Grinding device for steel pipe surface derusting device with good grinding uniformity

A technology for uniformity and steel pipes, which is applied in the field of steel pipe processing and grinding devices for steel pipe surface derusting devices. It can solve the problems of poor grinding uniformity, poor derusting effect, and affecting the service life of pipes, etc., and achieves wide adaptability and uniformity of grinding. Good, good rust removal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

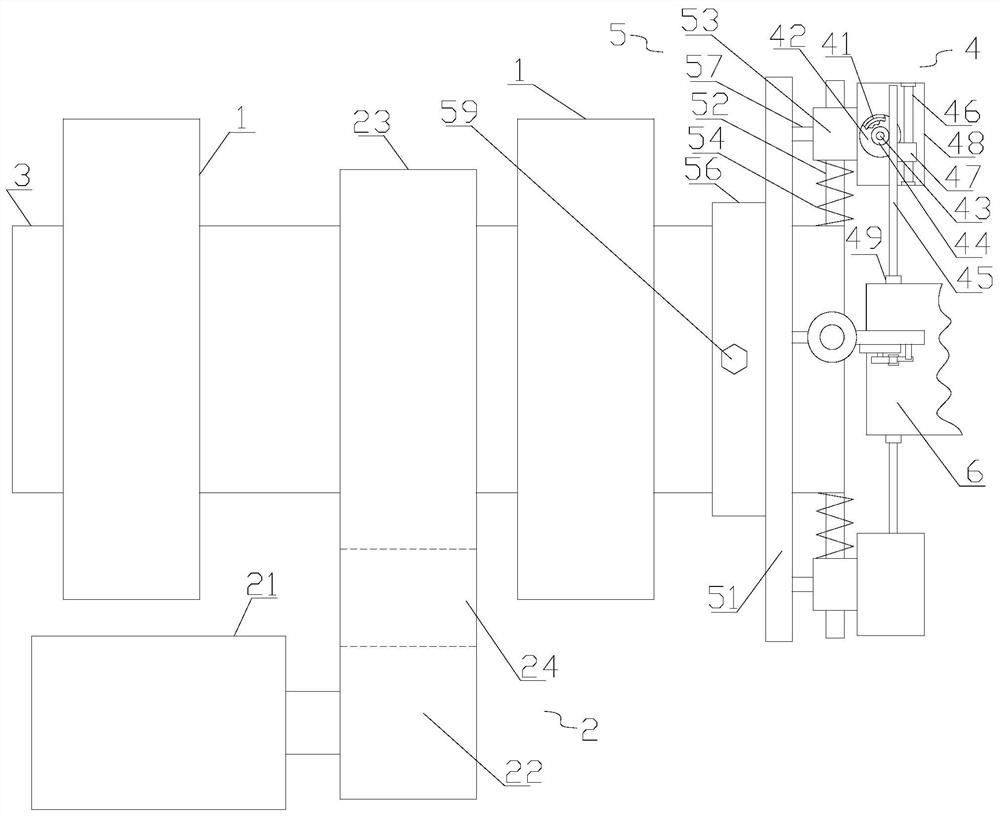

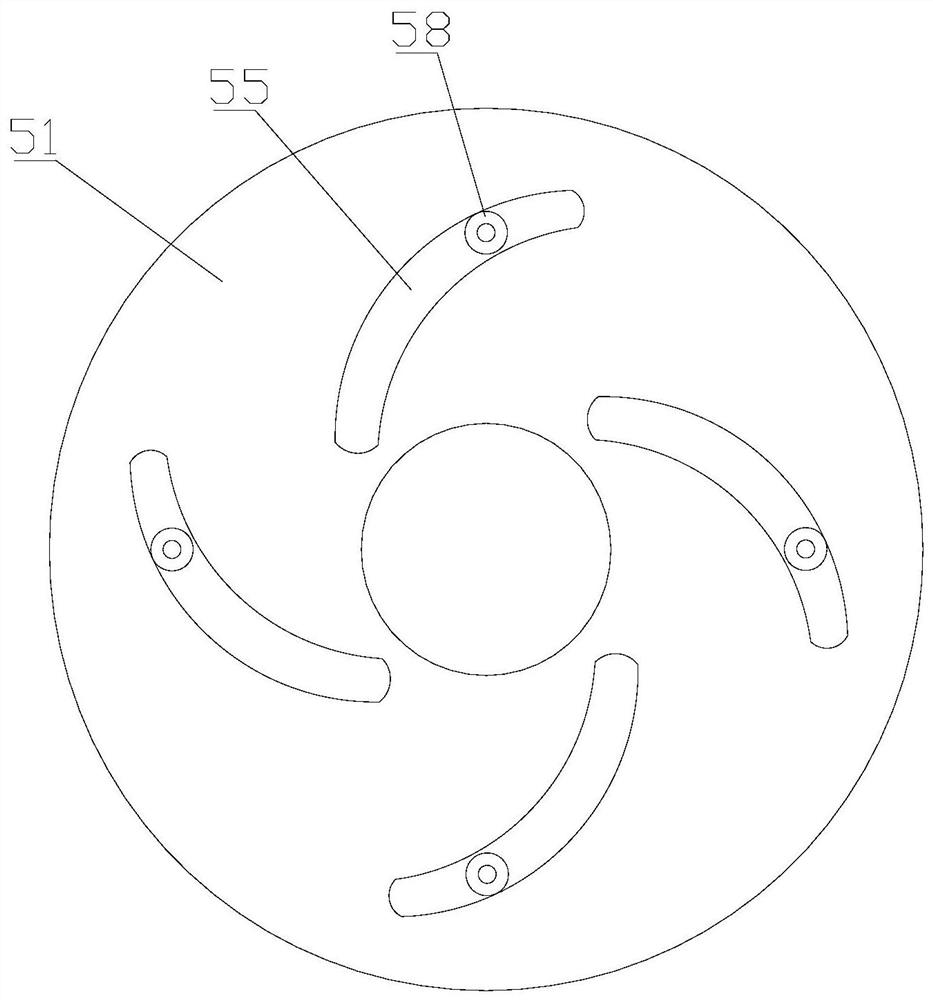

[0014] refer to figure 1 , 2 , a grinding device for a steel pipe surface derusting device with good grinding uniformity in the present invention, comprising two support bases 1, a driving mechanism 2, a hollow shaft 3, several grinding mechanisms 4 and an adjusting mechanism 5, and the hollow shaft 3 is rotatable Set on two supporting bases 1, the driving mechanism 2 drives the hollow shaft 3 to rotate, the rear end peripheral surface of the hollow shaft 3 is provided with an adjustment mechanism 5, and the adjustment mechanism 5 is provided with a grinding mechanism 4, the Grinding mechanism 4 comprises constant force clockwork spring 41, spring box 42, axle body 43, gear 44, rack 45, slide rail 46, slide seat 47, mounting seat 48 and grinding head 49, and described mounting seat 48 is provided with Spring box 42 and slide rail 46, described spring box 42 is provided with rotatable axle body 43, and described spring box 42 is provided with the constant force clockwork sprin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com