On-off synchronous control rail-hanging type brake

A start-stop synchronization and synchronous control technology, which is applied in the direction of brake types, brake components, brake actuators, etc., can solve the problems of increased acceleration of transportation equipment, injury to people, and insufficient smooth braking, so as to reduce the occurrence rate, Easy installation and layout, simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

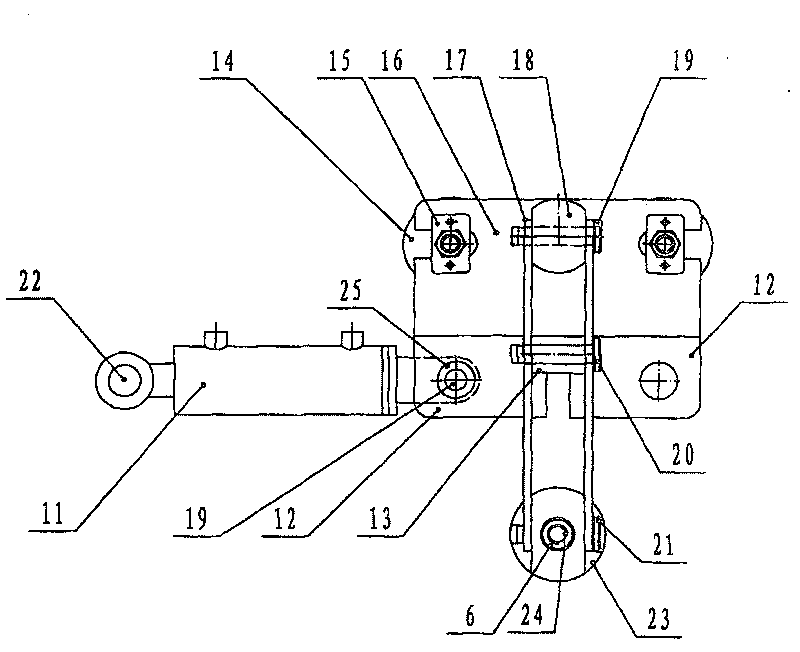

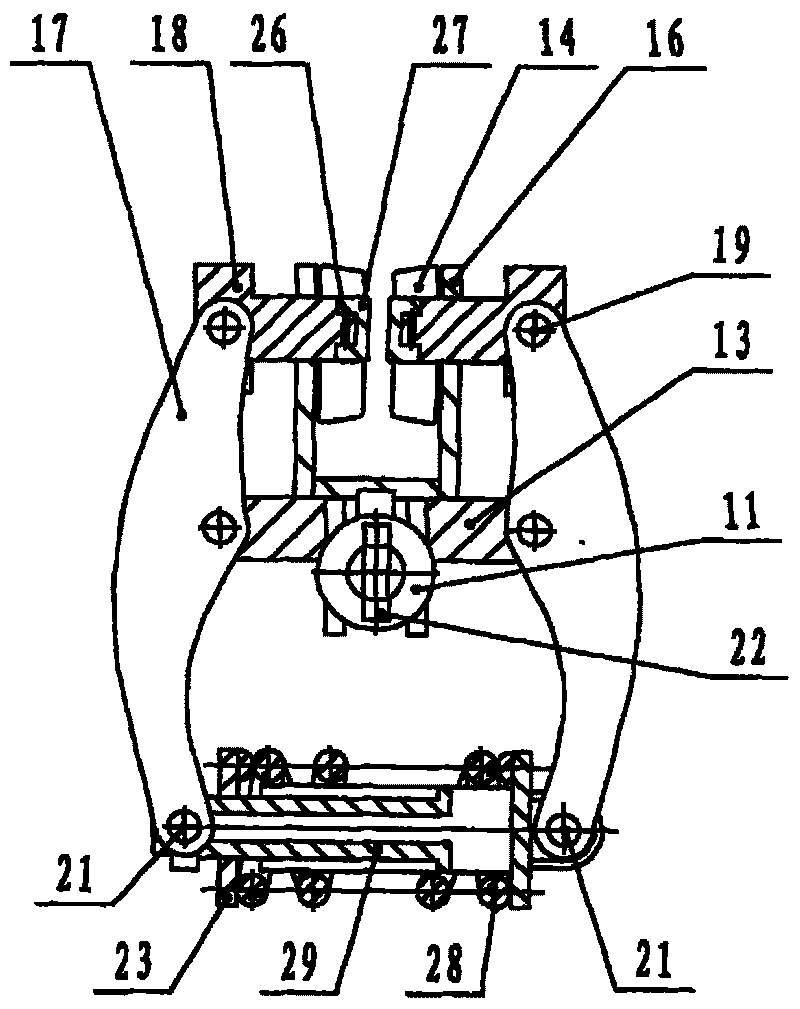

[0013] The roller 36 rotates around the support shaft 31 under the cooperation of the bearing 30, and the bearing end cover 34 is pressed on the bearing 30 under the cooperation of the circlip 35. There are two circular holes on the limit plate 15, and the limit plate 15 The function is to locate the support shaft 31 on the support frame 16 with the conical pin 33. The support frame 16 is a "U" type weldment, and two groups of earring connecting plates 12 are welded at the bottom of the supporting frame 16. The earring connecting plates 12 The effect is to connect double-acting oil cylinder 11, double-acting oil cylinder 11 is connected on the earring connecting plate 12 with pin 19, welded a square rigid body 13 for connecting drive plate 17 in the middle of two groups of earring connecting plates 12.

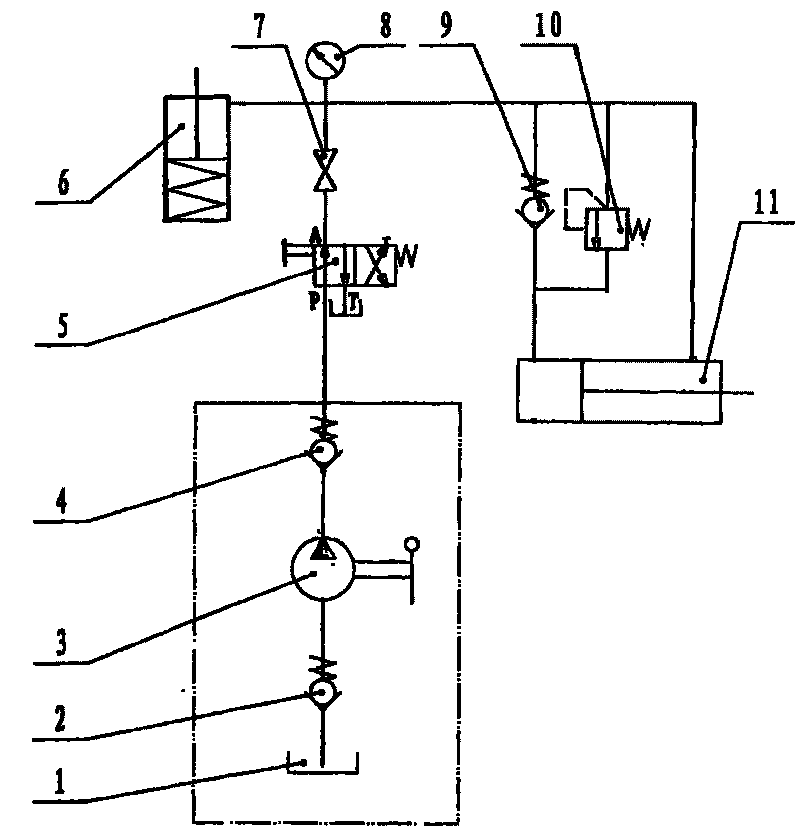

[0014] First, the oil inlet and outlet of the hand pump 3 are connected to the check valves 2 and 4 respectively, and the oil inlet of the reversing valve 5 is connected to the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com