Nonaqueous electrolyte solution for high-voltage lithium ion secondary battery and high-voltage lithium secondary battery

A non-aqueous electrolyte and secondary battery technology, applied in the field of non-aqueous electrolyte solution for high-voltage lithium-ion secondary batteries, high-voltage lithium secondary batteries, can solve problems such as side reactions, achieve high decomposition voltage and oxidation resistance , Excellent cycle performance and high temperature performance, the effect of excellent cycle performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036]The preparation method of the high-voltage lithium-ion battery in this embodiment is: according to the capacity design (1640mAh) of the battery, the capacity of the positive and negative electrode materials determines the coating surface density. The positive electrode active material was purchased from Hunan Shanshan high-voltage lithium cobalt oxide material; the negative electrode active material was purchased from Jiangxi Zichen Technology. The positive electrode preparation steps, negative electrode preparation steps, electrolyte preparation steps, diaphragm preparation steps and battery assembly steps are described as follows;

[0037] The preparation step of the positive electrode is: mix the high-voltage positive electrode active material lithium cobaltate, conductive carbon black and binder polyvinylidene fluoride at a mass ratio of 96.8:2.0:1.2, and disperse them in N-methyl-2-pyrrolidone , to obtain the positive electrode slurry, the positive electrode slurry ...

Embodiment 2~18

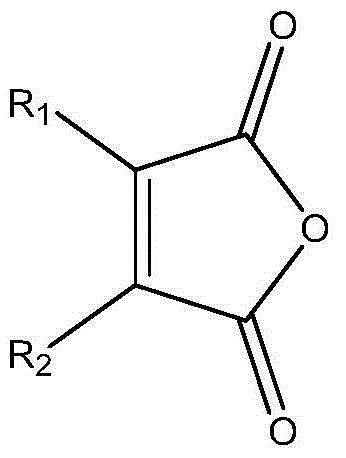

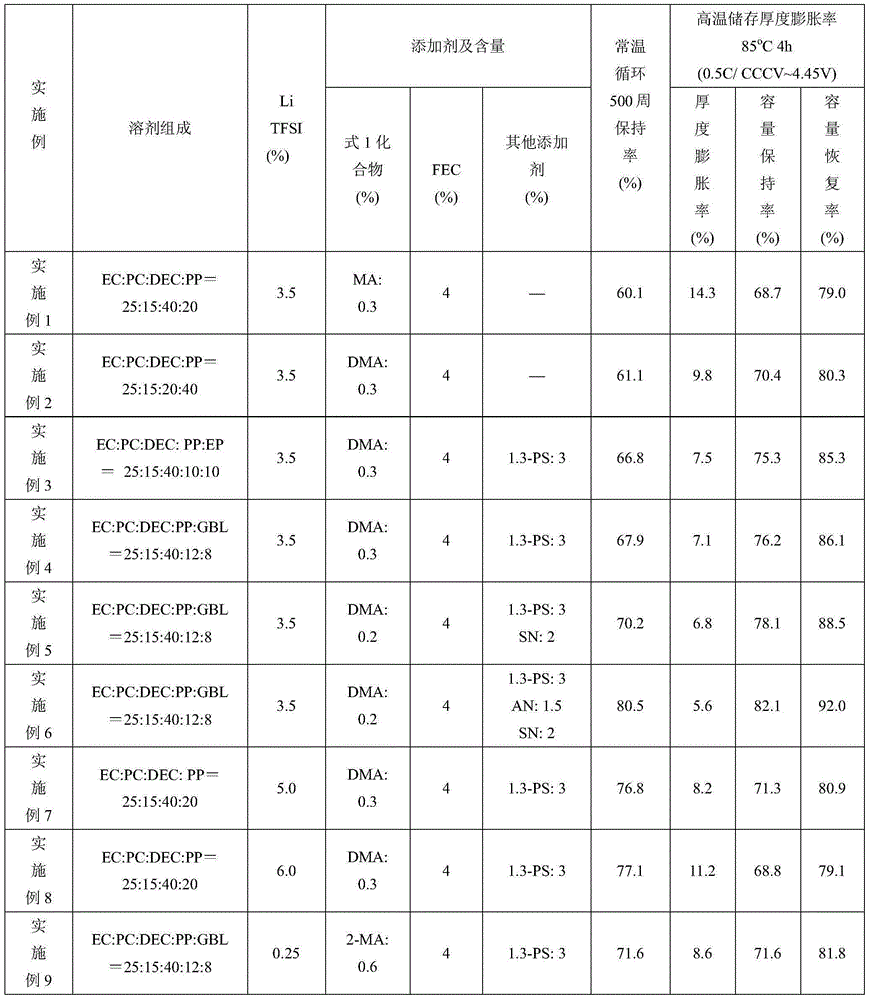

[0050] Examples 2-18 and Comparative Examples 1-4 are the same as Example 1 except that the composition of solvent in the electrolyte, the composition and content of additives (based on the total weight of the electrolyte) are added as shown in Table 1. Table 1 shows the content of each component of the electrolyte additive and the battery performance test results. In the table, PP is propyl propionate, GBL is butyrolactone, EP is ethyl propionate, 1,3-PS is 1,3-propane sultone, AN is adiponitrile, and SN is succinonitrile.

[0051] MA is maleic anhydride, 2-MA is 2-methylmaleic anhydride, and DMA is 2,3-dimethylmaleic anhydride.

[0052] Table 1

[0053]

[0054]

[0055]

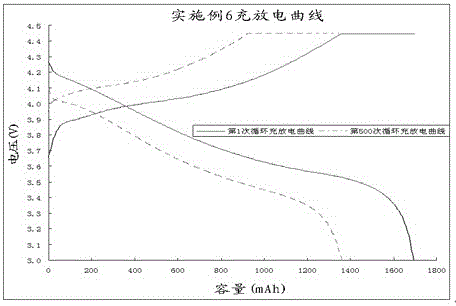

[0056] Comparing Example 6 with Comparative Examples 2 to 4, it can be seen that the comparative example does not contain the compound of formula 1, or does not contain LiTFSI and the compound of formula 1 at the same time, the capacity retention rate of the 500th cycle of normal temperature cycl...

Embodiment 24

[0062] Comparing Example 24 with Comparative Examples 6 and 7, it can be seen that with the same solvent composition, only the Comparative Example does not contain DMA, or does not contain LiTFSI and DMA at the same time. The corresponding capacity retention rate is low, and the battery is obviously bloated.

[0063] Compared with Comparative Example 1 in Example 24, Comparative Example 1 that does not contain carboxylate solvents, LiTFSI and DMA has serious gas swelling, and the corresponding normal temperature cycle and high temperature storage performance is poor. Further, by comparing each example with Comparative Examples 5-8, it is found that the carboxylate solvent containing the electrode / electrolyte interface can be effectively improved by combining additives such as LiTFSI, fluoroethylene carbonate and formula 1 compounds. The cycle performance of the high-voltage ternary battery can obviously suppress the battery inflation, and it takes into account the cycle and hi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com