A kind of preparation method of cu/ag (invar) composite material for electronic packaging

A composite material, electronic packaging technology, applied in metal material coating process, transportation and packaging, metal processing equipment, etc., to achieve the effect of improving mechanical and thermal physical properties, reducing thermal expansion coefficient, and excellent comprehensive performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Example 1: 40 wt% Cu / Ag(Invar) composite sintered at atmospheric pressure at 750°C

[0034] (1) Electroless silver plating on the surface of Invar alloy powder: the main salt in the electroless silver plating solution is AgNO 3 , the reducing agent is potassium sodium tartrate (KNaC 4 h 4 o 6 ), ammoniacal liquor is as complexing agent, and the step of chemical plating Ag is:

[0035] (1) Weigh 33.5 g of AgNO 3 , dissolved in 500 mL deionized water to prepare 67 g / L colorless, clear and transparent AgNO 3 solution;

[0036] (2) Add complexing agent ammonia water dropwise to the above solution, and the reaction begins to produce dark brown Ag 2 O precipitation, continue to drop complexing agent ammoniacal liquor, precipitation disappears gradually, till forming colorless transparent solution;

[0037] (3) In the colorless transparent solution described in step (2), add dropwise the NaOH aqueous solution of 10 g / L, regulate the pH value of solution to 11.5, obtain ...

Embodiment 2

[0045] Example 2: 40 wt% Cu / Ag(Invar) composite sintered at atmospheric pressure at 775°C

[0046] The preparation process of this example is the same as Example 1, the difference is that the normal pressure sintering temperature in step (5) is 775 °C, other processes and parameters remain unchanged, 40 wt% Cu / Ag(Invar ) Microstructure (a) and fracture morphology (b) of the composite material as image 3 shown.

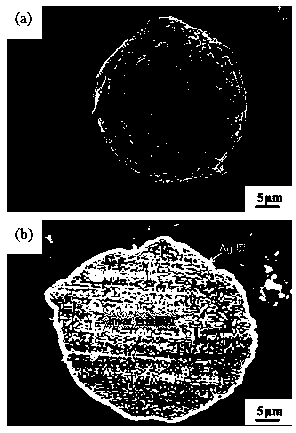

[0047] Such as figure 1 As shown, the Ag layer on the surface of the Ag(Invar) composite powder particles prepared by electroless plating in a silver ammonia solution with a pH of 11.5 for 30 min is uniform and continuous, has a compact structure, and is tightly combined with the Invar alloy substrate, with a thickness of 2-3 μm . Such as figure 2 , as shown in 3, the Ag(Invar) in the 40 wt% Cu / Ag(Invar) alloy composite sintered at atmospheric pressure is uniformly distributed in the Cu alloy matrix in a network shape, without agglomeration, and most of the pores...

Embodiment 3

[0048] Example 3: Deformation heat treatment of 40 wt% Cu / Ag(Invar) composite sintered at atmospheric pressure at 775°C

[0049] For the 775 °C normal pressure sintered 40 wt% Cu / Ag(Invar) composite material prepared in Example 2, the deformation heat treatment was carried out: the sintered Cu / Ag(Invar) composite material sample was subjected to multiple passes by using a twin-roll cold rolling process The first rolling, the rolling force is 500 kN, and the deformation in each pass is less than 5%. When the thickness of the sample is reduced to 40%, the intermediate annealing is carried out at 600 °C and kept for 1h, and the final annealing is carried out when the thickness of the sample is reduced to 55%. The annealing temperature was 400 °C, and the temperature was kept at 2 h. The heating rate of Cu / Ag(Invar) alloy composite was set at 5 °C / min. After the heat preservation was completed, the composite material was cooled to room temperature with the furnace. Both the interm...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com