Connecting structure for unmanned aerial vehicle body and wing

A technology for connecting structures and unmanned aerial vehicles, which is applied to the fuselage, aircraft parts, toy aircraft, etc., can solve the problems of difficult repair and replacement, low fatigue resistance, and complicated manufacturing process, and achieves strong replaceability and production. The effect of large batch size and simple manufacturing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

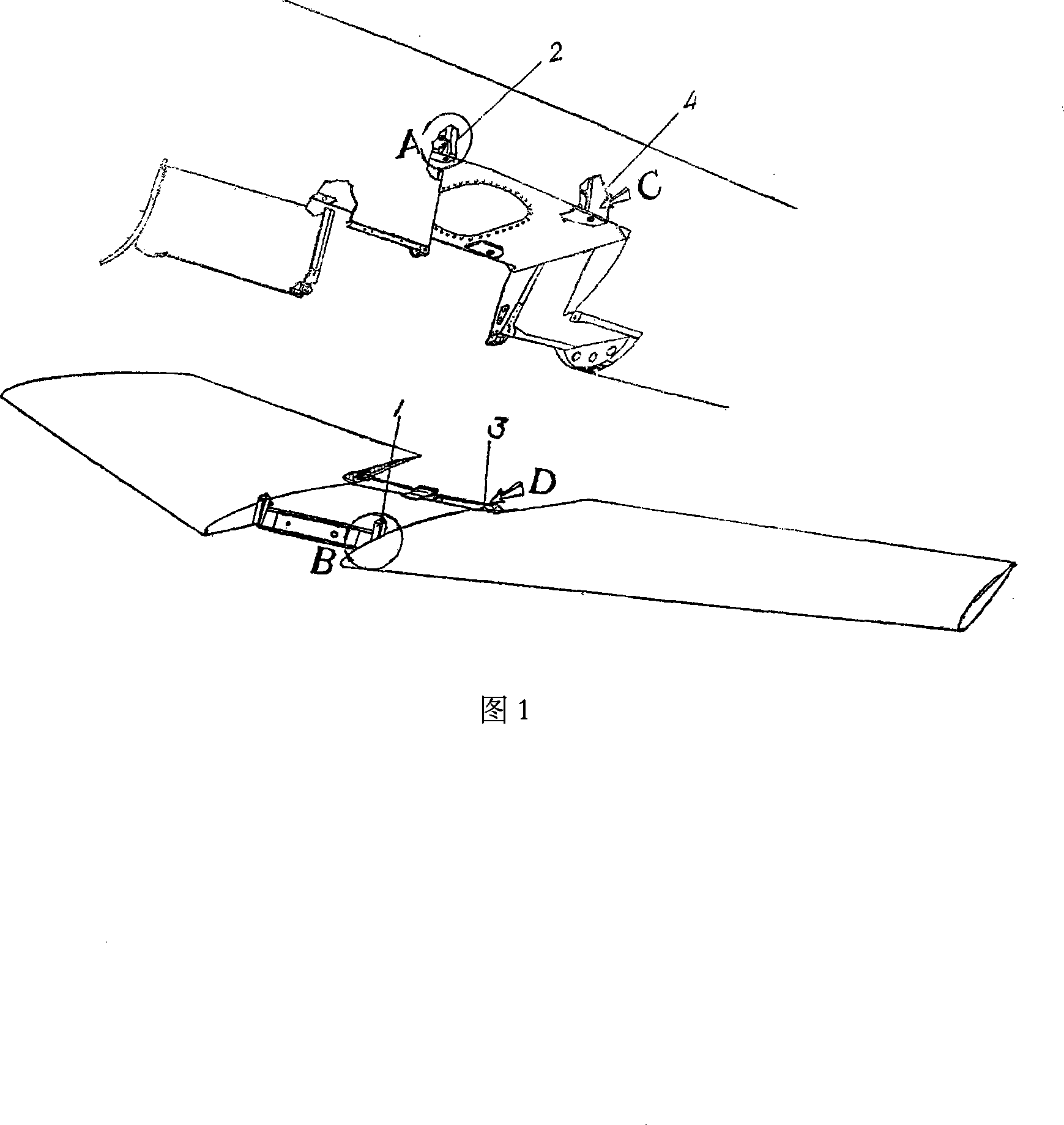

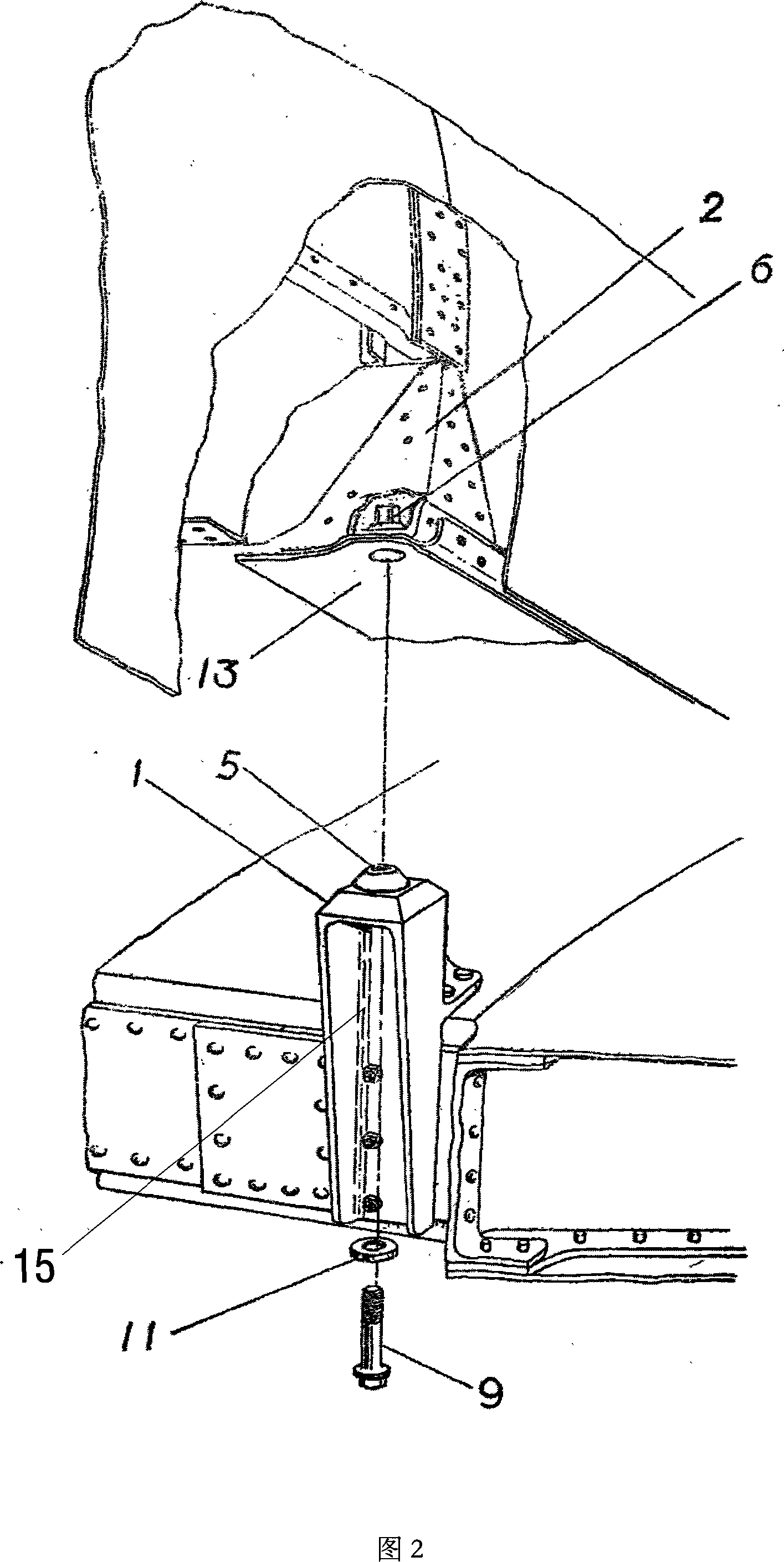

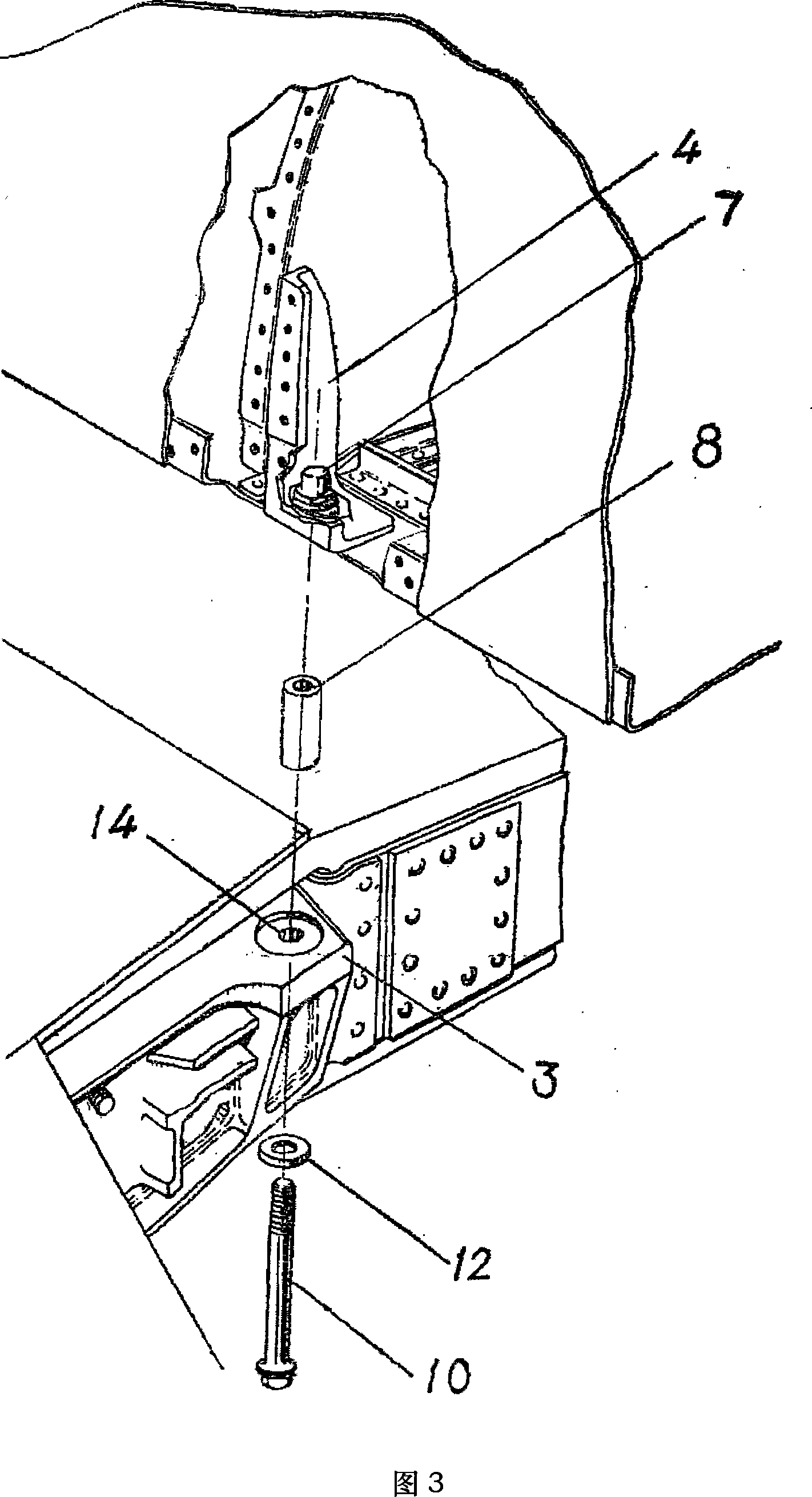

[0026] The present invention will be further described in detail below in conjunction with the accompanying drawings.

[0027] The connecting structure of a kind of unmanned aerial vehicle fuselage of the present invention and wing is realized by connecting a pair of front and rear joints on the wing and a pair of front and rear joints on the bottom plate of the fuselage fuel tank. The front joint 2 is connected, and the rear joint 3 of the wing is connected with the rear joint 4 of the fuselage. The enlarged view of the connection structure of parts A and B is shown in Figure 2, combined with the structural diagram of the front joint 1 of the wing in Figure 4 and the front of the fuselage in Figure 5 The structural diagram of the joint 2 shows that the front joint 1 of the wing is connected to the upper surface of the wing through the side ear 16, and the front part is riveted to the wing box wall plate through a number of screw holes in the washing tank 15, and its top is equ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com