Preparation method of high-strength ultralow-expansion invar-based composite material

An Invar alloy and composite material technology, which is applied in the field of preparing Invar alloy-based composite materials, can solve problems such as difficulty in processing large-sized components, complicated deformation processing techniques for strengthening Invar alloys, etc., and achieves low cost, simple production process, Composition and process control for simple effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

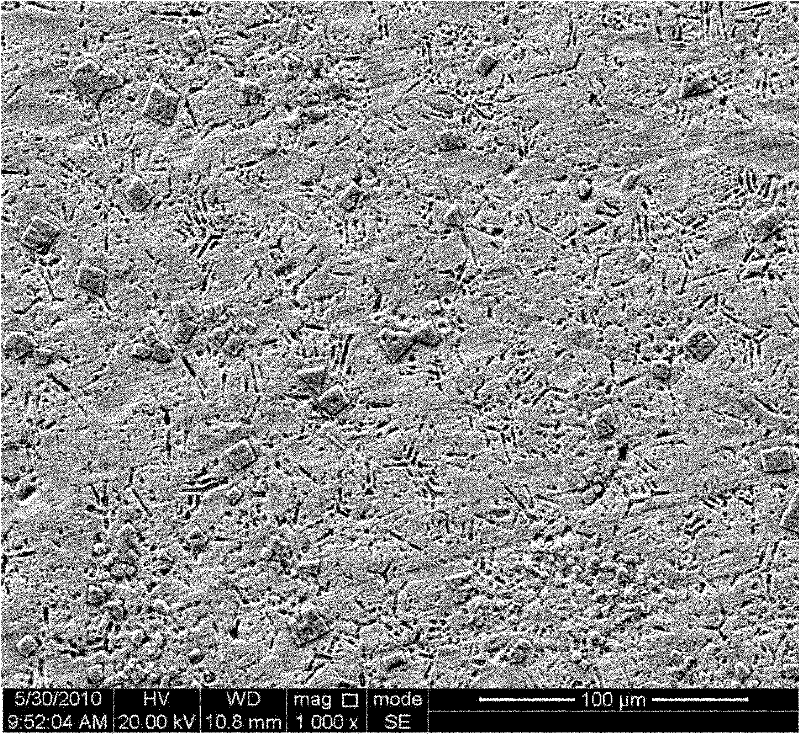

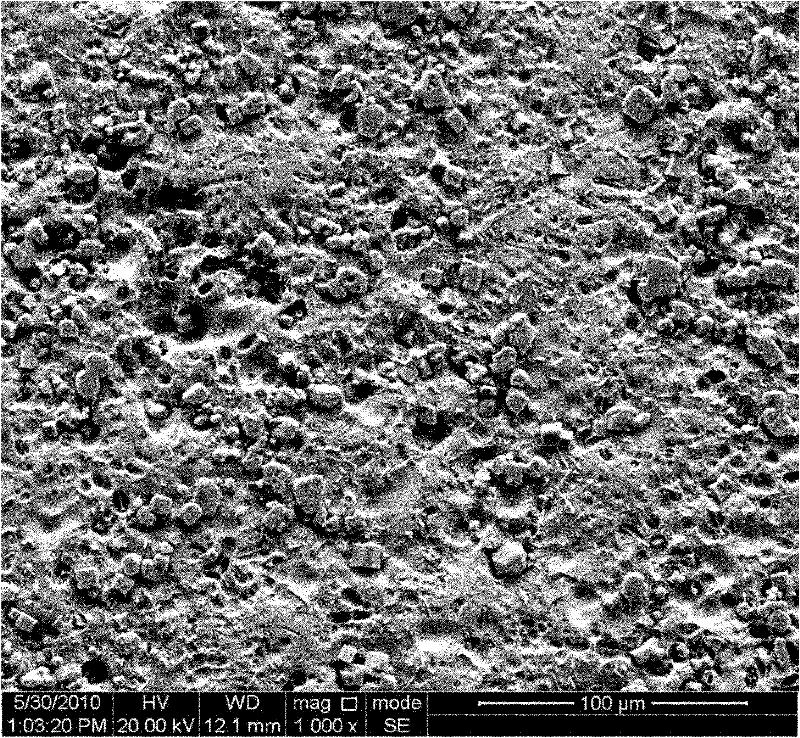

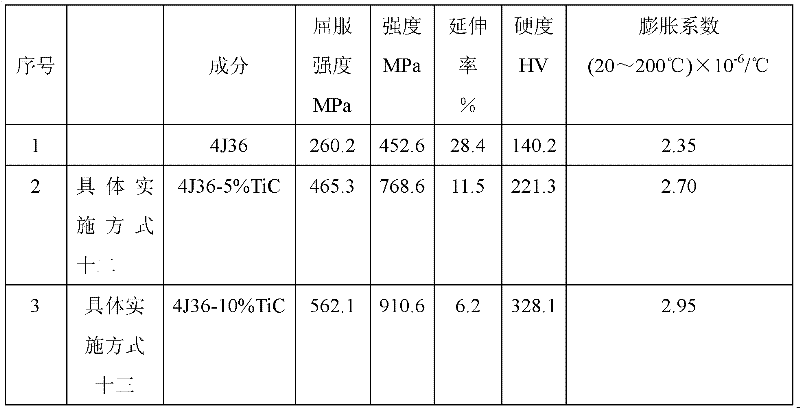

[0019]Embodiment 1: The preparation method of the high-strength ultra-low expansion Invar alloy-based composite material in this embodiment is carried out according to the following steps: 1. High-purity titanium powder (mass purity ≥ 99.5%) and mass purity greater than 99% The carbon powder is put into the powder mixer according to the atomic percentage of 50:50 and mixed evenly, and then pressed into a prefabricated block; 2. At a temperature of 1500-1550°C and a vacuum of 0.5×10 -2 ~6×10 -2 Vacuum arc melting Invar alloy under the condition of Pa to obtain a melt; 3. Add the prefabricated block prepared in step 1 to the melt in step 2 according to the mass ratio of prefabricated block and Invar alloy in a ratio of 0.01 to 0.5:1, and then Keep it warm at ~1550°C for 5-40 minutes, then cool it down to 1400-1460°C, and then pour it into ingots or castings; 4. Heat treat the ingots or castings obtained in step 4 at 600-800°C, and heat treatment time is 0.5 ~10h; that is, a hig...

specific Embodiment approach 2

[0020] Specific embodiment two: the difference between this embodiment and specific embodiment one is that the temperature in step two is 1530°C and the degree of vacuum is 2×10 -2 ~3×10 -2 Pa vacuum arc melting Invar alloy. Other steps and parameters are the same as in the first embodiment.

specific Embodiment approach 3

[0021] Embodiment 3: This embodiment differs from Embodiment 1 or Embodiment 2 in that the mass ratio of the prefabricated block to the Invar alloy in Step 3 is 0.05:1. Other steps and parameters are the same as those in Embodiment 1 or Embodiment 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com