A kind of high-temperature soot gas jet experimental device and method

A gas jet, experimental device technology, applied in measurement devices, instruments, surface/boundary effects, etc., can solve the problems of difficult formation, small specific heat, low gas density, etc., and achieve the effect of temperature controllable and stable speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

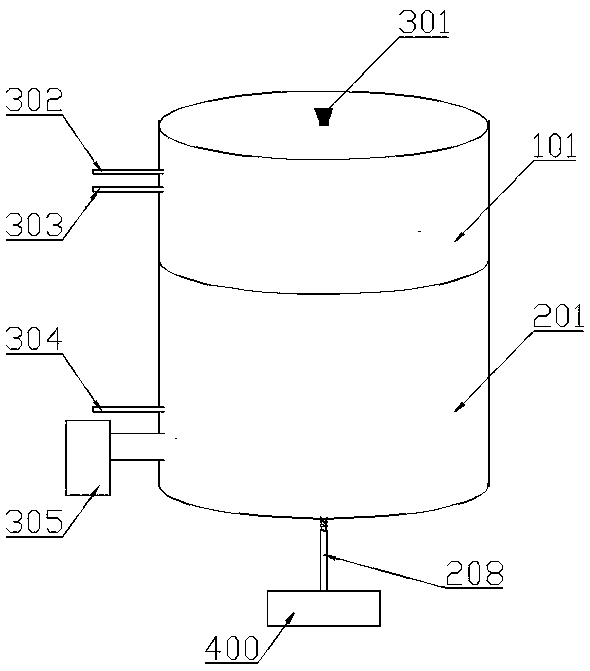

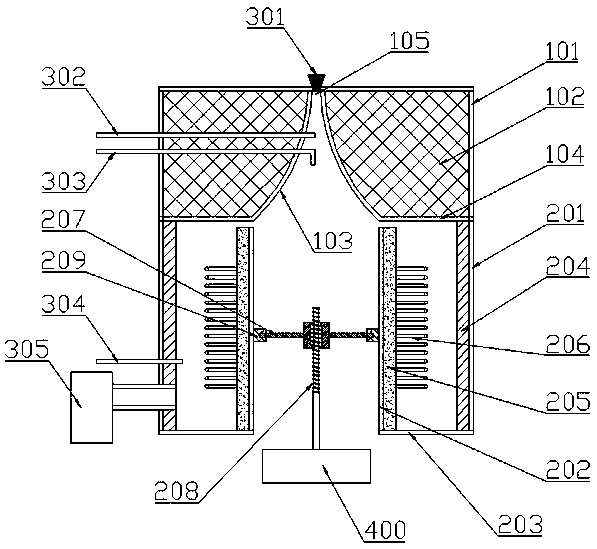

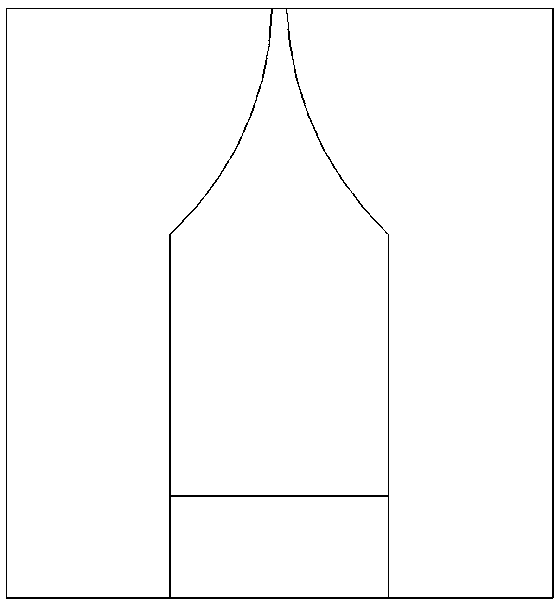

[0032] This embodiment provides a kind of high-temperature soot gas jet experimental device, such as figure 1 and figure 2As shown, it includes a jet outlet control assembly, a gas heating storage assembly, a drive assembly 400 and an auxiliary assembly; the jet outlet control assembly includes a jet outer tube 101, a jet guide structure and a first thermal insulation layer 102; the jet outer tube includes a top plate and is arranged on The side wall under the top plate; the jet guide structure includes a guide part 103 arranged in the jet outer tube 101 and a connecting part 104 connecting the guide part 103 and the lower edge of the side wall; the guide part 103 surrounds a guide space, The jet outlet 105 is located on the top plate; the connecting portion 104 is parallel to the top plate; the first thermal insulation layer 102 is arranged in the cavity formed by the jet outer tube 101 and the jet flow guiding structure; The sleeve 201, the inner sleeve 202 arranged in th...

Embodiment 2

[0048] Based on Example 1, this embodiment provides a high-temperature soot gas jet experimental device, the jet outlet 105 is circular, and the jet outlet 105 has an aperture R 1 =0.02m, inner diameter of inner sleeve 202 R 2 =0.3m, inner diameter of outer sleeve 201 R 3 =0.5m, the lead of the ball screw 208 is 0.004 m, the speed of the ball screw 208 is 300 r / min, and a jet gas with a velocity of 4.5m / s can be formed at the jet outlet 105.

Embodiment 3

[0050] Based on Example 1, this embodiment provides a high-temperature smoke gas jet experimental device, and the curve equation of the arc-shaped guide part is: f(x)=p 1 x 2 +p 2 x , where the parameter p 1 The value of 15, the parameter p 2 The value of is 0.46. The two-dimensional model modeling and grid division are completed in ANSYS ICEM software, and the dynamic grid method in FLUENT is used for simulation calculation, and the 105 aperture of the jet outlet is taken R 1 =0.02m, inner diameter of inner sleeve 202 R 2 =0.2m, inner diameter of outer sleeve 201 R 3 =0.35m, the jet outlet 105 is set as the pressure outlet, and the pressure of the pressure outlet is set as 0 Pa, compared when the flow velocity at the jet outlet 105 increases from 5m / s to 10m / s (because the section of the inner sleeve 202 is the section of the jet outlet 105 100 times of the ideal state, the moving speed of the baffle 207 increases from 0.05m / s to 0.1m / s), the change of dynamic ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thermal resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com