Continuous spiral traverse baffle double shell side combined special-shaped tube bundle heat exchanger

A continuous spiral, heat exchanger technology, applied in the direction of heat exchanger types, indirect heat exchangers, lighting and heating equipment, etc., can solve the problem of reduced heat transfer area of heat exchangers, decreased heat transfer performance of heat exchangers, and tube layout Reduce the number and other issues, achieve the effect of improving the total heat transfer coefficient, simple structure, and improving the heat transfer coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in detail below with reference to the accompanying drawings, but the embodiments of the present invention are not limited thereto.

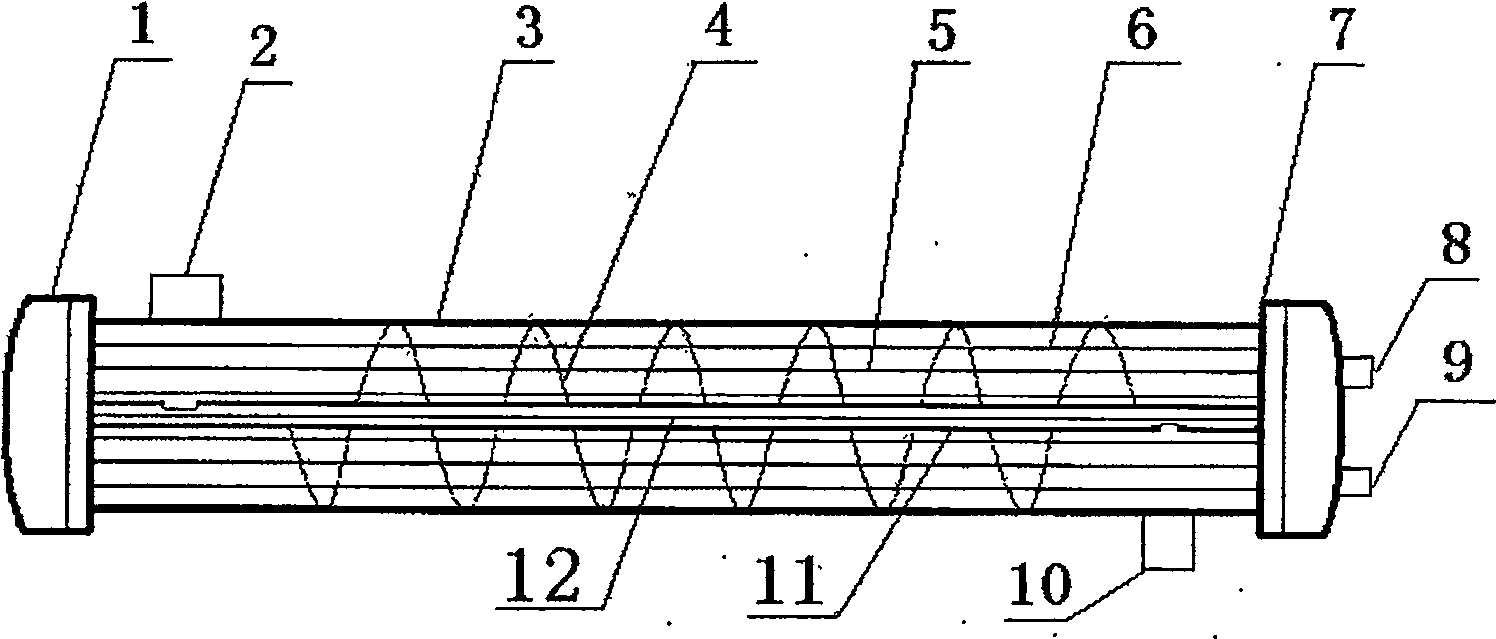

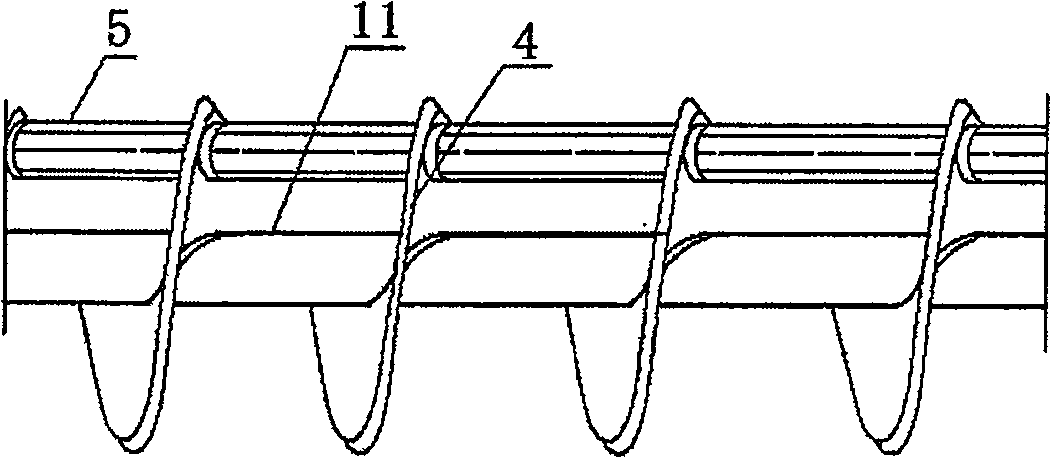

[0022] as attached figure 1 As shown, in this embodiment, the combined special-shaped tube bundle heat exchanger with continuous spiral baffles and double shell side is mainly composed of a head 1, a shell side inlet 2, a shell 3, a continuous spiral baffle 4, and the first tube bundle in the first tube bundle. A heat transfer tube 5, spacer tube 6, tube plate 7, tube side outlet 8, tube side inlet 9, shell side outlet 10, central tube 11, second heat transfer tube 12 in the second tube bundle. A continuous spiral baffle 4 , a first heat transfer tube 5 , a spacer tube 6 , a central tube 11 and a second heat transfer tube 12 are arranged between the tube sheets 7 . The first heat transfer tube 5 and the spacer tube 6 pass through the continuous spiral baffle 4 , and their two ends are respectively c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com