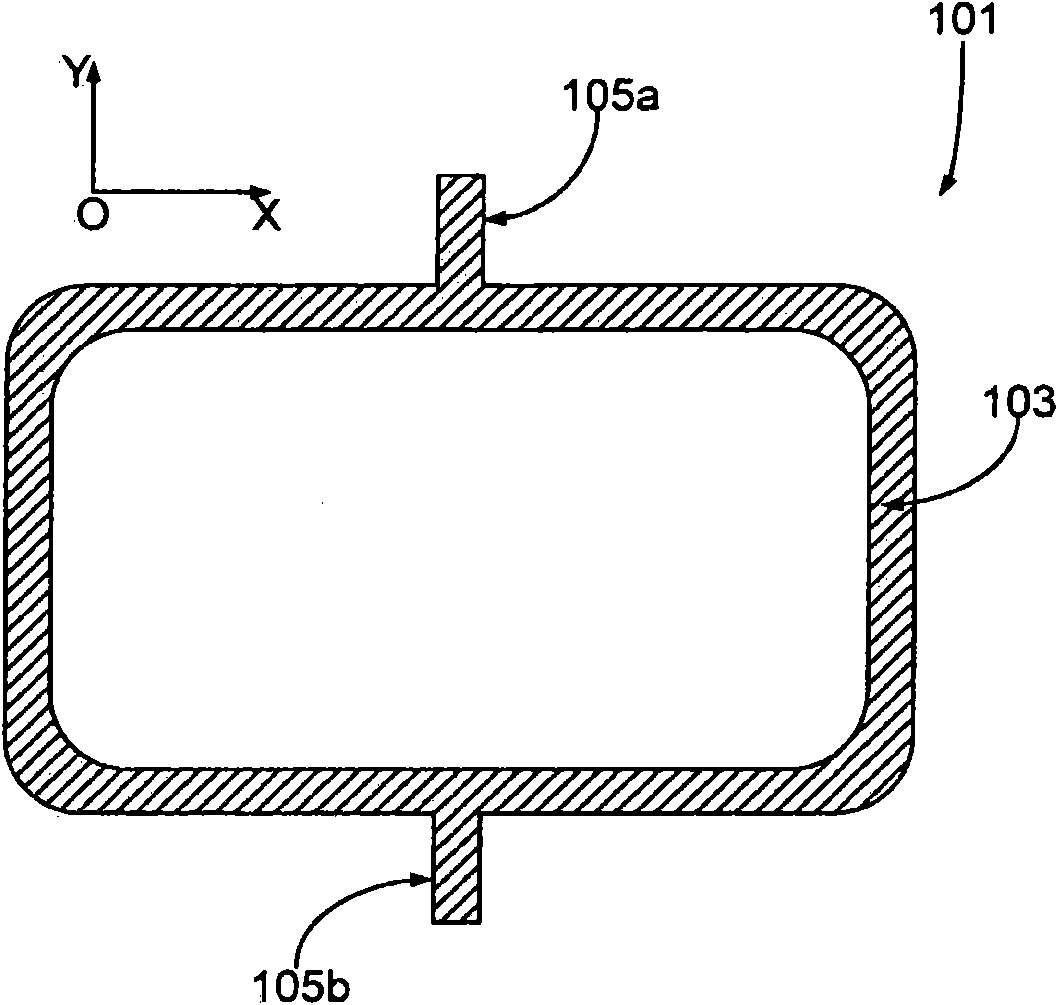

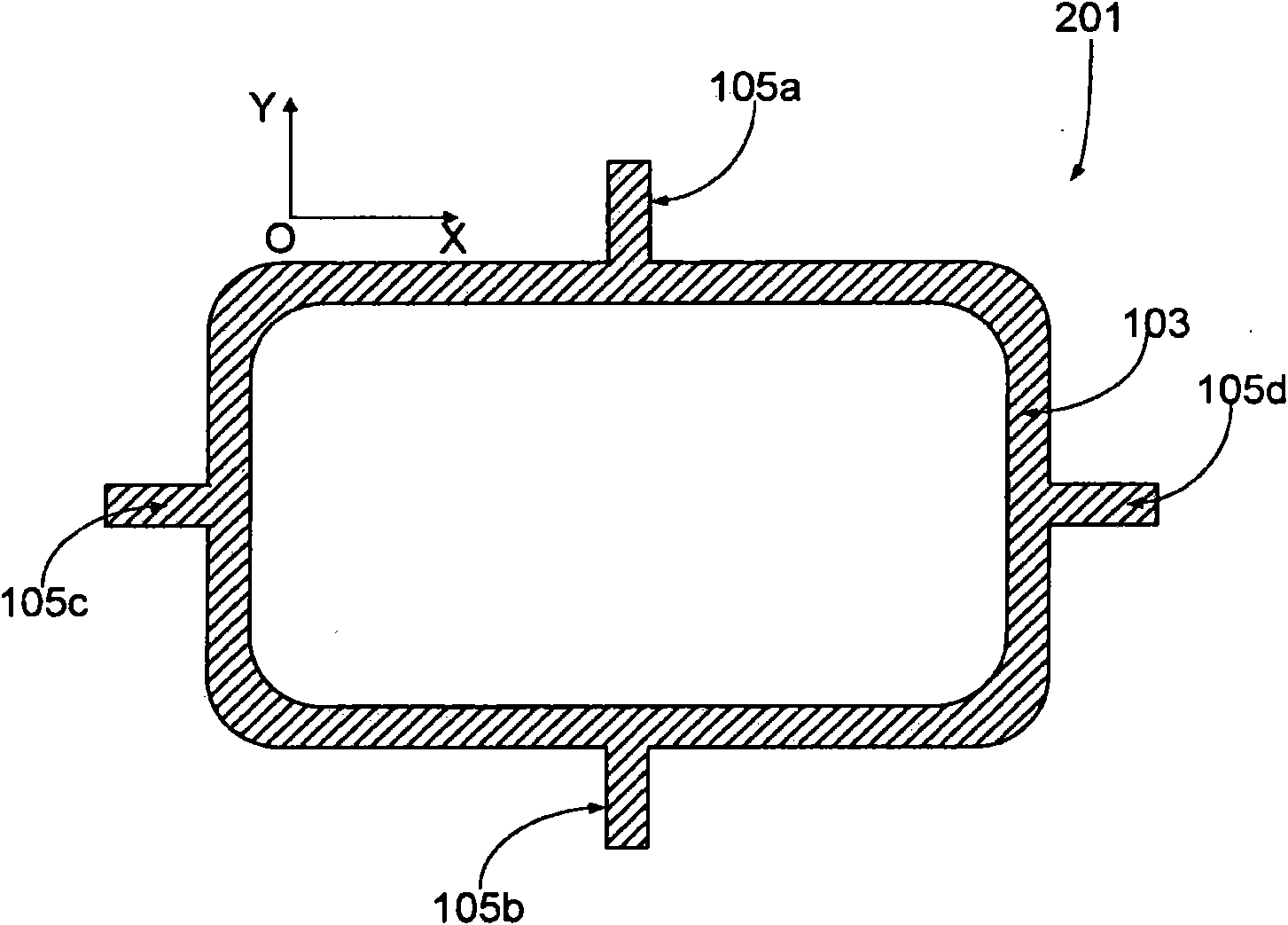

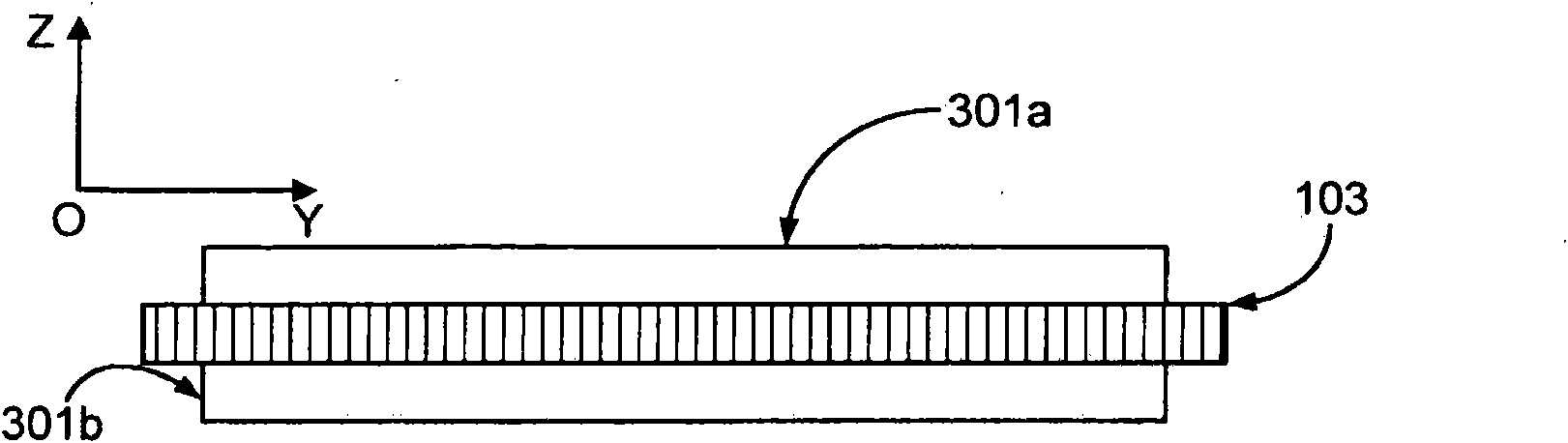

Frit sealing using direct resistive heating

An frit-sealed device comprising a resistive heating element having an electrically-closed-loop structure and process for frit-sealing a device by using such heating element. The element can be advantageously made of a metal such as Invar(R) and / or Kovar(R). The invention enables hermetic frit sealing with low residual stress in the seal. The invention is particularly advantageous for hermetic sealing of OLED display devices.

Owner:CORNING INC

Grilling surface

A grilling component employed to grill food items includes a grilling surface made of a material having a low constant of thermal expansion. In one example, the grilling surface is made of Invar(TM). Invar(TM) is a metal allow comprised of Iron and 36% Nickel, and may include other trace elements. The grilling surface further includes a non-stick coating, such as Teflon(TM). The grilling surface can also be a conveyor belt which travels over a heater.

Owner:RESTAURANT TECH

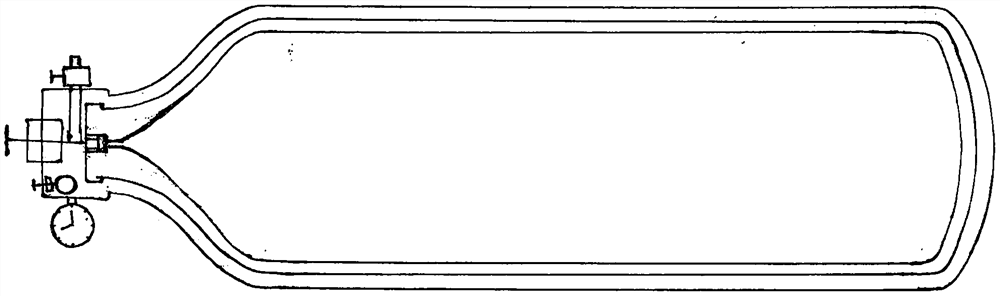

Liquid hydrogen storage bottle (tank) made of insulating material

The invention relates to an insulating material suitable for liquid hydrogen energy storage as an inner container of a liquid hydrogen storage bottle (tank). The insulating material is characterized in that the insulating material suitable for liquid hydrogen energy storage, especially a ceramic material, is used to make the inner container of the liquid hydrogen storage bottle (tank); an inner container body of the insulating ceramic bottle (tank) is seamlessly wrapped with a heat preservation body made of double-layer vacuum invar, and an opening of the inner container body of the insulatingceramic bottle (tank) and an opening of the double-layer vacuum invar heat preservation bottle (tank) are jointly designed to be an insulating valve (3) resistant to high pressure.

Owner:安劲海

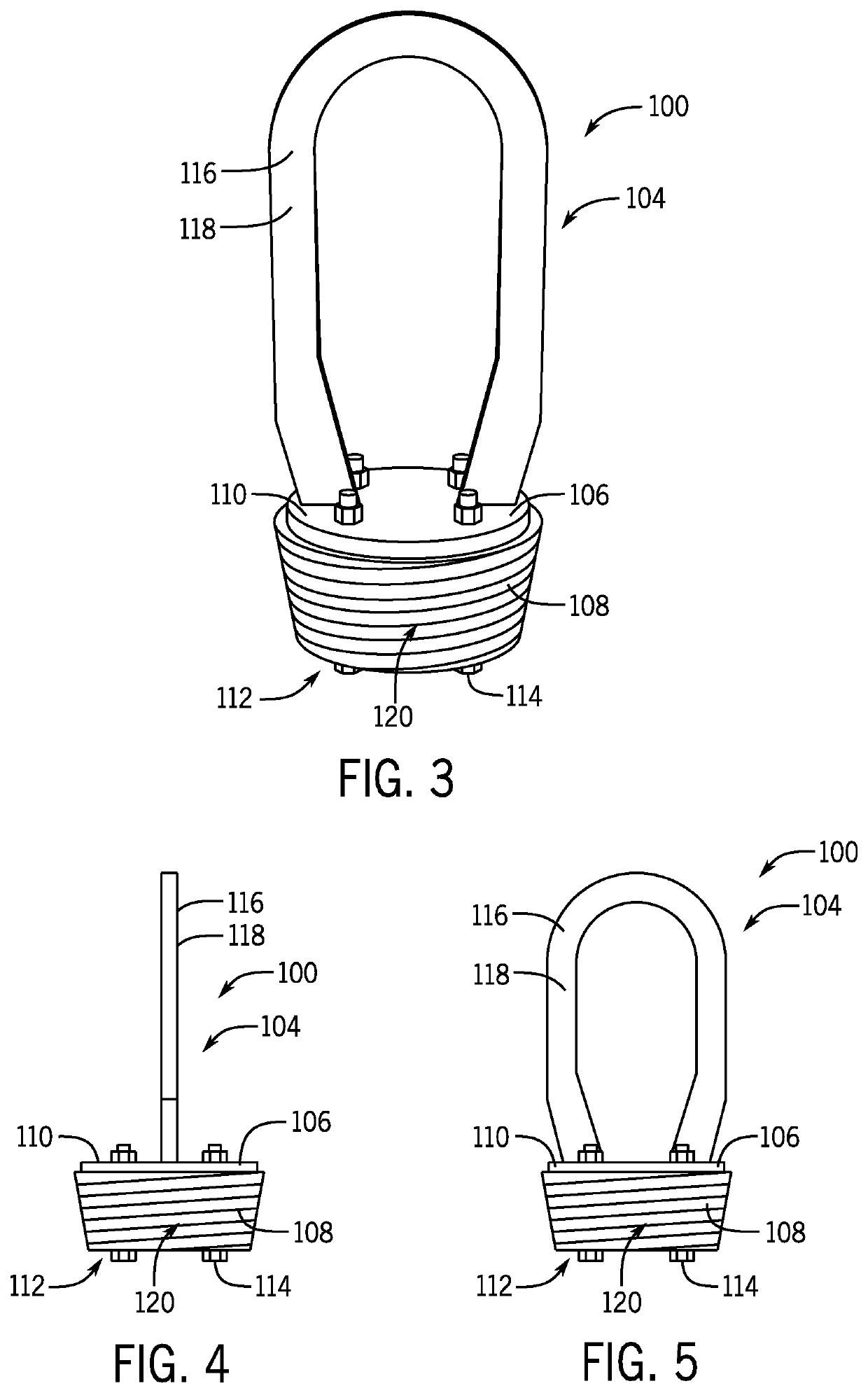

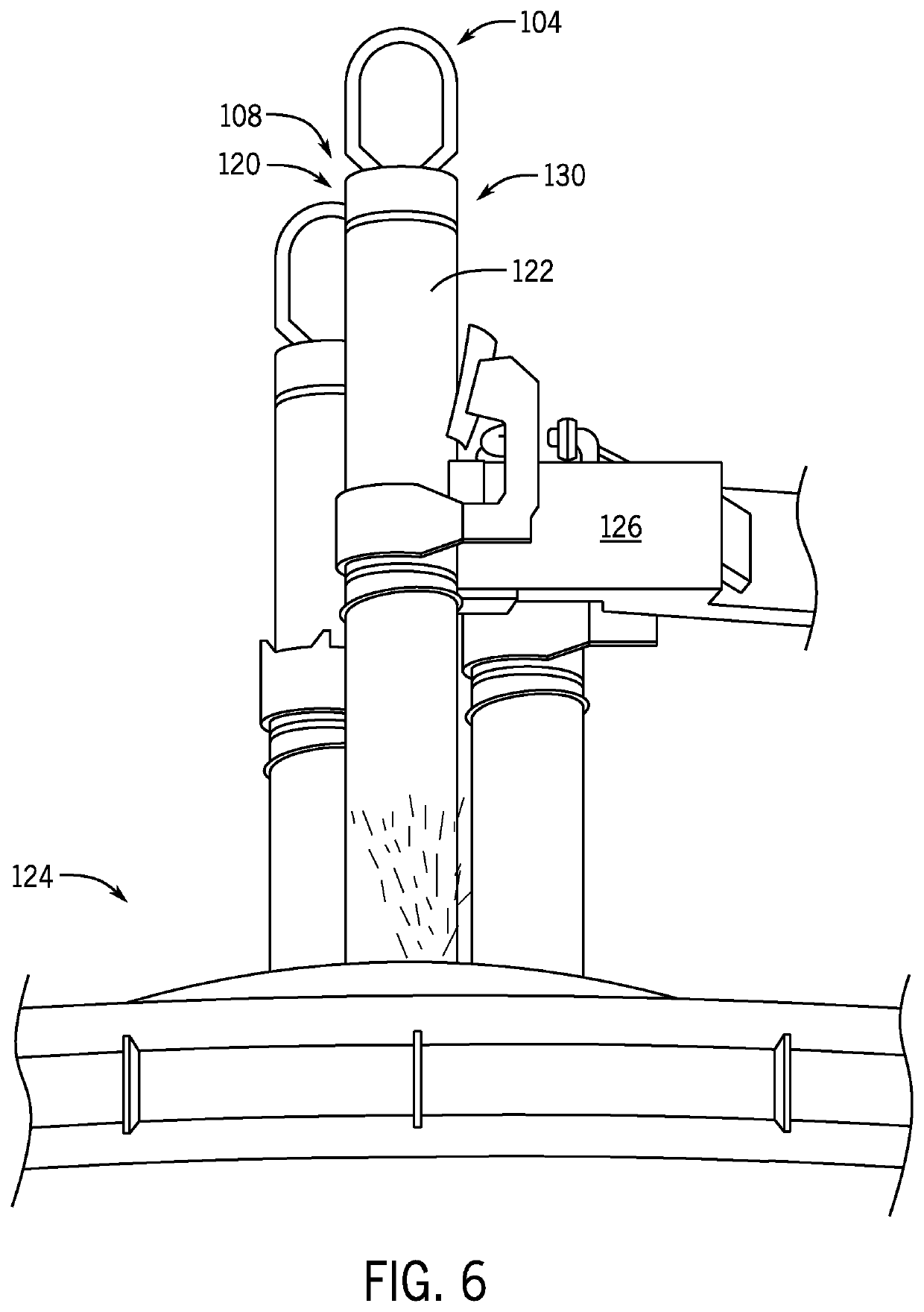

Apparatus for lifting graphite electrodes

A lifting adaptor configured to lift a graphite electrode includes a main body having a threaded end to secure the lifting adaptor to threads of the graphite electrode, and a lifting component coupled to the main body opposite the threaded end to lift the graphite electrode. The threaded end of the main body may comprise a non-graphite material with a coefficient of thermal expansion (CTE) similar to Invar, within + / −0 to 1 (μm / (m K)) over a range from room temperature to 400 degrees Fahrenheit.

Owner:EXO TECH LLC

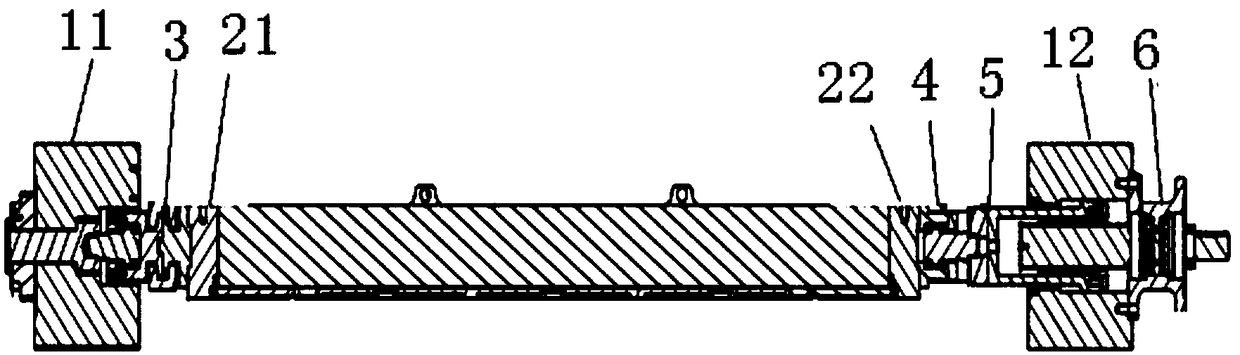

Telescopic invar barcode leveling rod, and precise leveling method using cooperation of telescopic invar barcode leveling rod with even number of stations

InactiveCN105865414AEliminate zero differencesAchieve elongationHeight/levelling measurementInvarBarcode

The invention relates to a telescopic invar barcode leveling rod, and a precise leveling method using cooperation of the telescopic invar barcode leveling rod with an even number of stations. The telescopic invar barcode leveling rod comprises an inner rectangular steel tube, an outer rectangular steel tube and spiral pins, the inner rectangular steel tube is sleeved in the outer rectangular steel tube, the outer rectangular steel tube is provided with the spiral pins, the front side surface of the outer rectangular steel tube is provided with an invar barcode ribbon, and the rear side surface of the outer rectangular steel tube is provided with a leveler. Even-number station measurement between a point A and a point B is carried out through the measurement method when the telescopic invar barcode leveling rod is used to measure a height difference between the point A and the point B, so the measurement precision in the leveling process is guaranteed. The telescopic invar barcode leveling rod has the advantages of simple structure, convenient use and carrying, economy cost saving, and reaching of precision requirements in the leveling process by means of the precise leveling method.

Owner:SHANDONG UNIV

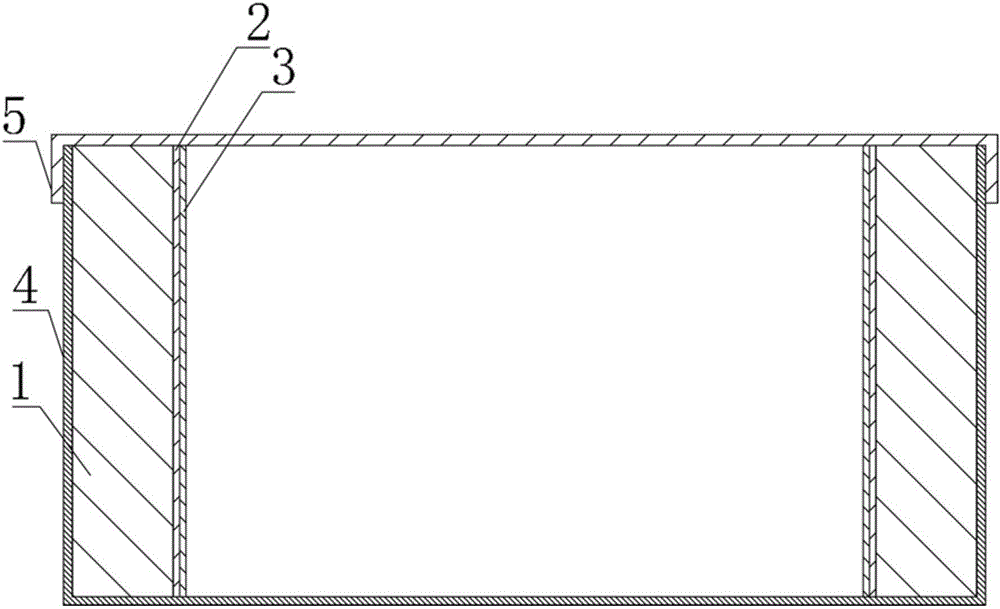

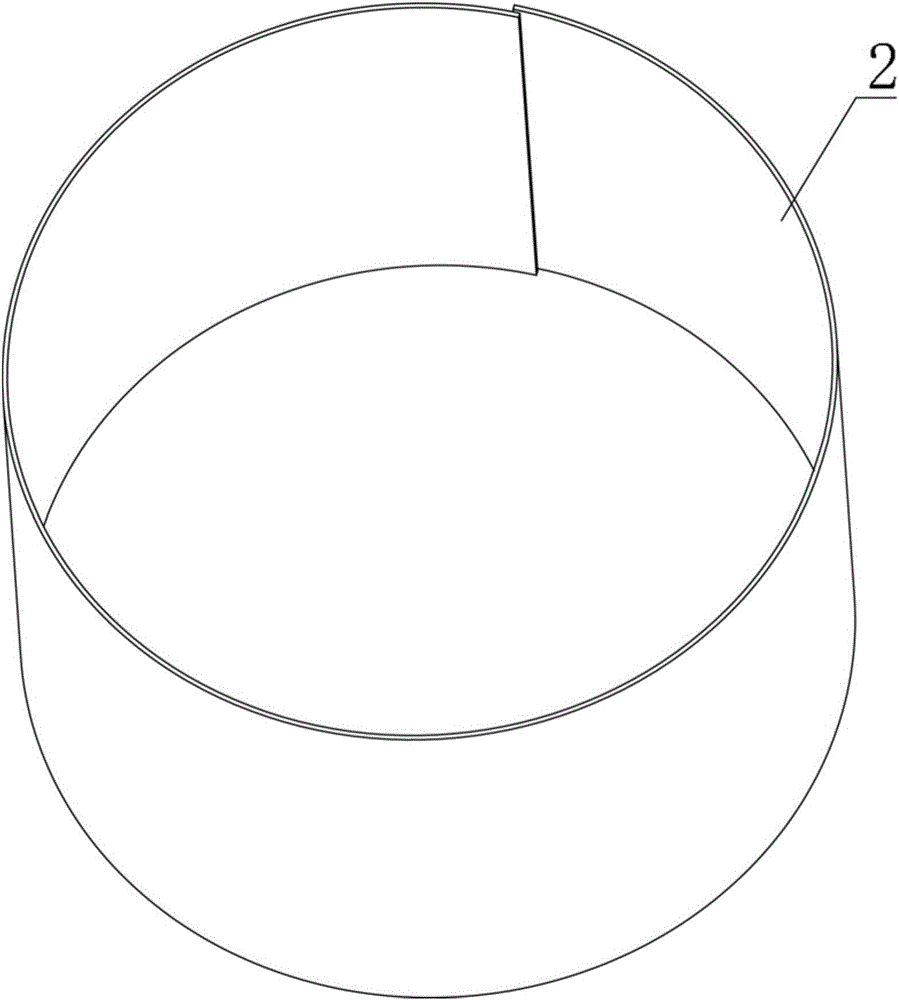

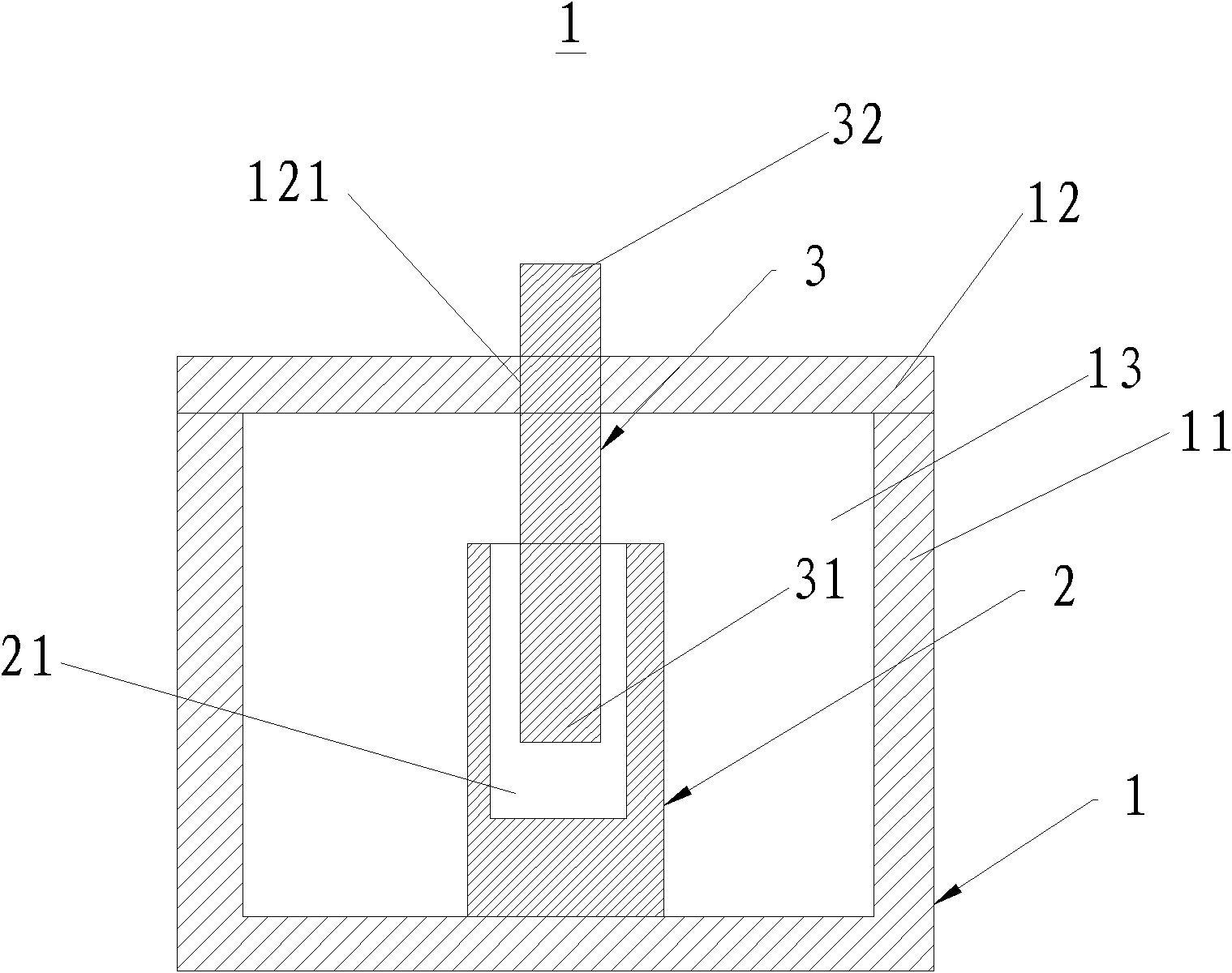

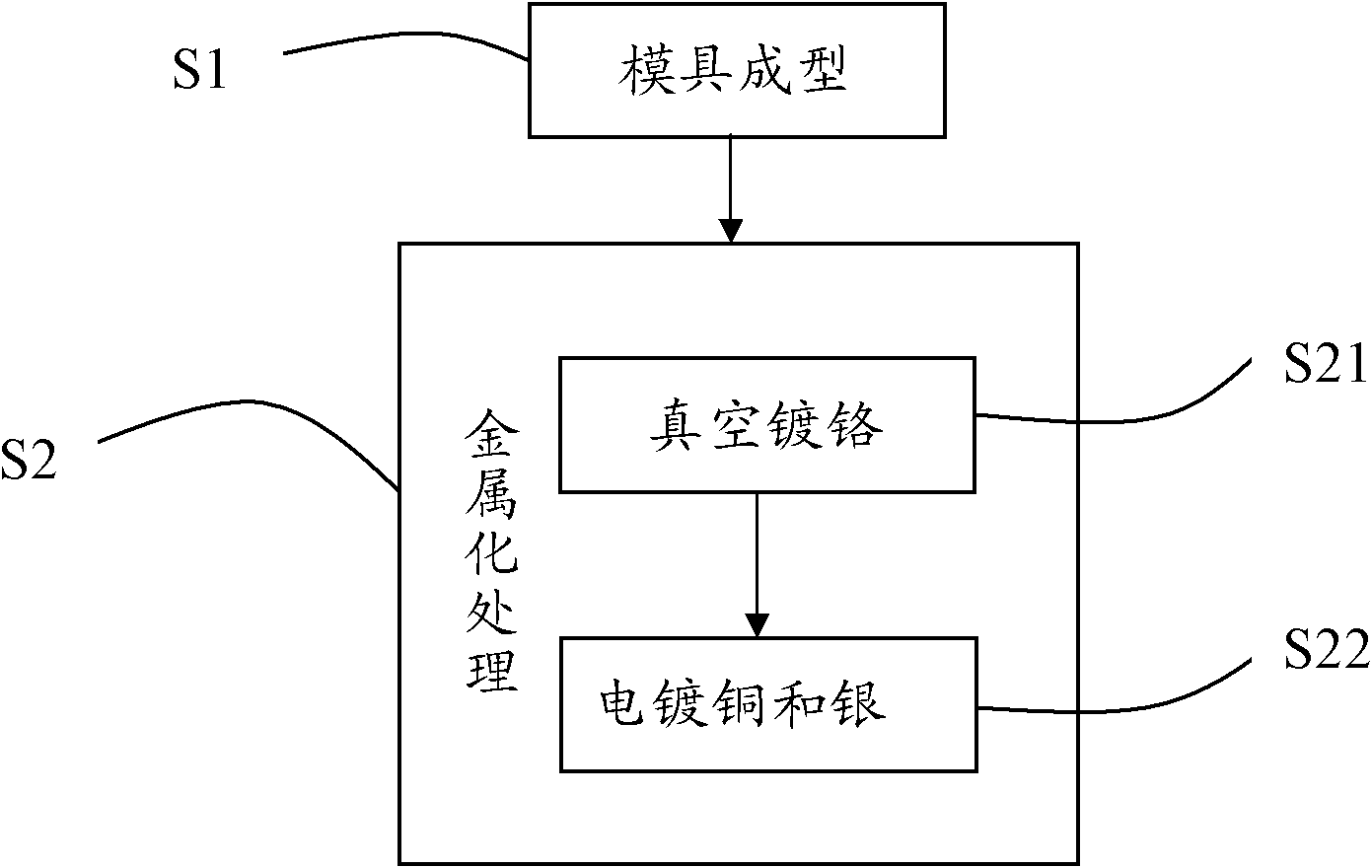

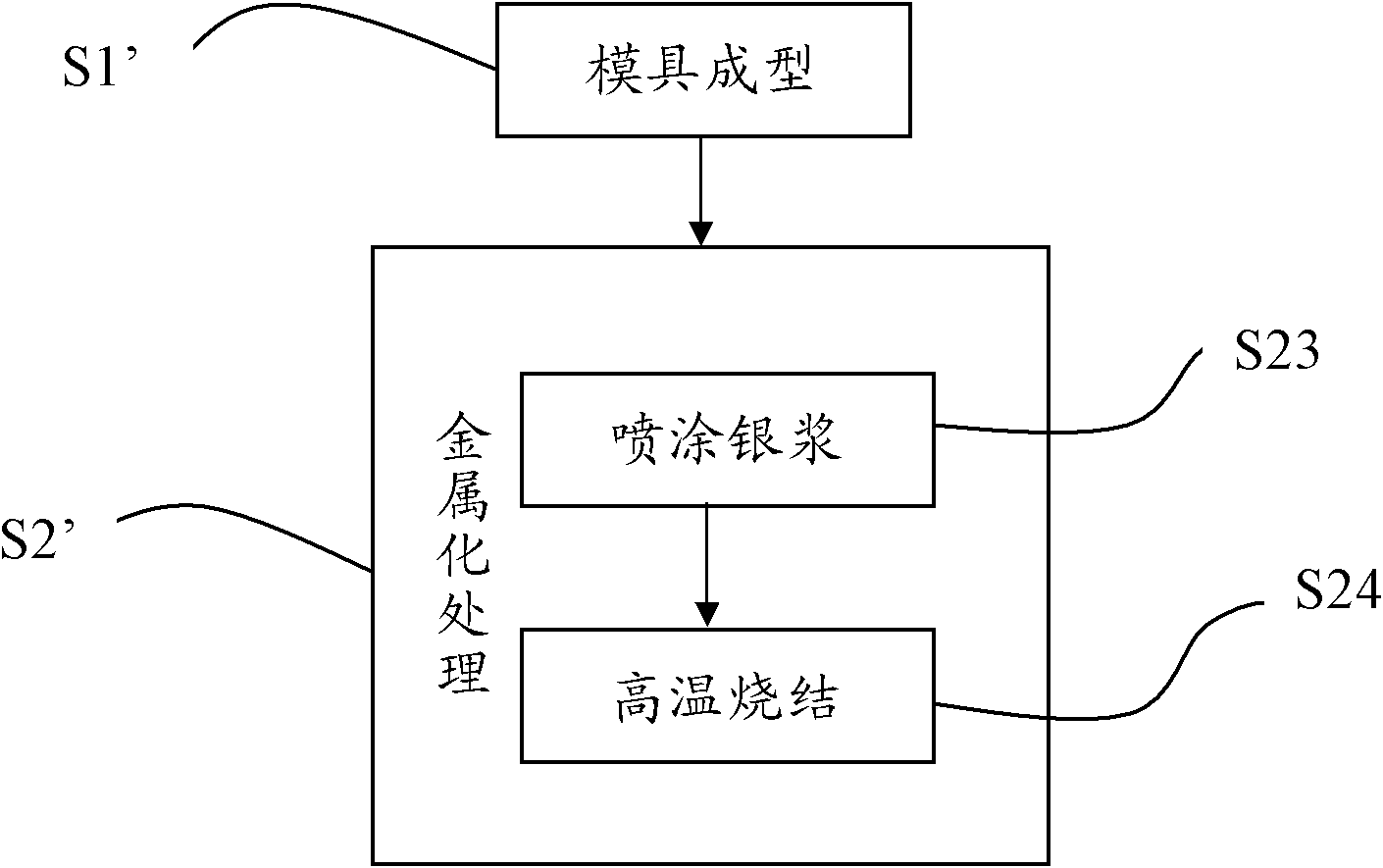

Communication device, cavity filter, resonating tube and manufacturing method thereof

ActiveCN101877427BSolve the temperature drift index problemReduce usageWaveguide type devicesInvarResonance

A cavity filter is disclosed, wherein, the cavity filter comprises a cavity (1) and a resonance tube (2) mounted in said cavity (1), and said resonance tube (2) is made of quartz glass. Compared with the cavity filter with a traditional resonance tube made of invar, said cavity filter reduces cost, and has a better temperature drift index. A communication device, resonance tube and manufacturing method thereof are also disclosed.

Owner:ANHUI TATFOOK M&E TECH

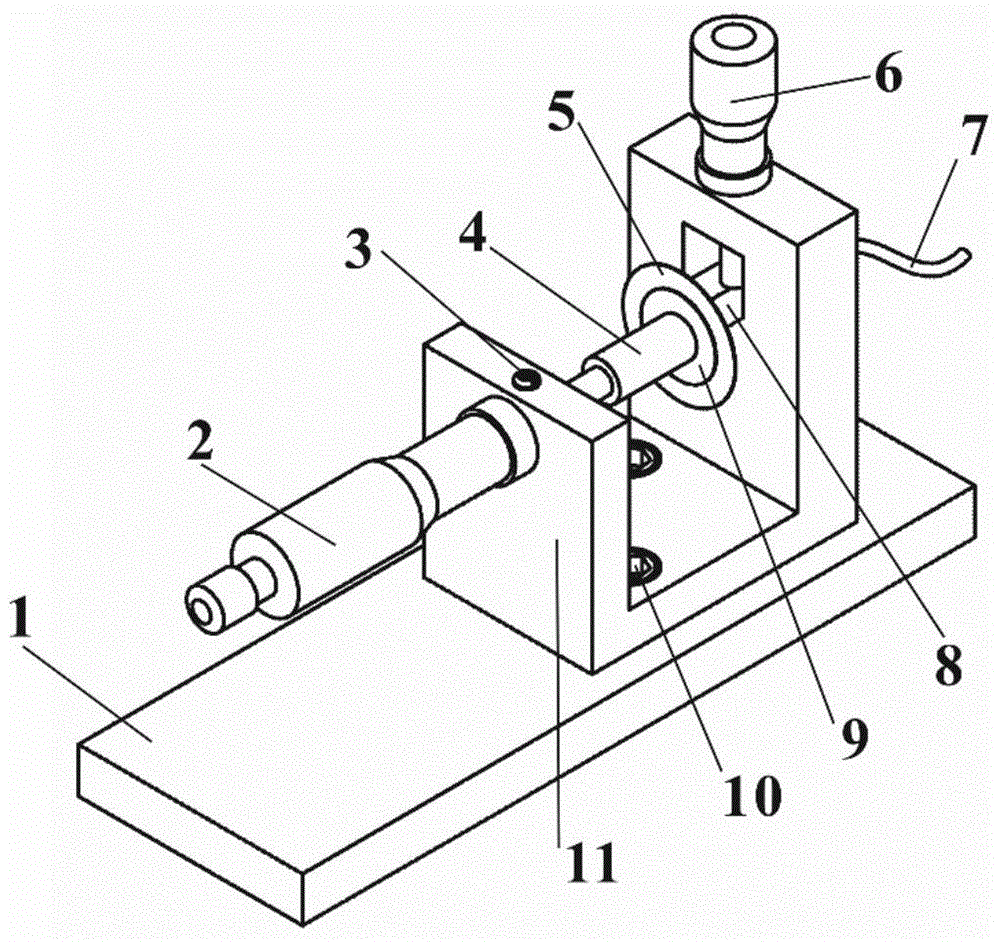

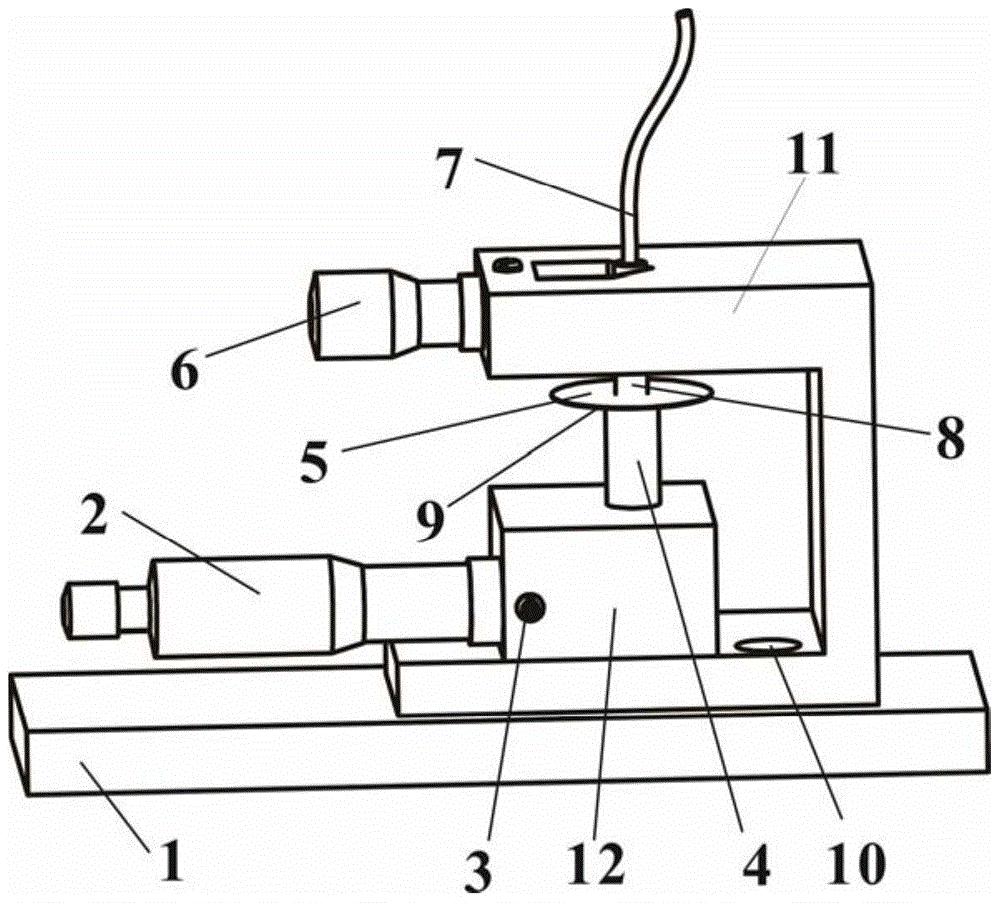

A Measuring Device for Temperature Drift Coefficient of Eddy Current Displacement Sensor

The invention discloses a measuring device for the temperature drift coefficient of an eddy current displacement sensor. The device uses a gasket with an ultra-low thermal expansion coefficient, a probe fixing structure made of common materials, an elastic body, a target conductor sheet, a bracket and a base to form a Very precise and stable displacement fixing system. Different from the temperature drift measurement devices made of low-temperature drift Invar alloy and other materials in the past, the main body of this device can be a common material that is cheap and easy to process and manufacture, and the gasket that determines the displacement is made of low thermal expansion coefficient material manufacturing. The device of the invention can be used to accurately measure the temperature drift of the high-resolution eddy current displacement sensor, and can also be installed with a precision displacement brake to calibrate the sensitivity and linearity and the like. The temperature coefficient measuring device of the eddy current sensor based on the present invention has simple structure and low cost, and the fixed displacement temperature drift coefficient can be as low as below 1nm / °C.

Owner:UNIV OF SCI & TECH OF CHINA

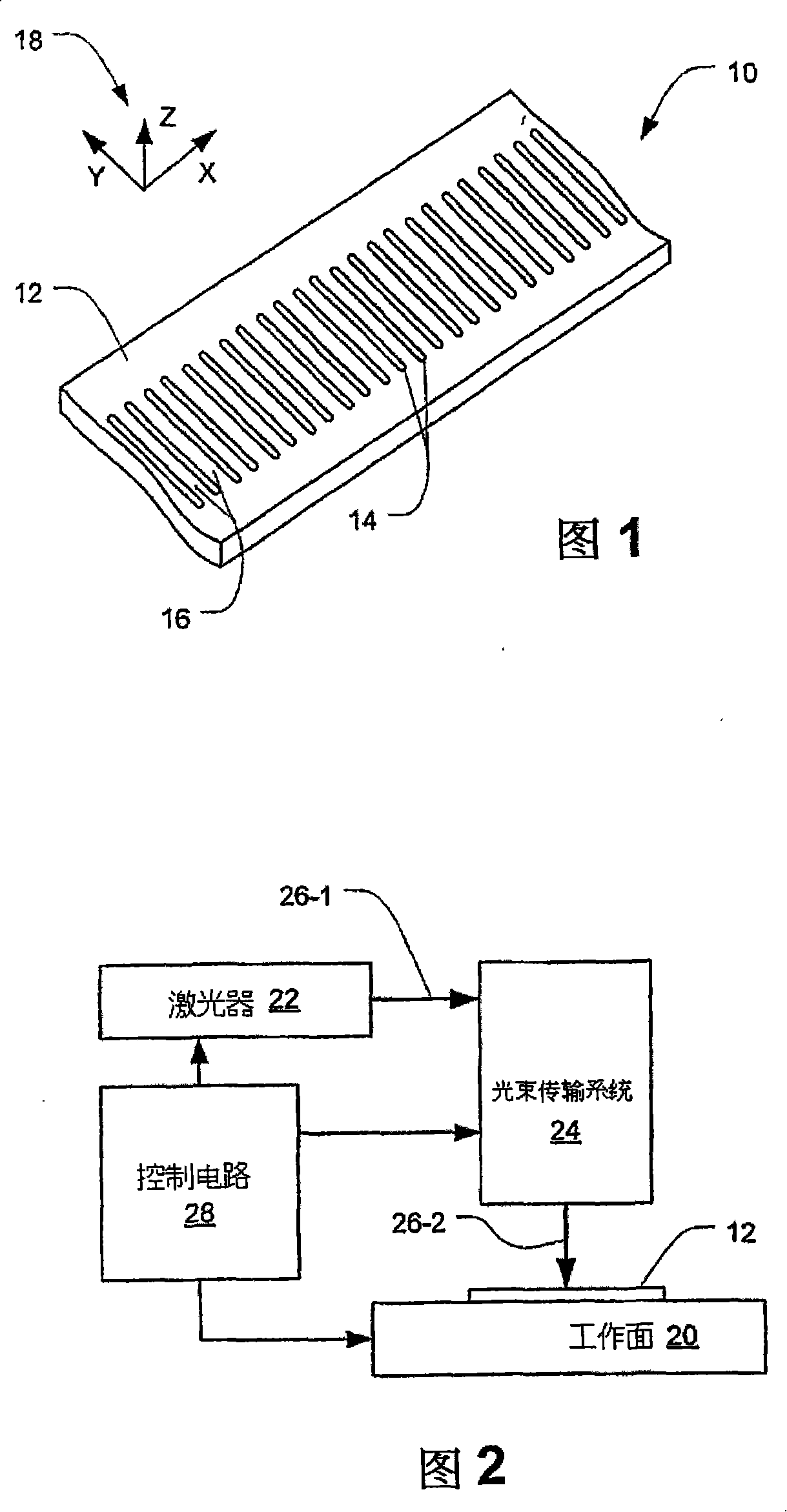

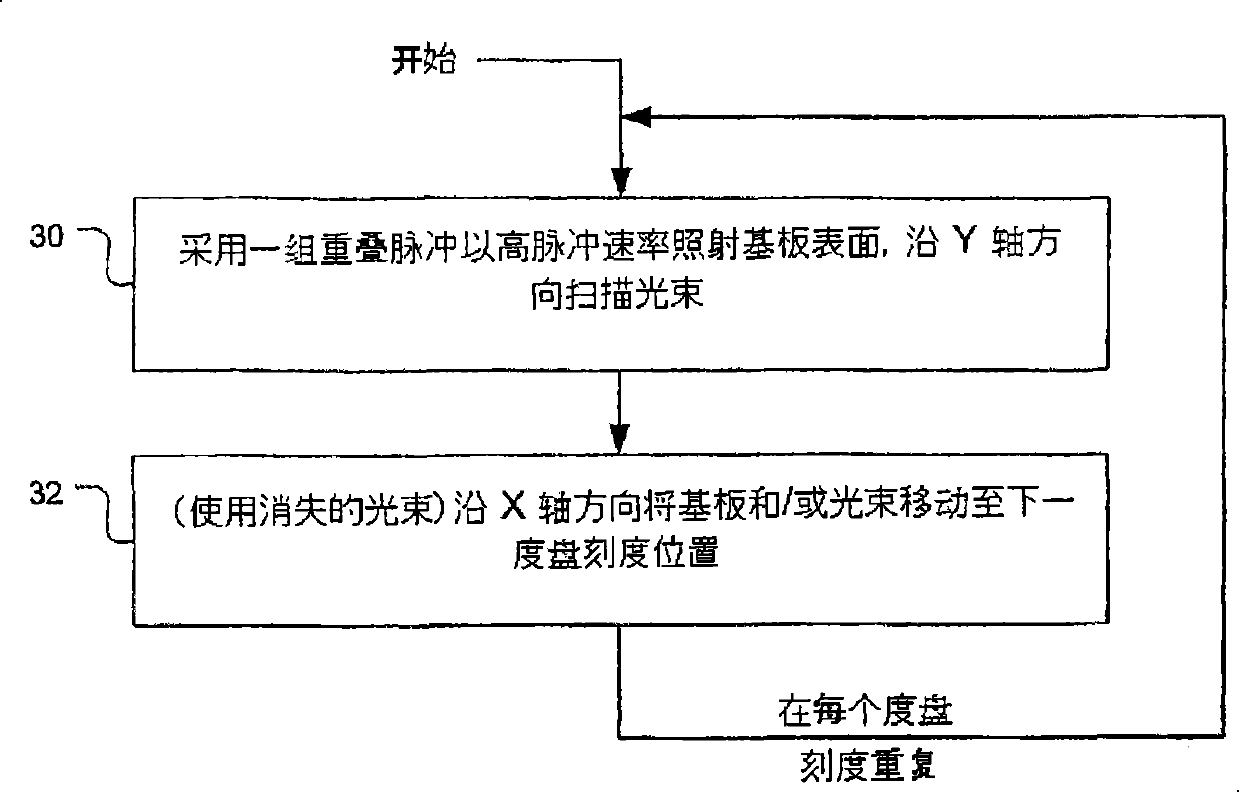

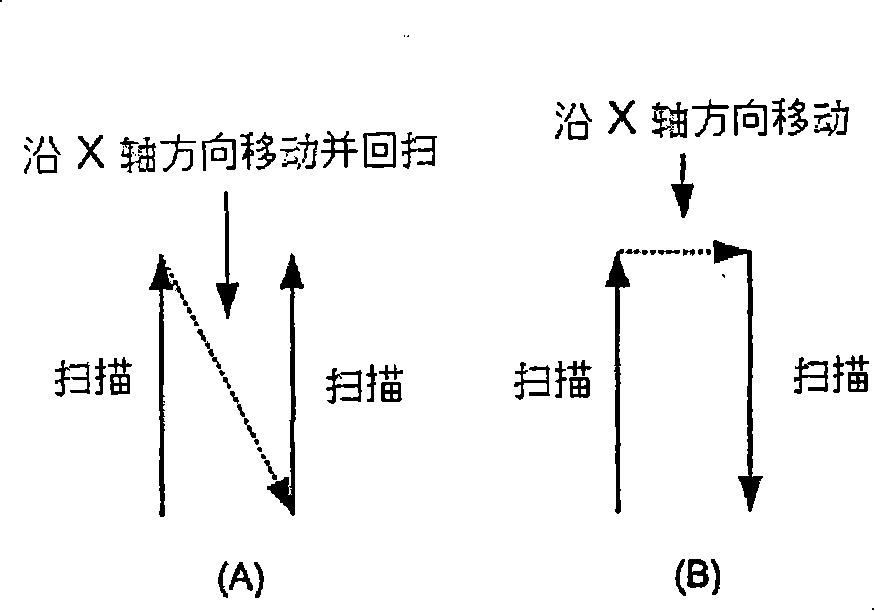

Optical metrological scale and laser-based manufacturing method therefor

A reflective metrological scale has a scale pattern of elongated side-by-side marks surrounded by reflective surface areas of a substrate, which may be a nickel-based metal alloy such as Invar <*> or Inconel <*> and may be a thin and elongated flexible tape. Each mark has a furrowed cross section and may have a depth in the range of 0.5 to 2 microns. The central region of each mark may be rippled or ridged and may be darkened to provide an enhanced optical reflection ratio with respect to surrounding reflective surface areas. A manufacturing method includes the repeated steps of (1) creating a scale mark by irradiating a surface of the substrate at a mark location with a series of overlapped pulses from a laser, each pulse having an energy density of less than about 1 joule per cm<2>, and (2) changing the relative position of the laser and the substrate by a displacement amount defining a next mark location on the substrate at which a next mark of the scale is to be created.

Owner:THE GSI GRP LLC

Preparation method of high-strength ultralow-expansion invar-based composite material

The invention relates to a preparation method of an invar-based composite material, in particular to a preparation method of a high-strength ultralow-expansion invar-based composite material. The invention aims to solve the technical problems that the deformation machining technique for the high-strength invar is complex and the high-strength invar is difficult to be machined into large-size components. The method comprises the following steps: 1. preparing high-purity titanium powder and carbon powder precast blocks; 2. smelting invar to obtain molten mass; 3. adding the precast blocks into the molten mass in step 2, and casting to obtain cast ingots or castings while keeping the temperature constant; and 4. carrying out heat treatment to obtain the high-strength ultralow-expansion invar-based composite material. Compared with the prior art, the high-strength ultralow-expansion invar-based composite material in the invention has the advantage of simple control on composition and technique and low cost, can be directly formed by casting without complex deformation hardening technique, does not contain precious metals, and particularly can control the coefficient of expansion of the invar at low level while greatly enhancing the strength of the low-expansion invar.

Owner:HARBIN INST OF TECH

Forging process special for mask plate support alloy Invar36

PendingCN111633164AImprove performanceEasily brokenMetal-working apparatusFurnace typesInvarSolution treatment

The invention discloses a forging process special for mask plate support alloy Invar 36. The forging process comprises the steps that after the surface of Invar36 alloy is cleaned with acetone, the cleaned Invar36 alloy is placed into a resistance furnace to be heated, the temperature in the resistance furnace is 950-980 DEG C, and heat preservation is conducted for 10-18 min; two-upsetting and two-drawing cogging forging is conducted, the first upsetting deformation is 30-35%, then first drawing is conducted, the drawing deformation is controlled to be 14-35%, and the Invar36 alloy is fed into a heating furnace at a temperature of 1100 DEG C for solution treatment; the second upsetting deformation is 50-60%, then second drawing is conducted, the drawing deformation is controlled to be 10-40%, and the Invar36 alloy is fed into the heating furnace at a temperature of 1050 DEG C for solution treatment, wherein the first solution treatment is conducted for 1.5 hours at the temperature of1100 DEG C, and the second solution treatment is conducted for 1 hour at the temperature of 1050 DEG C; and through two-upsetting and two-drawing cogging forging, the alloy is repeatedly forged, carbide in the alloy is better smashed, internal grains are finer through high-temperature calcination and repeated forging, and the strength, hardness, abrasion resistance, fatigue strength, toughness andthe like of channel steel are improved through quenching.

Owner:上海蓝铸特种合金材料有限公司

Concrete temperature stress testing machine with temperature deformation self-compensation function

ActiveCN106092724BAchieve impactImprove temperature regulation efficiencyMaterial testing goodsStrength propertiesTemperature stressInvar

The invention discloses a concrete temperature stress testing machine with a temperature deformation self-compensation function and belongs to the technical field of concrete temperature stress and deformation testing simulation. A polished rod is manufactured from No.4J36 invar, a left fixed end, a right fixed end, fixed end universal joints and movable end universal joints are manufactured from No.4J36 invar, and a fixed chuck, a movable chuck and a load sensor are manufactured from No.45 steel. Parts of the testing machine are made from different steel materials, the combination length of the parts is designed according to a certain proportion, when outside temperature changes, the total temperature deformation difference generated by all steel parts of the concrete temperature stress testing machine can be zero, accordingly temperature deformation, caused by outside temperature change, of steel of the testing machine is offset, and temperature deformation self-compensation of the testing machine is achieved.

Owner:TSINGHUA UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com