Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

172results about How to "Inhibit gas production" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

High-nickel single-crystal ternary cathode material with low surface residual alkali content and preparation method thereof

InactiveCN110436531AIn-situ encapsulationUniform coating in situCell electrodesSecondary cellsLithium hydroxideSingle crystal

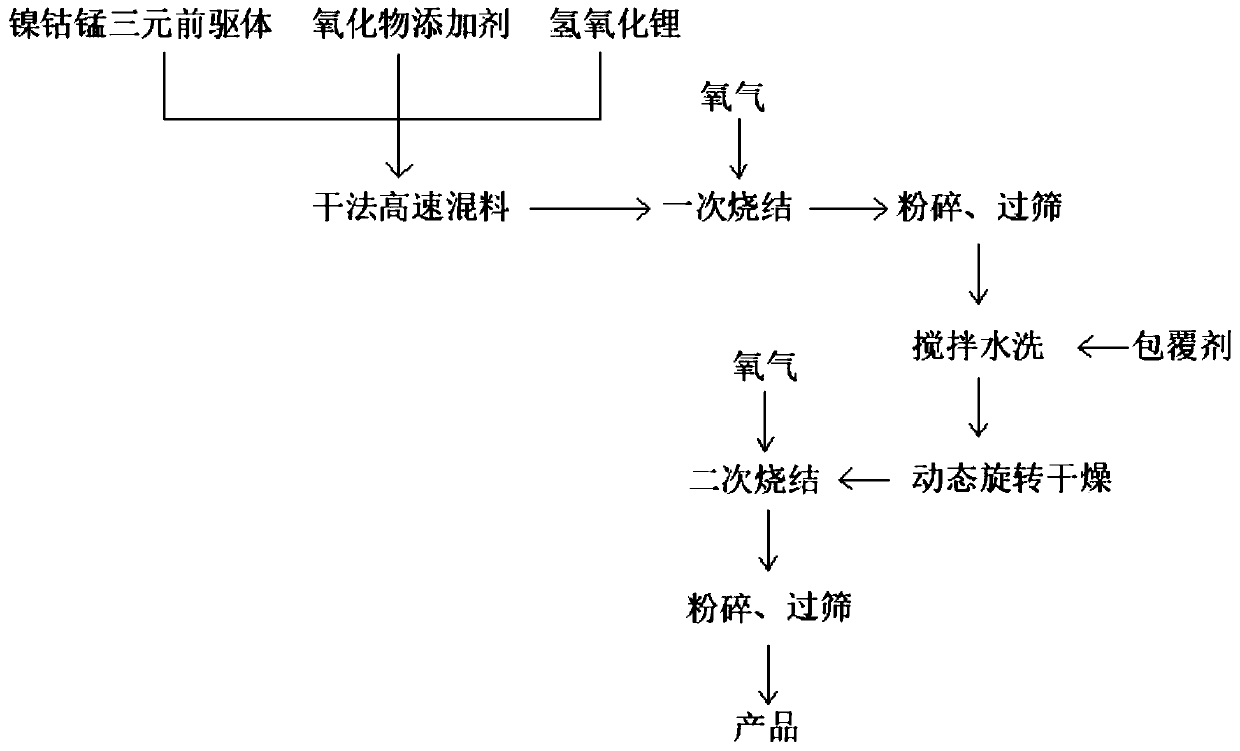

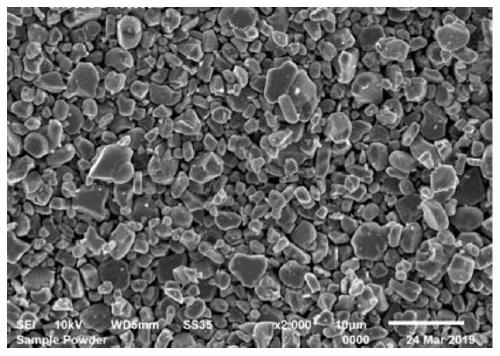

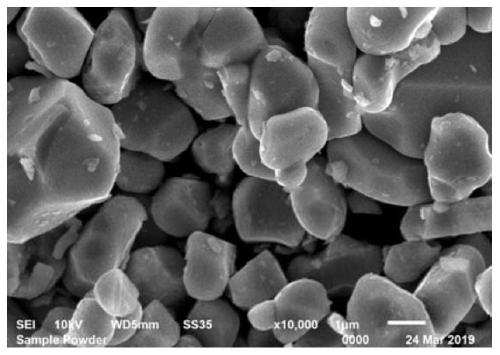

The invention discloses a high-nickel single-crystal ternary cathode material with low surface residual alkali content and a preparation method thereof. The preparation method comprises the followingsteps: weighing lithium hydroxide, an oxide additive and a nickel-cobalt-manganese ternary precursor, and carrying out uniform mixing through a dry high-speed mixing process so as to prepare a mixed material; subjecting the mixed material to first sintering so as to obtain a first sintered material; crushing the first sintered material, and carrying out sieving so as to obtain a first crushed material; weighing the first crushed material, a coating agent and deionized water, and carrying out water washing under stirring so as to prepare a slurry, wherein the coating agent comprises an elementX which is one or more selected from the group consisting of B, Al, Ba, Zr, Mg, Ca, Ti, Si, V, Sc, Nb, Ta and Z; drying the slurry under a vacuum condition through a dynamic rotary drying process so as to obtain a dry material; subjecting the dry material to secondary sintering so as to obtain a secondary sintered material; and crushing the secondary sintered material, and carrying out sieving soas to obtain a product. The high-nickel single-crystal ternary cathode material and the preparation method thereof provided by the invention has the following advantages: alkali reduction by water washing and in-situ coating by a wet process can be synchronously completed; the process is simple; high compaction density is realized; and the content of residual alkali is low.

Owner:ZHEJIANG MEIDU HITRANS LITHIUM BATTERY TECHNOLOGY CO LTD

Ion liquid electrolytic solution and secondary lithium battery containing electrolytic solution

ActiveCN103618111AImprove securityImprove flame retardant performanceSecondary cellsOrganic electrolytesOrganic solventHydrogen

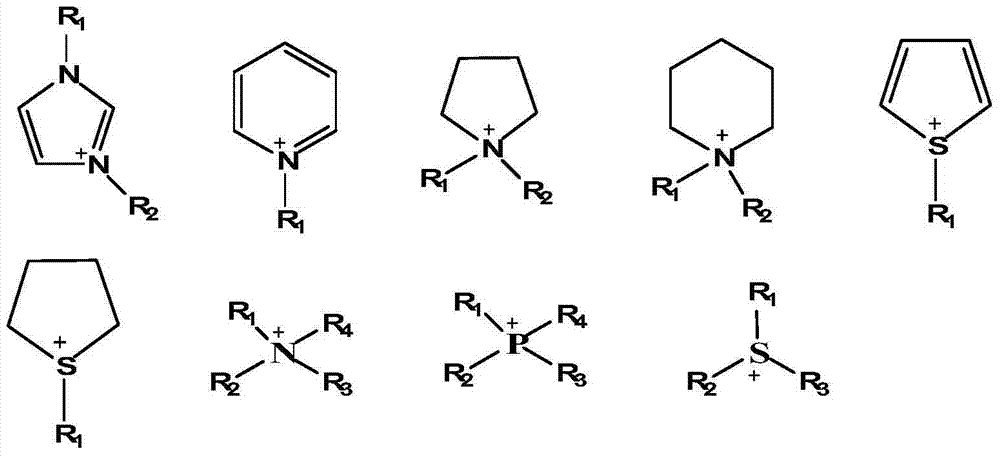

The invention discloses an ion liquid electrolytic solution and a secondary lithium battery containing the electrolytic solution. The ion liquid electrolytic solution is characterized in that a lithium secondary battery non-water electrolytic solution comprises an ion liquid containing electrolyte salt and a nitrile group functional group, a hydrogen fluorine ether, a non-water organic solvent and an addition agent; the ion liquid of the nitrile group functional group used by the electrolytic solution is beneficial to improving the security of the lithium secondary battery, the content of the ion liquid is more than 40%, and the electrolytic solution has the obvious flame retardant effect; the hydrogen fluorine ether is contributed to improving the wettability of the electrolytic solution containing the ion liquid on an electrode material and a diaphragm, and meanwhile, electrochemistry properties such as a cycle property, a high temperature keeping property of the lithium secondary battery are obviously improved; and an electrolytic solution system uses the ion liquid of the nitrile group functional group and the hydrogen fluorine ether in a composite manner, the combination properties such as the cycle property, the safety property and high temperature characteristics of the lithium secondary battery are obviously improved.

Owner:GUANGZHOU TINCI MATERIALS TECH

Lithium ion battery electrolyte and lithium ion battery

ActiveCN110265716AAvoid decompositionReduce generationFinal product manufactureSecondary cells servicing/maintenanceOrganic solventPhosphoric acid

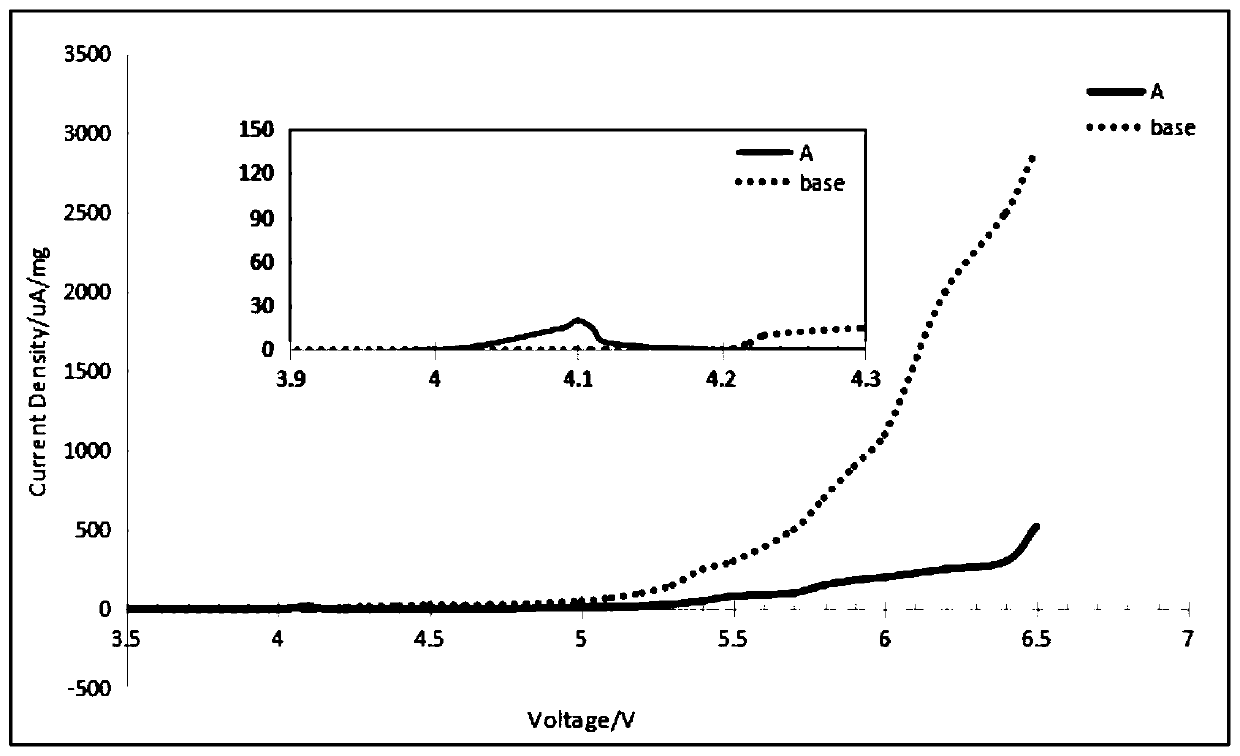

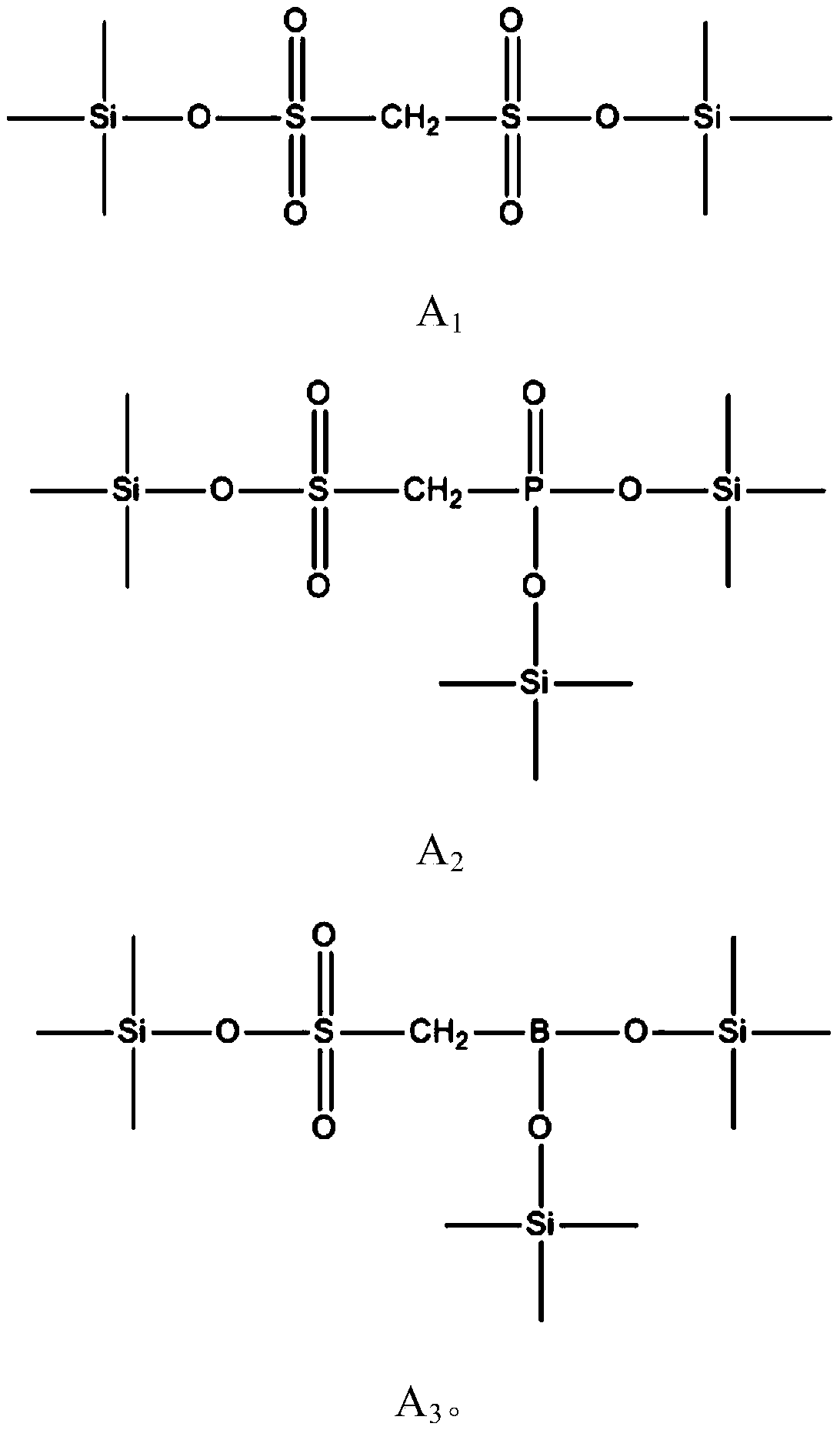

The invention belongs to the technical field of lithium ion batteries, and particularly relates to a lithium ion battery electrolyte and a lithium ion battery. The lithium ion battery electrolyte comprises a lithium salt, a non-aqueous organic solvent and an additive, wherein the additive comprises a functional additive A and an auxiliary additive, the functional additive A is provided with at least two sulfonic acid estersil groups or the functional additive A is provided with at least one sulfonic acid estersil group and at least one phosphoric acid estersil group or boric acid estersil group. The lithium ion battery prepared by the lithium ion battery electrolyte is excellent in positive / negative film formation, and the requirements of long cycle lifetime, good rate performance and adaptability to high- and low-temperature environment of the battery under high voltage are met.

Owner:东莞维科电池有限公司

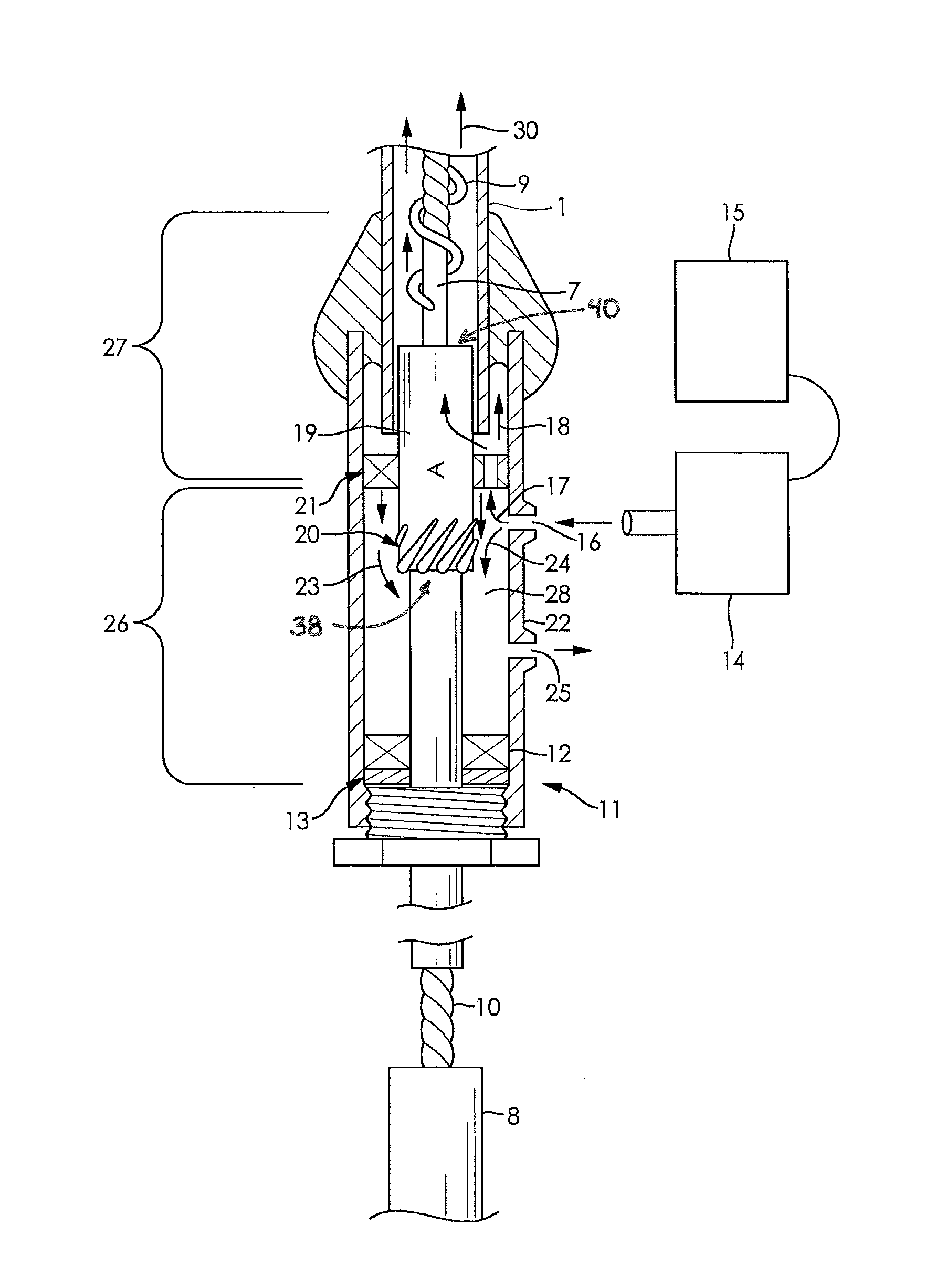

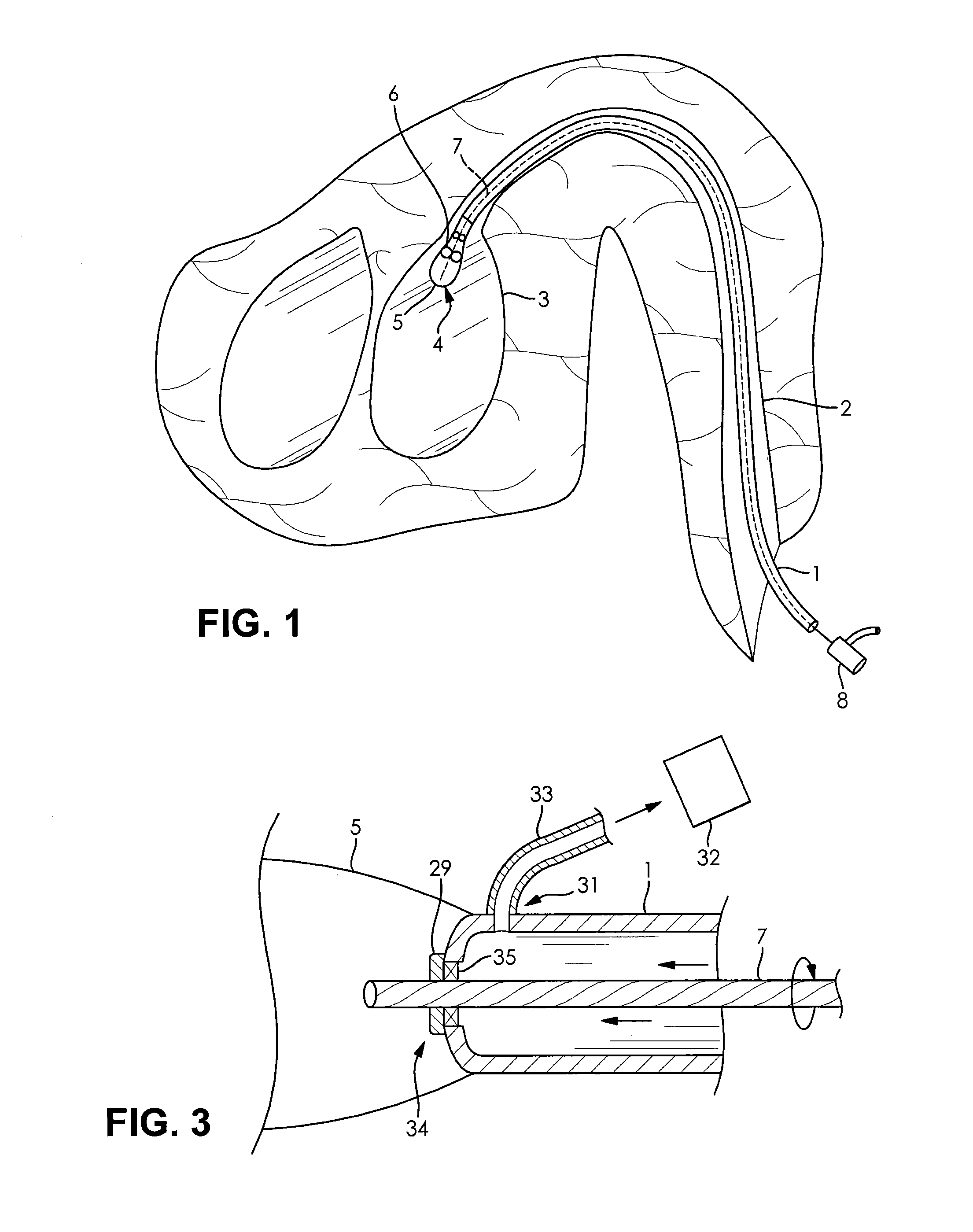

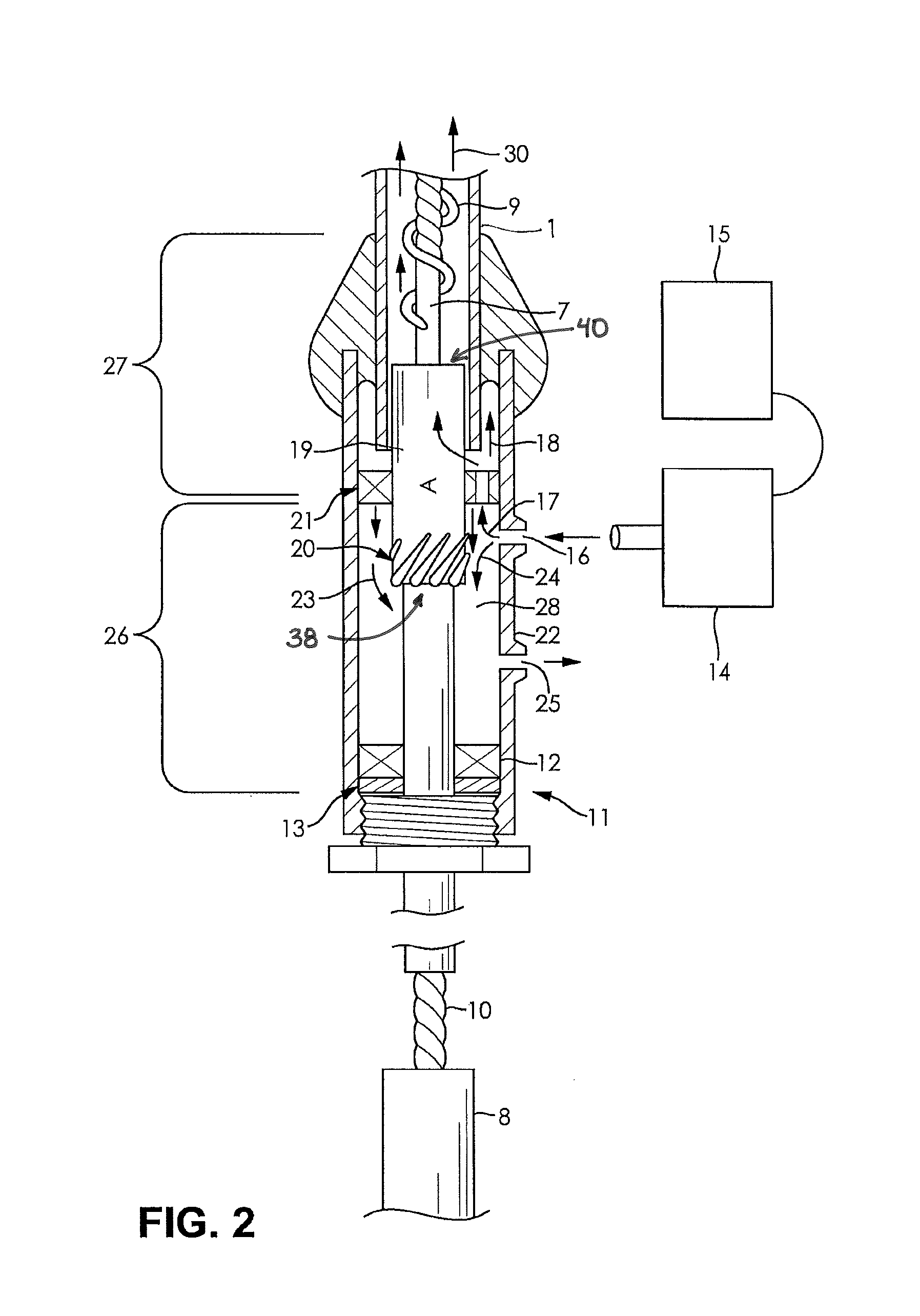

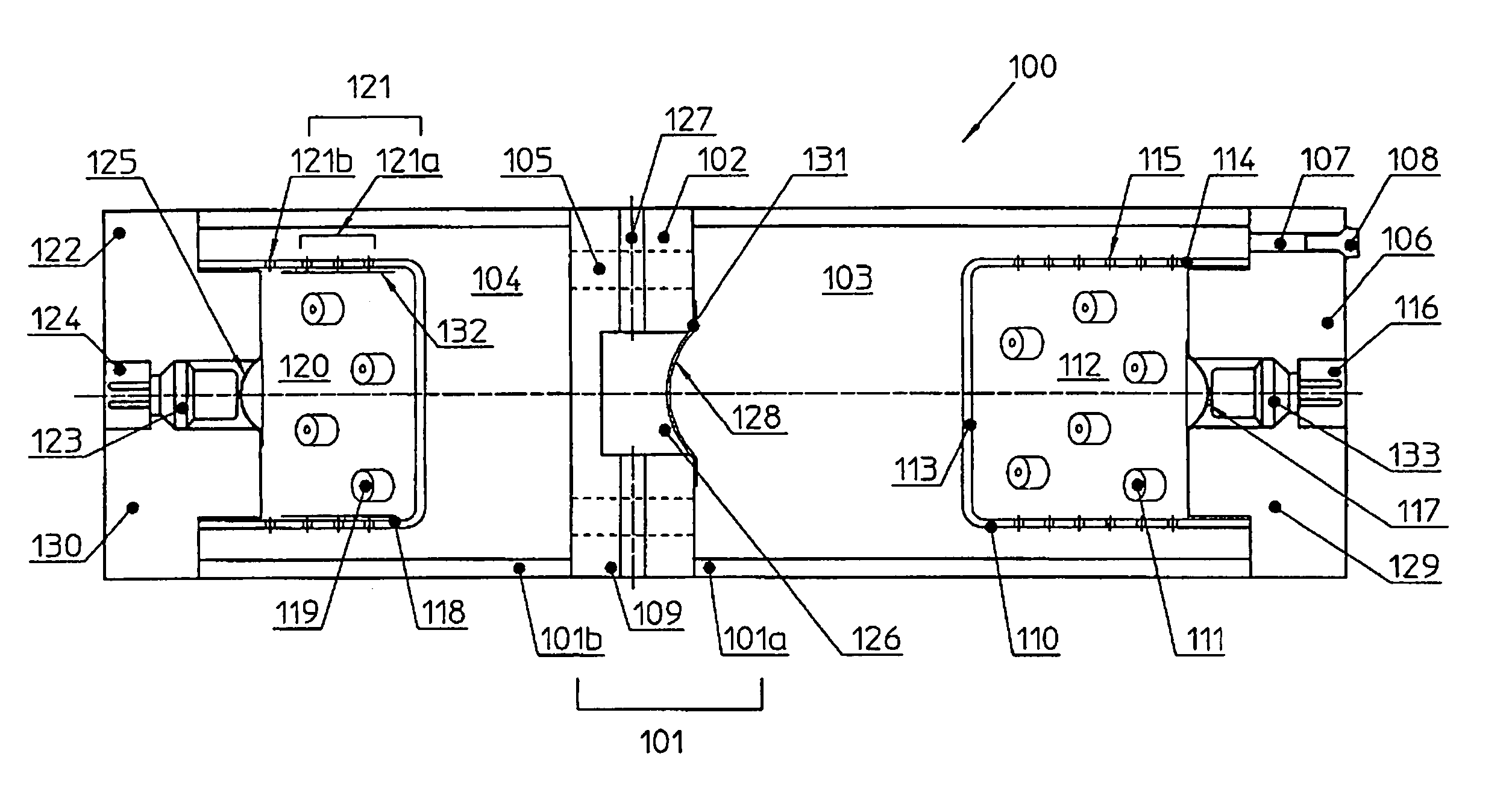

Shaft arrangement having a shaft which extends within a fluid-filled casing

ActiveUS8900060B2Reduce stressInhibit gas productionYielding couplingSurgeryEngineeringMechanical engineering

In the case of a shaft arrangement having a shaft (7) which extends within a casing (1) filled with a fluid and which can be actuated by means of a drive (8) from outwith the casing (1), the shaft (7) having on its outer peripheral surface a surface structure which conveys the fluid in a flow direction (30) in the longitudinal direction of the shaft during rotation, a sleeve (19) is provided according to the invention, which can rotate with the shaft and has at least one conveying element (20) for conveying the fluid in a counterflow direction opposite to the flow direction. As a result, a bubble-free conveyance of the fluid along the shaft (7) is facilitated.

Owner:ECP ENTWICKLUNGSGMBH

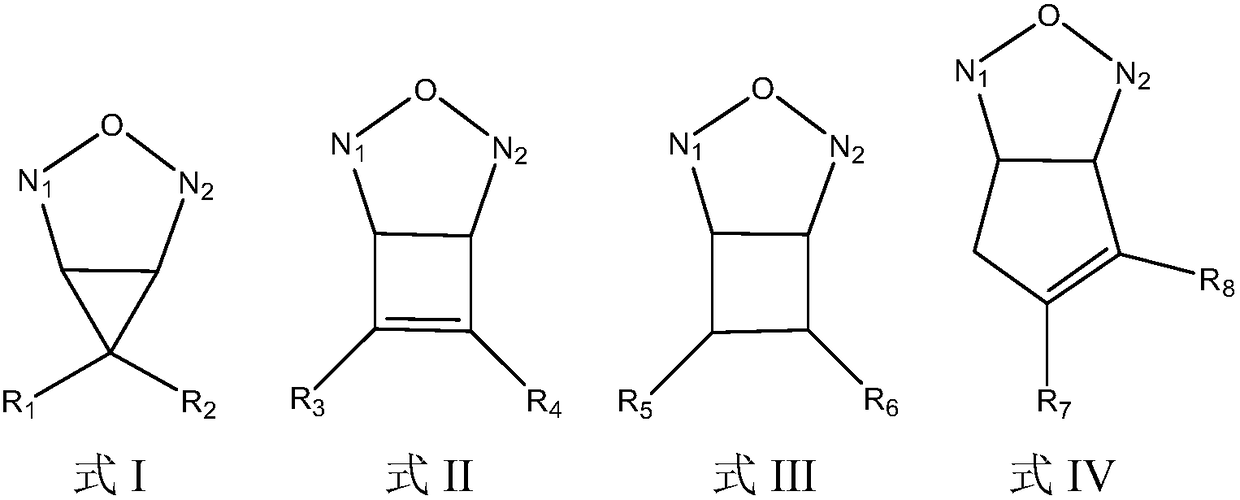

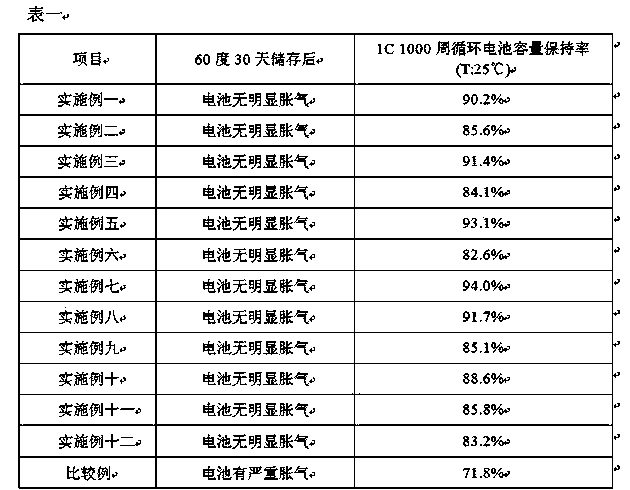

Lithium ion battery electrolyte and lithium ion battery comprising same

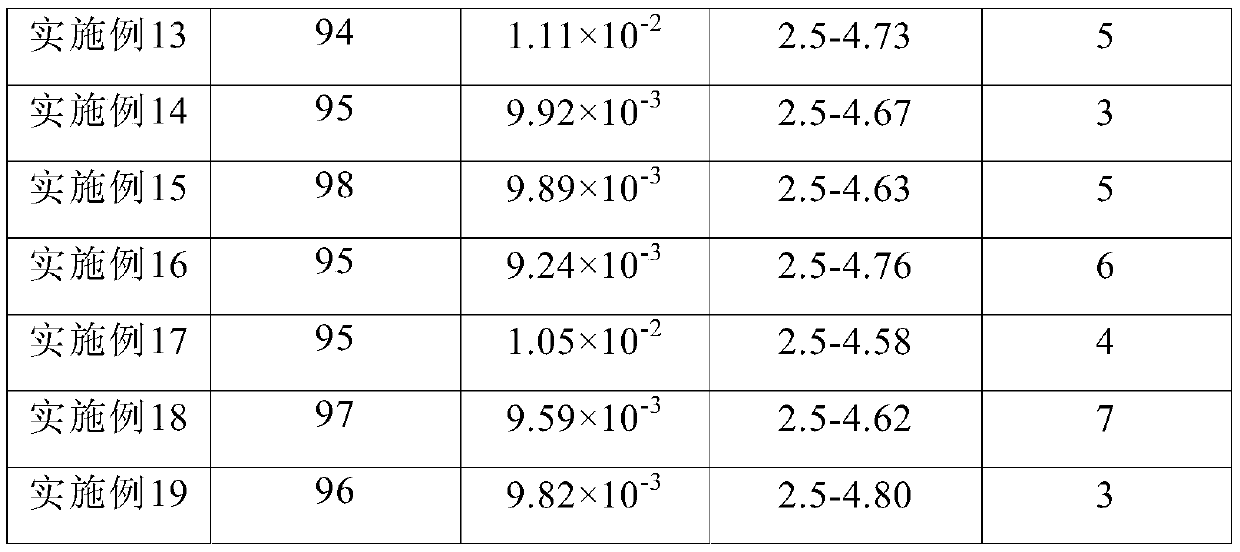

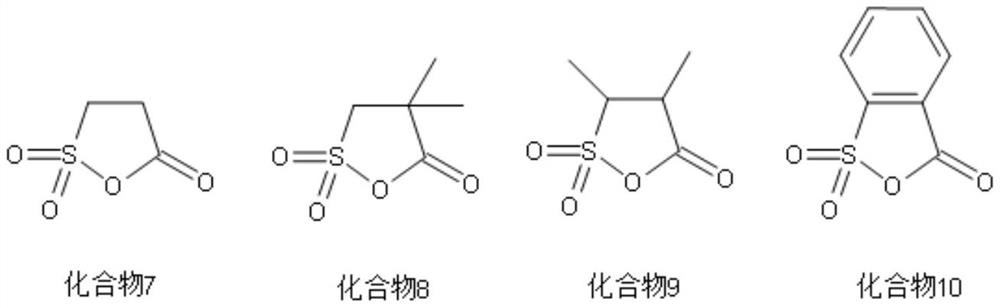

InactiveCN108598574AInhibit gas productionImprove cycle performanceSecondary cellsHigh temperature storagePower battery

The invention belongs to the technical field of a lithium ion battery, and particularly relates to a lithium ion battery electrolyte and a lithium ion battery comprising the same. The electrolyte comprises a lithium salt, a non-aqueous organic solvent and an additive, wherein the additive comprises a bridge ring anhydride additive and a low-impedance additive, and the bridge ring anhydride additive is at least one of compounds shown in a formula I, a formula II, a formula III and a formula IV. Compared with the prior art, the electrolyte has the advantages that the bridge ring anhydride additive participates in formation of a negative electrode SEI film, a protection film is also formed at a positive electrode, gas generation of the battery is prevented, the high-temperature storage performance and the cycle property of the battery are improved, and the demand of a power battery and a high-energy density battery can be satisfied.

Owner:DONGGUAN SHANSHAN BATTERY MATERIALS

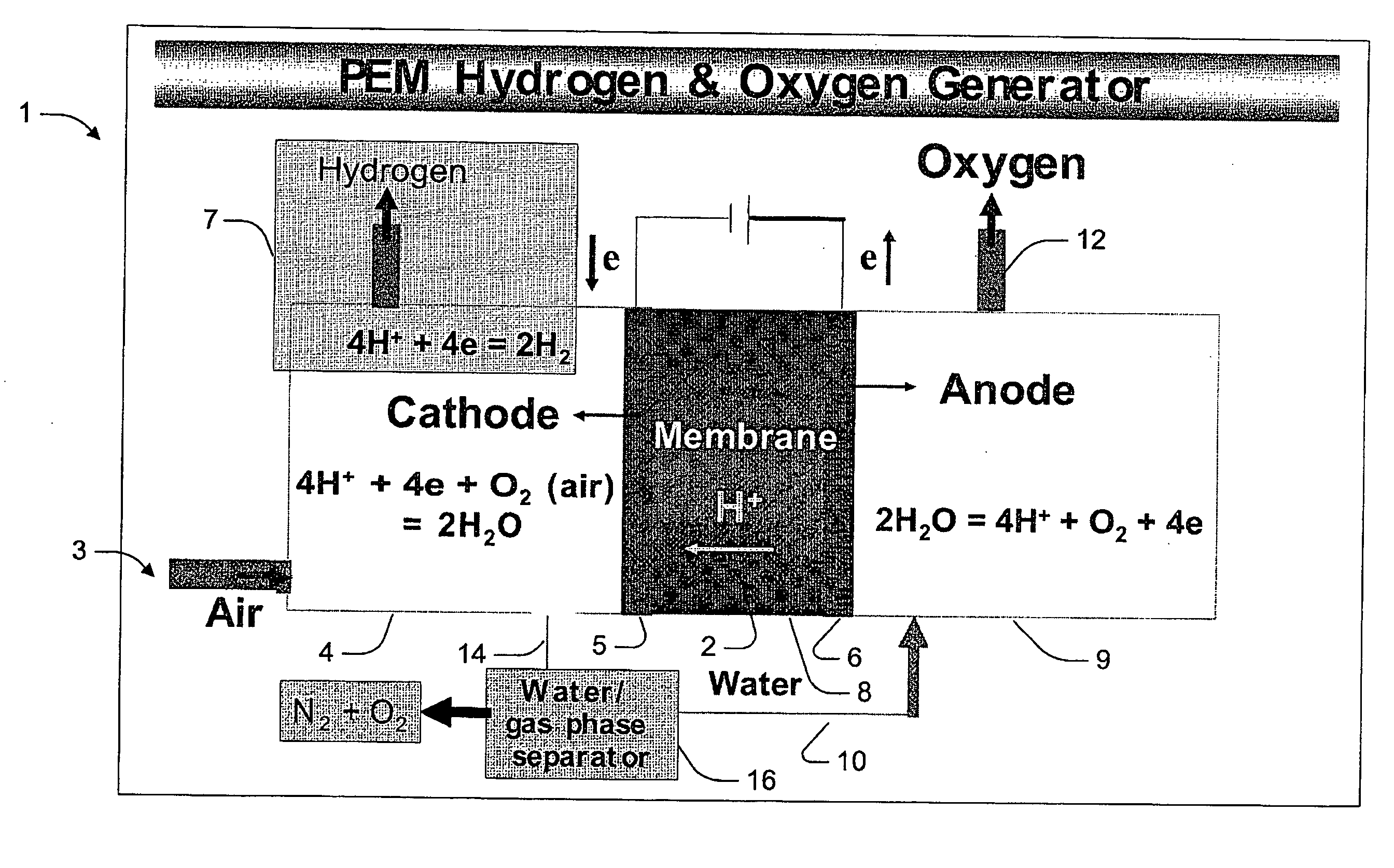

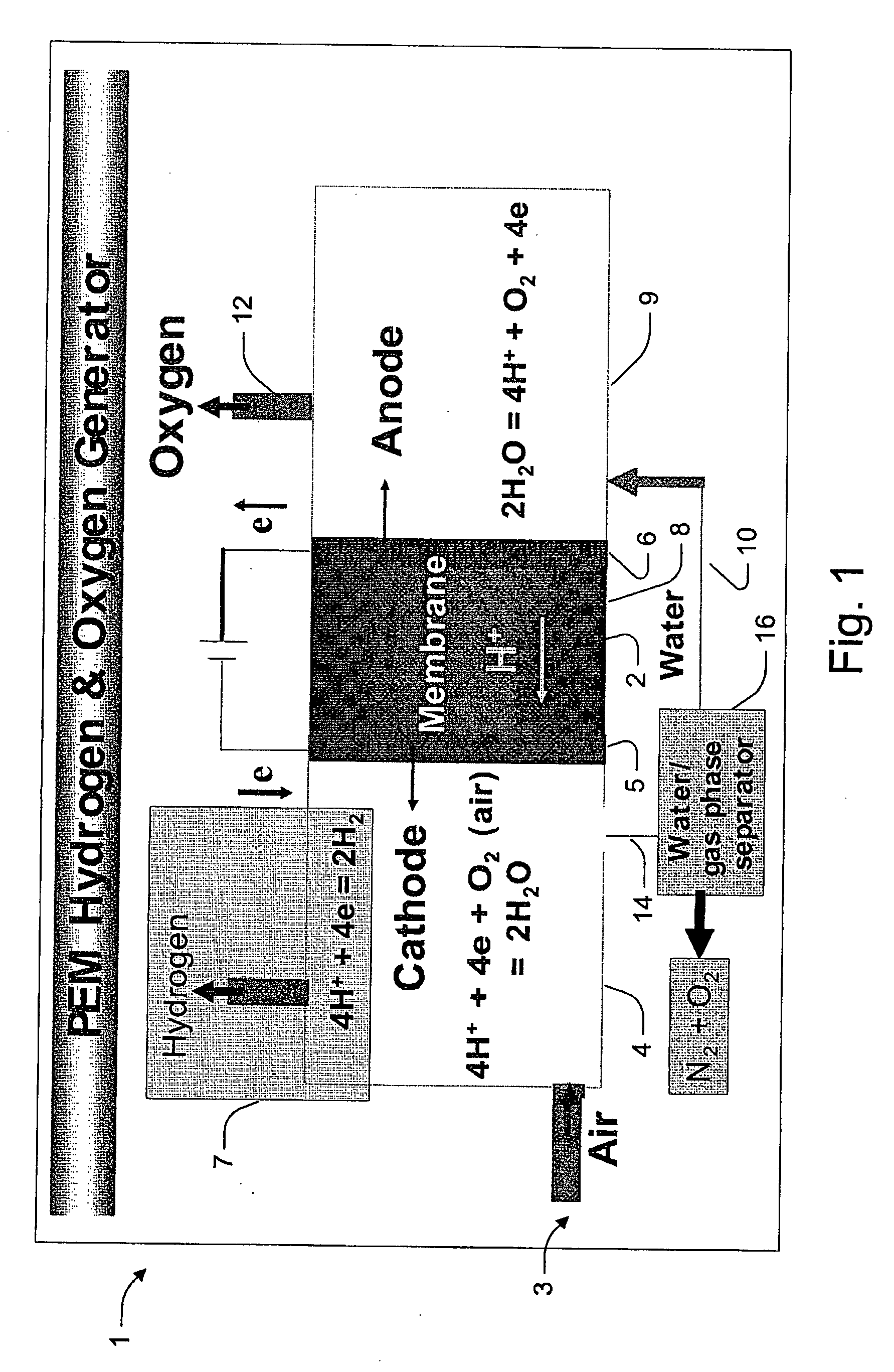

PEM water electrolysis for oxygen generation method and apparatus

ActiveUS20080283412A1Inhibit gas productionCellsPhotography auxillary processesElectrolysisElectrical battery

A PEM based water electrolysis stack consists of a number of cells connected in series by using interconnects. Water and electrical power (power supply) are the external inputs to the stack. Water supplied to the oxygen electrodes through flow fields in interconnects is dissociated into oxygen and protons. The protons are transported through the polymer membrane to the hydrogen electrodes, where they combine with electrons to form hydrogen gas. If the electrolysis stack is required to be used exclusively as an oxygen generator, the hydrogen gas generated would have to be disposed off safely. The disposal of hydrogen would lead to a number of system and safety related issues, resulting in the limited application of the device as an oxygen generator. Hydrogen can be combusted to produce heat or better disposed off in a separate fuel cell unit which will supply electricity generated, to the electrolysis stack to reduce power input requirements. This however, will add to system complexity, cost and efficiency loss. The present invention provides an improved method and a simple system for the production of oxygen.

Owner:COMMONWEALTH SCI & IND RES ORG

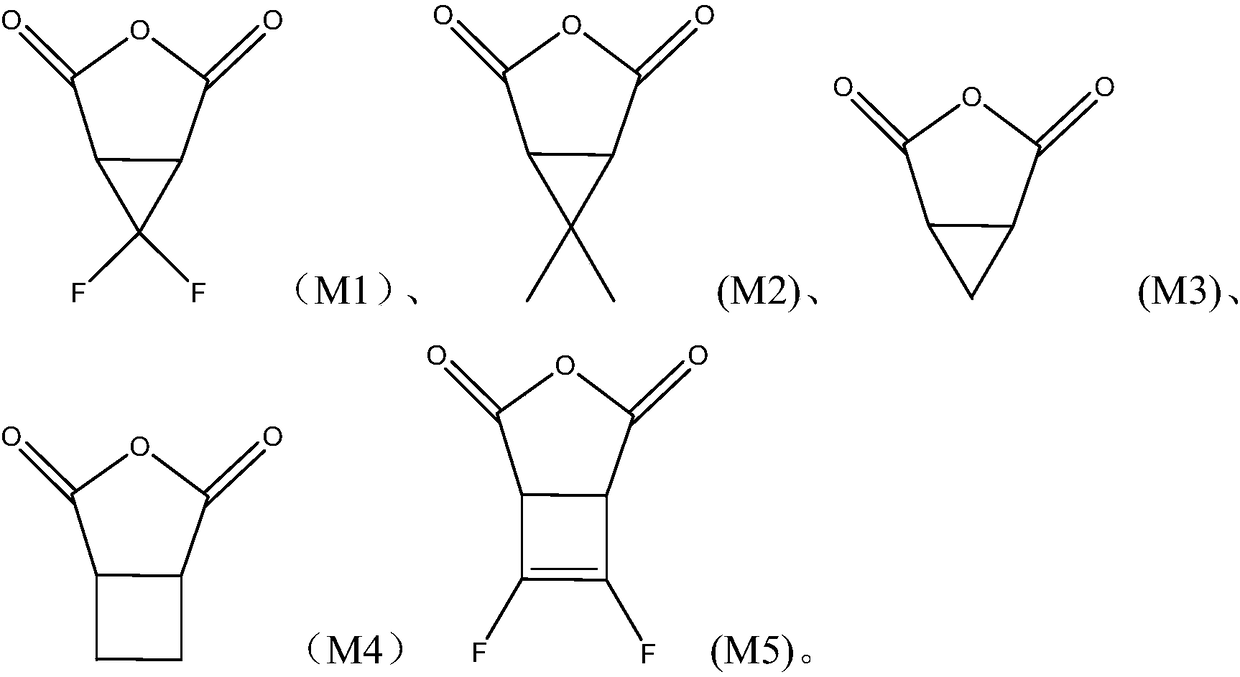

Electrolyte applicable to silicon carbon negative and lithium ion battery comprising electrolyte

ActiveCN109873205AImproved reversible capacity performanceImprove cycle performanceSecondary cells servicing/maintenanceHigh temperature storageSodium-ion battery

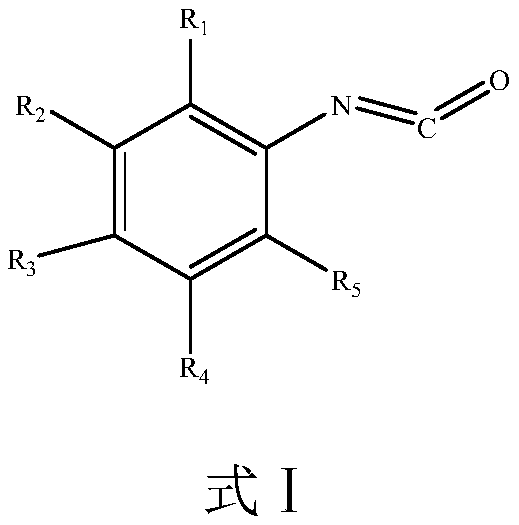

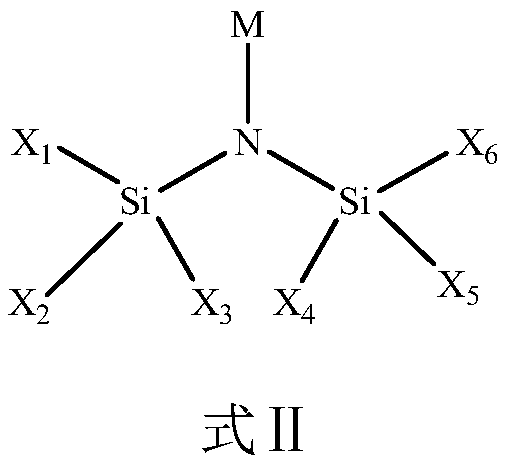

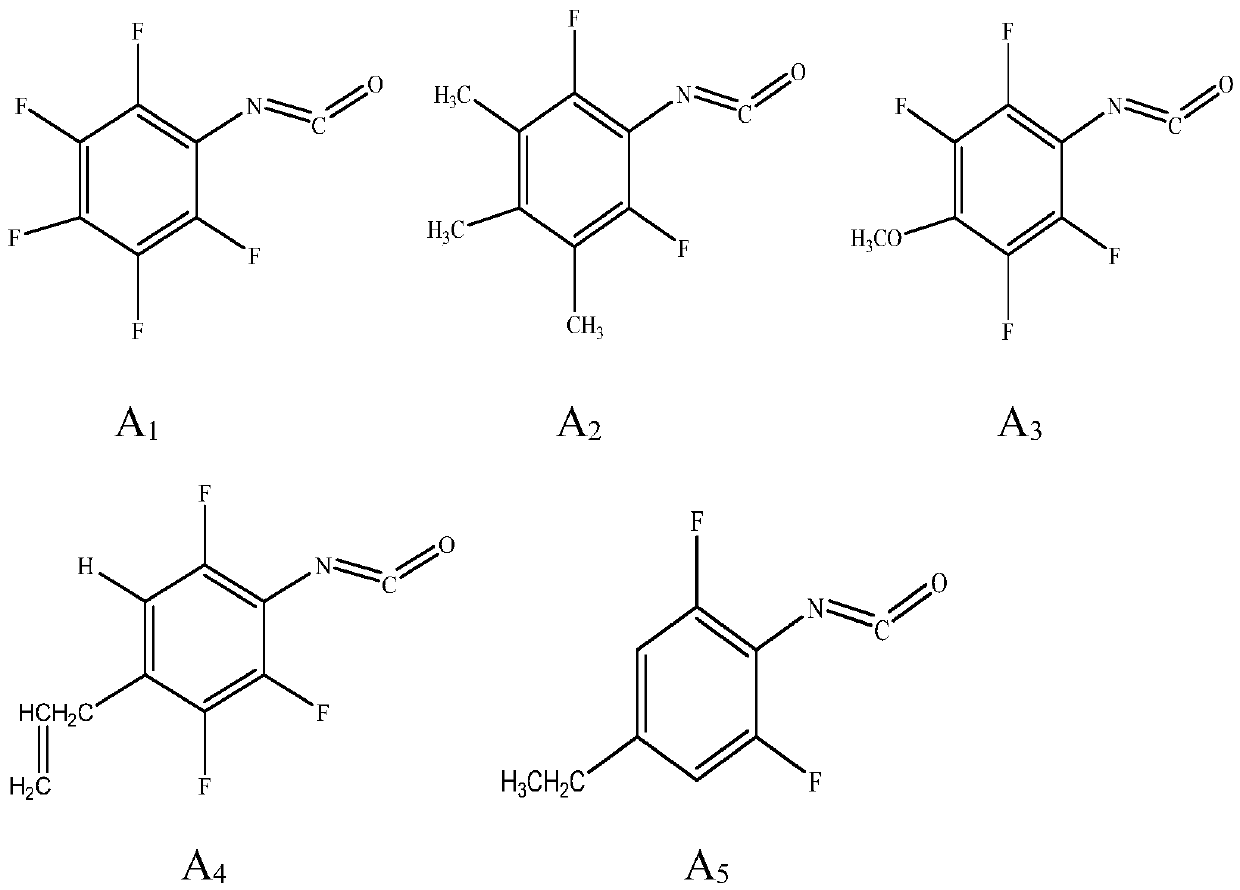

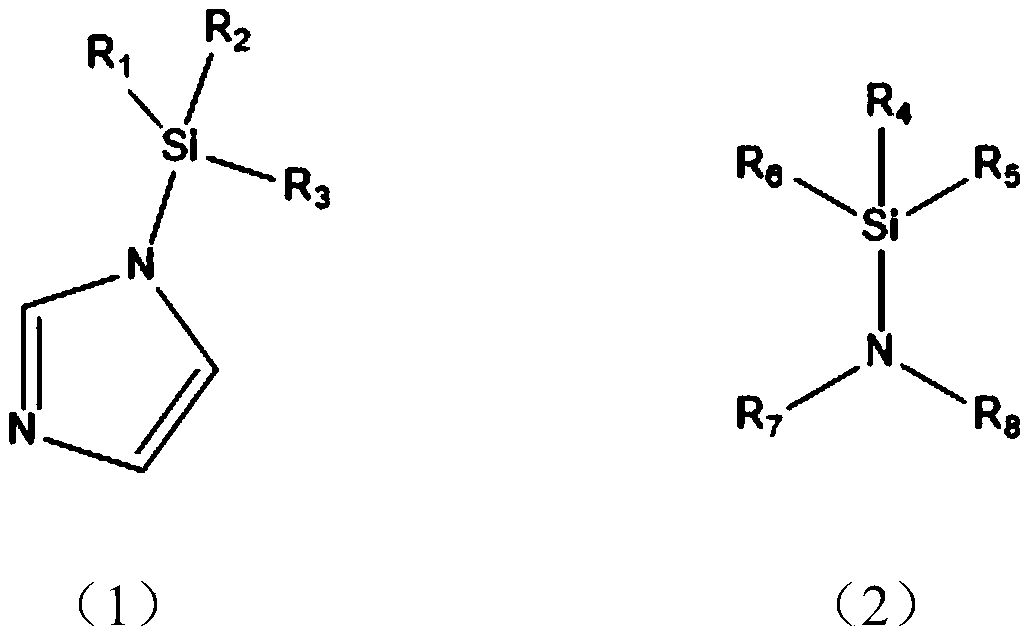

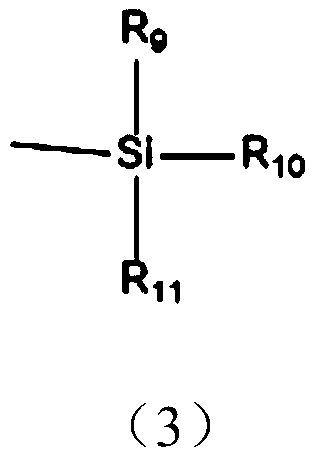

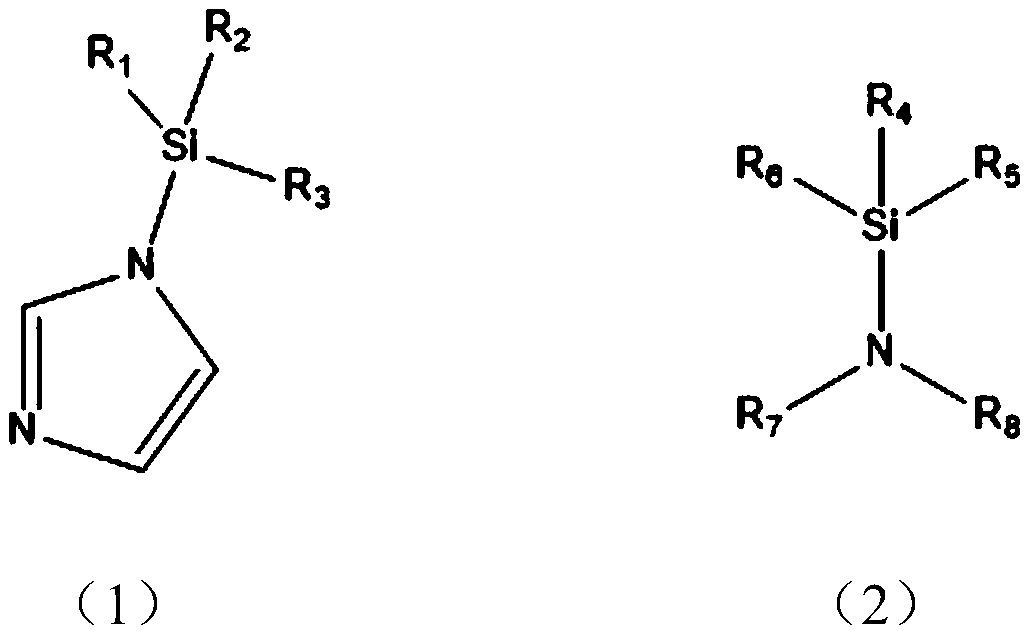

The invention belongs to the technical field of a lithium ion battery, and particularly relates to an electrolyte applicable to a silicon carbon negative and a lithium ion battery comprising the electrolyte. The electrolyte comprises an electrolyte lithium salt, a non-aqueous organic solvent and an additive. Wherein the additive comprises a negative film formation additive, a fluorine-substitutedphenyl isocyanate compound additive with a formula I structure and a dosilane nitrogen-based compound additive. Compared with the prior art, the actual discharging capability, the cycle stability andthe high-temperature storage performance of a silicon carbon negative electrode lithium ion battery are effectively improved by means of a synergic effect generated by combined application of variousadditives, gas generation is prevented, the problems of volume expansion and pole plate pulverization of the battery during the charge-discharge process are solved very well, and meanwhile, the electrolyte is compatible with relatively good high- and low-temperature performance.

Owner:SHANSHAN ADVANCED MATERIALS QUZHOU CO LTD

High-temperature high-voltage non-aqueous electrolyte and lithium ion battery containing non-aqueous electrolyte

ActiveCN109818064AImprove cycle performanceGood high and low temperature performanceSecondary cellsHigh temperature storageSodium-ion battery

The invention relates to the technical field of lithium ion batteries, in particular to a high-temperature high-voltage non-aqueous electrolyte and a lithium ion battery containing the non-aqueous electrolyte. The high-temperature high-voltage non-aqueous electrolyte comprises a lithium salt, a non-aqueous solvent and an additive, wherein the additive comprises a first borate additive, a second nitrogen-containing lithium salt additive, a third silicon-nitrogen-based additive and a fourth sulfonate and sulfate mixed additive. According to the present invention, after the various additives areproperly proportioned, the advantages of the additives can be provided, the disadvantages of the additives can be mutually inhibited, the high-temperature storage performance of the battery is improved through the synergistic effect of the additives, the high-temperature cycle performance of the battery is improved, and the application prospect is good under the conditions of high temperature andhigh voltage.

Owner:SHANSHAN ADVANCED MATERIALS QUZHOU CO LTD

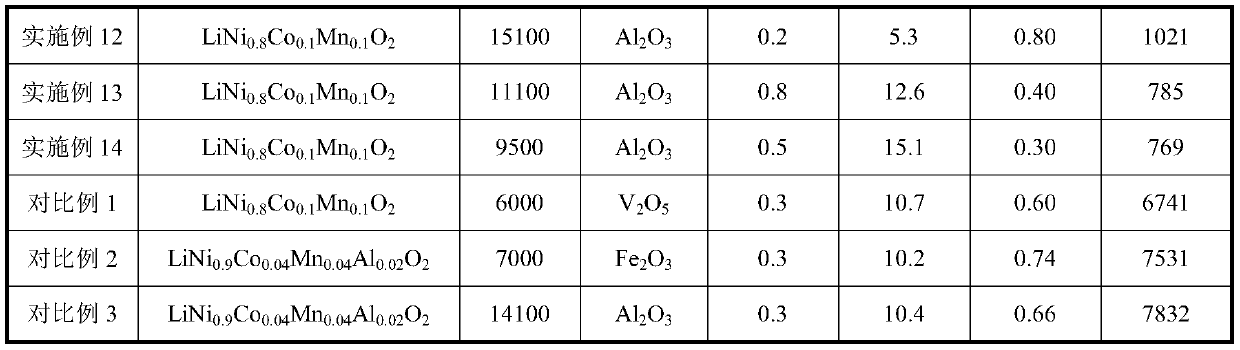

Positive electrode material and preparation method and application thereof

ActiveCN111384377APromote polarizationSmall specific surface areaPositive electrodesSecondary cells servicing/maintenanceComposite materialLithium electrode

The invention relates to the field of electrochemistry, in particular to a positive electrode material as well as a preparation method and application thereof. The invention provides a positive electrode material, which comprises a base material, the base material comprises secondary particles composed of primary particles, and the surface of the base material is provided with an oxide coating layer. According to the positive electrode material disclosed by the invention, doping and surface coating are carried out in a high-nickel base material; the powder resistivity of the positive electrodematerial is controlled within a proper range; and meanwhile, the specific surface area of the positive electrode active material is reduced, the surface miscellaneous lithium amount is reduced, the polarization problem of the positive electrode material is improved, the direct current impedance of the lithium ion battery is reduced, the side reaction between the positive electrode material and anelectrolyte is effectively reduced, the gas production problem of the battery is inhibited, the volume energy density of the battery is improved, and the cycle performance and the rate capability areoptimized.

Owner:CONTEMPORARY AMPEREX TECH CO

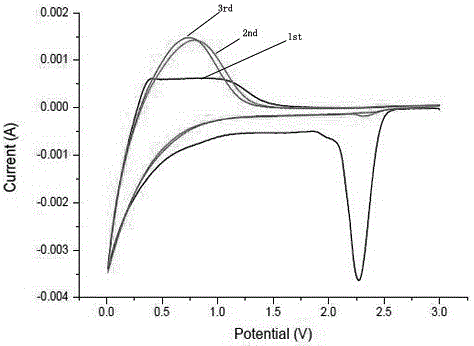

Lithium titanate battery and electrolyte for lithium titanate battery

ActiveCN102903956AInhibit gas productionAvoid flatulenceCell electrodesSecondary cellsLithiumOxalate

The invention discloses a lithium titanate battery and an electrolyte for the lithium titanate battery, and aims to provide the lithium titanate battery and the electrolyte for the lithium titanate battery which can prevent the swelling of a battery at a high temperature by inhibiting the aerogenesis of the lithium titanate battery. The lithium titanate battery comprises an anode material and the electrolyte; the anode material is lithium titanate; the electrolyte comprises a lithium salt, an organic solvent and additives; the additives comprise one or combinations of lithium bis(oxalate) borate (LiBOB), lithium difluoroborate (LiODFB) and 1,3-propane suhone (PS); and the using mass of the additives is equal to 1 to 5% of total mass of the lithium salt and the organic solvent. The lithium titanate battery can be widely applied to the field of lithium titanate batteries.

Owner:ZHUHAI SMOOTHWAY ELECTRONICS MATERIALS

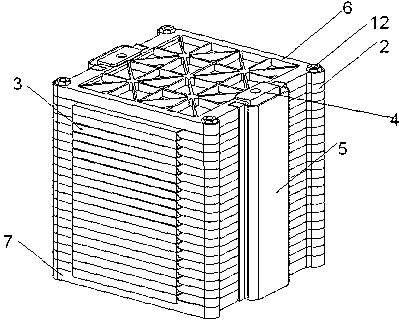

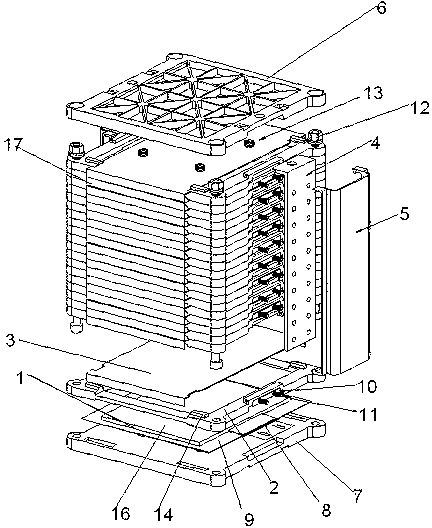

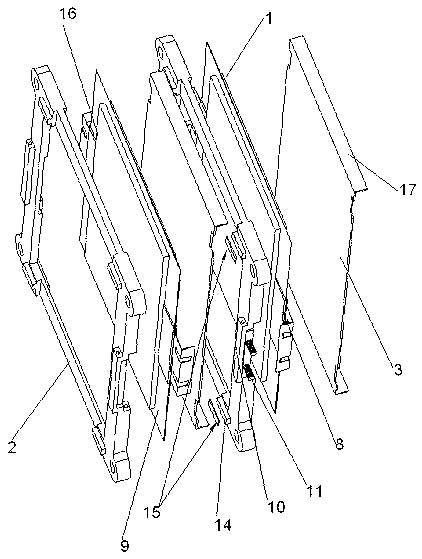

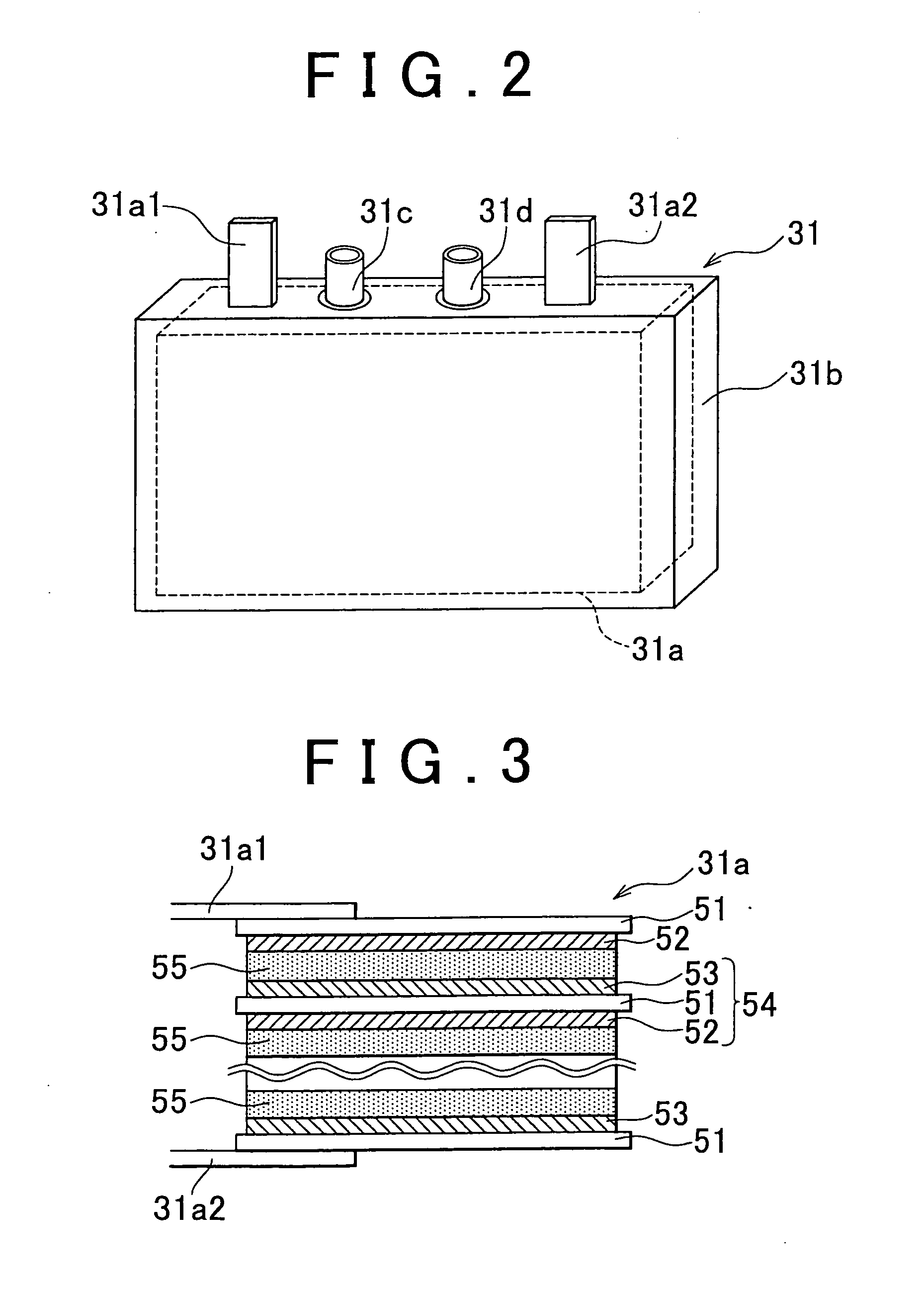

Lithium-ion flexible packaged battery pack structure

InactiveCN103346355AStructural advantagesEasy to replaceFinal product manufactureCell lids/coversElectrical batteryHeat sink

The invention discloses a lithium-ion flexible packaged battery pack structure which comprises individual lithium ion batteries, plastic clamping plates, heat radiating plates as well as current collection copper poles, current collection covers, an upper cover and a lower cover plate, wherein the current collection copper poles are arranged on the outer sides of two opposite side surfaces respectively; the current collection covers cover the current collection copper poles; the upper cover plate and the lower cover plate are arranged at the top end and the bottom end respectively, and a plurality of repetition units which are formed by the individual lithium ion batteries, the plastic clamping plates and the heat radiating plates are arranged between the upper cover plate and the lower cover plate; the side edges, corresponding to the current collection copper poles, of the individual lithium ion batteries are respectively provided with positive tabs and negative tabs, which are symmetric to each other; the plastic clamping plates and the individual lithium ion batteries are arranged at intervals sequentially, a galvanized copper block is arranged in each of two side surfaces of a frame of each plastic clamping plate, the inner sides of the galvanized copper blocks are connected with the tabs, the outer sides of the galvanized copper blocks are connected with the current collection copper poles through screws, and the heat radiating plates are respectively clamped between each individual lithium ion battery and each plastic clamping plate. The lithium-ion flexible packaged battery pack structure is high in energy density, strong in heat radiation capacity, high in safety, good in reliability and convenient to install and dismount.

Owner:SHANGHAI INST OF SPACE POWER SOURCES

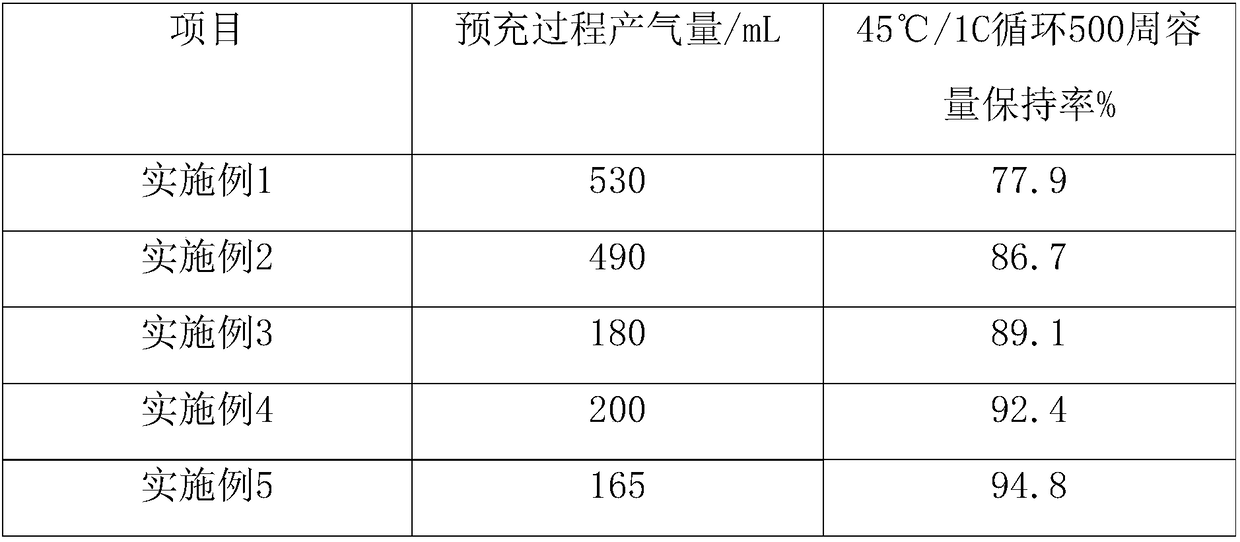

Electrolyte capable of inhibiting gas production of lithium-ion battery

InactiveCN108550912AInhibit gas productionImprove securitySecondary cellsOrganic electrolytesDifluorophosphatePhosphate

The invention provides an electrolyte capable of inhibiting gas production of a lithium-ion battery. The electrolyte comprises a lithium salt, an organic solvent and an additive, wherein the additiveis one or a composition of more of lithium difluoroborate, tetrafluoroethylene oxalic acid phosphate lithium, 1,3-propanesulfonate, ethylene sulfate, vinylethylene carbonate, propylene sulfite, vinylene carbonate, 1,4-butane sulfonate lactone, tris(trimethylsilyl) phosphate, fluoroethylene carbonate and lithium difluorophosphate. According to the electrolyte capable of inhibiting gas production ofthe lithium-ion battery, an excellent CEI / SEI film can be formed on the surface of an electrode of the lithium-ion battery, and gas production caused by direct contact of the electrode of the lithium-ion battery and an electrolyte solvent can be well prevented in the pre-charge process, so that gas production of the lithium-ion battery in the pre-charge process can be well inhibited.

Owner:TIANJIN ENERGIES

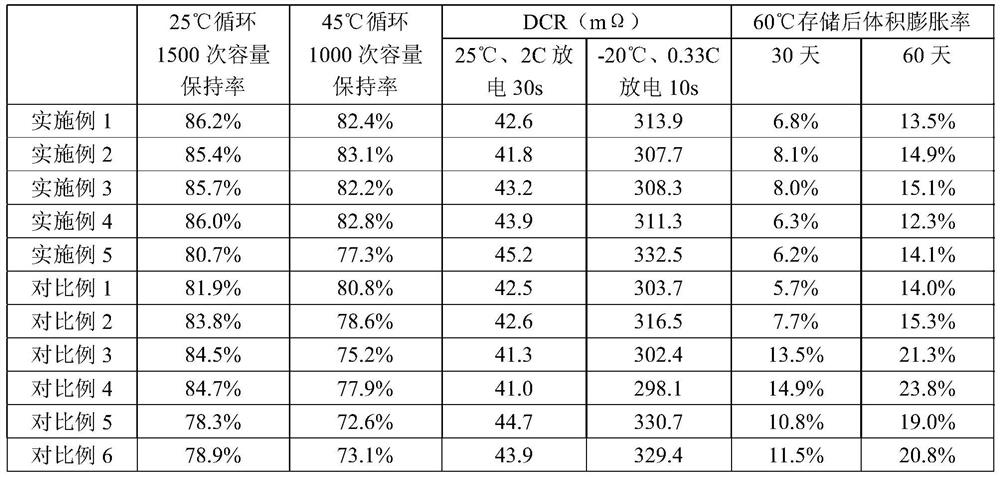

Non-aqueous electrolyte and lithium ion battery

ActiveCN110911753ALower impedanceImprove power performanceSecondary cellsOrganic electrolytesHigh temperature storageElectrolytic agent

The invention provides a non-aqueous electrolyte and a lithium ion battery. The non-aqueous electrolyte comprises a solvent, an electrolyte lithium salt and a functional additive, and the functional additive comprises pentafluorophenyl vinyl sulfonate, 3-trifluoromethyl-5-methoxybenzonitrile and lithium difluorophosphate. When the electrolyte disclosed by the invention is applied to the lithium ion battery of a nickel-cobalt-manganese ternary material / graphite system, the high-voltage resistance of the lithium ion battery is improved, and the rate capability, the normal-temperature cycle, thehigh-temperature cycle and the high-temperature storage performance of the lithium ion battery are remarkably improved.

Owner:DONGGUAN DONGYANG SOLAR SCI RES & DEV CO LTD

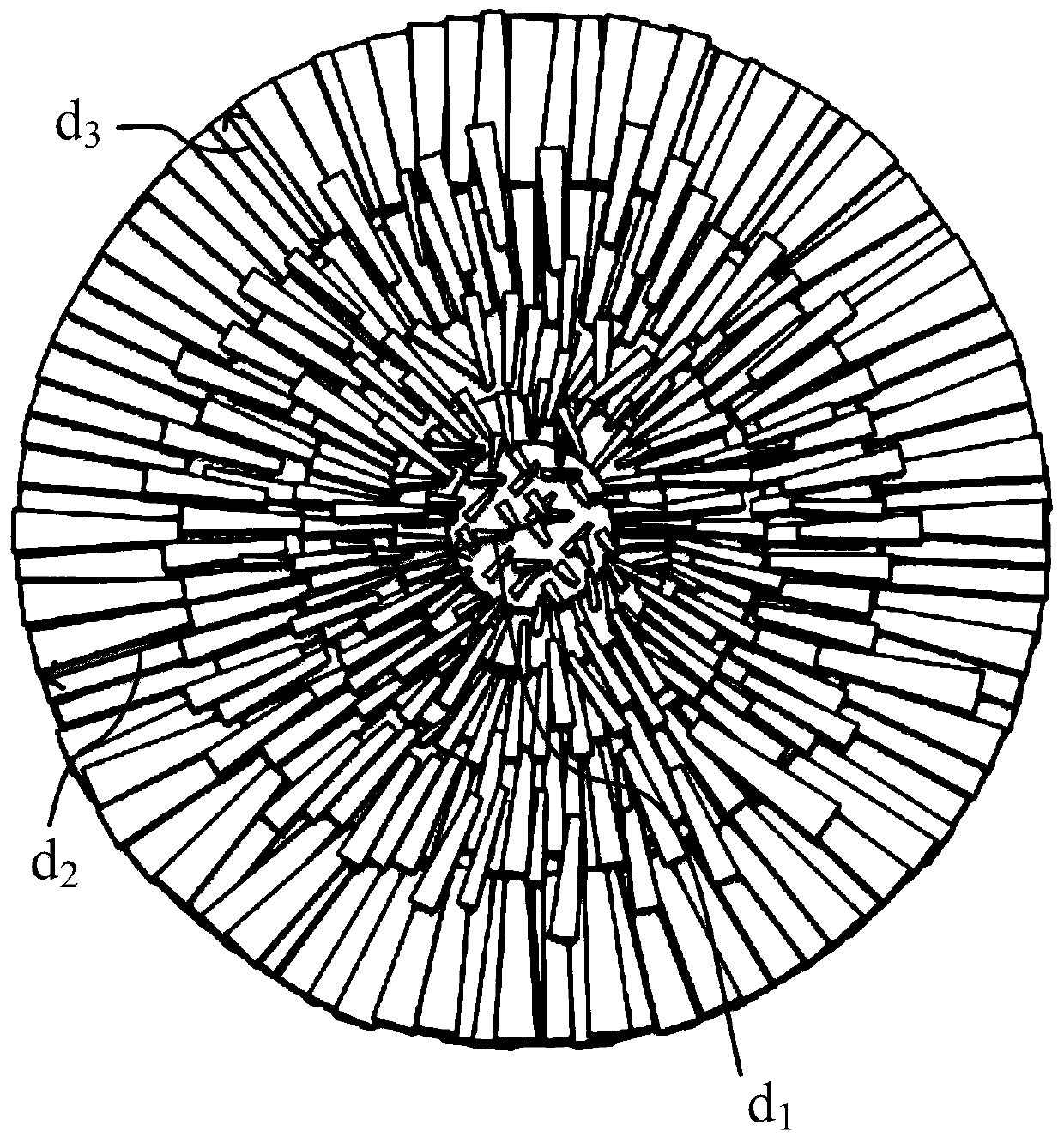

Positive electrode active material precursor and preparation method thereof, and positive electrode active material

InactiveCN111370679AHigh densityImprove cycle performanceCell electrodesSecondary cellsChemical engineeringBattery cell

The invention discloses a positive electrode active material precursor and a preparation method thereof, and a positive electrode active material. The positive electrode active material precursor comprises secondary particles formed by aggregation of a plurality of primary particles, each secondary particle comprises an internal area and an external area coating the external side of the internal area, the density of the internal area is smaller than that of the external area, and the density of the external area is gradually increased from inside to outside. According to the positive electrodeactive material precursor of the invention, the positive electrode active material adopting the positive electrode active material precursor has high initial charge specific capacity, initial discharge specific capacity, initial coulombic efficiency and cycle performance, so that the lithium ion secondary battery can have high initial charge specific capacity, initial discharge specific capacity,initial coulombic efficiency and cycle performance at the same time.

Owner:CONTEMPORARY AMPEREX TECH CO

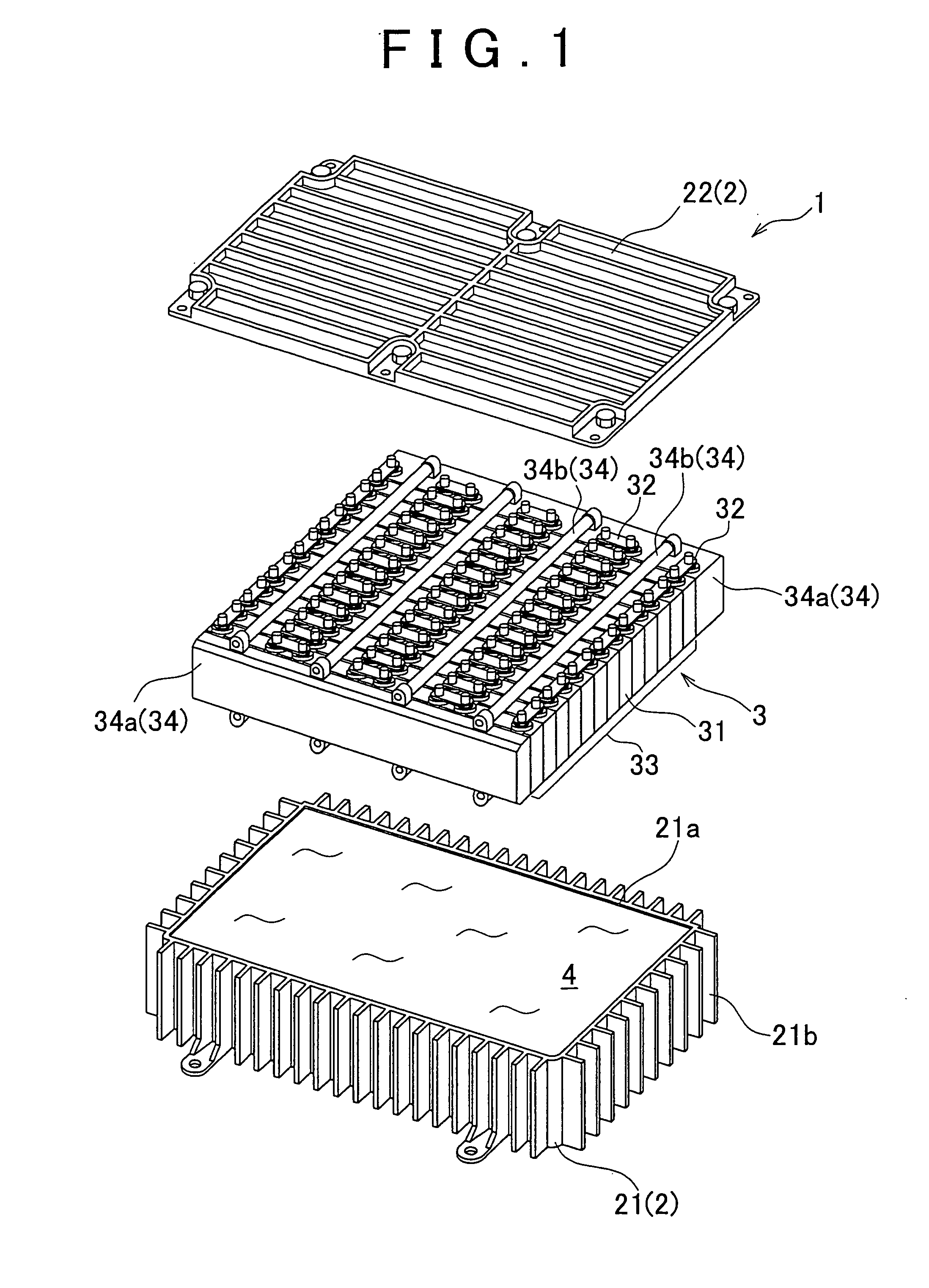

Power storage unit and vehicle

InactiveUS20090004553A1Inhibit gas productionIncrease in power resistanceSecondary cellsCell lids/coversClosed stateElectrical and Electronics engineering

A power storage unit has: a plurality of power storage modules each constituted of a power generation element which in a power generation element case containing the power generation element; and a power storage unit case containing the power storage modules and an insulative liquid, wherein at least two of the power storage modules have a first valve that switches from a closed state to an open state in response to the pressure in the power generation element case increasing up to a first threshold and a second valve that switches from a closed state to an open state in response to the pressure at the outside of the power generation element case increasing up to a second threshold.

Owner:TOYOTA JIDOSHA KK

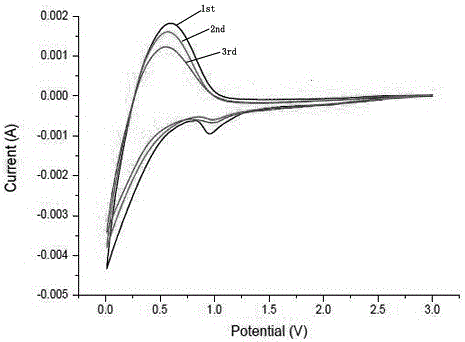

Lithium titanate battery non-water electrolyte and lithium titanate battery

The invention discloses a lithium titanate battery non-water electrolyte and a lithium titanate battery, and aims to provide the lithium titanate battery non-water electrolyte and the lithium titanate battery which can restrain the lithium titanate battery from generating gas to prevent the battery from gas expansion at a high temperature. The lithium titanate battery comprises a cathode material, an anode material and an electrolyte, wherein the anode material is lithium titanate; the electrolyte comprises lithium, an organic solvent and an additive; the additive is selected from at least one of difluoro bis(oxalato) lithium phosphate, tetra-fluoro (oxalato) lithium phosphate, tris-oxalate lithium phosphate, 1,8-naphthalene sulfonic acid lactone, and 1,3-propene sulfonic acid lactone; the use mass of the additive is equivalent to 1-5% of the total mass of the lithium and the organic solvent. The lithium titanate battery non-water electrolyte and the lithium titanate battery can be widely applied to the lithium titanate battery field.

Owner:ZHUHAI SMOOTHWAY ELECTRONICS MATERIALS

Method for preparing lithium titanate material

The invention provides a method for preparing a lithium titanate material. A certain quantity of lithium-containing compound, titanium-containing compound and additive are weighed, and a certain amount of deionized water and dispersion agent are added for primary dispersion; moisture is removed after drying to obtain solid 1; then the obtained solid 1 is roasted in air to obtain a primary battery material; a certain quantity of carbon-containing wrapping material and additive are weighed and dispersed in water, the primary battery material is added for secondary sufficient mixing, moisture is moved after drying, and solid 2 is obtained, finally the obtained solid 2 is roasted in the inert or reduction atmosphere, and the graphene-wrapped battery material containing a certain amount of additive is obtained. Due to two times of dispersion and roasting, it is guaranteed that the carbon-containing wrapping layer covers the surface of lithium titanate in a sufficiently uniform and compact mode and is not prone to being damaged or falling off, and accordingly the defect of insufficient wrapping is overcome. Due to use of the additive, conductivity of a lithium titanate body is improved, rate capability of the lithium titanate material is improved, conductivity is high, and gas generation is prevented.

Owner:天津普兰能源科技有限公司

Antistaling agent prescription for preserved dried turnip and process thereof

InactiveCN1729850AGrowth inhibitionInhibit gas productionFood preservationFood preparationFumaric acidEthanol

The invention relates to an antistaling agent prescription for preserved dried turnip and process, which comprises ozonization, regulating pH, integrating the complementary actions of bacterium inhibiting spectrum of different preservatives, controlling microbiological putridness and gas production in the vacuum-packing. The formulation of the antistaling agent comprises sodium dehydroacetate, methyl-p-hydroxybenzoate mixed ester, fumaric acid, citric acid, edible ethanol and Cinnamomum cassia extract.

Owner:ZHEJIANG GONGSHANG UNIVERSITY

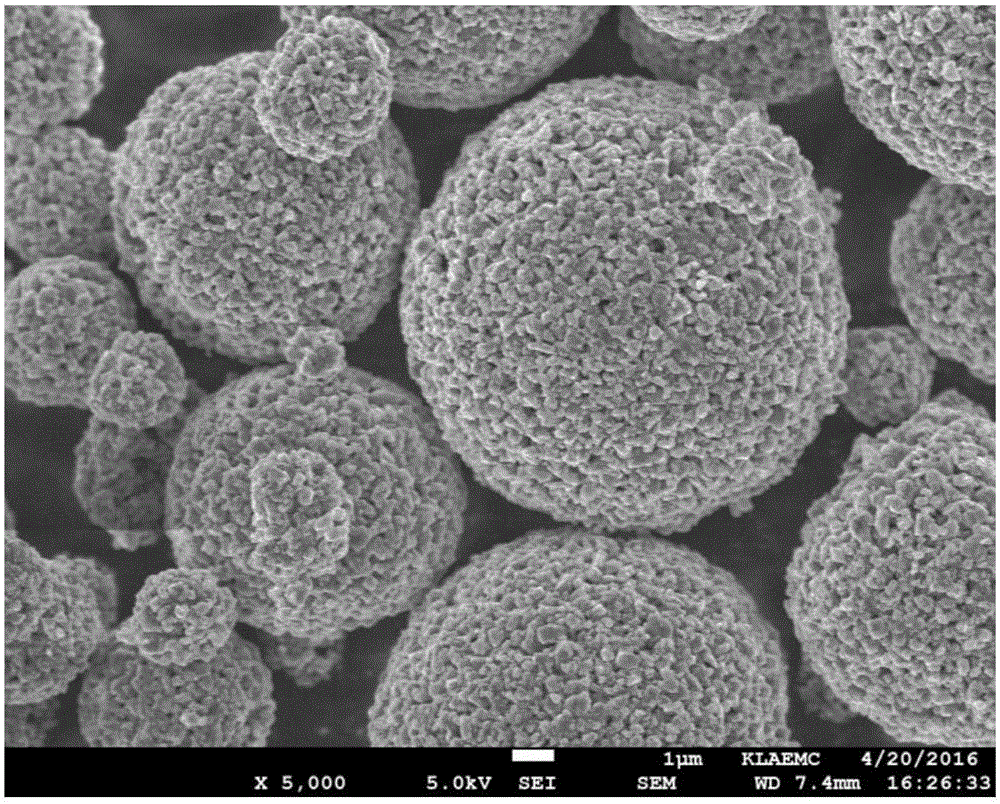

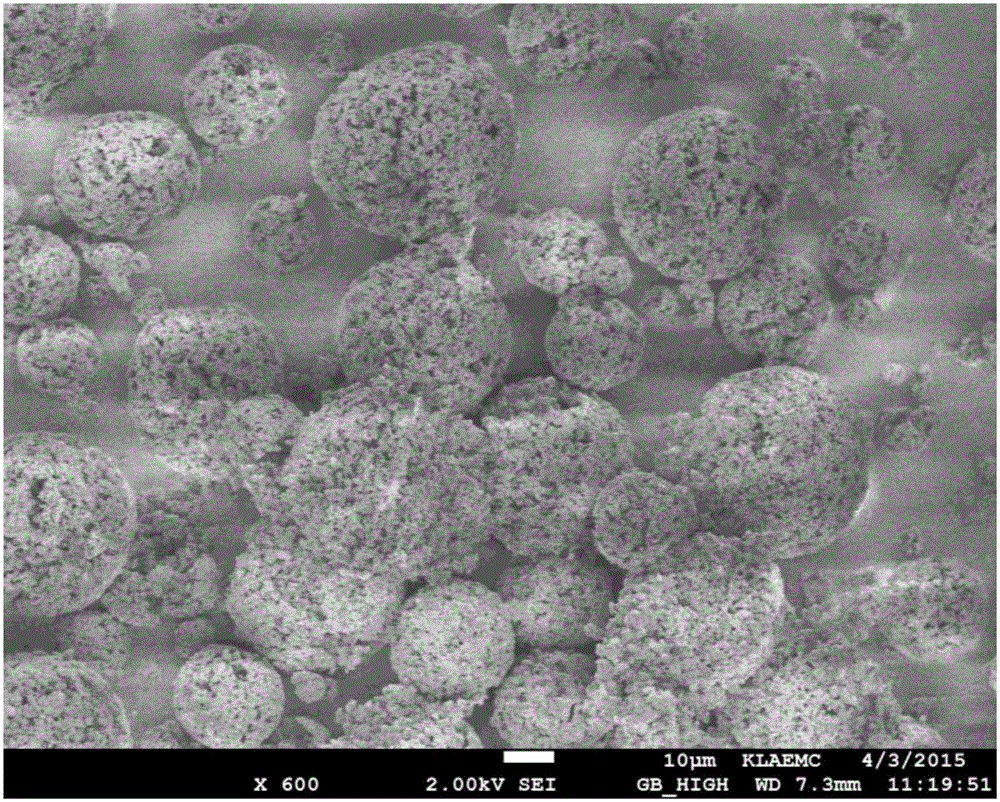

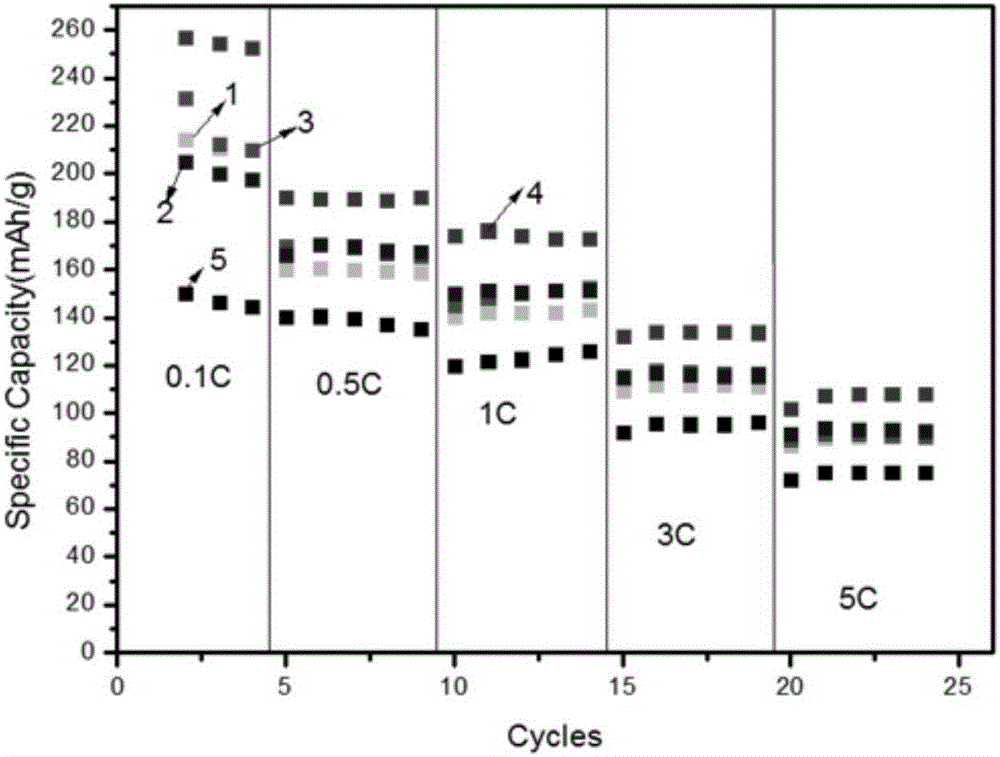

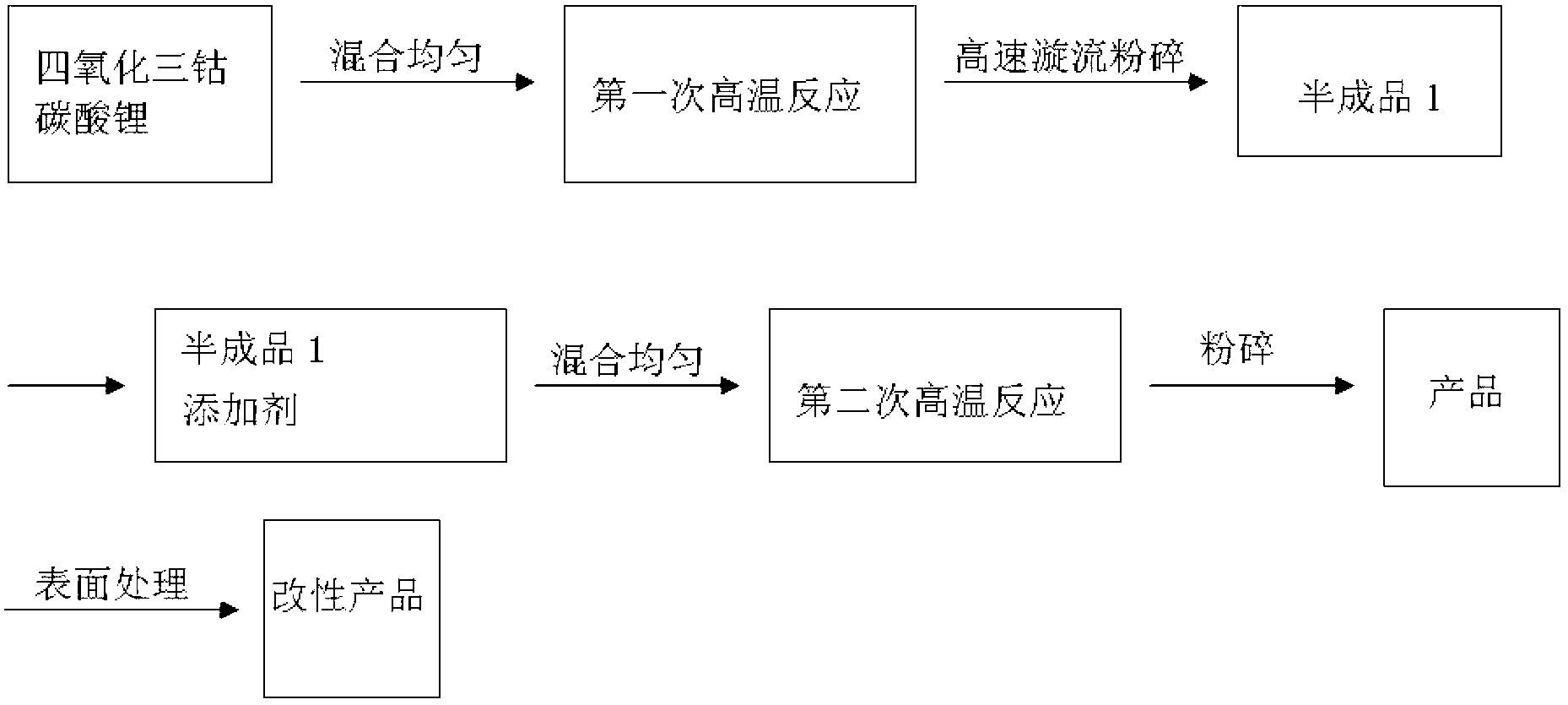

Method for improving storage performance of lithium cobalt oxide at high voltage and high temperature

InactiveCN103236541AReduce expansionGood effectCell electrodesHigh temperature storageReaction temperature

The invention relates to the field of lithium ion battery material, especially relates to a method for improving storage performance of lithium cobalt oxide at high voltage and high temperature. The traditional two stage method is employed by the invention, and comprises the following steps: adding special additives and controlling high temperature reaction temperature, obtaining lithium cobalt oxide products of particle size which accords with the requirement, doping additives into the lithium cobalt oxide structure, thereby guaranteeing the structure stability of lithium cobalt oxide during excess lithium removing under high voltage. The key step is that the synthesized finished product lithium cobalt oxide which accords with the requirement is used as raw material, a very simple surface treatment is used without high temperature treatment once more, thereby greatly improving high temperature storage performance under high voltage.

Owner:北京盟固利新材料科技有限公司

Lithium titanate battery and electrolyte thereof

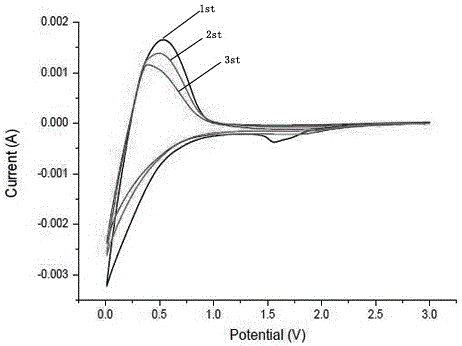

InactiveCN106328998AInhibit gas productionReduce exposureCell electrodesSecondary cellsHigh temperature storageOrganic solvent

The invention relates to the technical field of lithium ion batteries, in particular to a lithium titanate battery and electrolyte thereof. The electrolyte comprises lithium salt, non-aqueous organic solvent and additives, wherein the additives include cathode membrane-forming additive A, an anode protective additive B and a reactive hydrogen combining additive C, and the reduction potential, relative to metal lithium, of the additive A is not smaller than 1.4V. Compared with the prior art, the lithium titanate battery and the electrolyte thereof have the advantages that gas generation of the lithium titanate battery during high-temperature storage and high-temeprature circulation is inhibited by the synergic effects of the additive A, the additive B and the additive C, the rising of battery internal resistance is inhibited at the same time, and the high-temperature storage performance and high-temperature circulation performance of the lithium titanate battery are increased effectively.

Owner:DONGGUAN SHANSHAN BATTERY MATERIALS

Hybrid inflator

InactiveUS20050017490A1Improve flammabilitySecure safety of workPedestrian/occupant safety arrangementGas generation devicesInternal pressureCombustion chamber

To provide a hybrid inflator in which the combustibility of a second gas generating agent is improved. Some of the openings 121a out of second openings 121 are shielded with tape 132, and the opening area A2nd−1 of the remaining openings and the opening area Aex of an opening portion 131 of a recessed portion of a partition member for controlling an outflow pressure of gas satisfy the relationship Aex>A2nd−1, whereby the pressure inside a second combustion chamber 120 readily rises upon burning the second gas generating agent 119. The combustibility of the second gas generating agent 119 is thus favorable even when a pressurized medium has been discharged and hence the internal pressure has become equal to atmospheric pressure.

Owner:DAICEL CHEM IND LTD

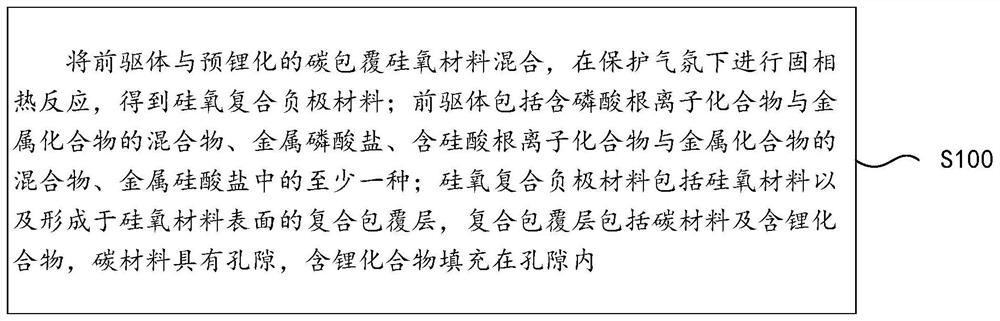

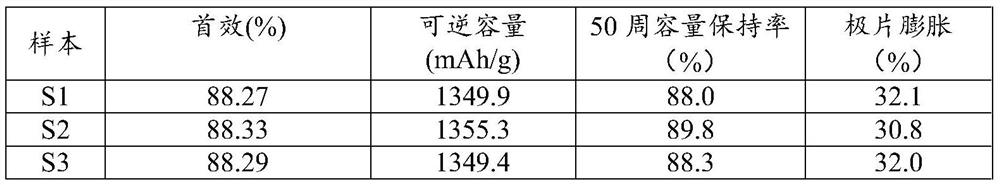

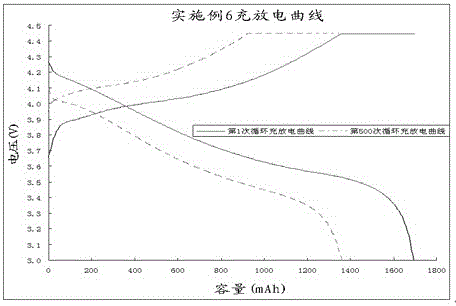

Silicon-oxygen composite negative electrode material, preparation method thereof and lithium ion battery

ActiveCN113066968AImprove stabilityLower pHNegative electrodesLi-accumulatorsSilicon oxygenLithium compound

The invention relates to a silicon-oxygen composite negative electrode material, a preparation method thereof and a lithium ion battery, the silicon-oxygen composite negative electrode material comprises a silicon-oxygen material and a composite coating layer coating the surface of the silicon-oxygen material, the composite coating layer comprises a carbon material and a lithium-containing compound, the carbon material has pores, and the pores are filled with the lithium-containing compound. The silicon-oxygen composite negative electrode material and the preparation method thereof are simple and low in cost, industrial production is easy to realize, the prepared silicon-oxygen composite negative electrode material has excellent electrochemical cycle and expansion inhibition performance, and the service life of a lithium ion battery can be prolonged.

Owner:BTR NEW MATERIAL GRP CO LTD +1

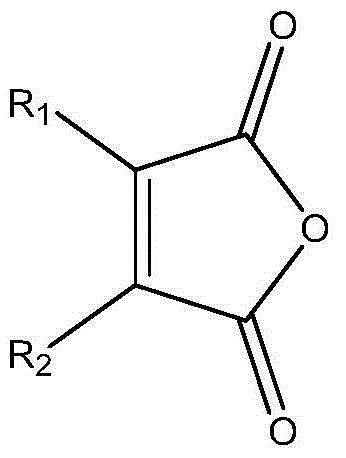

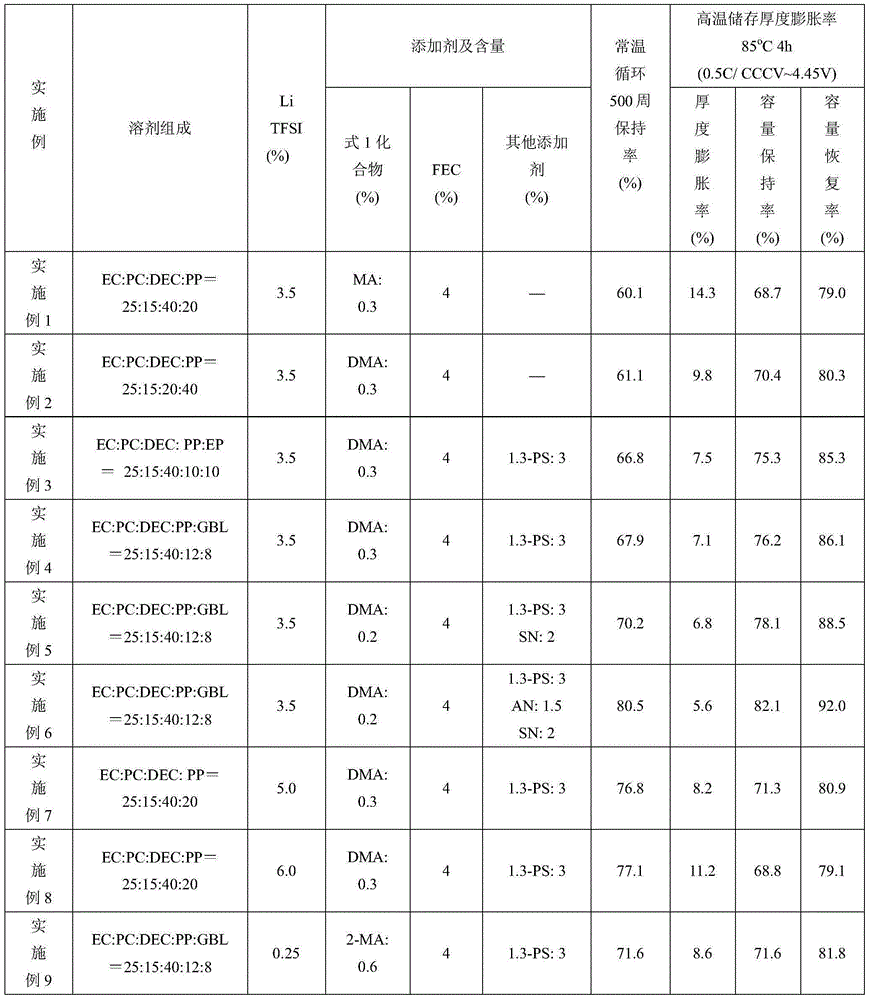

Nonaqueous electrolyte solution for high-voltage lithium ion secondary battery and high-voltage lithium secondary battery

InactiveCN105119017APromote circulationHigh decomposition voltageSecondary cellsOrganic electrolytesOrganic solventHydrogen

The invention discloses a nonaqueous electrolyte solution for a high-voltage lithium ion secondary battery. The nonaqueous electrolyte solution comprises nonaqueous organic solvent, lithium salt and additives, wherein the lithium salt and the additives are dissolved in the nonaqueous organic solvent. The nonaqueous organic solvent is a carboxylic acid ester compound with the mass percentage content being 1%-40% in the nonaqueous electrolyte solution. The additives comprise fluoroethylene carbonate (FEC), Li TFSI and at least one of compounds with the structures shown in the formula I (please see the specification for the formula), wherein R1 and R2 in the formula represent hydrogen or an alkyl group composed of 1-5 carbon atoms. The electrolyte solution for the high-voltage lithium ion secondary battery has the advantage that the high-voltage lithium ion secondary battery can achieve good cycle performance and high-temperature performance.

Owner:DONGUAN KAIXIN BATTERY MATERIAL

Non-aqueous electrolyte and lithium ion battery

ActiveCN111082139AIncrease HOMO levelImprove conductivitySecondary cells servicing/maintenanceHigh temperature storageElectrolytic agent

The invention provides a non-aqueous electrolyte and a lithium ion battery. The non-aqueous electrolyte comprises a solvent, an electrolyte lithium salt and a functional additive, wherein the functional additive comprises 4,4'-dipinacol borate diphenyl sulfone, dipyridyl carbonate and lithium difluorophosphate. When the electrolyte provided by the invention is applied to a lithium ion battery of ahigh-nickel ternary material / graphite system, the impedance of the lithium ion battery can be remarkably reduced, the power performance of the lithium ion battery can be improved, gas production of the lithium ion battery in circulation and storage processes can be remarkably inhibited, and the rate capability, the normal-temperature cycle performance, the high-temperature cycle performance, thehigh-temperature storage performance and the safety performance of the lithium ion battery are remarkably improved.

Owner:DONGGUAN DONGYANG SOLAR SCI RES & DEV CO LTD

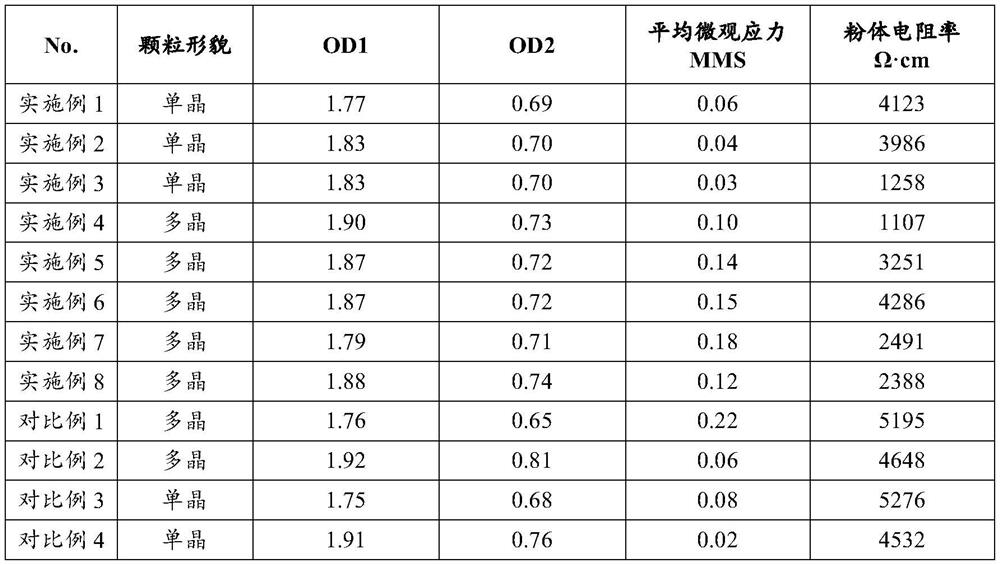

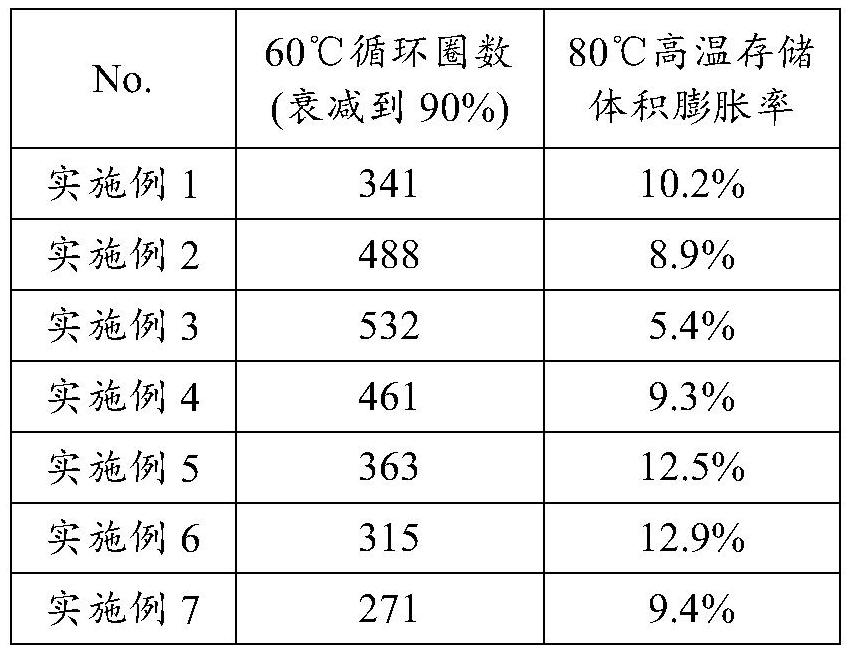

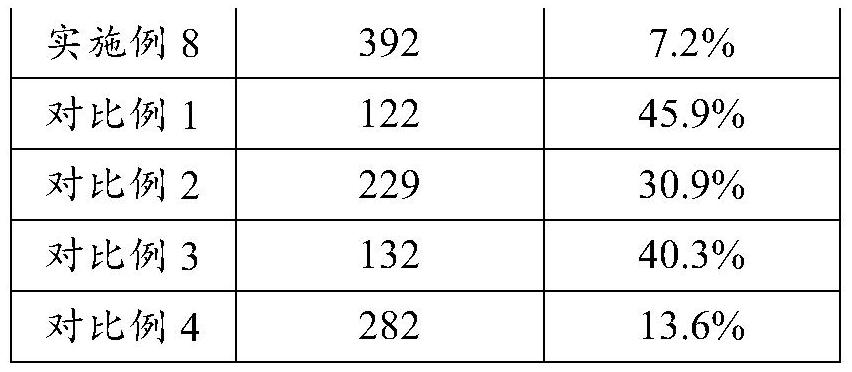

Cathode material and preparation method and application thereof

ActiveCN112151789AStrong crystal structure stabilityLow Li/Ni mixing degreeElectrode carriers/collectorsSecondary cellsPhysicsComposite material

The invention relates to the field of electrochemistry, particularly relates to a long-life positive electrode material as well as a preparation method and application thereof. The invention providesa long-life positive electrode material which comprises a matrix, the general formula of the matrix is LixNiyCozMkMepOrAm, 0.95 < / = x < / = 1.05, 0.5 < / = y < / = 1, 0 < / = z < / = 1, 0 < / = k < / = 1, 0 < / = p < / = 0.1, 1 < / = r < / = 52, 0 < / = m < / = 2 and m+r < / = 2; the oxygen defect degree of the positive electrode material satisfies at least one of condition (1) or condition (2), (1) 1.77 < / = OD1 < / = 1.90; and (2) OD2 is more than or equal to 0.69 and less than or equal to 0.74. According to the method, the positive electrode material has relatively strong crystal structure stability and relatively low Li / Ni mixed arrangement degree, the battery using the positive electrode material has relatively high energy density and long cycle life, and meanwhile, a gas production problem in the cycle process iseffectively inhibited.

Owner:CONTEMPORARY AMPEREX TECH CO

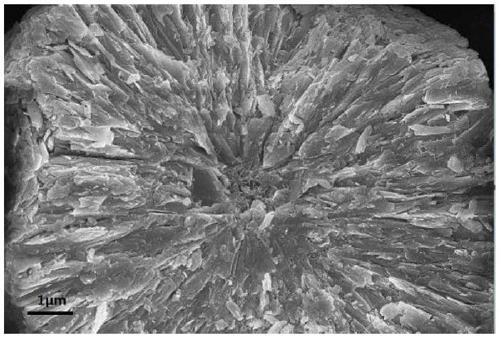

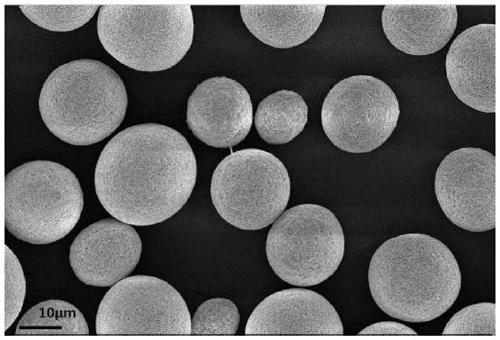

Pressure-resistant positive electrode active material and electrochemical energy storage device

ActiveCN111384371AModerate cracking problemEasy to crackCell electrodesSecondary cellsElectrical batteryElectrochemistry

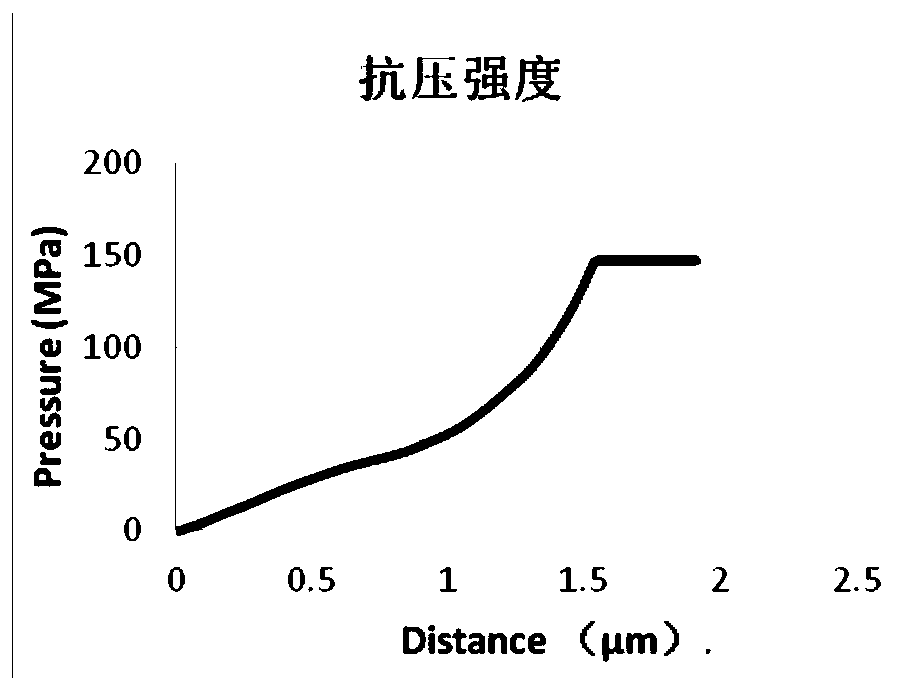

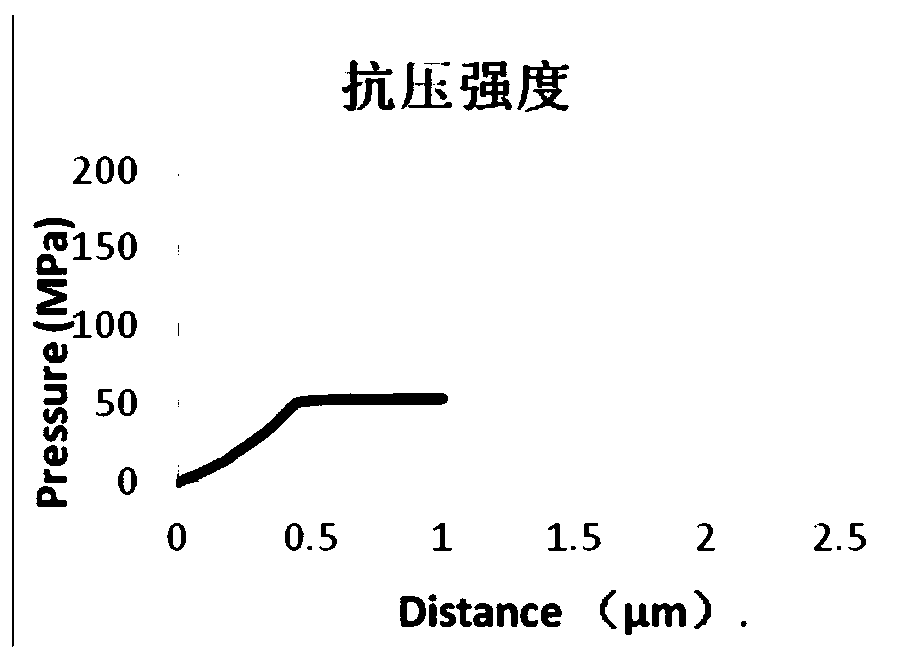

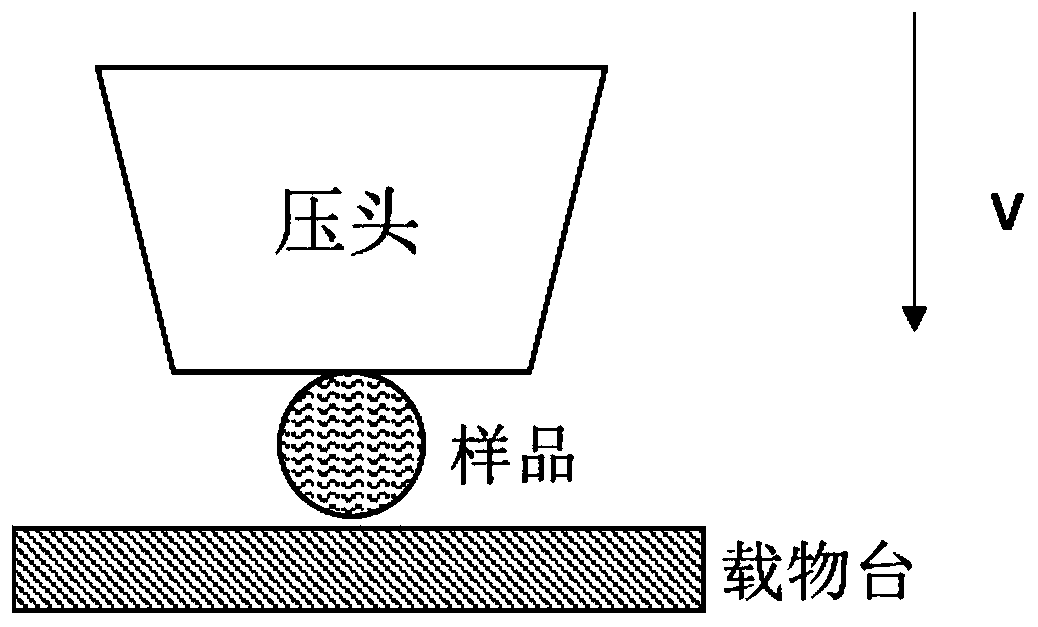

The invention relates to the technical field of batteries, in particular to a pressure-resistant positive electrode active material and an electrochemical energy storage device. The positive electrodeactive material comprises secondary particles consisting of primary particles; the number [sigma] of the primary particles in a unit spherical area in an SEM map of the secondary particles is 5-30 / [mu]m2; the single-particle compressive strength of the secondary particles is 60 MPa to 300 MPa; the molecular formula of the positive electrode active material is LixNiyCozMkMepOrAm, wherein 0.95 < =x < = 1.05; 0 < = y < = 1, 0 < = z < = 1, 0 < = k < = 1, 0 < = p < = 0.1, 1 < = r < = 2, 0 < = m < = 2 and m + r < = 2; the M is selected from Mn and / or Al, the Me is selected from one or a combination of Zr, Zn, Cu, Cr, Mg, Fe, V, Ti, Sr, Sb, Y, W and Nb, and the A is selected from N, F, S and Cl. The particle structure of the positive electrode active material is compact, the positive electrodeactive material has relatively high single-particle compressive strength, and the lithium ion battery using the positive electrode active material has good cycle performance, relatively low volume expansion rate and good dynamic performance.

Owner:CONTEMPORARY AMPEREX TECH CO

Nitrile electrolyte for lithium metal battery and lithium metal battery using the same

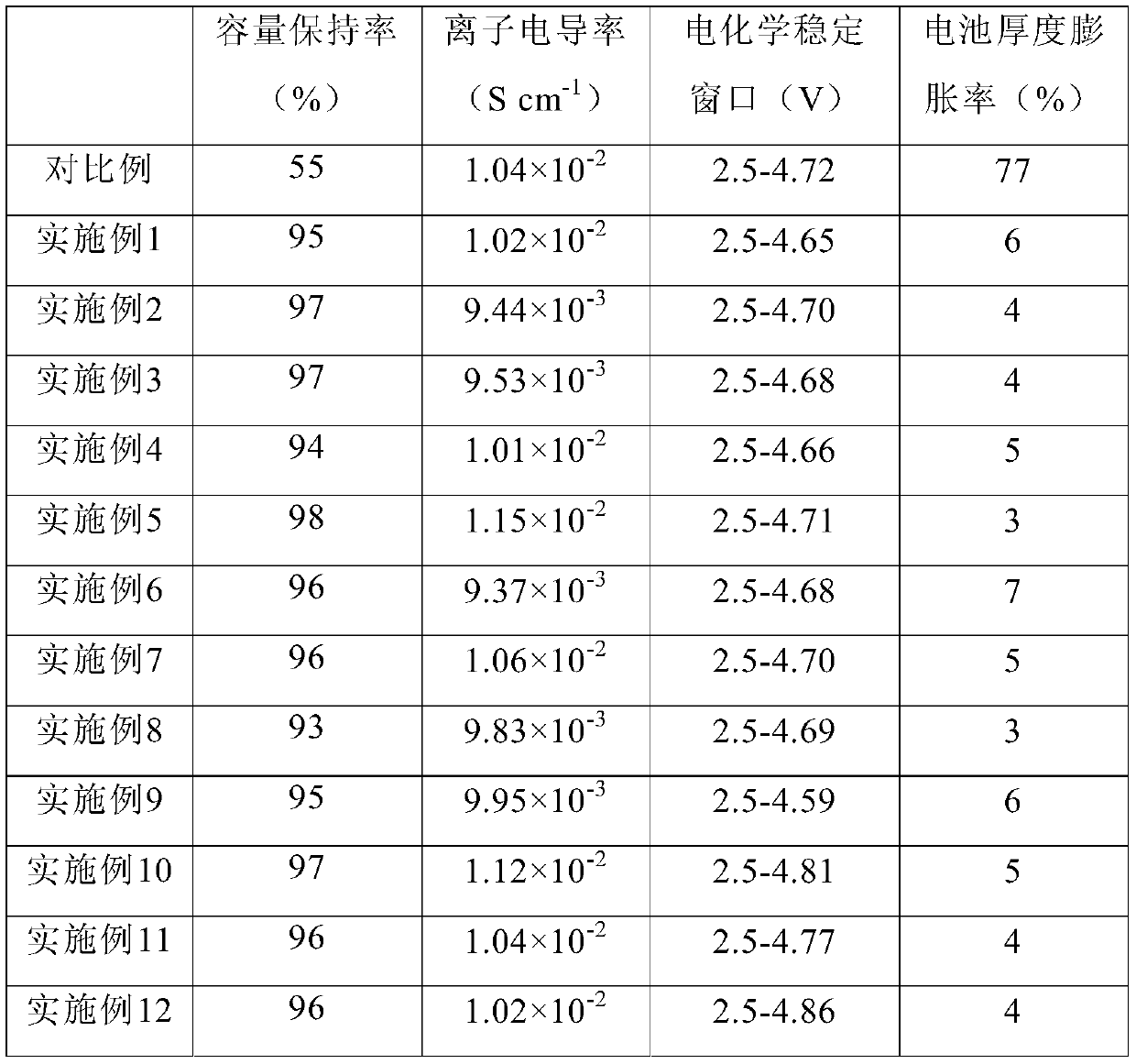

InactiveCN109786808ASimple preparation processEasy to operateSecondary cellsLithium metalRoom temperature

The invention discloses a nitrile electrolyte for a lithium metal battery and a lithium metal battery using the same, and the nitrile electrolyte is composed of at least two lithium salts and at leastone solid or liquid reagent containing cyano functional groups. For the nitrile electrolyte for the lithium metal battery provided by the invention, the ionic conductivity at the room temperature canreach a level equivalent to that of a traditional carbonic ester electrolyte and can reach 10<-2>S cm<-2>. The battery assembled by using the electrolyte with a lithium metal negative electrode as the soft package still has a capacity retention rate of about 95% after 30 turns of large-surface capacity (4mA h cm<-2>) circulation, compared with the capacity retention rate (55%) of the soft packageassembled by the traditional carbonic ester electrolyte, the capacity retention rate is much larger. Moreover, the half-cell of lithium cobalt oxide / lithium is cycled at a multiplying power of 1C under a high voltage of 3-4.7 V, and the capacity retention rate of 74% after 500 cycles can be still achieved. The nitrile electrolyte for the lithium metal battery can effectively inhibit expansion ofthe soft package battery.

Owner:QINGDAO INST OF BIOENERGY & BIOPROCESS TECH CHINESE ACADEMY OF SCI

Electrolyte, preparation method thereof and lithium ion battery

ActiveCN112670577ASolve cycle performanceAddress high temperature performanceSecondary cells servicing/maintenanceElectrolytic agentCarbonate ester

The invention provides an electrolyte, a preparation method thereof and a lithium ion battery. The electrolyte comprises an additive, and the additive comprises an unsaturated carbonate additive, a lithium salt additive, an additive A and an additive B; and the additive B comprises an isocyanuric acid derivative. The preparation method comprises the following steps: in a protective atmosphere, mixing a formula amount of additives with other raw materials to obtain the electrolyte, wherein the additives comprise an unsaturated carbonate additive, a lithium salt additive, an additive A and an additive B. The electrolyte provided by the invention solves the problem that the cycle performance, the high-temperature performance, the normal-temperature power performance and the low-temperature power performance of the battery electrolyte are difficult to consider at the same time.

Owner:EVE ENERGY CO LTD

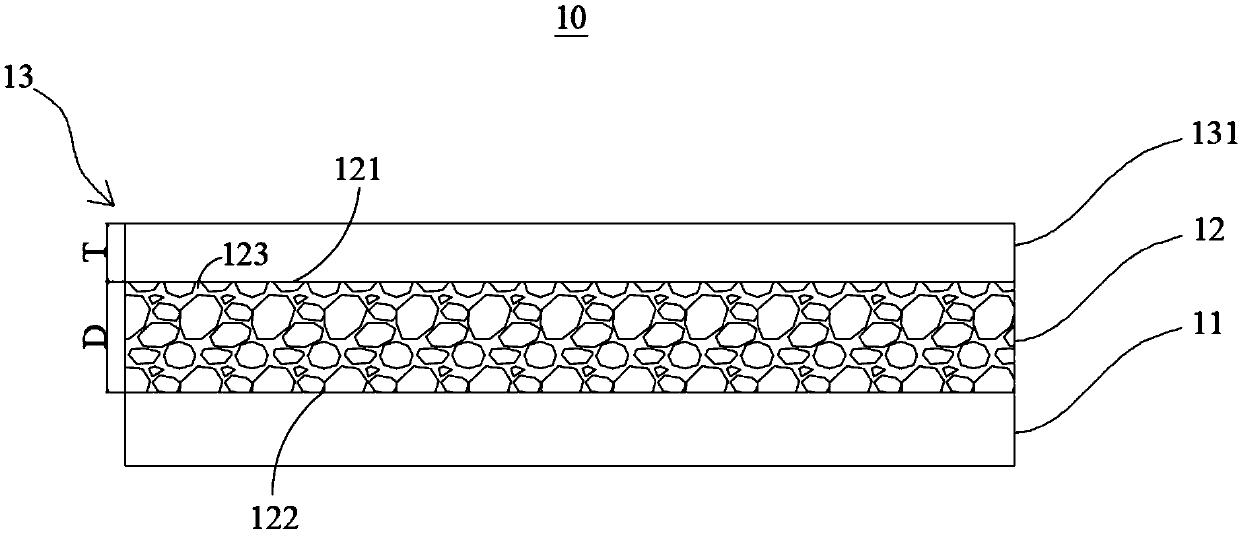

Negative pole piece, preparation method thereof and electrochemical device

ActiveCN110660955ALess side effectsPrevent precipitationVacuum evaporation coatingNegative electrodesElectrolytic agentPhysical chemistry

The invention discloses a negative pole piece, a preparation method thereof and an electrochemical device. The negative pole piece comprises a negative pole current collector, a negative pole active material layer and an inorganic dielectric layer which are stacked; the negative pole active material layer comprises a first surface and a second surface which are opposite to each other, wherein thefirst surface is far away from the negative pole current collector; the inorganic dielectric layer is arranged on the first surface of the negative pole active material layer; the inorganic dielectriclayer is composed of an inorganic dielectric material; the inorganic dielectric layer comprises a first dielectric layer located on the outer surface of the negative pole active material layer; the thickness of the first dielectric layer is 30-1000 nm; the compaction density of the negative pole piece is 1.2 g / cm <3>-2.0 g / cm<3>; the porosity of the negative pole piece is 25%-45%; and the electrolyte infiltration rate of every 10cm*10cm area of the negative pole piece is greater than or equal to 2 microgram / s. The negative pole piece provided by the invention is used for an electrochemical device, so that the electrochemical device has excellent safety performance and high cycle performance at the same time.

Owner:CONTEMPORARY AMPEREX TECH CO

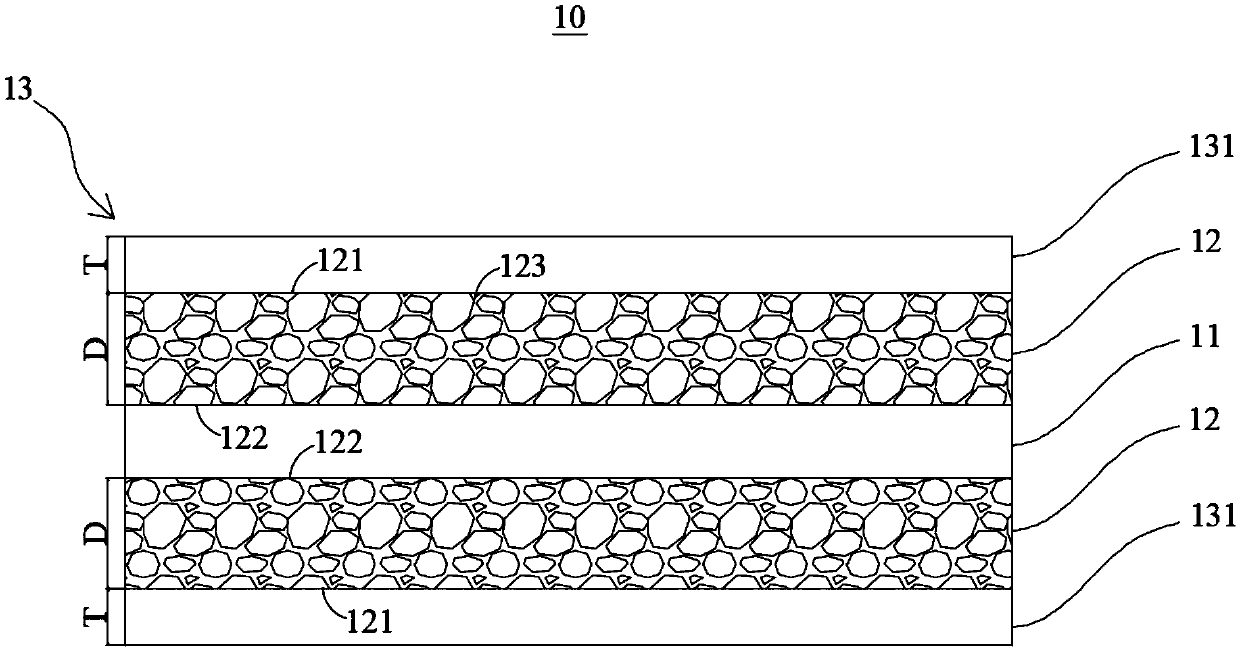

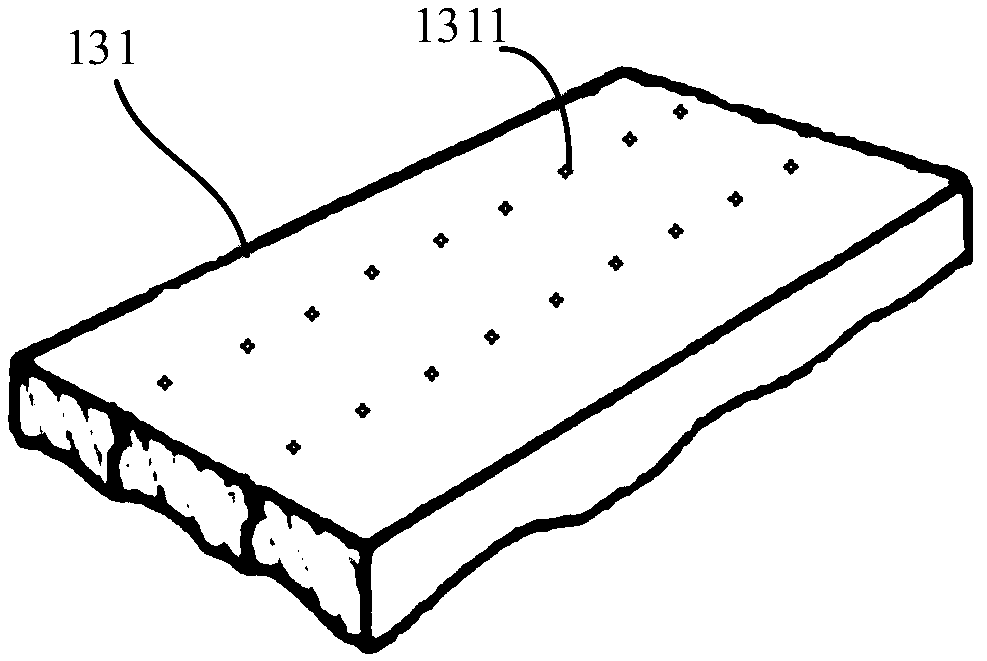

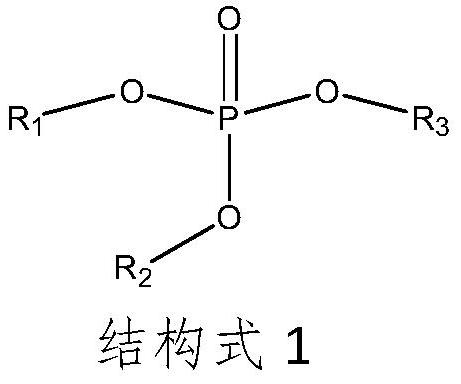

Lithium ion battery

PendingCN114695943ALower impedanceInhibit gas productionSecondary cells servicing/maintenanceCell electrodesElectrolytic agentPhysical chemistry

In order to solve the problems that an existing lithium ion battery with a high-compaction and high-specific-surface-area negative electrode is serious in electrolyte side reaction and high in gas production rate, the invention provides a lithium ion battery which comprises a positive electrode, a negative electrode and a non-aqueous electrolyte, the negative electrode comprises a negative electrode material layer, the compaction density of the negative electrode material layer is larger than or equal to 1.4 g / cm < 3 >, and the non-aqueous electrolyte is a non-aqueous electrolyte. The negative electrode material layer comprises a negative electrode active material, the non-aqueous electrolyte comprises a solvent, electrolyte salt, vinylene carbonate, fluoroethylene carbonate and unsaturated phosphate as shown in a structural formula 1, and the electrolyte salt comprises LiPF6 and LiFSI. The lithium ion battery provided by the invention has relatively good cycle performance, high and low temperature storage performance and lithium precipitation resistance.

Owner:SHENZHEN CAPCHEM TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com