Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

31 results about "Tube Spacer" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

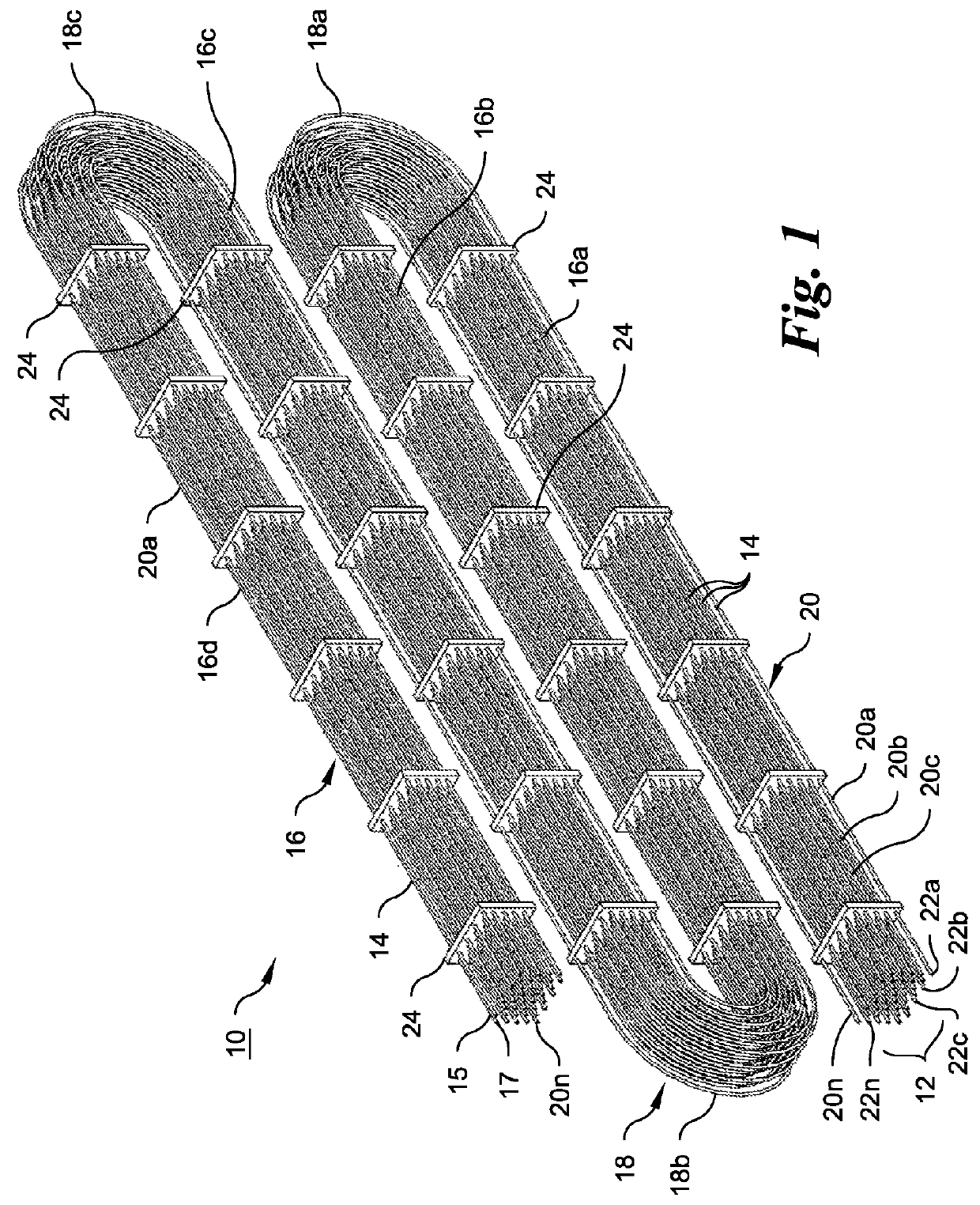

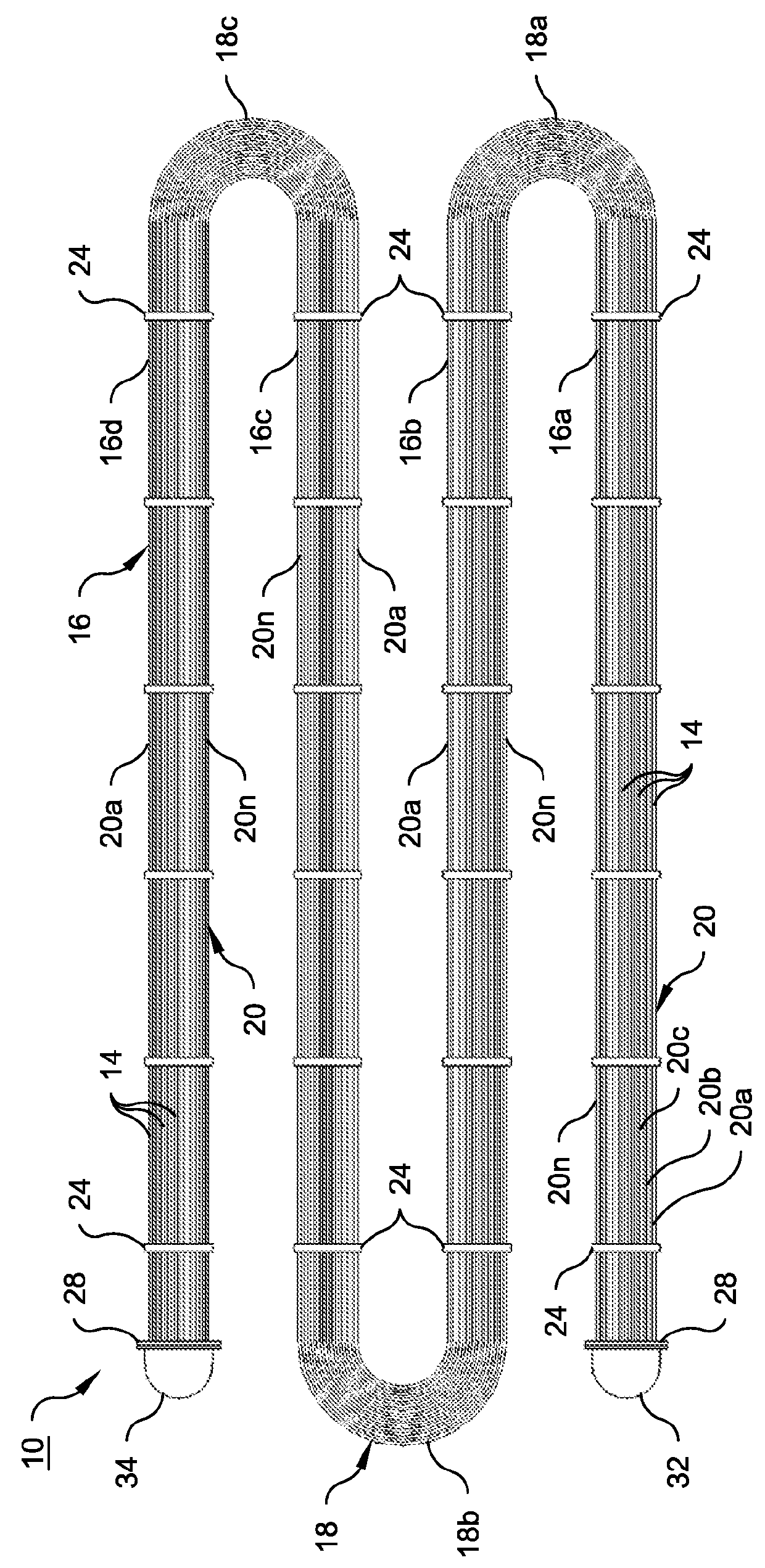

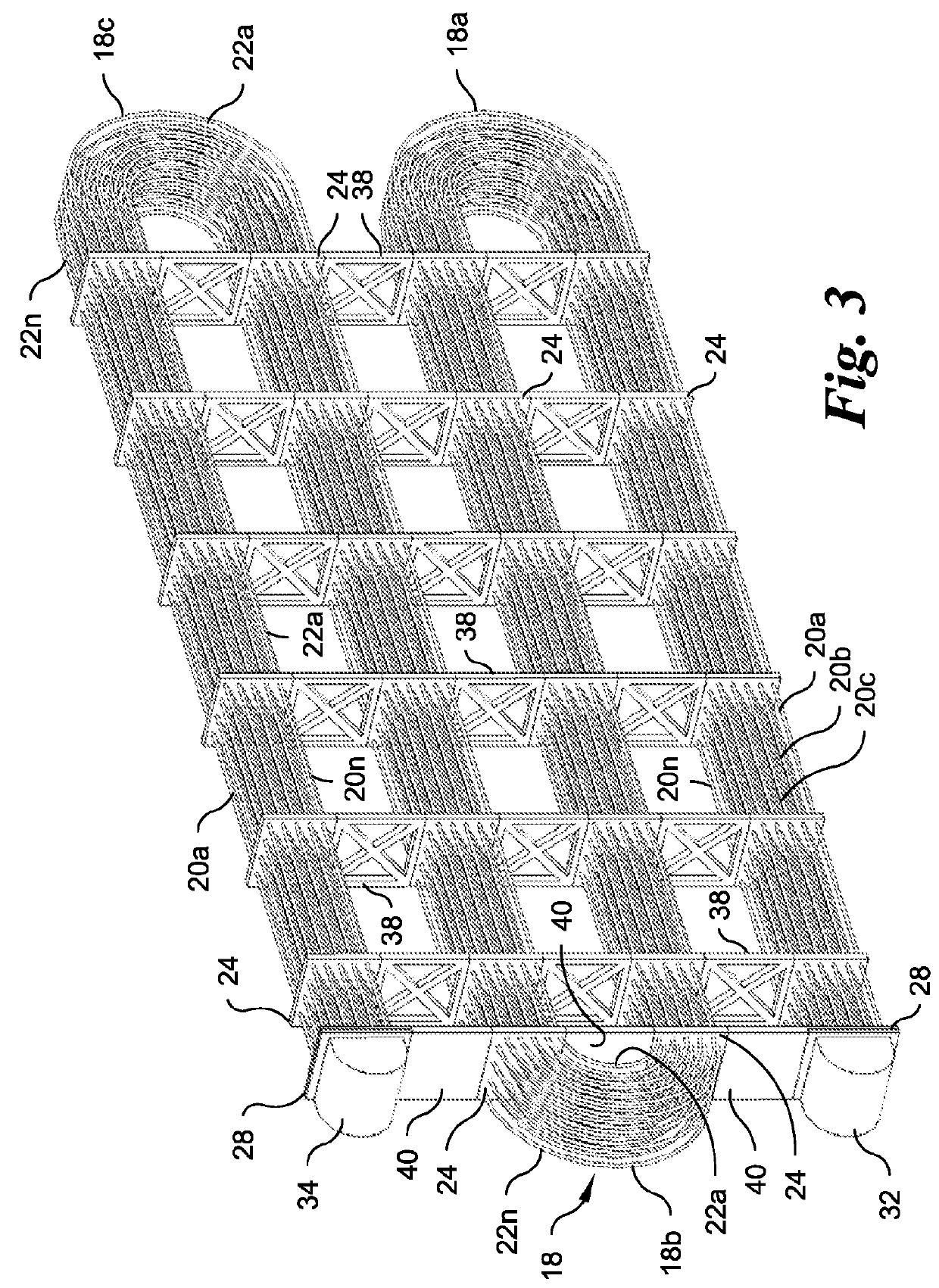

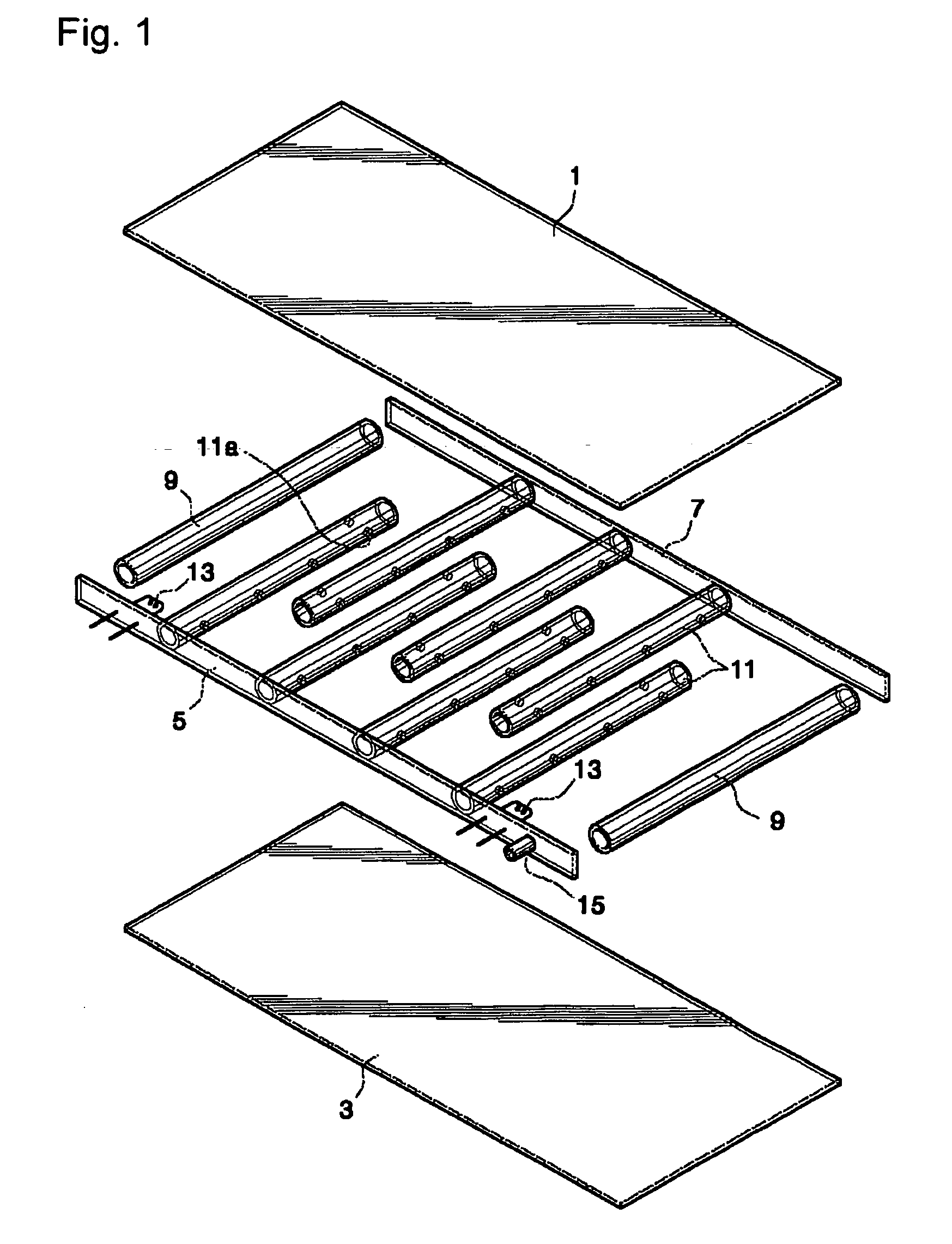

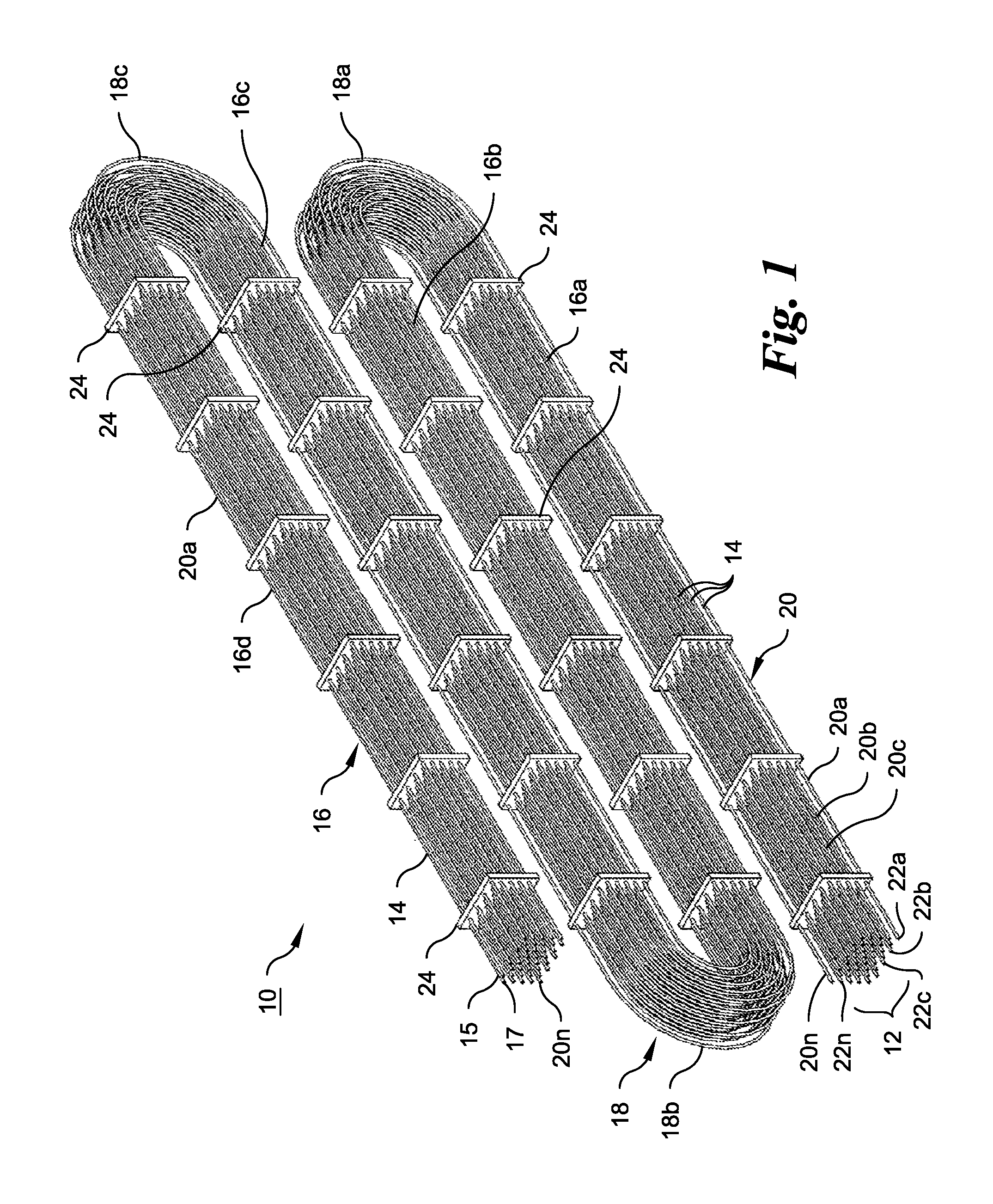

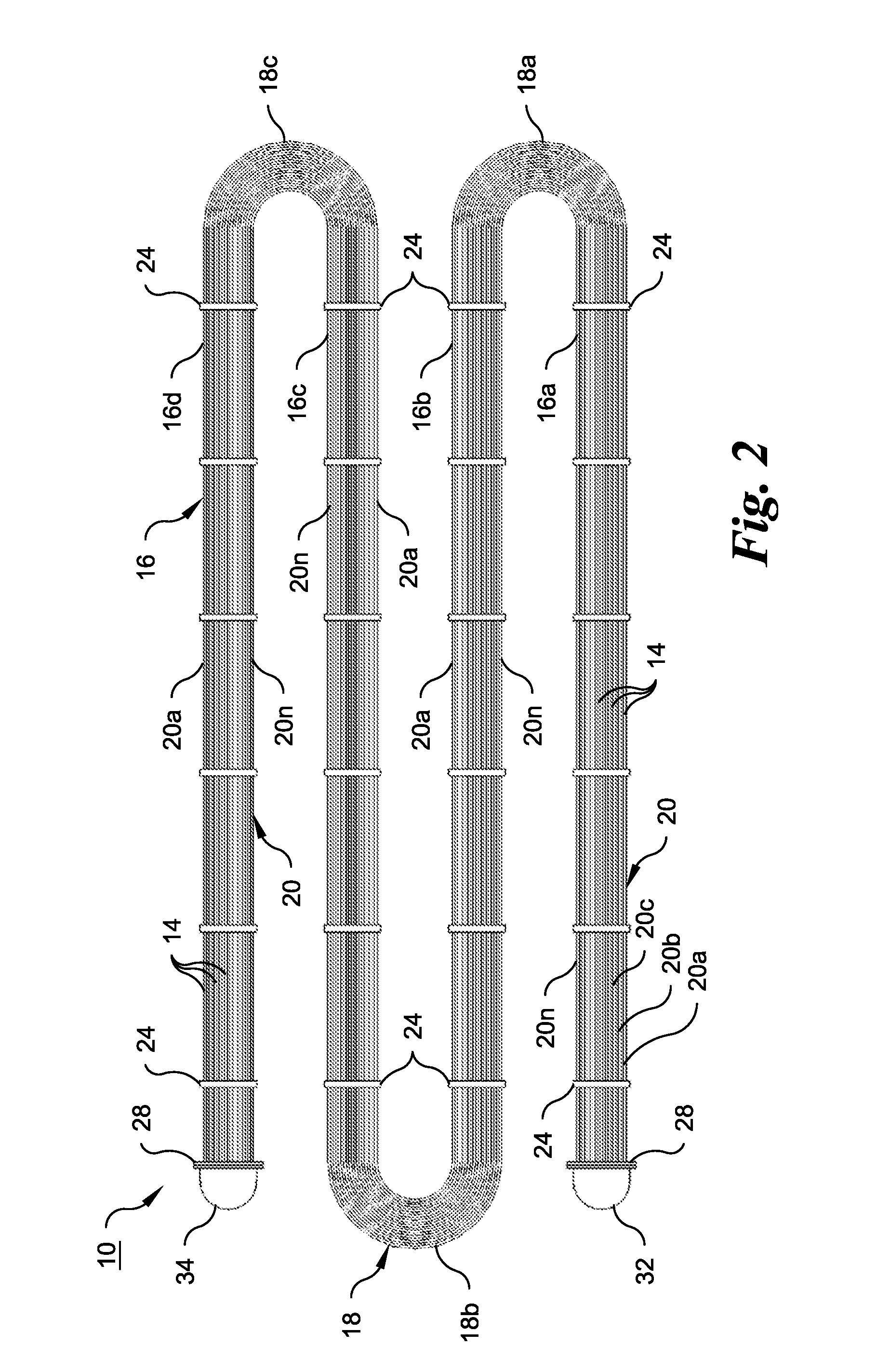

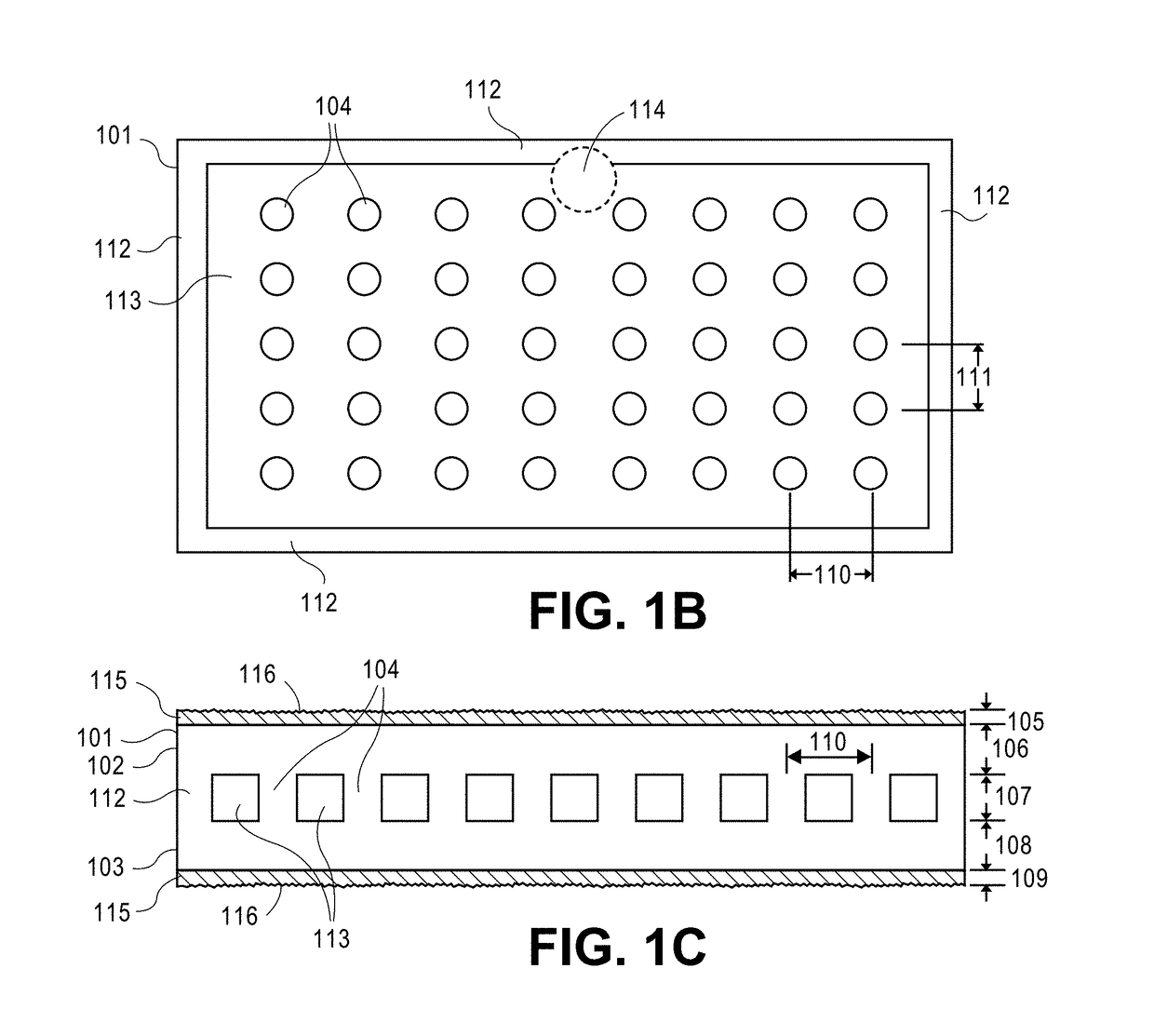

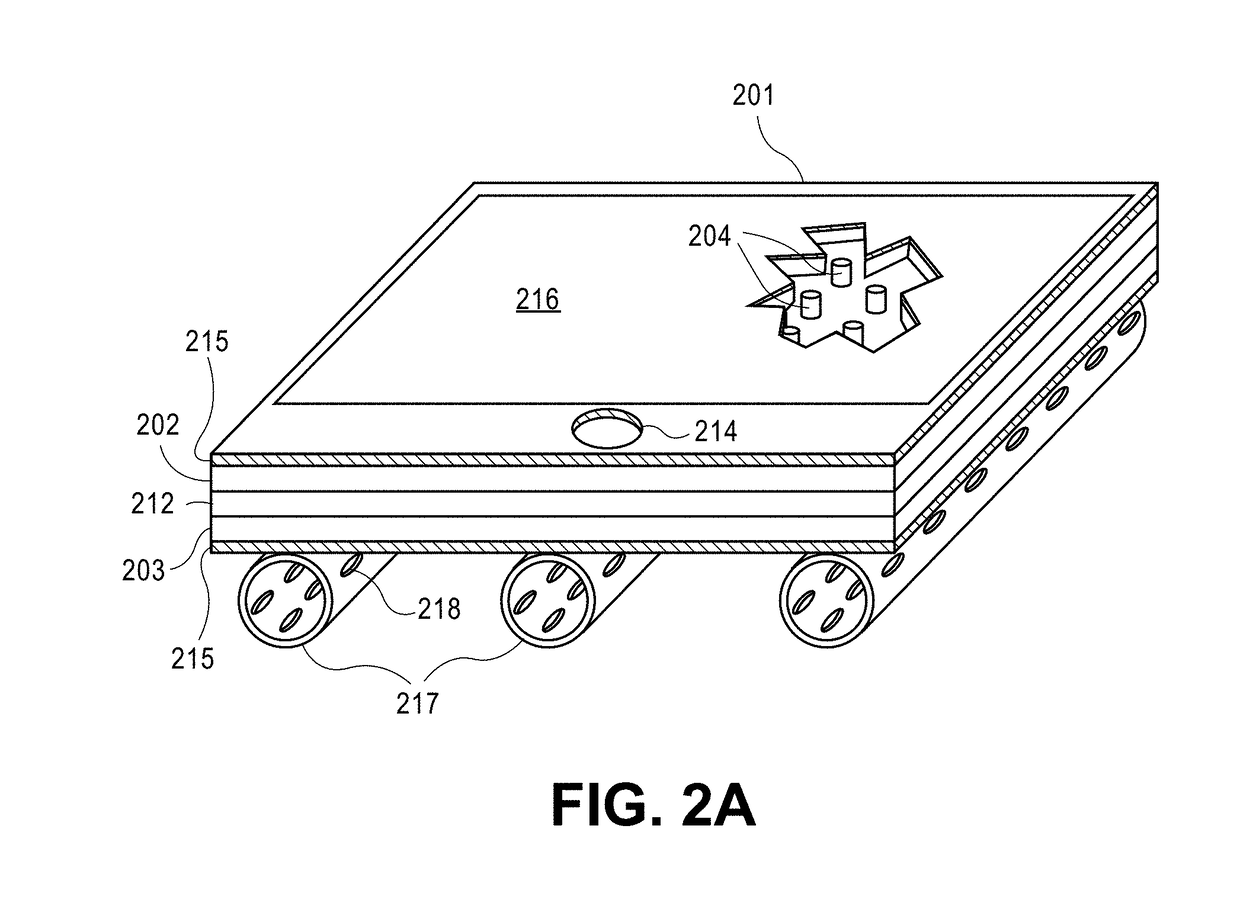

Polymeric coil assembly and method of making the same

Coil assemblies for use in heat exchange applications are made using polymeric tubes, some with heat exchange and water redistribution media integral with the coil assembly and others with a water distribution subassembly integral with the coil assembly. One coil assembly includes at least two generally linear passes that are connected by return bends formed by folding an array of polymeric tubes. The passes have an array of at least two layers of polymeric tubes that pass through alignment holes in tube spacers only along the passes to maintain the tubes in substantially the same relative positional relationship to each other in the passes and in the return bends. Methods are explained for forming the coil assemblies and components, including the tube spacers and tube sheets to connect the coil assembly to inlet and outlet manifolds for the processing fluid flowing internally through the tubes.

Owner:BRENTWOOD INDS

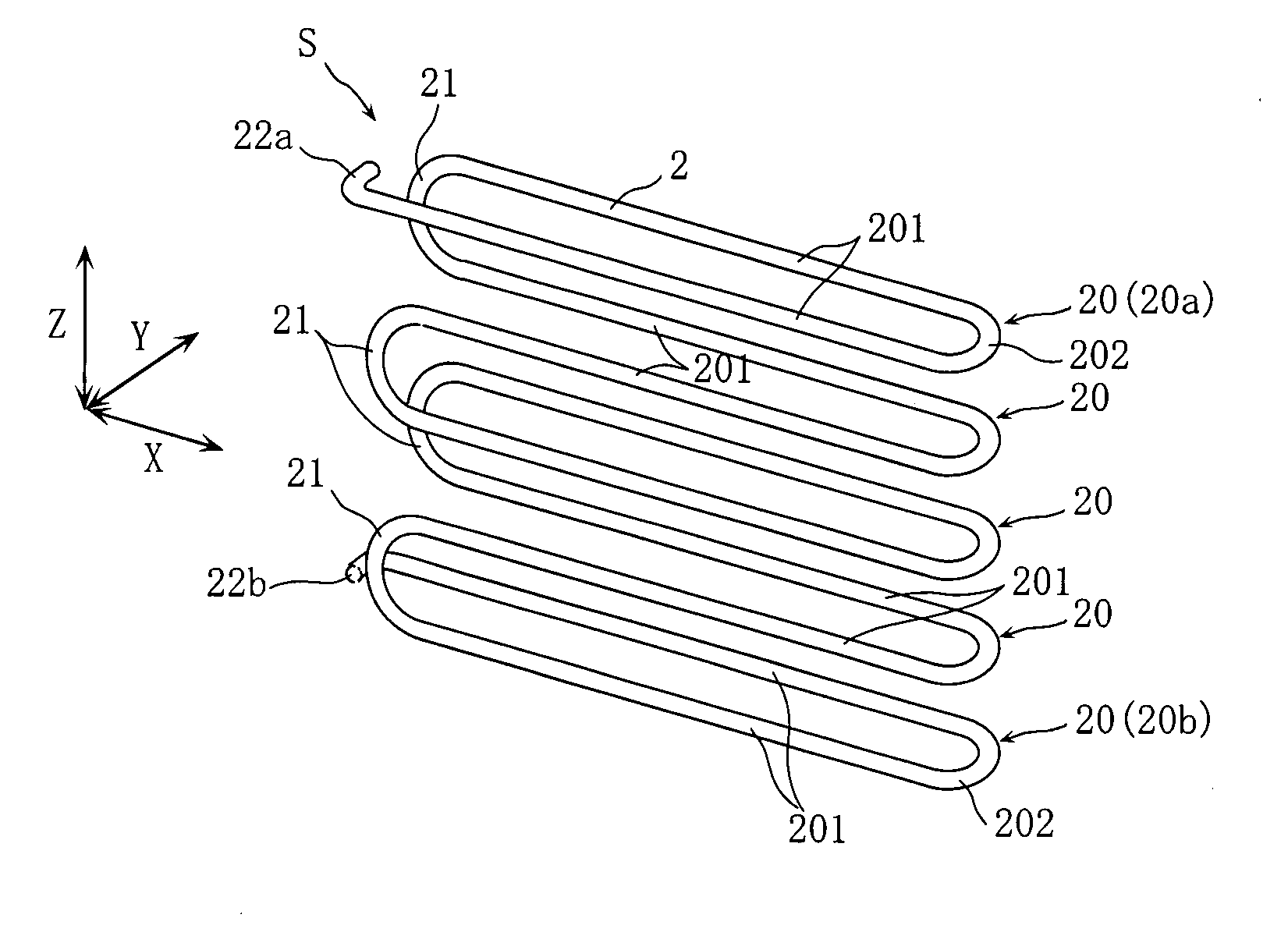

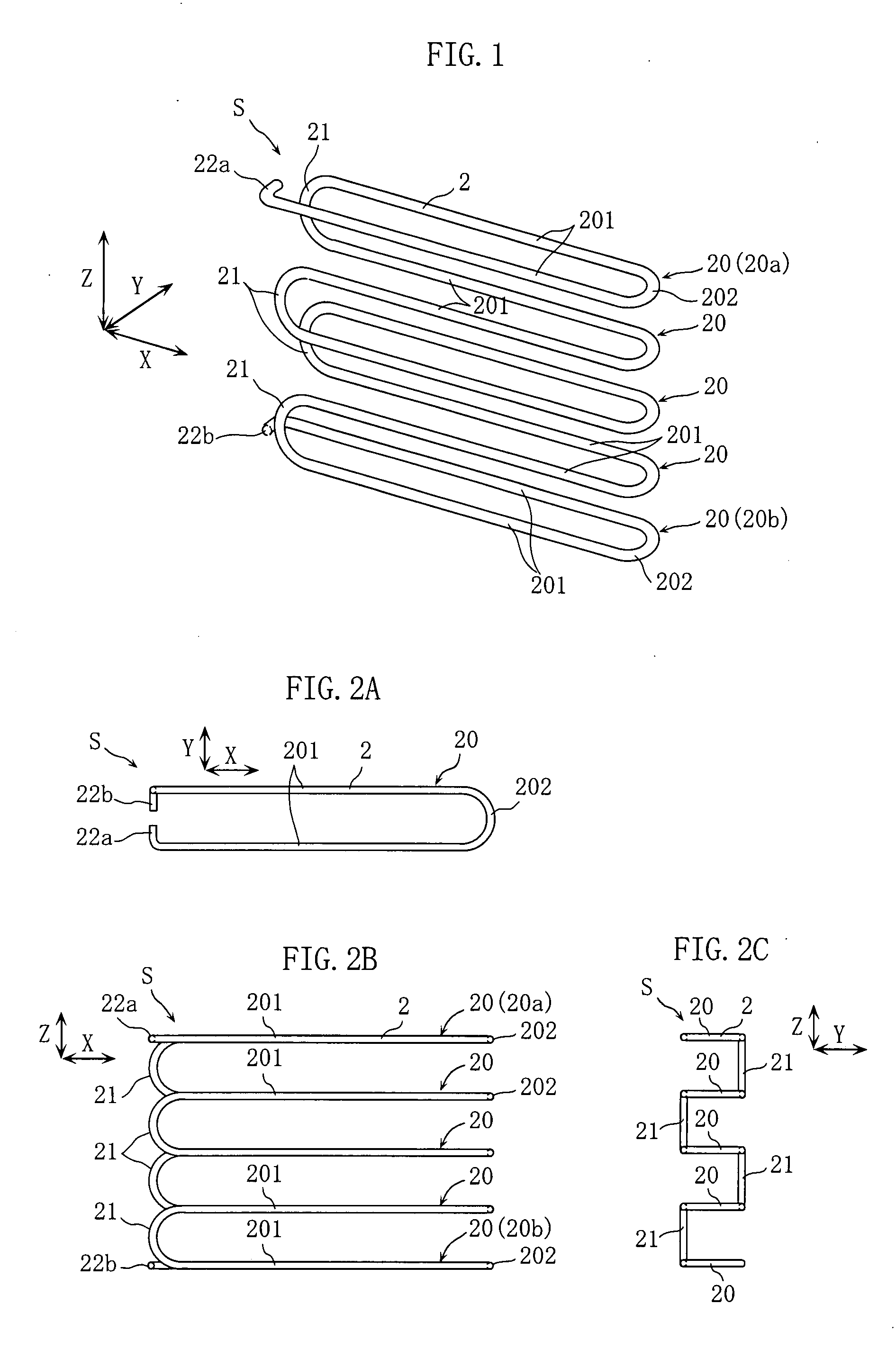

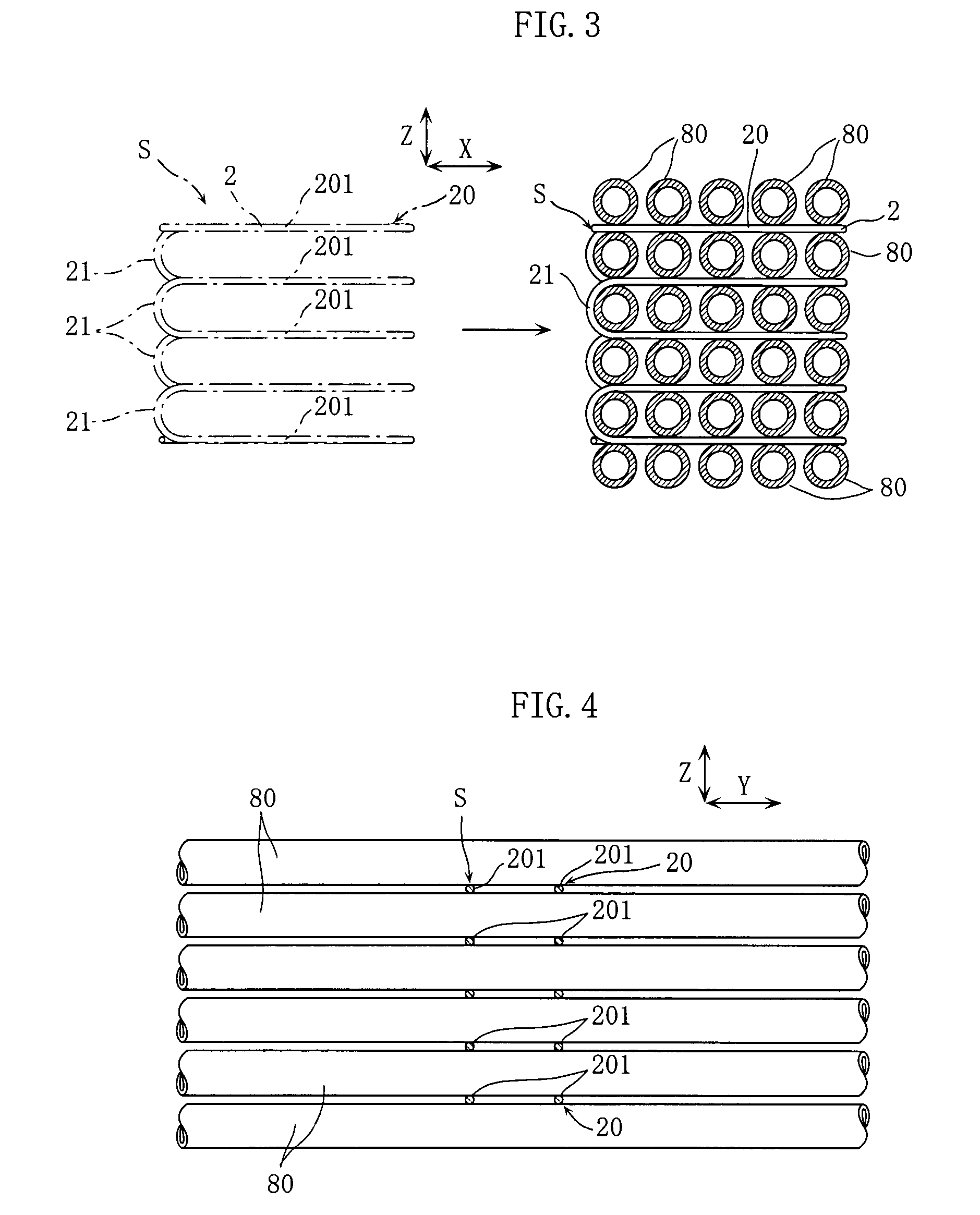

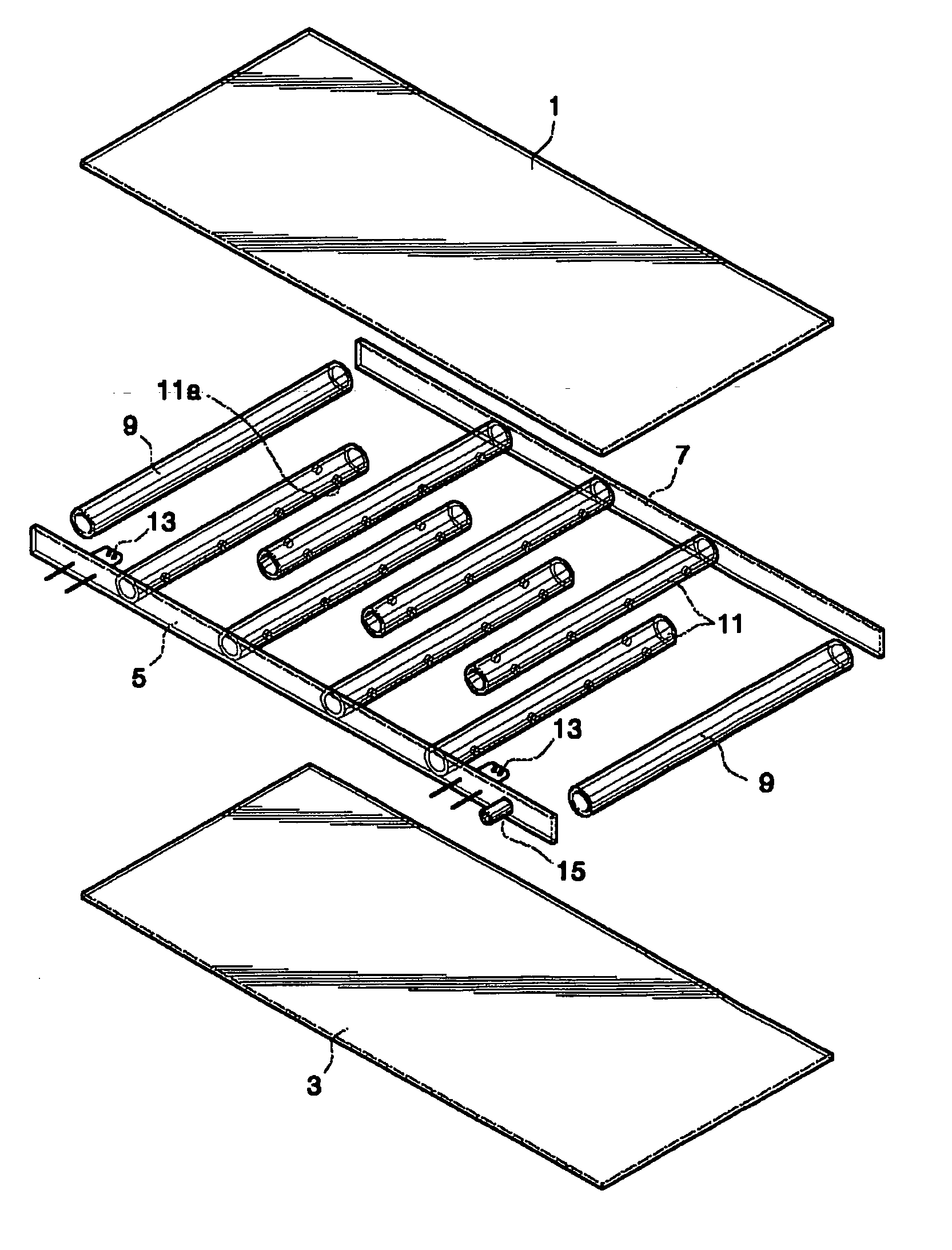

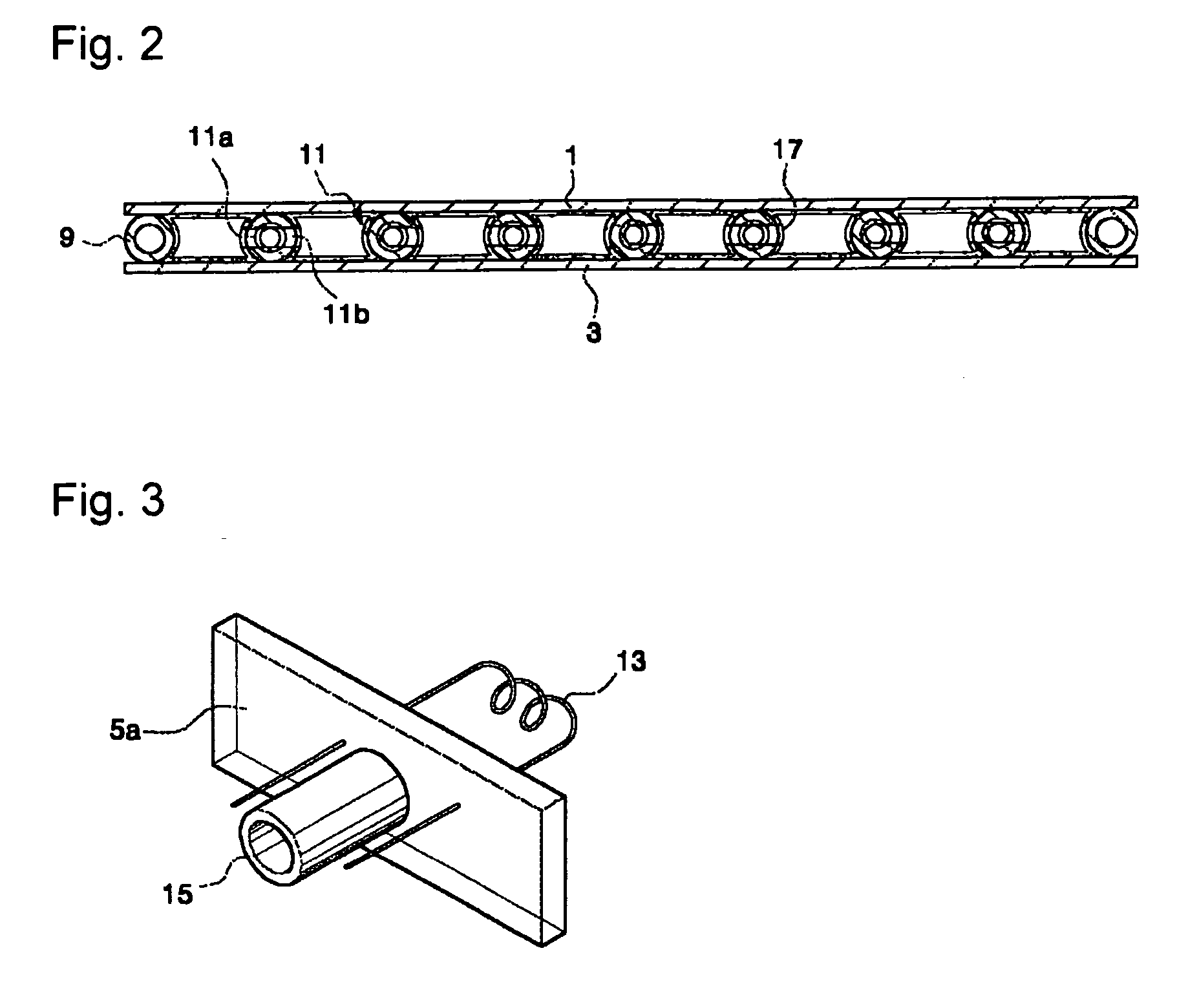

Tube spacer, method of manufacturing the same, and heat exchanger

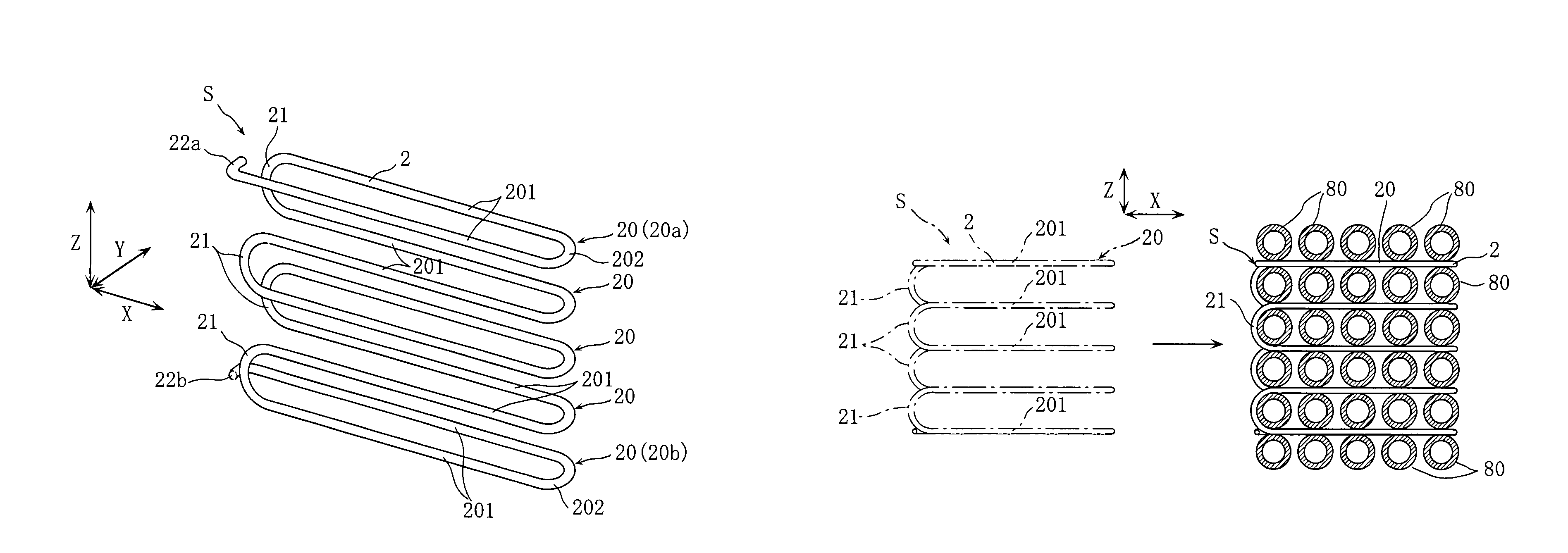

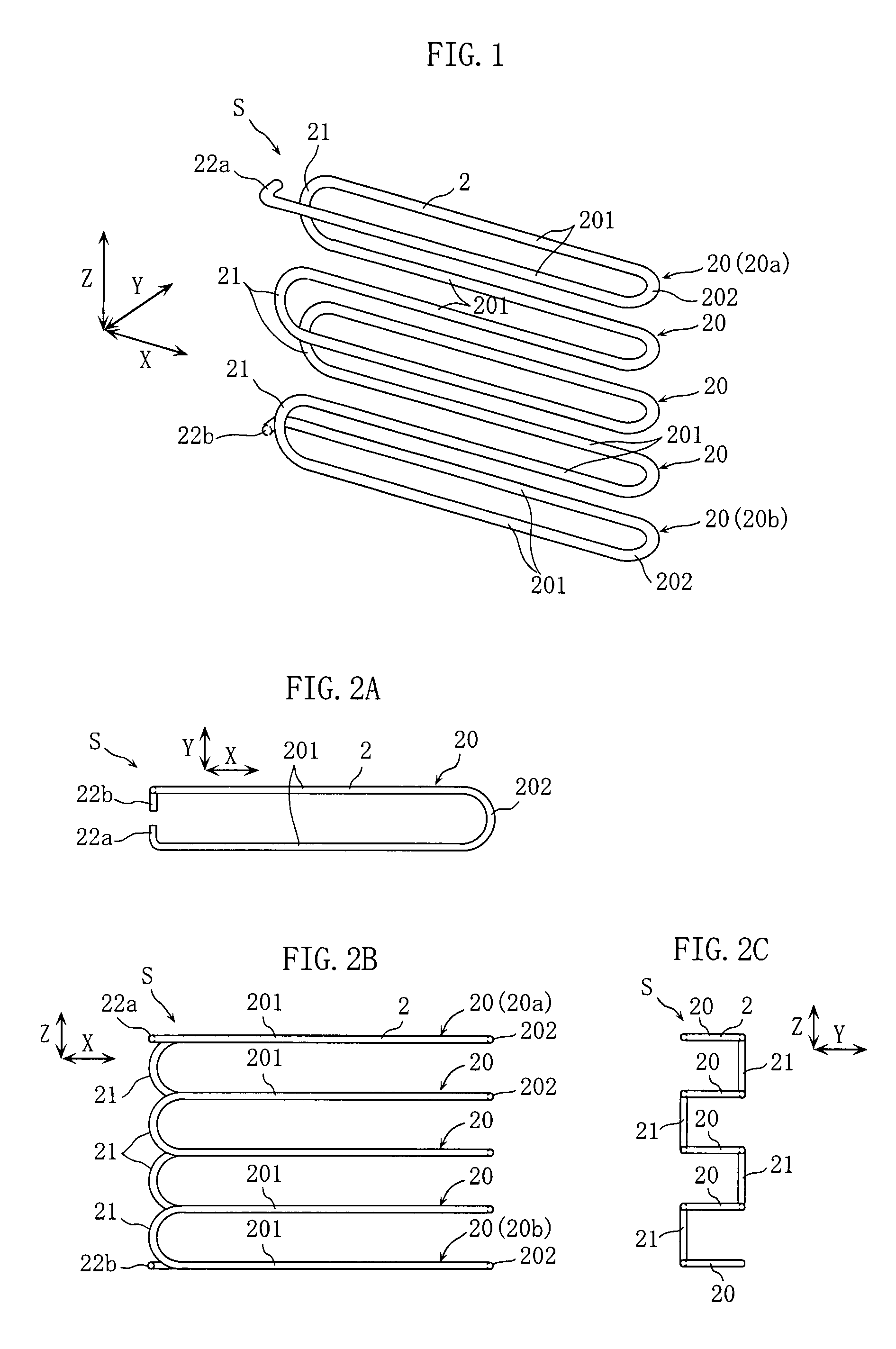

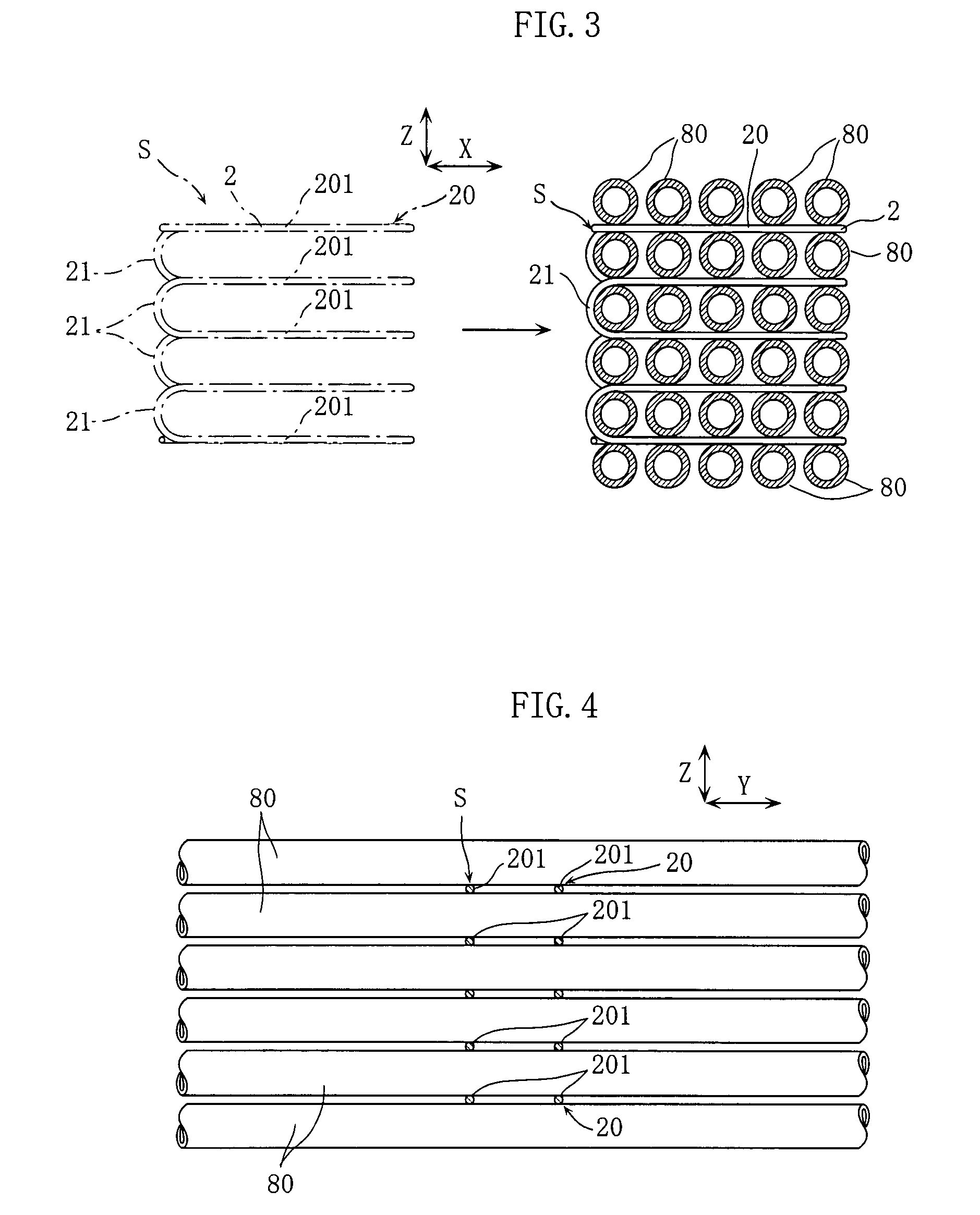

A tube spacer S formed by bending a wire, includes a plurality of projections 20 and a base-bending portion 21. Each of the projections 20 is inserted between tubes, and has a pair of extending portions 201 extend in X direction and a front-bending portion 202 for connecting both front ends of the pair of extending portions 201. The base-bending portion 21 connects both rear ends of the projections 20 so that the projections 20 are arranged at interval in Z direction. With this structure, manufacturing cost for the tube spacer S can be low, and the tubes can be stably supported.

Owner:NORITZ CORP

Flat type fluorescent lamp

InactiveUS20050162088A1Light brightnessLight emission efficiencySolid cathode detailsGas discharge lamp detailsTube SpacerPhosphor

The present invention discloses a flat type fluorescent lamp that is improved in its light emission efficiency and brightness by installing a tube spacer between 2 panels. A flat type fluorescent lamp includes an outer lamp body comprising front and rear panels, and circumference seal members, and tube spacers installed in the outer lamp body to divide the discharge spaces in plural sections communicating with each other to define a discharge path, a phosphor layer deposited on the outer lamp body and the tube spacers, and a discharge electrode supported on the outer lamp body.

Owner:LEE KYE SEUNG

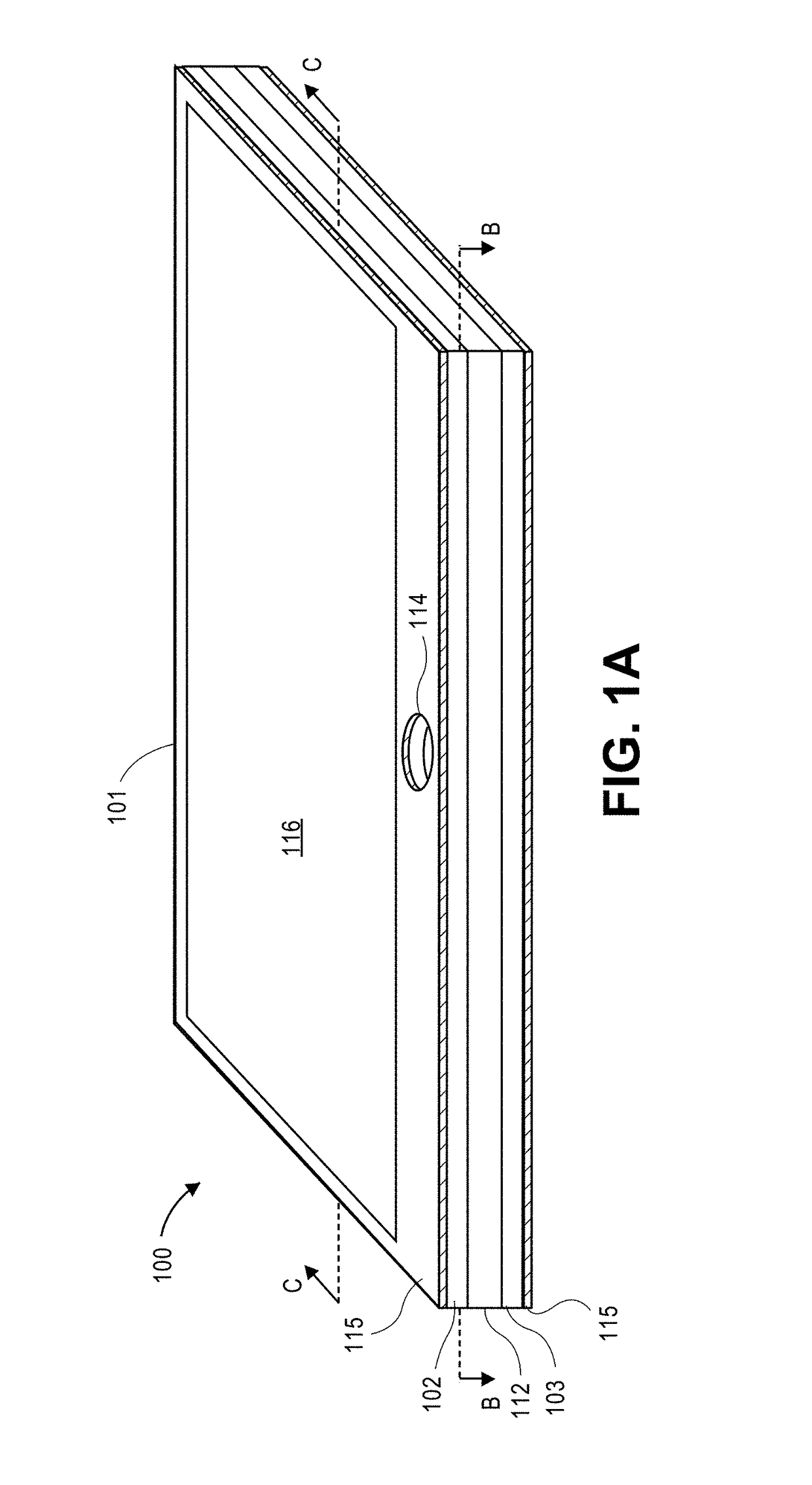

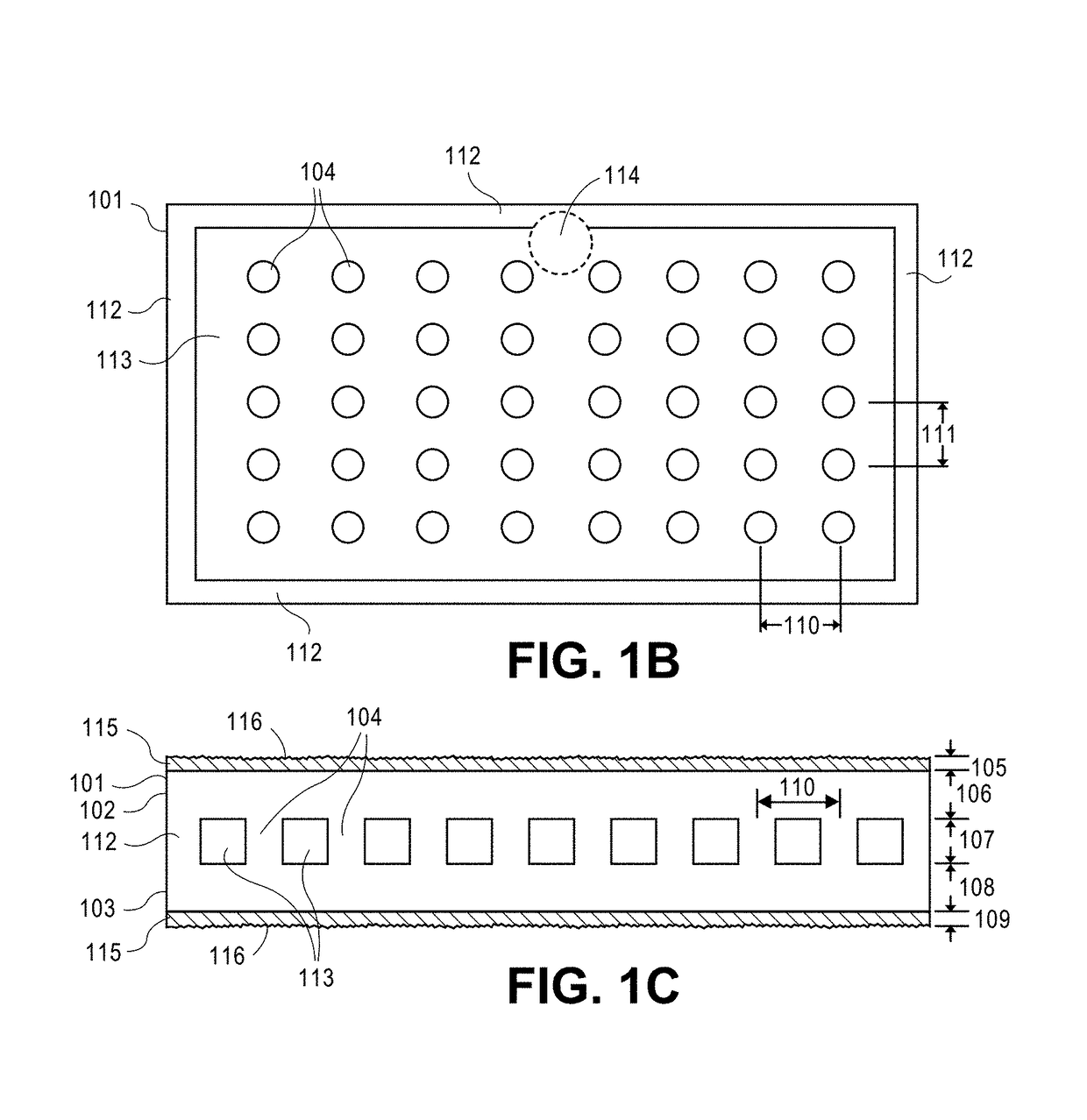

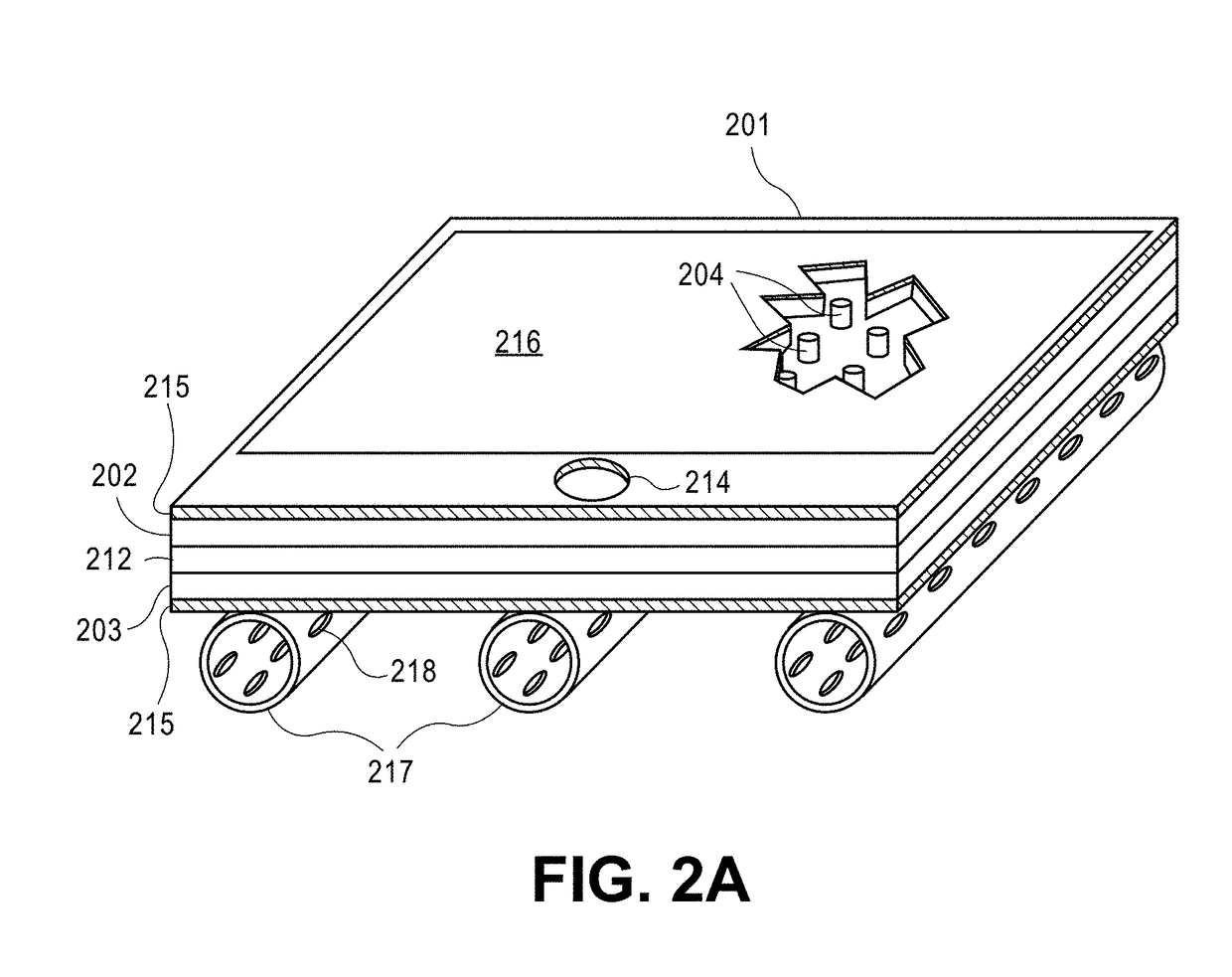

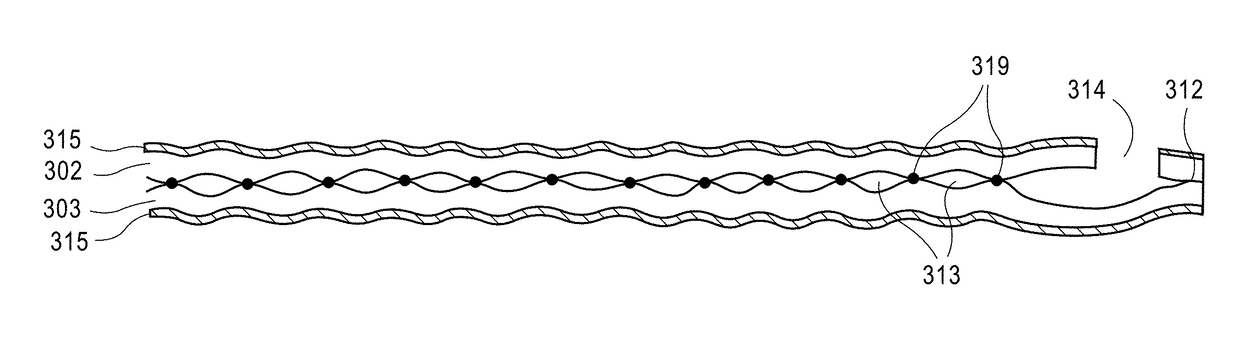

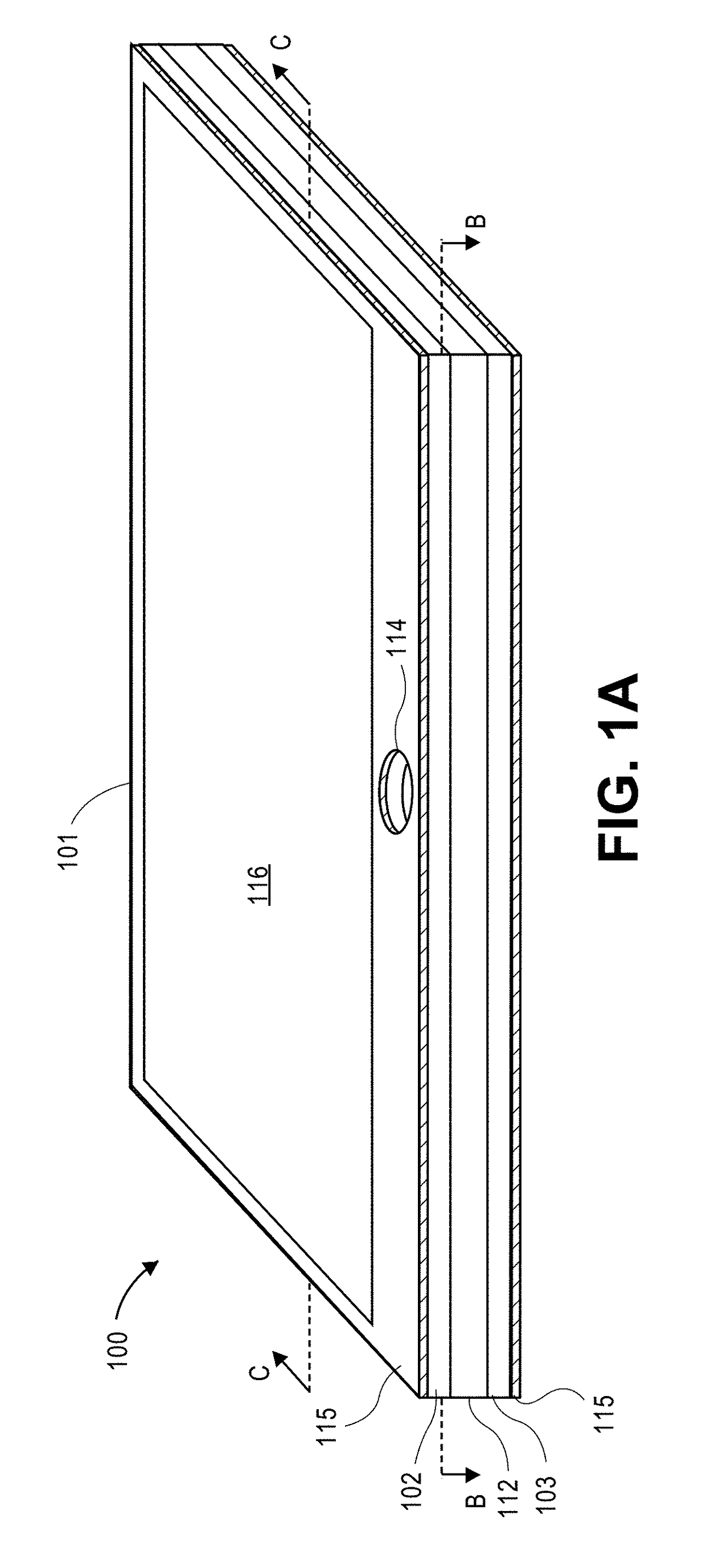

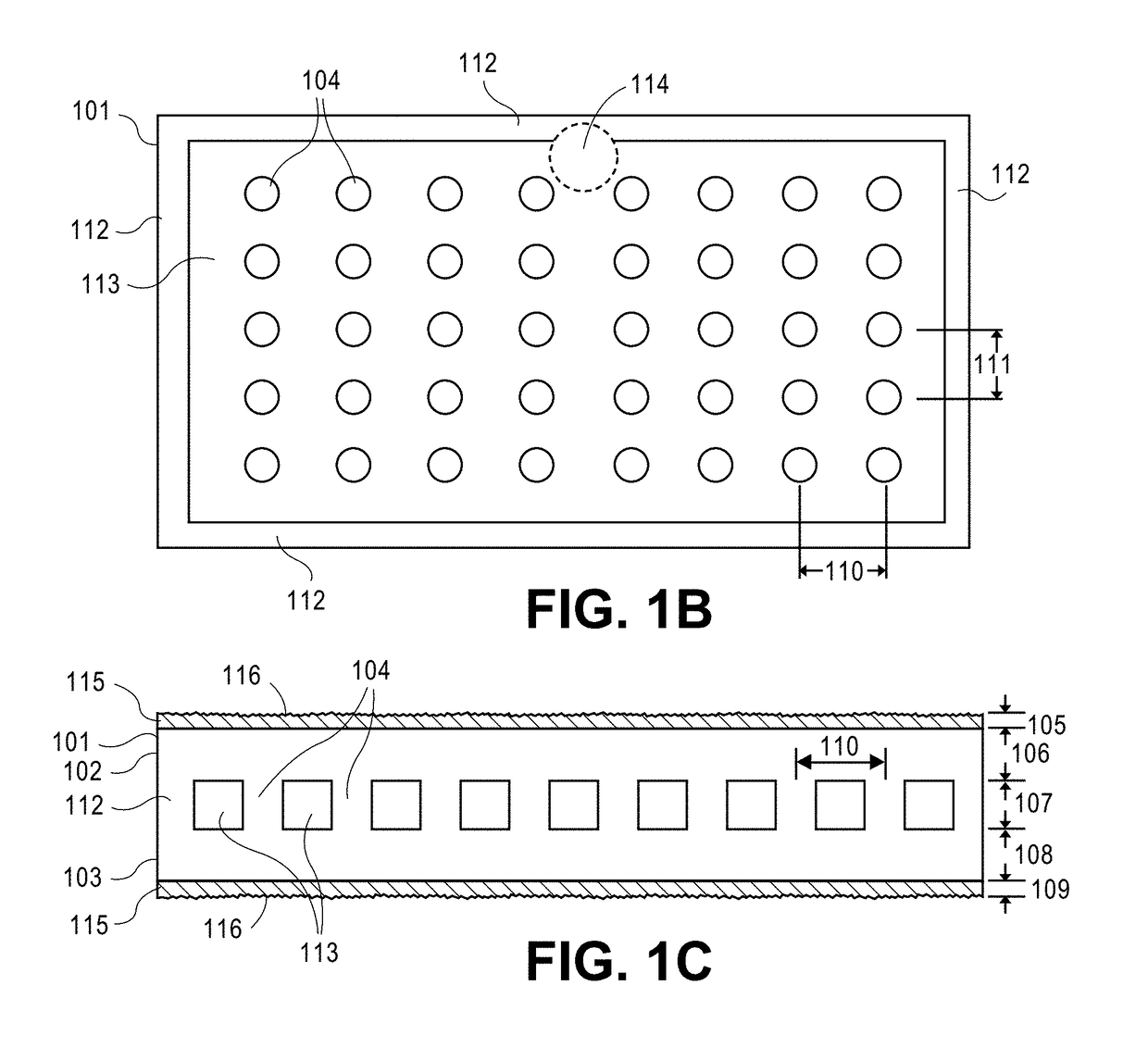

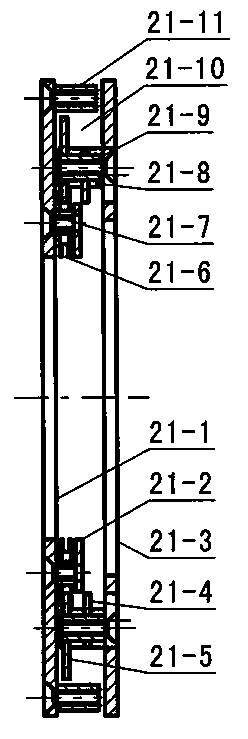

Substrates for high-density cell growth and metabolite exchange

ActiveUS20180016533A1Improve cell adhesionPrevent crashBioreactor/fermenter combinationsBiological substance pretreatmentsParyleneTube Spacer

A polymer or other substrate optimized for growing cells is described, which takes the form of a micro-thin bag with gas permeable sides. Sides of the bag can be held at a fixed distance from one another with a multitude of tiny micropillars or other spacers extending between them, keeping the bag at a predetermined thickness and preventing the bag from collapsing and the sides from sticking together. In other embodiments, the sides may be held apart by gas pressure alone. A 0.01 μm to 1000 μm parylene or other biocompatible coating over the bag outsides controls the permeability of the bag material and provides a bio-safe area for cell growth. An alternate configuration uses open-cell foam with skins coated with a biocompatible coating. Tubes going into multiple bags can be connected to a manifold that delivers gaseous oxygen or removes carbon dioxide and other waste gases. Multiple bags can be stacked together tightly, with o-ring spacers in between, and housed within a vessel to form a high-surface area, ultra-compact cell growing system. For cells growing on the bags, liquid nutrients can be fed by way of the tube spacers, and oxygen and waste gases permeated through the bag sides and transported within the bags.

Owner:CALIFORNIA INST OF TECH +1

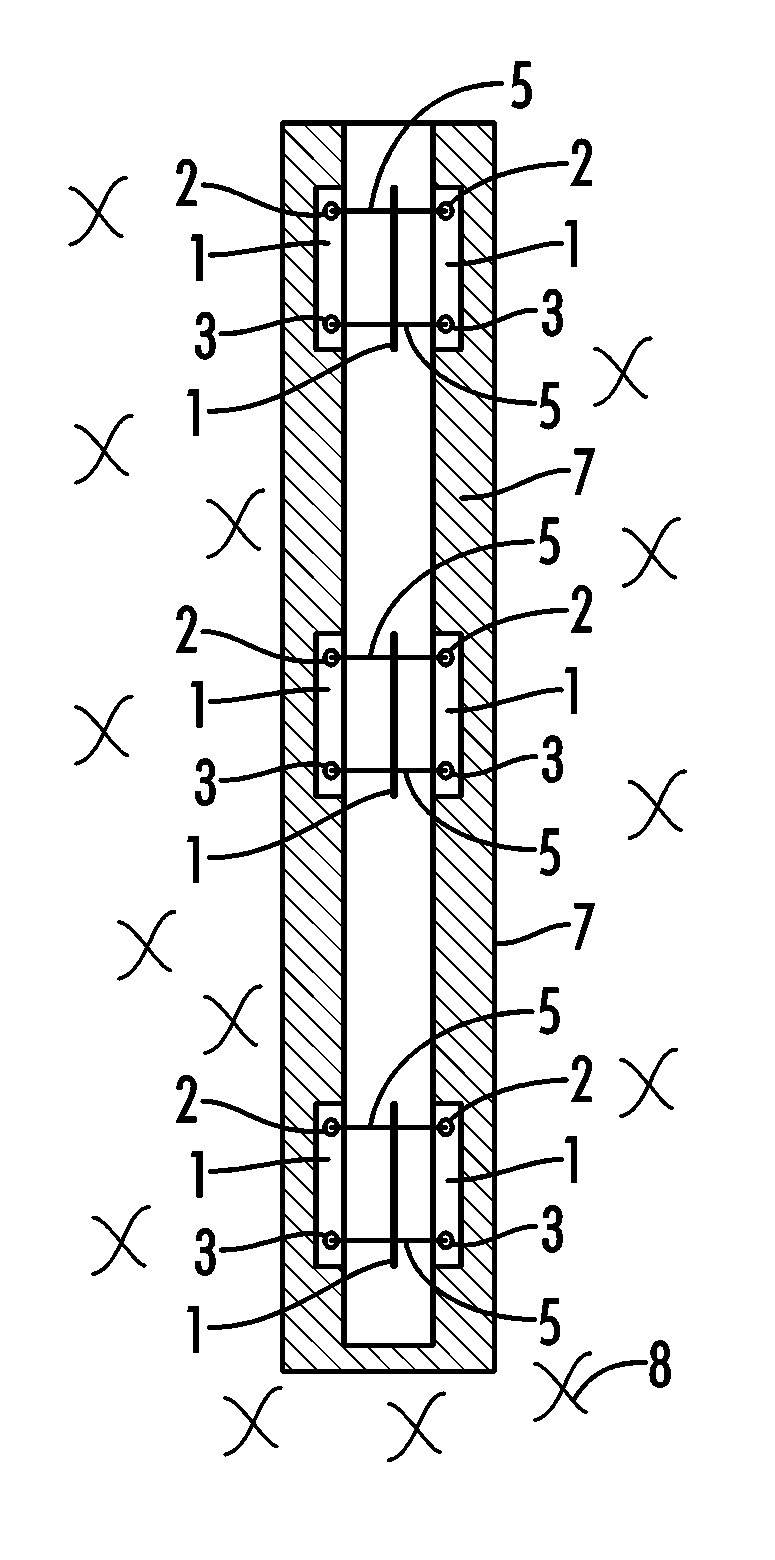

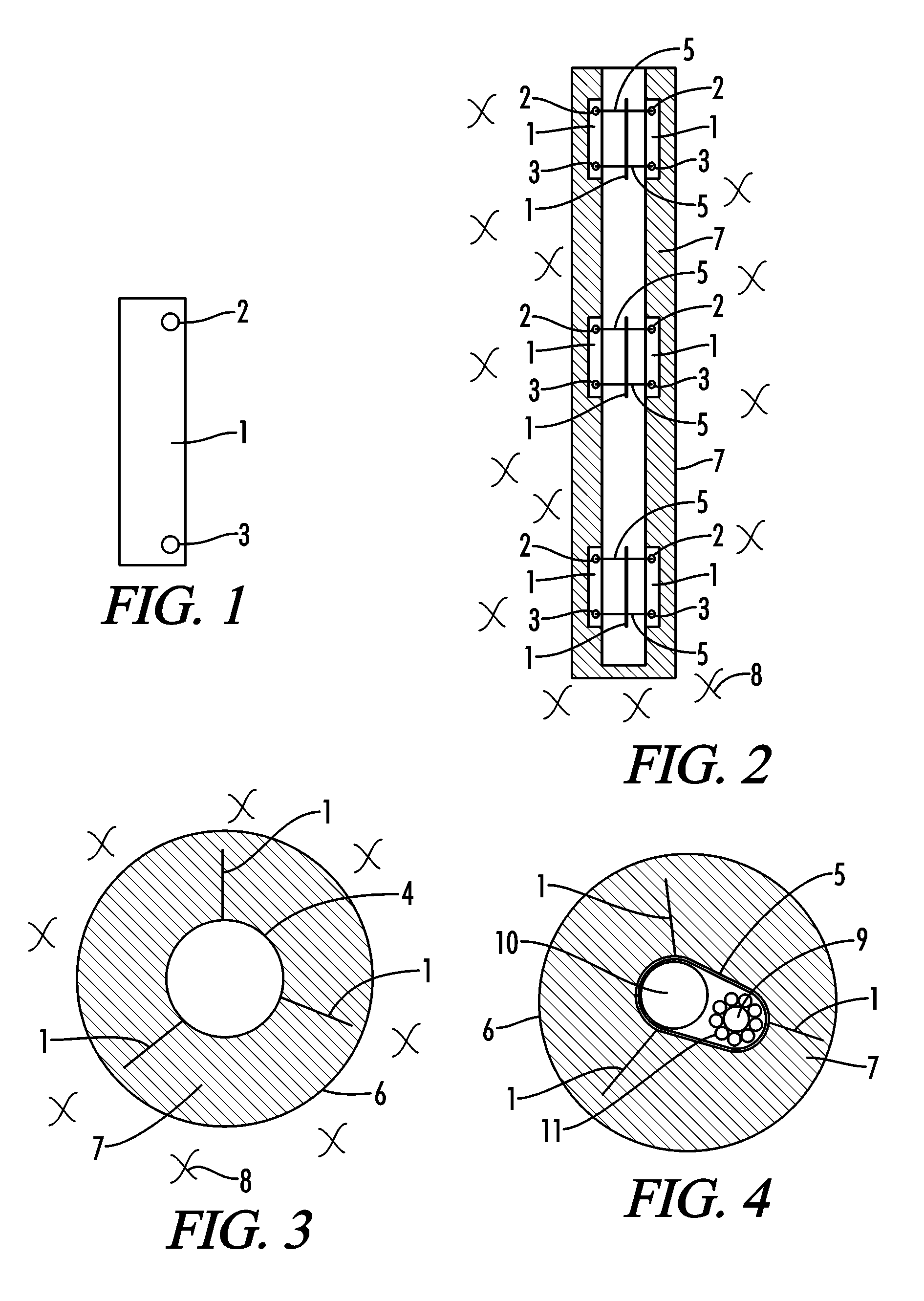

Sub-surface tubing spacer means for direct expansion heating/cooling systems

A direct expansion geothermal heat exchange system with spacer fins attached to at least one of a sub-surface refrigerant transport tubing containment pipe and to sub-surface refrigerant transport tubing, so as to ensure the sub-surface pipe / tubing does not come into direct contact with the ground and is surrounded / encased by a thermally conductive grout that is resistant to corrosive sub-surface elements.

Owner:EARTH TO AIR SYST

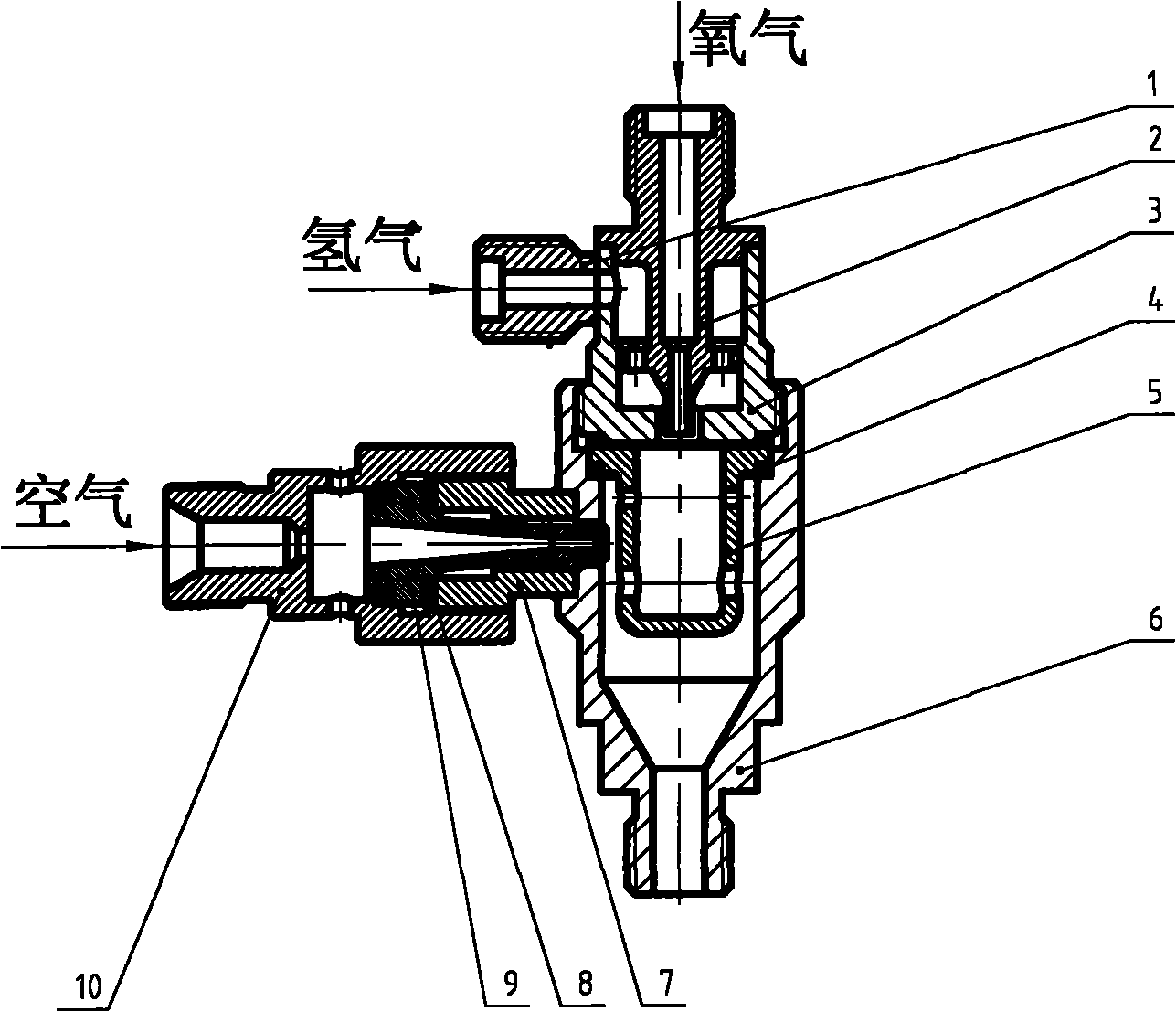

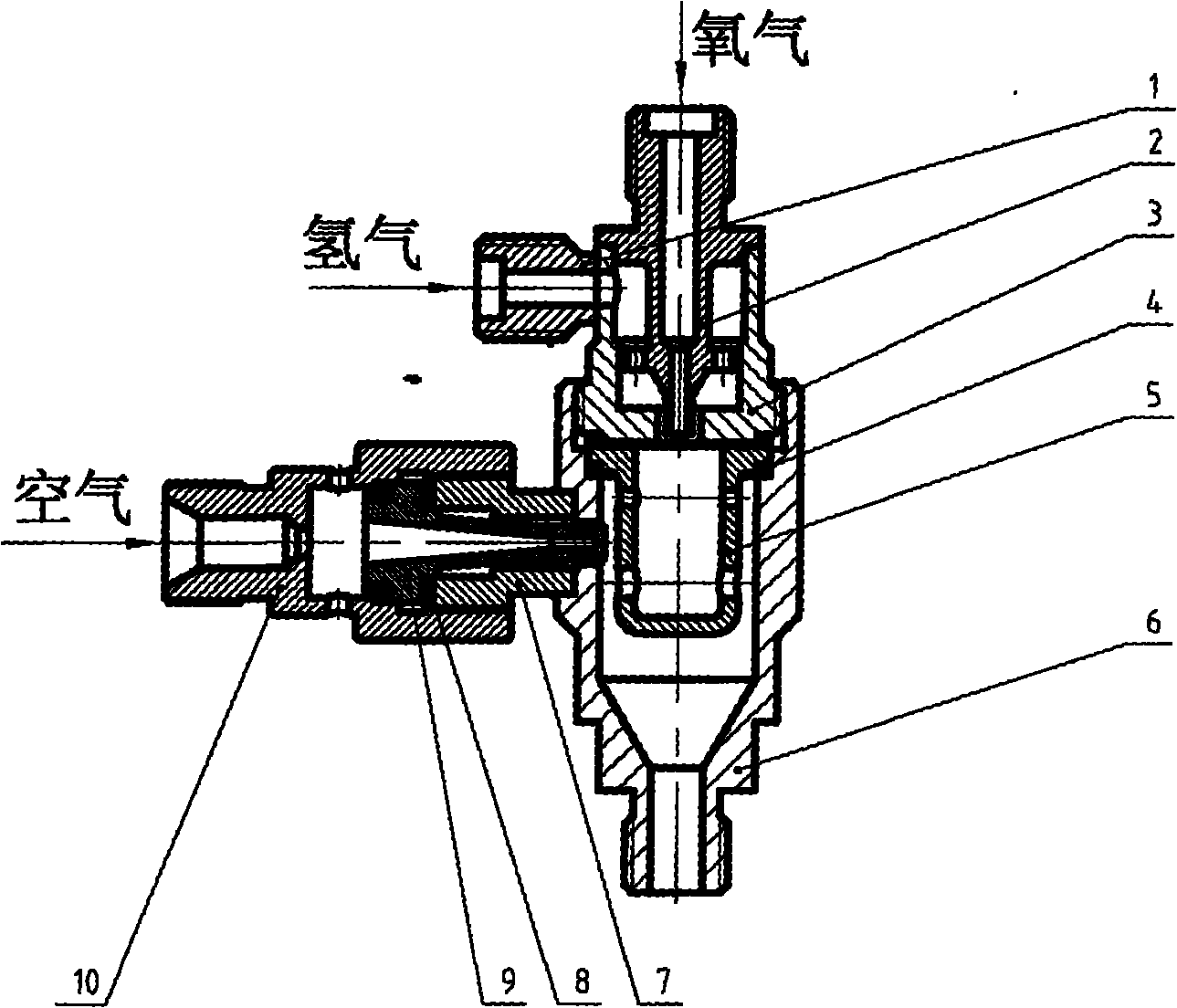

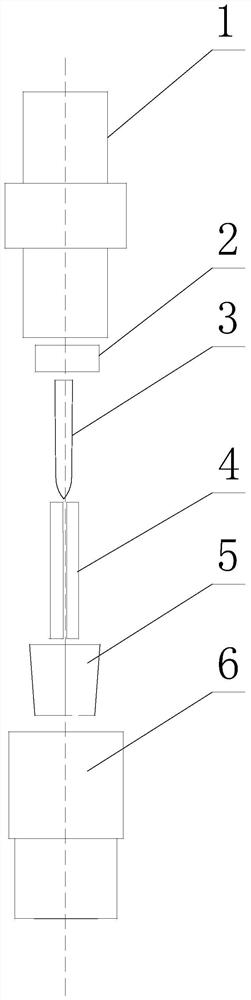

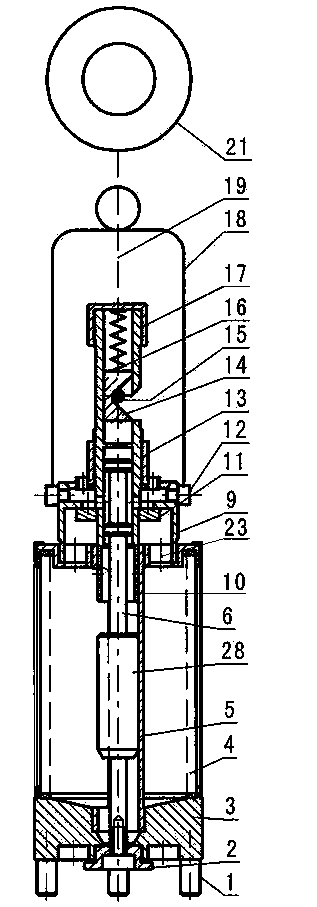

Hydrogen-oxygen gas dynamic resonance surface igniter

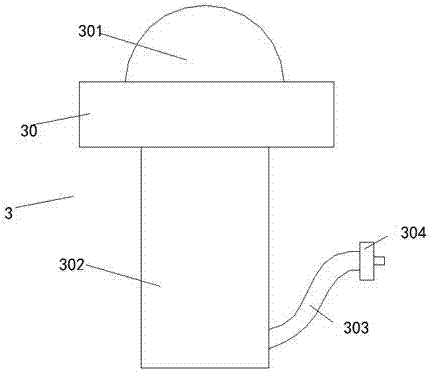

InactiveCN101852147ANo accumulation problemImprove blending effectRocket engine plantsTube SpacerHydrogen

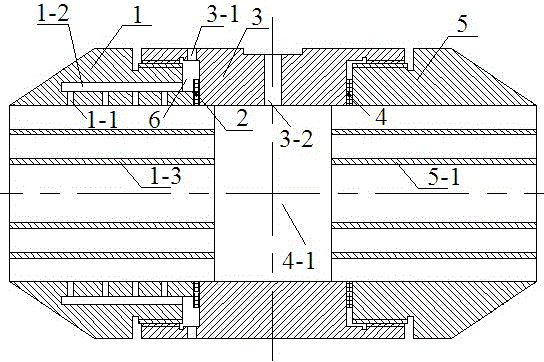

The invention discloses a hydrogen-oxygen gas dynamic resonance surface igniter, which belongs to the field of rocket engines. The hydrogen-oxygen gas dynamic resonance surface igniter consists of a hydrogen joint nozzle 1, an oxygen joint nozzle 2, a nozzle 3, a seal washer 4, a mixing cup 5, an ignition chamber 6, a resonating tube joint nozzle 7, a resonating tube spacer shim 8, a resonating tube 9 and an air joint nozzle 10, wherein the mixing cup is positioned between the nozzle and the ignition chamber and is provided with two rows of holes; the hydrogen and oxygen sprayed from the igniter nozzle pass through the mixing cup and then enter into the ignition chamber, thus being favor for blending and combusting; the resonating tube joint nozzle is positioned at the side face of the igniter, and the resonating tube joint nozzle is welded between the two rows of the holes of the mixing cup, thus being favor for igniting; the resonating tube stretches into the ignition chamber by means of the resonating tube joint nozzle, is fixed by screw threads between the air joint nozzle and the resonating tube joint nozzle, and can be sealed by utilizing the resonating tube spacer shim to regulate the depth of stretching into the ignition chamber of the resonating tube.

Owner:BEIHANG UNIV

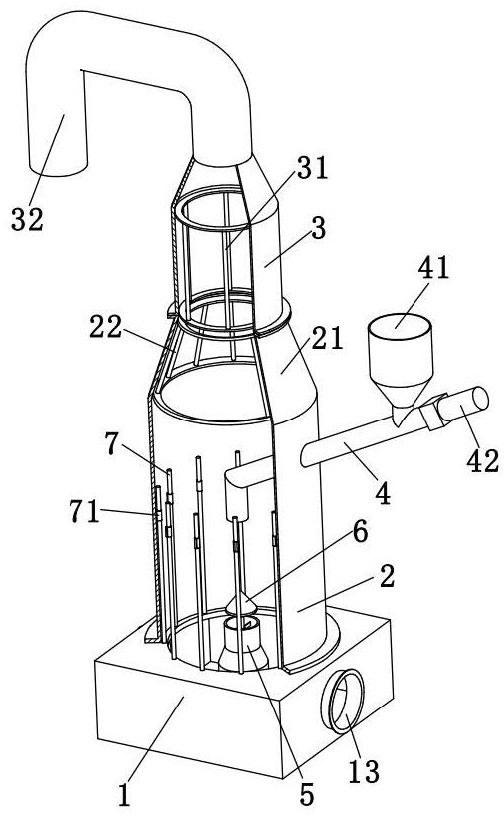

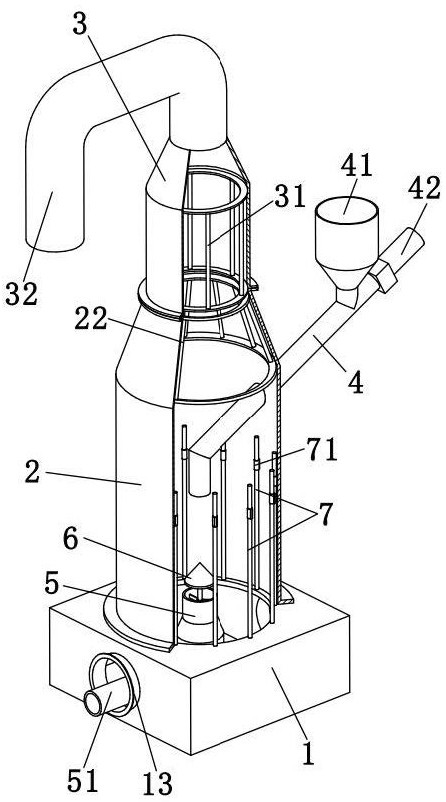

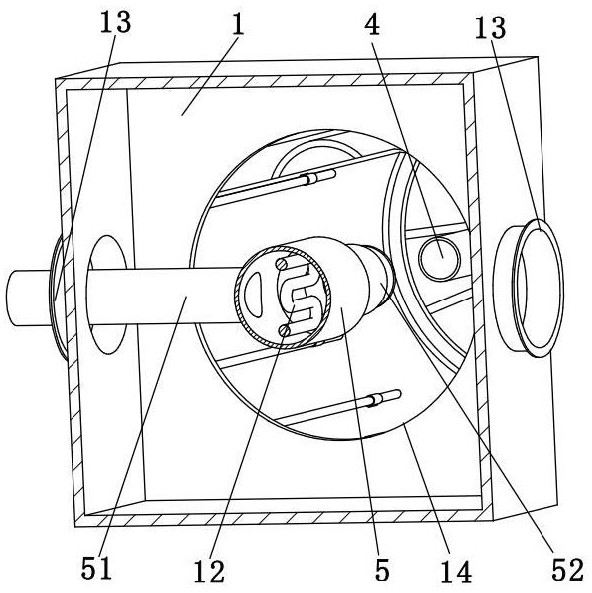

Intermittent Shellfish Release Vessels

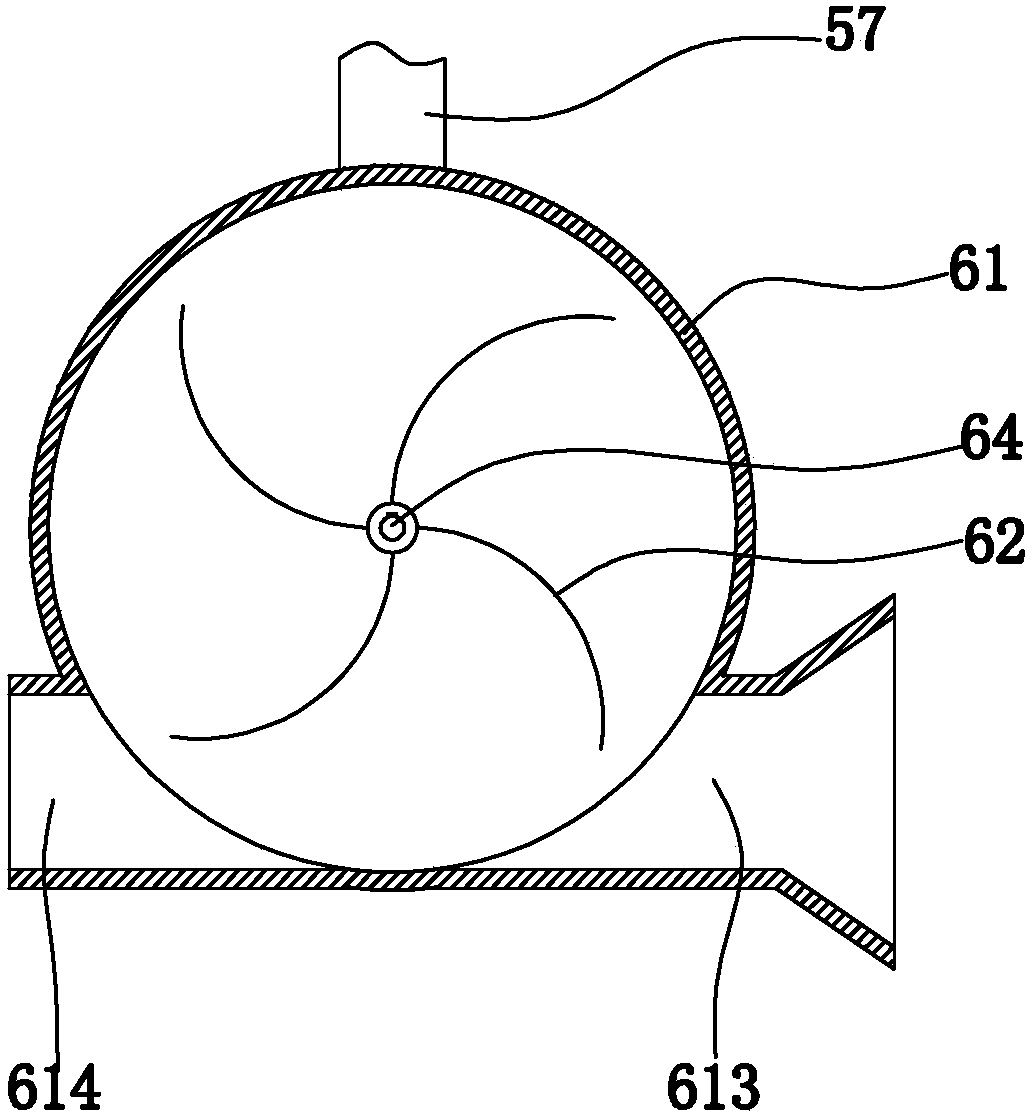

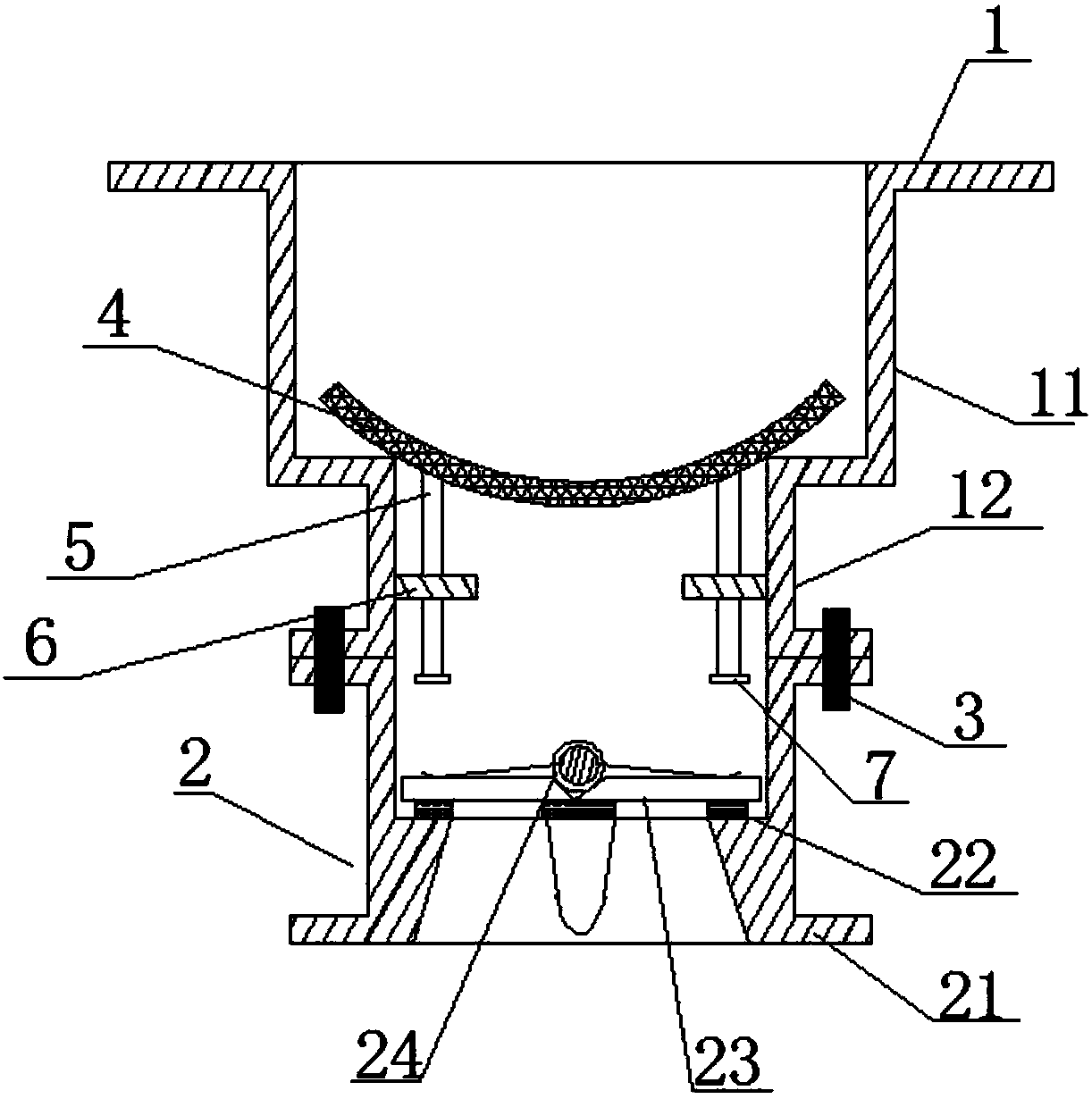

ActiveCN105519464BImprove survival rateReduce labor intensityWaterborne vesselsClimate change adaptationImpellerTube Spacer

The invention discloses an intermittent shellfish releasing ship, which aims to provide an intermittent shellfish releasing ship which not only has low labor intensity, but also has good releasing uniformity and can improve the survival rate of shellfish fry. It includes a counterweight, a column arranged on the hull, an elevating platform that can be lifted along the column, an intermittent self-discharging device that is arranged on the elevating platform and located below the elevating platform, and a deck that is arranged on the hull and runs through the hull. The vertical isolation sleeve of the bottom plate, the vertical isolation sleeve is located below the lifting platform, and the intermittent self-discharging device can pass through the vertical isolation sleeve and is located below the hull; the intermittent self-discharging device includes a fixed isolation cylinder with a horizontal axis, The dynamic discharge cylinder and the first driving impeller arranged on the rotation shaft can be rotated through the rotating shaft. The shaft coincides with the axis of the fixed isolation cylinder. The lower part of the outer surface of the fixed isolation cylinder is provided with a fixed discharge port. A dynamic discharge port is arranged on the outer surface of the dynamic discharge cylinder.

Owner:MARINE FISHERIES RES INST OF ZHEJIANG

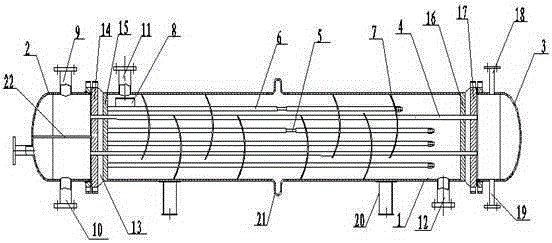

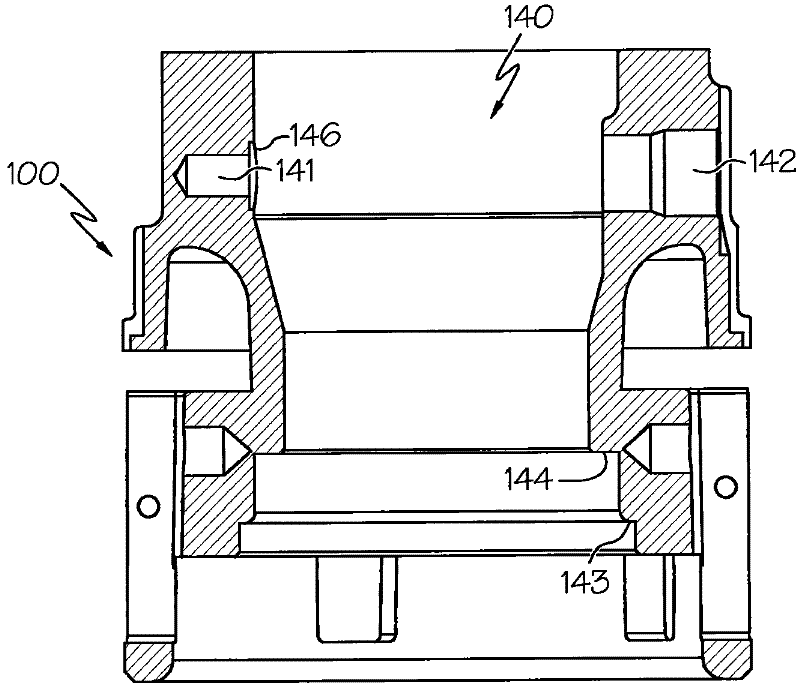

Graphite heat exchanger

InactiveCN105222622ASmall impactReduce vibrationHeat exchanger casingsStationary tubular conduit assembliesTube SpacerEngineering

The invention discloses a graphite heat exchanger. The graphite heat exchanger comprises a cylinder body, wherein a tube header is arranged on one side of the cylinder body, and an end socket is arranged on the other side of the cylinder body; a tube plate I and a tube plate II are arranged between the cylinder body and the tube header, a tube plate III and a tube plate IV are arranged between the cylinder body and the end socket, a spreader plate is arranged between the tube plate I and the tube plate II, and a spreader plate is arranged between the tube plate III and the tube plate IV; a graphite heat exchange tube is arranged between the tube plate I and the tube plate III; a pull rod is arranged in the cylinder body and sleeved with a tube spacer, and a baffle plate is installed on the tube spacer; a water inlet is formed in the upper end of the cylinder body, a water outlet is formed in the lower end of the cylinder body, and an anti-scour plate is arranged at the lower end of the water inlet. The graphite heat exchanger is reasonable in design and easy to operate. By means of the anti-scour plate, the impact of the water inlet on the heat exchange tube is reduced; by means of the interaction between the pull rod, the tube spacer and an expansion joint, vibration of the heat exchanger itself and vibration caused by external force are reduced, stress caused by temperature difference is reduced, and then the heat exchange tube is protected from damage, so that the service life of the heat exchanger is effectively prolonged.

Owner:NANTONG SHANJIAN GRAPHITE EQUIP

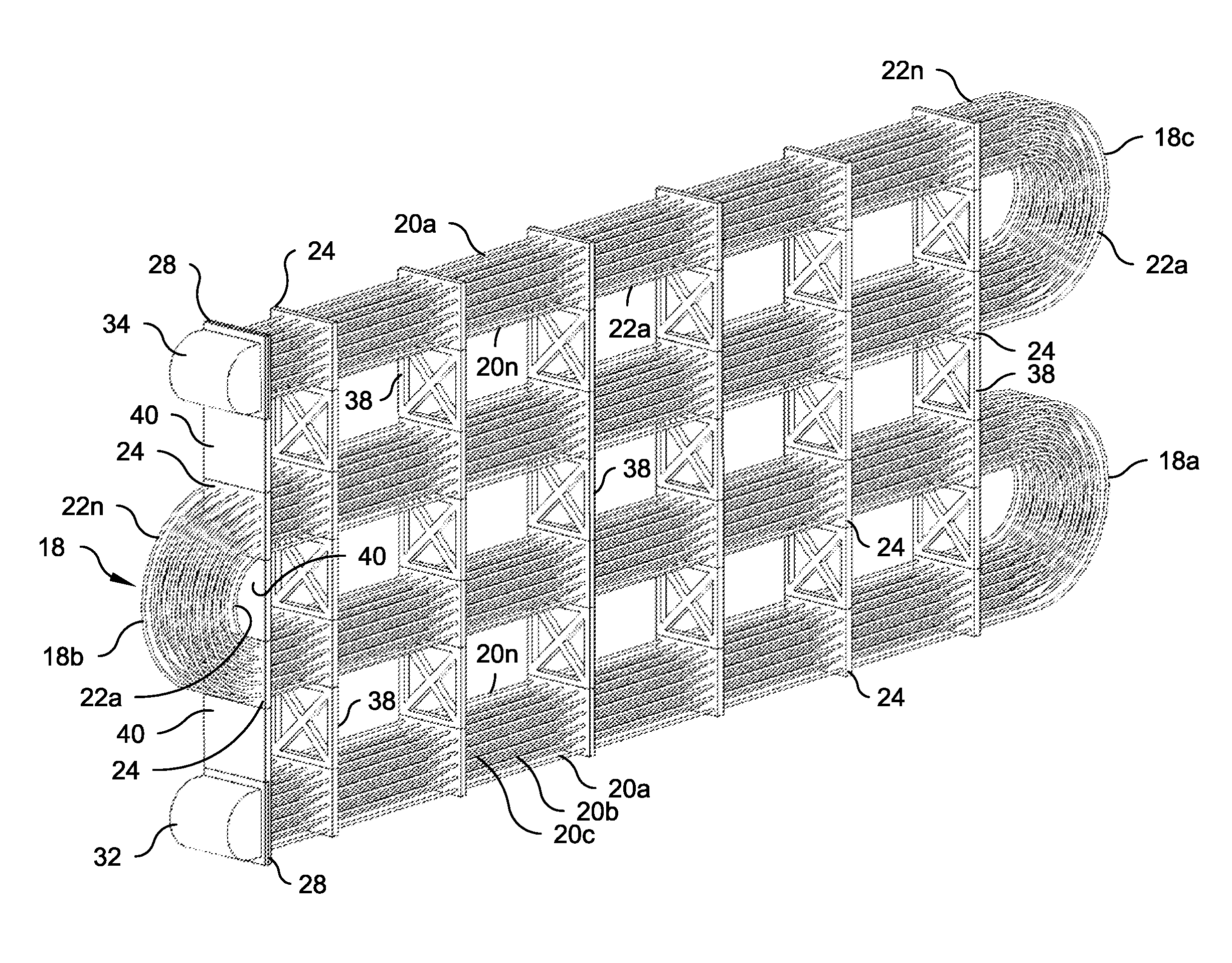

Polymeric coil assembly and method of making the same

Coil assemblies for use in heat exchange applications are made using polymeric tubes, some with heat exchange and water redistribution media integral with the coil assembly and others with a water distribution subassembly integral with the coil assembly. One coil assembly includes at least two generally linear passes that are connected by return bends formed by folding an array of polymeric tubes. The passes have an array of at least two layers of polymeric tubes that pass through alignment holes in tube spacers only along the passes to maintain the tubes in substantially the same relative positional relationship to each other in the passes and in the return bends. Methods are explained for forming the coil assemblies and components, including the tube spacers and tube sheets to connect the coil assembly to inlet and outlet manifolds for the processing fluid flowing internally through the tubes.

Owner:BRENTWOOD INDS

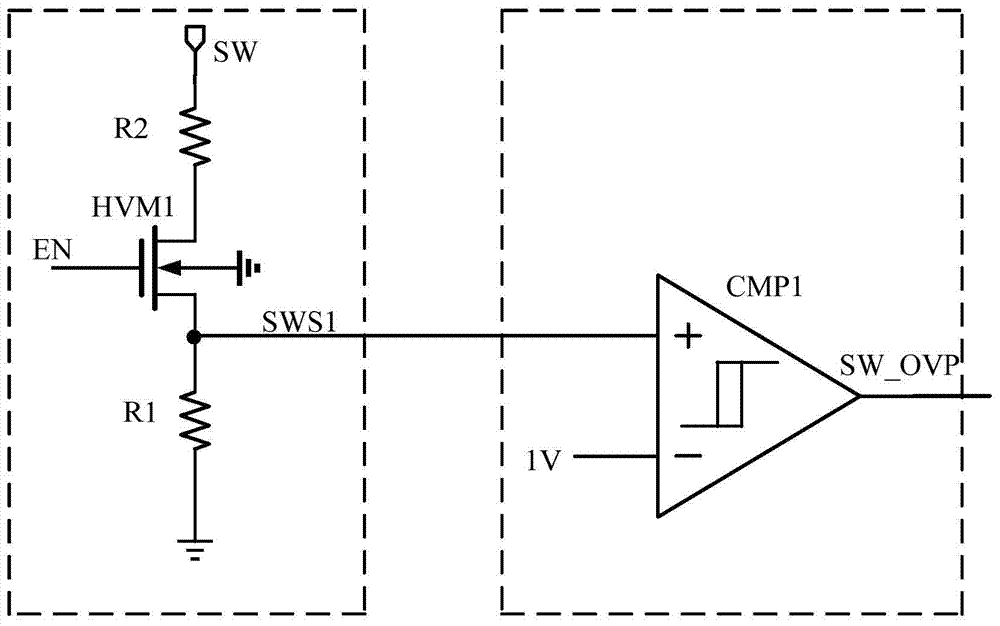

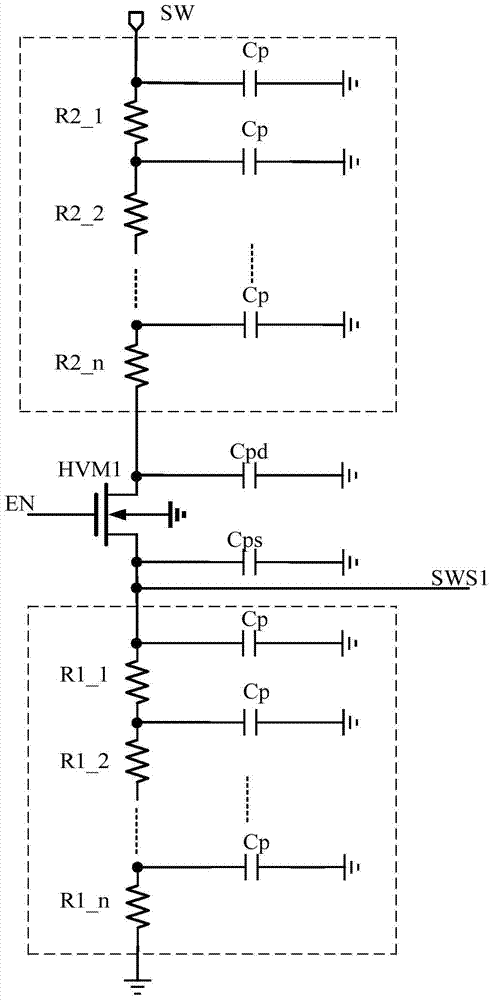

An output overvoltage protection circuit

ActiveCN104979804BReduce speed requirementsReduce complexityCurrent/voltage measurementEmergency protective circuit arrangementsOvervoltageTube Spacer

The present invention relates to an output overvoltage protection circuit, which includes a voltage detection module and a hysteresis comparator, wherein the voltage detection module includes: a first resistor, a second resistor, The high-voltage isolation tube and the third resistor also include a coupling capacitor connected in parallel to both ends of the second resistor; the output overvoltage protection circuit also includes a sample-and-hold connected between the voltage detection module and the hysteresis comparator module. In the present invention, the parasitic capacitance of the first resistor to the switch node offsets the parasitic capacitance of the second resistor to the ground, and at the same time, increases the coupling capacitance to offset the parasitic capacitance of the source and drain of the high-voltage isolation tube to the ground, so that the detection voltage follows the The voltage of the switch node realizes the purpose of rapidly detecting the voltage of the switch node of the boost chip.

Owner:SHANGHAI ORIENT CHIP TECH CO LTD

Flat type fluorescent lamp

InactiveCN1643643ACreativeEliminate non-luminous areasSolid cathode detailsGas discharge lamp detailsTube SpacerPhosphor

The present invention discloses a flat type fluorescent lamp that is improved in its light emission efficiency and brightness by installing a tube spacer between 2 panels. A flat type fluorescent lamp includes an outer lamp body comprising front and rear panels, and circumference seal members, and tube spacers installed in the outer lamp body to divide the discharge spaces in plural sections communicating with each other to define a discharge path, a phosphor layer deposited on the outer lamp body and the tube spacers, and a discharge electrode supported on the outer lamp body.

Owner:李桂承

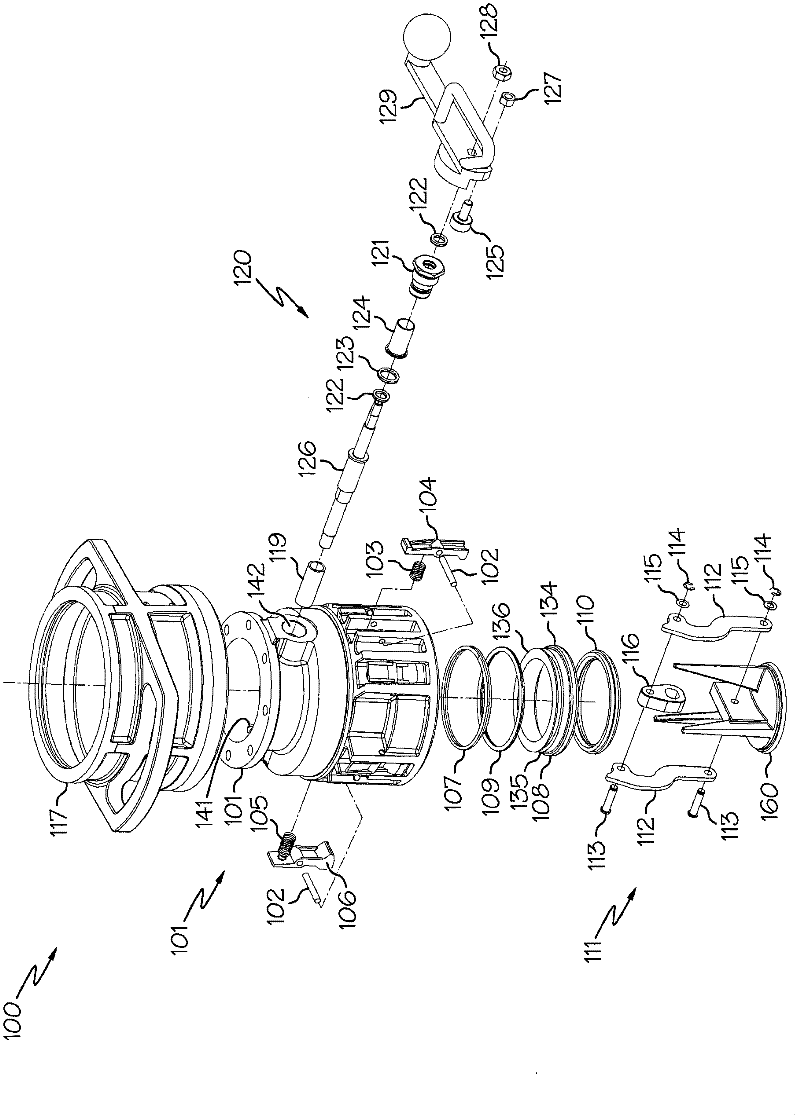

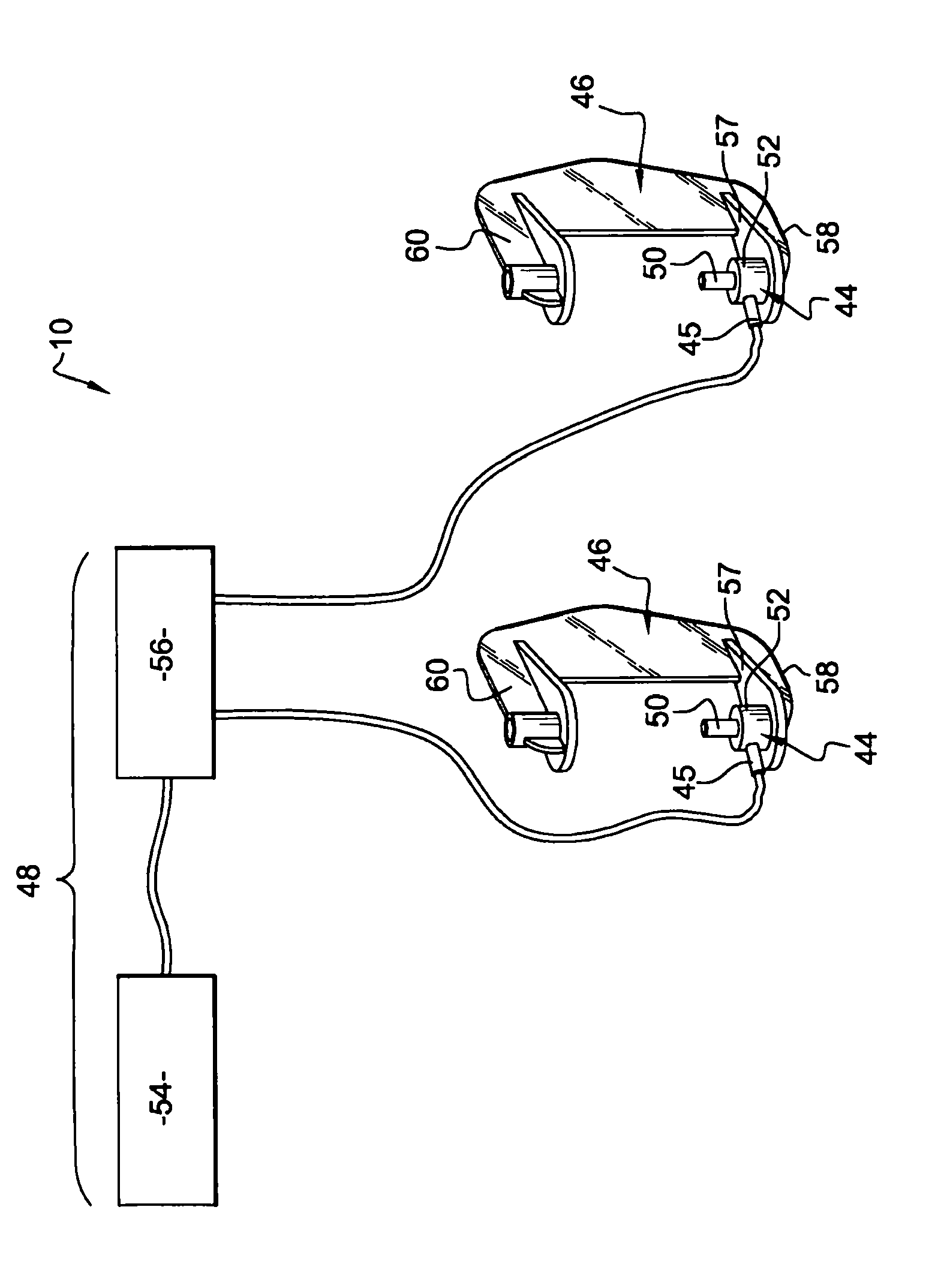

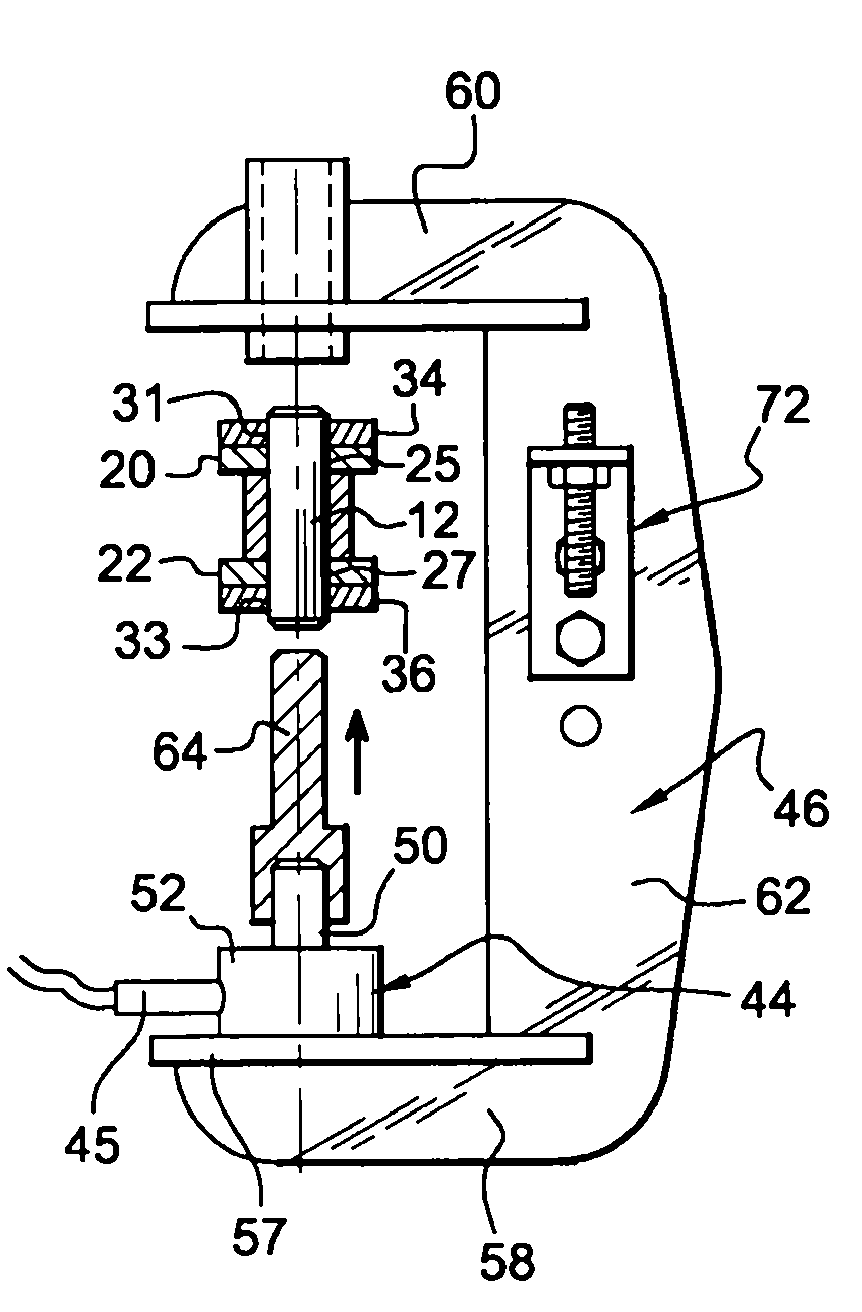

Handle shaft assemblies for bottom loading couplers

A handle shaft assembly includes a tube spacer, a handle shaft, a stuff box, and an operational handle. The stuff box may be configured for insertion into a through-hole within a bottom loading coupler body and include first and second stuff box ends defining a cylindrical cavity. A first sealing member may be positioned on the first stuff box end, and a second sealing member positioned on the second stuff box end. The tube spacer may be configured to be positioned within a blind counterbore of the bottom loading coupler body. The handle shaft may include a first end positioned within the tube spacer configured to be positioned with a blind bore of the bottom loading coupler body, a linkage section configured to be coupled to a drive linkage of a poppet valve assembly, and a second end extending through the cylindrical cavity of the stuff box. The operational handle is mechanically coupled to the second end of the handle shaft.

Owner:DELAWARE CAPITAL FORMATION INC

Substrates for high-density cell growth and metabolite exchange

ActiveUS10053660B2Improve cell adhesionPromote cell growthBioreactor/fermenter combinationsBiological substance pretreatmentsParyleneTube Spacer

A polymer or other substrate optimized for growing cells is described, which takes the form of a micro-thin bag with gas permeable sides. Sides of the bag can be held at a fixed distance from one another with a multitude of tiny micropillars or other spacers extending between them, keeping the bag at a predetermined thickness and preventing the bag from collapsing and the sides from sticking together. In other embodiments, the sides may be held apart by gas pressure alone. A 0.01 μm to 1000 μm parylene or other biocompatible coating over the bag outsides controls the permeability of the bag material and provides a bio-safe area for cell growth. An alternate configuration uses open-cell foam with skins coated with a biocompatible coating. Tubes going into multiple bags can be connected to a manifold that delivers gaseous oxygen or removes carbon dioxide and other waste gases. Multiple bags can be stacked together tightly, with o-ring spacers in between, and housed within a vessel to form a high-surface area, ultra-compact cell growing system. For cells growing on the bags, liquid nutrients can be fed by way of the tube spacers, and oxygen and waste gases permeated through the bag sides and transported within the bags.

Owner:CALIFORNIA INST OF TECH +1

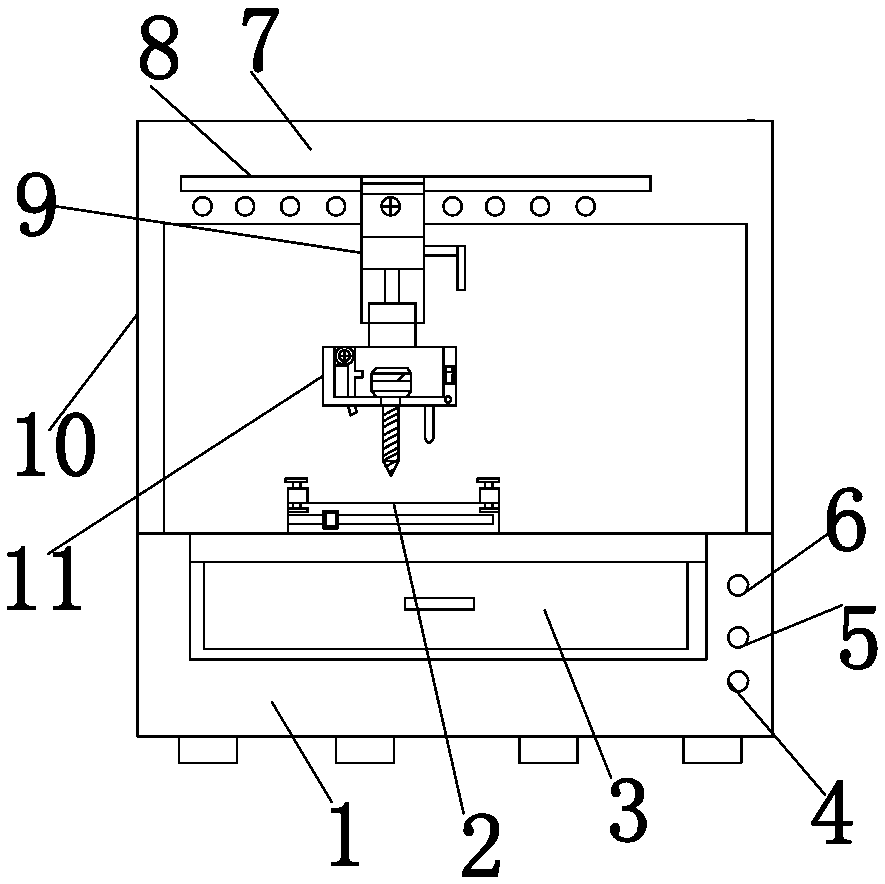

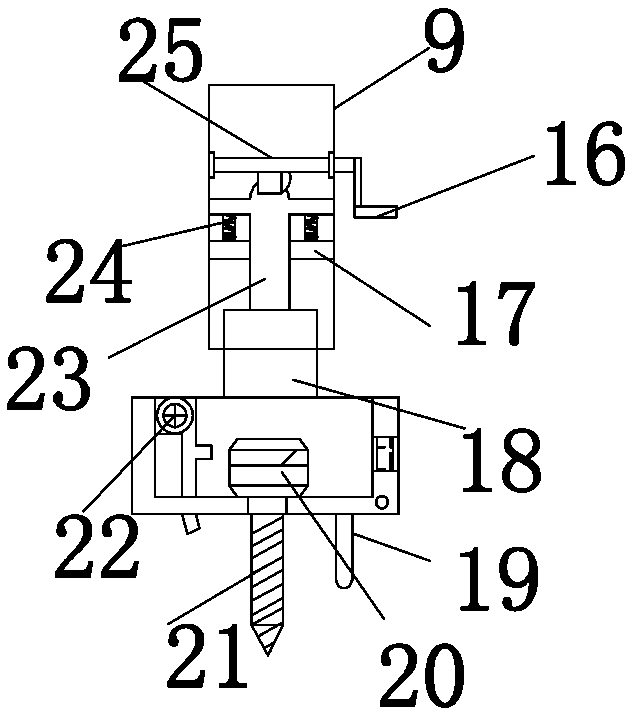

Perforating device for silicon carbide rod machining

The invention discloses a punching device for processing silicon carbon rods, which comprises a base, a fixed cylinder and a motor box. A blower switch is arranged on the right side of the base, a motor switch is arranged above the blower switch, and a motor switch is arranged above the motor switch. There is a light switch, the upper part of the base is fixedly connected to the frame, the top of the frame is fixedly connected to the top box, a rotating rod runs through the top of the fixed cylinder, and an extrusion block is arranged in the middle of the rotating rod, and the right end of the rotating rod A handle is provided, and a motor is installed inside the motor box. In the present invention, a partition is arranged inside the fixed cylinder, and return springs are installed at the left and right ends of the top of the partition. The pressing block squeezes the lifting rod and resets it to avoid drilling too deep, which may cause drilling failure.

Owner:河南格锐新材料科技有限公司

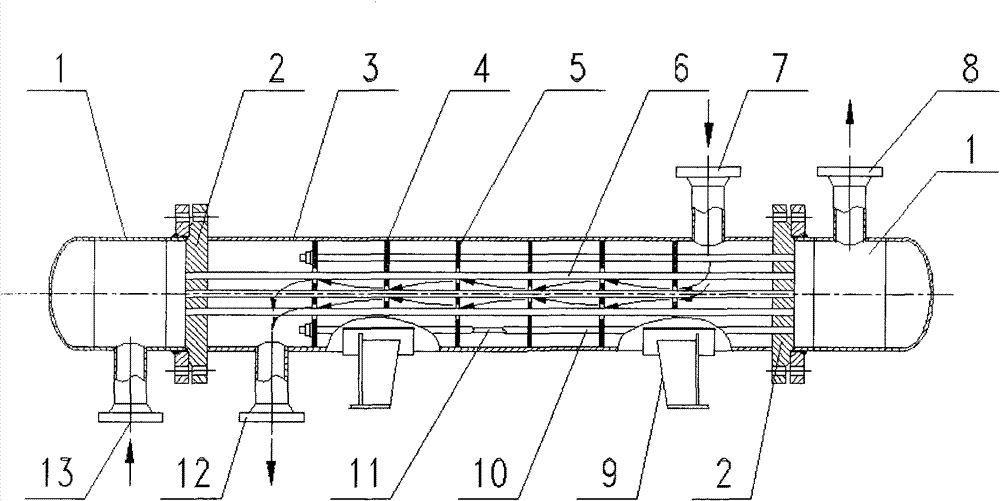

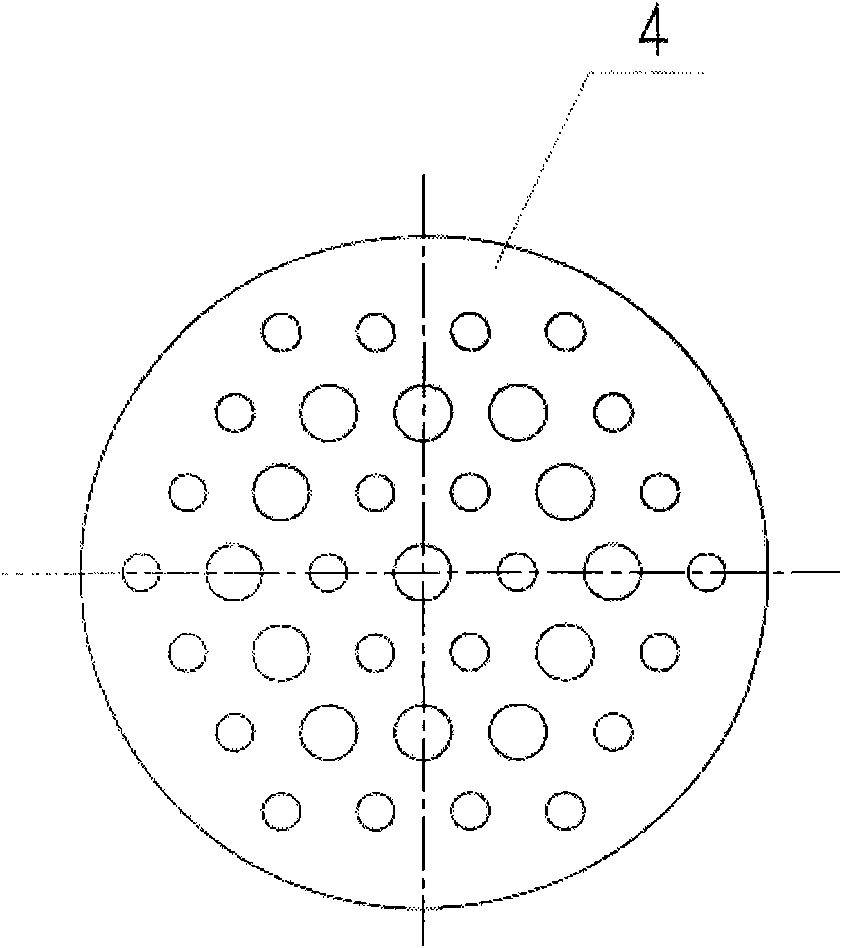

Petal pore plate longitudinal-flow heat exchanger

InactiveCN101551206ASimple structureEasy to processStationary tubular conduit assembliesHeat transfer modificationTube SpacerBlock effect

The invention relates to a longitudinal-flow heat exchanger which takes a petal pore plate as bundle support; the heat exchanger comprises a shell body, a seal head, a heat transfer tube bundle, a petal pore plate support, a pull tube and a tube spacer, a shell-side inlet and outlet tube, a tube-side inlet and outlet tube, and the like, wherein the petal pore plate is shown as the attached drawing 1, i.e., an entire circular plate which is a full circular plate composed of support strips and pedals which are arranged along the same direction, and is a key component of the heat exchanger; by the support strips which are arranged in a criss-cross way on two petal pore plates, the all-round support to the heat exchanger bundle is achieved, thereby leading the whole bundle to have good vibration prevention and resistance capacity; under the action of the petal pore plate, the heat exchanger shell-side fluid flows vertically along a tube axis; the functions of flow guide and disturbance of the pore plate petal can exacerbate fluid turbulence, thereby effectively enhancing convective heat transfer and producing good scale prevention and descaling functions; and the blocking effect of the periphery of the pore plate reduces the leakage flow ineffective on heat transfer; and the invention can be widely used in heat exchange equipment such as longitudinal-flow vertical and horizontal tube shell type heat exchanger, tube shell type condenser, etc.

Owner:ZHENGZHOU UNIV

Substrates for high-density cell growth and metabolite exchange

ActiveUS20190002813A1Improve cell adhesionPromote cell growthBioreactor/fermenter combinationsBiological substance pretreatmentsCo2 removalParylene

A polymer or other substrate optimized for growing cells is described, which takes the form of a micro-thin bag with gas permeable sides. Sides of the bag can be held at a fixed distance from one another with a multitude of tiny micropillars or other spacers extending between them, keeping the bag at a predetermined thickness and preventing the bag from collapsing and the sides from sticking together. In other embodiments, the sides may be held apart by gas pressure alone. A 0.01 μm to 1000 μm parylene or other biocompatible coating over the bag outsides controls the permeability of the bag material and provides a bio-safe area for cell growth. An alternate configuration uses open-cell foam with skins coated with a biocompatible coating. Tubes going into multiple bags can be connected to a manifold that delivers gaseous oxygen or removes carbon dioxide and other waste gases. Multiple bags can be stacked together tightly, with o-ring spacers in between, and housed within a vessel to form a high-surface area, ultra-compact cell growing system. For cells growing on the bags, liquid nutrients can be fed by way of the tube spacers, and oxygen and waste gases permeated through the bag sides and transported within the bags.

Owner:CALIFORNIA INST OF TECH +1

Clamp for zirconium pipe fatigue test and test method

PendingCN111829874AMachine part testingMaterial strength using repeated/pulsating forcesThermal dilatationTube Spacer

The invention discloses a clamp capable of being used for a zirconium pipe fatigue test and a test method. The clamp comprises a clamping part used for providing clamping constraint for the end of a tubular test piece, an inner plug used for filling the end of the test piece and a pipe gasket used for wrapping the outer side of the end of the test piece, and the inner plug and the pipe gasket areboth made of soft thermal expansion materials. The test method is based on the clamp. By adopting the clamp and the method provided by the scheme, the high-cycle fatigue test of the zirconium pipe ofthe fuel rod can be completed.

Owner:NUCLEAR POWER INSTITUTE OF CHINA

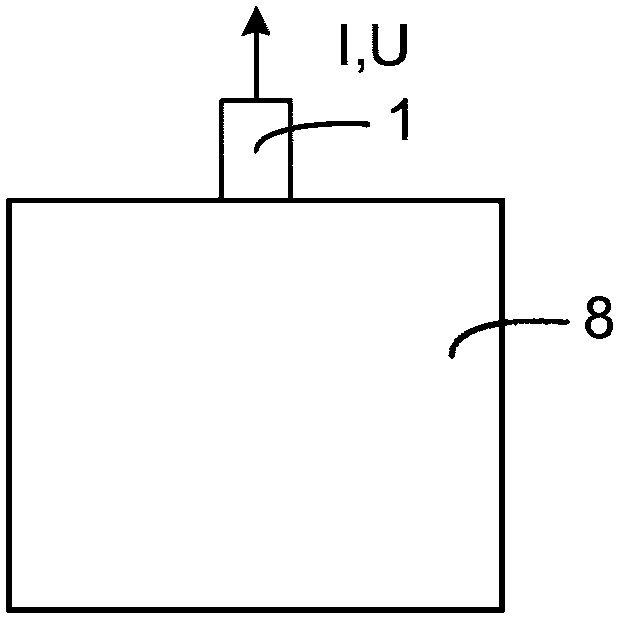

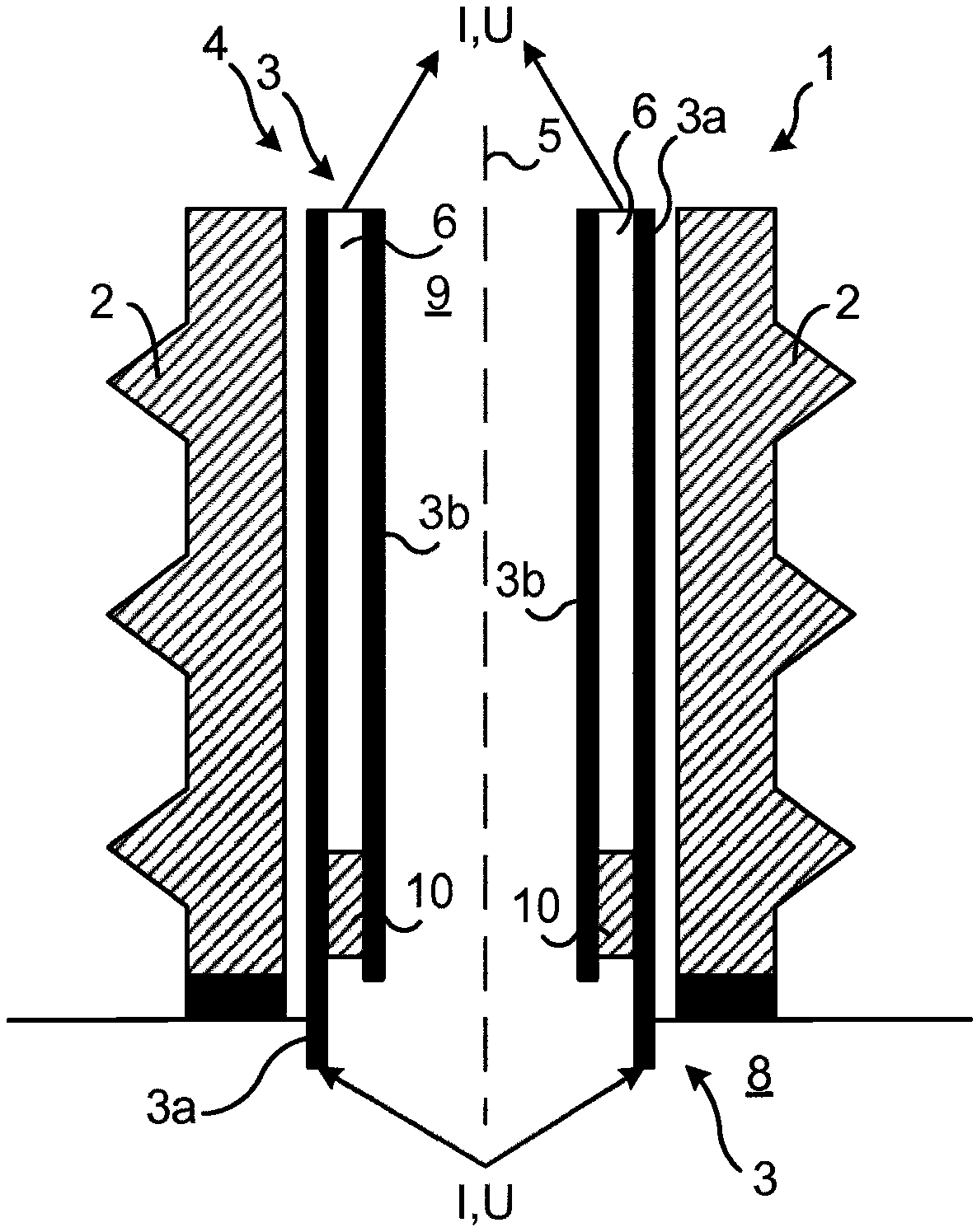

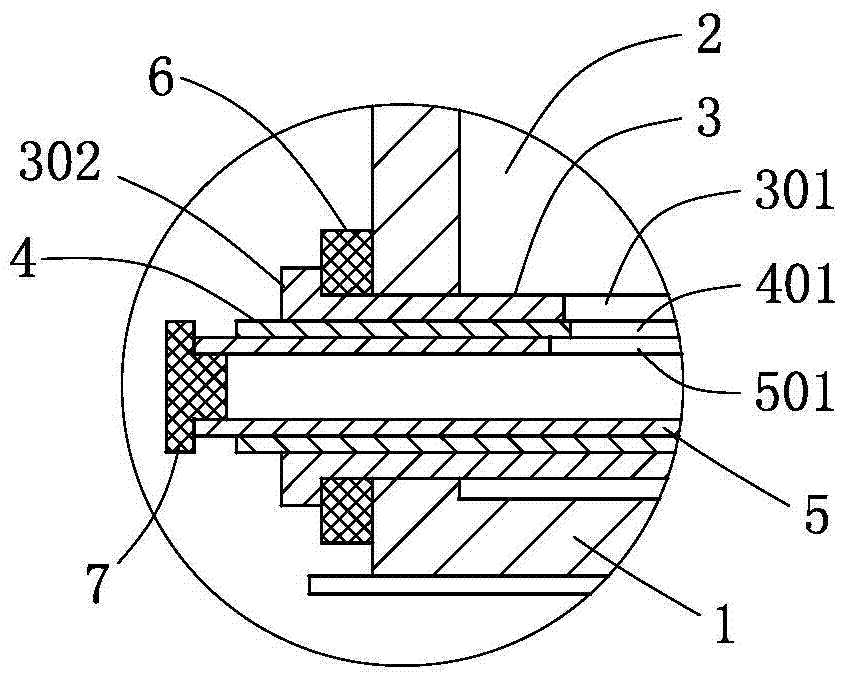

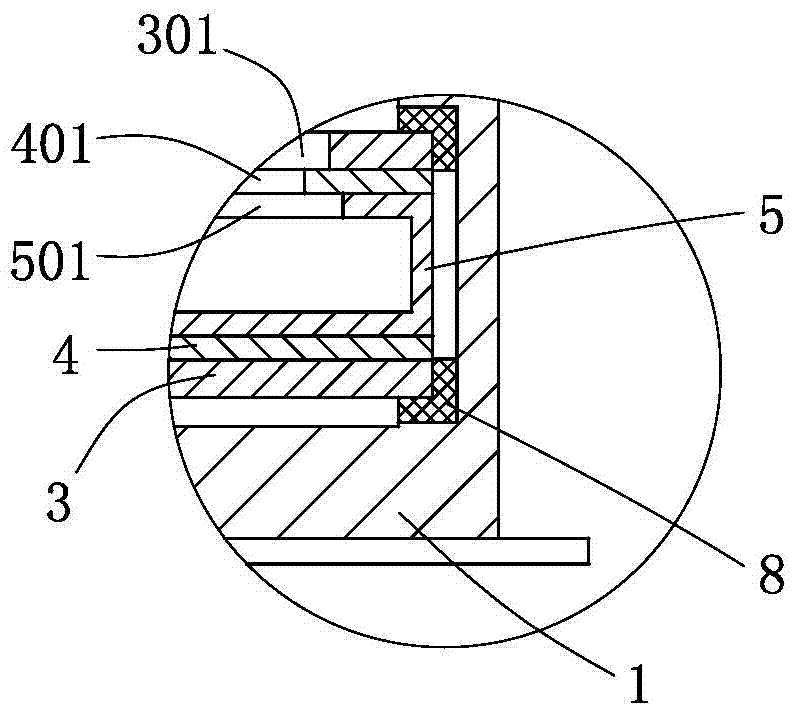

electrical bushing

ActiveCN106716560BIndirect heat exchangersLead-in/lead-through insulatorsTube SpacerElectrical conductor

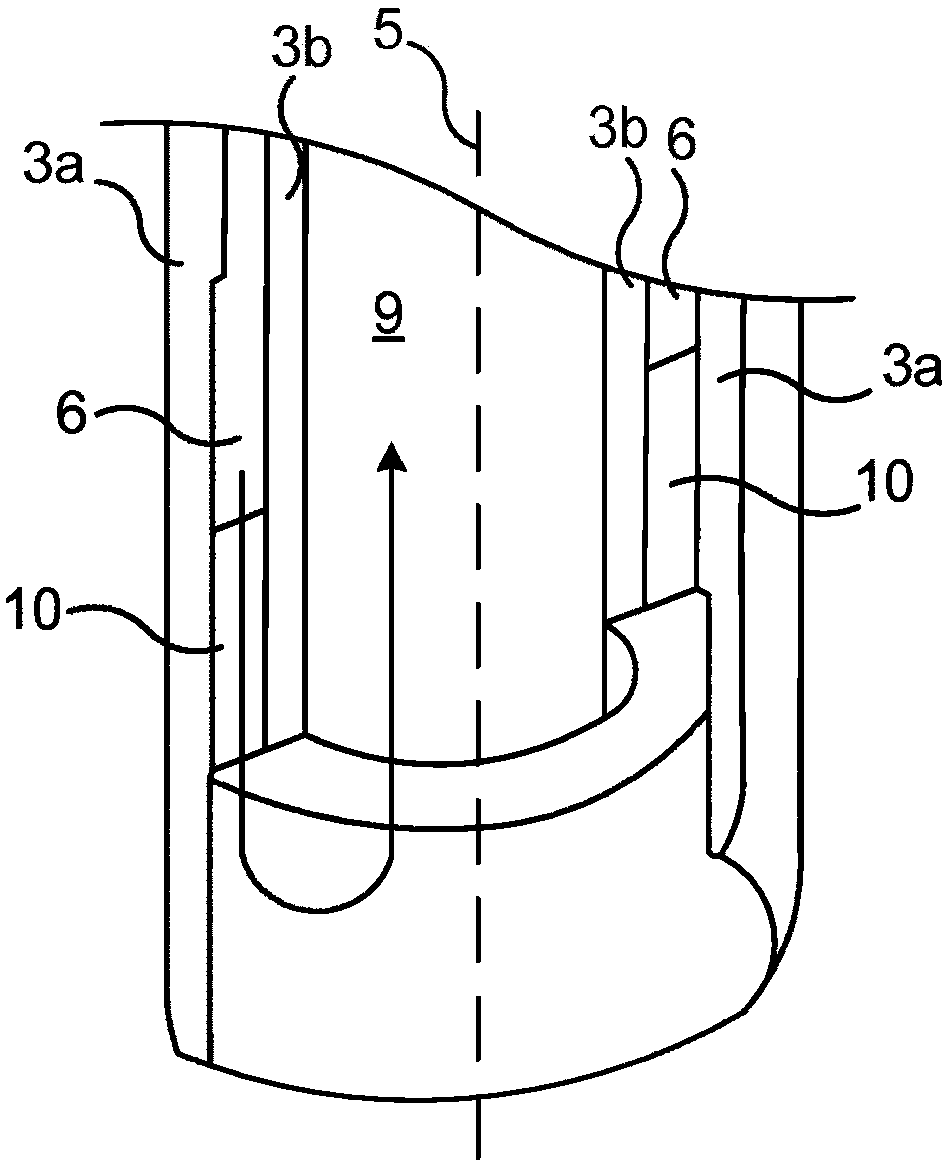

The present disclosure relates to an electrical bushing (1) comprising an electrically insulating sleeve (2) having a central longitudinal through hole (4) surrounding a central longitudinal axis (5) of the bushing and a central longitudinal bore positioned through the sleeve. The electrical conductor (3) through the hole (4). The conductor comprises a longitudinal outer tube and a longitudinal inner tube (3b) located concentrically within the outer tube (3a) such that a tubular space is formed between the outer tube and the inner tube. A first end of the tubular space is delimited by a tube spacer (10) between the outer tube and the inner tube, and the second end of the tubular space is capped to form a closed tubular space. The closed tubular space contains a heat transfer fluid thereby forming a heat pipe (6) between the outer and inner tubes of conductors. The outer tube extends longitudinally beyond the heat pipe bounded by the tube spacer at a first end of the tubular space, and the inner tube has at said first end a fluid passable from between the outer tube and the inner tube into the inner tube. In the central longitudinal space (9) in the design without passing longitudinally beyond the extension of the outer tube.

Owner:HITACHI ENERGY SWITZERLAND AG

Protection device for submersible pump

The invention provides a protection device for a submersible pump, which includes a variable diameter tube and a clip-on butterfly check valve from top to bottom, the variable-diameter tube includes an upper thick tube and a lower thin tube, and the clip-on butterfly check valve The check valve is connected to the lower thin pipe through a flange, and a sand filter screen is arranged at the junction of the upper thick pipe and the lower thin pipe, and a slide bar is fixed at the lower end of the sand filter screen. A positioning frame perpendicular to the central axis of the reducing tube is fixed on the inner wall of the lower thin tube, the slide bar passes through the positioning frame, and a crosspiece is provided at the lower end of the slide bar. The present invention can well prevent accumulation The water flows back, and it can prevent the sand and stones in the water from depositing in the wafer butterfly check valve, avoiding that when the submersible pump is powered on again, some sand and stones cannot be washed out in time and enter the impeller, causing unnecessary damage to the impeller. The friction effectively protects the submersible pump and prolongs the life of the submersible pump.

Owner:TIANJIN ZHENDA PUMP CO LTD

Novel LED lamp

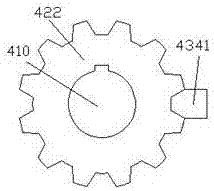

InactiveCN107314270AControl disengagement workSimple structureElectric circuit arrangementsSemiconductor devices for light sourcesTube SpacerAutomatic control

The invention discloses a new type of LED lamp, which includes a lamp part and a power transmission box. A first cavity is arranged inside the power transmission box, and a second cavity is arranged in the power transmission box on the top of the first cavity. The second cavity The inner top wall is provided with a sliding connection groove, and the outer wall of the power transmission box on the right side of the first cavity is provided with an installation groove, and there is a through groove between the installation groove and the first cavity, and the first cavity is provided with an upper and lower The elongated adapter shaft, the top of the adapter shaft penetrates the inner wall of the power transmission box and penetrates into the second cavity and is connected with the operation. The adapter shaft in the first cavity is fixed with an adapter tube. There are corresponding spacers on the upper and lower sides of the connecting pipe, cables are wound on the transfer pipe between the upper and lower sides of the spacers, and the first toothed wheel and the sliding groove are installed at the end of the top of the transfer shaft in the second cavity. There is a screw-shaped rod inside, and the left end surface of the screw-shaped rod is connected with the first electric rotating machine; the invention has simple structure, convenient operation, can automatically control the wire take-up and pay-off work, and improves work efficiency and safety.

Owner:DONGGUAN CITY GEDAMEI HARDWARE TOOLS CO LTD

A kind of oil volume compensating transformer

The invention discloses an oil quantity compensation type transformer, which belongs to the technical field of power supply equipment, and comprises a transformer box body, the transformer box body has an oil chamber for containing transformer oil, a compensation oil tank is arranged on the top of the transformer box body, and the sampling port is fixedly installed There is a fixed pipe, the fixed pipe runs through the oil chamber of the transformer box and the end is fixed on the transformer box, an oil inlet gap is arranged on the fixed pipe located in the oil chamber, and the extension direction of the oil inlet gap is consistent with the extension direction of the fixed pipe , an isolation tube is installed in the oil inlet pipe, and an oil passage groove corresponding to the oil inlet gap is arranged on the isolation tube. A sampling tube is inserted in the isolation tube. corresponding exposure. The invention can collect oil samples at multiple positions at the bottom of the transformer, improves the accuracy of oil sample collection, and avoids transformer oil loss in the oil cavity caused by oil sample collection, and is widely used in power supply systems.

Owner:STATE GRID SHANDONG GAOMI POWER SUPPLY +2

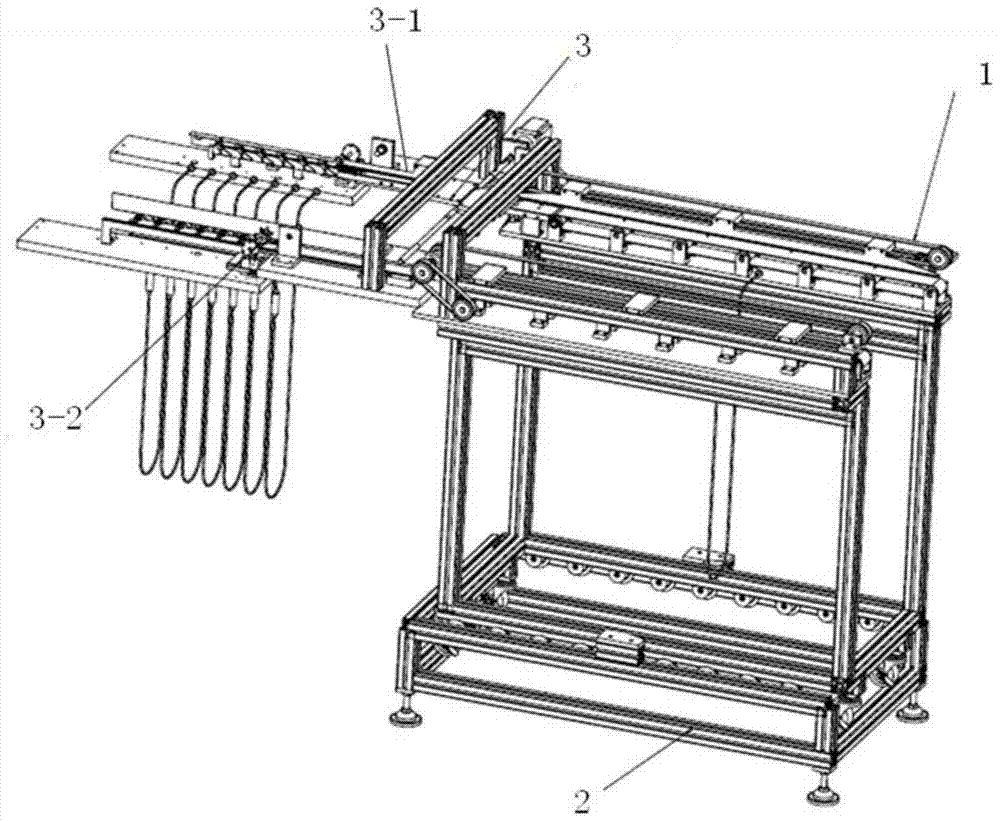

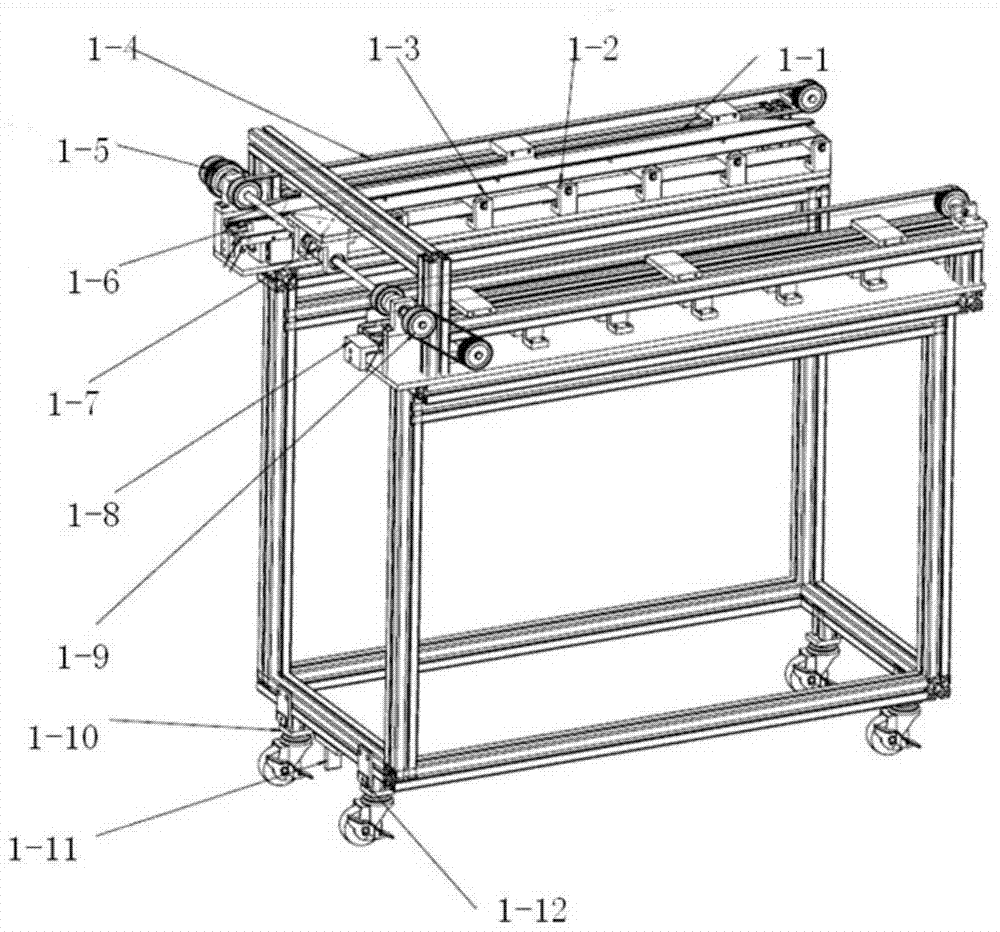

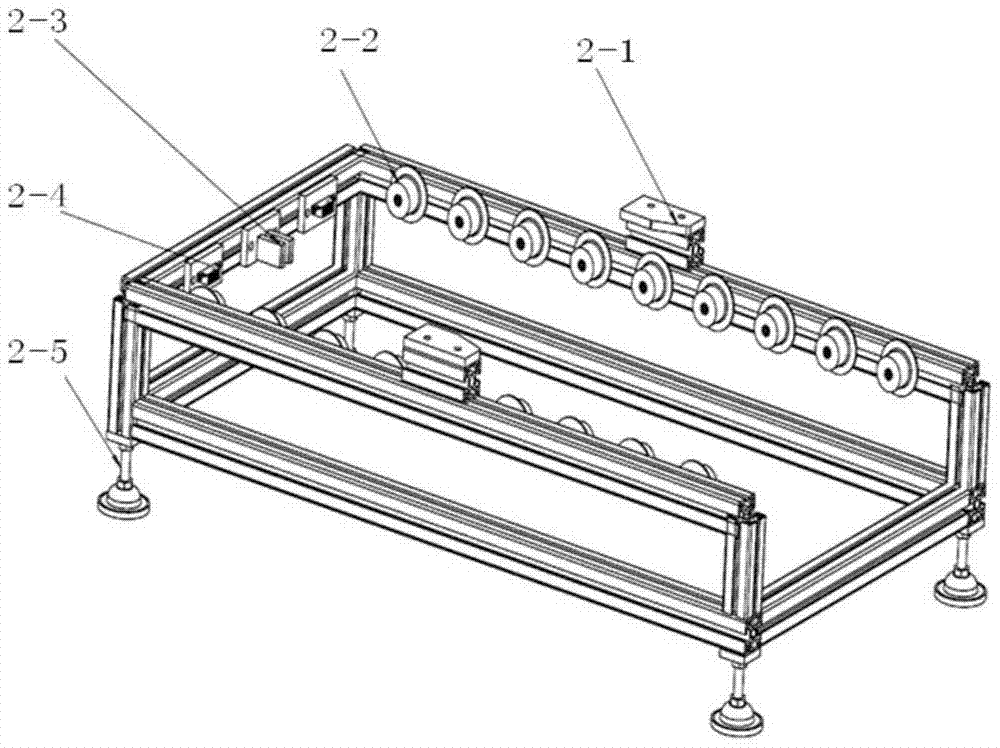

An infusion tube transmission mechanism

ActiveCN105109945BSolve the problem of easy windingEasy to operateSupporting framesMechanical conveyorsTube SpacerButt joint

Owner:HUAZHONG UNIV OF SCI & TECH

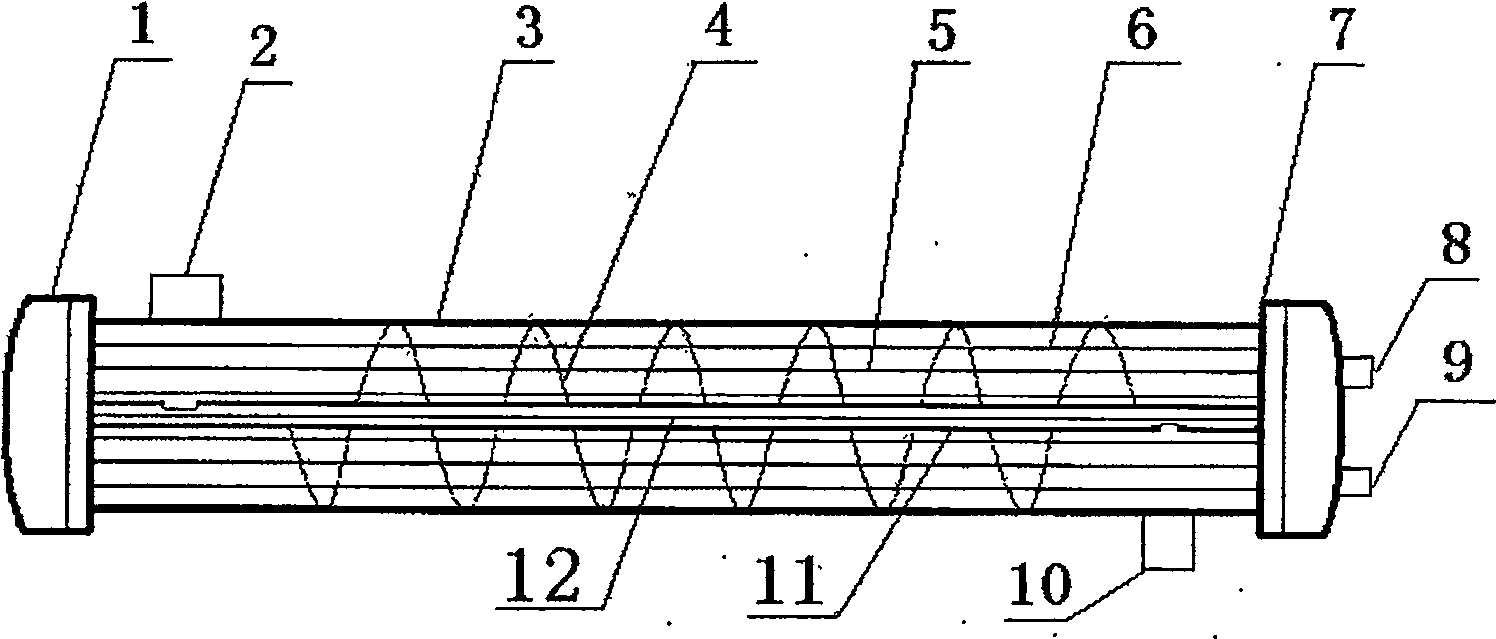

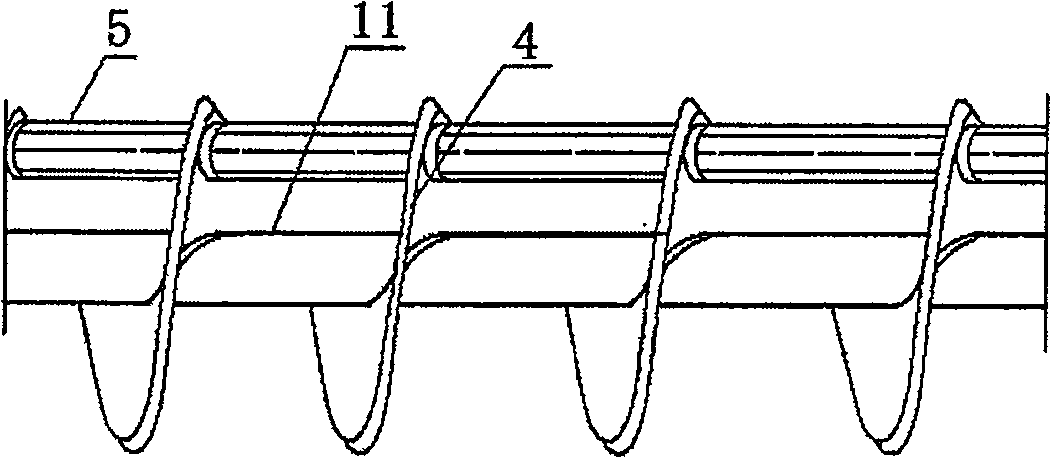

Continuous spiral traverse baffle double shell side combined special-shaped tube bundle heat exchanger

InactiveCN100533037CIncrease heat transfer areaImprove overall heat transfer coefficientStationary tubular conduit assembliesTube SpacerEngineering

The invention discloses a special-shaped tube bundle heat exchanger with continuous spiral baffle double-shell side combination. The head at one end is provided with a tube pass inlet and a tube pass outlet, and one of the tube bundles and one of the tube bundles are also arranged between the tube sheets. Two; one of the tube bundles is composed of one of a plurality of heat transfer tubes, arranged between the central tube and the shell; the second tube bundle is composed of two of a plurality of heat transfer tubes, arranged in the central tube; one of the heat transfer tubes is a non- Special-shaped tubes with smooth walls, the second of the heat transfer tubes is a spiral flat tube; one of the fixed-distance tubes and the tube bundle passes through the spiral baffle, and its two ends are respectively connected with the tube sheet, and the spiral baffle is fixed by the fixed-distance tube; the tube bundle The two ends of the second are also respectively connected with the tube sheet; there are two notches corresponding to the shell-side inlet and the shell-side outlet of the heat exchanger respectively on the central tube. The heat exchanger of the present invention adopts two tube bundles with different heat transfer tube structures, less fluid back-mixing, no flow dead zone, little influence of bypass flow and leakage flow, and can make full use of the diameter of the shell to arrange heat transfer tubes. High thermal coefficient.

Owner:SOUTH CHINA UNIV OF TECH

Water-removable microwave resonant cavity for steam humidity measurement

ActiveCN104267047BDoes not affect normal workReduce measurement errorMoisture content investigation using microwavesTube SpacerEngineering

The invention discloses a microwave resonant cavity capable of removing water film for steam humidity measurement, which comprises a steam flow inlet pipe, a resonant cavity pipe and a frequency adjustment pipe which are threadedly connected from front to back, the steam flow inlet pipe, the resonant cavity A ring-shaped droplet collection chamber is provided between the tube and the sealing gasket. The resonant cavity tube is provided with a droplet outlet that communicates with the droplet collection chamber. The airflow inlet tube is provided with an axial hole that communicates with the droplet collection chamber. , the axial hole communicates with the pipe hole of the steam flow inlet pipe through the radial hole set on the steam flow inlet pipe; The rear isolation tube, the part between the front isolation tube and the rear isolation tube in the resonant cavity tube hole constitutes the measurement chamber, the resonant cavity tube is provided with a coupling installation hole, and the end of the coupling installation hole is connected to the measurement chamber; The invention is a microwave resonant cavity capable of automatically removing water film deposits on the inner wall of the cavity, which has strong pipe environment adaptability and low cost.

Owner:STATE GRID HENAN ELECTRIC POWER ELECTRIC POWER SCI RES INST +3

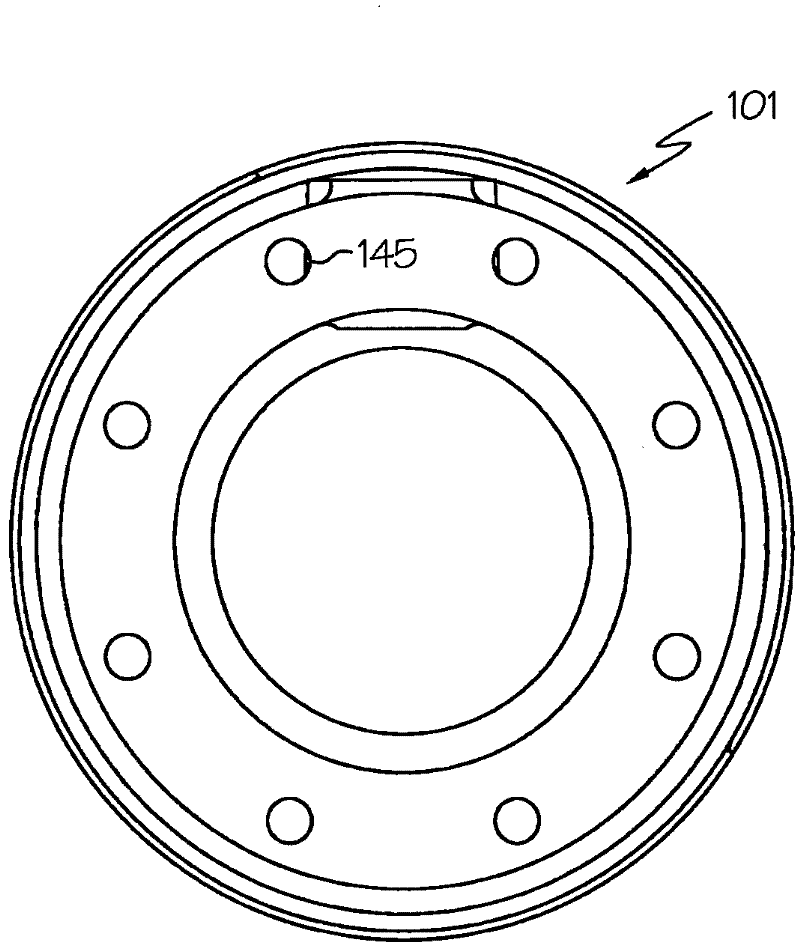

Tube spacer, method of manufacturing the same, and heat exchanger

A tube spacer S formed by bending a wire, includes a plurality of projections 20 and a base-bending portion 21. Each of the projections 20 is inserted between tubes, and has a pair of extending portions 201 extend in X direction and a front-bending portion 202 for connecting both front ends of the pair of extending portions 201. The base-bending portion 21 connects both rear ends of the projections 20 so that the projections 20 are arranged at interval in Z direction. With this structure, manufacturing cost for the tube spacer S can be low, and the tubes can be stably supported.

Owner:NORITZ CORP

A segmented heating oven for polyacrylamide drying

ActiveCN113432408BAchieve dryingAvoid enteringDrying gas arrangementsDrying chambers/containersThermodynamicsTube Spacer

The invention relates to a segmented heating oven for polyacrylamide drying, which relates to the technical field of chemical equipment, including a furnace base, a furnace body, a heat relay cylinder, a conveyor, a gas cylinder, a cone cylinder and a heating pipe. The furnace body is fixedly connected to the On the top of the furnace base, the heat relay cylinder is fixedly connected to the top of the furnace body, the conveyor is fixedly connected to the side of the furnace body, the gas cylinder is fixedly connected to the furnace base, the top of the gas cylinder extends into the furnace body and is located directly below the output end of the conveyor, and the cone cylinder is slidably connected At the upper end of the gas cylinder, pressurized air is passed into the gas cylinder to blow up the cone cylinder, and several heating pipes are distributed in the furnace body around the gas cylinder at intervals to heat the inner cavity of the furnace. The invention has the ability to quickly dry the polyacrylamide powder. advantage.

Owner:山东蓝湾新材料有限公司

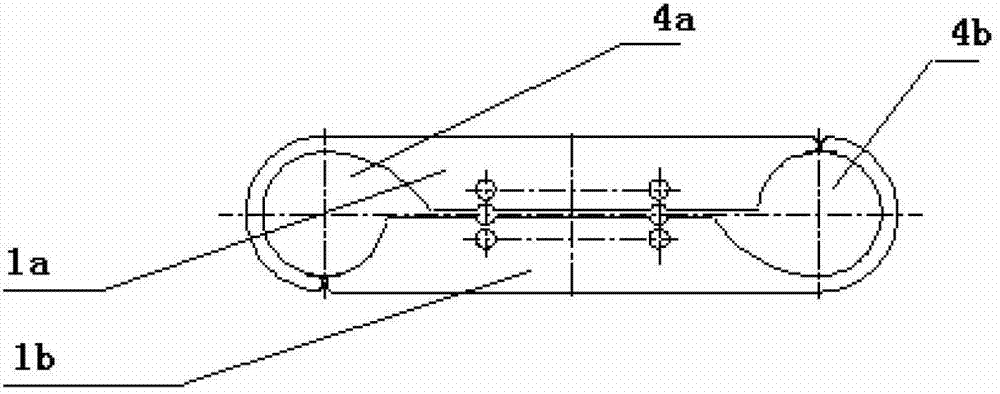

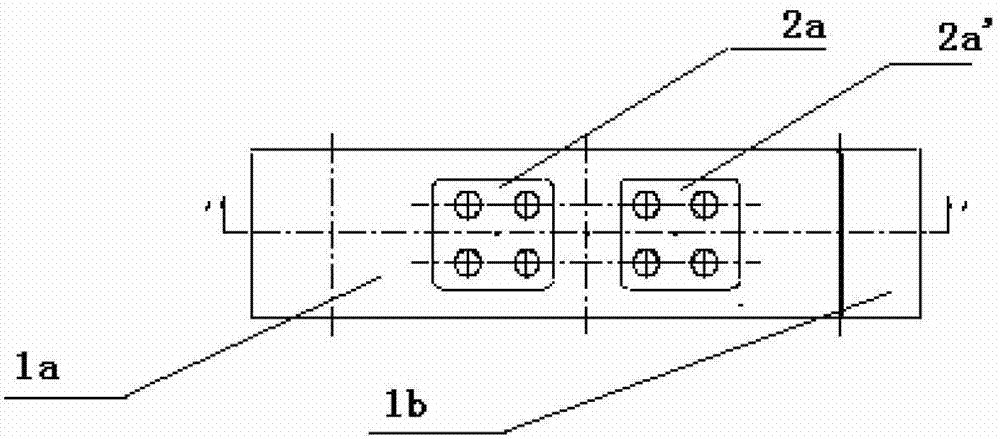

Anti-corona aluminum tube spacer bar

ActiveCN103001162BGood anti-corona performanceSimple structureMaintaining distance between parallel conductorsTube SpacerEngineering

The invention provides an anti-corona aluminum tube spacer bar. The anti-corona aluminum tube spacer bar consists of a wire clamp 1a and a wire clamp 1b which are same completely and are inverted oppositely. The anti-corona aluminum tube spacer bar is characterized in that the wire clamp 1a and the wire clamp 1b are hook-shaped wire clamps, two ends of the wire clamp 1a and two ends of the wire clamp 1b are circular arcs same in radius, the length of the circular arcs at one end are 3 / 4 of circumference length, and the length of the circular arcs at the other end are 1 / 4 of circumference length. The thickness of the wire clamp 1a and the wire clamp 1b is identical to the radius of the circular arcs. The circular arcs at two ends of the wire clamp 1a and at two ends of the wire clamp 1b form a round hole 4a and a round hole 4b which are used for installing aluminum tubes, and the opening positions of the round hole 4a and the round hole 4b are located at the upper portion and the lower portion of the anti-corona aluminum tube spacer bar. Compared with the prior art, the anti-corona aluminum tube spacer bar is good in anti-corona performance, simple in structure and convenient to install. A water discharging port is reserved to prevent water accumulation. In addition, functions of spacing, suspension and heavy hammer installation can be achieved.

Owner:CHINA ELECTRIC POWER RES INST +1

Shell-and-tube heat exchanger with un-notched traverse baffles

ActiveCN101706227BEasy to processEasy to installHeat exchanger casingsStationary tubular conduit assembliesPlate heat exchangerTube Spacer

Owner:BEIJING UNIV OF CHEM TECH

Petroleum liquid transparent glass sampler and sampling method thereof

InactiveCN102620951BEliminate inseparable problemsExquisite structureWithdrawing sample devicesTube SpacerPetrochemical

The invention relates to a petroleum liquid transparent glass sampler and a sampling method thereof, belonging to the technical field of petrochemical industry, and has the characteristics of multi-function, good versatility, accurate sampling fixed point, convenient operation, clean environment and no pollution, and the like. It is composed of a container part, a valve control mechanism and a tape disc; the container part includes a screw rod, a base, a container, a connecting pipe, a gasket, an upper cover, a valve cover, an ear handle and a handle. The valve control mechanism includes a cock, a valve sleeve, a valve stem, a valve plate, a positioning nut, a push rod, a hook, a spring and a valve cap. The structure of the ruler belt reel is composed of two parts: fixed and rotating. The fixed part includes the left fixed ring, inner fixed ring, pulley shaft, pulley and ruler door lever; the rotating part includes the right moving ring, left rail ring, warehouse bottom ring, Spacers, nuts, left rail ring and right moving ring form a ruler belt bin, the outer circle of the bottom ring of the bin is used as the bottom plate of the ruler belt bin, the inner circle of the left rail ring is inserted into the pulley groove as a rotating track, and the ruler door rods are distributed around the left ring.

Owner:杨 志明

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com