High-nickel single-crystal ternary cathode material with low surface residual alkali content and preparation method thereof

A positive electrode material, low surface technology, applied in the field of high-nickel single crystal ternary positive electrode material and its preparation, can solve the problem of high residual alkali on the surface, achieve the effect of improving compaction density, simple process and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

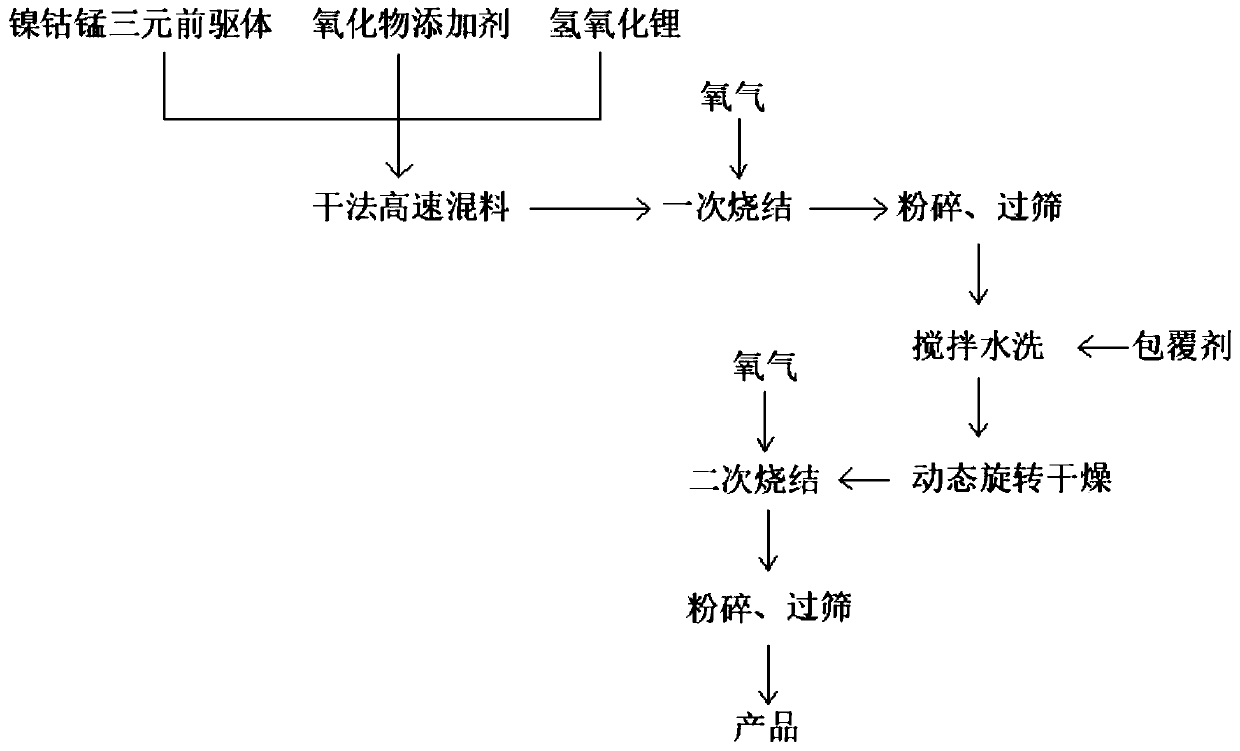

Method used

Image

Examples

Embodiment 1

[0043] First, lithium hydroxide powder, nano-sized zirconia (ZrO), D50 precursor material Ni 0.85 co 0.1 mn 0.05 (OH) 2 Put it in a ball mill tank, and perform high-speed ball milling to mix evenly; wherein, the molar ratio of lithium element to metal element in the precursor is 1.06, and the mass fraction of zirconium element added to the total material is 5000ppmw. Under the condition that the volume concentration of the oxygen atmosphere is 50-99%, the sintering is carried out once, the temperature is 830° C., and the temperature is kept for 16 hours. After cooling to room temperature, crushing with a jaw crusher, crushing with a roller crusher, and sieving to obtain a primary sintered material a for later use, the primary sintered material a is a single crystal matrix material LiNi 0.85 co 0.1 mn 0.05 o 2 .

[0044] The above-mentioned primary sintered material a was subjected to water-washed and non-water-washed comparison experiments; the primary sintered material...

Embodiment 2

[0049] First, lithium hydroxide powder, nano-titanium oxide, and D50 precursor material Ni 0.83 co 0.12 mn 0.05 (OH) 2 Put it in a ball mill tank, and carry out high-speed ball milling to mix evenly; wherein, the molar ratio of lithium element to metal element in the precursor is 1.04, and the mass fraction of titanium element added in the total material is 5000ppmw. Under the condition that the volume concentration of the oxygen atmosphere is 50-99%, the sintering is carried out once, the temperature is 840° C., and the temperature is kept for 16 hours. Cooling, jaw crushing, roller crushing, crushing, and sieving; after cooling to room temperature, crushing with a jaw crusher, crushing with a roller crusher, and sieving to obtain a primary sintered material b for subsequent use, and the primary sintered material b is a single crystal LiNi 0.83 co 0.12 mn 0.05 o 2 .

[0050] The above-mentioned primary sintered material b was washed and unwashed for comparative experi...

Embodiment 3

[0055] First, lithium hydroxide powder, nano-barium oxide, and D50 precursor material Ni 0.80 co 0.10 mn 0.10 (OH) 2 , placed in a ball mill tank, and mixed uniformly by high-speed ball milling; wherein, the molar ratio of lithium: precursor metal element is 1.03, and the mass fraction of barium element added to the total material is 5000ppmw. Under the condition that the volume concentration of the oxygen atmosphere is 50% to 99%, the primary sintering is carried out at a temperature of 850°C, and after cooling to room temperature, it is pulverized by a jaw crusher, crushed by a double-roll crusher, and sieved to obtain a primary sintered material c for later use. The primary sintering material c is a single crystal matrix material LiNi 0.80 co 0.10 mn 0.10 o 2 .

[0056] Take the primary sintered material c, and carry out the comparison experiment between washing and unwashed; take the primary sintered material c and put it in deionized water according to the solid-to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com