Petroleum liquid transparent glass sampler and sampling method thereof

A technology of transparent glass and sampler, which is applied in the direction of sampling devices, etc., can solve the problems of opaque shell, lack of representativeness and inability to take samples, and achieve the effects of convenient and intuitive observation, convenient appearance quality and reliable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

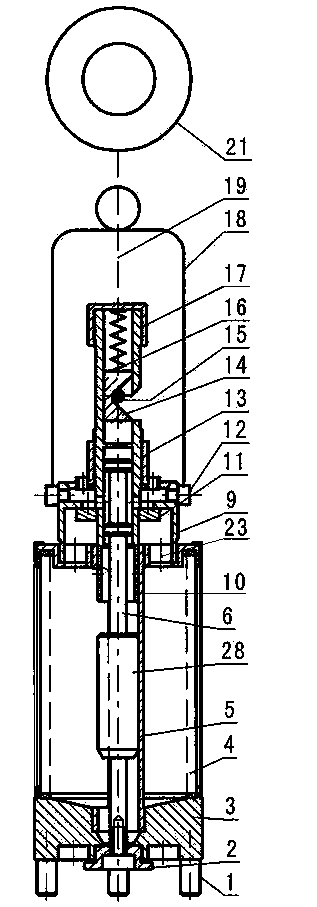

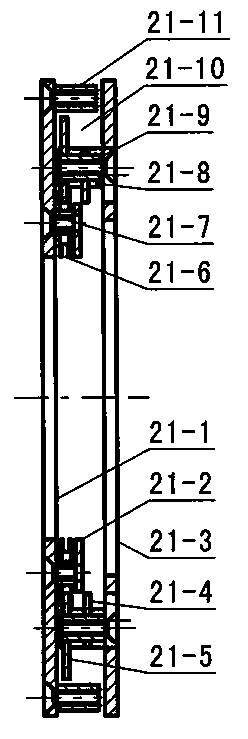

[0046] Refer to attached Figure 1~6 , Petroleum liquid transparent glass sampler of the present invention mainly is made up of parts such as container part, valve control mechanism and tape disc.

[0047] The container part includes a light-proof tube 22 , a screw rod 1 , a base 3 , a container 4 , a connecting pipe 5 , a gasket 7 , an upper cover 8 , a port valve cover 9 , an ear handle 12 and a handle 18 .

[0048] The valve control mechanism includes a cock 2, a valve stem 6, a valve sleeve 10, a valve plate 11, a positioning nut 13, a push rod 14, a hook 15, a spring 16, a valve cap 17, an air hole 20 under the valve sleeve, and an upper valve sleeve. Vent hole 26, positioning nut vent hole 27.

[0049] Several screw rods 1 are installed on the bottom of the base 3, the middle part of the base 3 is provided with a valve seat hole, the bottom of the valve seat hole is provided with a tapered hole, and the container 4 is installed on the base 3; For the tightness of the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com